Abstract

Subgrades may be subjected to intermittent cyclic loads such as traffic loads. Under these loading conditions, excess pore water pressure can accumulate in clayey soils during cyclic loading period and dissipate during resting time. The deformation behaviour of clayey soil after reconsolidation process may be different from that under consecutive cyclic loading. A series of undrained cyclic triaxial tests, including reconsolidation process between cyclic loading stages, were performed on kaolin clay. The axial strain accumulation, excess pore water pressure accumulation, deviatoric stress–strain loop and resilience modulus under different cyclic stress ratios, initial confining pressures and degrees of reconsolidation were discussed and presented. Test results show that the reconsolidation process has significant effects on the deformation characteristics of clayey soil. The coupling effects of change of void ratio and effective mean stress result in a non-monotonic relationship between normalised total axial strain and degree of reconsolidation. In addition, an increase in the degree of reconsolidation leads to an increase in the normalised excess pore water pressure increment during 2nd cyclic loading stage, regardless of cyclic stress ratio and initial confining pressure. Furthermore, the steady resilience modulus at the end of each cyclic loading stage depends on the effective cyclic stress ratio and initial confining pressure, irrespective of reconsolidation process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

For cities located in estuary deltas, many transportation infrastructure were constructed on sedimentary soft clay, such as high-speed railway, highway, airport and subway [39]. These infrastructures are inevitably subjected to long-time traffic loadings during their service period, which is ultimately spread to subsoil [2, 5, 15, 17, 44, 48]. Under these cyclic loadings, strain and excess pore water pressure (EPWP) can accumulate in soils, resulting in a series of engineering problems [15, 26, 29]. Traffic loading is always applied to subsoil discontinuously. Due to the low permeability of clayey soils, EPWP in soils may accumulate during cyclic loading period and dissipate in resting period under discontinuous traffic loadings [18, 25, 26]. After reconsolidation process in resting period, the subsoil became denser, and its mechanical characteristics may have changed. Thus, understanding the cyclic behaviours of clayey soils subjected to discontinuous traffic loading is critical to assess the performance of the existing structure in soft clay.

Many studies have been conducted to investigate the deformation behaviour of soil under consecutive cyclic loading. It is broadly recognised that the dynamic properties of soil are influenced by many factors, such as effective confining pressure, cyclic stress ratio (CSR), initial deviatoric stress ratio and loading frequency [6, 18, 28, 29, 38]. Qian et al. [29] performed a series of undrained cyclic heart-shaped tests on Shanghai clay using a hollow cylinder apparatus. The authors claimed that the undrained response of clay subjected to different stress levels can be described by the shakedown approach, including plastic shakedown, cyclic plastic creep and ratcheting (incremental instability). Qian et al. [28] conducted a series of undrained cyclic triaxial tests on over-consolidated Shanghai silty clay. These researchers observed that increasing the over-consolidation ratio (OCR) can result in a decrease in permanent and resilient strains, and the effect of OCR is remarkable for lightly over-consolidated samples. Guo et al. [6] investigated the undrained deformation behaviour of Wenzhou undisturbed soft clay subjected to long-term cyclic loading (50,000 loading cycles). The results indicated that with increase in confining pressure and CSR, the resilience modulus decreases more remarkably with increase in loading cycles. In addition, the authors established two equations to predict the long-term permanent strain and resilience modulus.

Most existing studies on the deformation behaviour of soft clay under traffic loading are based on partially drained or undrained consecutive cyclic tests [6, 14, 18, 19, 28, 29, 31]. However, consecutive cyclic loading patterns cannot properly reflect traffic loading. Partial or full cyclic loading-induced EPWP in subsoil can dissipate during nonoperational hours [18, 40, 41].

Considering the intermittent effect of traffic loading, some research based on multiple-stage cyclic loading tests where the drainage period is interspersed between loading cycles has been conducted [4, 13, 18, 25, 33, 46]. Yang and Cui [41] investigated the effect of intermittent traffic loads on saturated silty clay by cyclic triaxial tests. In their work, the samples were subjected to multiple-stage undrained cyclic loading, and 10 min was interspersed between loading cycles to allow drainage. An empirical prediction formula was established to describe the permanent strain of soil under such loading conditions. The effect of loading frequency on the deformation behaviour of Tianjin soft clay under 5-min interval cyclic loading was investigated by Lei et al. [13]. The authors discovered that intermittency strengthens the resistance of clay to degradation of shear modulus. A similar phenomenon was also reported by Zheng et al. [46], who conducted undrained triaxial tests on undisturbed marine sedimentary clay subjected to periodic intermittent cyclic loading. The effect of water content on cyclic deformation characteristics was investigated by Tong et al. [33] using hollow cylinder apparatus. To investigate the effect of resting period durations on the cyclic behaviour of clay, Liu and Xue [18] carried out both consecutive and intermittent cyclic loading on kaolin clay. These researchers observed that a decrease in the duration of the resting period can enlarge the overall accumulated axial strain of samples.

The above-mentioned studies regarding the intermittent effect of traffic loading are based on the duration of resting time. Liu and Xue [18] claimed that, however, under those reconsolidation approaches, the distribution of EPWP in sample is nonuniform, and the property degree of reconsolidation (Ur) is difficult to obtain, which brings uncertainties to the evolution of stress and strain in the sample.

