Abstract

Oxidative degradation of chloramphenicol (CAP) using a hybrid approach (US/HA+/n-Fe2O3/SPC) involving sodium percarbonate (SPC; “solid H2O2” carrier), Fe2O3 nanoparticles (n-Fe2O3; H2O2 decomposition catalyst), hydroxylamine in its protonated form (HA+; Fe (III) to Fe (II) reducer), and ultrasonic cavitation (to increase the generation of hydroxyl radicals) has been studied for the first time. The average size of n-Fe2O3 synthesized by the sonochemical method, as calculated according to the Debye–Scherrer equation, was ~ 18 nm. The maximum degradation degree of CAP (83.1%) and first-order oxidative degradation rate constant of CAP as 1.253 × 10–3 s−1 were achieved using the modified sono-Fenton process under the optimized conditions as the initial concentration of CAP – 50 mg/L, the molar ratio of CAP:HA+:n-Fe2O3:SPC of 1:100:100:100, pH as 3, the temperature as 318 K, the specific ultrasonic power as 53.3 W/L, and the treatment duration of 7200 s. In general, the efficiency and intensity of CAP degradation increased with a decrease in the pH value, an increase in the molar ratio of CAP:HA+:n-Fe2O3:SPC, a decrease in the initial concentration of CAP, an increase in temperature, and showed a minor change with the specific power of US. The synergistic coefficient for the combination of the US and the heterogeneous Fenton process was 17.9. The active participation of hydroxyl radicals in the oxidative degradation of CAP using the modified sono-Fenton process was confirmed by scavenging experiments performed using tert-butyl alcohol. The proposed process can be a promising direction in the remediation of pharmaceutical effluents with significant potential for commercial exploitation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chloramphenicol (CAP) is a bacteriostatic and bactericidal antibiotic commonly applied for oral and parenteral use against conjunctivitis, meningitis, plague, cholera, and typhoid fever (Rohana et al. 2023; Li et al. 2018). Accumulation of this antibiotic in the human body can lead to atrophy of the optic nerve, disturbances in the circulatory system, kidney and liver damage, etc., whereas accumulation in animals leads to the development of aplastic anemia (Nguyen et al. 2022). In addition, CAP has potential genotoxic carcinogenicity (Luo et al. 2018), and it also inhibits the growth and development of algae (Xiong et al. 2019). The main sources of contamination of aquatic environments with CAP are hospital wastewater, pharmaceutical production units, and aquaculture (Nguyen et al. 2022). Presence of CAP in water bodies leads to changes in natural water ecosystems and causes resistance to microbes.

Adsorption (Nguyen et al. 2022), biodegradation (Karungamye 2020), and advanced oxidation processes (AOPs) (Kurt et al. 2017) have been used to remove CAP from water. The most common adsorbents applied are activated carbon (Li et al. 2018; Lach 2019), biochar (Yang et al. 2020), porous carbon (Dai et al. 2018), metal–organic frameworks (Li et al. 2020), composites (Xu et al. 2020b), and clays and other silica-based adsorbents (Sun et al. 2017). It is important to note that the sorption capacity of various adsorbents for CAP is generally lower although dependent on the specific adsorbent. For example, the adsorption capacity for CAP adsorption using activated carbon (Picabiol) was equal to 215 mg/g (Lach 2019), 33 mg/g for biochar pyrolyzed at 700 °C (Yang et al. 2020), 494 mg/g for Fe3C/Fe/C magnetic hierarchical porous carbon (Dai et al. 2018), 24 mg/g for ZIF-8 (Li et al. 2020), 3000 mg/g for carbon powder-supported nanoscale zero-valent iron (Xu et al. 2020a), and finally 10 mg/g for ionic liquid-modified illite (Sun et al. 2017). Another disadvantage of most commonly applied sorbents is the difficulties associated with the reuse and disposal of used sorbents. Biological methods, which are another commonly applied methods, use microorganisms (operated under aerobic or anaerobic conditions), or plants (phytoremediation) to degrade antibiotics (Oberoi et al. 2019). Low antibiotic removal efficiency and long purification time are two key disadvantages of biodegradation. The biological wastewater treatment systems are only moderately effective (extent of removal as 48–77% depending on the operating conditions) in the removal of antibiotics (Oberoi et al. 2019).

AOPs offer promise for treatment of persistent organic pollutants, for example, aromatic compounds, dyes, and antibiotics (Kurt et al. 2017; Znak et al. 2018a; Sukhatskiy et al. 2020, 2022), where the pollutants are oxidized to biodegradable intermediates, and subsequently mineralized to CO2, H2O, or/and N2. The efficiency of AOPs depends on the generation of free radicals, in particular non-selective hydroxyl radicals (Wang and Xu 2012; Znak et al. 2018b; Znak and Sukhatskiy 2016; Yavorskiy et al. 2016). AOPs typically involve the use of strong oxidants (hydrogen peroxide, ozone, persulfates, periodates, etc.) and/or catalysts (Fe2+, Mn2+, MnO2, TiO2, etc.) (Cheng et al. 2021; Wu et al. 2015; Zhang et al. 2020; Cao et al. 2020; Sukhatskiy et al. 2023), usually in combination with high-energy radiation – ultraviolet or US radiation (Cabotaje et al. 2019; Meng et al. 2021; Yavorskyi et al. 2017; Neyens and Baeyens 2003) that can lead to intensification of generation of oxidants and hence the rates of pollutant degradation. Antibiotics is an important class of pharmaceutical compounds that have not been studied so well using AOPs and hence the present work has focused on one such antibiotic as CAP. Literature analysis revealed that Fenton-based process (Cheng et al. 2021) and Fenton-like processes (Wu et al. 2015; Meng et al. 2021), either an individual approaches or in combination with irradiation sources, have been used to degrade CAP. Cheng et al. (2021) reported that graphene oxide/Fe(III)/H2O2 combination in dark and visible light conditions can efficiently decompose CAP over the pH values from 2.0 to 4.7. The reported efficiency of CAP degradation at 60 min and initial pH of 3 in dark- and vis-graphene oxide/Fe(III)/H2O2 system was equal to 93.1 and 100%, respectively. In another study, it was reported that pyrite-catalyzed degradation of CAP can occur at low concentrations of hydrogen peroxide, attributed to the fact that pyrite performs the function of a “bond” between H2O2 and Fe3+, generating hydroxyl radicals and inhibiting quenching reactions (Wu et al. 2015). It was established that the removal efficiency of CAP using the pyrite–H2O2 system at pH of 3, the temperature of 298 K, the initial concentration of CAP of 50 mg/L, and dosages of H2O2, and pyrite of 1.0 mM and 100 mg/L respectively was more than 95% after 10 min. Meng et al. (2021) studied the combination of US with Fenton-like process and reported that pH had a much greater effect on CAP degradation than H2O2 concentration. The efficiency of CAP degradation using the US-enhanced Fenton-like sponge iron system at pH of 3, the initial concentration of CAP of 120 mg/L, 2 mmol/L H2O2, and a sponge iron concentration of 2 g/L reached over 93% after 30 min.

