Abstract

Hexagonal and cubic Li0.5TiO2 particles have been fabricated through magnesiothermic reduction of Li2TiO3 particles in a temperature range of 600 to 640 °C. The prolonged reduction time results in lattice transition from hexagonal to cubic structure of Li0.5TiO2. Their microstructures, valance state, chemical composition, as well as electrochemical performance as anode candidates for lithium ion batteries have been characterized and evaluated. The hexagonal Li0.5TiO2 exhibits better electrochemical activity compared with the cubic one. Further, the carbon-coated hexagonal Li0.5TiO2 displays improved electrochemical performance with initial reversible capacity of 176.6 mAh g−1 and excellent cyclic behavior except capacity fading in the initial 10 cycles, which demonstrate a novel anode candidate for long lifetime lithium ion batteries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lithium titanate compounds, such as spinel type Li4Ti5O12 [1,2,3,4,5,6,7,8], spinel type LiTi2O4 [9,10,11,12,13,14], and ramsdellite structured Li2Ti3O7 [15,16,17], have been extensively investigated as anode materials for long lifetime lithium ion batteries (LIBs), because of their excellent structural stability, electrochemical reversibility, safety, and environmental affinity. Nowadays, the Li4Ti5O12-based LIBs have been commercialized and applied in electric vehicles.

To meet increasing requirements for high safety and long lifetime LIBs, searching for new-type alternative electrode materials is necessary. The ramsdellite structured lithium titanate Li x TiO2 with x in a range of 0.5 to 1 has been predicted through ab initio calculations. The new phases are expected to be potential anode candidates with the lowest Li ion insertion potential among the lithium titanate family [18], which is very beneficial for enhancement of the energy density of lithium titanate-based LIBs. According to the prediction, the full lithiation of Li x TiO2 results in LiTiO2 with orthorhombic Pbnm symmetry.

Electrochemical performances of the ramsdellite structured Li x TiO2 with different x range have been investigated as anode candidates for LIBs, which exhibit very good electrochemical reversibility [10, 19,20,21]. The rock salt-type LiTiO2 was obtained through electrochemical insertion of Li ions into solid anatase type TiO2 in molten LiCl [22]. In addition, the rock salt-type LiTiO2 was fabricated by microwave heating of the starting materials Li2TiO3 and TiO [23]. However, impurity phases Li2TiO3 and Ti2O still existed in the final products. Herein, we report a novel anode candidate for LIBs, i.e., the hexagonal Li0.5TiO2 fabricated through magnesiothermic reduction of Li2TiO3. The structural transition and electrochemical performance of the hexagonal Li0.5TiO2 have been evaluated.

Experimental

The synthesis of TiO2 and carbon-coated TiO2/C was conducted in the following procedure reported elsewhere [14]. Li2CO3 was mixed with TiO2 or TiO2/C with molar ratio of Li/Ti equal to 2:1. The mixture was transferred to a tube furnace after being ground for 2 h and then heated at 650 °C for 8 h under Ar gas flow. After cooled down to ambient temperature, the products with or without carbon coating were washed with deionized water and dried overnight in vacuum.

The as-obtained products were mixed with Mg powders with molar ratio of 5:4, and then the mixture was transferred to a tube furnace and heated at desired temperature with desired time under protection of Ar gas flow. After cooled down to ambient temperature, the products were mixed with 1 M HCl and stirred for 2 h and then washed using deionized water and dried overnight in vacuum.

The microstructures and chemical compositions of the products were characterized by X-ray diffraction (XRD, D8 Advance), X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi), scanning electron microscopy (SEM, JSM6700F), and inductively coupled plasma atomic emission spectrometry (ICP-AES, SPECTRO BLUE SOP).

Electrodes were prepared by drying a slurry (a mixture of 70 wt% active materials, 10 wt% acetylene black, and 20 wt% polyvinylidene fluoride dissolved in 1-Methyl-2-pyrrolidone) at 120 °C for 12 h under vacuum. CR 2032 coin-type batteries were assembled with lithium metals as counter electrode. The diameter of the electrode film is 14 mm, and the active materials are ca. 3–4 mg. The electrolyte was composed of 1 M LiPF6 dissolved in a mixture of ethylene carbonate, diethyl carbonate, and dimethyl carbonate with volume ratio of 1:1:1. Cyclic voltammetry (CV) measurements were performed in an electrochemical workstation (CHI600A) at scanning rate of 0.1 mV s−1. Electrochemical impedance spectroscopy (EIS) measurements were performed by applying a sine wave with amplitude of 5.0 mV in a frequency range from 100 kHz to 0.01 Hz. The discharge–charge measurements were carried out on a battery cycler in a voltage range between 0.1 and 2.5 V (CT 2001A).

