Abstract

In this article, a surface plasmon resonance (SPR) biosensor based on D-typed optical fiber coated by Al2O3/Ag/Al2O3 film is investigated numerically. Resonance in near infrared with an optimized architecture is achieved. Refractive index sensitivity of 6558 nm/RIU (refractive index unit) and detection limit of 1.5 × 10−6 RIU, corresponding to 0.4357 nm/μM and detection limit of 23 nM in BSA (bovine serum albumin) concentration sensing, are obtained. The analysis of the performance of the sensor in gaseous sensing indicates that this proposed SPR sensor is much suitable for label-free biosensing in aqueous media.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

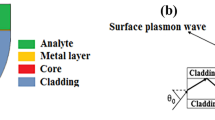

Surface plasmon resonance (SPR) is a charge-density oscillation existing at the metal/dielectric interfaces [1], which can be excited by transverse-magnetic (TM) wave. Such interaction leads SPR highly sensitive to the optical and structural properties of the interface.

Over the past few decades, remarkable progress has been made in the development of SPR-based devices [2,3,4,5,6]. Among them, SPR sensors especially fiber-optic SPR sensors have drawn much attention due to the fantastic features, such as high sensitivity, easy for alignment, online measurement, miniaturized probe, and remote sensing [7,8,9,10,11]. The proposed fiber-optic SPR sensors are based on the Kretchmann’s configuration, where SPR is excited at the interface of optical fiber and coated metal film by evanescent wave via attenuated total internal reflection (TIR).

However, most of these configurations provide resonance at visible wavelengths, where specific visible fibers are necessary. The transmission loss of visible fibers is much higher than that of telecom fibers. Also, the evanescent wave in the surrounding medium has a penetration depth proportional to the operation wavelength (λ). It usually ranges between λ/5 and λ/2, depending on the mode order [12]. Hence, operation in near infrared increases the penetration depth, therefore, the sensor sensitivity. Two strategies are utilized in order to achieve SPR at telecom wavelengths or in the near-infrared band: grating coupling [13, 14] and special plasmonic coating [15,16,17].

In this paper, we propose and numerically investigate an SPR sensor based on D-typed optical fiber coated with Al2O3/Ag/Al2O3 multilayer films. The structural parameters are optimized to achieve the resonance in near infrared and enhance the sensor performance for biosensing in aqueous media. The proposed sensor takes advantages such as easy-to-design, low-cost, and high-sensitivity in label-free BSA concentration sensing.

Theoretical Model

The optical fiber SPR sensor is a six-layer system consisting of a fiber core, cladding, Al2O3 layer, silver layer, Al2O3 layer, and the sensing medium, as shown in Fig. 1. The flat plane of the side-polished D-typed fiber is coated by Al2O3/Ag/Al2O3 multilayer films for refractive index sensing. The length of the polished region is L, and h is the height between the lower Al2O3 layer and the core/cladding interface of the other unpolished side. The diameter of the fiber core is D. θ is the total reflection angle inside the fiber core. Evanescent wave is generated at the core/cladding interface. The plasmon waves are excited by the evanescent wave at the upper and lower surfaces of the metal layer. When the energy is transferred from the incident photons to surface plasmons, a sharp dip can be observed in the transmission spectrum that refers to the resonance.

Refractive Indices of Various Layers

For the core of the silica optical fiber, Sellmeier relation has been used to determine the wavelength dependence of the refractive index (RI)

where the wavelength λ is in micrometer, a and b are the Sellmeier coefficients and the values are given as a1 = 0.6961663, a2 = 0.4079426, a3 = 0.8974794, b1 = 0.0684043, b2 = 0.1162414, b3 = 9.896161 [18].

The second and the fourth layers are Al2O3. In order to describe the wavelength dependence of the RI, one-term Sellmeier-like dispersion formula is obtained by fitting the experimental data [19] as

whereA1 = 2.05592 and λ1 = 0.10278 μm are the relative oscillator strength and the resonant wavelength, respectively.

For the silver layer, the wavelength dependence of the dielectric constant is described using the Drude model as

where λp = 0.14541 μm is the wavelength corresponding to the bulk plasma frequency and λc = 17.614 μm denotes the collision wavelength and is related to the losses.

The RI of the sensing medium ns is set to investigate the RI sensing performance of the proposed sensor.