Feng et al. [4] analysed the reconsolidation behaviour of Wenzhou soft clays under intermittent cyclic loading, in which the quiescent period is long enough to fully dissipate EPWP. The experimental results show that the reconsolidation process leads to the non-deformability of marine sedimentary clays. Similar conclusions were reported by Yildirim and Ersan [45] and O’Reilly et al. [25]. Karakan et al. [11] investigated liquefaction and post-liquefaction settlement of a nonplastic silt and established relationships among factor of safety to liquefaction, post-liquefaction volumetric strain and relative density. These investigations are significant to clarify the effect of full reconsolidation on the cyclic behaviours of soils. However, due to the low permeability of clay, the transient reconsolidation time and the complex seepage path in subsoil, the property condition in foundation soil after cyclic loading is between full reconsolidation and no reconsolidation [8, 35]. Wang et al. [35] conducted a series of undrained cyclic and post-cyclic triaxial tests on marine reconstituted silty clay to investigate the effect of Ur on the post-cyclic monotonic characteristics of soil. In their work, after being subjected to undrained cyclic loading, the samples were allowed to drain to a specific back pressure to achieve desired Ur. Based on the test results, a post-cyclic strength model considering different Ur was established. Similar work was carried out by Huang et al. [7, 8] on laterite clay. However, among existing studies, the effect of different Ur on the cyclic behaviours of clayey soils is not clear and needs to be further investigated.

Based on review of exiting studies regarding the effect of intermittent traffic loading, it is found that there is limited study on the intermittent cyclic deformation behaviours of clayey soils based on uniform samples with residual EPWP and certain stress state. In this study, a series of cyclic triaxial tests were carried out on kaolin clay. In the tests, to simulate residual EPWP, as recommended by Huang et al. [7, 8] and Wang et al. [35], undrained cyclic loading was applied to the samples, and a reconsolidation process was allowed between two cyclic loading stages by controlling the specific back pressure. The effects of different Ur on the cyclic behaviour of clayey soil were studied. Furthermore, the influence of the confining pressure and CSR under different Ur on the cyclic deformation behaviour of soil was analysed and discussed.

2 Sample preparation and test programme

2.1 Sample preparation

An advanced dynamic triaxial testing system at Guangxi University was used to perform the cyclic triaxial tests. The system was manufactured by GDS Instruments Ltd., UK. More details of the system can be found in the work of Qian et al. [28].

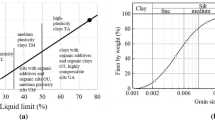

The tested material in this study was a kaolin clay, which was widely used in geotechnical research to investigate mechanical characteristics of clayey soils [16, 18, 19, 24, 37]. The specific gravity of the clay is 2.6. The plastic limit and liquid limit are approximately 35% and 75%, respectively, with a plastic index of approximately 40%. More details regarding the clay can be found in the work of Nie et al. [24].

Slurry consolidation method was firstly proposed by Sheeran and Krizek [32] and be widely used in unit tests of reconstituted clay [15, 18, 19, 24, 37]. According to Wichtmann et al. [37] and Lin and Peaumedu [16] by measuring the water content at different location within kaolin specimen, the pre-consolidated sample prepared by slurry consolidation method was found quite homogeneous. In addition, slurry consolidation method can easily reach saturation and simulate well the soil fabric found within a hydraulic fill deposit [34]. To investigate the sedimentary clay under traffic facilities, the slurry consolidation was adopted in the study.

As suggested by Liu et al. [19] and Liang et al. [15], de-air water was mixed with clay powder to prepare slurries with a water content of approximately 150% (two times the liquid limit). The slurry was placed into a perspex tube mould with a size of 50 mm (inner diameter) × 160 mm (height), and was pre-consolidated under a vertical pressure of 100 kPa. More details about the sample preparation process can be found in Liu et al. [19].

After pre-consolidation process, the samples were trimmed to a height of 60 mm with a diameter of 50 mm (h/d = 1.2). As claimed by Wichtmann et al. [36], the h/d ratio has limited effects on the cyclic behaviour of clayey soil under undrained triaxial dynamic loading. This dimension of sample was also used in Nie et al. [24] and is similar to that utilised in Ren et al. [30] and Liu et al. [19]. To saturate the sample, a back pressure of 400 kPa with an effective confining pressure of 20 kPa was applied. A Skempton’s B value of at least 0.96 in all samples was achieved.

2.2 Test programme

Before applying cyclic loading, the stress state of real soil should be simulated. K0 consolidation state is most realistic simulation method to the field, but requires high instruments, complicated test steps and relatively high cost [22, 23]. Compared to coarse grained materials, K0 value of clayey soil is closer to 1. Thus, for simplifying the test operation, referring the existing research [7, 18, 23, 24, 28, 29, 33, 35], the simplified isotropic consolidation method is adopted in the study.

After being saturated, the samples were isotropically consolidated under an effective confining pressure of p′0(100, 200, 400 kPa). The consolidation duration was kept at approximately 8 h to ensure full dissipation of EPWP of all samples. The axial strain rate of samples at the end of consolidation period is less than 0.018% per hour, which means that all the samples have completed primary consolidation [15, 19].

