Abstract

The activity of the hydrogen evolution reaction (HER) has been investigated on a polypyrrole-chitosan composite film decorated with a small amount of gold (Au) nanoparticles coated on an aluminium electrode. The facile aluminium modified with such a hybrid nanocomposite and its performance was investigated for hydrogen evolution for the first time. A simple two-step approach was applied, including the first co-electrodeposition of polypyrrole and chitosan at a constant current electrolysis accompanied by the electrodeposition of Au nanoparticles via cyclic voltammetry. The chitosan (Chi), which is available in abundant quantities as a raw material, was incorporated into polypyrrole (PPy) chains, and it plays a key role in keeping metal nanoparticles highly dispersed and interconnected through the formation of a collaborative hybrid network. The low loading (≈2 wt%) of Au on this composite film favoured the related reaction more with a high cathodic current density and reduced the Tafel slope (−152 mV dec−1) confirming that the reaction proceeded via the Volmer-Heyrovsky mechanism with a rate control step by the Volmer reaction (proton discharge step). In addition, the long-term durability over 8 h achieved this hybrid composite as a promising nano-electrocatalyst for HER.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The term ‘hydrogen economy’ refers to the vision of producing hydrogen from renewable sources by economically applicable methods. Although electrocatalytic hydrogen production from water is one of the most efficient technologies [1,2,3,4,5,6] among the other hydrogen production techniques, actually exploring cheap, efficient and stable electrocatalysts for hydrogen evolution is still a challengeable issue. In general, to enhance the electrocatalytic HER performance, the most effective method is to develop nanostructured electrocatalysts that facilitate the efficient diffusion of the electrolyte and provide sufficient active sites [1]. It is well documented that the noble metals, especially Pt-group metals have great catalytic activity for HER; however, their low abundance and consequently high cost limit their large-scale commercial applications. There are many works related to electrocatalytic hydrogen production on various electrode materials in the literature. The most important problem is the use of expensive materials and also quite complicated methods. The challenge is to develop HER alternative catalysts that are both highly effective and abundant.

Aluminium has been reported to be commonly used in everyday life and several industrial applications, such as aluminium-air technology [7], food industry, desalination plants [8] and corrosion studies [9], due to its low density, favourable mechanical and environment-friendly properties. In addition, its high conductivity, easy manufacturing and low cost make it an appropriate electrode material. The aim of the present study was to use this inexpensive and conductive metal as an electrode material for investigating HER, but modifying its surface with PPy-Chi/Au hybrid nanocomposite by using a small amount of gold. Chitosan is the second most abundant polysaccharide natural biopolymer present on the earth after cellulose, and it is obtained from chitin deacetylation. It has been attracting considerable interest for a broad range of applications, due to its unique properties including nontoxicity, biocompatibility, biodegradability and good film forming ability [10, 11]. It should be mentioned that there are a few reports on using chitosan modified aluminium electrodes for electrocatalysis applications [12, 13]. The use of the chitosan in the electrolyte milieu, which is a biocompatible polymer with a large number of amino and hydroxyl functional groups, enables the simultaneous synthesis of the composite film with polypyrrole as PPy-Chi. Furthermore, the excellent film-forming capability of chitosan enabled us to achieve homogenously distributed Au nanoparticles on PPy-Chi, as a hybrid nanocomposite film. The formation of nanocomposites based on abundantly available raw materials, presenting unique properties not found in the individual compounds, is an ideal process for the development of cheap materials with advanced properties [14, 15]. This hybrid nanocomposite, which only contains a very small amount of Au, presented comparable electrocatalytic HER activity with the existing well-developed metallic catalysts. Development of noble-metal free catalysts or catalysts with small quantities of noble metals is a good alternative approach to reduce the cost and enhance catalytic activities and stabilities of HER catalysts. Thus, our findings will lead a new road toward replacing bulk noble metal electrodes by alternatives in a wide variety of applications.

Experimental

Pyrrole was obtained from Merck, and it was purified by vacuum distillation prior to use. All the other chemicals were purchased from Sigma-Aldrich and used without further purification. All electrochemical measurements were carried out using an electrochemical workstation system (Gamry Interface 1000, Gamry Instruments, USA), and a conventional three-electrode cell assembly containing an Ag/AgCl electrode as the reference electrode, a platinum wire as the counter electrode and an aluminium rod (3 mm diameter) as the working electrode. All potentials in this study are reported vs NHE. The morphology of the electrode surfaces was characterized by scanning electron microscopy (FEI Quanta 250 FEG).The analyses of the chemical composition of the modified electrodes were performed using an energy dispersive spectrometer (EDS) and X-ray photoelectron spectroscopy (XPS) measurements were recorded on a Specs-Flex mode instrument. The FT-IR spectra measurements were used to obtain the bonding information of the PPy, chitosan and Au nanoparticles, carried out using a Perkin Elmer Spectrum 100 FTIR spectrophotometer. The wavenumber range of 4000–650 cm−1 was applied for the collection of IR spectra.