Results and discussion

The synthesis of Li2TiO3 can be expressed by the following equation:

And then, LiTiO2 can be obtained through magnesiothermic reduction of the as-synthesized Li2TiO3,

MgO and Li2O can be washed out from the products using diluted HCl solution. Finally, LiTiO2 is expected to be obtained.

Figure 1 exhibits XRD pattern of the products synthesized through reaction (1), which can be indexed as Li2TiO3 (JCPDS No. 33-0831) with monoclinic structure (space group C2/c). No other phase is resolved by XRD, implying high purity of the products. The sharp reflection peaks indicate that the as-synthesized Li2TiO3 has high crystallinity. SEM image of Li2TiO3 is shown in Fig. 2, which displays secondary aggregation morphology with sizes in a range of several hundred nanometers. It also can be seen that the primary particle sizes are less than 100 nm.

Figure 3a displays XRD patterns of the products fabricated through magnesiothermic reduction (Eq. (2)) with temperature ranging from 600 to 640 °C. It can be seen that the reduction products fabricated at 600, 620, and 640 °C exhibit the same reflection positions, where reflection peaks appear at 2θ = 18.7°, 43.57°, and 63.37° and corresponding to lattice spacing 0.473, 0.207, and 0.147 nm, respectively. The XRD patterns can be indexed as hexagonal LiTiO2 (JCPDS No. 40-1053, a = 0.2881 nm, c = 1.4602 nm) through careful identification of each possible Li-Ti-O compound. The standard reflection positions of the hexagonal LiTiO2 are also exhibited in the bottom of the figure, where the main reflection positions {003}, {104}, and {0010} are consistent with the experimental ones. Figure 3a demonstrates that hexagonal LiTiO2 can be obtained through magnesiothermic reduction (Eq. (2)) in a temperature range of 600 to 640 °C. It should be noted that additional unknown reflection peaks appear when the fabrication temperature is below 600 °C or above 640 °C, indicating formation of impurity phases (not shown).

ICP-AES measurements were performed to determine the contents of Li and Ti in the products (not shown). The results indicate that the molar ratio of Li/Ti is 0.5:1. Therefore, the magnesiothermic reduction products can be written as Li0.5TiO2.

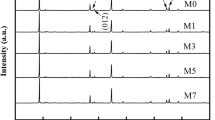

Figure 3b depicts XRD patterns of the products obtained through magnesiothermic reduction at 600 °C with different reduction time. The XRD pattern obtained with reduction time 5 h is the same as Fig. 3a. However, the intensity of the {003} reflection peak gradually decreases with an increase of the reduction time, and almost disappears after 10 h. Two reflection peaks remain and are located at 2θ = 43.83° and 63.56°. The XRD pattern obtained through 10-h reduction can be indexed as the cubic LiTiO2 (JCPDS No. 16-0223) with lattice constant a = 0.414 nm and space group Fm \( \overline{3} \) m. The standard reflection peaks of the cubic LiTiO2 are displayed in the bottom of the figure. ICP–AES measurements indicate that the molar ratio of Li/Ti is the same as the hexagonal Li0.5TiO2. It is therefore demonstrated that hexagonal Li0.5TiO2 can be transited to the cubic Li0.5TiO2 with elongation of the reduction time.

To identify valance state of the hexagonal Li0.5TiO2, XPS measurements were performed. Figure 4 depicts high resolution Ti 2p peaks of Li0.5TiO2, which is composed of Ti(2p 3/2) and Ti(2p 1/2) peaks, indicating presence of Ti4+ and Ti3+ cations. Each of the peaks can be fitted by two peaks corresponding to Ti4+(2p 3/2) (458.8 eV), Ti3+(2p 3/2) (458.1 eV), Ti4+(2p 1/2) (464.7 eV), and Ti3+(2p 1/2) (463.7 eV), respectively. Quantitative calculations made by integration of each curve reveal that the molar content of Ti3+ is 50% of the total titanium cations.

