Abstract

Purpose

Laundry is a frequent household activity, performed either manually or by washing machine. This process consumes chemical products (such as laundry detergent and fabric softener), electricity, and water. It is therefore important to understand the environmental impacts and costs associated with laundry. The goal of this paper was to assess its eco-efficiency based on the NBR ISO 14045:2014 standard.

Methods

Primary data were collected from laundry detergent and fabric softener producers in Teresina, Piauí, Brazil. Secondary data were collected from patents, a chemical industry association, the government labeling program, and municipal water and electricity suppliers. The product system boundaries were cradle-to-consumer, and the impact categories were global warming, freshwater eutrophication, and land use. The product system value indicator was the washing costs from the consumer's perspective. The environmental and product system value indicators were related using the eco-efficiency formula which resulted in the process eco-efficiency profile. An uncertainty analysis was carried out to measure errors intrinsic to the data and the methods. A sensitivity analysis was carried out to identify the influence of choices made during the study and to propose viable technical improvements.

Results

The results showed that the most impactful processes in the three categories were electricity, wastewater treatment, and the chemical products (laundry detergent and fabric softener). In terms of product system value, the costs of water and sewage treatment had the highest contribution to the overall costs. It was not possible to identify the laundry eco-efficiency profile degree and to calculate the X factor, due to the lack of studies in this area. Greater uncertainties were found in the global warming category, due to its global scope, while freshwater eutrophication category has country-specific characterization factors. A new scenario was proposed to identify possible economically and environmentally feasible changes. However, it did not generate significant changes that would improve the eco-efficiency profile of the evaluated process.

Conclusions

This work highlights the eco-efficiency importance as an environmental management tool to support business decision-making and to identify the environmental impacts of domestic activities. By the results, washers and laundry products manufacturers know which areas they should invest in research and development to reduce their products' impacts. For future studies, it is recommended to evaluate the use of a detergent that does not require fabric softener, such as those sold by the brands Biozgreen, TerpenOil, and Yvy in the Brazilian market, and a high-efficiency washer.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Human activities have environmental implications that are in greater prominence nowadays. Everyday activities, such as laundry, dishwashing, and house cleaning, are of interest due to the resources consumed and their potential for environmental pollution. Consumer behavior, regarding domestic laundry, has been changing due to the use of automatic washing machines, the family composition (influenced by the number of children), and the greater environmental concern (as the need to save water and electricity and improve the chemical product selection) (Yamaguchi et al. 2022). In this context, eco-efficiency assessment plays a crucial role in evaluating products, processes, and services to consider its environmental and value aspects to support decision-making.

The environmental impacts related to the life cycle of laundry include the production of machines, fabrics, detergents, water, and electricity that include emissions to water, soil, and air. The use stage is highlighted, which is environmentally critical because of its constant consumption of resources over time (Yates and Evans 2016). Clothing care has environmental consequences such as water pollution, eutrophication, greenhouse gas emissions, and toxicity (Laitala et al. 2020).

Spreafico and Russo (2020) assessed the carbon footprint of household components through life cycle assessment (LCA). According to them, activities like laundry and dishes, household cleaning, personal hygiene, and cooking food are responsible, approximately, for more than 60% of global greenhouse gas emissions. It is also related to 50 to 80% of the total use of land, materials, and water. Thirty percent of the total emissions come from household appliances due to electricity consumption during their use phase. It can be even more polluting depending on its source (Laitala et al. 2011). This reinforces the need for investments to seek energy efficiency in appliances and the transition to clean energy sources.

Therefore, an eco-efficiency assessment study can support public policies on water and energy efficiency for household appliances, as well as cleaning products (Yates and Evans 2016). These involve eco- and energy-labeling schemes that inform consumers about the environmental and cost-related aspects underlying their purchasing choices. It can also generate a positive effect on the environmental and economic performance of washing machines and detergents (Laitala et al. 2020). This tool can even support subsidy and educational programs to encourage people to buy more efficient products. An example is the Chinese tax subsidy to encourage the purchase of highly efficient appliances (horizontal-axis washers) (Fan et al. 2019).

In Brazil, washing machines must be sold with labels informing their consumption of electricity and water, the washing and spinning efficiency, and the noise level. These are part of the Brazilian Labeling Program, coordinated by the National Institute of Metrology, Quality and Technology. This institute stimulates the industry competitiveness by the search of increasingly efficient products, like television, stove, oven, and refrigerator (Instituto Nacional de Metrologia, Qualidade e Tecnologia-INMETRO 2021). Thus, studies considering the environmental and value aspects of products have the potential to help industries seek improvements and support consumer decision-making.

According to the 2022 Continuous National Household Sample Survey, 70.2% of Brazilian households have a washing machine. This data indicates that a portion of the market still does not have access to this item. In the Northeast region and the state of Piauí, where this paper was done, only 41.1 and 33.9%, respectively, of households have this appliance (Instituto Brasileiro de Geografia e Estatística-IBGE 2022). Therefore, evaluating clothing washing can serve as a basis for government policies aligned with the triple bottom line.

This work goal was to assess the eco-efficiency of a clothing washing cycle. For this, the eco-efficiency assessment tool was used, in which the environmental profile was presented, based on the global warming, freshwater eutrophication, and land use categories. The product system value assessment was based on the washing costs for consumers. The most critical processes and life cycle stages have been identified. The studied process eco-efficiency profile is presented and discussed.

2 Methodology

This study was carried out based on the eco-efficiency standard, NBR ISO 14045:2014, which establishes its principles, requirements, guidelines, and the steps to assess it in a product or service. They are goal and scope definition, environmental assessment, product system value assessment, and eco-efficiency quantification and interpretation (Associação Brasileira de Normas Técnicas-ABNT 2014a). Furthermore, the LCA standards (NBR ISO 14040:2014 and NBR ISO 14044:2014) were used in the development of the environmental assessment. The life cycle inventory (LCI) was carried out through the collection of primary and secondary data which is described in Table 1.

Data on raw materials, production stages, distribution, and costs of laundry detergent and fabric softeners were collected through visits to three different producers in Teresina, Piauí, Brazil, during the first semester of 2022. For this, a checklist was used with direct observation. The checklist covered data on the company's profile (such as size, activities, number of employees, and market served), the production process (resources, emissions, production and transportation stages), and economic aspects (production costs per product and sales prices).

For raw materials whose specifications were not authorized to be seen by manufacturers, secondary data were collected from patents (Pambou 2019; Boettcher 2017; Freitas 2005; Rainatto 2018; Fernandes and Pereira 2014) based on its role in the formula of the detergent or softener. Each one of the referred patents is connected to its respective raw material. From the processes retrieved in the Ecoinvent database, only the preservative isothiazolinone was not available, so its modeling was carried out with the data available in the patent by Jin et al. (2013).