The aluminium electrode was embedded in an epoxy resin, and the exposed surface was subjected to mechanical polishing with emery paper, with successive decreases in the grain size (180 to 2500). The polishing treatment was continued with 0.3 μm alumina powder until a mirror finish image was obtained, and then the electrode was immersed into ethanol and washed carefully with distilled water before immersing in the electrolyte solution.

The surface modification of the aluminium electrode was performed by co-electrodeposition of polypyrrole and chitosan at a constant current electrolysis (2.5 mA cm−2) for 15 min. The electropolymerization solutions were prepared in a 0.3 mol L−1 oxalic acid solution containing 0.1 mol L−1 pyrrole and 0.01 g chitosan in a final volume of 10 mL. After polymerization, the coated electrode was immersed in a 0.5 mol L−1 H2SO4 solution for 5 min to remove the residues. The electrodeposition of the Au nanoparticles was performed on the composite film by cyclic voltammetry in the potential range of −0.5 to +1.0 V, which was applied for two cycles at 50 mVs−1 in a 0.5 mol L−1 H2SO4 solution containing 1 mmol L−1 HAuCl4. The amount of loaded Au was calculated as 88 μg cm−2 from the electrical charge consumed during the deposition process from the equation of m Au = Q Au.M/nF, where Q Au (C cm−2) is the electrical charge for the reduction of Au3+, M is the atomic weight of Au (196.96 g mol−1), n is the number of electrons transferred and F is the Faraday constant (96,485 C mol−1). The composite films were ready to use for electrochemical measurements after holding them in the 0.5 mol L−1 H2SO4 solution for a few minutes. We also prepared and performed electrochemical measurements with only the PPy-coated aluminium electrode for comparison.

Results and discussion

Structural and morphological characterization

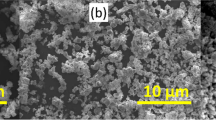

The morphological structures of the products were determined by the SEM images. SEM images of the PPy film as well as PPy-Chi and PPy-Chi/Au composite films coated on aluminium electrodes are shown in Fig. 1. The PPy reveals a typical cauliflower-like morphology (Fig. 1a), which shows a more compact structure and tighter film in the case of codeposition of PPy and chitosan (Fig. 1b). As illustrated by the SEM image (Fig. 1c), the Au particles electrodeposited on the PPy-Chi were distributed homogenously on the film, and in the magnified image of Fig. 1c, it can be clearly seen that the diameter of the particles ranges from 25 to 45 nm (Fig. 1d).

The energy diffraction spectrum (EDS) of the corresponding selected area from the PPy-Chi/Au composite film in Fig. 1e indicates that Au is coexistent, as well as the C, O and N elements that originated from the PPy-Chi composite film. It is noteworthy that even the 2% Au enhances the catalytic activity of the composite film. The X-ray photoelectron spectroscopical measurements were also performed for PPy-Chi and PPy-Chi/Au composite films to analyse their chemical composition. In the case of the PPy-Chi/Au composite film, signals due to Au, in addition to those due to C, N and O, are clearly apparent for the PPy-Chi/Au, which indicates the existence of Au nanoparticles on the composite surface. The result is accordant with the EDS and XPS, which indicates Au nanoparticles were deposited on the surface of the PPy-Chi composite film (Fig. 2).

The further structural analyses were performed by FT-IR spectroscopy. The obtained spectrum of PPy-Chi and PPy-Chi/Au composite films is shown in Fig. 3.

The stretching peak observed at 1560 cm−1 corresponds to C=C (pyrrole ring), which is the characteristic absorption peaks of the polypyrrole. The peaks at 1185 and 1045 cm−1 are related to the C=N and =C–H stretching vibrations, respectively. The spectra of the PPy-Chi composite film are also similar to that of the PPy with a difference in the broadening bands between 3300 and 3400 cm−1 due to the hydrogen bonds between PPy and chitosan via −NH2 and −OH groups. The characteristic peaks at 1685 and 1315 cm−1 represent, respectively, C=N and C–N bonds, which may reasonably be assigned to C=C stretching that got shifted toward lower wave numbers in the case of the PPy-Chi/Au nanocomposite hybrid film.