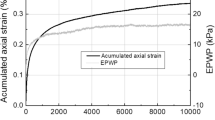

After isotropic consolidation, the first 10,000 one-way sinusoidal loading cycles with a frequency of 1 Hz were applied to all samples under undrained conditions. Considering the main purposes of this study, number of cycles and loading frequency were not considered as a research variable. Thus, to achieve stable EPWP of soils, 10,000 cycles were performed in each loading stage. As reported in previous studies [9, 10, 21], deformation behaviour of clay under undrained cyclic loading is essentially time-based creep phenomenon, and effect of frequency (lower than 10 Hz) on strain accumulation can be ignored. Thus, to simulate traffic load, the frequency of 1 Hz recommended by Qian et al. [29] is adopted in the study, which is in the range from 0.2 to 3 Hz recommended by Yang et al. [43]. The axial strain and EPWP of the samples would accumulate to εac1cls and Δu1cls at the end of this loading phase, as expressed in Fig. 1a, b and c.

Then, the drainage valve was opened and the cyclic loading-induced EPWP (Δu1cls) was allowed to dissipate to the applied back pressure (pu) to achieve a certain Ur. The reconsolidation duration was maintained at approximately 8 h which is same to the consolidation period, to assure the dissipation is complete and the residual EPWP is evenly distributed in the soil sample. Following the research of Wang et al. [35] and Huang et al. [8], the degree of reconsolidation Ur is defined as the ratio of the dissipation of EPWP (Δu′) to the cyclic loading-induced EPWP (Δu1cls) and can be expressed as:

By controlling the applied back pressure, five different Ur (0, 25, 50, 75, 100%) were employed in this study. Ur = 0% represents that the samples were not reconsolidated, which means continuous loading with 20,000 cycles was applied on the samples.

After the reconsolidation process, the second 10,000 sinusoidal loading cycles were applied to the samples under undrained conditions. Same to the first 10,000 loading cycles, a frequency of 1 Hz was adopted. The axial strain and EPWP of the samples would accumulate with εac2cls and Δu2cls at the end of this loading phase, as expressed in Fig. 1a, b and c.

The stress–strain relationship, effective stress path curves and change in void ratio from the tests are shown in Fig. 1a, b and c, respectively. The effective mean stress p′ = (σ′1 + 2σ′3)/3 and the deviatoric stress q = σ′1 − σ′3 are applied, where σ1 and σ3 are the major and minor principal stress in the triaxial test. In this study, to systematically investigate the effects of reconsolidation on the cyclic behaviours of clayey soil, five different Ur and three different effective confining pressures p′0 (100, 200, 400 kPa) under a cyclic stress ratio (CSR) of 0.2 were employed. In addition, a series of cyclic triaxial tests with different CSR (0.1, 0.15, 0.2) and five different Ur were carried out on samples with an effective confining pressure of 200 kPa. The cyclic test schemes are summarised in Table 1.

3 Results and analysis

This section presents the effects of different Ur on the axial strain accumulation, EPWP accumulation and resilience modulus of tested samples. To ensure the consistency of data, as recommended by Alam et al. [1], the resilience modulus (Mr) can be calculated as follows:

where qA and qB refer to approximately 90% of the maximum deviatoric stress and minimum deviatoric stress in an unloading cycle, respectively. εA and εB correspond to the axial strain at qA and qB in an unloading cycle, respectively, as shown in Fig. 2.

The definition of the resilience modulus Mr, after Alam et al. [1]

3.1 The cyclic behaviour of soil during the 1st cyclic loading stage

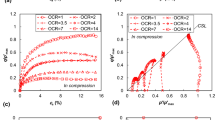

Figure 3 shows the typical cyclic response of samples in 1st cyclic loading stage, which is obtained from the sample p200q40u100. As shown in Fig. 3a, with an increase in number of cycles, the axial strain accumulated significantly at the beginning and then tended to a steady and very slow growth. For example, the plastic axial strain increased from 0% to 0.37% in the first 1000 loading cycles, while it increased by 0.02% between loading cycles No. 9000 and 10,000. The accumulated EPWP shows similar developing trend, which would increase to a stable value with small oscillations, as shown in Fig. 3b. Figure 3c depicts the stress–strain loops of the sample and highlights a certain number of cycles. With increase in number of cycles, the stress–strain loops became inclined and thinner, and the stress–strain hysteresis loops change from unclosed to closed. Figure 3d shows the variation in the resilience modulus versus the number of cycles. It is clearly exhibited that the resilience modulus decreases rapidly in the early few cycles and then keeps basically stable at a certain value. Under cyclic loading with small amplitude, soil particles rearrange may be the reason for rapid increase of axial strain and EPWP in the initial loading phase. As the cyclic loading goes on, the soil is in a state of dynamic equilibrium. In a loading–unloading cycle, thin and closed stress–strain loops signify that the soil stain is recoverable and the material damping of soil became smaller. However, the decrease of resilience modulus indicates that soil skeleton is more fragile to deformation. Similar experimental phenomena have been reported by Qian et al. [27] and Liu et al. [19].

Figures 4 and 5 show the accumulated axial strain and EPWP at the end of 1st cyclic loading versus CSR or effective confining pressure. Figure 6 shows the resilience modulus and normalised resilience modulus at the end of 1st cyclic loading stage versus effective cyclic stress ratio (qd/p′), in which p′ corresponds to the effective mean stress at the end of 1st cyclic loading stage. Several parallel tests in the 1st cyclic loading stage were applied at the same CSR and effective confining pressure as the next stage required different degrees of reconsolidation. The test results are summarised in Table 2. Similar results in Figs. 4, 5, 6 and Table 2 prove the validity and repeatability of parallel tests. In other words, the sample difference caused by the sample preparation process can be ignored to some extent. As shown in Fig. 4, at the same confining pressure (p′0 = 200 kPa), the accumulated axial strain and EPWP increase exponentially with increase in CSR, which is in accordance with the work of Guo et al. [6]. As shown in Fig. 5, for the same CSR of 0.2, the accumulated axial strain increases disproportionately with increase in confining pressure, while the EPWP increases linearly. The reason for such a phenomenon might be that a larger cyclic stress was applied to samples with greater p′0, as the CSR is constant at 0.2 [3, 18].