Subpanels a and b of Fig. 5 are SEM images exhibiting morphology of the hexagonal and the cubic Li0.5TiO2, respectively. It can be seen that the two products display irregular particle morphology. The particle sizes of the hexagonal Li0.5TiO2 are around 100 nm. However, the particle sizes of the cubic Li0.5TiO2 are about two times of those of the hexagonal Li0.5TiO2, i.e., around 200 nm. The prolonged reduction time results in particle growth.

The electrochemical performance of the products has been evaluated. Subpanels a and b of Fig. 6 are CV curves of the first three cycles of the hexagonal and the cubic Li0.5TiO2 with scanning rate of 0.1 mV s−1, respectively. To compare the electrochemical performance, CV curves of the carbon-coated hexagonal Li0.5TiO2 is shown in Fig. 6c. Inset in bottom right corner is SEM image showing that the particle sizes of the carbon-coated products decrease to ca. 20 nm, which is much smaller than the uncoated Li0.5TiO2. The carbon content is calculated to be 8 wt% through weight loss analysis after oxidization of the carbon-coated Li2TiO3 in an open muffle furnace at 800 °C, which was further modified according to reaction (2) with target product Li0.5TiO2.

It can be seen that all the three products exhibit similar CV profiles. In the first CV cycle of each of the three products, two cathodic peaks appear at ca. 1.6 and 0.7 V, respectively. The cathodic peak located at ca. 1.6 V probably corresponds to the lithiation process of Li0.5TiO2 [18],

Theoretically, the specific capacity of Li0.5TiO2 is calculated to be 160 mAh g−1. Correspondingly, the anodic peaks appear at ca. 1.9, 1.9, and 1.7 V for the hexagonal, the cubic, and the carbon-coated hexagonal Li0.5TiO2, respectively, which represents reverse delithiation process. The decreased voltage polarization of the carbon-coated product implies high electronic and ionic conductivity. The cathodic peaks located at ca. 0.7 V are believed to be derived from formation of SEI films [24] and disappear in the subsequent cycling.

The cyclic performances of the cubic, the hexagonal, and the carbon-coated hexagonal Li0.5TiO2 at current density 50 mA g−1 (ca. 0.3 C) are shown in Fig. 7a–c, respectively. In the first discharge process, all the three products exhibit much similar lithiation potential. Li ions start to insert into active materials at ca. 1.8 V, and then a long voltage slope appears, which correspond to lithiation of Li0.5TiO2. After that, another voltage slope appears at ca. 0.8 V, which is due to the formation of SEI films, and is consistent with CV performance. The first-cycle discharge capacities for the hexagonal, the cubic, and the carbon-coated hexagonal Li0.5TiO2 are 277.0, 173.4, and 539.9 mAh g−1, respectively. Correspondingly, the first-cycle charge capacities are 118.9, 68.5, and 176.6 mAh g−1, respectively, among which the carbon-coated product delivers the highest discharge/charge capacities. The cubic Li0.5TiO2 exhibits the most rapid capacity fading tendency, and the discharge/charge capacities are 44.5/44.5 mAh g−1 after 50 cycles.

The cyclic performances of the three products are shown in Fig. 8a. It can be seen that all the three products exhibit rapid capacity fading in the initial 10 cycles, and then, the capacities stabilize in the subsequent cycling. In overall, the cubic Li0.5TiO2 exhibits the lowest capacities, which indicates that its electrochemical activity is much limited. The electrochemical activity of the hexagonal Li0.5TiO2 is better than the cubic counterpart. Its reversible capacity is 69.6 mAh g−1 after 100 cycles. The carbon coating is very effective for improvement of the electrochemical activity of the hexagonal Li0.5TiO2. Its first-cycle reversible capacity can reach 176.6 mAh g−1. After 10 cycles, its reversible capacity decreases to 116.0 mAh g−1 and then exhibits very stable cyclic performance.

The rate capability of the carbon-coated hexagonal Li0.5TiO2 has been evaluated, as shown in Fig. 8b. The reversible capacity fades with an increase of the current density. The initial capacity is 73.8 mAh g−1 at current density 630 mA g−1 (ca. 4 C), which is 60% of the 10th cycle at current density 63 mA g−1 (123.7 mAh g−1). The carbon-coated hexagonal Li0.5TiO2 delivers capacity of 103.9 mAh g−1 when the current density recovers 63 mA g−1 after 80 cycles at different current density. Its capacity recovery ability is 84% compared with the 10th cycle at the same current density.