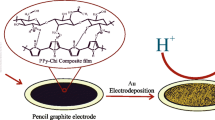

The overall experimental setup is shown schematically in Fig. 4.

The electron transfer from the Al electrode to the H+ ion in the acidic electrolyte medium takes place through the PPy-Chi composite film. The conducting polymeric film acts as a mediator [16]. The Au nanoparticles, which have a highly catalytic activity, enhance both the adsorption of the H+ ion and consequently the current density for the electrochemical reduction process.

HER activity of catalysts

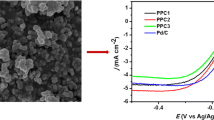

Linear sweep voltammetry (LSV), Tafel polarization curves and electrochemical impedance spectroscopy (EIS) were employed to evaluate the electrochemical characteristics of the prepared electrodes for hydrogen evolution. Figure 5a shows the measured polarization curves of the PPy film as well as the PPy-Chi and PPy-Chi/Au composite films. Due to an oxide layer forming naturally on the aluminium surface, it is usually not easy to coat the aluminium surface with conducting polymers, but on the other hand, this layer also acts as an ionic conductor in the electrolytic solutions [17]. It can be clearly seen that the current density obtained with the PPy-Chi coating is higher than that with just the PPy film. The functional groups (−OH and −NH2) of chitosan provide easy incorporation of the chitosan with the other substances [18, 19]. In the presence of the chitosan in the electrolyte medium, the polymer chains of the chitosan penetrated the PPy chains via H-bonds, which lead the composite film to be more conductive. This is attributed to the more compact and relatively less porous surface of the PPy-Chi film; confirmed by the SEM analysis, as this might increase the electron transfer ability [20]. In addition to this, the free amino groups of chitosan also can be responsible for an electrostatic interaction with the H+ ions in the electrolyte. These would lead to an increase in the current density for the HER.

After electrodeposition of the Au nanoparticles on the PPy-Chi surface, the obtained PPy-Chi/Au hybrid film showed the best HER properties with a lower overpotential and higher current flow, which suggests that the HER activities of the Au nanoparticles all contributed to the active coating material on the aluminium electrode (Fig. 5a). It is well known that the bulk form of gold is a poor catalyst but the nanosized form has an excellent catalytic activity [21]. The better activity of the PPy-Chi/Au hybrid film on HER is due to it having more active sites, which means it is more capable of providing more reaction sites to the HER [2]. Moreover, the film-forming capability of chitosan enables the Au nanoparticles to be highly dispersed, which are embedded into the polymeric composite matrix and this reduces the aggregation process that affects the stability of the Au nanoparticles [22].

On the other hand, the Tafel slope is an important parameter for the evaluation of the electrochemical HER activity, and a smaller Tafel slope indicates an enhanced HER rate. The corresponding Tafel slopes for the PPy film, PPy-Chi composite film and PPy-Chi/Au hybrid film are provided in Fig. 5b.

The HER mechanism in acidic electrolytes has been postulated to comprise three steps; the first step is the Volmer reaction, which is related to the discharge of protons (H3O+ + e−→Had + H2O, b = 2.303RT/αF = 120 mV, α = 0.5). Then, two possible steps are proposed: the Heyrovsky (Had + H3O+ + e−→H2 + H2O, b = 40 mV) and Tafel reaction (Had + Had → H2, b = 30 mV) [4,5,6].

The electrochemical parameters, such as b (Tafel slope), i o (exchange current density) and i (current density at a constant potential), are summarized in Table 1. The Tafel slope value for the PPy-coated electrode was found to be relatively high (234 mVdec−1), and it decreased to 192 mVdec−1 in the case of the PPy-Chi coating due to the chitosan penetrating the PPy chains that enabled them to carry more charge and facilitate the charge transfer for the HER. After the electrodeposition of a small amount of Au (2.09%), a further reduced Tafel slope of −152 mV dec−1 could be assigned to the Volmer-Heyrovsky mechanism with a rate control step by the Volmer reaction (proton discharge step), and this may result from the strong H adsorption onto the Au nanoparticles.

The exchange current density characterizes the electrocatalytic activity of the electrode at equilibrium conditions. However, the obtained current density value at a certain potential is more important to compare the electrocatalytic activity of the electrodes to proceed at a measurable rate for the HER. Therefore, the current densities for the PPy, PPy-Chi and PPy-Chi/Au nanostructured film were measured at −1.0 V; the obtained values were 0.64, 2.45 and 6.12 mA cm−2, respectively, indicating that the current densities are proportional to the activity of the electrode surface.

