Abstract

Proton-conducting polymer electrolytes based on biopolymer, agar-agar as the polymer host, ammonium bromide (NH4Br) as the salt and ethylene carbonate (EC) as the plasticizer have been prepared by solution casting technique with dimethylformamide as solvent. Addition of NH4Br and EC with the biopolymer resulted in an increase in the ionic conductivity of polymer electrolyte. EC was added to increase the degree of salt dissociation and also ionic mobility. The highest ionic conductivity achieved at room temperature was for 50 wt% agar/50 wt% NH4Br/0.3% EC with the conductivity 3.73 × 10−4 S cm−1. The conductivity of the polymer electrolyte increases with the increase in amount of plasticizer. The frequency-dependent conductivity, dielectric permittivity (ε′) and modulus (M′) studies were carried out.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fenton and Wright in 1973 were the pioneers of solid polymer electrolytes (SPEs) who worked with polyethylene oxide (PEO) and alkali metal salts. Since then, the field of solid polymer electrolytes gained a great deal of attention of the researchers. The main reason behind this was the advantages of using SPEs in solid-state devices like batteries, fuel cells, sensors, electrochromic displays and solar cells [1,2,3]. Other advantages of SPEs over conventional liquid electrolytes are flexibility, molded to desired shape, mechanical strength, leak-proof and has good electrode-electrolyte contact. Previously, researchers’ interests were towards the development of solid polymer electrolytes based on synthetic polymers like PVA [4], PVP [5], PAN [6], PMMA [7] and PVC [8] which exhibited good conductivity values. But currently, this has been adversely swapped with the biodegradable type through the employment of natural polymers. This effort has been undertaken to make the inventions go greener with the environment. Natural or biopolymers possess some outstanding criteria: (i) found in abundance, (ii) sustainable owing to its renewable nature that does not deplete as the petrochemical source, (iii) cheap in cost since it is a naturally occurring polymer and (iv) biodegradable nature that makes it more environmental friendly [9]. Several renewable resource-based biopolymers are suitable to be used as host polymer in the polymer electrolytes, such as starch [10], cellulose [11, 12], chitosan [13], carrageenan [14] and agar [15, 16].

Among all the biopolymers, agar-agar has gained a great attention due to its best film-forming capability. Agar is an unbranched polysaccharide, which is extracted from the family of seaweeds (Rhodophycae) having the structure of 1,4-linked-3,6-anhydro-α-L-galactopyranose. Agar forms a slightly viscous solution on dissolving in hot water and then becomes a thermoreversible gel when the temperature is brought down. It is widely used in the food industry, in cosmetics and for microbiology. Applications include use as a thickener, gelling agent, binding agent, suspension agent and as a stabilizer. It could be an alternative source for biodegradable films since it shows high mechanical strength with water resistance [17]. Agar has been used in the synthesis of agar chemical hydrogel which is used as electrode binder in fuel-electrolyte-fed fuel cells [18]. The suitability of agar gel as an alternative immobilized electrolyte media and as a polymer electrolyte for electrochemical studies has been explored by Kasem K. Kasem [19]. Dalal Jaber Suliman Abdullah Audeh et al. [20] has reported the influence of the NiO nanoparticles on the ionic conductivity of the agar-based electrolyte in which the conductivity value is of the order of 10−5 S cm−1. Nwanya et al. [15] has reported that the values of the ion conductivity obtained for the agar-based polymer films are 6.54 × 10−8, 9.12 × 10−8, 3.53 × 10−8 and 2.24 × 10−8 S cm−1 for the agar/acetic acid, agar/lactic acid, agar/LiClO4 and agar/KClO4 polymer films, respectively. Ammonium salts are termed as proton donors as they facilitate the number of protons in the polymer matrix and hence the conductivity. Selvalakshmi et al. [21] has reported the conductivity of agar with NH4SCN as 1.03 × 10−3S cm−1 and 1.17 × 10−4 S cm−1 for agar with NH4I [22], and Boopathi et al. [16] has reported 6.57 × 10−4 S cm−1 for agar with NH4NO3. Conductivity value of 1.12 × 10−4 S cm−1 has been reported for carboxy methylcellulose doped with NH4Br [23]. Sit et al. [24] has reported conductivity value of 3.61 × 10−4 S cm−1 for hydroxyethyl cellulose with NH4Br. The abovementioned authors have prepared their polymer electrolytes with distilled water as solvent. Cornstarch-based electrolytes doped with ammonium bromide (NH4Br) in acetic acid exhibited conductivity value of the order of 10−5 S cm−1 [25]. The conductivity value of the polymer electrolytes can be enhanced by the addition of plasticizers like ethylene carbonate [8, 26] and propylene carbonate [27]. Plasticizing enhances the polymer material in terms of its original physical properties like film formation, higher elasticity and more softness and enables it for diversified applications. The present work aims to develop a new biopolymer electrolyte with agar doped with NH4Br and plasticized with ethylene carbonate in dimethylformamide (DMF) solvent. The developed polymer is then subjected to Fourier transform infrared spectroscopic analysis and AC impedance spectroscopic analysis.