To investigate electrochemical kinetics of Li0.5TiO2 with cycling, the hexagonal Li0.5TiO2 was selected and we performed EIS measurements after different discharge/charge cycling and full relaxation of the cells. The Nyquist plots of the hexagonal Li0.5TiO2 cells after different cycle are shown in Fig. 9a. Each of the Nyquist plots is composed of a depressed semicircle at relatively high frequency domain, followed by another depressed semicircle. A slopped line appears at low frequency domain. In order to quantitatively investigate EIS performance, an equivalent circuit was proposed to fit the Nyquist plots, as shown in Fig. 9b. The equivalent circuit consists of one solution resistance R s, two units in series, each of which is composed of a resistance and a constant-phase element (CPE) in parallel, and a Warburg diffusion element Z w, where the subscripts sei and ct represent SEI film and double layer charge transfer performance, respectively. It can be seen that the fitting data of each plot represented by solid curve are in good agreement with the original data. The charge transfer resistances R ct at different cycle are plotted as a function of cycle number (Fig. 9c). R ct is 148 Ω after 3 cycles and then decreases steeply to 95 Ω after 10 cycles. Then, R ct decreases gradually to 72 Ω after 100 cycles. Compared with the cyclic performance of the hexagonal Li0.5TiO2 (Fig. 8a), it can be seen that the cyclic capacity and R ct vary a little after 10 cycles.

The hexagonal Li0.5TiO2 electrodes after 100 discharge/charge cycles (full delithiation state) have been collected and washed using dimethyl carbonate, and then ex situ XRD measurements were performed to characterize the structural variation, as shown in Fig. 10. It can be seen that Li0.5TiO2 maintains hexagonal structure after cycling, indicating its high structural stability. The broad reflection peak located at 2θ ≈ 25° to 35° may be derived from the acetylene blacks in the electrode.

To date, limited investigations of Li0.5TiO2 have been documented. The lithiation/delithiation behavior of the hexagonal Li0.5TiO2 is much similar with other lithium titanate anodes [25]. However, the hexagonal Li0.5TiO2 displays rapid capacity fading during the initial 10 cycles. The fading mechanism is still not fully clear. The lower electrochemical performance of the cubic Li0.5TiO2 may be due to its larger particle size compared with the hexagonal counterpart. The enhancements of the electrochemical performance of the carbon-coated hexagonal Li0.5TiO2 with an initial reversible capacity of 176.6 mAh g−1 may be ascribed to the decreased particle size and carbon coating effects compared with the uncoated counterparts, which demonstrates a novel anode candidate for long lifetime LIBs.

Conclusions

The hexagonal Li0.5TiO2 particles have been fabricated through magnesiothermic reduction of Li2TiO3 particles in a temperature range of 600 to 640 °C. The cubic Li0.5TiO2 particles can be obtained through prolonged reduction time. The hexagonal Li0.5TiO2 has high electrochemical activity compared with the cubic one as an anode candidate for LIBs. The electrochemical performance of the hexagonal Li0.5TiO2 has been improved after carbon coating, which delivers initial reversible capacity of 176.6 mAh g−1 and exhibits excellent electrochemical reversibility after capacity fading in the initial 10 cycles.

References

Huang SH, Wen ZY, Gu ZH, Zhu XJ (2005) Preparation and cycling performance of Al3+ and F− co-substituted compounds Li4AlxTi5−xFyO12−y. Electrochim Acta 50:4057–4062

Ge H, Li N, Li DY, Dai CS, Wang DL (2008) Study on the effect of Li doping in spinel Li4+xTi5-xO12 (0≦x≦0.2) materials for lithium-ion batteries. Electrochem Commun 10:1031–1034

Li HQ, Zhou HS (2012) Enhancing the performances of Li-ion batteries by carbon-coating: presented future. Chem Commun 48:1201–1217

Jung HG, Jang MW, Hassoun J, Sun YK, Scrosati B (2011) A high-rate long-life Li4Ti5O12/Li[Ni0.45Co0.1Mn1.45]O4 lithium-ion battery. Nat Commun 2:516–520

Kim HK, Bak SM, Kim KB (2010) Li4Ti5O12/reduced graphite oxide nano-hybrid material for high rate lithium-ion batteries. Electrochem Commun 12:1768–1771

Wolfenstine J, Lee U, Allen JL (2006) Electrical conductivity and rate-capability of Li4Ti5O12 as a function of heat-treatment atmosphere. J Power Sources 154:287–289