There is no obvious functional relationship between the steady resilience modulus at the end of the 1st cyclic loading stage and the effective CSR (qd/p′), as shown in Fig. 6a. Then, the steady resilience modulus was normalised by the k power of initial confining pressure (p′0), where the exponent k (in this study, k = 0.53) is a fitting parameter, which reflects the nonlinear relationship between initial confining pressure (p′0) and resilience modulus, as illustrated in Fig. 6b. The nonlinear relationship has also been reported in previous works [20, 47]. As can be seen in the figure, the resilience modulus under different initial confining pressures falls together into a single curve and decreases with increase in qd/p′. Similar results have been reported by Liu et al. [19] and Guo et al. [6].

3.2 The cyclic behaviour of soil after the reconsolidation process

As suggested by Liu and Xue [18], to investigate the effects of reconsolidation on the cyclic deformation behaviour of soils, the axial strain produced by the reconsolidation process was excluded from the accumulated axial strain in this section.

3.2.1 Variation in accumulated axial strain

Figure 7 illustrates the axial strain accumulation during the two cyclic loading stage of all samples. In the figures, the accumulated axial strain (εac) was normalised by the accumulated axial strain during the 1st cyclic loading stage (εac1cls). As seen, compared with those under consecutive cyclic loading (Ur = 0%), greater cyclic axial strain accumulation was observed in samples including reconsolidation process. For instance, the total normalised accumulated axial strain with samples subjected to p′0 = 200 kPa and qd = 40 kPa after two cyclic loading stages are approximately 1.34, 1.22 1.45 and 1.57 under the Ur of 25, 50, 75 and 100%, respectively, while it is approximately 1.16 under consecutive cyclic loading (Ur = 0%). Liu et al. [18, 19] claimed that after a number of consecutive cyclic loading cycles, the soil reaches a relatively stable state, resulting in continuous and steady axial strain accumulation. Reconsolidation process may disturb the stable state of the soil. Thus, during subsequent cyclic loading, a new balance needs to be established for soil particles, resulting in greater strain accumulation in soil [18].

To eliminate the influence of initial confining and cyclic stress ratio on the strain accumulation behaviour of soil, as illustrated in Fig. 8, the accumulated axial strain during the 2nd cyclic loading stage (εac2cls) was normalised by the accumulated axial strain during the 1st cyclic loading stage (εac1cls). It can be clearly seen in Fig. 8 that greater axial strain accumulates in samples including reconsolidation process than in those under consecutive cyclic loading (Ur = 0%). In addition, it is worth noting that the εac2cls/εac1cls values are less than 1 for all samples, which indicates that less strain accumulated in soil during the 2nd cyclic loading stage. According to Xia et al. [40] and Yildirim and Ersan [45], the reason for less strain accumulation is the dissipation of EPWP and the reduction in the void ratio in soils induced by reconsolidation, which could strengthen the cyclic resistance of soil.

The effects of reconsolidation on axial strain accumulation under different initial confining pressures and CSR are illustrated in Fig. 8a, b, respectively. As discussed earlier, less strain could accumulate in soil during the 2nd cyclic loading stage. Figure 8a, b reveals that the larger the initial confining pressure or CSR is, the smaller the εac2cls/εac1cls values. This is because a larger p′0 or CSR value corresponds to a larger accumulated EPWP, as illustrated in Figs. 4b and 5b, which leads to a greater volumetric strain during reconsolidation process, as illustrated in Fig. 9. Thus, a sample subjected to a larger p′0 or CSR value becomes denser, resulting in a greater decrease in axial strain during the 2nd cyclic loading stage. A similar effect of change of void ratio on the strain accumulation behaviour of soil was reported by Liu et al. [19]. Noting that the εac2cls/εac1cls value of sample p200q30u100 is 0.95, which is higher than that of sample p200q20u100. The possible reason for this might attribute to experimental errors. As can be seen in Table 2, εac1cls value of sample p200q30u100 is 0.134%, which is the lowest in the group (samples subjected to p′0 = 200 kPa and qd = 30 kPa), resulting in a higher εac2cls/εac1cls value, and this deviation may be induced by the discrepancy in sample preparation, temperature change and instrument operation.

As shown in Fig. 8, an increase in Ur will lead to an increase in the εac2cls/εac1cls value as a whole. Interestingly, the εac2cls/εac1cls ratio does not increase monotonically with increase in Ur, and it decreases as Ur increases from 25 to 50%. Such a phenomenon occurred in all tested samples, irrespective of p′0 and CSR, which has not been reported in previous studies. The reason for this finding might be attributed to the coupling effects of change of void ratio and the effective mean stress. On the one hand, under the same p′0 and CSR conditions, an increase in Ur will lead to a greater change of void ratio and a greater change of soil particle arrangement, resulting in violently breaking the cyclic balance established in the 1st cyclic loading stage, which will induce greater εac2cls. On the other hand, an increase in Ur refers to more dissipation of accumulated EPWP and an increase in the mean effective stress, so the particles are arranged more closely which is beneficial for cyclic resistance. For the samples under consecutive cyclic loading (Ur = 0%), although the effective mean stress at the beginning of the 2nd cyclic loading stage is the lowest compared with those including reconsolidation process, the axial strain accumulates at a slowest rate because the homeostasis established in the 1st cyclic loading stage was not disturbed. For the samples with Ur = 25%, 75% and 100%, the void ratio change plays a leading role in the 2nd cyclic loading, and the εac2cls/εac1cls values continue to increase. For the samples with Ur = 50%, the εac2cls/εac1cls are lower than those samples with Ur = 25%, which means the mean effective stress has prevailed on this occasion. When considering the effect of reconsolidation on settlement of foundation soil in practical engineering, it should not only pay attention to the favourable side of denser soil particle arrangement, but also pay more attention to the unfavourable side of broken cyclic balance.

