Abstract

The drying kinetics and quality characteristics of three potato (Solanum tuberosum) cultivars (Agria, Granola and Marabel) cut into circles and squares were studied at 60 °C and 70 °C using a convective drier. Drying times were varied between 105 and 220 min depending on variety, shape and temperature and falling rate period was observed during hot air drying. Four mathematical models were fitted to the experimental data. A logarithmic model was found to be the best for all the samples. The results showed that the drying kinetics of potato were significantly affected by variety, shape and temperature. Drying rate was found to be the highest in variety Marabel and it increased with the increase in temperature and was also higher in square-shaped potatoes than circle-shaped ones. Variety significantly affected the total polyphenol content (TPC) of dried potatoes, whereas variety, shape and their interactions had significant effects on their antioxidant capacities (AC). After drying, the highest TPC and AC were recorded for variety Agria. Concerning colour properties, while the drying temperature and shape had a significant effect on L value, variety and shape significantly affected other colour values of potato samples. These results demonstrated that when choosing the most suitable variety for convective drying of potato, it is necessary to consider the quality characteristics as well as the drying kinetics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potato is the third most important crop consumed after wheat and rice in the world. In addition to being eaten after cooking or processing, it is used as an ingredient in the composition of many processed foods such as sauces, soups and bakery products in fresh or dried forms (Wang et al. 2016). The high starch content of potato makes it more important to use in products like sauce where it is desired to have a high consistency.

Potato is affected by changes in temperature and moisture content, resulting in shorter shelf life (More et al. 2019). Moreover, with the onset of microbial growth, it becomes inedible. Drying is one method to increase the shelf life of foods (Jabeen et al. 2015) and drying with conventional air is the most common method (Bondaruk et al. 2007). This process decreases the water activity of the product, reduces microbiological activity and minimizes the physical and chemical changes during the storage (Yadollahinia and Jahangiri 2009). Also, it brings about substantial reduction in weight and volume, minimizing packaging, storage and transportation costs (Falade and Solademi 2010). However, the most important disadvantage of this method is the length of drying time, and so low energy efficiency (Jabeen et al. 2015). At the same time, it can adversely affect the quality parameters of the final product such as colour, texture and rehydration ability (Jarahizadeh and Dinani 2019).

Drying is influenced by many factors such as size and shape of material, dryer type and drying kinetics parameters (such as temperature, moisture ratio, drying rate and air velocity) (Song et al. 2009; Bakal et al. 2012). One of the important points in drying technology is the modelling of the drying process. An appropriate drying kinetics is needed to estimate the drying rate and optimize drying parameters (Naderinezhad et al. 2016). Drying kinetics are also affected by the process conditions such as air temperature and velocity as well as the properties of the material such as thickness and shape (Song et al. 2009).

Based on literature data, even though considerable work (Falade and Abbo 2007; Naderinezhad et al. 2016) has been done on the impact of various factors on drying kinetics and some quality parameters of fruit and vegetables, no scientific work has been published related to the effects of shape, variety and temperature on polyphenol content and antioxidant capacity of potato as well as drying behaviour. Therefore, the present investigation was undertaken to evaluate the effect of product shape (square and circle) and drying temperature (60 °C and 70 °C) on drying kinetics and quality properties of potato varieties Agria, Granola and Marabel.

Materials and Methods

Fresh, high-quality potatoes of varieties Agria, Granola and Marabel were purchased from a local store via local farmers. All varieties were grown in Yenice-Inegöl (Bursa, Turkey, 40° 5′ 48″ N 29° 25′ 41″ E) and harvested in July in 2018. They were selected because of their high economic interest for industrial production. The samples were kept at 4 °C for a day before the experiments were conducted.

Just before drying, peeled potatoes were washed under tap water and blotted with towel paper. They were cut into 2.8-mm-thick slices with a domestic slicer and then one part was prepared as a circle with a diameter of 38.5 mm using a circular cutting tool. The second part was cut into a square with dimensions of 12.2 × 12.2 mm.

In order to preserve colour of the sample during drying, a pre-treatment procedure was done. Previous studies (Naderinezhad et al. 2016; Olatunde et al. 2016) reported blanching in boiling water for a certain time as a pre-treatment. But above 65 °C, the starch in potatoes undergoes gelatinization accompanied by swelling so that the starch does not swell again when dried potato is used as an ingredient, which can restrict use of potato (Tan et al. 2019). That is why potato samples were soaked in citric acid solution (1%) for 5 min to prevent browning during drying. Concentration and duration of soaking in anti-browning solution were standardized based on the results of preliminary studies. Excess solution was removed using a filter paper. Initial moisture content of fresh potato samples was about 85%.