The visited manufacturers did not provide information about their suppliers. Therefore, to estimate the distance between the supplier's location and Teresina, the Brazilian Chemicals database was consulted on the website of the Brazilian Chemical Industry Association (Associação Brasileira da Indústria Química—ABIQUIM). Through the ABIQUIM website, the name, host city, and production plant location of each chemical product used in the manufacture of the laundry detergent and softener were identified. The distance between the suppliers' cities and Teresina was obtained from Google Maps and then a simple average was calculated. The LCI shows the total distance that raw materials are transported from their respective cities to Teresina.

Data on water and electricity consumption and emissions into the water during the washing stage were collected from documents available on the internet. According to Mordor Intelligence (2023), the washing machine from Panasonic is one of the best-selling in the Brazilian market, being the one chosen for this study. Its water and electricity consumption were obtained in its label from the Brazilian Labeling Program for the Panasonic 12-kg washing machine (model NA-F120B1WB—220 V) (INMETRO 2022). The chosen machine has the lowest water and electricity consumption per cycle among those with the same washing capacity.

After that, the environmental assessment was carried out using the OpenLCA software, version 1.11, and the Ecoinvent database, version 3.7.1. The data was modeled on the defined product system and the selected impact categories.

The laundry detergent and fabric softener selling price were collected during visits. They were corrected based on the Broad Consumer Price Index, available on the website of the Brazilian Institute of Geography and Statistic. This index measures the price variation of a basket of products and services consumed by the Brazilian population. This is a reference for the government's inflation targets and for the Central Bank of Brazil to decide changes in the interest rate (IBGE 2020).

The costs of water, electricity, and wastewater treatment were obtained from the municipal electricity (Equatorial Piauí)Footnote 1 and water/wastewater (Águas de Teresina)Footnote 2 concessionaires. The electricity cost for a residential consumer from 101 to 220 kWh is R$0.914762/kWh (Equatorial Energia 2023), while the cost of water and wastewater treatment (R$/m3) for a residential consumer, in the range from 11 to 25 m3, is R$7660/m3 (Águas de Teresina 2023). After this, the eco-efficiency was quantified using its formula that relates the environmental and value aspects. It is a division of the product system indicator by the indicators of the environmental impact categories.

An uncertainty analysis was performed in the interpretation stage, which is a procedure to understand how measurement uncertainties in the input data affect the reliability of the results. The Pedigree matrix and Monte Carlo simulation, available in the OpenLCA software, were used. The referred matrix is made of columns and rows with the topics of reliability, completeness, and temporal, geographic, and technological coverage with grades ranging from 1 to 5. This is a tool with solid application in LCA studies whose version used (also included in the Ecoinvent database) is in accordance with studies of Ciroth et al. (2016). This provided quantitative data, about the quality of inputs, to be used in the Monte Carlo simulation with a thousand interactions and a 95% confidence interval. Then, probability distribution was used to determine the uncertainty of the results, in accordance with the eco-efficiency standard (ABNT 2014a).

Furthermore, sensitivity analysis was performed to understand how changes in input data and methodological choices affect the evaluation results (ABNT 2014b). It assesses how the results of the study change when certain input parameters are varied and helps researchers understand how feasible the proposed changes are. To do this, the input data linked to hotspots were changed and the percentage difference for the impact category indicator was calculated between different scenarios.

3 Results

3.1 Goal and scope definition

This study aimed to evaluate the eco-efficiency profile of an automatic washing process for cotton clothes. The target audience are consumers and laundry product manufacturers, as well as the academic community interested in their environmental and economic assessment. Through the results, the washing process critical points were identified, and a new scenario was proposed to identify technically feasible improvements on its eco-efficiency profile.

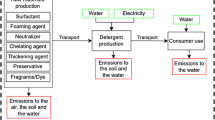

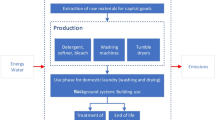

The product system is the process of washing and softening clothes, which is on a domestic scale, using an automatic washing machine without water heating. The system boundaries were from cradle to grave, encompassing the stages of raw material extraction and processing, transportation to Teresina, laundry detergent and softener production, distribution, use by the consumer (during washing), and end-of-life. It is highlighted that only the stage of raw material extraction and production, for laundry detergent and fabric softener production, takes place outside Teresina. Figure 1 shows the product system boundaries.

It is noteworthy that emissions in the detergent and softener production process were disregarded by the researchers. These emissions were to the soil and water in which most raw materials packaging (gallons, drums, and containers) are reused in other activities or resold and the small losses between production processes were considered irrelevant (and they evaporate). The soap and fabric softener packaging (plastic bottle) are purchased from a local supplier, being disregarded in this study as it requires data collection in companies completely different from the main area of this work. Primary data were collected for the process evaluated in this study (which is the clothes washing) and the production of laundry products, through visits to industries, as well as in-depth knowledge about these products in the standards of regulatory bodies, on labels, and in current literature. This supported the recovery of secondary data in the Ecoinvent database, patents, and official sources in the sector, as highlighted in the “Methodology” section (Table 1). The input and output boxes (green and gray) from the stages of raw material extraction, processing, and transportation to Teresina—Piauí (Brazil) and the detergent and softener distribution were retrieved in the Ecoinvent database and are detailed in the environmental assessment section.

The process of domestic washing of clothes represents the use stage of this study and has as inputs washing products (detergent and softener), water, and electricity. Water and electricity are obtained from the municipal supply system by consumers, while washing products are purchased in markets or supermarkets in Teresina. The outputs of this process are the end-of-life stage of the product system, in which the effluents (composed of diluted detergent, fabric softener, and dirt from clothes) are channeled to an effluent treatment plant. Another important output is clean and softened clothes.

Due to the importance that washing products have for the evaluated process, primary data on their production were collected, such as composition, production stages, transportation to the industry, and distribution. This supported the recovery of the raw material extraction and production in the Ecoinvent database, which brings an inventory of inputs and outputs, so that the modeling used in the study covers the steps prior to the washing stage and presents complete results. This ensures that impacts associated with the extraction and production of raw materials, such as a petrochemical surfactant (sulfonic acid) or electricity applied in manufacturing, are included in the impact categories indicator.

Emissions to water, soil, and air related to the extraction and production of raw materials that make up washing products involve a wide variety of substances. These come from renewable sources, such as sea water, to obtain the sodium chloride used in the production of sodium hydroxide present in the detergent, and coconut oil, used in coconut diethanolamide, and from non-renewable sources such as petroleum and the natural gas present in sulfuric acid, sodium lauryl sulfate, and isothiazolinone.

The process function is to make clothes clean and tidy for use, which involves removing dirt (particles of grease, dust, and dirt) and bad odor. The functional unit is one cycle of automatic washing for 12 kg of white or colored cotton clothes, from a domestic perspective. The reference flow set for liquid laundry detergent is 100 mL and for fabric softener it is 80 mL, based on the manufacturer's usage guidelines.