To further understand the electrocatalytic activity of the coated films, electrochemical impedance spectroscopy (EIS) tests were carried out within the frequency range from 100 to 0.1 kHz with an amplitude of 10 mV at −1.0 V to investigate the kinetics of the HER. The impedance data are represented in a form of Nyquist plots in Fig. 6a.

All the spectra on the Nyquist plots display a semi-circular trend, which is consistent with electrochemical impedance data obtained on various HER electrocatalysts [23, 24]. The diameter of the semi-circle indicates the charge transfer resistance for the hydrogen evolution reaction. When compared with the PPy film, the PPy-Chi composite film exhibits smaller charge-transfer resistances for the HER of approximately 2.1 and 0.9 kΩ, respectively. By adding chitosan within the polypyrrole chains, the electrical conductivity of the film was increased and, consequently, the charge-transfer resistance decreased. After depositing Au nanoparticles on this composite surface, the charge-transfer resistance decreased more to 0.6 kΩ. The larger accessible surface area, the higher intrinsic conductivity by electrodepositing the Au nanoparticles on the PPy-Chi composite film and the ability of chitosan to bring the H+ to the electrode surface mainly contribute to enhance the HER performance and the decrease of the impedance of the nanocomposite hybrid film.

The potential dependence of the Nyquist diagrams of the PPy-Chi/Au was also studied at selected overpotentials and presented in Fig. 6b. The diagrams were recorded at −0.9, −1.0 and −1.1 V. With an increase in the overpotential, the diameter of the semi-circle decreases, which expresses a decrease in the HER resistance and an increase in HER current, depending on Ohm’s law [23]. Since the vigorous hydrogen production rate, scattering data were observed at the potentials more negative than −1.0 V.

The stability of the developed electrocatalyst is another key parameter for hydrogen evolution applications, because the durability is also as important as the high activity to decide if it is a promising material for electrocatalytic HER. To investigate the durability of the electrocatalyst, stability tests were conducted by continuous cyclic voltammetry with the potential range of −0.4 to −1.3 V for 1000 cycles at an accelerated scanning rate of 100 mVs−1. The polarization curves before and after 1000 cycles are illustrated in Fig. 7a, and they indicate no significant loss after the cycling test.

Moreover, the durability test was also performed by electrolysis at a fixed overpotential (Fig. 7b), which represents the expected catalytic durability of the PPy-Chi/Au nanocomposite hybrid electrode.

Conclusion

In conclusion, PPy-Chi composite film and PPy-Chi/Au nanocomposite hybrid film have been fabricated on an aluminium electrode, through a simple two-step approach including the first co-electrodeposition of polypyrrole and chitosan at a constant current electrolysis (2.5 mA cm−2) accompanied by the electrodeposition of Au nanoparticles via cyclic voltammetry. The aluminium, as a not-widely used electrode for HER, showed high electrochemical HER activity and durability, by modifying its surface with PPy-Chi/Au nanocomposite hybrid film; after potential sweep tests for 1000 cycles and catalytic stability for electrolysis over 8 h, it indicated it could be a preferable and effective electrocatalyst for the HER application. The higher HER activity and stability of the PPy-Chi/Au hybrid film is mainly due to its large surface area that allows for the exposure of more active sites and the collaborative network of Au nanoparticles that are highly homogenously dispersed in the PPy-Chi matrix due to functional groups of chitosan which favours the interaction with H+ ions in the electrolyte facilitates efficient pathways for electrolyte and H2 evolution. In addition, using the Au metal at the nano scale lowers the cost, which means it will be a more cost-effective electrode material, and this will lead to more applications in energy conversion.

References

Zhang Z, Liu Y, Ren L, Zhang H, Huang Z, Qi X, Wei X, Zhong J (2016) Three-dimensional-networked Ni-Co-Se nanosheet/nanowire arrays on carbon cloth: a flexible electrode for efficient hydrogen evolution. Electrochim Acta 200:142–151

Zhu L, Cai Q, Liao F, Sheng M, Wu B, Shao M (2015) Ru-modified silicon nanowires as electrocatalysts for hydrogen evolution reaction. Electroche Commun 52:29–33

Devadas B, Imae T (2016) Hydrogen evolution reaction efficiency by low loading of platinum nanoparticles protected by dendrimers on carbon materials. Electrochem Commun 72:135–139

Navarro-Flores E, Omanovic S (2005) Hydrogen evolution on nickel incorporated in three-dimensional conducting polymer layers. J Mol Catal A:Chem 242:182–194

