Abstract

In nature, soils are often composed of varying amounts of clay, silt and sand. Variation of the percentage of these compositions can affect the final strength of the soils when stabilised with cement. In this study, focus was placed on clayey soils with different gradation of sand impurities up to 40% in mass. An extensive study of such clayey soils treated with cement was investigated. For the results, it is noted that water:cement ratio was a major influence of strength development of cement-treated clayey soils. In contrast, the soil:cement ratio was found to have minor effects on the strength development. The presence of sand impurities has a significant reduction on the strength development of the cement-treated clayey soil mixture due to more free water available for hydration. The use of free-water:cement ratio is adopted which was shown to be capable of adjusting for such change in amount of free water and water holding capacity of the clay which is determined with Atterberg’s liquid limit tests. The effects of gradation (fine, coarse and well-graded) of the sand impurities were found to affect strength development minimally, owing to similarities in their liquid limits when mixed with clay. Ordinary Portland cement (OPC)-treated clayey soils produced a more rapid gain in strength but lower final strength at 28 days of curing as compared with Portland blast furnace cement (PBFC). This is found to be persistent for different gradation of sand impurities. A linear correlation can be established based on the log of the unconfined compressive strengths developed at different curing age, with slopes of these linear trends found to be similar for PBFC and OPC-treated clayey soil specimens. Finally, a strength prediction model comprising of these findings is developed. The parameters adopted in this model coincide with values proposed by past studies, thereby validating the robustness of the model. The practical benefits from this study offer a quality control scheme to forecast long-term performance of cement-treated clayey soils as well as optimise cement dosage in cement stabilisation to produce a more cost-effective and less environmental-invasive usage of the technology in geotechnical applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

1.1 Background

Land reclamation has conventionally been carried out with sand as the primary fill material. With the huge amount of excavated soils generated from subterranean construction and sea dredging, there are enormous benefits to reuse these unwanted materials as fill materials so as to reduce pressures on disposal grounds in Singapore. However, these excavated materials are often highly compressible and low in shear strength, which are both undesirable qualities as reclamation fill material. Therefore, the engineering properties of these excavated materials have to be improved in order to be a viable solution. This can be easily achieved by treating the soils with cement [8, 25]. Unfortunately, the excavated materials are often highly heterogeneous in nature with the presence of granular impurities. This could result in differences in engineering properties of the cement-treated soil [9, 39].

The purpose of this study is to investigate the influence of sand grain size on the strength development of cement-treated clay over a wide range of water:cement ratio, soil:cement ratio and curing time. Additionally, the effects of cement type and percentage of impurities by mass are studied to provide a more holistic assessment. A total of more than 1000 specimens were prepared to provide a substantial database for objective comparison. Atterberg’s limit tests were also carried out to measure the water absorbing capacity with presence of sand impurities with different quantities and grain sizes. Due to the nature of the application for land reclamation, flowable mixes achieved with high moisture content and low cement dosage was adopted, in contrast to onshore ground improvement operations. The unconfined compression test is the common yardstick in the industry to determine the quality of mix and hence adopted as the basis of assessment in this study to coincide with industrial practice. Fine, coarse and well-graded sands were used in the mix to assess the influence of grain size of sand impurities on the strength development of cement-treated clay. The curing duration considered ranges between 3 and 91 days. This permits correlation of early and later age strength of the mix specimens and can potentially serve as an early detection for defective mixes. Two types of cement, ordinary Portland cement (OPC) and Portland blast furnace cement (PBFC), are investigated to contrast differences in strength gain.

2 Mechanism of soil cement stabilisation

Soft clay generally has low strength, high compressibility, low permeability and high water content. Some studies [29] have demonstrated that in soft clays, the microfabrics consist of a collection of clay particle clusters enclosed by intercluster spaces. When the cement bonds and strengthens, intercluster spaces are filled, forming a compact matrix that offers higher strength and lower compressibility. There are four main chemical components that influence the strength of the cement clay mixtures: Tricalcium Silicate (C3S), Dicalcium Silicate (C2S), Tricalcium Aluminate (C3A) and Tetracalcium alumina-ferrite (C4A) [23]. The cement-clay reaction can be broken down into 2 major phases of chemical reactions: the primary cement hydration reaction and the secondary pozzolanic reaction [3]. Equations (1) and (4) show the chemical reactions of the major components involved:

Primary Cement Reaction

Secondary Cement Reaction

When pore water in the clay reacts with the cement, the primary cement hydration reaction occurs, producing the primary cementitious products. These cement particles are crucial in binding the adjacent cement grains together, resulting in the hardening of the specimen. The hydration of cement results in the dissociation of hydrated lime gives rise to a strong basic pore water solution, resulting in the mixture becoming more alkali. This encourages the secondary reaction to occur. Calcium hydroxides (Ca(OH)2) are needed to trigger the pozzolanic reaction. The pozzolanic reaction consists of hydrous silica and alumina from soil particles with the calcium ions that have been liberated from the hydrolysis of cement. This new insoluble compound formed hardens and stabilises the specimen. The pozzolanic reaction can last for months or even years after mixing, and thus the strength of cement-treated clay is expected to increase with time [3]. In the case of cement-treated clays, the clay particles participate in the secondary reaction which enhances strength development. However, the pozzolanic reaction requires sufficient calcium hydroxides (Ca(OH)2) to proceed. Hence, the greater the extent of cement hydration, the greater the extent of pozzolanic reaction and vice versa, assuming that the soil particles are sufficient for pozzolanic reactions. If calcium hydroxides (Ca(OH)2) are limited, a lower strength is expected since the secondary reaction is reduced. The pozzolanic reaction is also a much slower process as compared to hydration reaction since it depends on the presence of the hydrated lime-calcium hydroxide and silica or alumina from hydration reaction and clay, respectively. Similar to the pozzolanic reaction by lime treatment, the pozzolanic reaction by cement treatment also further increases in the formation of extra calcium–silicate–hydrates (C–S–H) and calcium-aluminates-hydrates (C–A–H or C–A–S–H).

