Abstract

The presence of lateritic soils occurs in tropical and subtropical regions. The improvement of lateritic soils that are not suitable for a particular purpose through techniques that combine modification of grain size through the insertion of sand, incorporation of Portland cement and densification through compaction is seen as an alternative. In this context, a dosage method to use a local lateritic soil as construction material in a most rational way reducing the economic and environmental impacts related to this activity is still missing. Therefore, the current research aims to evaluate the performance of a lateritic soil via modification of grain size through the insertion of sand, incorporation of Portland cement and densification through compaction. For this, unconfined compression, and durability (wetting and drying) tests were carried out on specimens of compacted clayey gravel lateritic soil, whose granulometry was modified by the insertion of distinct amounts (from zero to 45%) of weathered sand, treated with distinct Portland cement contents (from 4 to 10%), molded at different dry unit weights (from 16.8 to 20.1 kN/m3) and cured for 7 and 28 days. Results of the mechanical tests have shown the significant influence exerted by cement content and dry unit weight of the blend, followed by curing time and finally sand insertion. Satisfactory correlations between the response variables (qu and ALM) and the adjusted porosity/cement index (η/Cv) were obtained. Furthermore, an innovative approach to replacing the laborious durability test is proposed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Engineering is increasingly exposed to new challenges for the use of soil as a construction material, such as paving roads, stabilized layers supporting spread footings and embankments. In the paving area, expressive sources of granular material are needed to shape the base or sub-base of roads. These materials are transported to the construction sites, which increase costs of the earthwork and can render it economically unfeasible. Therefore, the search for geotechnical techniques that privilege the local soil as raw material for paving is essential for regions where the supply of construction material is located remotely.

In this case, in tropical and subtropical regions, the presence of lateritic soils occurs in continents such as Latin America, Africa, Asia and Oceania [33]. Lateritic soils are greatly altered by the weathering that has the presence of meteorized materials enriched by minerals of low solubility (e.g. iron and aluminum oxides) known as laterite gravel (LG). This soil is abundant in northeastern Bolivia; however, usually it does not have requirements solicited by road agencies for heavy traffic road pavement application and in some cases even for medium to light traffic [9, 29]. For example, these soils usually have gaps in the grain size curve (e.g., in the coarse fraction of sand), lower soaked California Bearing Ratio values, and higher plasticity indices determined in standards. The restriction of using this soil for sub-base and base course materials requires the capture of standardized materials from sources outside the construction range. Distances of up to 400 km are required to provide material for roads in areas with lateritic soil in Bolivia. Local soil use for construction roads avoids: depletion of natural resources from distant sources, burning of fossil fuel for transport and high costs.

Engineering techniques are necessary to take advantage of the sources of laterite gravel present in regions with lateritic soils for road construction. Modification of the grain size, variation of the compaction energy and addition of cementing agents promote the physical and chemical stabilization of soils, providing better geomechanical behavior of the material and consequently its use in the field. Joel and Agbede [27] used the addition of sand (15%, 30% and 45%) and cement (3%, 6%, 9% and 12%) to stabilize a Nigerian lateritic soil in two compaction energies. The authors found that the addition of sand, cement and increased compaction energy enabled this stabilized soil to achieve the requirements for use as a road material. Phummiphan et al. [34] stabilized a Thailand lateritic soil with fly ash, carbide lime and addition of sodium silicate solutions (Na2SiO3) with sodium hydroxide (NaOH) in the formation of a binder. The authors concluded that binder provided the soil stabilization that achieved the required strengths for road agency in Thailand for light (> 1,724 kPa) and heavy (> 2,413 kPa) traffic pavements with 7 days of curing. With the same interest in taking advantage of laterite sources in engineering works, Biswal et al. [10] also used cement (2, 3, 6 and 8%) for the stabilization of a granular lateritic soil. In this work, the authors found that the addition of cement improves the durability performance of the soil, requiring at least 6% cement in order to make the losses of mass in durability feasible for use in road pavement layer construction.

