Abstract

The spinel LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) including LiNi0.5Mn1.5O4, LiNi0.45Mn1.55O4, and LiNi0.4Mn1.6O4 hollow microspheres has been prepared by adjusting the stoichiometric ratios of Ni and Mn with an impregnation method followed by a simple solid-state reaction. They are characterized by X-ray diffraction, Fourier transform infrared spectroscopy, scanning electron microscope, high-resolution transmission electron microscope, X-ray photoelectron spectroscopy, and electrochemical tests. The results show that LiNi0.5Mn1.5O4 is the ordered with the space group of P4332, but LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4 are the disordered with the space group of Fd3m. All the three types of hollow microspheres have the similar primary particles. Compared to LiNi0.5Mn1.5O4, partial Ni atoms are substituted by Mn atoms in LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4 lattices along with incorporation of small amounts of Mn3+. Although the ordered LiNi0.5Mn1.5O4 hollow microspheres deliver the highest capacity of 128.5 mAh/g at 1 C among the three types of spinel materials, the disordered LiNi0.45Mn1.55O4 hollow microspheres exhibit the highest capacity of 96.8 mAh/g at 10 C. The superior rate capability of LiNi0.45Mn1.55O4 hollow microspheres is attributed to the combination of the increased electronic conductivity and Li+-ion diffusion by moderate Mn3+ incorporation, along with the hierarchical structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lithium-ion batteries (LIBs) have been widely used in consumer electronics products, owing to their highest energy density among the present commercial rechargeable batteries [1, 2]. However, for the applications in electric vehicles and smart grids, it is desired to further increase their energy density. Since energy of a battery is the product of stored capacity and output voltage, the approaches to increase energy density include increasing the voltage of cathode materials and the capacity of electrode materials. Spinel LiNi0.5Mn1.5O4 as the representative of high-voltage cathode can provide a working plateau at 4.7 V and thus offer much higher energy density (650 Wh/kg) than those commercial 3.2 or 4 V class cathode materials, such as LiCoO2 (540 Wh/kg), LiMn2O4 (500 Wh/kg), and LiFePO4 (500 Wh/kg) [3]. Therefore, high-voltage LiNi0.5Mn1.5O4 has been regarded as one of the most promising cathode materials for high-energy LIBs [4].

Spinel LiNi0.5Mn1.5O4 has two types of space groups: P4332 and Fd3m [5]. The former has Ni and Mn orderly distributed in the 4a and 12d octahedral sites, respectively; thus, this P4332-type spinel is called ordered LiNi0.5Mn1.5O4. On the contrary, because of random Ni/Mn occupation in the 16d octahedral sites, the Fd3m-type spinel is named disordered LiNi0.5Mn1.5O4. Usually, the disordered LiNi0.5Mn1.5O4 is facile to be received during high-temperature (above 700 °C) preparation, along with a small amount of oxygen loss, as LiNi0.5Mn1.5O4−δ. The significant difference between the ordered and the disordered is the presence of Mn3+ in the latter, which leads to their obviously different electrochemical properties. Mn3+ can disproportionate to Mn4+ and Mn2+, which has the high solubility in the electrolyte. Therefore, the disordered LiNi0.5Mn1.5O4−δ has the inferior cycling stability than ordered LiNi0.5Mn1.5O4 [4–6]. However, Mn3+ in the disordered phase has the positive contribution on charge transfer because of its higher electronic conductivity and bigger ionic radius than Mn4+. Many literatures reported that disordered Fd3m-type LiNi0.5Mn1.5O4−δ has better rate capability than ordered P4332-type LiNi0.5Mn1.5O4 [5, 7–11]. What is confusing is that Mn3+ only exists at a small regime of the electrochemical reaction (beginning of charging and end of discharging), and its contribution on electronic conductivity should be very limited [12].