N-Layer Matrix Method

For simplification, we only consider the fundamental LP01 mode of the optical fiber [20]. Then, the sensor transmission is modeled with a simple ray optics approach, and the D-typed fiber-optic sensor can be simplified as an elongated micro-prism coated with Al2O3/Ag/Al2O3 multilayer films [21]. By the well-established N-layer matrix method [22], the normalized transmitted power at the output end of the D-typed fiber is given as

where θ is the angle of the ray normal to the core-cladding interface, nc is the RI of the fiber core, Rp is the net reflection coefficient of the ray incident at the core-Al2O3 interface, and θcr = sin−1(ncl/nc) is the critical angle of the TIR, ncl is the RI of the fiber cladding. Nref (θ) is the total number of reflections undergone by the ray in sensing region, given by

Results and Discussion

To investigate and optimize the performance of the proposed fiber-optic SPR sensor, we made a series of simulation based on standard single-mode fiber (Corning SMF-28) with core diameter of 8.2 μm and refractive indices of the core and the cladding are nc = 1.4494 and ncl = 1.444 (@ 1550 nm), respectively.

Optimization of the Fiber Cladding

First, the effects of polished depths on the performance of the proposed sensor are discussed through the transmission spectrum characteristics. Figure 2a shows the transmission spectra of the proposed SPR sensor with different heights h, where 4.1 μm represents the fiber core is half polished, 8.2 μm represents the polished plane stops at the core/cladding interface, and 13.2 μm means the residual cladding thickness is 5.0 μm. Figure 2b gives the corresponding resonance dip FWHM (full width at half maximum) and contrasts, where the contrast is described as the difference of transmissions at dip and long-wavelength equilibrium. The thicknesses of silver layer and Al2O3 layer are set to be 70 and 90 nm, respectively. The surrounding sensing medium is water, whose RI is 1.3330.

From Fig. 2, we can see that the resonance FWHM decreases monotonously with the increase of height. This is because deeper polish leads to larger loss, therefore broader resonance peak. When 2.0 μm fiber cladding is left, i.e., the height is 10.2 μm, the relative depth of the resonance dip reaches the maximum, where the contrast is 0.41 and the FWHM is 52.74 nm. In this case, more evanescent field can excite the SPR at Al2O3/Ag/Al2O3 multilayer film, so that more light energy is transferred to surface plasmon. It is noted that when the height is 11.2 μm, the corresponding FWHM and contrast are 45.52 nm and 0.40, respectively. The deeper resonance dip contributes to higher SNR (signal noise ratio), and narrower resonance dip to higher detection accuracy. Thus, we choose 11.2 μm as the optimized height, i.e., the residual thickness of the fiber cladding is 3 μm.

Optimization of the Metal and Oxide Layers

The effects of thicknesses of the metal and oxide layers on the performance of the proposed sensor are discussed through the transmission spectrum characteristics in terms of FWHM and spectrum contrasts, as plotted in Fig. 3. For the optimization of the silver thickness, the Al2O3 layer is set to 90 nm and the sensing medium is water. As shown in Fig. 3a, b, the resonance spectra are highly related to the silver layer thickness, i.e., with increase of silver layer thickness from 40 to 90 nm, the FWHM decrease by four times from 134 to 31 nm, but the contrast reaches the peak of 0.5371 at 60 nm. So 60 nm is chosen as the optimized thickness for silver layer.

Then, the effect of Al2O3 layer thickness on the resonance spectra can be investigated. Figure 3c, d depicts the resonance spectra when the Al2O3 layer thickness varies from 70 to 120 nm with 60 nm silver layer and sensing medium of water. It can be seen that when the Al2O3 layer becomes thick, the resonance wavelength exists a dramatically monotonous red shift from 1141 to 1553 nm, which provides the capability to tune the resonance wavelength to a band of interest. More interestingly, FWHM and contrasts show a slight but opposite change with the increase of Al2O3 layer thickness, where FWHM increases with Al2O3 layer thickness while contrasts drop. In this point of view, thin Al2O3 layer stands out. However, considering the cutoff wavelength of SMF-28 fiber 1260 nm, we choose 90 nm as the optimized thickness of Al2O3 layer.

For sensing in aqueous environments, the optimization analysis yields the following design parameters of the SPR sensing architecture: a complete fiber core, side-polished cladding with 3 μm left, and 60 nm Ag sandwiched by two 90 nm Al2O3 layers.

Sensing Performance of the SPR Sensor

The proposed SPR sensor is discussed to be applied in biosensing in aqueous media. The variation of bovine serum albumin (BSA) concentration leads to RI change of the sensing medium ns, which can be mathematically expressed as [23].

where nC is the RI of the buffer solution, herein 1.3330 of water is assumed, C is the concentration of BSA, and dn/dC is the increment in RI due to the concentration alteration. The refractive index increment parameter is dn/dC = 0.17 cm3/g [23], in the case of BSA solution.