The global warming category was selected because climate change is a topic of relevant interest for current discussions in the environmental area and is linked to Sustainable Development Goal (SDG) 13 (Action against global climate change). The freshwater eutrophication and land use categories were selected due to its importance for the Brazilian context, as recommended by the Life Cycle Impact Assessment Research Network (Ugaya et al. 2019), and its importance to SDG 14 (Life below water) and SDG 15 (Life on land). The selected assessment method was ReCiPe 2016 Midpoint (H). It has global coverage in most impact categories with characterization factors for Brazil (making the results more reliable) (Mendes et al. 2015) and is widely used in LCA studies. For example, the LCA studies applied to cleaning products and its raw materials done by Akizu-Gardoki et al. (2022), Kapur et al. (2012), and Shah et al. (2016) used the ReCiPe method.

The product system assessment method was monetary, being expressed by the costs, in Brazilian Real, paid by consumers. The eco-efficiency indicator was presented, being obtained by the eco-efficiency formula, available in NBR ISO 14045:2014, in which the environmental and value indicators of the product system are listed. The data was analyzed for uncertainty and, finally, scenarios with viable improvements were proposed, through sensibility analysis.

3.2 Environmental assessment

To develop the environmental assessment, the washing process inputs and outputs, according to the defined functional unit, were collected. Table 2 presents the data collected with its equivalent process retrieved from the Ecoinvent database, which were used in the modeling. For laundry detergent and fabric softener, the quantities refer to their respective reference flows.

For the inputs used in the laundry detergent and fabric softener production, the process recovered in Ecoinvent covered the raw material extraction, their transportation to the production plant, and their manufacture. In the case of water, its process included the stages of extracting this resource from the environment, treatment in a conventional treatment plant, and distribution to the place of use (covering the distribution network and water losses during transmission). This water process did not consider energy consumption during distribution and emissions to groundwater associated with distribution losses. The electrical energy process covered its production, transmission, and distribution to the place of use (Ecoinvent 2022).

The process recovered in Ecoinvent for the raw material transport included the construction, operation, maintenance, and end-of-life of vehicles and road infrastructures; fuel consumption; and emissions into air, water, and soil. The distribution process considered the production, maintenance, and operation of the vehicle; road construction; energy consumed; direct and indirect air emissions; water emissions; and fuel consumption. Wastewater treatment (from the user stage) included its treatment in a conventional sewage treatment plant and activities upstream to this process, as well as infrastructure materials, transportation, environmental burden from land use, and end-of-life dismantling (Ecoinvent 2022).

Laundry soap is a detergent for treating fabrics and clothes, ensuring cleanliness and providing well-being to the user. Its composition must have alkaline hydrogenionic potential (Hp), to guarantee the ability to remove dirt from clothes, with a greater amount of alkalizing agent than dish detergents (Agência Nacional de Vigilância Sanitária-ANVISA 2022a). In the last stage of washing, fabric softener is used, whether washed manually or in washing machines. Its use aims to make fabrics softer, realigning its fibers and prolonging the perfume. In both, the use of ethylenediamine tetraacetic acid (EDTA) is necessary due to the water hardness (well water) that is used in its production, as reported by the visited manufacturer.

According to the data collected, the laundry detergent and the softener production occurs manually in the researched context, whose electricity consumption at this stage refers only to the weighing of the raw materials. Brazilian companies producing cleaning products must check the current legislation regarding products controlled by the Brazilian Army and the Federal Police. The use of controlled products as raw materials in the production process requires an authorization from the respective body. For the army (Federal Decree No. 3665/2000), items with destructive power and that threaten the country's social and military security are restricted for use by legally qualified individuals and legal entities (Brasil 2000). For the Federal Police (Ordinance no. 240/2019), control focuses on those capable of being used in the preparation of drugs (Brasil 2019a).

Among the raw materials used in the detergent and softener production in the visited manufacturers, only triethanolamine is on the army list as a precursor to chemical warfare agents, permitted for use in accordance with Federal Decree No. 10030 of September 30, 2019 (Brazil 2019b). Its use in detergent production is in small quantities, and the company is exempt from registration. Thus, it needs to communicate to the nearest army command (Fortaleza, Ceará) that will keep this product in stock and where it is being used (Brasil 2000). No products controlled by the Federal Police, according to Ordinance No. 240, of March 12, 2019, are used by the visited companies.

Based on the data in Table 2, the environmental profile of the assessed process is presented for the three selected impact categories, as shown in Table 3.

The global warming category represents the potential for climate change, resulting from the rise in the planet's temperature linked to carbon emissions. This is calculated based on the Intergovernmental Panel on Climate Change 2013 Report and represents a 100-year perspective. Freshwater eutrophication encompasses impacts related to nutrients discharges (phosphorus) into freshwater bodies, which can be strongly affected by the production and use of laundry products. The land use category considers the amount of land transformed or occupied for a given time, as well as the relative species loss and soil transformation (Pré Sustainability 2020). In Fig. 2, the percentages of contribution by processes for each selected category are presented.

In relation to the global warming category, processes related to electricity (28.96%), laundry detergent (26.85%), water (13.26%), and fabric softener (13.00%) are responsible for more than 80% of all impacts of the laundry process considered in this study. They are linked to the emission of fossil carbon dioxide, methane, carbon dioxide, nitrogen monoxide, and hexafluoric sulfur. For example, they occur during the burning of fossil fuels used in the electricity generation or surfactant production, according to data obtained from modeling in Ecoinvent.

In the study by Joner et al. (2016), the carbon footprint of a pair of women's jeans was evaluated covering the stages from cradle to grave (raw material acquisition, production, distribution, use, and end-of-life) for 1 year. The use stage, which includes laundry with an automatic washer, was the one that had the greatest contribution to the global warming category. Despite the differences between the functional units, this result is like that found in this study. In it, the processes with the greatest contribution to global warming are associated with the use stage (electricity, laundry detergent, water, and fabric softener).

In a LCA of Japanese automatic washers (with different types: conventional, with heating and pulsation), the use stage was the most impactful in relation to equivalent CO2 emissions. Its impacts were greater than the emissions from the washing machine production. This was linked to the consumption of detergent, electricity, and water during use, which were also the most impactful processes in the current research (Yamaguchi et al. 2011).

The current and other research (Joner et al. 2016; Yamaguchi et al. 2011) highlight the use stage as a major environmental hotspot in the global warming category, even compared to the entire life cycle of clothing production. It is important to consider that this finding is interesting when considering that some raw materials are from petrochemical sources and are transported over long distances to Teresina. It also emphasizes the importance of focusing on practices that can reduce energy and resource consumption during laundry to minimize its environmental impacts.