3.2.2 Variation in the accumulated EPWP

Figure 10 illustrates the EPWP accumulation of all samples. In the figures, the accumulated EPWP (Δu) was normalised by the accumulated EPWP during the 1st cyclic loading stage (Δu1cls). After the reconsolidation process, partial or all EPWP was dissipated in soils, resulting in the Δu/Δu1cls values of samples of Ur = 25, 50, 75 and 100% “jump” to 0.75, 0.5, 0.25 and 0 at the beginning of the 2nd cyclic loading stage, respectively. Compared with those under consecutive cyclic loading (Ur = 0%), the EPWP accumulated significantly in the sample including reconsolidation process. Clearly, as shown in Fig. 10, including reconsolidation process can reduce the EPWP in samples during 2nd cyclic loading stage, and the greater the Ur value is, the lower the Δu/Δu1cls values at the end of the 2nd cyclic loading. For instance, the Δu/Δu1cls values with samples subjected to p′0 = 200 kPa and qd = 40 kPa after two cyclic loading stages are approximately 0.89, 0.79, 0.59 and 0.37 under the Ur values of 25, 50, 75 and 100%, respectively, while they are approximately 0.98 under consecutive cyclic loading (Ur = 0%). Such findings might be attributed to the smaller void ratio of samples with higher Ur. Under the same p′0 and CSR conditions, an increase in Ur will lead to a greater change of volume strain, as illustrated in Fig. 9, resulting in a lower void ratio of samples. The EPWP at the end of the 2nd cyclic loading stage decreased due to the lower void ratio Yildirim and Ersan [45].

To eliminate the influence of initial confining and cyclic stress ratio on the EPWP accumulation behaviour of soil, as illustrated in Fig. 11, the accumulated EPWP during the 2nd cyclic loading stage (Δu2cls) was normalised by the accumulated EPWP during the 1st cyclic loading stage (Δu1cls). Interestingly, the Δu2cls/Δu1cls values increase with increase in Ur, regardless of initial confining pressure p’0 and CSR. The larger the Ur value is, the greater the change in the void ratio, which leads to a more thorough break in the cyclic equilibrium, resulting in a greater normalised EPWP in the 2nd cyclic loading stage. Notably, increasing Ur will also lead to an increase in the effective mean stress, resulting in an increase in cyclic resistance of the sample. In addition, the Δu2cls/Δu1cls values show a monotonic increasing relationship with Ur. This means that, compared with increase in effective stress, the change of void ratio plays a predominant role in pore pressure accumulation behaviour during 2nd cyclic loading stage.

Notable is, the Δu2cls/Δu1cls values of samples (subjected to p′0 = 200 kPa and CSR = 0.1) decrease as Ur values increase from 75 to 100%. Under a relative low CSR condition, EPWP accumulates little. As can be seen in Table 2, Δu1cls values of samples (subjected to p′0 = 200 kPa and CSR = 0.1) are in the range from 10.4 to 12.4 kPa and Δu2cls values of these sample are less than 6 kPa. In this case, the fluctuation of pore pressure due to temperature change or other reasons has significant effect on the value of Δu2cls/Δu1cls, and this may be the reason for this abnormal downward trend. Despite these experimental errors, it can still be concluded that the Δu2cls/Δu1cls values monotonically increase along with Ur values.

3.2.3 Variation in the resilience modulus

To investigate the effects of reconsolidation process on the resilience modulus of soil, Fig. 12a, b shows the typical deviatoric stress–strain loop and normalised resilience modulus versus the number of cycles, respectively. In the figures, the samples were subjected to a confining pressure of 200 kPa and a CSR of 0.2. To compare the stress–strain response at different numbers of cycles, the typical stress–strain loops (Nos. 1, 100, 10,000, 10,001, 10,100, 20,000) of the sample with Ur = 100% are plotted in Fig. 12a, in which the accumulated strain was subtracted from total strain. During the 1st cyclic loading stage, as mentioned above, the stress–strain loops became thinner and the stress–strain hysteresis loops change from unclosed to closed. However, after the reconsolidation process, the stress–strain loop of No. 10001 cycle reopened and became steep, which implies axial strain reaccumulation and stiffness hardening. The increase in stiffness might be attributed to the increase in effective mean stress and decrease of void ratio [4, 18]. As cyclic loading continued in 2nd loading stage, the stress–strain loops became thinner again and the stress–strain hysteresis loops change to be closed, and the new dynamic elastic equilibrium has been formed. The stress–strain loop inclined to the horizontal axis, indicating cyclic stiffness degradation also occurred during the 2nd cyclic loading stage, which can be explained by the accumulation of the EPWP, as illustrated in Fig. 10d.