Recently, we synthesized hierarchically nanostructured framework ordered LiNi0.5Mn1.5O4 hollow microspheres which exhibited superior rate capability than the disordered LiNi0.5Mn1.5O4 hollow microspheres. And we found that the better rate capability can be attributed to the signal-crystal structure on the surface of the ordered LiNi0.5Mn1.5O4, which is helpful for the fast Li+-ion insertion/extraction kinetics [13]. In that work, we introduced Mn3+ and prepared the disordered LiNi0.5Mn1.5O4−δ by increasing the reaction temperature from 800 °C to 900 or 1000 °C. However, the increased temperature inevitably resulted in the morphology change, which also caused the unfair comparison between the two types of materials. In fact, it is easier to form the disordered structure by adjusting the stoichiometric ratio of Ni and Mn. In this way, we can overcome the problem of morphology change during different temperatures and obtain two types of LiNi0.5Mn1.5O4 spinel with the same morphology.

To further investigate the two types of spinel LiNi0.5Mn1.5O4 hollow microspheres, we prepared LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) hollow microspheres by adjusting the stoichiometric ratio of Ni and Mn. Herein, partial replacement of Ni by Mn will reduce the average valence state of Mn, introduce small amount of Mn3+, and form the disordered structure. Thus, ordered LiNi0.5Mn1.5O4, disordered LiNi0.45Mn1.55O4, and disordered LiNi0.4Mn1.6O4 hollow microspheres have been synthesized successfully. Furthermore, their structures and electrochemical performance have been deeply investigated.

Experimental

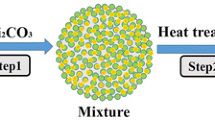

Spinel LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) hollow microspheres were prepared by an impregnation method followed by a simple solid-state reaction, similar as we reported previously [13]. The MnCO3 microspheres were synthesized by a precipitation method [14]. Then, the porous MnO2 microspheres were got by decomposition of MnCO3 at 400 °C for 5 h. Further, different stoichiometric Ni(NO3)2 · 6H2O and LiOH · H2O were dispersed in the ethanol and impregnated in the MnO2 microspheres to obtain a precursor after the ethanol was completely evaporated at 50 °C. Exactly, for the preparation of LiNi0.5Mn1.5O4, 5 mmol Ni(NO3)2 · 6H2O and 10.5 mmol LiOH · H2O were impregnated into 15 mmol MnO2 microspheres. But for LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4, 4.5 mmol Ni(NO3)2 · 6H2O + 10.5 mmol LiOH · H2O + 15.5 mmol MnO2 microspheres and 4 mmol Ni(NO3)2 · 6H2O + 10.5 mmol LiOH · H2O + 16 mmol MnO2 microspheres were used, respectively. Finally, the spinel hollow microspheres were obtained by calcining the precursor at 800 °C for 20 h, followed by a posttreatment at 700 °C for 10 h.

The phase structures of the spinel hollow microspheres were identified by X-ray diffraction (XRD) using a D/MAX 2500 V diffractometer in the range of 10 ~ 70° (2θ). The Fourier transform infrared spectroscopy (FTIR) analysis was performed with America Thermo Nicolet-67. The morphologies and microstructures of the spinel hollow microspheres were taken by scan electron microscope (SEM, JSM-6490LV) and high-resolution transmission electron microscope (HR-TEM, JEM-2100 F). X-ray photoelectron spectroscopy (XPS) analysis was carried out by using the America Thermo ESCALAB250 instrument.

The electrochemical performance of the spinel hollow microspheres was investigated by using CR2032 coin-type cells assembled in an argon-filled glove box (MBraun). In order to make the LiNi0.5Mn1.5O4 electrode laminate, a slurry containing 84 wt.% active material, 8 wt.% acetylene black, and 8 wt.% polyvinylidene fluoride (PVDF) dispersed in N-methyl-2-pyrrolidinone (NMP) was cast onto an aluminum current collector. After vacuum drying at 70 °C, the laminate was punched into discs (Φ14 mm) as the electrode for assembling the coin cells. The mass loading in the electrode was controlled at about 6 mg cm−2. Celgard 2400 microporous polypropylene membrane was used as separator. Highly pure lithium foil was used as the counter electrode and reference electrode for the cell assembly. The electrolyte was 1 M LiPF6/ethylene carbonate (EC) + dimethyl carbonate (DMC) (1:1, w/w). The Li/LiNi0.5Mn1.5O4 cells were galvanostatically cycled between 3.5 and 5 V on a multi-channel battery cycler (Neware BTS2300, Shenzhen). And all the cell tests were taken in the constant current-constant voltage (CC-CV) model. The constant voltage (CV) regime ended until the current rate was lower than 0.5 C. Electrochemical impedance spectra (EIS) measurements of the Li/LiNi0.5Mn1.5O4 cells charged to 5.0 V were performed on a CHI 604D electrochemical workstation with applied 10 mV sinusoidal perturbation in a frequency range from 100 kHz to 10 mHz at room temperature. The EIS results were fitted by using the Z-view software.