The stabilization of lateritic soils promotes the use of this material for engineering works. However, there are no methods for cement dosage, density definition and the influence of sand content to predict the mechanical behavior of this cemented soil. In this context, studies by [30], 17, 19, 22] have shown that the porosity (η) per volumetric cement content (Cv) is a key parameter for the prediction and geomechanical behavior of soil–cement mixtures. For example, [20] used this index to evaluate a material composed of reclaimed asphalt paving with powdered rock and Portland cement for using in road base and sub-base. The authors concluded that this index is appropriate for the evaluation of parameters such as unconfined compression and split tensile strengths and mainly on the viscoelastic behavior. For the durability, several works proved the efficiency of this index in predicting mass loss for compacted soils stabilized with binders [21,22,23]. However, there is no systematic method in the literature for predicting the mechanical behavior of cement and sand stabilized lateritic soils.

In this scenario, the present research aims to contribute to the development and application of lateritic soils in geotechnical engineering for road construction. The variables analyzed for the formulation of a new approach for the prediction of strength and durability of stabilized lateritic soil were curing time, porosity, cement content and modification of grain size through the insertion of sand. Thus, through geotechnical techniques and dosage method it is possible to use a local lateritic soil as construction material in a most rational way reducing the economic and environmental impacts related to this activity.

2 Experimental program

2.1 Materials

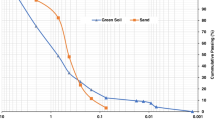

The soil investigated is lateritic soil (LS) with laterite gravel collected in the northeast region of Bolivia. The granulometric curve of the soil analyzed is shown in Fig. 1. The high content of fines in the samples collected in this study (%) is related to the fact that, during the exploration with machines, the layers of laterite gravel (Horizon B) are mixed, involuntarily, with a portion of the lower layer (Horizon C) that is composed mainly of fine soil. The material resulting from the mixing is representative of the exploration process in the field during the construction phase of road projects. Table 1 shows the physical properties of the soil studied and the standards used for characterization tests. This material is classified as clayey gravel by the Unified Soil Classification System [5].

The chemical composition of the fine fraction (particle size < 2 mm), analyzed by atomic absorption test, is composed of oxides of: aluminum (6.35%), iron (3.95%), silicon (35.3%) and potassium (2.32%), which composes the minerals quartz, kaolinite, mica, smectite and pyrophyllite identified by X-Ray Diffraction (DRX). The meteorized/gravel fraction (particle size > 4.75 mm) is composed of aluminum (5.69%), iron (44.25%) and silicon (9.05%), which comprise the minerals quartz, kaolinite, mica, goethite and hematite. The highest iron content (goethite and hematite), in this fraction, reflects the characteristic of laterite gravel. These chemical and mineralogical characteristics are similar to other studies conducted in Brazil, India, Australia and Africa [31, 32].

The material added in the stabilization of the lateritic soil corresponds to a residual sandy soil, formed as a result of the weathering of granitic rocks. The natural deposits are in northeast Bolivia (city of Guayaramerín) near the investigated soil. This sand presents the best granulometric characteristics for its use as construction material in the region. The sample was collected from sales stocks of aggregates located in the city. This material is classified by AASHTO [1] as medium sand (A-1-b) and by [5,6,7] as poorly graded sand (SP), with a coefficient of curvature of 0.91, coefficient of uniformity of 3.3 and specific gravity of 2.69. The granulometric curve is shown in Fig. 1.

Portland cement (PC IV–[8] was used for the chemical stabilization process of the soil. This cement has between 20 and 27% pozzolan in its composition. Portland cement Type IV is the binder widely produced and used for construction in Bolivia. The cement has a specific gravity of 2.90. Distilled water was used for all characterization tests, and tap water for the molding specimens used in the mechanical tests.

2.2 Methods

In the investigation of the stabilized lateritic soil with cement and sand, variable parameters of the soil-cement-sand mixture were established in the modification of the unconfined compressive strength (qu) and accumulated loss of mass (ALM). The controllable variables studied in this work were: (i) density; (ii) curing time; (iii) cement content and (iv) sand addition. These parameters are important in the evaluation of the geomechanical behavior of stabilized soils [14,15,16], and [36]. The mechanical investigation of soil-cement-sand was through the porosity/volumetric cement content index [Eq. (1)] developed by Consoli et al. [13] where A is the scalar of the equation; b is the adjustment exponent for the volumetric cement content (Cv); η is the porosity of the mixture; Cv is the volumetric cement content; and c is the exponent of the power-type equation.