The RI change of the sensing medium results in a variation of the propagation constant of the surface plasmon, therefore a shift of the resonance wavelength. The sensitivity can be defined as S=Δλ/Δns, where Δλ is the shift in resonance wavelength due to a change Δns of sensing medium’s RI.

Figure 4 shows the resonance spectra and sensitivity in respect to ns, where the corresponding concentrations of BSA solutions are 0, 1, 10, 20, 50, 100, 200, and 500 μM. The insets in Fig. 4a, b are the corresponding zoom-in curves at low RI marked with dashed frames. As shown in Fig. 4, the wavelengths exhibit a redshift as the RI increases, and spectral analysis shows that the relationship between the resonant wavelength shift and the solution refractive index is consistent with a linear fit. As detailed in Table 1, a much higher sensitivity of 6558 nm/RIU (refractive index unit) is obtained with a correlation parameter of 0.9945, which corresponds to 0.4357 nm/μM sensitivity against BSA concentration variation. Assume the resolution of an optical spectrum analyzer is 0.01 nm, the detection limit of the proposed SPR sensor is 1.5 × 10−6 RIU or 23 nM.

Note that the resonance wavelength is highly sensitive to the thickness of Al2O3 and the RI of the sensing medium as shown in Fig. 3c and Fig. 4, so that for sensing in gaseous medium, the optimized architecture of the as-proposed SPR sensor is different. The optimized structure consists of a complete fiber core, 3 μm cladding, and 50 nm Ag sandwiched by two 200 nm Al2O3 layers. Also, the sensitivity is 872 nm/RIU, which is almost one order of magnitude smaller than that in aqueous sensing (see Appendix for more details). This indicates that the proposed SPR sensor is more suitable for aqueous sensing and much potential for biosensing.

Conclusion

We proposed a SPR label-free biosensor based on Al2O3/Ag/Al2O3-coated D-typed fiber. For aqueous medium sensing, the structure of the sensor is optimized in order to achieve resonance in near infrared. Refractive index sensitivity of 6558 nm/RIU and detection limit of 1.5 × 10−6 RIU, corresponding to 0.4357 nm/μM and detection limit of 23 nM for label-free BSA concentration sensing, are obtained. Analysis of the sensing performance in gaseous medium has been demonstrated, indicating that this proposed SPR sensor is much suitable for biosensing in aqueous media.

References

Schasfoort RB (2017) Handbook of surface plasmon resonance. Royal Society of Chemistry

Liedberg B, Nylander C, Lunström I (1983) Surface plasmon resonance for gas detection and biosensing. Sensors Actuators 4:299–304

Jorgenson R, Yee S (1993) A fiber-optic chemical sensor based on surface plasmon resonance. Sensors Actuators B Chem 12:213–220

Muehlschlegel P, Eisler H-J, Martin OJ et al (2005) Resonant optical antennas. Science 308:1607–1609

Shan X, Patel U, Wang S, Iglesias R, Tao N (2010) Imaging local electrochemical current via surface plasmon resonance. Science 327:1363–1366

Maley AM, Lu GJ, Shapiro MG, Corn RM (2017) Characterizing single polymeric and protein nanoparticles with surface plasmon resonance imaging measurements. ACS Nano 11:7447–7456

Dıez A, Andres M, Cruz J (2001) In-line fiber-optic sensors based on the excitation of surface plasma modes in metal-coated tapered fibers. Sensors Actuators B Chem 73:95–99

Gangwar RK, Singh VK (2017) Highly sensitive surface plasmon resonance based D-shaped photonic crystal fiber refractive index sensor. Plasmonics 12:1367–1372

Chiu M-H, Wang S-F, Chang R-S (2005) D-type fiber biosensor based on surface-plasmon resonance technology and heterodyne interferometry. Opt Lett 30:233–235

Shi S, Wang L, Su R et al (2015) Apolydopamine-modified optical fiber SPR biosensor using electroless-plated gold films for immunoassays. Biosens.Bioelectron 74:454–460

Sepúlveda B, Angelomé PC, Lechuga LM et al (2009) LSPR-based nanobiosensors. Nano Today 4:244–251

Baldini F, Brenci M, Chiavaioli F, Giannetti A, Trono C (2012) Optical fibre gratings as tools for chemical and biochemical sensing. Anal Bioanal Chem 402:109–116

Caucheteur C, Voisin V, Albert J (2015) Near-infrared grating-assisted SPR optical fiber sensors: design rules for ultimate refractometric sensitivity. Opt Express 23:2918–2932