Materials and method

Materials

Agar of average molecular weight 120,000 (manufactured by Condo-Forja, 9 Madrid, Spain, sold by Colloids Impex Pvt. Ltd., India) and NH4Br (spectrum) were used in the present work. Ethylene carbonate (EC) was obtained from Himedia, and dimethylformamide (DMF) was purchased from Merck.

Preparation of electrolyte

The total weight of the polymer and salt was fixed to be 1 g. Different weight percentages of agar and NH4Br such as 90 mol% agar/10 mol% NH4Br, 80 mol% agar/20 mol% NH4Br, 70 mol% agar/30 mol% NH4Br, 60 mol% agar/40 mol% NH4Br, 50 mol% agar/50 mol% NH4Br and 40 mol% agar/60 mol% NH4Br are estimated. Agar was dissolved in 40 ml of DMF at 60 °C. After that, the known ratio of NH4Br was dissolved in the agar solution and stirred continuously for 2 h. The stirred solution was casted in the clean glass petri dish and allowed to evaporate in a hot air oven at 50 °C. After 48 h, free standing films were obtained. The system was optimized, and it was found that 50 wt% agar/50 wt% NH4Br exhibited highest conductivity of value 7.24 × 10−5 S cm−1. In the present work, the weight% of agar and NH4Br corresponding to 50 mol% agar/50 mol% NH4Br composition is taken and ethylene carbonate (EC) is added to it in different compositions as 0.1, 0.2, 0.3 and 0.4 mol% of EC. A similar procedure is applied for the preparation of polymer electrolyte using EC as plasticizer. The prepared electrolyte films are subjected to vibrational and electrical characterizations. FTIR spectra were recorded for the proton-conducting polymer electrolyte films in the range of 400–4000 cm−1 at room temperature using a SHIMADZU-IR Affinity-1 Spectrometer with resolution 1 cm−1. Electrical measurements were performed on the polymer electrolyte films in the frequency range 42 Hz–1 MHz, over the temperature range 303–373 K by sandwiching them between aluminum blocking electrodes using HIOKI 3532 LCZ meter interfaced with a computer. Though the vibrational and impedance characterizations have been done for pure agar in DMF electrolyte, agar doped with different compositions of NH4Br (such as 90:10, 80:20, 70:30, 60:40, 50:50 and 40:60) and 50 mol% agar/50 mol% NH4Br/x mol% EC (where x = 0.1, 0.2, 0.3, 0.4%), the plots of pure agar in DMF, 50 mol% agar/50 mol% NH4Br and 50 mol% agar/50 mol% NH4Br/0.3 mol% EC polymer electrolytes have been projected.

Results and discussion

Fourier transform infrared analysis

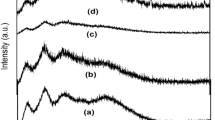

The FTIR analysis has wide applicability in investigating the structure of materials synthesized chemically or obtained naturally. FTIR is also used to study the interaction between cations, anions, solvents and polymers The FTIR spectra for pure agar in DMF, 50 wt% agar doped with 50 wt% NH4Br and 0.3% EC plasticized with 50 wt% agar/50 wt% NH4Br are shown in Fig. 1.