The recent interest into heterogeneous Fenton process, often referred to as Fenton-like approach, has grown due to the disadvantages of the homogeneous Fenton process in terms of instability of aqueous solutions of hydrogen peroxide and iron (II) salts, their significant consumption leading to higher costs, as well as the accumulation of precipitate of iron (III) compounds (Sukhatskiy et al. 2021). In the heterogeneous Fenton, the catalyst is in a solid state, for example in the form of natural (Thomas et al. 2021) or artificially synthesized mineral—hematite, magnetite, goethite, schwertmannite, spinels, clays, etc., nanoparticles of zero-valent iron (nZVI) immobilized on support materials (zeolites, graphene oxide, silicon dioxide, etc.), bimetallic nanocomposites and metal–organic frameworks. Compared to the homogeneous process, the advantages of a heterogeneous approach include a low leaching degree of iron (II) ions from catalysts, the possibility of easy separation and repeated use of the catalyst, and the wider range of working pH values. There has been interest into developing more efficient catalysts or combinations for intensifying the oxidant production and hence the rates of treatment. The use of adduct of Na2CO3 and H2O2– micro granules of SPC (Na2CO3·1.5H2O2) has been considered in the present work as a promising direction for improving the Fenton process. SPC is a carrier of “solid H2O2” and, compared to H2O2 in the liquid phase, it is thermally more stable (Pimentel et al. 2021), and the costs of its storage and transportation are three times lower (Liu et al. 2021). In addition, the decomposition products of SPC (CO2, H2O, and Na2CO3) are not toxic, and present in natural water systems (Mohammadi et al. 2022). SPC can be activated with ultraviolet (Gao et al. 2020; Ma et al. 2022) and/or US irradiation (Lin et al. 2020), dielectric barrier discharge plasma (Tang et al. 2019a), ions of transition metals, in particular in the presence of chelating agents – citric, oxalic, glutamic acids, cysteine (Tang et al. 2019b; Fu et al. 2016, 2022; Huang et al. 2022a,b; Gao et al. 2021; Farooq et al. 2023; Li et al. 2019), heterogeneous catalysts – sulfides of transition metals (Li et al. 2022), iron nanoparticles immobilized on supported materials (zeolite, graphene oxide) (Danish et al. 2016; Farooq et al. 2017b) or nanoparticles of iron compounds (for example, Fe3O4) (Dai et al. 2019), bimetallic nanocomposites (Danish et al. 2017; Farooq et al. 2017a; Xu et al. 2020b) and ferrocene (Lin et al. 2017).

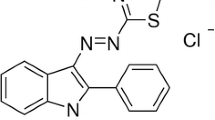

One of the other main drawback of Fenton process is the accumulation of iron (III) compounds in the reaction system. To reduce accumulation of Fe (III), reducing agents with a low rate of formation of reactive species, such as hydroxylamine (HA), has been applied in the current work for the first time. HA is a reducing agent that interacts with hydroxyl radicals at a very low rate and can reduce Fe (III) to Fe (II). Hydroxylamine has two pKa values 5.96 and 13.74 (Chen et al. 2015). The protonated form of HA (HA+) is dominant at pH < 5, and the unprotonated form (HA) is dominant at pH range of 7 to 12. \({\text{NO}}_{3}^{-}\) and N2O are the dominant products of the decomposition of HA in the Fenton process (Chen et al. 2011, Chen et al. 2015). The results of other studies indicated that N2, N2O, \({\text{NO}}_{3}^{-}\), and \({\text{NO}}_{2}^{-}\) were the products of the reduction of Fe (III) by HA (Bengtsson et al. 2002; Wang et al. 2021). It should be noted that the rate of generation of \({}^{\bullet }\text{OH}\) radicals in the modified Fenton process based on the addition of HA reductant is significantly higher (Chen et al. 2015; Merouani et al. 2022) than without the use of HA. In the sono-Fenton process, US radiation further intensifies the regeneration of Fe (II) ions and leads to the formation of a larger number of hydroxyl radicals, which are products of water sonolysis (Ammar 2016). Considering all the above governing mechanisms, a modified sono-Fenton process (US/HA+/n-Fe2O3/SPC) has been proposed and applied for the oxidative degradation of the antibiotic CAP for the first time. n-Fe2O3 synthesized by the sonochemical method was applied as a catalyst for the decomposition of H2O2. The source of H2O2 is SPC, and the reducing agent of Fe (III) to Fe (II) is HA in the form of NH2OH·HCl (HA+). Overall, the main purpose of the work was to demonstrate effective oxidative degradation of CAP using a modified sono-Fenton process (US/HA+/n-Fe2O3/SPC) and also evaluate the synergism between US cavitation and a modified Fenton process (HA+/n-Fe2O3/SPC).

Materials and methods

Reagents

CAP (molecular formula: C11H12Cl2N2O5), SPC (molecular formula: Na2CO3·1.5H2O2), hydroxylamine hydrochloride (HA+; molecular formula: NH2OH·HCl), iron sulfate heptahydrate (molecular formula: FeSO4·7H2O), an aqueous solution of ammonia (25% w/v NH3·H2O), and chloride acid (0.1 M HCl) were obtained from Merck (Germany). Tert-butyl alcohol (TBA; molecular formula: C4H10O) was purchased from Central Drug House (P) Ltd., India.

Sonochemical synthesis of n-Fe2O3

The use of US for the synthesis of n-Fe2O3 makes it possible to obtain a more monodisperse system, compared to other methods such as MW irradiation, chemical vapor deposition, sol–gel process, pulsed laser evaporation, reactive sputtering, forced hydrolysis and precipitation, hydrothermal technique and spray pyrolysis (Hassanjani-Roshan et al. 2011). In addition, in sonochemical synthesis, it is easy to control the particle size by changing the operating conditions for example, US intensity (Hassanjani-Roshan et al. 2011; Morales-Morales 2017). An aqueous solution of ferrous sulfate heptahydrate (FeSO4·7H2O) was used as a precursor for the sonochemical synthesis of n-Fe2O3. First, 2.2 g of FeSO4·7H2O was dissolved in 100 mL of distilled water. 20 mL of an aqueous ammonia solution (concentration of 2 M) was added dropwise to the obtained solution under the action of the US field for 10 min. The device for US cavitation (fixed frequency of US, 20 kHz) is a magnetostriction-type US generator (Bandelin Sonopuls HD 2200.2, Germany) operated with a power of 60 W. The calorimetric power was 32 W, and the power density was 0.27 W/mL. The obtained precipitate was separated by centrifugation (duration, 5 min; frequency, 10,000 rpm), washed with distilled water and ethanol, dried in air for 24 h at room temperature, and calcined in air for 3 h at a temperature of 773 K. The temperature of 773 K affects the final iron oxide characteristics and composition. At this calcination temperature, only hematite (α-Fe2O3) was obtained, which was the main purpose of the synthesis. At the calcination temperature of 573 K, the formation of magnetite, hematite, and maghemite was possible (Fauzi and Ratnawulan 2021).

