Abstract

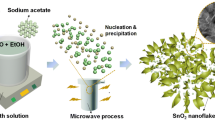

Hierarchical SnO2 nanoflowers assembled by atomic thickness nanosheets were prepared by facile one-pot solvothermal method with acetone/water mixture as solvent. The crystal structure, morphology and the microstructure of the as-prepared products were characterized by X-ray diffraction, scanning electron microscopy, transmission electron microscopy and atomic force microscope (AFM). Results revealed that the nanoflowers (2–4 μm) were assembled by the ultrathin SnO2 nanosheets (3.1 nm estimated by AFM). When tested as anode material for lithium ion batteries, the SnO2 nanoflowers showed improved cycling stability comparing with the commercial SnO2 particles. The reversible charge capacity of SnO2 nanoflowers maintained 350.7 mAh/g after 30 cycles, while that of the commercial SnO2 was only 112.2 mAh/g. The high reversible capacity and good cycling stability could be ascribed to the hierarchical nanostructure, atomic thickness nanosheets and large surface area of the SnO2 nanoflowers.

摘要

便携式电子设备和电动汽车等的发展对高性能电池的需求日益迫切。锂离子电池由于其高能量密度,长循环寿命,环境友好等优点受到广泛关注。决定锂离子电池性能的重要因素是电极材料。SnO2因其具有较高的理论容量、较低的嵌锂电压,常被用作负极材料。但是商品化SnO2在嵌/脱锂过程中引起的体积变化会导致材料的聚集和粉末化,使材料的电化学性能大大减弱。构建纳米结构的SnO2可以缓解这个问题。最近的研究表明二维原子层厚度纳米片具有优异的电化学性能,由此我们得到启发,通过一步溶剂热法合成了原子层厚度纳米片组装而成的SnO2纳米花。该纳米花用作锂离子电池负极材料,显示出较大的可逆容量和良好的循环性能。SnO2纳米花良好的电化学性能与SnO2纳米花具有疏松结构、超薄原子层厚度的纳米片、大的比表面积等有关。与商品化SnO2相比较,SnO2纳米花电化学性能得到显著提高。

Similar content being viewed by others

References

Guo J, Zhang J, Ju DX et al (2013) Powder Technol 250:40–45

Park JT, Lee CS, Kim JH (2014) RSC Adv 4:31452–31461

Dou XC, Sabba D, Mathews N et al (2011) Chem Mater 23:3938–3945

Wu HB, Chen JS, Lou XW et al (2011) J Phys Chem C 115:24605–24610

Zhou XS, Wan LJ, Guo YG (2013) Adv Mater 25:2152–2157

Guo ZP, Du GD, Nuli Y et al (2009) J Mater Chem 19:3253–3257

Liu JP, Li YY, Huang XT et al (2009) J Mater Chem 19:1859–1864

Ding SJ, Lou XW (2011) Nanoscale 3:3586–3588

Yim CH, Baranova EA, Courtel FM et al (2011) J Power Sources 196:9731–9736

Yang R, Gu YG, Li YQ et al (2010) Acta Mater 58:866–874

Wu WZ, Wang L, Li YL et al (2014) Nature 514:470–474

Zhang XD, Xie Y (2013) Chem Soc Rev 42:8187–8199

Wang C, Zhou Y, Ge MY et al (2010) J Am Chem Soc 132:46–47

Fu MS, Ni L, Du N (2014) J Alloys Compd 591:65–71

Acknowledgments

This work was supported by the National Natural Science Foundation of China (21475085, 21271125 and B010601) and the Innovation Scientists and Technicians Troop Construction Projects of Henan Province, Program for Innovative Research Team in Science and Technology in University of Henan Province (2012TRTSTHN018).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

About this article

Cite this article

Song, L., Yang, S., Wei, W. et al. Hierarchical SnO2 nanoflowers assembled by atomic thickness nanosheets as anode material for lithium ion battery. Sci. Bull. 60, 892–895 (2015). https://doi.org/10.1007/s11434-015-0767-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-015-0767-2