Drying Process

The drying process was carried out at 60 °C and 70 °C, based on literature, in 20% relative humidity and at 0.2 m/s air velocity using a convective cabinet-type laboratory drier (Yucebas Machine Analytical Equipment Industry Y35, Izmir, Turkey). The initial moisture content of the potato was measured using an infrared moisture analyzer (Sartorius MA150) at 105 °C. Prior to placing the sample in the drying cabinet, the system was run for at least 1 h to stabilize. About 20 g of potatoes was distributed uniformly on a greaseproof paper of known weight as a thin layer. Drying experiments were performed in three replicates. During the drying period, samples were taken out of the dryer at regular intervals (every 15 min at the early stage of drying and every 10 min and/or 5 min at the later stages of drying depending on the drying parameters applied) and weighed in a short time with digital weighing device (Mettler Toledo, MS3002S) with an accuracy of ±0.01 g. Weighing of samples was done manually outside the dryer until their moisture content reached below the 10% safe moisture level where microorganisms are not active (Hafezi et al. 2015). The dried potatoes were cooled to room temperature, then packaged in zip-lock plastic bags to prevent moisture exchanges and stored in a refrigerator at 4 °C until analyzed.

Determination of Moisture Content

During drying of the potato samples at different temperatures, the moisture content at any time t was calculated as follows:

- M t :

-

the moisture content at any time of t (g water/g dry matter-DM)

- m :

-

mass (g)

- DM :

-

the amount of dry matter (g)

Determination of Drying Rate

To calculate the drying rate (g water/g DM min), an appropriate empirical equation was fitted to the experimental moisture removal data and was then differentiated with respect to time using the following equation:

- M t + dt :

-

moisture content at t + dt (g water/g DM)

- dt :

-

time between two sample weighings (min)

Determination of Moisture Ratio

The moisture ratio (MR) was calculated from the weight changes of the samples and these values were used in the modelling related to drying kinetics as follows:

- MR:

-

moisture ratio (dimensionless)

- M t :

-

moisture content at time t (g water/g DM)

- M o :

-

initial moisture content (g water/g DM)

- M e :

-

equilibrium moisture content (g water/g DM)

Mathematical Modelling

Four thin layer drying models, commonly cited in the literature, were tested to describe the drying characteristics of potato samples (Table 1). The models were evaluated based on the coefficient of determination (R2), the root mean square error (RMSE) and Chi-square (χ2) (Faustino et al. 2007). The best model describing the thin layer drying characteristics of potato was chosen as the one with the lowest χ2 and RMSE, and the highest (R2). The constants k and n of model equations below were evaluated through nonlinear regression analysis using the MINITAB-16 software.

Model validation was also performed to determine the most suitable model. For this purpose, the averages of two data sets were used to build the model and the validation was achieved by applying nonlinear regression method by using the third data set. Model parameters were calculated using equations (Walther and Moore 2005) as follows:

- N :

-

the number of observations

- z :

-

the number of drying constants

- MRexp, i:

-

the experimental moisture ratio of ith data

- MRpred, i:

-

the predicted moisture ratio of ith data

Colour Measurement

The colour properties of dried potatoes were measured by a Konica Minolta Chroma Meter (CR-5, Bench-top, Japan). This instrument was automatically calibrated with respect to black and white prior to the experiment. Colour values were recorded as L (brightness), a (redness-greenness), b (yellowness-blueness), C (chroma) and h (hue angle). Samples were placed at the light port of colorimeter in a cylindrical glass dish (50-mm diameter and 40-mm depth) and for each sample, at least three measurements were made at different positions of the sample.

Extraction of Polyphenols

Dried samples (0.2 g) were extracted with 80% aqueous methanol (4.5 mL) on a mechanical shaker for 2 h. The mixture was centrifuged (Sigma 3K 30) at 10,000 rpm for 15 min and the supernatant decanted into polypropylene tubes. The pellets were extracted under identical conditions. Supernatants were combined and filtered through a Whatman no. 1 filter paper. The clear extracts were analyzed for both determination of phenolic content and antioxidant capacity. For the fresh sample, 1.0 g flesh tissue (equal to 0.2 g dry weight) was extracted using the above procedure.