IR, EDX spectroscopic analysis, XRD, and SEM analysis

The qualitative and quantitative composition and the structure of the catalyst synthesized using the sonochemical method were confirmed by the methods of IR spectroscopy, EDX spectroscopy (energy-dispersive X-ray spectroscopy), and XRD analysis (X-ray diffraction analysis), respectively. Scanning electron microscopy (SEM) was also used to evaluate the particle size of the synthesized product. The different equipment applied for the analysis are as follows:

-

1)

IR spectroscopy – spectrum Two FT-IR Spectrometer (PerkinElmer, USA), equipped with a universal attachment of attenuated total reflectance;

-

2)

EDX spectroscopy – X-ray fluorescence analyzer ElvaX Pro (Elvatech, Ukraine);

-

3)

XRD analysis – X-ray diffractometer AERIS Research (Malvern Panalytical, Great Britain);

-

4)

SEM – SEM-microscope Tescan Vega 3 LMU (TESCAN Brno, The Czech Republic), equipped with SE (topographic contrast of the surface) and BSE detectors (contrast by the number of electrons in the phases).

Experimental setup for oxidative degradation of CAP

The laboratory setup for studying the oxidative degradation of CAP under isothermal conditions was a glass reactor with a volume of 300 mL (reactor filling coefficient, 67%) equipped with a magnetostrictive-type US emitter “Ultrasonic Disintegrator” UD-20 (Poland), a magnetic stirrer, and CORIO C-BT5 thermostat (JULABO GmbH), which was equipped with a removable thermostat bath, in which the reactor was placed. The frequency of US vibrations for the ultrasonic disintegrator is 22 kHz whereas the specific power of the US reactor was varied in the range from 53.3 to 83.3 W/L.

ADWA AD1200 ATC pH meter (Hungary) with a set of electrodes (combined glass electrode AD1131B and replaceable platinum redox electrode AD3230B) was used to measure the pH and thermos-compensator AD7662 was used to measure the redox potential.

Methodology for oxidative degradation of CAP

One hundred milliliters of an aqueous solution of the antibiotic CAP with a concentration of 100 mg/L was prepared using distilled water. One hundred milliliters of an aqueous solution of SPC was then added to 100 mL of an antibiotic solution under constant stirring. Thus, the concentration of CAP in the solution (net volume of 200 mL), which was obtained as a result of mixing two aqueous solutions (CAP and SPC), was equal to 50 mg/L (1.548 × 10–4 M). HA+ and n-Fe2O3 were successively added to the reaction medium. The molar ratio of CAP:HA+:n-Fe2O3:SPC was varied in the range from 1:50:50:50 to 1:100:100:100. The required pH value (in the range from 3.00 to 7.00) was obtained by adding required volume of an aqueous solution of HCl (strength of 0.1 M). In order to confirm the participation of hydroxyl radicals in the degradation of CAP using the modified sono-Fenton process, TBA was used as a specific scavenger of hydroxyl radicals.

Analytical procedure

At certain time intervals, 5 mL of the reaction medium was taken and n-Fe2O3 was separated from the liquid phase by centrifugation (centrifuge MPW-310, Poland) at rotation frequency of 5000 rpm applied for 5 min. The obtained samples of the liquid phase were analyzed for the content of CAP using a UV–Vis spectrophotometer UV-3100PC (China), equipped with quartz cuvettes (thickness of 1 cm) at a wavelength of 278 nm. The concentration of CAP was calculated on the basis of previously constructed calibration curves. After analysis using UV–Vis spectroscopy, the liquid phase was returned to the glass reactor to ensure a constant volume. The separated catalyst (n-Fe2O3) was also returned to the reactor. Even though utmost care was taken for efficient separation, it was observed that about 10% of the catalyst was lost during the separation as measured based on the final residual quantity. The efficiency of oxidative degradation of CAP was evaluated in terms of the degradation degree (x, %)

where C0, initial concentration of CAP in the reaction medium; and C, concentration of CAP at any time τ, M.

To check the reproducibility of the results, each experiment was repeated three times and the average values used in the discussion and data illustration. In addition, the obtained variation has also been depicted in the form of error bars.

Results and discussion

Characteristics of the catalyst synthesized using the sonochemical method

During the sonochemical synthesis of n-Fe2O3 from aqueous solutions of ferrous sulfate heptahydrate and ammonia, the following reactions occur (Hassanjani-Roshan et al. 2011; Morales-Morales 2017):

According to Eq. (2), Fe2+ ions present in the sulfate are transformed into iron (II) hydroxide (Fe(OH)2), which interacts with oxygen dissolved in an aqueous solution to form iron (III) hydroxide (Fe(OH)3) according to Eq. (3). Fe(OH)3 is successively transformed into FeOOH and α-Fe2O3 according to Eqs. (4)–(5), respectively.

The IR spectrum of the powder of n-Fe2O3 synthesized using the sonochemical method is shown in Fig. 1a. Peaks at 1631 and 3372 cm−1 correspond to valence vibrations of hydroxyl groups on the surface of nanoparticles. Characteristic bands on the IR spectrum of the product at 516 and 431 cm−1 indicate Fe–O valence vibrations and α-Fe2O3 shear deformation vibrations (Morales-Morales 2017).

Peaks in the EDX spectrum of the product (Fig. 1b) confirmed the presence of iron and oxygen with weight percentages as 66.4 and 33.6%, respectively. There were no other unidentified peaks in the EDX spectrum, indicating the purity of the sample.

The XRD pattern of the powder sample (Fig. 1c) elucidated that the product is rhombohedral α-Fe2O3 (hematite) (R-3c, JCPDS card, No. 01–1053, a = 0.5028 nm, c = 1.3730 nm) (Hassanjani-Roshan et al. 2011) without any other phases. From the peak at 2θ = 33.17°, and using the Debye–Scherrer equation (Lassoued et al. 2017), the average size of the α-Fe2O3 crystallite was calculated as ~ 18 nm.

SEM image of n-Fe2O3 powder synthesized by the sonochemical method is shown in Fig. 1d. It was seen that α-Fe2O3 nanoparticles are slightly agglomerated, which is characteristic of powdery materials, and have a spherical shape with a diameter over the range of 15—50 nm, which was consistent with the XRD measurement results.