The stiffness hardening behaviour after the reconsolidation process can be observed in Fig. 12b, in which the resilience modulus Mr was normalised by the resilience modulus of the first cycle Mr,1. Figure 12b shows that an increase in Ur will result in an increase in the Mr/Mr,1 value at No.10001 cycle, indicating greater stiffness hardening behaviour due to the reconsolidation process. Under the same p′0 and CSR conditions, an increase in Ur can lead to a decrease of void ratio and an increase in the effective mean stress, which are both beneficial for cyclic resistance [4, 18]. As cyclic loading continued, the resilience modulus decreased and reached a steady value at the end of the 2nd cyclic loading stage. However, for the samples under a relatively low cyclic stress ratio (CSR = 0.1), the resilience modulus seems to be little affected by the reconsolidation process, regardless of the degree of reconsolidation, as illustrated in Fig. 13.

The resilience modulus at the end of 1st cyclic loading stage (Mr,10000) and 2nd cyclic loading stage (Mr,20000) versus qd/p′ are plotted in Fig. 14a, in which p′ is the mean effective stress at the end of corresponding cyclic loading stage, and the solid points represent Mr,10000 and the hollow points represent Mr,20000. For the samples of CSR = 0.2, both Mr,10000 and Mr,20000 will be bigger as the confining pressure is higher. Compared with Mr,10000, data points of Mr,20000 move up to the upper left, indicating that the resilience modulus has increased to some extent. For the samples of CSR = 0.1, however, the hollow points are very close to the solid points. This is because a lower CSR leads to smaller EPWP accumulation during the 1st cyclic loading stage, as illustrated in Fig. 4b, resulting in fewer effective mean stress increments and void ratio changes. Thus, the resilience modulus was minimally affected by the reconsolidation process. The increase in p′0 has a similar effect to the increase in CSR on EPWP accumulation during the 1st cyclic loading stage, as illustrated in Fig. 5b, which results in a similar effect of qd/p′ value on the resilience modulus, as illustrated in Fig. 14a.

The Mr,10000 and Mr,20000 values normalised by the k power of initial confining pressure p′0 versus qd/p′ are shown in Fig. 14b. As discussed early, symbol k reflects the nonlinear relationship between initial confining pressure and resilience modulus and in this study, k = 0.53. The normalised Mr data fall together into a single curve, which is obtained from optimal fitting of Mr,10000, as illustrated in Fig. 6b. It can be concluded that the steady resilience modulus at the end of cyclic loading depends on the initial confining pressure p′0 and qd/p′ value, regardless of the reconsolidation process.

According to Zhou et al. [47] and Qian et al. [28], under the same loading conditions, the sample with a smaller void ratio (a higher OCR) corresponds to a closer particle arrangement, which brings a smaller elastic strain and higher resilient modulus in cyclic loading. In this study, after reconsolidation process, tested specimens became denser due to the dissipation of cyclic loading-induced EPWP, as illustrated in Fig. 1c. However, the hollow point (Mr,20000) does not deviate from the optimal fitting curve of the solid point (Mr,10000), as illustrated in Fig. 14b. This means that compared to qd/p′ and p′0, the change of void ratio has limited effect on resilience modulus of tested samples. A possible reason for this phenomenon might attributed to the smaller void ratio changes in reconsolidation process compared to over-consolidation process and it needs to be further investigated.

4 Discussions

Figure 15 shows the first stress–strain loops of 2nd cyclic loading stage after different degrees of reconsolidation under the same p′0 = 200 kPa, in which Ur/N = 0/10001 represents the stress–strain loop of N = 10,001 under continuously cyclic loading, and Ur/N = 25/10001 represents the first stress–strain loop after a reconsolidation of 25% excess pore water pressure dissipated. The initial stress–strain loop is also displayed in Fig. 15 a in the form of dotted line for comparison. It can be seen from the shape evolution process of stress–strain loops, during the 1st cyclic loading stage, as mentioned above, the stress–strain loops change from fatter and unclosed to thinner and closed, which indicates the soil change from elastoplastic to dynamic elastic. Moreover, obvious stiffness weakening is found under larger dynamic stress (qd = 40 kPa). The reconsolidation process breaks the dynamic equilibrium. The higher the Ur value, the more intensely breaking the dynamic elastic equilibrium. As reflected in Fig. 15a, b, in which stress–strain loops became fatter and unclosed again after reconsolidation, and the higher the Ur value, the more skewed to the vertical axis. Steeper initial loading curves signify the soil rearranged more closely after reconsolidation. The shape evolution process of stress–strain loops reveals again that the effect of reconsolidation on 2nd cyclic loading is reflected in two aspects. On the one hand, reconsolidation violently break the cyclic balance established in the 1st cyclic loading, which will induce greater εac2cls and Δu2cls in the 2nd cyclic loading. On the other hand, an increase in Ur refers to an increase in the mean effective stress, so the particles are arranged more closely, which might be the reason for the obvious growth of resilience modulus Mr and excess pore pressure in the initial stage of 2nd cyclic loading.

5 Conclusions

To investigate the effects of reconsolidation on the undrained cyclic behaviours of clayey soils, a series of undrained cyclic triaxial tests including reconsolidation processes between loading cycles were performed on kaolin clay. The variation in axial strain accumulation, excess pore water pressure accumulation, stress–strain characteristics and resilience modulus of samples under different degrees of reconsolidation, effective confining pressures and cyclic stress ratios were discussed and presented. Based on the limited number of cyclic triaxial tests, the conclusions are summarised as follows:

-

1.