According to Saitoh et al. [38] and Horpibulsuk et al. [17], the microfabric of cement-treated clay can be portrayed as an amorphous structure where the clay particles are surrounded by the cement to form clusters. The soil particles are embedded in a hardened cement paste which binds to form a continuous structure, contributing to the strength of the specimen. Over time, the clay particle clusters themselves also harden due to their participation in the pozzolanic reaction. This is supported with observations using the scanning electron microscope (SEM) on Kaolin Clay by Verástegui Flores et al. [47].

3 Factors influencing strength of cement-treated clay

The strength of the cement-treated soils had been investigated extensively and found to be dependent on a range of factors. They can be broadly categorised into the four aspects: soil, cement, water and preparation [20]. These would be discussed in detail in the following sections.

3.1 Soil

The type of soil affects the strength development of the cement-treated clay specimen. The pozzolanic reactivity of soil has an influence on the secondary reaction. For the soils of a higher pozzolanic reactivity, the strength characteristic of the treated soil is governed by the strength of the hardened cement rather than the hardened soils. Thus, the higher the pozzolanic reactivity, the greater the strength gained, providing that the improvement conditions are equal. Among all the clayey soils, the kaolin clay used in this study is considered to be an effective pozzolanic agent over other soils [15]. Additionally, Taki and Yang [44] observed that coarse materials such as sand and gravel produced higher unconfined compressive strength than finer materials such as silt and clay with the same amount of cement added. However, Chian et al. [9] showed that a sandy clay mix can potentially reduce the strength of the cement-treated soil at a given moisture content. In this study, further tests on different grading of sand impurities will verify if the observation persists.

3.2 Cement

The effectiveness of the cement-clay mixture is also dependent on the type of cement. Many researches [7, 16, 24, 45] have studied the influence of artificial cementation by Portland cement on cement-treated clay. The adding of ordinary Portland cement (OPC) into a soil sample would result in hydration reaction, followed by the pozzolanic reaction. According to Bhattacharja et al. [2], and Herzog and Mitchell [14], the former happens in any mixture of cement and water. The latter occurs only in the vicinity of soil particles between calcium hydroxide supplied by the cement, and alumina or silica from the clay. The calcium hydroxide produced by the Portland cement during the hydration reaction is purer and finer than ordinary lime which result in a stronger reaction with the soil [2, 14]. Noble and Plaster [34] studied the chemical reactions in OPC-treated clay mixtures and concluded that the rate of cement hydration in clays mixed with cement was slower than normal rate of cement hydration in concrete. Their results also showed that the reaction of calcium hydroxide with the soil minerals (pozzolanic reaction) was related to the size of the clay fraction, while soil mineralogy and size distribution control the strength development.

Portland cement has been widely replaced by the blast furnace slag due to the ability of the blast furnace slag to improve long-term performance and reduce impact to the environment. According to Verástegui Flores et al. [47], the Portland blast furnace cement has a slower rate of strength development in the early stage as compared to Ordinary Portland cement, although the long-term strength is higher. Based on the studied from Escalante et al. [12], as the slag replacement level was increased, the amount of calcium hydrates was reduced. This is because the hydrates produced by the cement were consumed by the slag in the early couple of weeks. By 28 days, the hydration has completed, however the slag continues to consume small amounts of calcium hydrates to form C –S –H products which enhances the strength of the matrix [12]. This study will investigate if this is valid for cement mixed sandy-clay.

3.3 Curing time

The unconfined compressive strength of cement-treated soil increases with curing time. This behaviour can be explained by the extent of reaction time of cement hydration and pozzolanic reactions that could take few months or even years as long as sufficient water and alkaline condition are present. As stated by Nagaraj et al. [33], the normalised unconfined compressive strength (UCS) with curing time follows a linear semi-logarithmic relationship as shown in Eq. 5.

UCST is the unconfined compressive strength at t days, UCSTref is the unconfined compressive strength at a reference day, while a and b are fitting constant obtained through experiments. A similar function is also proposed by Ahnberg [1] and Mitchell et al. [30]. Eq. 6 shows the equation by Mitchell et al. [30].

where qu (t) and qu (t0) are unconfined compressive strengths at t days and t0 days, respectively. K is a function of cement content (C) in % by mass (x·C), where x is recommended to be 480 and 70 for granular soil and fine-grained soil, respectively.