In the sono-Fenton process, the application of US radiation induces sonolysis of water molecules (Eq. (6)) resulting in the formation of hydroxyl radicals, which can be further enhanced by the catalyst characteristics. For example, conversion of Fe3+ from hematite into Fe2+ based on the reaction with water by Eq. (7) (Dindarsafa et al. 2017) also yields additional \({}^{\bullet }\text{OH}\) radicals in the aqueous solution as per following equations:

The presence of solid particles of catalysts (for example, hematite particles) in the solution also provides additional nuclei for the development of cavitation phenomena (Melero et al. 2008). Disaggregation of hematite nanoparticles under US radiation will lead to an increase in their surface area, which will promote better accessibility to active centers and hence still better production of oxidizing species.

Effect of pH on the oxidative degradation of CAP

With an increase in the pH of the reaction medium from 3.00 to 5.00 applied for the modified sono-Fenton process (Fig. 2a), the degree of oxidative degradation of CAP decreased by 48.2% (from 62.0 to 13.8%) during 3600 s. An increase in the treatment duration from 3600 to 7200 s led to an increase in the degradation degree by 8.7%, i.e., from 62.0 to 70.7% (at pH of 3) although a very marginal change by 0.4% from 13.8 to 14.2% was seen at pH of 5. At pH of 7, the degree of oxidative degradation of CAP for treatment durations of 3600 and 7200 s was again similar at 7.8 and 8.3%, respectively. For direct oxidation of CAP by SPC at the minimum tested concentration of SPC of 7.74 mM (at the molar ratio of CAP:SPC = 1:50), the initial concentration of CAP of 1.548 × 10–4 M, the temperature of the reaction medium of 298 K, and pH of 3, degradation of CAP over a period of 7200 s was 3.8%. Inhibition of CAP degradation using the US/Fenton-like treatment (US/sponge iron/H2O2) with increasing pH is caused by a decrease in the redox potential and activity of \({}^{\bullet }\text{OH}\) radicals (Meng et al. 2021). The efficiency of CAP degradation using just sonication without the sponge iron and hydrogen peroxide at pH of 3, the initial concentration of CAP of 120 mg/L, US power of 200 W, and US frequency of 20 kHz was only 4.6% after 60 min. At the solution pH higher than 3, the hydrolysis of Fe3+ ions in the solution caused a sharp decrease in the generation rate of hydroxyl radicals (Hsueh et al. 2005). As a result, the increase in the solution pH was accompanied by a decrease in the efficiency of degradation of azo dyes using Fenton and Fenton-like reactions. Instead, in low pH condition, iron ion was more eluting (Tokumura et al. 2006) leading to an increase in the rate of generation of hydroxyl radicals. At pH > 4.0, precipitation of Fe3+ ions occurs based on the formation of Fe2+ complexes as per Eq. (8) and the Fe3+ oxyhydroxides as per Eqs. (9) – (11) (Xu and Li 2010), which have a low activation efficiency of SPC. As a result, fewer hydroxyl radicals are formed and, accordingly, the efficiency of CAP degradation decreases at higher operating pH.

The effect of pH on a the oxidative degradation of CAP, b pseudo-first-order kinetic plots of CAP degradation, and c changes in the redox potential of the reaction medium at pH = 3.00 when using the modified sono-Fenton process (experimental conditions: C0(CAP) = 1.548 × 10–4 M, the molar ratio of CAP:HA+:n-Fe2O3:SPC = 1:100:100:100, V = 200 mL, T = 298 К, the specific power of US cavitation – 53.3 W/L)

The TOC percentage decreased by 42.8% over 7200 s as time of treatment using modified sono-Fenton process (US/HA+/n-Fe2O3/SPC) at the initial concentration of CAP of 1.548 × 10–4 M, the molar ratio of CAP:HA+:n-Fe2O3:SPC of 1:100:100:100, the temperature of the reaction medium of 298 K, pH of 3.00, and specific power of US of 53.3 W/L.

The results shown in Fig. 2b indicate that CAP degradation using the US/HA+/n-Fe2O3/SPC process follows a pseudo-first-order reaction mechanism. The maximum value of the degradation rate constant of CAP using the modified sono-Fenton process (7.492 × 10–4 s−1) was reached at pH of 3 (Fig. 2b). With an increase in pH from 3 to 5, the degradation rate constant of CAP (Table 1) decreased by 4.2 times (from 7.492 × 10–4 to 1.800 × 10–4 s−1). A further increase in pH to 7.00 led to a decrease in the degradation rate constant by 33.5% – from 1.800 × 10–4 to 1.197 × 10–4 s−1. Zhang et al. (2020) also reported that the degradation rate constant of CAP using the US-enhanced nZVI/persulfate treatment decreased from 1.728 × 10–4 to 1.200 × 10–4 s−1 with increasing pH from 3.06 to 11.09. It was thus clearly elucidated that the efficiency and intensity of oxidation are greatest in an acidic medium, which was also confirmed based on the measurements of the redox potential during the implementation of the modified sono-Fenton process with maximum value seen at pH of 3.00 as 417 mV obtained after 7200 s of treatment (Fig. 2c).

Effect of molar ratio of CAP:HA+:n-Fe2O3:SPC on the oxidative degradation of CAP

With an increase in the quantity of reagents (HA+, n-Fe2O3, SPC), which form a redox system, by two times, the degradation degree of CAP increased by 5.7% (from 56.3 to 62.0%) within 3600 s. The applied increase in the reagents was equivalent to an increase in the molar ratio of CAP:HA+:n-Fe2O3:SPC from 1:50:50:50 to 1:100:100:100 (Fig. 3a). An increase in the treatment duration to 7200 s led to an increase in the oxidative degradation degree of CAP at the molar ratio: 1:50:50:50—by 5.6% (from 56.3 to 61.9%) whereas at 1:100:100:100, observed increase was by 8.7% (from 62.0 to 70.7%). For the molar ratio of CAP:HA+:n-Fe2O3:SPC of 1:50:50:50, the ratio in mg/L was 50:538:1238:1215, and the concentration of H2O2 was equal to 7.7 mM. For the molar ratio of CAP:HA+:n-Fe2O3:SPC of 1:75:75:75, the ratio in mg/L was 50:807:1858:1823, and the concentration of H2O2 was equal to 11.6 mM. For the molar ratio of CAP:HA+:n-Fe2O3:SPC of 1:100:100:100, the ratio in mg/L was 50:1076:2477:2430, and the concentration of H2O2 was equal to 15.5 mM Wu et al. (2015). also reported that with an increase in H2O2 and pyrite dosages, the oxidative degradation degree of CAP increased. As the dose of oxidant (H2O2) increases, more hydroxyl radicals can be formed (Wu et al. 2015; Meng et al. 2021), which increases the efficiency of CAP degradation. Increasing the catalyst dosage expands the contact surface in the heterogeneous process (Wu et al. 2015), which accelerates the decomposition of SPC resulting in higher oxidation capacity. An increase in the amount of hydroxylamine in the protonated form (HA+) also contributes to a more intensive reduction of Fe (III) compounds to Fe (II) according to Eqs. (14)–(17) contributing to higher oxidation rates [58, 59]. N2, N2O, \({\text{NO}}_{3}^{-}\), and \({\text{NO}}_{2}^{-}\) were the final products of reduction of Fe (III) by hydroxylamine as demonstrated in Eqs. (17)–(23) (Merouani et al. 2022).