Equations (2) and (3) are used for the determination of porosity (η) and volumetric cement content (Cv), respectively. The following definitions are used in the equations: (i) total volume of the specimen (Vt) in cm3, (ii) dry unit weight of the specimen (γd) in g/cm3, (iii) content of lateritic gravel (LG) in percentage, (iv) content of sand (S) and cement (C) in percentage and (v) specific gravity of grains for each material used (γs) in g/cm3 (Table 1).

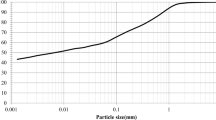

The cement contents defined were 4, 6, 8 and 10% in relation to the dry mass of soil. These variations were also recommended by several authors in the stabilization of lateritic soils with cement [11, 25, 32]. The defined sand contents were 0%, 15%, 30% and 45% over the dry soil mass to supply the lack of sand fraction in the studied soil. The granulometric curves of the mixtures are presented in Fig. 2. In general, the addition of sand in cement-stabilized lateritic soils has the potential to improve the soil's bearing capacity and in certain cases (high clay contents) to decrease cement contents [27, 28]. The curing time was set at 7 and 28 days to verify the ability of pozzolanic cement to promote better mechanical performance over time.

Proctor tests were performed to define the dry unit weight and moisture content (ω) for the molding of specimens. The results are presented in Fig. 3(a, b, c, d) for 0%, 15%, 30% and 45% of sand addition and in two compaction energies (standard and modified). For all tests, the average content of 6% cement was added. No compaction tests were carried for other cement contents because the influence of cement content is not perceptible in the compaction curve [26]. The molding points were defined using the line of optimums obtained from the compaction tests. However, in the mixture without sand it was verified a similarity of the maximum dry unit weight and optimum moisture between the two energies; consequently, the line was defined as a vertical without alteration of moisture content. Table 2 shows all the parameters assessed and the levels of variation used in this work.

A complete factorial for the statistical analysis of variance (ANOVA) was performed for the evaluation of the significance of each parameter and its investigated levels of unconfined compressive strength and durability of stabilized soil. This statistical method allows the evaluation of the difference between the distributions of a measure between three or more groups. The established significance level was 95%, and statistical software was used to evaluate the influence of the studied independent variables on the response variable (ALM and qu).

2.2.1 Specimen preparation

The preparation of the specimens for unconfined compression tests and durability tests was carried out in the following steps: (i) weighing of the material, (ii) mixing and homogenization, (iii) sample for moisture determination, (iv) static compaction, (v) release the sample, (vi) measurement of dimensions and weight, and (vii) packaging for curing. The soil used passed through the 19 mm sieve.

The mixing process consisted of adding the established amount of cement to the dry soil plus supplementary sand. Subsequently, manual mixing of the materials was performed until a completely homogeneous mixture was achieved; the process lasted approximately 10 min. Finally, water was added to reach the moisture content established for the mixture. At this stage, a portion of the mixture (LG + sand + cement + water) was preserved to determine the moisture content. The variation limit for moisture content was ± 0.5% relative to the designed moisture.

The homogenized mixture was statically compacted (5 layers for unconfined compression and in 3 layers for durability) to achieve the designed dry unit weight. The accepted degree of compaction for the specimens was 95 or 105%. The specimens were conditioned in hermetically sealed plastic bags and storage for 7 and 28 days in the curing room at 25 °C.

2.2.2 Unconfined compression tests

The unconfined compression tests followed the specifications of ASTM D1633 [7]. The dimensions used for this test were 100 mm in diameter and 200 mm of height. Before testing, specimens were immersed in water for a period of 24 h to reduce suction effects on the strength. Three samples were prepared for each test condition to guarantee the repeatability of the results. An automatic press machine (capacity of 50 kN) was used to perform the test, equipped with properly calibrated S-type load sensors with range of 10 kN and 50 kN. The qu results were used for the determination of the ratio between porosity and volumetric cement content for the prediction of the strength of the established mixtures.