Dalla Corte DA, Torres CP, Correa S, Rieder ES, Malfatti CF (2012) The hydrogen evolution reaction on nickel-polyaniline composite electrodes. Int J Hydrog Energy 37:3025–3032

Liao L, Zhu J, Bian X, Zhu L, Scanlon MD, Girault HH, Liu B (2013) MoS2 formed on mesoporous graphene as a highly active catalyst for hydrogen evolution. Adv Func Mater 23:5326–5333

Liu J, Wang D, Zhang D, Gao L, Lin T (2016) Synergistic effects of carboxymethyl cellulose and ZnO as alkaline electrolyte additives for aluminium anodes with a view towards al-air batteries. J Power Sources 335:1–11

Chandrashekara M, Yadav A (2017) Water desalination system using solar heat: a review. Renew Sustainable Energy Rev 67:1308–1330

Abd El Haleem SM, Abd El Wanees S, Abd El Aal EE, Farouk A (2013) Factors affecting the corrosion behaviour of aluminium in acid solutions. I. Nitrogen and/or sulphur-containing organic compounds as corrosion inhibitors for Al in HCl solutions. Corros Sci 68:1–13

El-Nagar GA, Derr I, Fetyan A, Roth C (2017) One-pot synthesis of a high performance chitosan-nickel oxyhydroxide nanocomposite for glucose fuel cell and electro-sensing applications. Appl Catal B:Environ 204:185–199

Osman Z (2005) Thermal and conductivity studies of chitosan acetate-based polymer electrolytes. Ionics 11:397–401

Sugama T, Cook M (2000) Poly (itaconic acid)-modified chitosan coatings for mitigating corrosion of aluminum substrates. Progr Org Coatings 38:79–87

Abdallah M, Zaafarany I, Fawzy A, Radwan MA, Abdfattah E (2013) Inhibition of aluminum corrosion in hydrochloric acid by cellulose and chitosan. J Am Sci 9(4):580–586

Christoforidis KC, Montini T, Bontempi E, Zafeiratos S, Jaén JJD, Fornasiero P (2016) Synthesis and photocatalytic application of visible-light active β-Fe2O3/g-C3N4 hybrid nanocomposites. Appl Catal B:Environ 187:171–180

Camargo PHC, Satyanarayana KG, Wypych F (2009) Nanocomposites: synthesis, structure, properties and new application opportunities. Mater Res 12(1):1–39

Köleli F, Balun Kayan D (2010) Low overpotential reduction of dinitrogen to ammonia in aqueous media. J Electroanal Chem 638:119–122

Eftekhari A (2002) Aluminium as a suitable substrate for the deposition of conducting polymers: application to polyaniline and enzyme-modified electrode. Synth Met 125:295–300

Silva RC, Sarmento MV, Nogueira ARF, Tonholo J, Mortimer RJ, Faez R, Ribeiro AS (2014) Enhancing the electrochromic response of polyaniline films by the preparation of hybrid materials based on polyaniline, chitosan and organically modified clay. RSC Adv 4:14948–14955

Paleček E, Římánková L (2014) Chitosan catalyzes hydrogen evolution at mercury electrodes. Electrochem Commun 44:59–62

Gök A, Omastova M, Yavuz AG (2007) Synthesis and characterization of polythiophenes prepared in the presence of surfactants. Synth Met 157:23–29

Qiu H, Xue L, Ji G, Zhou G, Huang X, Qu Y, Gao P (2009) Enzyme-modified nanoporous gold-based electrochemical biosensors. Biosens Bioelectron 24:3014–3018

Carlo GD, Curulli A, Toro RG, Bianchini C, Caro TD, Padeletti G, Zane D, Ingo GM (2012) Green synthesis of gold−chitosan nanocomposites for caffeic acid sensing. Langmuir 28:5471–5479

Navarro-Flores E, Chong Z, Omanovic S (2005) Characterization of Ni, NiMo, NiW and NiFe electroactive coatings as electrocatalysts for hydrogen evolution in an acidic medium. J Mol Catal A:Chem 226:179–197

Safavi A, Kazemi SH, Kazemi H (2014) Electrocatalytic behaviors of silver–palladium nanoalloys modified carbon ionic liquid electrode towards hydrogen evolution reaction. Fuel 118:156–162

Acknowledgments

The authors would like to acknowledge the financial support of The Scientific and Technological Research Council of Turkey (TUBITAK) (Project Number: TBAG-114Z315).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kayan, D.B., İlhan, M. & Koçak, D. Chitosan-based hybrid nanocomposite on aluminium for hydrogen production from water. Ionics 24, 563–569 (2018). https://doi.org/10.1007/s11581-017-2208-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2208-5