The effect of CAP:HA+:n-Fe2O3:SPC molar ratio on a the oxidative degradation of CAP, and b pseudo-first-order kinetic plots of CAP degradation using the modified sono-Fenton process (experimental conditions: C0(CAP) = 1.548 × 10–4 M, V = 200 mL, pH = 3.00, T = 298 К, the specific power of US cavitation – 53.3 W/L)

It should be noted that the oxidative degradation rate constant of CAP with increasing the molar ratio of CAP:HA+:n-Fe2O3:SPC from 1:50:50:50 to 1:100:100:100 increased by 1.3 times from 5.550 × 10–4 to 7.492 × 10–4 s−1 (Fig. 3b, Table 2). In a similar trend reported in literature, the pseudo-first-order kinetic rate constant for the decomposition of CAP using the pyrite–H2O2 system at pH = 3, the temperature of 298 K, the initial concentration of CAP of 50 mg/L, dosages of H2O2 and pyrite of 1.0 mM and 50 mg/L, respectively, was equal to 1.550 × 10–4 s−1 (Wu et al. 2015). The higher value of the kinetic rate constant reported in the current work clearly demonstrates the higher efficacy of the oxidation capacity applied for CAP degradation.

Effect of specific power of US on the oxidative degradation of CAP

An increase in the specific power of US cavitation processing had not much effect on the degradation of CAP. Using the hybrid advanced oxidation process of US/HA+/n-Fe2O3/SPC for 7200 s, the degradation degree of CAP was 70.7% at a specific power of 53.3 W/L; 71.7% at a specific power of 68.0 W/L and 72.2% at a specific power of 83.3 W/L. An increase in the US power from 60 to 180 W was reported cause a similar very marginal change in the decolorization degree of methylene blue (MB) (by 0.6% from 73.5 to 74.1%) using the “Sonoperoxate” process—US/H2O2/KIO4 (Sukhatskiy et al. 2022). In general, a higher US power leads to violent turbulence and, accordingly, to increased homogenization and intensification of mass transfer in the solution (Zhang et al. 2020). In addition, at higher US intensity, more cavitation bubbles are expected, and as a result of their collapse, more free radicals (Meng et al. 2021), primarily hydroxyl ones, are formed, which can contribute to the increase in the degradation degree of pollutants. Very small changes in the degradation degree of CAP with increasing specific power of US cavitation, which were in good agreement with small changes in the degradation rate constant (Table 3), can be attributed to the dominant contribution of the oxidants used in the process. It is important to note that a low US frequency (22 kHz) used in the current work results in longer acoustic cycles, which is accompanied by a longer duration of cavitation bubbles collapse and, accordingly, causes self-quenching of the free radicals inside the cavitation bubbles (Zhang et al. 2020). Therefore, at the low US frequency, the oxidants used in this case are dominating over the degradation process rather than the hydroxyl radicals produced by the cavitation bubbles. At the same time, ultrasonic vibrations contribute to an increase in mass transfer. In general, changing the US frequency affects the single bubble yield and the number of active bubbles. Although not studied in the current work, credence to effect of frequency can be given on the basis of literature illustration. During the sonochemical degradation of naphthol blue black in water at 585 kHz, it was reported that the bubble has more time to expand, resulting in a higher expansion ratio and so a higher compression ratio of the bubble (Ferkous et al. 2015). Accordingly, the bubble collapse efficiency was greater resulting in a higher collapse temperature, which intensifies the dissociation of water vapor and oxygen molecules with the higher formation of free radicals and atoms, which will lead to an increase in the efficiency of pollutant degradation. With an increase in the US frequency to 1140 kHz, a lot of bubbles with a smaller diameter were formed, which are characterized by a shorter collapse time and a lower collapse temperature (Ferkous et al. 2015), which led to a lower dissociation of water vapor and oxygen molecules and, accordingly, a decrease in the rate of formation of free radicals and atoms. Therefore, the degree of sonochemical degradation of naphthol blue black decreased indicating the optimum selection of frequency is also important. Based on the current results of insignificant effect of the change in the specific power of US on the oxidative degradation degree of CAP and the degradation rate constant, it was suggested to carry out cavitation processing of the reaction medium at a specific power of 53.3 W/L, which was the minimum possible based on the processor applied in the work and can help to minimize energy consumption.

Effect of CAP initial concentration on its oxidative degradation

An increase in the initial concentration of CAP in the water medium led to a decrease in its oxidative degradation degree. Quantitatively, for the treatment duration of 3600 s, the degradation degree of CAP was equal to: 75.9% at the C0(CAP) of 25 mg/L (0.774 × 10–4 M); 62.0% at the C0(CAP) of 50 mg/L (1.548 × 10–4 M) and 55.7% at the C0(CAP) of 75 mg/L (2.322 × 10–4 M). The degradation degree of CAP for the treatment duration of 7200 s increased to 81.5, 70.7, and 66.2% (Fig. 4), respectively. At a constant dose of the oxidant (SPC), the yield of active species remains the same, and hence, with an increase in the initial concentration of CAP in the solution, lower degradation is seen as more free radicals, in particular hydroxyl ones, are needed for the effective degradation of CAP. In addition, intermediates formed during CAP oxidation competed with CAP molecules for the limited hydroxyl radicals. Therefore, the oxidative degradation degree of CAP decreased with an increase in its initial concentration. Similar results were obtained by Zhang et al. (2020). With an increase in the initial concentration of CAP from 2 to 10 mg/L, the obtained degradation within 90 min using US-enhanced nZVI/persulfate treatment decreased from 99.0 to 82.2%. However, it is interesting to note in the current work that the number of moles of CAP degraded at the initial concentration of CAP 75 mg/L for 7200 s was greater (1.537 × 10–4 M) than at the initial concentration of CAP 50 mg/L (1.094 × 10–4 M), and 25 mg/L (0.631 × 10–4 M).

In the current work, it was also elucidated that the oxidative degradation rate constant of CAP decreased by 2.5 times (from 7.492 × 10–4 to 3.010 × 10–4 s−1) with an increase in its initial concentration from 50 to 75 mg/L (Table 4). Therefore, it was clearly elucidated that with an increase in the initial CAP concentration in its aqueous solution, the efficiency and intensity of its removal decreases, which needs to be carefully looked at while optimizing the treatment process. For higher initial pollutant concentrations, it would be advisable to use higher degree of oxidants so as to achieve desired treatment efficacy.