Total Polyphenol Content

The amount of total phenolics was determined using the Folin-Ciocalteu method (Obanda and Owuor 1997). The measurement was performed at 700 nm against blank using a spectrophotometer (Shimadzu UV-VIS 1208). A calibration curve of gallic acid (5-50 μg/mL) was prepared and the results determined from regression equation of the calibration curve (y = 0.0157x, R2 = 0.99) were expressed as mg gallic acid equivalents per g of dry matter.

Antioxidant Capacity

Antioxidant capacity (AC) was determined by the 2,2,diphenyl-2-picryl-hydrazyl (DPPH) method of Turkmen et al. (2005) at 517 nm and calculated as percentage inhibition of the DPPH radical by the following equation:

Standard curve of reference antioxidant ascorbic acid (0-20 μg/mL) was assayed under identical conditions for affinity to scavenge DPPH. Antioxidant capacity of samples was converted to ascorbic acid equivalent (AEAC) defined as mmol of ascorbic acid equivalents per 100 g of DM.

Statistical Analysis

All data were expressed as mean ± standard deviation of triplicate measurements and analyzed by the SPSS software (SPSS statistics 23, IBM.2015). Quality characteristics were analyzed by analysis of variance (ANOVA) for a factorial experiment with three varieties, two shapes and two drying temperatures, using the GLM procedure. Means were compared using Duncan’s multiple comparison test. Values of P < 0.05 were considered significantly different.

Results and Discussion

Drying Kinetics

Moisture Ratio

The effects of variety, temperature and shape on drying times of potato samples are presented in Table 2. The results showed that variety, air temperature and shape had an effect on drying time. Initial moisture contents of varieties Agria, Marabel and Granola were 4.34, 4.22 and 3.48 g water/g DM, respectively. Square and circle-shaped potatoes were dried in a thin layer at 60 °C and 70 °C in a hot air drier to a final average moisture content of 0.08 g water/g DM. While the longest drying time (220 min) was observed in circle-shaped Agria variety dried at 60 °C, the shortest drying time (105 min) was in square-shaped Granola variety dried at 70 °C. Increase in drying temperature for all potato samples resulted in reduction of drying time which is in agreement with the result of Bakal et al. (2012). With the increasing of temperature from 60 to 70 °C, reductions of drying time of square-shaped Agria, Marabel and Granola were 3.45%, 14.28% and 12.5%, respectively, and for circle-shaped potatoes, these reductions were 27.27%, 30.77% and 20%, respectively. Also, square-shaped potatoes dried faster than circle shaped ones for each drying temperature and variety, which is consistent with the results of Naderinezhad et al. (2016). However, Bakal et al. (2012) reported that drying time was not dependent on shape for potato. The longer drying times for circle-shaped potatoes could be explained by the increase of the amount of water to be removed from the material, because of the increased surface area.

The changes in moisture ratio of potato samples dried at different temperatures as a function of time are presented in Fig. 1. For all potato samples, the moisture ratio decreased with increasing drying temperature. Also, at the beginning of drying, the moisture ratio was very high and decreased as time progressed. This could be explained by increasing resistance to moisture diffusion inside the material due to toughening of the outer layers of the potato (Nadi and Tzempelikos 2018).

Drying Rate

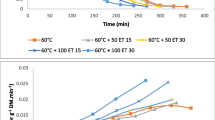

In order to investigate the effect of variety, temperature and shape on drying rate of three potato varieties, drying rate was calculated according to logarithmic model (see below) and plotted against moisture content (dry basis) (Fig. 2). It is apparent that drying rate decreased continuously due to decrease in moisture content, which causes the decreased moisture migration and evaporation rate from the surface of the product (Kaur et al. 2018; Jarahizadeh and Dinani 2019). For potato samples, a constant rate period was not observed in the drying experiments. Therefore, the entire drying process occurred in the falling rate period, which was also consistent with the studies reported for bell pepper (Singh et al. 2000), potato (Bakal et al. 2012; Hafezi et al. 2015; Jabeen et al. 2015; Naderinezhad et al. 2016) and apple (Nadi and Tzempelikos 2018). This could be because diffusion was the dominant physical mechanism governing moisture movement in the samples (Falade and Abbo 2007). In other words, reducing moisture content and increasing the surface shrinkage of potatoes during process could cause decreasing heat penetration through the dried layer and so descending phase.