3.4 Water:cement ratio

In past studies by Nagaraj et al. [32, 33], Matsuo et al. [26] and Porbaha et al. [36], the water:cement ratio (w/c) of cement-treated clays have been found to have an inverse relationship with their unconfined compressive strength. Gallavresi [13] proposed that the qu of cement-treated soils can be correlated to the w/c as follows:

where qo = experimentally fitted coefficient (5,000–10,000 kPa), and n is an experimentally fitted coefficient within the range of 1.5–3.

This was then further modified by Horpibulsuk et al. [16, 18] through conducting several unconfined compression tests. The proposed strength development model was expressed by a power function similar to that of Gallaversi [13]:

where A and B are experimentally fitted coefficients, depending on soil type.

3.5 Soil:cement ratio

According to Lu et al. [25], the effect of soil to cement ratio (s/c) on the strength of cement-treated soil is minimal. This is because for a given constant water to cement ratio, a lower soil to cement ratio would infer a higher moisture content as well as a larger amount of cement content. Thus, the effect of soil to cement ratio on the strength of cement-treated soil is insignificant.

However, based on a research study by Lee et al. [24], the influence of the soil:cement ratio must also be included. From their study, the qu strength of a cement-treated clay increases with soil:cement ratio for a constant water:cement ratio. In a supporting work by Chew et al.’s [7] research work, the scanning electron microscope (SEM) showed that the release of Ca2+ ions arising from the hydration reaction of the cement leads to a flocculated microstructure of the soil:cement mix. Moreover, for a given constant water to cement ratio, lower soil to cement ratio would give a higher water content, which would have a higher void ratio in the sample. Hence, the flocculation process would lead to more porous structure and lower the qu strength. This phenomenon would be more prominent for the samples with higher water:cement ratio.

Chian et al. [8] showed that the s/c would only affect the parameter X in Eq. 9 linearly. Therefore, the model can be described with the following equation consisting of 3 parameters:

where a and b are y-axis and slope of parameter X against s/c.

3.6 Sand impurities in clay

Several studies [22, 28, 44, 46] have investigated the effect of different grain size on treated soils, however results reported differ between them. According to Taki and Yang [44] and Mitchell [28], larger coarse grain size would give a higher strength to the cement-treated soil. However, according to Lasisi and Ogunjide [22], smaller grains size of soil would produce a higher compressive strength in the cement-stabilised soils. According to recent study by Tang et al. [46], larger maximum diameter of aggregate Dmax would produce lower small strain shear modulus G0 owing to the difference in total surface of grains. On the other hand, McKissock et al. [27] found out that adding clay into sandy soil would help to reduce water repellency. The relationship between the amount of clay applied and water drop penetration time (WDPT) is logarithmic, i.e. a small initial additions of clay produces a large reduction in water repellency. In other words, the higher is the amount of sand content, the greater is the water repellent effect and therefore a lower compressive strength.

There is hence no conclusive outcome on the influence of sand content and the strength development of cement-treated sandy-clay at present. However, it appears that larger coarse grain size soils tend to produce higher strength when mixed with cement. On the other hand, more amount of sand in the clayey soil would lead to greater water repellent effect which affects the bonding formation between the cement and clay. As a result, lower strength of the cement-stabilised soil may be expected with increase in amount of sand in the cement-treated soil. In order to provide a more holistic analysis, this paper investigates the effect of size and grading of sand impurities on the strength development of cement-stabilised clayey soils.

4 Experimental procedures

4.1 Materials

Kaolin clay is selected for its common use in fundamental studies of soil behaviour and in physical model tests [37, 40].The Kaolin clay was procured from Kaolin (Malaysia) Sdn Bhd. The minerals in Kaolin clay is primarily kaolinite. According to the Unified Soil Classification System (USCS), the clay is classified as high plasticity clay (CH). Tables 1 and 2 summarise the basic physical and chemical properties of the clay, respectively.

Two types of cement were used in this study, namely the ordinary Portland cement (OPC) and Portland blast furnace cement (PBFC). EnGro Corporation Limited supplied the CEM I Portland cement and CEM III Portland blast furnace cement in this study. The details of the physical properties and chemical compositions of the cements are tabulated in Tables 3 and 4.

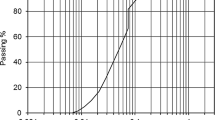

In order to ascertain the effect of sand grain size distribution in cement-treated clayey soils, which is the emphasis of this study, 3 grading of silica sand were used: fine, coarse and well-graded. For fine sand, the particle size distribution was poorly graded, with a mean effective diameter (D50) of 0.25 mm. In the case of coarse graded sand, D50 was 0.90 mm. Well-graded sand samples had D50 of 0.85 mm with coefficient of uniformity (Cu) of at least 6 and coefficient of curvature (Cc) between 1 and 3. More details on the gradation can be found in Table 5 and Fig. 1.

4.2 Specimen preparation

More than a thousand samples were made for this study. The target amount of cement, water and soil was measured based on mass. In order to establish the influence of sand impurities, 0–100%, 20–80% and 40–60% of sand-clay proportions were adopted, while keeping the total mass of soil consistent with the desired soil to cement ratio. In order to ensure homogeneity of the soil batch, the mixture was prepared by mixing the proposed amount of sand, kaolin clay and water together using the Hobart N50 mixer for 10 min. Next, the appropriate amount of cement is added to the mix to achieve the desired cement content, before mixing for a further 10 min. Additionally, the mixing was paused for one minute in between to scrape off contents left at the dead corners of the mixing blade, particularly soil attached to the side wall and bottom of the mixer bowl by using a spatula, following the Japanese Standard JGS 0821-2009 [19].