Regarding freshwater eutrophication, the most representative processes are wastewater treatment (50.12%), laundry detergent production (17.25%), and electricity (13.40%). Together, these processes are responsible for more than 80% of all impacts in that category for the defined product system. The main cause is the emission of phosphorus (P) into surface and underground waters. It is highlighted that the surfactant production requires P that is used in the detergent production. Then, the wastewater from the laundry is rich in P that, despite the wastewater treatment, has some dissolved nutrients that reach water bodies. They are permitted by the Brazilian Resolution of the National Council for the Environment (Conselho Nacional de Meio Ambiente—CONAMA) nº 430/11.

Meira et al. (2018) evaluated a laundry cycle using the eco-efficiency tool. Its functional unit was laundry in a residence with 4 people (8 kg) in a 9-kg machine. The authors identified that among the ten categories used in their study, with the normalized results, freshwater eutrophication and global warming were the most impactful. The contribution analysis of the referred categories indicated that their impacts mainly corresponded to wastewater treatment (92 and 84%, respectively). In the current study, only wastewater treatment has just over 50% contribution to the impacts of the entire laundry life cycle, according to the definitions made in the goal and scope. It reinforces the importance of sanitation to both improve the quality of life and to contribute to the SDGs’ achievement.

The laundry detergent (59.84%) and fabric softener (29.96%) production were responsible for 89% of the laundry impacts in the land use category, for the defined product system. The land occupation and transformation for plantations and pasture are the causes linked to the impacts of this category, which can involve deforestation, fires, agrarian conflicts, and attacks on indigenous and traditional communities. This becomes even more important in the Brazilian context, which has a large area of threatened forests, such as the Amazon and Atlantic Rainforests. The raw materials used in laundry products are linked to the land use impacts. For example, the glycerin used in the softener comes from the esterification of soybean oil, which requires large areas for soybean plantations. Soybean is one of the main exportation products from the state of Piauí (ComexStat 2024) which has environmental, economic, and social repercussions on what is exported in this product (labor, land, water, etc.).

3.3 Product system value assessment

The product system value represents the value or desirability attributed to the product by different stakeholders. The value indicator can be expressed in terms of functional and monetary, among others (ABNT 2014a). In this study, the laundry process costs to the consumer were selected as the product system value, due to its importance to the stakeholder most affected by variations in costs. Table 4 presents the costs, according to the defined functional unit.

For laundry detergent and fabric softener, the average selling price for the consumer was considered for the first half of 2023. As a result, production costs, raw material transportation to Teresina, and distribution to the store are considered in the sales price. Transport costs between the store and the consumer's home were not considered in this study. The prices for water, electricity, and effluent treatment are those charged by concessionaires in the first half of 2023. The highest costs for laundry are related to water and wastewater treatment, while fabric softener has the lowest cost among all inputs.

3.4 Ecoefficiency quantification

At this stage, the environmental assessment results are related to the product system value assessment results. The result is the eco-efficiency profile of the laundry process. The NBR standard suggests dividing the product system value indicator by the environmental indicator for each impact category assessed (ABNT 2014a). The results are presented in Table 5.

The results represent the assessed process eco-efficiency performance. They can be used as a reference point for evaluating different measures suggested for improvement or for comparison with findings from other papers (depending on their approach) (ABNT 2014a). It is noteworthy that the product system value indicator is directly proportional to the eco-efficiency indicator, while the environmental indicator is inversely proportional. This means that the higher the eco-efficiency profile, the lower the environmental impacts. As no other works were identified that use this tool in laundry, there was no reference indicator that would make it possible to indicate whether the eco-efficiency was high or low and to calculate the X factor. It is noteworthy that the consumption of fabric softener had an important result in environmental assessment, while its impact on the product system value was the lowest.

3.5 Interpretation

Initially, the uncertainty analysis was carried out. For this, the input data was evaluated using the Pedigree matrix. The detergent and softener evaluation with the Pedigree matrix considered that some data were obtained from patents. It reflected in the reliability and the temporal correlation grades. In turn, data on water and electricity (consumed by the washer) reflected in reliability and completeness grades, while transport data affected the reliability and geographic correlation grades. Table 6 presents the uncertainty analysis results.

The greatest uncertainty was in the global warming category, with the highest mean and standard deviation values, as it does not have characterization factors at a global, regional, or Brazilian level. Therefore, in calculating this category, data from Europe are used, which bring greater uncertainties when applied to Brazil (Huijbregts et al. 2017). This justifies the fact that this category was not recommended for Brazilian studies by Ugaya et al. (2019). Nevertheless, we considered it in this research due to its relevance at a global level.

The freshwater eutrophication category has country-specific characterization factors, which explains its lowest uncertainty among all the categories. The land use category has characterization factors at a global level, in which it got an intermediate uncertainty between the values for a global and a national one (Huijbregts et al. 2017).

Next, sensitivity analysis was performed. For this, new scenarios were created, considering the most critical processes for the life cycle of laundry (from an environmental point of view). Thus, scenario 1 is the standard (developed throughout this work), while scenario 2 encompasses changes in electricity consumption and chemical products (laundry detergent and fabric softener). Changes were not considered from a cost perspective due to lack of access to data on the production costs from the visited companies.

In scenario 2, in the use stage, the electricity consumption per cycle by the washer was reduced to 0.31 kWh. This is the consumption of the washer "Colormaq lca 12," available on the Brazilian market. This data was obtained in its label from the Brazilian Labeling Program and represents the advancement of industries in the search for products that have lower environmental impacts. The electricity consumption of washing machines is affected by the frequency they are used, the washing program chosen and the clothes load. It is noteworthy that although this machine has lower electricity consumption (compared to the one from the standard scenario), its water consumption was much higher (above 50%) (INMETRO 2022). Reductions in water consumed were not considered, as no other washer brand had lower consumption than Panasonic.

Another aspect considered in scenario 2 was in the laundry detergent and fabric softener composition at the production stage. In the detergent, the petrochemical surfactants were replaced by one of natural origin. Thus, the linear, petrochemical alkylbenzene sulfonate was replaced by esterquat (from coconut and palm kernel oil) and the fatty alcohol sulfate from petrochemical origin was changed by a natural one (palm kernel oil). In the softener, esterquat was replaced by fatty alcohol sulfate (natural).

Furthermore, in scenario 2, the water used in the production of both chemicals came from the municipal water supply system. This eliminates the need to include EDTA in the detergent and softener composition, as water hardness corrections are already carried out in the treatment plant itself. In the softener, the preservative isothiazolinone was replaced by diazolidinyl urea, selected after consulting the list of preservatives permitted by the National Health Surveillance Agency and has an equivalent process available in the Ecoinvent (Urea) database. This product has national suppliers and the amount of urea considered in the composition was 0.5%, which is the maximum concentration allowed by the regulatory body (ANVISA 2022b).