Results and discussion

The XRD patterns of the LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) products are shown in Fig. 1a. All the synthesized products present typical diffractions of a cubic spinel phase. With x increasing to 0.1 (LiNi0.4Mn1.6O4), the impurity diffraction peak near (400) peak becomes obvious and it is corresponding to Li x Ni1−x O or NiO x , which was often formed in the solid-state synthesis of LiNi0.5Mn1.5O4 [15–17]. For LiNi0.5Mn1.5O4 and LiNi0.45Mn1.55O4, this impurity phase is negligible. Additionally, we found that the (111) diffraction peak of LiNi0.45Mn1.55O4 had a shift to low angle (from 18.82° to 18.75°) in LiNi0.5Mn1.5O4. That is because partial Mn4+ (0.54 Å) converting to bigger Mn3+ (0.66 Å) by the replacement of Ni by Mn could result in the enlargement of lattice. The effect will also be confirmed by XPS below. However, in XRD, it is difficult to identify whether the sample has P4332 or Fd3m structure. Thus, the FTIR spectra of the LiNi0.5Mn1.5O4, LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4 powders are investigated in Fig. 1b. Amatucci and co-workers reported that the ordered LiNi0.5Mn1.5O4 (P4332) had eight IR absorption bands while the disordered LiNi0.5Mn1.5O4−δ (Fd3m) had only five [8, 9]. Here, LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4 have five IR absorption bands at 465, 496, 556, 581, and 622 cm−1, which are the fingerprint of the disordered LiNi0.5Mn1.5O4−δ [18]. Since there are additional three peaks at 430, 478, and 650 cm−1, LiNi0.5Mn1.5O4 has low symmetry, which results from the well-separated Ni and Mn sites. Therefore, it is concluded that here, LiNi0.5Mn1.5O4 is ordered with the space group of P4332, but the other two are disordered with the space group of Fd3m.

To investigate oxidation state of Mn of LiNi0.5Mn1.5O4, LiNi0.45Mn1.55O4, and LiNi0.4Mn1.6O4, XPS analysis has been carried out in Fig. 2. The sets of Mn2p2/3 peaks in Fig. 2a–c show that Mn4+ and Mn3+ are coexistence. As shown in Fig. 2a, the majority of LiNi0.5Mn1.5O4 product is mostly composed of Mn4+. From a peak separation, however, in relatively low binding energy, there was a small peak, indicating that the trace amounts of Mn3+ exist [19, 20]. For the LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4, the existence of Mn3+ could be found obviously. Furthermore, the amount of Mn3+ increased with the increment of Mn replacing Ni. As we all know, the presence of Mn3+ in the structure can improve the electronic and ionic conductivities [5, 7–11]. All above, from the XPS, XRD, and FTIR results, we can confirm that ordered LiNi0.5Mn1.5O4, disordered LiNi0.45Mn1.55O4, and disordered LiNi0.4Mn1.6O4 samples have been synthesized successfully by adjusting the stoichiometric ratios of Ni and Mn.