The normalised axial strain of samples after the reconsolidation process was significantly accumulated. An increase in the initial confining pressure or cyclic stress ratio could lead to a decrease in the normalised total axial strain. The coupling effects of the change of void ratio and effective mean stress result in a non-monotonic relationship between the degree of reconsolidation and normalised total axial strain. The settlement of foundation soil in practical engineering might be underestimated if ignoring the influence of reconsolidation.

-

2.

The normalised excess pore water pressure increment during the 2nd cyclic loading stage depends on the degree of reconsolidation, and the larger the degree of reconsolidation is, the greater the values, regardless of the cyclic stress ratio and initial confining pressure.

-

3.

The steady Mr values at the end of cyclic loading depend on the initial confining pressure and qd/p′ values, regardless of the reconsolidation process.

Data availability

Some or all data, models or code that supports the findings of this study is available from the corresponding author upon reasonable request.

References

Alam MJI, Gnanendran CT, Lo SR (2017) Modelling the settlement behavior of a strip footing on sloping sandy fill under cyclic loading conditions. Comp Geotech 86:181–192

Chai JC, Miura N (2002) Traffic-load-induced permanent deformation of road on soft subsoil. J Geotech Geoenviron Eng 128(11):907–916

Chen C, Zhou ZM, Kong LW, Zhang XW, Yin S (2018) Undrained dynamic behavior of peaty organic soil under long-term cyclic loading, Part I: experimental investigation. Soil Dynam Earthq Eng 107:279–291

Feng D, Zhu X, Wang J, Cai Y, Guo L, Du Y (2020) The effects of cyclic loading on the reconsolidation behaviors of marine sedimentary clays under intermittent drainage conditions. Soil Dynam Earthq Eng 140:106510

Ge SP, Yao XJ, Ye B, Pu ST, Liu XZ (2016) Analysis of long-term settlement of soft clay under train vibration. Chin J Rock Mech Eng 35(11):2359–2368

Guo L, Wang J, Cai Y, Liu H, Gao Y, Sun H (2013) Undrained deformation behavior of saturated soft clay under long-term cyclic loading. Soil Dyn Earthq Eng 50:28–37

Huang J, Chen J, Yu S (2023) Postcyclic stiffness behaviors of laterite clay under various conditions. int J GeoMech 20(4):06023003

Huang J, Chen J, Ke W, Zhong Y, Lu Y, Yi S (2021) Post-cyclic mechanical behaviors of laterite clay with different cyclic confining pressures and degrees of reconsolidation. Soil Dyn Earthq Eng 151:106986

Hyde AFL, Brown SF (1976) The plastic deformation of a silty clay under creep and repeated loading. Geotechnique 26(1):173–184

Hyde AFL, Yasuhara K, Hirao K (1993) Stability criteria for marine clay under one-way cyclic loading. J Geotech Eng ASCE 119(11):1771–1789

Karakan E, Tanrinian N, Sezer A (2019) Cyclic undrained behavior and post liquefaction settlement of a nonplastic silt. Soil Dyn Earthq Eng 120:214–227

Kuerbis RH, Vaid YP (1988) Sand sample preparation-the slurry deposition method. Soils Found 28(4):107–118

Lei H, Liu M, Feng S, Liu J, Jiang M (2020) Cyclic behavior of Tianjin soft clay under intermittent combined-frequency cyclic loading. Int J GeoMech 20(10):04020186

Li D, Selig ET (1996) Cumulative plastic deformation for fine-grained subgrade soils. J Geotech Engrg 122:1006–1013

Liang Z, Liu Y, Liu Z (2023) The undrained behavior of over-consolidated clay subjected to pure rotation of principal stress directions. Mar Georesour Geotec 41(9):1013–1025

Lin H, Penumadu D (2005) Experimental investigation on principal stress rotation in Kaolin clay. J Geotech Geoenviron 131(5):633–642

Liu Y, Liang Z, Liu Z, Nie G (2022) Post-cyclic drained shear behavior of Fujian sand under various loading conditions. J Mar Sci Eng 10(10):1499

Liu Z, Xue J (2022) The deformation characteristics of a kaolin clay under intermittent cyclic loadings. Soil Dyn Earthq En 153:107112

Liu ZY, Xue JF, Mei GX (2021) The impact of stress disturbance on undrained cyclic behavior of a kaolin clay and settlement of tunnels under cyclic loading. Acta Geotech 16(12):3947–3961

Lu C, Chen JY, Gu C, Wang J, Cai YQ, Zhang TT, Lin G (2021) Resilient and permanent deformation behaviors of construction and demolition wastes in unbound pavement base and subbase applications. Transp Geotech 28:100541

Matsui T, Ohara H, Ito T (1980) Cyclic stress-strain history and shear characteristics of clay. J Geotech Engrg Div ASCE 106(10):1101–1119

Mayne PW (1985) Stress anisotropy effects on clay strength[J]. J Geotech Eng 111(3):356–366

Meng XC, Liu R, Liang C (2024) Research on undrained shear strength properties of saturated clay. J Civ Eng 57(05):86–98

Nie GP, Liu Y, Liu ZY, Liang ZX, Xue JF, Liang YW (2023) The Effects of drainage conditions on the cyclic deformation characteristics of over consolidated clayey soil. Int J Civ Eng 21(4):603–615

O’reilly MP, Brown SF, Overy RF (1991) Cyclic loading of silty clay with drainage periods. J Geotech Geoenviron 117(2):354–362