Petrochemical surfactants are linked to environmental impacts due to the use of non-renewable resources. Those used in the products in this study were replaced by one of plant origin, from palm kernel oil, as done by Akizu-Gardoki et al. (2022) and Kapur et al. (2012) in their work evaluating cleaning products. Biosurfactants are recognized as the next generation of industrial surfactants, as they have low toxicity, high biodegradability, and meet the low environmental impact requirements for industrial-scale production (Farias et al. 2021). Replacing environmentally harmful chemicals with bio-based ingredients (with good biodegradability) can bring important improvements to the detergents' and softeners' life cycle. Furthermore, adopting a concentrated format reduces transportation, packaging, chemicals, water, and storage needs, resulting in environmental benefits (Laitala et al. 2011).

It is noteworthy that, despite the significant contribution to the environmental impacts, changes in water consumption and emissions into the water were not considered. It was due to the lack of parameters to indicate technically viable changes that maintain the same performance from scenario 1 (standard). Table 7 presents the sensitivity analysis results.

According to the NBR ISO 14044:2014 standard, the sensitivity analysis results are considered significant when they are above 10%. Significant results are those in which the proposed changes have the capacity to generate an important impact reduction (ABNT 2014b). In this study, scenario 2 results did not obtain a reduction potential considered significant, so that the proposed modifications generate a low reduction in environmental impacts.

4 Discussion

The laundry process is carried out daily in several homes around the world, occurs very frequently in different locations at the same time, and generates considerable environmental repercussions. This involves laundry chemical consumption as well as an important natural resource (water). Therefore, measuring its environmental impacts is important to identify how individual decision-making affects the environment and to contribute to achieving the SDGs.

Laundry generates well-being for users and guarantees a healthy life; however, the chemicals used are linked to worrying environmental impacts. Their compositions have associated risks, such as harmful toxicity for fish, algae, and other small invertebrates, damage to ecological balance linked to life in the water, and causing skin diseases in users (Nair et al. 2019). It reinforces the importance of evaluating products, establishing environmental criteria, and investing in changes that mitigate negative impacts. Consumers have a crucial role to play in knowing the products they consume, demanding transparency from manufacturers and giving preference to laundry products that respect environmental and social issues.

Petrochemical products, such as alkylbenzene sulfonate from the detergent and ethoxylated alcohol (AE > 20) from the softener, indicate the industries' dependence on petroleum derivatives. This occurs despite the frequent discussions of global warming, emission reduction targets, and water pollution, evaluated in one of the categories selected in this study. The switch to plant-based products (obtained from palm kernel or coconut oil, for example) is normally carried out by large cleaning products players in Brazil (for example, Ypê 2022; Unilever 2023), as they can do this without a significant increase in costs.

Although plant-based raw materials are preferred, for reasons of environmental sustainability, better or worse environmental performance will depend on each local context. It will be influenced by the complexity of its supply chain and the trade-offs from both plantations and oil. In the case of Brazil, its production may be linked to environmental impacts in the deforestation and indigenous conflicts, for the implementation of exploitative monocultures, as assessed in the land use category. Furthermore, the Brazilian natural surfactants' supply chain is still unable to fully serve the national market, making the country dependent on the foreign market (Shah et al. 2016). Therefore, companies need to evaluate their supply chains to ensure that the global impact of their products will be really reduced and also not transferred between life cycle stages. This decision must consider the industries' commitment to achieving SDG 12 (Sustainable consumption and production) but must not disregard the relationship this has with SDG 15 (Life on Earth) in other stages of the products' life cycle.

In the corporate environmental area, decisions always involve considering aspects related to change decisions, such as costs and impacts on people. With this, it is important to balance between achieving SDG 12 (Sustainable consumption and production) and ensuring it does not adversely affect SDG 15 (Life on Earth). Decision makers must have a systemic and comprehensive view of the evaluated context to ensure that internally positive results are achieved.

As an optional step in the laundry process, the use of fabric softeners comes with an ambivalence. While it aims to reduce the need for ironing (and saving electricity), it has negative environmental impacts (Scalon 2021). The softeners' active principle are quaternary ammonium salts (esterquat), which the excessive alkyl chain length can generate hydrophobic structures leading to strong aggregation between the polymers and promoting the fabric fiber's alignment. However, such salts have high toxicity and low solubility in water (Sütterlin et al. 2008). Therefore, quaternaries can have a detrimental effect on the biological treatment of effluents in sewage treatment plants, affecting the absorption of ammonium in nitrifying bacteria (Druvari et al. 2021).

Even with the wastewater treatment, this process had important contribution to the freshwater eutrophication category. This becomes a problem in cities with low sewage coverage, such as Teresina, whose total sewage service rate is only 41.06% in 2022 (Sistema Nacional de Informações sobre Saneamento-SNIS 2023). As a result, most domestic effluents are released into water bodies without minimal treatment, generating environmental problems even greater than those described in this work. By failing to comply with current legislation from the National Environmental Council no. 430/2011, changes in river conditions, such as Hp, temperature, and chemical and biochemical oxygen demand, are not avoided.

Dumping untreated effluents into water bodies alters the natural composition of the aquatic ecosystem, affecting fauna and flora, making water consumption useless for other purposes and the spread of human diseases. In the case of washing clothes, the effluent is rich in nitrogen and phosphorus from the use of detergent and fabric softener. This directly affects the reproduction of algae, the river oxygenation, and the fish survival. In the local context, one of the rivers that cross Teresina (Poti River) faces eutrophication in the non-rainy season due to the greater concentration of organic substances. In 2020, the legal framework for basic sanitation was approved (Law No. 14026/2020) which establishes new goals and strategies to universalize sanitary sewage, with the definition of deadlines for the environmentally adequate final disposal of waste being a key point.

According to Hustvedt et al. (2013), top-loading standard (vertical-axis model) washers (as used in this study) have higher water and electricity consumption. One solution would be to use front-loading horizontal axis (h-axis) washers, which have been shown to consume 38% less water and 58% less electricity. In h-axis washers, it is not necessary to cover clothes with water, which reduces water and electricity consumption. Its high acquisition cost is a barrier to a broader adoption by the public (Fan et al. 2019).

With this, exploring government incentives, tax reduction for raw materials, or h-axis machine leasing could incentivize more sustainable choices. In addition, promoting the long-term cost savings through reduced water and electricity bills could justify the machine’s higher purchase investment by consumers. Fostering education and awareness campaigns can help consumers understand the environmental benefits of h-axis machines, potentially leading to a shift in preferences over time. It could encourage a transition toward more sustainable laundry practices.