It is clear from the plot that there is a significant change in the FTIR spectra of agar with the addition of NH4Br and EC. The characteristic peak of pure agar at 1654 cm−1 assigned to C=O stretching is shifted to 1648 and 1646 cm−1 in 50 mol% agar doped with 50 mol% NH4Br and 0.3% EC plasticized with 50 mol% agar/50 mol% NH4Br, respectively. Esam et al. [28] has reported that a peak at 1654 cm−1 is due to stretching vibration of the conjugated peptide bond formed by amine (NH) and acetone (CO) groups. The carbonyl stretch of the 50 mol% agar/50 mol% NH4Br polymer complex located at 1648 cm−1 is shifted to lower frequency side (1645 cm−1) with the addition of 0.3 wt% EC. The vibrational band of C=O stretching evolved between 1648 and 1645 cm−1 is due to Fermi resonance of skeletal breathing in EC [29]. This C=O band seems to be broadened in the plasticized polymer-salt complex, which indicates the interaction of plasticizer with the polymer. The perturbation in the carbonyl band due to the presence of NH4Br salt arises from interaction of H+ ion with the carbonyl oxygen. It is clear that the basicity of carbonyl group of agar is increased with addition of EC, implying that the C=O group is able to act as a strong electron donor to interact with H+ ion. Similar reports of Li+ and Na+ ion interactions with the carbonyl oxygen of polymers have already been reported in the literature [30, 31]. The vibrational frequencies observed in the FTIR spectra of pure agar in DMF, 50 wt% agar doped with 50 wt% NH4Br and 0.3% EC plasticized with 50 wt% agar/50 wt% NH4Br polymer electrolytes are given in Table 1.

A characteristic peak of pure agar at 928 cm−1 corresponding to 3,6-anhydrogalactose bridges [32] is found in salt-doped agar sample with a slight shift. The intense band observed at 1038 cm−1, common to all polysaccharides, is mainly due to the coupling of the C-O or the C-C stretching modes with the C-O-H bending modes. The modes due to the C-O-C bridge of the 3,6 anhydro units may also contribute at this frequency, but the strong absorbance at 930 cm−1 is the one attributed to the vibration of the C-O-C bridge of 3,6-anhydrogalactose. The absorption band at 1382 cm−1 is due to the vibration mode of sulfate groups [33]. The band at 1149 cm−1 is due to vibration mode of ester-sulfate link vibrations and C-N stretching. The broad band at 3350 cm−1 corresponds to the stretching of O-H hydroxyl group of agar that participates in inter- and intra-molecular hydrogen bond formation and has been shifted to 3383 and 3393 cm−1 in 50 mol% agar/50 mol% NH4Br and EC doped 50 mol% agar/50 mol% NH4Br, respectively. It has already been reported that stretching hydroxyl group occurs between 3570 and 3200 cm−1 [34]. The shifts in these bands were due to the interaction of the salt with the polymer matrix. The above result confirms the complex formation between the polymer, salt and the plasticizer.

AC impedance spectroscopic analysis

Electrical properties of all the prepared agar-based polymer electrolyte has been analysed using AC impedance spectroscopy technique. Figure 2 shows the complex impedance plots of pure agar in DMF, 50 mol% agar/50 mol% NH4Br and 50 mol% agar/50 mol% NH4Br/0.3% EC polymer electrolytes at 303 K.

The plot for pure agar in DMF consists of a high-frequency depressed semicircle, and a low-frequency spike and the semicircle disappear in the plots for other compositions with addition of NH4Br and EC. The high-frequency semicircle is related to the parallel combination of a resistor (Rb) and a capacitor (Cb), and the low-frequency spike represents the formation of double layer capacitance (CPE) at the electrode–electrolyte interface due to migration of ions at low frequency. The equivalent electrical circuit representing the behaviour of pure agar in DMF is given as Scheme 1a. The hopping of ions occurs through the free volume of polymer matrix, and it is represented by a resistor (Rb). The polymer chains get polarized due to the alternating field and become immobile which is represented by a capacitor (Cb). The values of bulk resistance and bulk capacitance of pure agar was found to be 9.8 × 102 Ω and 2.9 × 10−7 F, respectively. The equivalent electrical circuit corresponding to 50 mol% agar/50 mol% NH4Br and 0.3% EC in 50 mol% agar/50 mol% NH4Br are given as Scheme 1b and Scheme 1c, respectively. The low-frequency response appearing as an inclined spike at an angle less than 90° to the real axis indicates the inhomogeneous nature of the electrode–electrolyte interface, and it is represented as constant phase element (CPE) in the equivalent circuit. The bulk resistance of the polymer electrolytes is obtained either by the intersection of semicircle or the spike with the real axis [5] or by Boukamp’s EQ software. The various factors that influence ionic conductivity are the number of charge carriers, ionic mobility and the availability of a connecting polar domain as the conduction pathway [35]. Ionic conductivity of the solid polymer electrolyte was calculated from the measured bulk resistance, area and thickness of the polymer film using the following formula.