Allsop T, Neal R, Rehman S, Webb DJ, Mapps D, Bennion I (2007) Generation of infrared surface plasmon resonances with high refractive index sensitivity utilizing tilted fiber Bragg gratings. Appl Opt 46:5456–5460

Huang T (2017) Highly sensitive SPR sensor based on D-shaped photonic crystal fiber coated with indium tin oxide at near-infrared wavelength. Plasmonics 12:583–588

Rhodes C, Franzen S, Maria J-P, Losego M, Leonard DN, Laughlin B, Duscher G, Weibel S (2006) Surface plasmon resonance in conducting metal oxides. J Appl Phys 100:054905

Liu X, Wang X, Zhou B et al (2013) Size-controlled synthesis of Cu2-xE (E= S, se) nanocrystals with strong tunable near-infrared localized surface plasmon resonance and high conductivity in thin films. Adv. Funct. Mater 23:1256–1264

Ghatak A, Thyagarajan K (1998) An introduction to fiber optics. Cambridge university press

Barth J, Johnson R, Cardona M et al (1991) Handbook of optical constants of solids II. Academic Press, New York

Villatoro J, Monzón-Hernández D, Mejía E (2003) Fabrication and modeling of uniform-waist single-mode tapered optical fiber sensors. Appl Opt 42:2278–2283

Wang S-F, Chiu M-H, Hsu J-C, Chang RS, Wang FT (2005) Theoretical analysis and experimental evaluation of D-type optical fiber sensor with a thin gold film. Opt Commun 253:283–289

Mishra AK, Mishra SK, Verma RK (2016) Graphene and beyond graphene MoS2: a new window in surface-plasmon-resonance-based fiber optic sensing. J Phys Chem C 120:2893–2900

Ball V, Ramsden JJ (1998) Buffer dependence of refractive index increments of protein solutions. Biopolymers 46:489–492

Rezaei N, Yahaghi A (2014) A high sensitivity surface plasmon resonance D-shaped fiber sensor based on a waveguide-coupled bimetallic structure: modeling and optimization. IEEE Sensors J 14:3611–3615

Patnaik A, Senthilnathan K, Jha R (2015) Graphene-based conducting metal oxide coated D-shaped optical fiber SPR sensor. IEEE Photon Technol Lett 27:2437–2440

An G, Li S, Cheng T et al. (2018) Ultra-stable D-shaped Optical Fiber Refractive Index Sensor with Graphene-Gold Deposited Platform. Plasmonics:1–9

Cennamo N, Zuppella P, Bacco D et al. (2016) SPR sensor platform based on a novel metal bilayer applied on D–shaped plastic optical fibers for refractive index measurements in the range 1.38–1.42. IEEE Sens. J 16:4822–4827

Funding

This work is supported by the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (Grant No.CX201818).

Author information

Authors and Affiliations

Corresponding author

Appendix: Optimal Architecture of the Sensor for Gaseous Sensing

Appendix: Optimal Architecture of the Sensor for Gaseous Sensing

Optimization of the Fiber Cladding

The thicknesses of silver layer and Al2O3 layer are set to be 50 and 200 nm, respectively. The surrounding sensing medium is air, whose RI is 1.0003.

Based on the FWHM and contrasts as shown in Fig. 5, we choose 11.2 μm as the optimized height, i.e., the residual thickness of the fiber cladding is 3 μm.

Optimization of the Metal and Oxide Layers

For the optimization of the silver thickness, the Al2O3 layer is set to 200 nm and the sensing medium is air. Fifty nanometers is chosen as the optimized thickness for silver layer as shown in Fig. 6a, b.

Considering the cutoff wavelength of SMF-28 fiber is 1260 nm, we choose 200 nm as the optimized thickness of Al2O3 layer as shown in Fig. 6c, d.

Performance of the SPR sensor for gaseous sensing

For sensing in gaseous media, the resonance spectra and sensitivity in respect to ns, varying from 1.0001 to 1.001 with a step of 0.0001 are plotted in Fig. 7.

A sensitivity of 872.73 nm/RIU with a correlation parameter of 0.9999 is obtained, which is almost one order of magnitude smaller than that in aqueous sensing. This indicates that the proposed SPR sensor is more suitable for aqueous sensing and much potential for biosensing.

Rights and permissions

About this article

Cite this article

Du, B., Yang, Y., Zhang, Y. et al. SPR Label-Free Biosensor with Oxide-Metal-Oxide-Coated D-Typed Optical Fiber: a Theoretical Study. Plasmonics 14, 457–463 (2019). https://doi.org/10.1007/s11468-018-0824-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11468-018-0824-1