The biggest costs for the consumer, in the context of this research, are with water and wastewater treatment. It should encourage users to save water (and generate less wastewater) as well as take into consideration water consumption in the purchasing decision. It is also noteworthy that in the region of this research the climate is tropical with high temperatures all over the year, which eliminates the use of hot water for the washing and the drying stage. This means lower electricity and water consumption, while reducing environmental impacts, as identified in studies by Yamaguchi et al. (2022) and Spreafico and Russo (2020).

Although the Brazilian electrical matrix comes, for the most part, from renewable sources, the impacts of electricity in laundry, obtained in Ecoinvent, raise the importance of developing products with lower consumption and the search for cleaner energy sources. This is aligned with SDG 12, which involves the relationship between producers and consumers, and SDG 7 (Clean and affordable energy), which consumers must consider when seeking to produce their own electricity.

Some user actions can influence the laundry environmental impacts in a long term, such as following the washer, detergent, and the softener manufacturer's recommendations, using the machine only with its maximum load (aiming to reduce the number of washes, which regardless of the water level will have the same electricity consumption per cycle), prefer detergents with plant-based surfactants (with a certified production chain), use cold water (in washers that use heated water or steam dryers), and wash clothes only when they are really dirty.

5 Conclusion

Assessing the laundry eco-efficiency is fundamental in the search for greater environmental sustainability in household activities. For this, the environmental and value (economic) perspectives were considered when evaluating the laundry process. The results indicate that the laundry eco-efficiency profile is strongly affected by the environmental hotspots. These include the processes of the electricity consumed by the washer, the wastewater treatment and the use of detergent and softener, in the categories of global warming, freshwater eutrophication, and land use. In the product system value, the water, wastewater treatment, and electricity were the most representative in the laundry life cycle. This sheds light on important aspects regarding the environmental impacts and the costs paid by consumers, so that manufacturer investment in this area is crucial.

The laundry eco-efficiency performance was presented and can be used by consumers, manufacturers, and government as a reference indicator for future studies and the development of corporate sustainability strategies. A new scenario was proposed in the sensitivity analysis, but it considered only the environmental indicator. It was due to the lack of access to product's production costs and sales price's composition from the studied companies. Moreover, the reduction potential was not significant. This indicates that other aspects that make up laundry should be investigated. Further research is a way to seek to reduce these process impacts and it is already stimulated by the Brazilian Labeling Program for washing machines.

In alignment with the Sustainable Development Goals (SDGs), public policies play a crucial role in addressing the environmental challenges associated with household laundry practices. By integrating eco-efficiency assessments and promoting energy and water efficiency in household appliances through labeling schemes and subsidies, governments can incentivize consumers to make sustainable choices. Initiatives aimed at reducing greenhouse gas emissions, promoting clean energy sources, and encouraging the use of environmentally friendly products can contribute to achieving SDG 12 (Sustainable consumption and production) and SDG 7 (Clean and affordable energy).

The main limitation of this work was the lack of access to the production costs, so that changes in composition were evaluated only from an environmental perspective. For future studies, it is recommended to assess the eco-efficiency by incorporating washing with an h-axis washer and using a detergent that does not require the use of fabric softeners, such as those sold by the brands Biozgreen, TerpenOil, and Yvy in the Brazilian market. Besides that, it is important to map and include the raw material production processes from Brazil in the Ecoinvent database and in the Brazilian National Bank of Life Cycle Inventories as a way to improve the assessment accuracy.

Data availability

All data supporting the findings of this study are available within the paper.

Notes

Website: https://pi.equatorialenergia.com.br/

Website: https://www.aguasdeteresina.com.br/

Abbreviations

- •:

-

Cetostearyl alcohol is a mixture of fatty alcohols (cetyl and stearyl alcohols).

- •:

-

Coconut diethanolamide/cocamide diethanolamine is a clear, amber-colored, viscous liquid obtained by reacting the mixture of fatty acids from coconut oils with diethanolamine.

- •:

-

Esterquat is a cationic surfactant compound and are a class of surface-active quaternary ammonium compounds characterized by the fact that the hydrophobic parts of the moieties "R" are linked to the charged head group via ester bonds (R–C(O)–O– or ROC(O)–), with an anionic counterion (x−).

- •:

-

Diazolidinyl urea is a heterocyclic-substituted urea that functions as a preservative preventing spoilage by inhibiting the growth of bacteria and other microorganisms.

- •:

-

Double-distilled glycerin is a co-product of the biodiesel industry and is colorless, odorless, viscous, and has a sweet-tasting liquid appearance.

- •:

-

Ethylenediamine tetraacetic acid (EDTA) is a synthetic organic compound with the ability to bind to metal ions and form stable complexes and is widely used for its chelating properties.

- •:

-

Front-loading horizontal axis (h-axis) washers have a round door on the front through which you add clothes. They use an impeller to rotate the load and tumble it during washing.

- •:

-

Isothiazolinone is an organic compound with the formula (CH)₂SN(H)CO, structurally related to isothiazole and widely used as preservative/antimicrobial.

- •:

-

Monte Carlo simulation is a type of computational algorithm that uses repeated random sampling to estimate the likelihood of a range of results occurring.

- •:

-

Pedigree matrix is a method used to characterize data quality aspects and quantify the quality rating. It plays a crucial role in ensuring the robustness of scientific results by assessing the quality of data used for decision-making processes.

- •:

-

Polyacrylic acid stearate is a high molecular weight polymer composed of many small repeating units or monomers of acrylic acid. Its chemical formula is C₃H₄O₂, which gives the entire polymer a structure laden with carboxylic functional groups (–COOH).

- •:

-

Silicone emulsion is a chemical formulation composed of silicone (oil), water, and emulsifying systems (to achieve a stable emulsion).

- •:

-

Sodium hydroxide is a corrosive inorganic compound with the formula NaOH. It is a white, translucent crystalline solid that readily absorbs moisture until it dissolves.

- •:

-

Sodium lauryl sulfate is a surfactant derived from petrochemical, coconut, and/or palm kernel oil sources. It consists of a mixture of sodium alkyl sulfates. Its hydrocarbon tail combined with a polar "headgroup" gives it amphiphilic properties.

- •:

-

Sulfonic acid is an organosulfur compound with the general formula R–S(=O)₂–OH, where R represents an organic alkyl or aryl group, and the S(=O)₂(OH) group is a sulfonyl hydroxide.

- •:

-

Top-loading standard (vertical-axis model) washers have a door on the top of the machine, allowing you to load clothes from above.

- •:

-

Triethanolamine is a clear, colorless, thick liquid, made by the reaction between ethylene oxide and ammonia.