where l is the thickness of the polymer electrolyte (cm), A is the area of the blocking electrode (cm2) and Rb is the bulk resistance of polymer electrolyte.

The conductivity value of 100% agar in DMF was 3.30 × 10−8 S cm−1. The conductivity values of 90 mol% agar/10 mol% NH4Br, 80 mol% agar/20 mol% NH4Br, 70 mol% agar/30 mol% NH4Br, 60 mol% agar/40 mol% NH4Br, 50 mol% agar/50 mol% NH4Br and 40 mol% agar/60 mol% NH4Br are 5.30 × 10−8, 7.86 × 10−6, 1.08 × 10−5, 3.85 × 10−5, 7.24 × 10−5 and 9.16 × 10−8 S cm−1, respectively. The maximum conductivity of 7.24 × 10−5 S cm−1 was achieved for sample with composition of 50 mol% agar/50 mol% NH4Br. Similarly, the conductivity values of 0.1, 0.2, 0.3 and 0.4% EC plasticized in the highest conductivity sample of agar/NH4Br system (i.e., 50 mol% agar/50 mol% NH4Br) are 9.08 × 10−5, 1.15 × 10−4, 3.73 × 10−4 and 9.16 × 10−5 S cm−1, respectively. Conductivity value of 2.38 × 10−5 S cm−1 has been obtained for pure agar membrane using distilled water as solvent [21, 22]. In the present work, the conductivity of pure agar membrane prepared using DMF as solvent is 3.30 × 10−8 S cm−1. The membrane with composition 50 mol% agar/50 mol% NH4Br (in DMF solvent) shows a conductivity value of 7.24 × 10−5S cm−1. So to increase the conductivity, the plasticizer EC has been used. However, by the addition of 0.3% ethylene carbonate (EC) as plasticizer in 50 mol% agar/50 mol% NH4Br, the conductivity value increased by one order and the calculated value of ionic conductivity is 3.73 × 10−4 S cm−1. In this present work, the increase in conductivity could be attributed to the increment of charge carriers and hopping of the mobile ions. The higher dielectric constant of EC (εr = 85.1) may allow greater dissolution of the salt resulting in increased number of charge carriers and hence the conductivity. The major role of a plasticizer in a host polymer is to decrease viscosity of the electrolyte and assist in the dissociation of the salt thereby increasing the number of charge carriers [36].

Conductance spectra analysis

The conductance spectra for the prepared biopolymer electrolytes at room temperature have been shown in Fig. 3. The conductance spectra of 50 mol% agar/50 mol% NH4Br and 50 mol% agar/50 mol% NH4Br/0.3% EC exhibit two distinct regions. At lower frequencies, the conductivity is found to increase which is due to the interfacial dispersion or the space charge polarization. A frequency-independent conductivity plateau is observed in the mid-frequency region. The plateau region characterizes the conduction, which is caused due to the hopping of the mobile ions, and extrapolations determine the dc value of conductivity and are tabulated in Table 2. The conductance spectra of pure agar in DMF exhibit a plateau region and a high-frequency dispersion region. The high-frequency dispersion region is attributed to the relaxation of the mobile ion hopping which is due to the Coulomb interactions of the charge carriers and the disorder within the structure [37].

The highest dc conductivity value has been obtained for the biopolymer electrolyte 50 mol% agar/50 mol% NH4Br/0.3% EC. The dc conductivity increases with increase of temperature due to the free volume created around the polymer chain which provides migration pathway for the mobile ions and polymer segments [38].