2.2.3 Tests of durability by wetting, drying and brushing cycles

The durability of soil–cement mixtures was evaluated by the mass loss test after drying, wetting and brushing cycles following the procedures established in ASTM D559 [4]. The size of the cylindrical samples was 101 mm diameter and 116 mm height. The test consists basically of immersing the specimen for 5 h and then placing it for 42 h in an oven at a temperature of 71ºC ± 3ºC. In the next phase, lasting approximately 1 h, the specimens were brushed twenty times (13.3 N force) over the entire surface and four at the top and bottom. Finally, the mass and dimensions of the tested specimen were determined. This cycle was performed 12 times to determine the final loss of mass of the specimen. As for qu, the η/Cv index was used to predict the accumulated loss of mass (ALM) of the tested mixtures.

3 Results and discussion

3.1 Unconfined compressive strength (q u)

Figure 4 shows the unconfined compressive strength results for different contents of sand (0, 15, 30 and 45%) added to the lateritic soil for 7 and 28 days of curing. For all qu results, the porosity/volumetric cement content index was used, and thus the decrease in the porosity parameter to the same cement content provides an increase in strength. Likewise, higher cement content for the same porosity also increases the strength of the mixture. In the same figure, it is possible to verify a satisfactory fit between the tested results and the proposed strength prediction curve with correlation coefficients higher than 85%. A unique equation of (η/Cv)−1 was generated to predict the effects of porosity and cement content for the proposed mixtures, and only the magnitude (scalar) of the equations is altered. All mixture has two trend lines (equations), which correspond to the results for 7 days and 28 days of curing. In general, the variation from 7 to 28 days of curing increases the qu by about 1.3 times.

Consoli et al. [18] attested that in cemented granular soils an internal exponent for volumetric cement content equal to one (1) is applicable when using this index. In the present work, this exponent (1) was satisfactory in the modeling of the strength behavior of the mixtures. For the external exponent of the equation, the value equal to –1 was used. This definition is supported by the work developed by Diambra et al. [24], which defines a mathematical correlation for the qu prediction between the internal and external exponent [c = 1/b from Eq. (1)]. Therefore, unique equations with different magnitudes (scalars) define the behavior and prediction of the qu for different sand contents and curing time studied. Table 3 presents the equations [Eqs. (4)–(12)] for different sand contents and times of curing.

Analyzing the equations, it is possible to verify that different sand contents have different scalars (A) in the equations for the same time of curing. Even so, it is feasible to add the influence of sand in the equation. Figure 5 shows the straight-line tendency that correlates the scalar of the generated equations for different sand contents versus amount of sand (S). The trend lines provide a unique equation for 7 and 28 days of curing [Eq. (13, 14)], correlating: porosity, cement content and sand content. For example, using Eq. (13) with parameter η/Cv equal to 7 with 0% sand the expected strength result is 951 kPa, and with 45% sand the strength is 1,144 kPa. Several combinations of cement contents, sand contents and porosity (density) can be performed by the designer according to the requirements and limitations of the project.

The ability of adding sand to modify physical aspects of the compacted mixture is an important point to analyze. In the Proctor test (Fig. 3), it is evident that for the same compaction energy it is possible to obtain a higher density for the mixture with sand. This is because of the better grain size distribution and consequently a better packing of the particles. In this case, different densities are obtained considering similar compaction (e.g. same soil compactor roller) for the cement- and cement-sand-stabilized lateritic soil.