After the batch has been mixed, the mixture was then poured into plastic moulds coated lightly with petroleum jelly on the inside. These plastic moulds are disposable and have a diameter and height of 50 mm and 100 mm, respectively. The mix was poured into these moulds in 4 layers with compaction by manual tapping. Due to the slurry condition of the mix, the manual tapping is effective in avoiding formation of large pores within the specimen, but do not actually densify the mix. This was ascertained by the consistencies in density of the specimens prepared. The top end was sealed with paraffin film and plastic cap to prevent moisture loss in the mix. The specimens were then fully submerged in water in a controlled room temperature of 23 ± 2 °C till the desired curing ages.

Different mix ratios were prepared, by varying the water:cement ratio (w/c), soil:cement ratio (s/c) and the percentage of sand impurities as shown in Table 6. The curing ages studied were 3, 7, 14, 28 and 91 days for both OPC and PBFC specimens. It is interesting to note that specimens with the same w/c and s/c but higher sand percentage produced more slurry mixes than those of a lower sand percentage. The amount of free water was therefore more apparent in these mixes with higher sand percentage [9].

4.3 Unconfined compression testing

The unconfined compression strength is commonly conducted on cement-stabilised soils as a measure of strength and quality control in practice. In this study, the test was conducted in accordance to the BS 1377-7 [4]. When the curing age was reached, the specimens were carefully extruded out from the moulds. Minor trimming at the ends of the specimens was carried out to ensure even contact surfaces on the loading platens. Additionally, the diameters, heights and weights of the specimens were measured and recorded. A ratio of the height to diameter of about 2 was maintained for all specimens. The unconfined compression apparatus is loaded at an axial strain rate of 1 mm/min, measured with a linear variable displacement transducer.

4.4 Atterberg limits

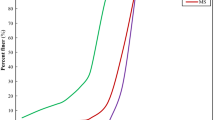

The Atterberg limits were also tested to determine the plastic and liquid limits of the Kaolin clay with varying percentages of sand impurities. A wide range of percentages of sand were tested: 0%, 10%, 20%, 30%, 40% and 50% of the total mass of the soil. Figure 2 shows the plastic and liquid limits at these percentages of fine, coarse and well-graded sand impurities. The Atterberg limits are measures of the amount of water content present in the soil at the boundaries of each of the states (solid, semi-solid, liquid). The procedures of obtaining the Atterberg limits are according to BS 1377-2 [5]. Early study by Casagrande [6] suggested that fine-grained soil consistency limit is more important than soil gradation for the characterisation of state and engineering properties of soils. In addition, several other researchers have also indicated that the composite effects of soil constituents and their interactions with pore fluid are largely reflected in their liquid limit [35, 41, 42]. Hence, the liquid limit forms a basis in the assessment of soil characteristics, having taken into account the presence of coarser fraction. Figure 2 shows that the increase in sand percentage decreases the Atterberg limits of the sandy clay specimens. This can be explained by the lower specific surface area of sand as compared to clay particles, hence lowers the physio-chemical interaction with water. As a result, higher percentage of sand impurities would lead to a reduction in gross-water holding capacity or liquid limit. This is analogous to observations by Dumbleton and West [11] who studied the addition of quartz sand and silt in various clay types. More recent studies by Srinivasa Murthy et al. [43] and Chian et al. [9] also produced similar outcomes for black cotton clay and Singapore marine clay, respectively. Specific to this present study, the values of these limits are similar for fine, coarse and well-graded sand impurities, thereby indicating comparable water holding capacity.

5 Strength development of cement stabilised clayey soils

In order to establish a holistic analysis of the strength development of cement stabilised clayey soils, the effects of mix proportions of water, soil and cement were considered using the water:cement (w/c) and soil:cement (s/c) ratios. The effect of sand impurities was accounted based on its proportion out of the total dry soil in mass. Curing ages as early as 3 days to 91 days were investigated to provide a short to medium term strength performance of these improved soils. The preparation was repeated for 3 different grain size gradation. Figure 3 shows a typical stress–strain plot of specimens tested and typical mode of failure after 28 days of curing. The stress–strain plots demonstrate that the specimens are brittle, particularly the pure clay-cement mix. Specimens with sand impurities tend to produce a lower strength but more ductile failure. Observations did not indicate significant differences in strength development between specimens with different grain sizes. More detailed discussions would be covered in subsequent sections.

5.1 Effect of water:cement ratio

It was discussed earlier in the literature that the w/c ratio is the governing factor of the strength development of cement-stabilised soils. Hence, specimens with sufficient range of water and cement contents were investigated.

Figure 4 shows a typical relationship between water:cement ratio and unconfined compressive strength. It can be observed that higher unconfined compressive strength (qu) was obtained for specimens with lower w/c ratio. The increase in strength was more rapid with lower w/c ratio, resembling classic qu-w/c curves observed in Gallavresi [13], Miura et al. [31], Horpibulsuk et al. [16] and Chian et al. [8]. Interestingly, the strength development trends for fine, coarse and well-graded appeared to be rather similar. This applies also to higher percentage of sand impurities at 40% of the total mass of the soil as shown in Fig. 5.