Effect of the temperature on the oxidative degradation of CAP

Due to an increase in the temperature by 10 K (from 298 to 308 K), the oxidative degradation degree of CAP using the modified sono-Fenton process within 3600 s increased by 13.1% from 62.0 to 75.1% (Fig. 5a). A further increase in the temperature to 318 K led to an increase in the degradation degree of CAP by another 6.9% from 75.1 to 82.0%. As a result of increasing the treatment duration from 3600 to 7200 s, the degradation degree of CAP increased by 8.7% (from 62.0 to 70.7%) at the reaction medium temperature of 298 K; by 4.1% (from 75.1 to 79.2%) at the reaction medium temperature of 308 K and by only 1.1% (from 82.0 to 83.1%) at the reaction medium temperature of 318 K (Fig. 5a). An initial increase in the temperature accelerates the decomposition of SPC and the dissolution of hydrogen peroxide, (Lin et al. 2017; Zhang et al. 2018). In a similar study, it was also reported that as the temperature increased from 288 to 323 K, the degradation degree of sulfamethazine using the CuS/SPC/tetraacetylethylenediamine process within 30 min increased from 69.7 to 100% (Li et al. 2022).

The effect of the temperature on a the oxidative degradation of CAP, b pseudo-first-order kinetic plots of CAP degradation, and c Arrhenius plots of rate constant (k) for oxidative degradation of CAP using the modified sono-Fenton process (experimental conditions: C0(CAP) = 1.548 × 10–4 M, the molar ratio of CAP:HA+:n-Fe2O3:SPC = 1:100:100:100, V = 200 mL, pH = 3.00, the specific power of US cavitation– 53.3 W/L)

With an increase in the medium temperature from 298 to 308 K, the oxidative degradation rate constant of CAP using the modified sono-Fenton process increased by 1.2 times—from 7.492 × 10–4 to 9.062 × 10–4 s−1 (Fig. 5b, Table 5). A further increase in the temperature from 308 to 318 K led to an increase in the rate constant by 1.4 times—from 9.062 × 10–4 to 1.253 × 10–3 s−1. Zhang et al. (2018) also reported that with an increase in temperature from 283 to 323 K, the degradation rate constant of the azo dye Reactive Red 195 using the UV/Fe(III)-oxalate complex/SPC process increased from 3.717 × 10–4 to 6.833 × 10–4 s−1.

Based on the Arrhenius plots of rate constant for oxidative degradation of CAP using the modified sono-Fenton process (Fig. 5c), the activation energy (Ea) was calculated according to Eq. (24).

where R, universal gas constant, J/(mol × K); tg α, the tangent of the angle of inclination of the straight line ln k = f(1/T) to the abscissa axis. Ea for the sulfamethazine degradation using the CuS/SPC/tetraacetylethylenediamine process was also reported in similar range of 31.26 kJ/mol (Li et al. 2022). Chen et al. (2000) reported that Ea of around 21 kJ/mol is typical for the degradation reactions of most organic pollutants involving hydroxyl radicals. This indicates that hydroxyl radicals were involved in the oxidative degradation of CAP using the modified sono-Fenton process (US/HA+/n-Fe2O3/SPC) as elucidated in the current work.

Synergistic effect for the combined process

It was established that the degradation of CAP using US processing, the modified Fenton process (HA+/n-Fe2O3/SPC), and the combined process of the modified sono-Fenton process (US/HA+/n-Fe2O3/SPC) obtained in 7200 s were equal to 2.9, 37.9, and 70.7%, respectively. Similarly, the degradation rate constant of CAP using US processing, the modified Fenton process, and the combined process (Fig. 6) were equal to 3.739 × 10–5, 4.550 × 10–6, and 7.492 × 10–4 s−1, respectively. A significant increase in the extent of degradation and rate constant of CAP degradation for the modified sono-Fenton process was due to the synergistic effect of the combination of US and the modified Fenton process, which resulted in the enhanced generation of hydroxyl radicals (Dindarsafa et al. 2017). The synergistic coefficient (f) for the combination of the US and the heterogeneous Fenton process at the temperature of 298 K was calculated based on the values of the degradation rate constants of CAP for individual processes according to Eq. (25).

In a recent study, it was reported that at the molar ratio of MB:H2O2:KIO4of1:100:25, the synergistic coefficient of the “Sonoperoxate” process was 3.25 (Sukhatskiy et al. 2022). Therefore, the proposed AOP (US/HA+/n-Fe2O3/SPC) is significantly more intensive and efficient, compared to the individual processes used for its development as well as other oxidation systems reported in the literature.

Elucidating the role of hydroxyl radicals

TBA is a strong hydroxyl radical scavenger, which is broadly and routinely used in AOPs (Merouani et al. 2022). A significant decrease in the oxidative degradation degree of CAP due to the introduction of an aqueous solution of TBA into the reaction medium (Fig. 7) was revealed with actual decrease in the degradation as 36.7% (from 70.7 to 34.0%) at a concentration of TBA of 25 mM; 41.7% (from 70.7 to 29.0%) at a concentration of TBA of 50 mM; and by 54.6% (from 70.7 to 16.1%) at a concentration of TBA of 100 mM. An increase in the concentration of an aqueous solution of TBA also led to a decrease in the oxidative degradation rate constant of CAP (Table 6). The above observed trend confirms the extensive participation of \({}^{\bullet }\text{OH}\) radicals in the oxidative degradation of CAP using the modified sono-Fenton process.

The effect of the concentration of an aqueous solution of TBA (in mM) on the oxidative degradation of CAP using the modified sono-Fenton process (experimental conditions: C0(CAP) = 1.548 × 10–4 M, the molar ratio of CAP:HA+:n-Fe2O3:SPC = 1:100:100:100, V = 200 mL, pH = 3.00, T = 298 К, the specific power of US cavitation – 53.3 W/L)