For all samples, as the temperature increased from 60 to 70 °C, drying rate increased (Fig. 2). Similar results were observed by Kaur et al. (2018) for fenugreek, and Kaleta and Górnicki (2010) for apple. It can be explained by increased heat transfer between potatoes and their environment and that is why increased the acceleration of water migration from the core to the surface of the potatoes (Bakal et al. 2012; Nadi and Tzempelikos 2018). Also, it is known that air relative humidity which decreases as a result of increasing temperature has a high drying potential (Doymaz and Aktas 2018). Consequently, increased temperature accelerated the drying process resulting in a decrease in time required to draw out the moisture from the sample (Jabeen et al. 2015).

Square-shaped potatoes had higher drying rates than circle-shaped ones (Fig. 2), which showed that drying rate was dependent on the shape. Similarly, Kaleta and Górnicki (2010) reported that drying rate of apple cubes was higher than slices due to the higher surface area exposed for a given volume of the product. This is consistent with the result of Shi et al. (2008) who found that drying rates increased with decrease in berry size. It might be due to the fact that minimizing the size of the product reduced the distance for the water to diffuse and so caused the product to dry faster (Ertekin and Yaldız 2004). A similar finding was observed for red pepper (chilli) (Gupta et al. 2002).

From the results, the variety also affected the drying rate, which is in agreement with the findings by Markowski et al. (2006) for carrot. During the initial phase of drying, the highest drying rate (0.07676 g water/g DM min) was observed for square-shaped Marabel variety which was dried at 70 °C, followed by Agria (0.0567 g water/g DM min) and Granola (0.04667 g water/g DM min) varieties, respectively. Differences in drying rates of potato varieties could be due to variation in their initial moisture content and composition (Falade and Abbo 2007).

Mathematical Modelling

Four different mathematical models, namely Newton, Page, logarithmic and Henderson and Pabis were tested to describe the behaviour of potato samples during drying using non-linear regression analysis technique. The model parameters and the statistics used to evaluate the suitability of models for Agria, Marabel and Granola varieties are presented in Table 3.

The best model describing the drying characteristics of potato samples was chosen as the one with the highest R2 values and the lowest χ2 and RMSE values (Faustino et al. 2007). Logarithmic model mostly provided these values so it was found to be the best for describing the drying characteristics of potato samples according to these values (Table 3). Similarly, drying behaviours of green bell pepper (Doymaz and Ismail 2010) and apple (Kaleta et al. 2013) were described best with logarithmic model.

The coefficient “k” which is a measure of the drying rate (Singh et al. 2000) increased with increase in drying temperature applied (Kaleta et al. 2013), which indicated that drying kinetics was dependent on temperature (Kaur et al. 2018) and it was also found to be higher for square-shaped potatoes than circle-shaped ones indicating that the k value was also dependent on the shape.

Validation of the selected model was confirmed by comparing the predicted moisture contents with the measured values for different drying temperatures and shapes of each variety. The plots of experimental versus predicted moisture ratios by logarithmic model are shown in Fig. 3. The data points were closely banding around 1:1 line, which indicates very good agreement between the calculated and the experimental data (R2 >0.99). Therefore, logarithmic model could adequately describe the drying behaviour of potato and so the change in the moisture content of the product could be estimated to be close to the experimental data by the logarithmic model.

Total Polyphenol Content and Antioxidant Capacity

The total polyphenol content (TPC) of the dried potato samples is presented in Table 4. The results in this study indicated that TPC of dried potato samples varied in the range of 1.13-2.11 mg GAE/g DM. The initial total polyphenol contents of fresh potatoes of Marabel, Granola and Agria were 2.70, 2.40 and 1.64 mg GAE/g DM, respectively. It was observed that after drying, Agria had an increase in TPC compared to the fresh sample. A similar result was reported for apples by Lutz et al. (2015). It is attributed to the release of phenolic compounds from food matrix during drying process (Chang et al. 2006; Yang et al. 2010) or the formation of Maillard reaction products which could cause new phenolic compounds to form from precursors (Önal et al. 2019). In other words, although natural antioxidants are lost during heating, the overall antioxidant properties of foods could be maintained or enhanced by the development of new antioxidants (Zura-Bravo et al. 2013). Joshi et al. (2011) also reported that TPC of apple was not affected by air and oven drying. However, the dried samples of the two varieties Marabel and Granola had a reduction of TPC compared to fresh samples, as observed by Francini et al. (2017) for apples, which could be due to chemical degradation of phenolic compounds during drying (Kuyu et al. 2018; Önal et al. 2019). The other reason for decrease in polyphenol content during drying could be attributed to the binding of polyphenols with other compounds like proteins or modifications in the chemical structure of polyphenols, which could not be extracted or determined by available methods (Zura-Bravo et al. 2013). Additionally, the polyphenols are affected by hydrolysis and oxidation reactions. Polyphenol oxidase (PPO) catalyzes the oxidation of phenolic compounds. Damage to the cell membrane releases the enzyme and therefore activates it (Aghilinategh et al. 2015). For this reason, under our experimental conditions (drying temperatures of 60 °C and 70 °C), PPO activity could have remained high for longer periods depending on the variety due to the fact that higher temperatures such as 75-80 °C are needed to inactivate the enzyme (Madrau et al. 2009).