Dielectric spectra analysis

Dielectric relaxation study is a vital tool to reveal the relaxation of dipoles in polymer electrolytes. Dielectric constant is ascribed to the charge stored in a material, while dielectric loss is a measure of energy losses to move ions when the polarity of electric field reverses rapidly [39, 40]. The frequency dependence of ε′ and ε″ for 50 mol% agar/50 mol% NH4Br and 50 mol% agar/50 mol% NH4Br/0.3% EC at 303 K is shown in Figs. 4 and 5, respectively.

The higher ε′ and ε″ values obtained by 50 mol% agar/50 mol% NH4Br/0.3% EC at low-frequency region indicates that the existence of plasticizer may result in more localization of charge carriers along with mobile ions causing higher ionic conductivity [41]. The decreasing ε′ and ε″ with increasing frequency is attributed to the tendency of the dipoles in the polymer chains to orient themselves in the direction of the applied electric field [42]. At higher frequencies, the fast periodic reversal of the electric field occurs; hence, the polarization due to charge accumulation decreases at the electrode–electrolyte interface, which in turn contributes to the decrease in ε′ and ε″ [43]. The frequency dependence of ε″ for 50 mol% agar/50 mol% NH4Br/0.3% EC clearly shows the high-frequency β relaxation peak which may be caused by the dipolar type of relaxation caused by the presence of carboxyl side group in the system [44] and low-frequency α relaxation which may be due to the movement of main segments of the polymer chain. Dielectric results imply that the electrolyte systems in the present work confirm the non-Debye behavior.

Loss tangent spectra

The dielectric relaxation parameter of the polymer electrolytes can be obtained from the study of tan δ as a function of frequency. The dielectric loss tangent, tan δ can be defined by the equation

The variation of tan δ with frequency for all the prepared polymer complexes at 303 K is presented in Fig. 6. It has been observed that tan δ increases with increasing frequency and reaches a maximum. Then, it decreases for further increase of frequency.

For maximum dielectric loss (tan δ) at a particular frequency, the absorption peak is described by

Here, τ is the relaxation time, ω is the angular velocity with ω = 2πf, and f is the frequency value corresponding to maximum tan δ in Hz. Relaxation time occurs when ionic charges carriers within the polymer follow the change in the direction of the applied field. When polarization does not follow the AC field, dielectric constant decreases (ε′) with frequency, and so, tan delta is maximum for 50 mol% agar/50 mol% NH4Br. With the addition of EC, there is a significant increase in the values of dielectric constant (ε′) and dielectric loss (ε″). Hence, the value of tan delta becomes less compared to that of 50 mol% agar/50 mol% NH4Br. It is observed from Fig. 6 that the peak frequency shifted towards higher frequency with the addition of NH4Br and EC. The shift of the peak towards higher frequency leads to very small relaxation time. This in turn leads to increase in ionic conductivity which may also be due to the enhancement in number of charge carriers (mobile ions). The enhancement of charge carriers may be attributed to the plasticizing effect of EC. Thus, the relatively fast segmental motion coupled with mobile ions enhances the transport properties of the sample which explains the decrease in relaxation time with conductivity.

The relaxation time is calculated for all the prepared biopolymer electrolytes at 303 K and tabulated in Table 2. A low relaxation time of 2.02 × 10−6 s has been obtained for 0.3% EC salt-doped polymer electrolyte which is consistent with the conductivity analysis.

Electrical modulus studies

Figures 7a and 8 show the frequency dependence of the real, M′ and imaginary, M″ parts of the modulus formalism of 50 mol% agar doped with 50 mol% of NH4Br plasticized with 0.3% EC at different temperatures, respectively. According to Ramesh and Arof [37], the presence of peaks in the modulus formalism at higher frequencies for the polymer system at different temperatures is an indicator that the polymer electrolyte films are ionic conductors. However, in this study, the peaks are visibly absent in M″ and are present in M′ vs log frequency. The values of M′ and M″ approach zero at low frequencies which indicates that electrode polarization is negligible. The appearance of a long tail at low frequencies indicates that there might be a large capacitance associated with the electrodes used in electrochemical impedance spectroscopy which further confirms non-Debye behavior in the sample [45].