References

Agência Nacional de Vigilância Sanitária (ANVISA) (2022a) Resolução da Diretoria Colegiada no 694, de 13 de Maio de 2022. ANVISA, Brasília, DF. http://antigo.anvisa.gov.br/documents/10181/6437847/RDC_694_2022_.pdf/dfd68a5a-1521-4bd4-b715-d9b8b7629728

Agência Nacional de Vigilância Sanitária (ANVISA) (2022b) Instrução Normativa no 153, de 13 de Maio de 2022. ANVISA, Brasília, DF. http://antigo.anvisa.gov.br/documents/10181/5993368/IN_153_2022_.pdf/5be6f38d-a1fb-46cd-b2fc-26e4312d1f1c

Águas de Teresina (2023) Legislação e Tarifas. https://www.aguasdeteresina.com.br/legislacao-e-tarifas/

Akizu-Gardoki O, Otazu RLLD, Ulibarri B, Iturrondobeitia M, Minguez R, Lizundiaad E (2022) Ecodesign coupled with Life Cycle Assessment to reduce the environmental impacts of an industrial enzymatic cleaner. Sustain Prod Consum 29:718–729. https://doi.org/10.1016/j.spc.2021.11.016

Associação Brasileira de Normas Técnicas (ABNT) (2014a) NBR ISO 14045: Gestão ambiental – Avaliação da ecoeficiência de sistemas de produto – Princípios, requisitos e orientações. ABNT, Rio de Janeiro

Associação Brasileira de Normas Técnicas (ABNT) (2014b) NBR ISO 14044: Gestão ambiental - Avaliação do ciclo de vida - Requisitos e orientações. ABNT, Rio de Janeiro

Boettcher RA (2017) Composição detergente na forma de uma folha. Depositor: Solubag SPA. BR no 112019004454-0 A2. Deposit date: 5 Sep 2017

Brasil (2000) Decreto Federal no 3.665, de 20 de Novembro de 2000. Dá nova redação ao Regulamento para a Fiscalização de Produtos Controlados (R-105). Presidência da República, Brasília. https://www.matheusdefine.com.br/leis/DECRETO%203.665%20R-105%20-%20Exercito%20Brasileiro%20-%20Produtos%20Controlados.pdf

Brasil (2019a) Ministério da Justiça e Segurança Pública. Portaria no 240, de 12 de Março de 2019. Estabelece procedimentos para o controle e a fiscalização de produtos químicos e define os produtos químicos sujeitos a controle pela Polícia Federal. Ministério da Justiça e Segurança Pública, Brasília, DF. https://www.in.gov.br/materia/-/asset_publisher/Kujrw0TZC2Mb/content/id/66952742/do1-2019-03-14-portaria-n-240-de-12-de-marco-de-2019-66952457

Brasil (2019b) Decreto Federal no 10.030, de 30 de Setembro de 2019. Aprova o Regulamento de Produtos Controlados. Presidência da República, Brasília, DF. http://www.planalto.gov.br/ccivil_03/_ato2019-2022/2019/decreto/D10030.htm

Ciroth A, Muller S, Weidema B et al (2016) Empirically based uncertainty factors for the pedigree matrix in Ecoinvent. Int J Life Cycle Assess 21:1338–1348. https://doi.org/10.1007/s11367-013-0670-5

ComexStat (2024) Comex Vis: Piauí: Exportações, Importações e Balança Comercial. http://comexstat.mdic.gov.br/pt/comex-vis

Druvari D, Antonopoulou A, Lainioti GC, Vlamis-Gardikas A, Bokias G, Kallitsis JK (2021) Preparation of antimicrobial coatings from cross-linked copolymers containing quaternary dodecyl-ammonium compounds. Int J Mol Sci 22(24):13236. https://doi.org/10.3390/ijms222413236

Ecoinvent (2022) Ecoinvent version 3.7.1. Available in the Ecoinvent software

Equatorial Energia (2023) Valor de tarifas e serviços. https://pi.equatorialenergia.com.br/informacoes-gerais/valor-de-tarifas-e-servicos/

Fan L, Tong Y, Niu H (2019) Promoting consumer adoption of water-efficient washing machines in China: barriers and countermeasures. J Clean Prod 209:1044–1051. https://doi.org/10.1016/j.jclepro.2018.10.325

Farias CBB, Almeida FCG, Silva IA, Souza TC, Meira HM et al (2021) Production of green surfactants: market prospects. Electron J Biotechnol 51:28–39. https://doi.org/10.1016/j.ejbt.2021.02.002

Fernandes A, Pereira D (2014) Amaciante de roupas repelente de insetos. Holders: Angiomar Fernandes; Dagoberto Pereira. Legal representative: Anel Marcas E. Patentes Eireli. BR no 102014017620-9 A2. Deposit date: 27 Jul 2014

Freitas JT (2005) Processo para fabricação de concentrado em pasta para preparação de amaciante de roupas glicerinado. Depositor: José Tarcísio de Freitas. Legal representative: Ana Lúcia Ribeiro Nascimento. Pl 0514320-9 A. Deposit date: 31 Jan 2005

Huijbregts MAJ, Steinmann ZJN, Elshout PMF et al (2017) ReCiPe2016: a harmonized life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138–147. https://doi.org/10.1007/s11367-016-1246-y

Hustvedt G, Ahn M, Emmel J (2013) The adoption of sustainable laundry technologies by US consumers. Int J Consum Stud 37(3):291–298. https://doi.org/10.1111/ijcs.12007

Instituto Brasileiro de Geografia e Estatística (IBGE) (2020) IPCA - Índice Nacional de Preços ao Consumidor Amplo: Calculadora do IPCA. Rio de Janeiro, IBGE. https://www.ibge.gov.br/estatisticas/economicas/precos-e-custos/9256-indice-nacional-de-precos-ao-consumidor-amplo.html?=&t=calculadora-do-ipca

Instituto Brasileiro de Geografia e Estatística (IBGE) (2022) Pesquisa Nacional por Amostra de Domicílios Contínua: Domicílios e Moradores, por posse de bens. Rio de Janeiro, IBGE. https://sidra.ibge.gov.br/tabela/6677#resultado

Instituto Nacional de Metrologia, Qualidade e Tecnologia (INMETRO) (2021) Conheça o Programa Brasileiro de Etiquetagem - PBE. https://www.gov.br/inmetro/pt-br/assuntos/avaliacao-da-conformidade/programa-brasileiro-de-etiquetagem/conheca-o-programa

Instituto Nacional de Metrologia, Qualidade e Tecnologia (INMETRO) (2022) Programa Brasileiro de Etiquetagem. Eficiência Energética - lavadoras de roupa automáticas com abertura superior (Top Load). http://www.inmetro.gov.br/consumidor/pbe/lavadorasTopLoad.pdf

Jin Y, Li K, Lu X, Zhang X, Wang Y, Zhou S, Li C (2013) Process for continuously producing 3-isothiazolinone derivatives and intermediate products thereof. Depositante: Beijing Tianqing Chemicals Co., Ltd. U.S. Patent n. 8,507,691. Deposit date: 13 Aug 2013