For example, a soil–cement without sand obtains γd of 18.8 kN/m3 at its optimum moisture content of 15.5% while mixing with 45% sand has 20.1 kN/m3 for an optimum moisture content of 10.26% considering the modified compaction energy. In this case, the porosity of the mixture without sand is 33.5% and with sand is 27.5% for a cement content of 7%. The parameter η/Cv is 8 for the mixture without sand and 6.6 for the mixture with 45% sand for 7 days of curing. According to Eq. (13) the qu for the mixture without sand is 831 kPa, while for the mixture with sand is 1,225 kPa. Considering a minimum strength requirement for 1,200 kPa in sub-base (CEBPT 1984) the addition of sand will enable the use of lateritic soil for light traffic in 7 days of curing. The same correlations can be applied for 28 days of curing [Eq. (14)] which results in 1,122 kPa for the mixture with 0% sand and 1,579 kPa for the mixture with 45%. With 10% cement in the mixture, it is possible to obtain qu of 1,815 kPa for the mixture with sand and 1,153 kPa for the mixture without sand for 7 days of curing. In this case, the addition of sand, for the same cement content, enables the use of this mixture for base of pavement with minimum requirement of 1,800 kPa (CEBPT 1984).

Another (less sensitive) approach to analyze the strength behavior is to consider the results distributed in single curves according to the curing periods (7 and 28 days) for the different sand contents. Figure 6 shows the distribution of the results in two different fit lines for the curing periods used. It is possible to use the same index η/Cv for the formulation of Eqs. (15) and (16). For cement-stabilized soil without sand for 7 or 28 days of curing, the porosity of the mixture with density of 18.8 kN/m3 is 33.6% (Eq. 2). On the other extreme, mixtures with 45% of sand have a porosity of 32.3%. Applying equation Eq. 15 (7 days), for example, results in a qu of 1,290 kPa and 1,342 kPa, respectively. Considering the equations more sensitive to variations in the sand content (Eq. 13), these same mixtures present the strength of 1,153 kPa (0% sand) and 1,451 (45% sand). Therefore, the small variation in porosity absorbed by the η/Cv index does not completely represent the influence of sand addition in the strength of the stabilized soil. Consoli et al. [18], in a study involving several different sands, verified that their morphology is preponderant in the unconfined compressive strength when stabilized with cement. For the present study, the insertion of sand derived from granite into the lateritic soil changes its structure, alters the interlock of the lateritic soil matrix and increases its shear strength. Future research in the microstructural aspect must be carried out in order to detail this influence in lateritic soils stabilized with cement and sand addition.

3.1.1 Statistical data analysis

Table 4 presents the analysis of variance (ANOVA) for all results obtained in the unconfined compression tests considering all the studied variables. The interaction of linear regression was of second order with 95% determination coefficients. Through the significance test (P-value < 0.05), it is possible to determine that all the studied variables and their interactions are significant in the modification of the response variable (qu) to the limits established in the study.

Through the F-value, it is possible to determine the capacity of each investigated variable to change the response variable. The main variable that has the greatest impact in changing the qu is cement content, followed by the density of the mixture, curing time and sand content. These results corroborate with the analysis of the mechanical behavior of the material. The exponent of 1.0 for the volumetric cement content (Cv) demonstrates that cement is a preponderant factor in the alteration of the unconfined compressive strength; the density represented by the porosity (η) is fundamental for the strength of the stabilized soil. The curing time allows significant gains in the strength of the mixtures; however, the cement reactions were not so expressive in 28 days compared to 7 days. The proximity of the scales of the equations formulated for the qu prediction is supported by the lower capacity of this variable to change the response variable.

3.2 Durability

Figure 7 shows the accumulated loss of mass versus the η/Cv for durability tests. As for strength, it is possible to use a single equation for defining the behavior and predicting the loss of mass for all different sand contents, porosity and cement content with 7 and 28 days of curing. The exponent for parameter volumetric cement content is 1.0 (even for qu); however, the external exponent is two (2) and refers to the best correlation between the results and the power type equation. Consoli and Tomasi [12] found similar exponent for the stabilization of sand with Portland cement in durability tests. The coefficient of determination (R2) is greater than 75% for all equations.

The influence of the curing time is observed with the displacement of the curve to the lower part in relation to the 7-day results that provides smaller scalars (A) in the equations. On average, the curing time from 7 to 28 days allowed a reduction of 27% in the loss of mass. In general, the greatest losses of mass are observed in the mixture without sand and 7 days of curing. The best performance was for mixtures with sand addition and 28 days of curing. In Table 5 are presented all equations [from Eqs. (17– 24)] formulated for the difference sand contents with 7 and 28 days of curing.