Nagaraj et al. [33] suggested that more water would induce a higher porosity or pore volume in the soil, hence hampering the cementation bonding with the soil clusters. On the other hand, lower porosity enables the mobilisation of additional resistance from granular particles during shearing, thereby resulting in higher strength obtained. This is particularly the case with longer curing age where more cementation bonding derived from hydration is formed, as evident in the figures.

5.2 Effect of soil:cement ratio

In Fig. 6, it can also be observed that the effect of soil:cement ratio (s/c) on the qu strength of cement-treated soil is relatively lower as compared to w/c. In addition, there was no apparent improvement in unconfined compressive strength in either increasing or decreasing s/c across the different mixture of clay and sand grain size. As discussed by Tan et al. [45], for a given constant w/c, lower s/c ratio results in higher w/s ratio. The former would promote higher strength due to the higher density of cement in soil body, while the latter reduces strength due to higher porosity in the specimen. Hence, these effects counteract each other and produced minor effect on the resultant strength of the cement-treated soil as observed in the figure. Similar observations are reported for cement stabilised clays [17, 18, 39].

5.3 Effect of percentage of sand impurities

The percentage of sand impurities in the clayey soil was also modified in this study to depict the effect of sand impurities on the strength development after mixing with cement.

Based on Taki and Yang [44], coarser-grained soils tend to produce higher strength when mixed with cement. This would infer that the strength of the specimen would be stronger for higher percentage of sand. However, this observation was contradictory to the results presented in Fig. 7.

From the figures, it is observed that specimens with higher percentage of sand impurities gave lower qu strength values. This is attributed to the higher free water content available due to the sand’s lower physio-chemical interaction with water which led to the inability to retain water as much as clay as observed in Fig. 2, leading to a more slurry condition. Such increase in available water for cement hydration is detrimental to the strength development of the specimen as observed in past studies [9]. As a result, the porous soil clusters would easily slide over one other when shearing, which results a lower qu.

In order to account for the change in water affinity, the “free-water:cement ratio” is used to replace the conventional water:cement ratio (w/c). The free-water:cement ratio is defined as the moisture content of the sample divided by the liquid limit (wL) of the sample and thus divided by the cement content (i.e. (w/wL)/c). This parameter also offers the ability to account for different clay types with different liquid limit where the amount of water absorbed by the clay can be omitted from the cement hydration process. According to Wroth [48], all the fine-grained soils tend to equilibrate from the same high initial water content to their respective liquid limit water content at an effective stress state. Figure 8 shows the relationship between qu versus w/wL/c of cement-treated samples. A more unified trend can be observed where unconfined compressive strength between pure clay, 20% and 40% sand impurities are aligned, thus postulating the free-water:cement ratio as a more suitable relationship to encompass the effects of sand impurities in cement-treated clayey soils.

5.4 Effect of cement type

As mentioned earlier, two types of cement were used in this study: Portland blast furnace cement (PBFC) and the ordinary Portland cement (OPC). Their strengths of the curing ages between 3 to 91 days are presented in Fig. 9. In the early curing stage till about 14 day, the specimens treated with OPC showed higher strength as compared to the PBFC, but a lower later strength was observed instead beyond that till 91-day. This is because OPC hydrates more readily, forming strength enhancing calcium hydrate silicates in this early stage of curing. On the other hand, PBFC hydrates more slowly within the same period due to lower amount of calcium silicates present. However, the mixture continues to gain strength due to pozzolanic reaction between the hydrated products and iron slag which produce more secondary cementitious products. This resulted in a much slower initial increase in strength but yielded higher final age strength. The above observation holds for different sand grain size.

5.5 Effect of curing time

Generally, strength enhancing reactions progress with time. Thus, strength attained by cement-treated soils always increases with curing age. Figure 9 shows that the strength development of OPC and PBFC stabilised soil with different gradation of sand exhibit linear relationship with logarithmic of time. Similar behaviour was reported for cement-treated clayey soils [8, 30, 33]. This is caused by the rapid gain in strength in the early phase of hydration, followed by slower strength increase in the later phase of pozzolanic reaction.

5.6 Effect of gradation of sand

In this section, comparisons are made with respect to the difference in strength between cement-treated clay with coarse, fine, well-graded soil specimens. According to Fig. 9, coarse sand shows slightly faster early strength development. While in Fig. 10, coarse sand specimens produced a lower strength than the fine sand. This is attributed to the fact that larger particle size has smaller total surface area that results in the soil’s tendency to have a lower optimum moisture content value and also greater voids for the free-flow water in the mixture. Since the hydration process is a chemical reaction between the compounds in cement and water to form the chemical bond, the cement-treated specimens with coarse sand would have a faster rate of hydration process as compared to well-graded and fine sand. According to Kuhlman [21], the finer soils tend to have a higher optimum moisture content which results in more cement contents are required, making them more prone to drying shrinkage issues. However, the greater voids caused by the presence of coarse sand in the mixture prevents the clay particles bond with cement and induce structural integrity in the samples. The voids can be more significant when limited bonding materials are produced. In this case, the effect of the latter dominates the former and result in lower strength development of coarse sand specimens. In contrast, results showed samples with fine sand had a slightly higher strength than the well-graded sand at low strength region, and slightly lower strength than well-graded sand at high strength region exceeding 1500 kPa. However, such enhancement in strength is marginal which points to the fact that the sand gradation has relatively minor influence. Given that the liquid limits of the clay with either fine, coarse and well-graded sand were similar, this infers that the percentage of sand impurities has a far larger influence on strength development of cement-treated clayey soils than sand gradation.