Conclusion

The agar-based ion-conducting polymer electrolytes containing EC and NH4Br have been prepared by solution casting technique with DMF as solvent and studied by AC impedance spectroscopy. The complexation behaviour between the polymer, the salt and the plasticizer has been confirmed by FTIR studies. The maximum conductivity of value 3.73 × 10−4 S cm−1 has been obtained for the film 50 wt% agar/50 wt% NH4Br/0.3% EC. Ionic conductivity of the electrolyte increases by one order of magnitude with the addition of 0.3% of EC. This may be due to the lowering of viscosity of the electrolyte with the addition of plasticizer. The dielectric loss spectrum of the polymer electrolyte plasticized with 0.3% of EC exhibits α and β relaxations. The relaxation parameters of the electrolytes have been obtained by the study of tan δ as a function of frequency. From the conductance and modulus spectra, it may be concluded that the charge carriers responsible for both conductivity and relaxation are the same. Modulus analysis shows the non-Debye nature of the electrolyte films. All these preliminary results suggest that such agar-based biopolymer film has a good potential for applications as conducting biopolymer electrolytes.

References

Bezerra CWB, Zhang L, Liu H, Lee K, Marques ALB, Marques EP, Wang H, Zhang J (2007) A review of heat-treatment effects on activity and stability of PEM fuel cell catalysts for oxygen reduction reaction. J Power Sources 173(2):891–908. https://doi.org/10.1016/j.jpowsour.2007.08.028

Gerteisen D, Hakenjos A, Schumacher JO (2007) AC impedance modelling study on porous electrodes of proton exchange membrane fuel cells using an agglomerate model. J Power Sources 173(1):346–356. https://doi.org/10.1016/j.jpowsour.2007.04.071

Wee JH (2007) Applications of proton exchange membrane fuel cell systems. Renew Sust Energ Rev 11(8):1720–1738. https://doi.org/10.1016/j.rser.2006.01.005

Ahmad HM, Sabeeh SH, Hussen SA (2012) Electrical and optical properties of PVA/LiI polymer electrolyte films. Asian Transactions on Science & Technology 1(6):16–20

Vijaya N, Selvasekarapandian S, Hirankumar G, Karthikeyan S, Nithya H, Ramya CS, Prabu M (2012) Structural, vibrational, thermal, and conductivity studies on proton-conducting polymer electrolyte based on poly(N-vinylpyrrolidone). Ionics 18(1-2):91–99. https://doi.org/10.1007/s11581-011-0589-4

Chong WG, Osman Z (2014) The effect of carbonate-phthalate plasticizers on structural, morphological and electrical properties of polyacrylonitrile-based solid polymer electrolytes. J Polym Res 21(3):381. https://doi.org/10.1007/s10965-014-0381-z

Shukla N, Thakur AK, Shukla A, Marx DT (2014) Ion conduction mechanism in solid polymer electrolyte: an applicability of almond-west formalism. Int J Electrochem Sci 9:7644–7659

Rahman MYA, Ahmad A, Lee TK, Farina Y, Dahlan HM (2011) Effect of ethylene carbonate (EC) plasticizer on poly (vinyl chloride)-liquid 50% epoxidised natural rubber (LENR50) based polymer electrolyte. Mater Sci Appl 2:818–826

Xu JJ, Ye H (2005) Polymer gel electrolytes based on oligomeric polyether/cross-linked PMMA blends prepared via in situ polymerization. Electrochem Commun 7(8):829–835. https://doi.org/10.1016/j.elecom.2005.04.034

Khiar ASA, Arof AK (2011) Electrical properties of starch/chitosan-NH4NO3 polymer electrolyte. Int J Math Comput Phys Elec Comput Eng 5(11):1662–1666

Chai MN, Isa MIN (2013) The oleic acid composition effect on the carboxymethyl cellulose based biopolymer electrolyte. J Crystallization Process Technol 3(01):1–4. https://doi.org/10.4236/jcpt.2013.31001

Monisha S, Mathavan T, Selvasekarapandian S, Milton Franklin Benial A, Aristatil G, Mani N, Premalatha M, Vinoth pandi D (2016) Investigation of bio polymer electrolyte based on cellulose acetate-ammonium nitrate for potential use in electrochemical devices. Carbohydr Polym 157:38–47

Aziz SB, Abidin ZHZ (2015) Ion-transport study in nanocomposite solid polymer electrolytes based on chitosan: electrical and dielectric analysis. J Appl Poly Sci 132(15). https://doi.org/10.1002/APP.41774