The durability test is an important parameter for stabilized soils used in road construction (e.g.). Recommendations for mass loss are suggested by the Portland Cement Association [35] according to soil type. In Fig. 7 are traced the established limits of accumulated loss of mass for different mixtures with sand. The addition of sand (15–45%) allows all combinations between porosity and cement content to be applicable for pavement. However, lateritic soil (without the addition of sand) has limitations as to density/porosity, cement content and curing time necessary to meet restrictions on mass loss.

The influence of sand on durability is measured through the scalars of equations (A) formulated for each proposed mixture. Figure 8 shows the linear trend of sand addition as a function of the ALM/(η/Cv)2 obtained for each equation according to sand content. In general, the addition of sand slightly reduces the loss of mass. The trend line generated a unique equation for the prediction of the loss of mass of the lateritic soil stabilized with sand and cement for 7 and 28 days of curing [Eqs. (25, 26), respectively].

Considering the same example for qu, compacted in the same energy with and without sand, different durability estimations are obtained with Eqs. (25, 26). The mass loss is 3.1% for the mixture without sand and 2.0% for the mixture with 45% of sand with 7 days of cure. For 28 days of curing, the loss of mass is 2.2% for the mixture without sand and 1.5% for the mixture with sand. Basically, mixture without sand needs 28 days to achieve the same performance as the mixture with 45% of sand cured for 7 days. In general, the addition of sand provides a higher capacity of the soil to support harsh environmental conditions.

Figure 9 presents unique curve lines to represent the behavior of the ALM for 7 and 28 days of curing. As for previous analyses, it is possible to use the same η/Cv index for an equation with an exponent equal to 2. Equations (27, 28) represent the variation of the accumulated loss of mass for 7 and 28 days of curing, respectively. There is a higher proximity between the results of ALM with 7 and 28 days of curing when compared to the results of strength with the same curing time difference. The lower influence of the curing time generates a smaller difference of scalar between the two prediction equations. This occurs because the temperature used in the durability test increases the cementing reactions and decreases the effect of time before the durability tests.

3.2.1 Statistical data analysis for durability

Table 6 presents the analysis of variance (ANOVA) for all results obtained in the durability test considering all variables studied. As well as for the analysis of qu, all studied variables and their interactions are significant (P-value < 0.05) in the alteration of the response variable (ALM) to the limits established in the study. The variable with greater capacity (higher F-value) of alteration in the loss of mass is the cement content, followed by density, time of curing and sand content. Therefore, the durability behavior is similar to the qu, which justifies the use of the same internal exponent for all equations.

4 Correlation between strength and durability

Figure 10 shows the correlation between the averages of unconfined compression strength (qu) results versus loss of mass (ALM) results obtained from the different mixtures studied. Therefore, for the same mixing parameter (sand content, density, curing time and cement content) used for the unconfined compression test, it was correlated with the same mixing parameter for the durability tests. A power type relation between these two tests was obtained with correlation coefficients of 0.86. Specimens with higher strengths have lower mass loss.

Therefore, it is feasible to formulate an equation [Eq. (29)] that determines the accumulated loss of mass of the lateritic soil stabilized with Portland cement and sand through the strength test. This correlation is an important tool in reducing the need for long laboratory tests such as wetting, drying and brushing tests per 12 cycles.

It can be observed in Fig. 10 that the ALM after 12 cycles tends to be smaller than 5% for compacted lateritic soil–residual sand–Portland cement specimens that presented qu greater than 1,000 kPa.