Price AB, DeJong JT, Boulanger RW (2017) Cyclic loading response of silt with multiple loading events. J Geotech Geoenviron Eng 143(10):04017080

Qian JG, Du ZB, Yin ZY (2018) Cyclic degradation and non-coaxiality of soft clay subjected to pure rotation of principal stress directions. Acta Geotech 13(4):943–959

Qian JG, Li SY, Zhang JL, Jiang JH, Wang QY (2019) Effects of OCR on monotonic and cyclic behavior of reconstituted Shanghai silty clay. Soil Dyn Earthq Eng 118:111–119

Qian JG, Wang YG, Yin ZY, Huang MS (2016) Experimental identification of plastic shakedown behavior of saturated clay subjected to traffic loading with principal stress rotation. Eng Geol 214:29–42

Ren XW, Xu Q, Teng JD, Zhao N, Lv L (2018) A novel model for the cumulative plastic strain of soft marine clay under long-term low cyclic loads. Ocean Eng 149:194–204

Sakai A, Samang L, Miura N (2003) Partially-drained cyclic behavior and its application to the settlement of a low embankment road on silty-clay. Soils Found 43(1):33–46

Sheeran DE, Krizek RJ (1971) Preparation of homogeneous soil samples by slurry consolidation. J Mater 6(2):356–373

Tong L, Xue W, Ding H (2023) Influence of water content on clay deformation characteristics subjected to periodic intermittent loading. Soil Dyn Earthq Eng 171:107996. https://doi.org/10.1016/j.soildyn.2023.107996

Wang S, Luna R, Stephenson RW (2011) A slurry consolidation approach to reconstitute low-plasticity silt specimens for laboratory triaxial testing. Geotec Testing J 34(4):288–296

Wang Y, Lei J, Wang Y, Li S (2019) Post-cyclic shear behavior of reconstituted marine silty clay with different degrees of reconsolidation. Soil Dyn Earthq Eng 116:530–540. https://doi.org/10.1016/j.soildyn.2018.10.042

Wichtmann T, Andersen KH, Sjursen MA, Berre T (2013) Cyclic behavior of high-quality undisturbed block samples of Onsøy clay. Can Geotech J 50(4):400–412

Wichtmann T, Triantafyllidis T (2018) Monotonic and cyclic tests on kaolin: a database for the development, calibration and verification of constitutive models for cohesive soils with focus to cyclic loading. Acta Geotec 13:1103–1128

Wu HN, Shen SL, Chai JC, Zhang DM, Xu YS (2015) Evaluation of train-load-induced settlement in metro tunnels. P I Civil Eng-Geotec 168(5):396–406

Wu T, Cai Y, Guo L (2017) Influence of shear stress level on deformation behaviour of undisturbed soft clay under traffic loading. Eng Geol 228

Xia ZF, Ye GL, Wang JH, Ye B, Zhang F (2010) Fully coupled numerical analysis of repeated shake-consolidation process of earth embankment on liquefiable foundation. Soil Dynam Earthq Eng 30(11):1309–1318

Yang JQ, Cui ZD (2020) Influences of train speed on permanent deformation of saturated soft soil under partial drainage conditions. Soil Dynam Earthq Eng 133:106120

Yang Q, Tang YQ, Yuan B, Zhou J (2019) Cyclic stress-strain behavior of soft clay under traffic loading through hollow cylinder apparatus: effect of loading frequency. Road Mater Pavem Des 20:1026–1058

Yang Q, Tang YQ, Yuan B, Zhou J (2019) Cyclic stress-strain behaviour of soft clay under traffic loading through hollow cylinder apparatus: effect of loading frequency. Road Mater Pavement Des 20:1026–1058

Yasuhara K, Andersen KH (1991) Recompression of normally consolidated clay after cyclic loading. Soils Found 31(1):83–94

Yildirim H, Ersan H (2007) Settlements under consecutive series of cyclic loading. Soil Dynam Earthq Eng 27(6):577–585

Zheng Q, Xia T, Ding Z, He S (2019) The effect of periodic intermittency on the cyclic behavior of marine sedimentary clay. Mar Georesour Geotechnol 37(8):945–959

Zhou ZW, Bai RQ, Shen MD, Wang QZ (2021) The effect of overconsolidation on monotonic and cyclic behaviours of frozen subgrade soil. Transp Geotech 32:100710

Zou WL, Ding LQ, Han Z, Wang XQ (2020) Effects of freeze-thaw cycles on the moisture sensitivity of a compacted clay. Eng Geol 278(5):105832

Acknowledgements

The project was funded by the National Natural Science Foundation of China (No.52278337, No.51968005), the Guangxi Natural Science Foundation (No. 2019GXNSFBA185038) and Guangxi Science and Technology Major Project (No. AA23073018).

Author information

Authors and Affiliations

Contributions

Zhixuan Liang was involved in conceptualization, methodology, investigation, validation, formal analysis, visualisation, writing—review and editing. Mingyue Kong helped in data curation, investigation, writing—original draft. Ying Liu helped in funding acquisition, writing—review and editing. Maosong Huang contributed to writing—review and editing. Jian Gong contributed to writing—review and editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, Z., Kong, M., Liu, Y. et al. Effects of reconsolidation on cyclic deformation behaviours of a kaolin clay. Acta Geotech. (2024). https://doi.org/10.1007/s11440-024-02399-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11440-024-02399-5