According to Table 5, variety significantly affected TPC of dried potatoes, but there were no interactions with the other treatments despite the largest differences being for squares at 70 °C (Table 4, P < 0.05). After drying, the highest TPC was recorded from Agria followed generally by Marabel and Granola, respectively, which was different from the order of fresh potatoes. There is not enough literature on the effects of potato varieties on polyphenols. Kuyu et al. (2018) reported that sweet potato varieties showed differences in polyphenol content, which is in agreement with our results. In contrast, according to Lutz et al. (2015), there was no difference between TPC of Granny Smith and Red delicious apple varieties. Drying temperature and shape did not have significant effect on TPC of potatoes (Table 5). Contrary to the results of this study, Ahmed et al. (2010) stated that higher temperatures release more of the bound polyphenols due to breakdown of cell wall phenolic compounds. Oliveira et al. (2015) described similar observations.

The initial antioxidant capacity values of fresh potatoes of Granola, Agria and Marabel were 444.23, 346.84 and 279.82 mmol AEAC/100 g DM, respectively. In contrast to the trend for TPC after drying, Agria and Marabel varieties had higher antioxidant capacities than their fresh counterparts. This is in accordance with the study of Chang et al. (2006) who reported that the drying process could enhance antioxidant activity through the increase of antioxidant components in tomato. Similar results were reported by Yang et al. (2010) that drying enhanced antioxidant activity of sweet potatoes despite a decrease in antioxidant components such as ascorbic acid at drying temperature above 60 °C, suggesting the formation of new phenolic compounds. In addition, increase in reducing sugars and the formation of Maillard reaction products with high AC may be other factors related to the increase in AC (Wang et al. 2018). Conversely, hot air drying resulted in a decrease in AC of Granola variety with respect to fresh potato. This agrees with the studies reported by Lutz et al. (2015) for different fruits and vegetables and López et al. (2016) for blueberry. This decrease in AC of Granola could be attributed to the decrease in its TPC at the same time, as indicated above, or the decrease in its non-phenolic compounds (e.g. ascorbic acid) with antioxidant capacity, although this was not evidenced in this study.

Variety, shape and their interaction, but not temperature, had significant effects on antioxidant capacities of dried potato samples (Table 5). The highest antioxidant capacities were recorded from Agria, followed generally by Marabel and then Granola (Table 4). This ranking is compatible with that in TPC. Kuyu et al. (2018) stated that antioxidant activity varied with variety, which is in agreement with our results. With respect to shape, in general, circle-shaped potatoes at 60 °C and square-shaped potatoes at 70 °C had higher antioxidant capacities. Higher antioxidant capacity of circle-shaped potatoes dried at 60 °C may be attributed to the release of some more phenolic compounds which are bound to the food matrix after convective drying (Valadez-Carmona et al. 2017; Tan et al. 2020), as a result of longer drying time. On the other hand, the reason for the higher antioxidant capacity of square-shaped potatoes dried at 70 °C can be explained by less thermal degradation of the polyphenols and other bioactive compounds, such as ascorbic acid, with antioxidant activity (Henríquez et al. 2014; Méndez-Lagunas et al. 2017) due to shorter drying time compared to circle ones.