5 Conclusions

This study was carried out in order to assess the mechanical performance of a lateritic soil whose grain size is amended by the insertion of distinct amounts of residual sand. Portland cement is then added to the soil, and the blend is compacted at distinct dry unit weights and cured for distinct periods. From the results and analysis presented in current research, the following conclusions can be drawn:

-

The employment of the adjusted porosity/cement index (η/Civ) with the purpose of expressing the performance of lateritic soils combined with modification of grain size through the insertion of sand, incorporation of Portland cement and densification through compaction can be considered successful. High coefficients of determination were obtained when qu, and ALM results were correlated with this parameter;

-

According to statistical analysis, both qu and ALM are significantly influenced by the studied variables. The greatest impact is given by the Portland cement content, followed by the density of the mixture, the curing time, and finally by the sand content;

-

The suggestion to correlate ALM to qu proved valid considering the lateritic soil amended by the insertion of distinct amounts of residual sand, distinct Portland cement amounts, compacted porosities and curing times used in this study. Thus, it can be said that the ALM after 12 cycles tends to be smaller than 5% for compacted lateritic soil–residual sand–Portland cement specimens that presented an unconfined compressive strength greater than 1,000 kPa;

-

Finally, carrying out unconfined compression tests in intact compacted lateritic soil–residual sand–Portland cement specimens would be enough to assess its performance, especially for qu results greater than 1,000 kPa.

Data availability

All data from laboratory tests, and the fitting procedure models used during the study are available from the corresponding author upon reasonable request.

References

AASHTO (1991). Standard specification for classification of soils and soil-aggregate mixtures for highway construction purposes. AASHTO M 145. Washington, DC: AASHTO

ASTM (2007). Standard test method for particle-size analysis of soils. ASTM D422. West Conshohocken, PA: ASTM

ASTM. (2014) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM D854. West Conshohocken, PA: ASTM

ASTM (2015) Standard test methods for wetting and drying compacted soil-cement mixtures. ASTM D559. West Conshohocken, PA: ASTM

ASTM (2017a). Standard practice for classification of soils for engineering purposes (Unified soil classification system). ASTM D2487. West Conshohocken, PA: ASTM

ASTM (2017b) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM D4318. West Conshohocken, PA: ASTM

ASTM (2017c) Standard test methods for compressive strength of molded soil-cement cylinders. ASTM D1633. West Conshohocken, PA: ASTM

ASTM (2020) Standard specification for Portland cement. ASTM C150. West Conshohocken, PA: ASTM

Biswal DR, Sahoo UC, Dash SR (2018) Mechanical characteristics of cement stabilised granular lateritic soils for use as structural layer of pavement. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2018.1545687

Biswal DR, Sahoo UC, Dash SR (2019) Durability and shrinkage studies of cement stabilised granular lateritic soils. Int J Pavement Eng 20(12):1451–1462

Caro S, Agudelo JP, Caicedo B, Orozco LF, Patiño F, Rodado N (2019) Advanced characterisation of cement-stabilised lateritic soils to be used as road materials. Int J Pavement Eng 20(12):1425–1434

Consoli NC, Tomasi LF (2018) The impact of dry unit weight and cement content on the durability of sand–cement blends. Proc Inst Civ Eng Ground Improvement 171(2):96–102

Consoli NC, Foppa D, Festugato L, Heineck KS (2007) Key parameters for strength control of artificially cemented soils. J Geotech Geoenviron Eng 133(2):197–205

Consoli NC, Lopes Junior LS, Foppa D, Heineck KS (2009) Key parameters dictating strength of lime/cement treated soils. Proc Inst Civ Eng Geotech Eng 162(2):111–118

Consoli NC, Cruz RC, Floss MF (2011) Variables controlling strength of artificially cemented sand: influence of curing time. J Mater Civ Eng 23(5):692–696

Consoli NC, Viana da Fonseca A, Cruz RC, Silva SR, Fonini A (2012) Parameters controlling stiffness and strength of artificially cemented soils. Géotechnique 62(2):177–183

Consoli NC, Foppa D (2014) Porosity/cement ratio controlling initial bulk modulus and incremental yield stress of an artificially cemented soil cured under stress. Géotech Lett 4(1):22–26

Consoli NC, Marques SFV, Floss MF, Festugato L (2017) Broad-spectrum empirical correlation determining tensile and compressive strength of cement-bonded clean granular soils. J Mater Civ Eng 29(6):06017004

Consoli NC, Peccin da Silva A, Nierwinski HP, Sosnoski J (2018) Durability, strength, and stiffness of compacted gold tailings-cement mixes. Can Geotech J 55(4):486–494