Comparing the efficacy of different applied processes, it can be said that the oxidative degradation of CAP using different processes increased in the following order: US < direct oxidation by SPC < US/n-Fe2O3 < US/SPC < n-Fe2O3/SPC < HA+/n-Fe2O3/SPC (actual values as 2.9% < 5.1% < 8.7% < 17.4% < 29.5% < 37.9%) under best treatment conditions of specific power of US as 53.3 W/L, the concentration of SPC as 15.48 mM (at the molar ratio of CAP:SPC of 1:100), the n-Fe2O3 loading as ~ 2.5 g/L, the concentration of HA+ as ~ 1.1 g/L (at the molar ratio of CAP:HA+ of 1:100), the temperature of the reaction medium as 298 K, the treatment duration as 7200 s, and pH as 3.00. The efficiency of degradation of CAP using US treatment or direct oxidation by SPC was low attributed to the low yield of hydroxyl radicals during the sonolysis of water or the chemical resistance of CAP to direct oxidation by SPC. The efficiency of US-assisted removal of CAP by n-Fe2O3 was slightly higher compared to the efficiency of only US treatment. US activated SPC, causing synergism, which was manifested in an increase in the generation of hydroxyl radicals resulted in an increase in the degradation of CAP to 17.4%. n-Fe2O3/SPC is a modification of the Fenton process, in which n-Fe2O3 was applied as a catalyst for the decomposition of H2O2 to form hydroxyl radicals, and the source of H2O2 was SPC. HA+ acted as a Fe (III) to Fe (II) reducer, ensuring the stability of the Fe3+/Fe2+ redox cycle and, accordingly, an increase in the number of hydroxyl radicals and the degradation degree of CAP. Considering the above, the presence of a hydrogen peroxide decomposition catalyst (n-Fe2O3) and Fe (III) to Fe (II) reducer (HA+) were the key factors for the enhanced generation of hydroxyl radicals that attacked CAP molecules resulting in higher degradation.

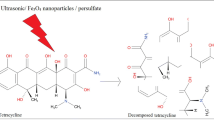

Figure 8 shows the UV–Vis spectra of the CAP oxidative degradation using the modified sono-Fenton process. For the CAP oxidative degradation using the modified sono-Fenton process, the maximum absorption peak lowered and red-shifted (Wu et al. 2018) from 278 nm to about 281 nm, confirming the CAP degradation. According to literature (Wu et al. 2015; Meng et al. 2021), a dehydroxylation reaction of CAP occurs to form 2, 2-dichloro-n-(1-(4-nitrobenzoyl)vinyl)acetamide. The C–N and C–C cleavage also occurs due to the \({}^{\bullet }\text{OH}\) attack during the oxidative degradation of CAP resulting in the formation of nitrobenzaldehyde and dichloroacetamide. The intermediates are finally mineralized to inorganic ions (such as \({\text{NO}}_{3}^{-}\) and \({\text{Cl}}^{-}\)) and small molecular compounds (such as H2O and CO2).

Conclusions

Use of the modified sono-Fenton process (US/HA+/n-Fe2O3/SPC) for the oxidative degradation of the antibiotic CAP was effectively demonstrated in the current work for the first time. The hybrid process resulted in significant synergism based on the contribution of SPC as a carrier of “solid H2O2,” n-Fe2O3 as a catalyst for the decomposition of H2O2, HA+ as a reducer of Fe (III) to Fe(II), and US cavitation that enhance the production of \({}^{\bullet }\text{OH}\) radicals. The analytical methods of IR spectroscopy, EDX spectroscopy, and XRD analysis confirmed that the elemental composition and structure of the synthesized catalyst corresponded to the chemical formula α-Fe2O3 (hematite), and the average size of the α-Fe2O3 crystallite, which was calculated using the Debye–Scherrer equation, was ~ 18 nm, which was also confirmed by the analysis of SEM images. Application of the hybrid process of modified sono-Fenton resulted in the maximum degradation of CAP as 83.1% under the optimized conditions along with the maximum oxidative degradation rate constant of CAP as 1.253 × 10–3 s−1 and synergistic coefficient of 17.9. The current work has clearly shown the efficacy of modified sono-Fenton process for most effective degradation of CAP and the optimum set of operating conditions for achieving maximum benefits.

Data availability

Data will be made available on request.

References

Ammar HB (2016) Sono-Fenton process for metronidazole degradation in aqueous solution: effect of acoustic cavitation and peroxydisulfate anion. Ultrason Sonochem 33:164–169. https://doi.org/10.1016/j.ultsonch.2016.04.035

Bengtsson G, Fronæus S, Bengtsson-Kloo L (2002) The kinetics and mechanism of oxidation of hydroxylamine by iron(III), J. Chem. Soc. Dalton Trans 12:2548–2552. https://doi.org/10.1039/B201602H

Cabotaje ACG, Teodoro ACC, Climaco LS, Rubi RVD, Olay JG (2019) Photocatalytic degradation of chloramphenicol using hydroxyapatitederived from egg shells. J BIMP-EAGA Reg Dev 5(2):22–40. https://doi.org/10.51200/jbimpeagard.v5i2.3267

Cao Y, Qiu W, Zhao Y, Li J, Jiang J, Yang Y, Pang S-Y, Liu G (2020) The degradation of chloramphenicol by O3/PMS and the impact of O3-based AOPs pre-oxidation on dichloroacetamide generation in post-chlorination. Chem Eng J 401:126146. https://doi.org/10.1016/j.cej.2020.126146

Chen D, Sivakumar M, Ray AK (2000) Heterogeneous photocatalysis in environmental remediation. Dev Chem Eng Mineral Process 8(5/6):505–550. https://doi.org/10.1002/apj.5500080507

Chen L, Ma J, Li X, Zhang J, Fang J, Guan Y, Xie P (2011) Strong enhancement on Fenton oxidation by addition of hydroxylamine to accelerate the Ferric and Ferrous iron cycles. Environ Sci Technol 45(9):3925–3930. https://doi.org/10.1021/es2002748

Chen L, Li X, Zhang J, Fang J, Huang Y, Wang P, Ma J (2015) Production of hydroxyl radical via the activation of hydrogen peroxide by hydroxylamine. Environ Sci Technol 49(17):10373–10379. https://doi.org/10.1021/acs.est.5b00483

Cheng F, Zhou P, Liu Y, Huo X, Zhang J, Yuan Y, Zhang H, Lai B, Zhang Y (2021) Graphene oxide mediated Fe(III) reduction for enhancing Fe(III)/H2O2 Fenton and photo-Fenton oxidation toward chloramphenicol degradation. Sci Total Environ 797:149097. https://doi.org/10.1016/j.scitotenv.2021.149097

Dai J, Tian S, Jiang Y, Chang Z, Xie A, Zhang R, Li C, Yan Y (2018) Fe3C/Fe/C magnetic hierarchical porous carbon with micromesopores for highly efficient chloramphenicol adsorption: magnetization, graphitization, and adsorption properties investigation. Ind Eng Chem Res 57(10):3510–3522. https://doi.org/10.1021/acs.iecr.7b05300

Dai Z, Liang L, Wang M, Du E (2019) Degradation of DDTs by nano Fe3O4/sodium percarbonate and their degradation products. Acta Sci Circumstantiae 39(4):1183–1190. https://doi.org/10.13671/j.hjkxxb.2018.0449

Danish M, Gu X, Lu S, Xu M, Zhang X, Fu X, Xue Y, Miao Z, Naqvi M, Nasir M (2016) Role of reactive oxygen species and effect of solution matrix in trichloroethylene degradation from aqueous solution by zeolite-supported nano iron as percarbonate activator. Res Chem Intermed 42(9):6959–6973. https://doi.org/10.1007/s11164-016-2509-8