5.7 Early versus later age strength of cement-treated clayey soils (q u,t vs q u,3-day)

Further analysis on the unconfined compressive strength, qu, of cement-treated clay with different gradation of sand was carried out, particularly on its development with time. Figure 11 shows the later age strength (7, 14, 28, 91-day) versus early age strength (3-day) of OPC and PBFC samples with fine, coarse and well-graded sand impurities over the entire range of water:cement and soil:cement ratios. A linear trend can be observed in Fig. 11, thereby indicating the prospect of estimating later age strength of cement-treated clayey soils based on early age strength. The initial strength gained is dependent largely on the hydration process between the compounds in cement and water to form the chemical bond. According to Eqs. (1) and (2), when cement hydration increases, more strength enhancing products C–S–H and Ca(OH)2 are produced. The former enhances the initial strength development while the latter promotes the secondary pozzolanic reaction of soil particles and enhances the later strength development accordingly. As a result, positive relationships can be observed between early and later age strength development of cement stabilised clayey soil.

In addition, the grain size appears to have negligible effect on the relationship between early and later age strength as evident in the figure. This infers that sand gradation does not have apparent influence on the cement hydration and pozzolanic reaction process. The cement hydration involves cement and water while the pozzolanic reaction occurs between Ca(OH)2 and soil particles. According to Croft [10], pozzolanic reaction is highly dependent on the surface area and activity of soil, while the colloidal properties of soil are largely contributed by clay fraction [42]. Granular particles such as sand are much less chemically reactive and are thus less involved in pozzolanic reaction as compared to clay particles. Therefore, the strength development contributed by pozzolanic reaction is more dependent on the type of clay rather than type of sand.

The slopes of the best fit linear trend lines in Fig. 11 can be represented with curing duration as shown in Fig. 12. In all cases of sand impurities percentage, water:cement, soil:cement and cement type, the slope increases with curing ages following a log function. This indicates that the amount of strength enhancement slows down gradually with curing time, which corresponds to the slower pozzolanic reaction in the long-term curing. Overall, PBFC shows steeper slope as compared to OPC. This suggests that PBFC stabilised clayey soils have greater amount of strength increment during mid-to-long term curing (≥ 7 days), which supports the observation in Fig. 9. In addition, 40% sand shows slightly gentler slope than 20% sand. This can be due to the fact that increasing sand content increases the free water in the soil matrix and prevents the formation of large cement-clay lump [9]. Thus, the reaction between compounds can occur more readily and higher strength is developed in the early stage. As a result, the ratio between late age and early age strength is lower for specimens with higher percentage of sand.

Figures 11 and 12 capture the relationships between early and late strength development as well as their evolution with time, thereby permitting quality control to be carried out where defective mixes can be identified earlier before they harden excessively, thereby avoiding high cost of rectifying in field applications.

6 Strength prediction of cement-treated clayey specimens

In view of the success in predicting strength development of cement-treated clays using Eq. 9 over a wide range clays, cement types and mixing ratios [8], the focus in the section would be placed on determining the robustness of extending a similar prediction methodology into cement-treated clayey soils with sand impurities of different sand grain sizes. The free-water:cement ratio, (w/wL)/c proposed by Chian et al. [9] would be adopted to assess if the effect of sand grain sizes could be encompassed based on their liquid limits.

Figure 13 shows the prediction versus measured unconfined compressive strength of mixes consisting of pure clays, clayey soils with sand impurities of fine, coarse and well-graded sands at 20% and 40% of the total mass of soils treated with PBFC. It can be observed that the strength can be well predicted using the equation stated in the figure in the form of:

This equation is aligned with the findings in this study that: (1) water:cement ratio follows an exponential gain with reduction of the ratio, (2) minimal influence of soil:cement ratio, (3) linear relationship of strength with logarithmic curing duration and (3) accounting of presence of sand impurities and gradation with the free-water:cement ratio. Given similar form as Eq. 9, the α parameter is dependent on the mixing method, type of clay and cement types, while β parameter is a function of the liquid limit of the clay, similar to the X and Y coefficients in Eq. 9. Hence, estimates of α and β values may be made relying on the choice of X and Y coefficients. Chian et al. [8] suggested a Y value of 1.25 for Kaolin clay, which is similar to the β estimate of 1.26 in this study. Likewise, α parameter of 20,000 in this study corresponds to X value of 19,256 with reference to 28-day curing. This confirms the comparability of these two parameters with X and Y coefficients established by Chian et al. [8] based on a wide database published in the literature comprising of Japanese Ariake clay, Thai Bangkok clay, British Kaolin clay and Chinese Yangtze River and Black clays. In view of the corresponding prediction of strength development over a wide range of variables, it is therefore evident that prediction of unconfined compressive strength of cement-treated clayey soils is promising based on the methodology proposed in conjunction with the adoption of free-water:cement ratio in order to account for presence of granular impurities. This opens up opportunities to optimise cement dosage in order to produce a more cost-effective and less environmental-invasive usage of cement stabilisation technology in geotechnical applications.