Colour Values

Colour is one of the important quality characteristics in food acceptance (Bochnak and Swieca 2020). That is why potato samples were pre-treated with citric acid solution to prevent colour deterioration, which was based on preliminary trials indicating that samples with no pre-treatment prior to drying became darker. Colours of dried potatoes were analyzed and the results are detailed in Table 6. It was observed that there were significant differences among colour values of potato samples dried at 60 °C and 70 °C. The analysis of variance showed that the effect of temperature and shape on L value was significant (Table 7). Dipping in citric acid solution prior to drying preserved the colour of all samples, which is consistent with L (brightness) values (61.38-77.27). A similar observation was made by Doymaz (2012). Regardless of the variety, the highest L values were recorded from square-shaped potatoes dried at 70 °C, which could be due to their shortest drying times. The effect of variety on a (redness), b (yellowness), C and h values was found to be significant (P < 0.05), which could be due to differences in composition of these three potato varieties. There were significant differences among a, b and C values of square- and circle-shaped potatoes (P < 0.05) (Tables 6 and 7). Despite higher a value of square-shaped samples, browning reactions were not observed in potato samples during drying. Similarly, Bondaruk et al. (2007) reported that enzymatic browning did not occur for potatoes dried with hot air at 50 °C and 70 °C. Lower b values of circle-shaped samples might be due to carotenoid loss as yellow colour of potato is attributed to carotenoids (Ahmed et al. 2010).

Conclusion

The results showed that the drying kinetics of potato were significantly affected by variety, shape and temperature. Drying rate was found to be the highest in variety Marabel and it increased with the increase in temperature and was also higher in square-shaped potatoes than circle-shaped ones. Thin layer drying of potato took place in the falling drying rate period. A logarithmic model was found to be the best to describe the drying behaviour of potatoes for the thin layer drying conditions of this study. Variety significantly affected the total polyphenol content (TPC) of dried potatoes, whereas variety, shape and their interactions had significant effects on their antioxidant capacities (AC). After drying, the highest TPC and AC were recorded for variety Agria. Concerning colour properties, while the drying temperature and shape had a significant effect on L value, variety and shape significantly affected other colour values of potato samples. These results demonstrated that when choosing the most suitable variety for convective drying of potato, it is necessary to consider the quality characteristics as well as the drying kinetics.

References

Aghilinategh N, Rafiee S, Gholikhani A, Hosseinpur S, Omid M, Mohtasebi SS, Maleki NA (2015) Comparative study of dried apple using hot air, intermittent and continuous microwave: evaluation of kinetic parameters and physicochemical quality attributes. Food Sci Nutr 3(6):519–526

Ahmed M, Sorifa AM, Eun JB (2010) Effect of pretreatments and drying temperatures on sweet potato flour. Int J Food Sci Technol 45(4):726–732

Bakal SB, Sharma GP, Sonawane SP, Verma RC (2012) Kinetics of potato drying using fluidized bed dryer. J Food Sci Technol 49(5):608–613

Bochnak J, Swieca M (2020) Potentially bioaccessible phenolics, antioxidant capacities and the colour of carrot, pumpkin and apple powders–effect of drying temperature and sample structure. Int J Food Sci Technol 55:136–145

Bondaruk J, Markowski M, Błaszczak W (2007) Effect of drying conditions on the quality of vacuum-microwave dried potato cubes. J Food Eng 81(2):306–312

Chang CH, Lin H, Chang CH, Liu YC (2006) Comparisons on the antioxidant properties of fresh, freeze-dried and hot-air-dried tomatoes. J Food Eng 77:478–485

Diamante LM, Ihns R, Savage GP, Vanhanen L (2010) A new mathematical model for thin layer drying of fruits. Int J Food Sci Technol 45(9):1956–1962

Doymaz İ (2012) Drying of potato slices: effect of pretreatments and mathematical modeling. J Food Process Preserv 36:310–319

Doymaz İ, Aktas C (2018) Determination of drying and rehydration characteristics of eggplant slices. J Fac Eng Archit Gaz 33(3):833–841

Doymaz İ, İsmail O (2010) Drying and rehydration behaviors of green bell peppers. Food Sci Biotechnol 19(6):1449–1455

Ertekin C, Yaldız O (2004) Drying of eggplant and selection of a suitable thin layer drying model. J Food Eng 63(3):349–359

Falade KO, Abbo SE (2007) Air-drying and rehydration characteristics of date palm (Phoenix dactylifera L.) fruits. J Food Eng 79:724–730

Falade KO, Solademi OJ (2010) Modelling of air drying of fresh and blanched sweet potato slices. Int J Food Sci Technol 45(2):278–288

Faustino JMF, Barroca MJ, Guiné RPF (2007) Study of the drying kinetics of green bell pepper and chemical characterization. Food Bioprod Process 85:163–170