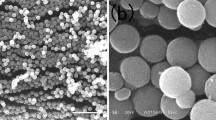

Figure 3 depicts the morphologies of LiNi0.5Mn1.5O4, LiNi0.45Mn1.55O4, and LiNi0.4Mn1.6O4. The low-magnification SEM images (Fig. 3a, c, e) reveal that all the products are consisted of regular microspheres with a diameter of 4 ~ 6 μm. Most LiNi0.5Mn1.5O4 microspheres have the comparative diameter with the LiNi0.45Mn1.55O4 microspheres, but the LiNi0.4Mn1.6O4 microspheres are slightly smaller than the other two types of microspheres. The main reason could be the smaller amounts of Li and Ni sources impregnated into the same amount of MnO2 microspheres during the preparation of LiNi0.4Mn1.6O4. As shown in Fig. 3b, d, f, high-magnification SEM images illustrate that all the microspheres have the hollow structure. From Fig. 3b, the wall thickness of the hollow microspheres is about 0.5–1.0 μm. Such a thick wall can make the hollow structure keep stable during the electrode preparation. In our previous report [13], we prepared the similar hollow microspheres with different space groups under different reaction temperatures, but the different temperatures cause the obvious differences on morphology, crystallinity, and surface structure of the primary particles. But here, the primary particles for the three samples have quite similar morphology and crystallinity. Furthermore, in Fig. 4, the HR-TEM images show the single-crystalline nature of the surface for the primary particles in the three samples, and the measured neighboring interplanar distance of 0.46 nm matches well with the spacing between the (111) planes.

The initial voltage profiles of all Li/LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) cells are compared in Fig. 5. It is clear that all the voltage profiles at 1 C include a flat plateau at 4.7 V, corresponding to the reversible reactions of Ni2+/Ni3+ and Ni3+/Ni4+ [21, 22]. Furthermore, for the cells using LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4, an obvious voltage plateau can be observed between 3.8 and 4.2 V, corresponding to the Mn3+/Mn4+ redox process [23]. This also supports the fact that a small fraction of Mn3+ existed in disordered LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4. However, the cell using the ordered LiNi0.5Mn1.5O4 shows a negligible plateau in the 3.8 ~ 4.2 V region. The capacity of this plateau can indirectly reflect the amount of Mn3+ ions in the spinel materials. That is, the higher capacity results from the more Mn3+ ions. It is further observed that the initial discharge capacities of LiNi0.5Mn1.5O4, LiNi0.45Mn1.55O4, and LiNi0.4Mn1.6O4 are 128.5, 116.5, and 115.2 mAh/g at 1 C, respectively. The lower discharge capacities of LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4 can be contributed to the decrease of Ni in LiNi0.5−x Mn1.5+x O4 and the increment of Mn3+. LiNi0.5Mn1.5O4 and LiNi0.45Mn1.55O4 have the comparable coulombic efficiencies of 88.7 and 90.3 %, respectively, but LiNi0.4Mn1.6O4 has the lower coulombic efficiency of 80.6 %, probably because of the existence of Li x Ni1−x O impurities [24, 25].

Rate capabilities of all Li/LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) cells are presented in Fig. 6. At 1 C and 2 C, LiNi0.5Mn1.5O4 exhibits much higher discharge capacities than LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4. However, at 5 C, LiNi0.45Mn1.55O4 has the comparative capacity with LiNi0.5Mn1.5O4, even though the capacity of LiNi0.4Mn1.6O4 has a large fading. At 10 C, the disordered LiNi0.45Mn1.55O4 can deliver the higher discharge capacities of 96.8 mAh/g than the ordered LiNi0.5Mn1.5O4 (85 mAh/g). Among the three samples, LiNi0.4Mn1.6O4 presents the lowest discharge capacities at various rates, which is mainly attributed to the presence of Li x Ni1−x O impurities [25]. In our previous work, the ordered LiNi0.5Mn1.5O4 hollow microspheres were synthesized with superior rate capability and good cycling stability, which were much better than the disordered LiNi0.5Mn1.5O4 [13]. But in this work, we prepare the spinel LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) hollow microspheres with quite similar structure and find that the disordered LiNi0.45Mn1.55O4 exhibits better rate capability than the ordered LiNi0.5Mn1.5O4 at high rates. As reported previously, disordered (Fd3m) LiNi0.5Mn1.5O5 presented large diffusion coefficient of Li+ (DLi +) than the ordered (P4332) in grain because of the existence of Mn3+ with the higher ionic conductivity and the large ionic radius in disordered LiNi0.5Mn1.5O4 [7–9]. In addition, as recently reported [26–28], single-crystal nanostructures favor charge transfer and accelerate the electrochemical reactions. Therefore, we believe that the higher rate capability of LiNi0.45Mn1.55O4 is attributed to both the high ionic conductivity and the large ionic transfer channel of the existed Mn3+ and the single-crystal surface configuration that also benefits for Li insertion and extraction [7–9, 13].