Rhim J-W (2012) Physical-mechanical properties of agar/κ-carrageenan blend film and derived clay nanocomposite film. J Food Sci 77:N66–73

Nwanya AC, Amaechi CI, Udounwa AE, Osuji RU, Maaza M, Ezema FI (2015) Complex impedance and conductivity of agar-based ion-conducting polymer electrolytes. Appl Phys A Mater Sci Process 119(1):387–396. https://doi.org/10.1007/s00339-014-8979-x

Boopathi G, Pugalendhi S, Selvasekarapandian S, Premalatha M, Monisha S, Aristatil G (2016) Development of proton conducting biopolymer membrane based on agar–agar for fuel cell. Ionics 23(10):2781–2790. https://doi.org/10.1007/s11581-016-1876-x

Guerrero P, Etxabide A, Leceta I, Peñalba M, de la Caba K (2014) Extraction of agar from Gelidium sesquipedale (Rodhopyta) and surface characterization of agar based films. Carbohydr Polym 99:491–498. https://doi.org/10.1016/j.carbpol.2013.08.049

An L, Zhao TS, Zeng L (2013) Agar chemical hydrogel electrode binder for fuel-electrolyte-fed fuel cells. Appl Energy 109:67–71. https://doi.org/10.1016/j.apenergy.2013.03.077

Kasem KK (2005) Electrochemical behavior of some redox systems pendant in agar gel. J New Mat Electrochem Syst 8:189–195

Audeh DJSA, Alcázar JB, Barbosa CV, Carreño NLV, Avellaneda CAO Influence of the NiO nanoparticles on the ionic conductivity of the agar-based electrolyte. Polímeros Ciência e Tecnologia 24:8–12. https://doi.org/10.4322/polimeros.2014.055

Selvalakshmi S, Vijaya N, Selvasekarapandian S, Premalatha M (2017) Biopolymer agar-agar doped with NH4SCN as solid polymer electrolyte for electrochemical cell application. J Appl Polym Sci 134(15). https://doi.org/10.1002/APP.44702

Selvalakshmi S, Mathavan T, Selvasekarapandian S, Premalatha M (2017) Study on NH4I composition effect in agar–agar-based biopolymer electrolyte. Ionics 23(10):2791–2797. https://doi.org/10.1007/s11581-016-1952-2

Samsudin AS, Isa MIN (2012) Structural and ionic transport studies on CMC doped NH4Br: a new types of biopolymer electrolytes. J Appl Sci 12(2):174–179

Sit YK, Samsudin AS, Isa MIN (2012) Ionic conductivity study on hydroxyethyl cellulose (HEC) doped with NH4Br based biopolymer electrolytes. Res J Recent Sci 1(11):16–21

Shukur MF & Kadir MFZ (2015) Electrical and transport properties of NH4Br-doped cornstarch-based solid biopolymer electrolyte. Ionics 21(1):111–124 https://doi.org/10.1007/s11581-014-1157-5

Ibrahim S, Yasin SMM, Nee NM, Ahmad R, Johan MR (2012) Conductivity and dielectric behaviour of PEO-based solid nanocomposite polymer electrolytes. Solid State Commun 152(5):426–434. https://doi.org/10.1016/j.ssc.2011.11.037

Lee HS, Yang XQ and McBreen J (1994) Ionic conductivity of a polymer electrolyte with modified carbonate as a plasticizer for poly(ethylene oxide), J Electrochern Soc 141(4):886–889

El-Hefian EA, Nasef MM, Yahaya AH (2012) Preparation and characterization of chitosan/agar blended films: part 1. Chemical Structure and Morphology. E J Chem 9(3):1431–1439 ISSN: 0973–4945; CODEN ECJHAO

Wang Z, Huang B, Wang S, Xue R, Huang X, Chen L (1997) Vibrational spectroscopic study of the interaction between lithium perchlorate and dimethylsulfoxide. Electrochim Acta 42(17):2611–2617. https://doi.org/10.1016/S0013-4686(96)00440-9

Wieczoreck W, Stevens JR (1997) Impedance spectroscopy and phase structure of polyether−poly(methyl methacrylate)−LiCF3SO3 blend-based electrolytes. J Phys Chem B 101(9):1529–1534. https://doi.org/10.1021/jp962517w