Consoli NC, Pasche E, Specht LP, Tanski M (2018) Key parameters controlling dynamic modulus of crushed reclaimed asphalt paving-powdered rock-Portland cement blends. Road Mater Pavement Des 19(8):1716–1733

Consoli NC, Winter D, Leon HB, Scheuermann Filho HC (2018) Durability, strength, and stiffness of green stabilized sand. J Geotech Geoenviron Eng 144(9):04018057

Consoli NC, Carretta MS, Leon HB, Schneider MEB, Reginato NC, Carraro JAH (2020) Behaviour of cement-stabilised silty sands subjected to harsh environmental conditions. Proc Inst Civ Eng-Geotech Eng 173(1):40–48

Consoli NC, Carretta MS, Festugato L, Leon HB, Tomasi LF, Heineck KS (2020) Ground waste glass-carbide lime as a sustainable binder stabilizing three different silica sands. Géotechnique. https://doi.org/10.1680/jgeot.18.P.099

Diambra A, Ibraim E, Peccin da Silva A, Consoli NC, Festugato L (2017) Theoretical derivation of artificially cemented granular soil strength. J Geotech Geoenviron Eng 143(5):04017003

Eze-Uzomaka OJ, Agbo D (2010) Suitability of quarry dust as improvement to cement stabilized-laterite for road bases. Electron J Geotech Eng 15(2010):1053–1066

Horpibulsuk S, Katkan W, Sirilerdwattana W, Rachan R (2006) Strength development in cement stabilized low plasticity and coarse-grained soils: laboratory and field study. Soils Found 46(3):351–366

Joel M, Agbede IO (2011) Mechanical-cement stabilization of laterite for use as flexible pavement material. J Mater Civ Eng 23(2):146–152

Lasisi F, Ogunjide AM (1984) Effect of grain size on the strength characteristics of cement-stabilized lateritic soils. Build Environ 19(1):49–54

Makasa B (2007). Utilisation and improvement of lateritic gravels in road bases, International institute for aerospace survey and earth science ITC section engineering geology, Delft, The Netherlands

Marques SFV, Consoli NC, Sousa JA (2014) Testing cement improved residual soil layers. J Mater Civ Eng 26(3):544–550

Mengue E, Mroueh H, Lancelot L, Eko RM (2017) Mechanical improvement of a fine-grained lateritic soil treated with cement for use in road construction. J Mater Civ Eng 29(11):04017206

Millogo Y, Traoré K, Ouedraogo R, Kaboré K, Blanchart P, Thomassin JH (2008) Geotechnical, mechanical, chemical and mineralogical characterization of lateritic gravels of Sapouy (Burkina Faso) used in road construction. Constr Build Mater 22(2):70–76

Osinubi KJ, Nwaiwu CMO (2006) Design of compacted lateritic soil liners and covers. J Geotech Geoenviron Eng 132(2):203–213

Phummiphan I, Horpibulsuk S, Sukmak P, Chinkulkijniwat A, Arulrajah A, Shen SL (2016) Stabilisation of marginal lateritic soil using high calcium fly ash-based geopolymer. Road Mater Pavement Des 17(4):877–891

PCA (1992) Soil-cement laboratory handbook. Portland cement association, Illinois

Stracke F, Jung J, Korf EP, Consoli NC (2012) The influence of moisture content on tensile and compressive strength of artificially cemented sand. Soils Rocks 35(3):303–308

Acknowledgement

The research was supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (Editais Institutos Nacionais de Ciência e Tecnologia (INCT), Universal and Produtividade em Pesquisa), Programa de Núcleos de Excelência—Fundação de Amparo a Pesquisa do Estado do Rio Grande do Sul (Project # 16/2551-0000469-2) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Programa de Excelência).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declared that there is no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Consoli, N.C., Párraga Morales, D. & Saldanha, R.B. A new approach for stabilization of lateritic soil with Portland cement and sand: strength and durability. Acta Geotech. 16, 1473–1486 (2021). https://doi.org/10.1007/s11440-020-01136-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01136-y