Cycling performance of Li/LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) cells is shown in Fig. 7, and all the three samples exhibit quite good cycling stability, possibly because of the unique nano/micro hierarchical structure. Also, their good cycling performance suggests that the hollow structure is stable enough during cycling. To understand the electrochemical performance in depth, EIS was carried out by using Li/LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) cells after the third cycle, shown in Fig. 8. All impedance spectra show a similar profile consisting of two semicircles and a sloping line. The semicircle in the high-to-medium frequency range is ascribed to the process of Li+-ion migration through the surface layer, the other semicircle in the medium-to-low frequency range is related to the charge transfer kinetics of the electrode, and the sloping line in the low frequency range is for the diffusion of Li+ in the solid electrode [29–33]. The impedance spectra can be explained on the basis of an equivalent circuit (inset of Fig. 8), and the fitting results are summarized in Table 1. In the equivalent circuit, Re represents the electrolyte resistance, Rs is the surface impedance, and Rct is the charge transfer impedance. CPE1 and CPE2 signify the corresponding constant-phase elements, which describe the nonideal capacitances of the surface layer and the double layer, respectively. Zw is the Warburg impedance. From Table 1, there is only negligible difference on Re, but remarkable difference can be found on Rs and Rct between the three samples. LiNi0.5Mn1.5O4 has the lower Rs of 19.4 Ω than LiNi0.45Mn1.55O4 (25.2 Ω) and LiNi0.4Mn1.6O4 (46.2 Ω), explaining for the higher initial capacity of LiNi0.5Mn1.5O4 at low rates (1 C and 2 C). But the Rct (26.4 Ω) of LiNi0.5Mn1.5O4 is higher than that of LiNi0.45Mn1.55O4 (19.0 Ω). Since the lower Rct is highly significant for the superior rate capability, LiNi0.45Mn1.55O4 exhibits the better rate capability than LiNi0.5Mn1.5O4 and LiNi0.4Mn1.6O4 at high rates. Basically, the good charge transfer kinetics of LiNi0.45Mn1.55O4 is attributed to the increased electronic conductivity and Li+ diffusion ability from the participation of Mn3+, even though too many Mn3+ in LiNi0.4Mn1.6O4 could increase both Rs and Rct as the result of the distortion of the lattice and the undesirable disproportionation. Therefore, introducing a moderate amount of Mn3+ in LiNi0.5Mn1.5O4 with the Fd3m, space group significantly improves the rate capability of the spinel hollow microspheres.

Conclusions

In summary, the ordered and disordered spinel hollow microspheres with highly similar structure were synthesized by simply adjusting the stoichiometric ratio of Ni/Mn in LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1). LiNi0.5Mn1.5O4 is the ordered, but LiNi0.45Mn1.55O4 and LiNi0.4Mn1.6O4 are the disordered along with the presence of Mn3+ in the lattice. Although the ordered LiNi0.5Mn1.5O4 hollow microspheres deliver the highest capacity at low rates among the three spinel materials, the disordered LiNi0.45Mn1.55O4 hollow microspheres exhibit the superior rate capability at high rates. That is, the disordered spinel LiNi0.5−x Mn1.5+x O4 with a moderate amount of Mn3+ has the better electrochemical performance than the ordered spinel with the similar morphology and structure. The improved high rate capability of LiNi0.45Mn1.55O5 is attributed to the combination of the increased electronic conductivity and Li+-ion diffusion by moderate Mn3+ incorporation, along with the hierarchical structure. Therefore, adjusting good stoichiometric ratio of Ni and Mn in LiNi0.5−x Mn1.5+x O4 is proved as an efficient way to improve the electrochemical performance of LiNi0.5Mn1.5O4 spinel hollow microspheres. The obtained LiNi0.45Mn1.55O4 hollow microspheres are worthy of further investigation and application as cathode material for advanced Li-ion batteries.