Jung HG, Myung ST, Yoon CS, Son SB, Oh KH, Amine K, Scrosati B, Sun YK (2011) Microscale spherical carbon-coated Li4Ti5O12 as ultra high power anode material for lithium batteries. Energy Environ Sci 4:1345–1351

Peramunage D, Abraham KM (1998) The Li4Ti5O12/PAN electrolyte//LiMn2O4 rechargeable battery with passivation-free electrodes. J Electrochem Soc 145:2615–2622

Ra W, Nakayama M, Uchimoto Y, Wakihara M (2005) Experimental and computational study of the electronic structural changes in LiTi2O4 spinel compounds upon electrochemical Li insertion reactions. J Phys Chem B 109:1130–1134

Cava RJ, Murphy DW, Zahurak S, Santoro A, Roth RS (1984) The crystal structures of the lithium-inserted oxides Li0.5TiO2 anatase, LiTi2O4 spinel, and Li2Ti2O4. J Solid State Chem 53:64–75

Kuhn A, Baehtz C, Garcia-Alvarado F (2007) Structural evolution of ramsdellite-type LixTi2O4 upon electrochemical lithium insertion-deinsertion (0≤ x ≤ 2). J Power Sources 174:421–427

Yang JW, Zhao J, Chen YZ (2010) Preparation and characterization of LiTi2O4 anode material synthesized by one-step solid-state reaction. Ionics 16:425–429

Kanno T, Awaka J, Kariya F, Ebisu S, Nagata S (2006) Electrical and magnetic properties of the spinel-type Li(Ti0.8Cr0.2)2O4. Physica B 381:30–33

Pan MJ, Chen YX, Liu HB (2015) Carbon-coated spinel-structured Li1-xTi2O4 (0<x<0.5) anode materials with reversible two-stage lithiation potentials. Ionics 21:2417–2422

Garcia-Alvarado F, Arroyo de Dompablo ME, Moran E, Gutierrez MT, Kuhn A, Varez A (1999) New electrode materials for lithium rechargeable batteries. J Power Sources 81-82:85–89

Van Thournout M, Picard A, Womes M, Olivier-Fourcade J, Jumas JC (2006) Effect of the substitution Ti/(Fe,Ni) on the electrochemical properties of Li2Ti3O7 as electrode materials for Li-ion accumulators. J Phys Chem Solids 67:1355–1358

Van Thournout M, Aldon L, Womes M, Ducourant B, Olivier-Fourcade J, Tessier C, Levasseur S (2007) Metal-doped Li2Ti3O7 with ramsdellite structure as high voltage anode for new generation Li-ion batteries. J Power Sources 174:1270–1274

Koudriachova MV (2008) Ramsdellite-structured LiTiO2: a new phase predicted from ab initio calculations. Chem Phys Lett 458:108–112

Kuhn A, Amandi R, García-Alvarado F (2001) Electrochemical lithium insertion in TiO2 with the ramsdellite structure. J Power Sources 92:221–227

Tsuyumoto I, Moriguchi T (2015) Synthesis and lithium insertion properties of ramsdellite LixTiO2 anode materials. Mater Res Bull 70:748–752

Soares A, Fraisse B, Morato F, Ionica-Bousquet CM, Monconduit L (2012) On the synthesis conditions for tailoring lithium composition in ramsdellite phases: Application for Li-ion batteries. J Power Sources 208:440–446

Jiang K, Hu XH, Sun HJ, Wang DH, Jin XB, Ren YY, Chen GZ (2004) Electrochemical synthesis of LiTiO2 and LiTi2O4 in molten LiCl. Chem Mater 16:4324–4329

Yang LH, Dong C, Guo J (2008) Hybrid microwave synthesis and characterization of the compounds in the Li–Ti–O system. J Power Sources 175:575–580

Goodenough JB, Kim Y (2010) Challenges for rechargeable Li batteries. Chem Mater 22:587–603

Zhu GN, Wang YG, Xia YY (2012) Ti-based compounds as anode materials for Li-ion batteries. Energy Environ Sci 5:6652–6667

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51472083 and 51402101) and Science and Technology Planning Project of Hunan Province (2016GK2064).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuang, Y., Chen, Y., Xia, X. et al. Fabrication and electrochemical investigation of Li0.5TiO2 as anode materials for lithium ion batteries. Ionics 23, 3265–3271 (2017). https://doi.org/10.1007/s11581-017-2148-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2148-0