Zhu W, Wang X, Yang B, Tang X (2001) A novel ionic-conduction mechanism based on polyurethane electrolyte. J Polym Sci B Polym Phys 39(11):1246–1254. https://doi.org/10.1002/polb.1098

Orduña-Rojasa J, Robledoa D (2002) Studies on the tropical Agarophyte Gracilaria cornea J. Agardh (Rhodophyta, Gracilariales) from Yucatán, Mexico. II. Biomass assessment and reproductive phenology. Bot Mar 45:459–464

Stancioff DJ, Stanley NF (1969) Infrared and chemical studies of algal polysaccharides. Proc Int Seaweed Symp 6:595–609

Bhuvaneswari MS, Selvasekarapandian S, Hirankumar G, Baskaran R, Vijaya kumar M (2005) Ionic conductivity studies on Sr stabilized zirconia by impedance spectroscopy. Ionics 11(5–6):362–365. https://doi.org/10.1007/BF02430246

Linford RG (1993) Electrical and electrochemical properties of ion conducting polymer. In: Scrosati B (ed) Applications of Electroactive Polymers. Chapman and Hall, London, pp 1–28. https://doi.org/10.1007/978-94-011-1568-1_1

MacFarlane DR, Sun J, Meakin P, Fasoulopoulos P, Hey J, Forsyth M (1995) Structure–property relationships in plasticized solid polymer electrolytes. Electrochim Acta 40(13–14):2131–2136. https://doi.org/10.1016/0013-4686(95)00152-5

Ramesh S, Arof AK (2001) Ionic conductivity studies of plasticized poly (vinyl chloride) polymer electrolytes. Mater Sci Eng B 85(1):11–15. https://doi.org/10.1016/S0921-5107(01)00555-4

Ramya CS, Selvasekarapandian S, Hirankumar G, Savitha T, Angelo PC (2008) Investigation on dielectric relaxations of PVP-NH4SCN polymer electrolyte. J Non-Cryst Solids 354(14):1494–1502. https://doi.org/10.1016/j.jnoncrysol.2007.08.038

Woo HJ, Majid SR, Arof AK (2012) Dielectric properties and morphology of polymer electrolyte based on poly(ε-caprolactone) and ammonium thiocyanate. Mater Chem Phys 134(2-3):755–761. https://doi.org/10.1016/j.matchemphys.2012.03.064

BuraidahMH TLP, Majid SR, Arof AK (2009) Ionic conductivity by correlated barrier hopping in NH4I doped chitosan solid electrolyte. Physica B 404(8-11):1373–1379. https://doi.org/10.1016/j.physb.2008.12.027

Khiar ASA, Arof AK (2010) Conductivity studies of starch-based polymer electrolytes. Ionics 16(2):123–129. https://doi.org/10.1007/s11581-009-0356-y

Pradhan DK, Choudhary RNP, Samantaray BK (2009) Studies of dielectric and electrical properties of plasticized polymer nanocomposite electrolytes. Mater Chem Phys 115(2-3):557–561. https://doi.org/10.1016/j.matchemphys.2009.01.008

Nithya H, Selvasekarapandian S, Kumar DA, Sakunthala A, Hema M, Christopherselvin P, Kawamura J, Baskaran R, Sanjeeviraja C (2011) Thermal and dielectric studies of polymer electrolyte based on P(ECH-EO). Mater Chem Phys 126(1-2):404–408. https://doi.org/10.1016/j.matchemphys.2010.10.047

Ramesh S, Yahaya AH, Arof AK (2002) Dielectric behaviour of PVC-based polymer electrolytes. Solid State Ionics 152–153:291–294.

Schmidt-Rohr K, Kulik AS, Beckham HW, Ohlemacher A, Pawelzik U, Boeffel C, Spiess HW (1994) Molecular nature of the .Beta. Relaxation in poly(methyl methacrylate) investigated by multidimensional NMR. Macromolecules 27(17):4733–4745. https://doi.org/10.1021/ma00095a014

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Selvalakshmi, S., Mathavan, T., Selvasekarapandian, S. et al. Effect of ethylene carbonate plasticizer on agar-agar: NH4Br-based solid polymer electrolytes. Ionics 24, 2209–2217 (2018). https://doi.org/10.1007/s11581-017-2417-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2417-y