References

Armand M, Tarascon JM (2008) Nature 451:652

Bruce PG, Scrosati B, Tarascon JM (2008) Angew Chem Int Ed 47:2930

Zhong GB, Wang YY, Zhang ZC, Chen CH (2011) Electrochim Acta 56:6554

Yi TF, Xie Y, Ye MF, Jiang LJ, Zhu RS, Zhu YR (2011) Ionics 17:383

Kim JH, Myung ST, Yoon CS, Kang SG, Sun YK (2004) Chem Mater 16:906

Amdouni N, Zaghib K, Gendron F, Mauger A, Julien CM (2006) Ionics 12:117

Kunduraci M, Amatucci GG (2008) Electrochim Acta 53:4193

Kunduraci M, Al-Sharab J, Amatucci G (2006) Chem Mater 18:3585

Kunduraci M, Amatucci GG (2006) J Electrochem Soc 153:A1345

Shaju KM, Bruce PG (2008) Dalt Trans 40:5471

Wang LP, Li H, Huang XJ, Baudrin E (2011) Solid State Ionics 193:32

Ma XH, Kang B, Ceder G (2010) J Electrochem Soc 157:A925

Wu WW, Xiang HF, Zhong GB, Su W, Tang W, Zhang Y, Yu Y, Chen CH (2014) Electrochim Acta 119:206

Fei JB, Cui Y, Yan XH, Qi W, Yang Y, Wang KW, He Q, Li JB (2008) Adv Mater 20:452

Huang H, Chen CH, Perego RC, Kelder EM, Chen L, Schoonman J, Weydanz WJ, Nielsen DW (2000) Solid State Ionics 127:31

Zhou L, Zhao DY, Lou XW (2012) Angew Chem Int Ed 51:239

Liu YJ, Chen L (2012) Ionics 18:649

Song J, Shin DW, Yu Y, Amos CD, Manthiram A, Goodenough JB (2012) Chem Mater 24:3101

Yang TY, Zhang NQ, Lang Y, Sun KN (2011) Electrochim Acta 56:4058

Hao XG, Austin MH, Bartlett BM (2012) Dalt Trans 41:8067

Ariyoshi K, Iwakoshi Y, Nakayama N, Ohzuku T (2004) J Electrochem Soc 151:A296

Xu HY, Xie S, Ding N, Liu BL, Shang Y, Chen CH (2006) Electrochim Acta 51:4352

Ohzuku T, Takeda S, Iwanaga M (1999) J Power Sources 81:90

Kawaura H, Takamatsu D, Mor Si, Orikasa Y, Sugaya H, Murayama H, Nakanishi K, Tanida H, Koyama Y, Arai H, Uchimoto Y, Ogumi Z (2014) J Power Sources 245:816.

Zhang XF, Liu J, Yu HY, Yang GL, Wang JW, Yu ZJ, Xie HM, Wang RS (2010) Electrochim Acta 55:2414

Zhang GQ, Wu HB, Hoster HE, Chan-Park MB, Lou XW (2012) Energy Environ Sci 5:9453

Lu ZY, Rui XH, Tan HT, Zhang WY, Hng HH, Yan QY (2013) Chempluschem 78:218

Lee S, Cho Y, Song H-K, Lee KT, Cho J (2012) Angew Chem Int Ed 51:8748

Liu J, Manthiram A (2009) Chem Mater 21:1695

Liu J, Manthiram A (2009) J Electrochem Soc 156:A833

Zhang NQ, Yang TY, Lang Y, Sun KN (2011) J Alloys Compd 509:3783

Wu HM, Belharouak I, Abouimrane A, Sun YK, Amine K (2010) J Power Sources 195:2909

Mao J, Dai KH, Zhai YC (2012) Electrochim Acta 63:381

Acknowledgments

This study was supported by National Science Foundation of China (Grant Nos. 21006033 and 51372060) and the Fundamental Research Funds for the Central Universities (2013HGCH0002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, W.W., Chen, J.J., Cheng, S. et al. Preparation and electrochemical performance of spinel LiNi0.5−x Mn1.5+x O4 (x = 0, 0.05, 0.1) hollow microspheres as cathode materials for lithium-ion batteries. Ionics 21, 1843–1849 (2015). https://doi.org/10.1007/s11581-015-1374-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-015-1374-6