Francini A, Romeo S, Cifelli M, Gori D, Domenici V, Sebastiani L (2017) 1H NMR and PCA-based analysis revealed variety dependent changes in phenolic contents of apple fruit after drying. Food Chem 221:1206–1213

Gupta P, Ahmed J, Shivhare US, Raghavan GSV (2002) Drying characteristics of red chilli. Dry Technol 20:1975–1987

Hafezi N, Sheikhdavoodi MJ, Sajadiye SM (2015) Evaluation of quality characteristics of potato slices during drying by infrared radiation heating method under vacuum. Int J Agr Food Res 4(3):1–8

Henríquez C, Córdova A, Almonacid S, Saavedra J (2014) Kinetic modeling of phenolic compound degradation during drum-drying of apple peel by-products. J Food Eng 143:146–153

Jabeen R, Aijaz T, Gul K (2015) Drying kinetics of potato using a self-designed cabinet dryer. Cogent Food & Agric 1(1):1036485

Jarahizadeh H, Dinani ST (2019) Influence of applied time and power of ultrasonic pretreatment on convective drying of potato slices. Food Sci Biotechnol 28(2):365–376

Joshi APK, Rupasinghe HPV, Khanizadeh S (2011) Impact of drying processes on bioactive phenolics, vitamin C and antioxidant capacity of red-fleshed apple slices. J Food Process Preserv 35:453–457

Kaleta A, Górnicki K (2010) Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int J Food Sci Technol 45(5):891–898

Kaleta A, Górnicki K, Winiczenko R, Chojnacka A (2013) Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers Manag 67:179–185

Kaur R, Kumar M, Gupta OP, Sharma S, Kumar S (2018) Drying characteristics of Fenugreek and its computer simulation for automatic operation. Int J Curr Microbiol App Sci 7(3):3275–3291

Kuyu CG, Tola YB, Mohammed A, Ramaswamy HS (2018) Determination of citric acid pretreatment effect on nutrient content, bioactive components, and total antioxidant capacity of dried sweet potato flour. Food Sci Nutr 6(1):1724–1733

López J, Uribe E, Vega-Gálvez A, Miranda M, Vergara J, Gonzalez E, Scala K (2016) Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning and firmness of blueberries variety O´Neil. Food Bioprocess Technol 3:772–777

Lutz M, Hernández J, Henríquez C (2015) Phenolic content and antioxidant capacity in fresh and dry fruits and vegetables grown in Chile. Cyta-J Food 13:541–547

Madrau MA, Piscopo A, Sanguinetti AM, Caro DC, Poiana M, Romeo FV, Piga A (2009) Effect of drying temperature on polyphenolic content and antioxidant activity of apricots. Eur Food Res Technol 228:441–448

Markowski M, Stankiewicz I, Zapotoczny P, Borowska J (2006) Effect of variety on drying characteristics and selected quality attributes of dried carrots. Dry Technol 24:1011–1018

Méndez-Lagunas L, Rodríguez-Ramírez J, Cruz-Gracida M, Sandoval-Torres S, Barriada-Bernal G (2017) Convective drying kinetics of strawberry (Fragaria ananassa): effects on antioxidant activity, anthocyanins and total phenolic content. Food Chem 230:174–181

More SJ, Ravi V, Raju S (2019) Postharvest physiological disorders in fruits and vegetables. In: Freitas ST, Pareek S (eds) CRC Press. Taylor&Francis Group, Boca Raton, FL Tropical Tuber Crops Section IV, p 719

Naderinezhad S, Etesami N, Poormalek Najafabady A, Ghasemi Falavarjani M (2016) Mathematical modeling of drying of potato slices in a forced convective dryer based on important parameters. Food Sci Nutr 4(1):110–118

Nadi F, Tzempelikos D (2018) Vacuum drying of apples (cv. Golden delicious): drying characteristics, thermodynamic properties, and mass transfer parameters. Heat Mass Transf 54:1853–1866

Obanda M, Owuor PO (1997) Flavanol composition and caffeine content of green leaf as quality potential indicators of Kenyan black teas. J Sci Food Agric 74:209–215

Olatunde GO, Henshaw FO, Idowu MA, Tomlins K (2016) Quality attributes of sweet potato flour as influenced by variety, pretreatment and drying method. Food Sci Nutr 4(4):623–635