Joner S, Morél IS, Malfatti VM, Dinato RM (2016) Pegada de carbono de uma calça jeans produzida no Brasil e a influência dos cenários da etapa de uso. V Congresso Brasileiro em Gestão do Ciclo de Vida. Anais. Fortaleza. https://redeacv.org.br/files/294bd4e7573e665becdb9ac9c9b9767c.pdf

Kapur A, Baldwin C, Swanson M, Wilberforce N, McClenachan G, Rentschler M (2012) Comparative life cycle assessment of conventional and green seal-compliant industrial and institutional cleaning products. Int J Life Cycle Assess 17(4):377–387. https://doi.org/10.1007/s11367-011-0373-8

Laitala K, Boks C, Klepp IG (2011) Potential for environmental improvements in laundering. Int J Consum Stud 35(2):254–264. https://doi.org/10.1111/j.1470-6431.2010.00968.x

Laitala K, Klepp IG, Kettlewell R, Wiedemann S (2020) Laundry care regimes: do the practices of keeping clothes clean have different environmental impacts based on the fibre content? Sustainability 12(18):7537. https://doi.org/10.3390/su12187537

Meira MM, Domingos A, Zanardi L (2018) Benefícios ambientais e econômicos da adição de Sokalan HP 56 aos detergentes destinados à lavagem de roupas por meio de uma análise de ecoeficiência. Anais do VI Congresso Brasileiro sobre Gestão do Ciclo de Vida. p 13. https://acv.ibict.br/wp-content/uploads/2018/09/Anais_GCV2018.pdf

Mendes NC, Bueno C, Ometto AR (2015) Avaliação de Impacto do Ciclo de Vida: revisão dos principais métodos. Production 26:160–175. https://doi.org/10.1590/0103-6513.153213

Mordor Intelligence (2023) Mercado de máquinas de lavar domésticas - crescimento, tendências, impacto do Covid-19 e previsões (2023–2028). https://www.mordorintelligence.com/pt/industry-reports/residential-washing-machines-market

Nair G, Jadeja Y, Donga M, Vaghasiya D, Vora V (2019) Production of ecofriendly fabric softener. Int J Appl Eng 14(1):8–15. https://www.ripublication.com/ijaerspl2019/ijaerv14n1spl_02.pdf

Pambou E (2019) Composição de detergente. Depositor: Lonza, LLC. BR no 112021001014-9 A2. Deposit date: 19 Jul 2019

Panasonic (2022) Instruções de Operação e Instalação Lavadora de Roupas (Uso doméstico). https://panasonic-br.zendesk.com/hc/pt-br/article_attachments/17162338023060

Pré Sustainability (2020) SimaPro database manual methods library. SimaPro: Utrecht, The Netherlands. https://simapro.com/wp-content/uploads/2020/10/DatabaseManualMethods.pdf

Rainatto FL (2018) Produto amaciante e perfumador de roupas. Depositors: Laboratório Químico Brasileiro; Indústria e Comércio Eireli-EPP. BR no 102018015747-7 A2. Deposit date: 18 Aug 2018

Scalon LG (2021) Composição para produto amaciante para roupas de aplicação doméstica. Depositor: Luiz Gonzaga Scalon. BR no 102021016427-1 A2. Deposit date: 19 Aug 2021

Shah J, Arslan E, Cirucci J, O’Brien J, Moss D (2016) Comparison of oleo- vs petro-sourcing of fatty alcohols via cradle-to-gate life cycle assessment. J Surfactants Deterg 19(6):1333–1351. https://doi.org/10.1007/s11743-016-1867-y

Sistema Nacional de Informações sobre Saneamento (SNIS) (2023) SNIS - Série Histórica. Brasília. http://app4.mdr.gov.br/serieHistorica/

Spreafico C, Russo D (2020) Assessing domestic environmental impacts through LCA using data from the scientific literature. J Clean Prod 266:121883. https://doi.org/10.1016/j.jclepro.2020.121883

Sütterlin H, Alexy R, Coker A, Kümmerer K (2008) Mixtures of quaternary ammonium compounds and anionic organic compounds in the aquatic environment: elimination and biodegradability in the closed bottle test monitored by LC-MS/MS. Chemosphere 72(3):479–484. https://doi.org/10.1016/j.chemosphere.2008.03.008

Ugaya CML, Neto JAA, Figueiredo MCB (2019) Recomendação de Modelos de Avaliação de Impacto do Ciclo de Vida para o Contexto Brasileiro. Relatório da Rede de Pesquisa de Avaliação do Impacto do Ciclo de Vida-RAICV. IBICT/MCT, Brasília. https://acv.ibict.br/wp-content/uploads/2019/07/Relat%C3%B3rio-de-Recomenda%C3%A7%C3%B5es-de-Modelos-de-Avalia%C3%A7%C3%A3o-de-Impacto-para-o-Contexto-Brasileiro.pdf

Unilever (2023) Como estamos fazendo para tornar nossas formulações biodegradáveis. https://www.unilever.com.br/planet-and-society/como-estamos-fazendo-para-tornar-nossas-formulacoes-biodegradaveis/

Yamaguchi Y, Kuwamura N, Nagayama M (2022) The application of social LCA as an analytical tool for optimizing home laundry. J Oleo Sci 51(10):627–636. https://doi.org/10.5650/jos.51.627

Yamaguchi Y, Seii E, Itagaki M, Nagayama M (2011) Evaluation of domestic washing in Japan using life cycle assessment (LCA). Int J Consum Stud 35(2):243–253. https://doi.org/10.1111/j.1470-6431.2010.00975.x

Yates L, Evans D (2016) Dirtying linen: re-evaluating the sustainability of domestic laundry. Environ Policy Gov 26(2):101–115. https://doi.org/10.1002/eet.1704

Ypê (2022) Relatório de Impacto 2022. https://www.ype.ind.br/wp-content/uploads/2023/05/YPE_Relatorio-de-Impacto-2022.pdf

Funding

This work was supported by the National Council for Scientific and Technological Development (CNPq) and the Piauí State Research Support Foundation (FAPEPI) [Grant number: PDCTR—Process 301246/2022-0].

Author information

Authors and Affiliations

Contributions

I.E.M.O.M.: conceptualization, data curation, formal analysis, investigation, methodology, software, visualization, writing—original draft, and writing—review and editing. J.M.M.N.: funding acquisition, project administration, supervision and validation, and writing—review and editing. E.A.S.: conceptualization, funding acquisition, methodology, project administration, supervision and validation, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Communicated by Peter Rudolf Saling.

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Moura, I.E.M.O., Neto, J.M.M. & da Silva, E.A. Environmental performance of a household laundry cycle. Int J Life Cycle Assess (2024). https://doi.org/10.1007/s11367-024-02339-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11367-024-02339-1