7 Conclusion

An extensive study of cement-treated clayey soils with different gradation of sand impurities were conducted with over 1000 specimens covering a wide range of influencing factors. In this study, it is confirmed that water:cement ratio remains to be the major influence of strength development of cement-treated clayey soils. This is in line with cement technology where more unreacted moisture in the cement matrix leads to higher porosity and lower compressive strength. The soil:cement ratio has minor effects on the strength development of cement-treated clayey soils, which is consistent with findings from past studies. According to Atterberg’s limit test, the presence of sand impurities decreases the water holding ability of the soil matrix and lead to increased amount of free water at the same mix ratio, which in turn lead to lower compressive strength. The use of free-water:cement ratio is therefore adopted which was shown to be more suited as a proxy to adjust for the amount of free water available for cement hydration and water holding capacity of the clay. The effects of gradation (fine, coarse and well-graded) of the sand impurities were found to affect strength development minimally, owing to similarities in their liquid limits when mixed with clay. This implies that laborious work to determine the particle size distribution of the sand impurities may not be required so long as the liquid limit of the clayey soil is established for the purpose of strength prediction when stabilising with cement. The effect of cement type, namely the PBFC and OPC, on strength development of cement-treated clayey soils follows similar to its hydration properties. OPC-treated clayey soils produced a more rapid gain in early strength but lower long-term strength as compared with PBFC. With respect to early and later age curing strength of cement-treated clayey soils, a linear correlation can be established based on the unconfined compressive strengths developed at different log of curing age. This observation persists for both PBFC- and OPC-treated clayey soil specimens. Finally, a strength prediction model comprising of these findings is developed which shows good estimates of the measured unconfined compressive strength obtained from experiments. The relationship of the parameters adopted in this strength prediction model is also found to coincide with values proposed by past studies. The practical benefits from this study offer a quality control scheme to forecast long-term performance of cement-treated clayey soils as well as optimise cement dosage in cement stabilisation to produce a more cost-effective and less environmental-invasive usage of the technology in geotechnical applications.

References

Ahnberg H (2006) Strength of stabilized soils—a laboratory study on clays and organic soils stabilized with different types of binder. PhD Thesis, Lund University

Bhattacharja S, Bhatty JI, Todres HA (2003) Stabilization of clay soils by Portland cement or lime—a critical review of literature, research and development, Serial No. 2066, Portland Cement Association, Skokie, IL

Bergado DT, Anderson LR, Miura N, Balasubramaniam AS (1996) Soft ground improvement in lowland and other environments. ASCE Press, New York

BSI 1377-2 (1990) Methods of test for soils for civil engineering purposes—Part 2: classification tests. British Standards Institution, London

BSI 1377-7 (1990) Methods of test for soils for civil engineering purposes—Part 7: shear strength tests (total stresses). British Standards Institution, London

Casagrande A (1932) Research on the Atterberg limits of soils. Public Roads 12(8):121–136

Chew SH, Kamruzzaman AHM, Lee FH (2004) Physicochemical and engineering behavior of cement-treated clays. J GeotechGeoenvironEng 130(7):696–706

Chian SC, Nguyuen ST, Phoon KK (2015) An extended strength development model of cement treated clay. J GeotechGeoenvironEng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001400

Chian SC, Chim YQ, Wong JW (2017) Influence of sand impurities in cement-treated clays. Géotechnique 67(1):31–41

Croft JB (1967) The influence of soil mineralogical composition on cement stabilization. Geotechnique 17(2):119–135

Dumbleton MJ, West G (1966) The influence of the coarse fraction on the plastic properties of clay soils, Report LR36. Transport and Road Research Laboratory, Crowthorne

Escalante JI, Gomez LY, Johal KK, Mendoza G, Mancha H, Mendez J (2001) Reactivity of blast furnace slag in Portland cement blends hydrated under different conditions. CemConcr Res 31:1403–1409

Gallavresi F (1992) Grouting improvement of foundation soils. In: Proceedings of grouting, soil improvement and geosynthetics, vol 1. ASCE, pp 1–38

Herzog A, Mitchell JK (1963) Reactions accompanying the stabilization of clay with cement. Highw Res Rec 36:146–171

Hilt GH, Davidson DT (1960) Lime fixation in clayey soils. Highw Res Board Bull (262).

Horpibulsuk S, Miura N, Nagaraj TS (2003) Assessment of strength development in cement-admixed high water content clays with Abrams’ law as a basis. Geotechnique 53(4):439–444

Horpibulsuk S, Miura N, Nagaraj TS (2005) Clay-water/cement ratio identity for cement admixed soft clays. J GeotechGeoenvironEng 131(2):187–192

Horpibulsuk S, Rachan R, Suddeepong A (2011) Assessment of strength development in blended cement admixed Bangkok clay. Constr Build Mater 25(4):1521–1531

Japanese Geotechnical Society (JGS) (2009) Practice for making and curing stabilized soil specimens without compaction. JGS 0821-2009, Japanese Geotechnical Society (in Japanese)