Oliveira SM, Ramos IN, Brandão TRS, Silva CLM (2015) Effect of air-drying temperature on the quality and bioactive characteristics of dried Galega Kale (Brassica oleracea L. Var. Acephala). J Food Process Preserv 39:2485–2496

Önal B, Adiletta G, Crescitelle A, Matteo DM, Russo P (2019) Optimization of hot air drying temperature combined with pre-treatment to improve physico-chemical and nutritional quality of ‘Annurca’ apple. Food Bioprod Process 115:87–99

Roberts JS, Kidd DR, Padilla-Zakour O (2008) Drying kinetics of grape seeds. J Food Eng 89:460–465

Shi J, Pan Z, Mchugh TH, Wood D, Zhu Y, Avena-Bustillos RJ, Hirschberg E (2008) Effect of berry size and sodium hydroxide pretreatment on the drying characteristics of blueberries under infrared radiation heating. J Food Sci 73(6):259–265

Singh M, Shivhare US, Ahmed J (2000) Drying characteristics and product quality of bell pepper. Int J Food Prop 3(2):249–257

Sobukola OP, Dairo OU (2007) Modeling drying kinetics of fever leaves (Ocimum viride) in a convective hot air dryer. Niger Food J 25:146–154

Song XJ, Zhang M, Mujumdar AS, Fan L (2009) Drying characteristics and kinetics of vacuum microwave–dried potato slices. Dry Technol 27(9):969–974

Tan S, Wang Z, Xiang Y, Deng T, Zhao X, Shi S, Zheng Q, Gao X, Li W (2020) The effects of drying methods on chemical profiles and antioxidant activities of two cultivars of Psidium guajava fruits. LWT Food Sci Technol 118:108723

Tan Y, Zhaoc Y, Hu H, Fud N, Zhang C, Zhang H, Daia X (2019) Drying kinetics and particle formation of potato powder during spray drying probed by microrheology and single droplet drying. Food Res Int 116:483–491

Turkmen N, Sari F, Velioglu YS (2005) The effect of cooking methods on total phenolics and antioxidant activity of selected green vegetables. Food Chem 93:713–718

Valadez-Carmona L, Plazola-Jacinto CP, Hernández-Ortega M, Hernández-Navarro MD, Villarreal F, Necoechea-Mondragón H, Ortiz-Moreno A, Ceballos-Reyes G (2017) Effects of microwaves, hot air and freeze-drying on the phenolic compounds, antioxidant capacity, enzyme activity and microstructure of cacao pod husks (Theobroma cacao L.). Innov Food Sci Emerg Technol 41:378–386

Walther BA, Moore JL (2005) The concepts of bias, precision and accuracy, and their use in testing the performance of species richness estimators, with a literature review of estimator performance. Ecography 28(6):815–829

Wang J, Yang XH, Mujumdar AS, Fang XM, Zhang Q, Zheng ZA, Gao ZJ, Xiao HW (2018) Effects of high-humidity hot air impingement blanching (HHAIB) pretreatment on the change of antioxidant capacity, the degradation kinetics of red pigment, ascorbic acid in dehydrated red peppers during storage. Food Chem 259:65–72

Wang L, Guo J, Wang R, Shen C, Li Y, Luo X, Li Y, Chen Z (2016) Studies on quality of potato flour blends with rice flour for making extruded noodles. Cereal Chem 93(6):593–598

Yadollahinia A, Jahangiri M (2009) Shrinkage of potato slice during drying. J Food Eng 94(1):52–58

Yagcioglu A, Degirmencioglu A, Cagatay F (1999) Drying characteristics of laurel leaves under different drying conditions. In: Proceedings of the 7th International Congress on Agricultural Mechanization and Energy, Adana, Turkey, May 26-27:565-569

Yang J, Chen J, Zhao Y, Mao L (2010) Effects of drying processes on the antioxidant properties in sweet potatoes. Agric Sci China 9:1522–1529

Zura-Bravo L, Ah-Hen K, Vega-Gálvez A, Garcia-Segovia P, Lemus-Mondaca R (2013) Effect of rehydration temperature on functional properties, antioxidant capacity and structural characteristics of apple (Granny smith) slices in relation to mass transfer kinetics. J Food Process Eng 36:559–571

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Türkmen Erol, N. Mathematical Modelling of Thin Layer Dried Potato and Effects of Different Variables on Drying Behaviour and Quality Characteristics. Potato Res. 65, 65–82 (2022). https://doi.org/10.1007/s11540-021-09509-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11540-021-09509-w