Kezdi A (1979) Soil physics. Elsevier, Amsterdam

Kuhlman RH (1994) Cracking in soil cement: cause, effect, control. Concr Int 16(8):56–59

Lasisi F, Ogunjide AM (1984) Effect of grain size on the strength characteristics of cement-stabilized lateritic soils. Build Environ 19(1):49–54

Lea FM (1956) The chemistry of cement and concrete. Edward Arnold Publisher, London

Lee FH, Lee Y, Chew SH, Yong KY (2005) Strength and modulus of marine clay-cement mixes. J GeotechGeoenvironEng 131(2):178–186

Lu Y, Tan TS, Phoon KK (2011) Accelerated testing of cement treated Singapore marine clay cured under elevated temperature. Technical report. National University of Singapore, Centre for Soft Ground Engineering, Singapore

Matsuo T, Nisibayashi K, Hosoya Y (1996) Studies on soil improvement adjusted at low compressive strength in deep mixing method. In: Proceedings of IS-Tokyo’96, The 2nd international conference on ground improvement geosystems, pp 807–824

McKissock I, Gilkes RJ, Walker EL (2002) The reduction of water repllency by added clay is influenced by clay and soil properties. Appl Clay Sci 20(4–5):225–241

Mitchell JK (1993) Fundamentals of Soil Behavior, 2nd edn. Wiley, New York

Mitchell JK, El-Jack SA (1965) The fabric of soil-cement and its formation. Clays Clay Miner 14(1):297–305

Mitchell JK, Ueng TS, Monismith CL (1972) Behaviour of stabilized soils under repeated loading - Report 5: Performance evaluation of cement-stabilized soil layers and its relationship to pavement design. Technical report. University of California, Berkeley

Miura N, Horpisulbuk S, Nagaraj TS (2001) Engineering behaviour of cement stabilized clay at high water contents. Soils Found 41(5):33–45

Nagaraj TS, Miura N, Yamadera A (1998) Induced cementation of soft clays—analysis and assessment. In: 1st International symposium on lowland technology, pp 267–278

Nagaraj TS, Yarigar P, Miura N, Yamadera A (1996) Prediction of strength development cement admixture based on water content. In: Proceedings of the 2nd international conference on ground improvement geosystems, vol 1, pp 431–436

Noble DF, Plaster RW (1970) Reactions in Portland cement–clay mixtures. Final report, Virginia Highway Research Council, Charlottesville

Pandian NS, Nagaraj TS (1990) Critical reappraisal of colloidal activity of clays. J GeotechEng 116(2):285–296

Porbaha A, Shibuya S, Kishida T (2000) State of the art in deep mixing technology. Part III: geomaterial characterization. ProcInstCivEng Ground Improv 4(3):91–110

Rossato G, Ninis N, Jardine R (1992) Properties of some kaolin-based model clay soils. Geotech Test J 15(2):166–179

Saitoh S, Suzuki Y, Shirai K (1985) Hardening of soil improved by deep mixing. In: Proceedings 11th international conference soil mechanics and foundation engineering, San Fransisco, pp 1745–1748

Santoso AM, Phoon KK, Tan TS (2013) Estimating strength of stabilized dredged fill using multivariate normal model. J GeotechGeoenvironEng 139(11):1944–1953

Sasanakul I, Abdoun T, Sharp M (2010) Physical modeling studies to evaluate performance of New Orleans levees during hurricanes. In: Proceedings of the 7th international conference on physical modelling in geotechnics, Zurich, pp 1195–1200

Seed HB, Woodward RJ, Lundgren R (1964) Fundamental aspects of Atterberg limits. J GeotechnEng 117(9):1288–1330

Skempton AW (1953) Colloidal activity of clays. In: Proceedings 3rd international conference on soil mechanics and foundation engineering, Zurich, Switzerland, pp 57–67

Srinivasa Murthy BR, Nagaraj TS, Bindumadhava (1987) Influence of coarse particles on compressibility of soils. In: Proceedings of international sym. on prediction and performance in geotech. eng., calgary, Canada, Balkema, Rotterdam, pp 195–200

Taki O, Yang D (1991) Soil-cement mixed wall technique. In: Geotechnical engineering congress, ASCE, vol 27. Special Publication, pp 298–309

Tan TS, Goh TL, Yong KY (2002) Properties of Singapore marine clay improved by cement mixing. Geotech Test J 25(4):422–433

Tang YX, Miyazaki Y, Tsuchida T (2001) Practice of reused dredgings by cement treatment. Soils Found 41(5):129–143

Verástegui Flores RD, DiEmidio G, Van Impe W (2010) Small-strain shear modulus and strength increase of cement-treated clay. Geotech Test J 33(1):62–71

Wroth CP (1979) Correlations of some engineering properties of soils. In: Proceedings of 2nd BOSS conference London, pp 121–132

Acknowledgements

The authors are grateful for the financial support from the Ministry of Education of Singapore. The assistance from B.Eng. final year students, Mr. Jianwen Wong, Mr. Keng Hwa Lee and Ms. Vanessa Sok Ju Koh, in the experimental testing are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chian, S.C., Bi, J. Influence of grain size gradation of sand impurities on strength behaviour of cement-treated clay. Acta Geotech. 16, 1127–1145 (2021). https://doi.org/10.1007/s11440-020-01090-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01090-9