Danish M, Gu X, Lu S, Ahmad A, Naqvi M, Farooq U, Zhang X, Fu X, Miao Z, Xue Y (2017) Efficient transformation of trichloroethylene activated through sodium percarbonate using heterogeneous zeolite supported nano zero valent iron-copper bimetallic composite. Chem Eng J 308:396–407. https://doi.org/10.1016/j.cej.2016.09.051

Dindarsafa M, Khataee A, Kaymak B, Vahid B, Karimi A, Rahmani A (2017) Heterogeneous sono-Fenton-like process using martite nanocatalyst prepared by high energy planetary ball milling for treatment of a textile dye. Ultrason Sonochem 34:389–399. https://doi.org/10.1016/j.ultsonch.2016.06.016

Farooq U, Danish M, Lu S, Brusseau ML, Naqvi M, Fu X, Zhang X, Sui Q, Qiu Z (2017a) Efficient transformation in characteristics of cations supported-reduced graphene oxide nanocomposites for the destruction of trichloroethane. Appl Catal A Gener 544:10–20. https://doi.org/10.1016/j.apcata.2017.07.007

Farooq U, Danish M, Lu S, Naqvi M, Gu X, Fu X, Zhang X, Nasir M (2017b) Synthesis of nZVI@reduced graphene oxide: an efficient catalyst for degradation of 1,1,1-trichloroethane (TCA) in percarbonate system. Res Chem Intermed 43(5):3219–3236. https://doi.org/10.1007/s11164-016-2821-3

Farooq U, Wang F, Shang J, Shahid MZ, Akram W, Wang X (2023) Heightening effects of cysteine on degradation of trichloroethylene in Fe3+/SPC process. Chem Eng J 454(1):139996. https://doi.org/10.1016/j.cej.2022.139996

Fauzi A, Ratnawulan R (2021) The effect of calcination temperature on the structure of iron oxide phase from west Sumatra. J Phys Conf Ser 1876:012028. https://doi.org/10.1088/1742-6596/1876/1/012028

Ferkous H, Hamdaoui O, Merouani S (2015) Sonochemical degradation of naphthol blue black in water: effect of operating parameters. Ultrason Sonochem 26:40–47. https://doi.org/10.1016/j.ultsonch.2015.03.013

Fu X, Gu X, Lu S, Xu M, Miao Z, Zhang X, Zhang Y, Xue Y, Qiu Z, Sui Q (2016) Enhanced degradation of benzene in aqueous solution by sodium percarbonate activated with chelated-Fe(II). Chem Eng J 285:180–188. https://doi.org/10.1016/j.cej.2015.09.112

Fu X, Wei X, Zhang W, Yan W, Wei P, Lyu S (2022) Enhanced effects of reducing agent on oxalate chelated Fe(II) catalyzed percarbonate system for benzene degradation. Water Supply 22(1):208–219. https://doi.org/10.2166/ws.2021.278

Gao J, Duan X, O’Shea K, Dionysiou DD (2020) Degradation and transformation of bisphenol A in UV/sodium percarbonate: dual role of carbonate radical anion. Water Res 171:115394. https://doi.org/10.1016/j.watres.2019.115394

Gao Y, Yang F, Jian H, Zhen K, Zhang P, Tang X, Fu Z, Xu W, Wang C, Sun H (2021) Pyrene degradation in an aqueous system using ferrous citrate complex activated persulfate over a wide pH range. J Environ Chem Eng 9(6):106733. https://doi.org/10.1016/j.jece.2021.106733

Hassanjani-Roshan A, Vaezi MR, Shokuhfar A, Rajabali Z (2011) Synthesis of iron oxide nanoparticles via sonochemical method and their characterization. Particuology 9(1):95–99. https://doi.org/10.1016/j.partic.2010.05.013

Hsueh CL, Huang YH, Wang CC, Chen CY (2005) Degradation of azo dyes using low iron concentration of Fenton and Fenton-like system. Chemosphere 58:1409–1414. https://doi.org/10.1016/j.chemosphere.2004.09.091

Huang J, Zhou Z, Danish M, Sui Q, Lyu S (2022a) Synergistic strengthening of SPC/Fe(II) system by CA coupled with mZVI for trichloroethylene degradation in SDS-containing aqueous solution. J Environ Chem Eng 10:108276. https://doi.org/10.1016/j.jece.2022.108276

Huang J, Zhou Z, Lyu S (2022b) Comparative study on trichloroethylene degradation enhanced by three organic acid chelating agents in sodium percarbonate/Fe(II) system in the presence of surfactant. J Environ Chem Eng 10:108464. https://doi.org/10.1016/j.jece.2022.108464

Karungamye PN (2020) Methods used for removal of pharmaceuticals from wastewater: a review. Appl J Envir Eng Sci 6(4):412–428. https://doi.org/10.48422/IMIST.PRSM/ajees-v6i4.23828

Kurt A, Mert BK, Özengin N, Sivrioğlu Ö, Yonar T (2017) Treatment of antibiotics in wastewater using advanced oxidation processes (AOPs). In: Farooq R, Ahmad Z (eds) Physico-chemical wastewater treatment and resource recovery. IntechOpen, London, pp 175–211. https://doi.org/10.5772/67538

Lach J (2019) Adsorption of chloramphenicol on commercial and modified activated carbons. Water 11(6):1141. https://doi.org/10.3390/w11061141

Lassoued A, Dkhil B, Gadri A, Ammar S (2017) Control of the shape and size of iron oxide (α-Fe2O3) nanoparticles synthesized through the chemical precipitation method. Results Phys 7:3007–3015. https://doi.org/10.1016/j.rinp.2017.07.066

Li Y, Zhang J, Liu H (2018) Removal of chloramphenicol from aqueous solution using low-cost activated carbon prepared from Typha orientalis, onto powdered activated carbon and its desorption performance by ultrasound. Water 10(4):351. https://doi.org/10.3390/w10040351

Li L, Huang J, Hu X, Zhang S, Dai Q, Chai H, Gu L (2019) Activation of sodium percarbonate by vanadium for the degradation of aniline in water: mechanism and identification of reactive species. Chemosphere 215:647–656. https://doi.org/10.1016/j.chemosphere.2018.10.047

Li X, Yang X, Xue H, Pang H, Xu Q (2020) Metal–organic frameworks as a platform for clean energy applications. EnergyChem 2:100027. https://doi.org/10.1016/j.enchem.2020.100027

Li Y, Dong H, Xiao J, Li L, Chu D, Hou X, Xiang S, Dong Q (2022) Insights into a novel CuS/percarbonate/tetraacetylethylenediamine process for sulfamethazine degradation in alkaline medium. J Hazard Mater 435:128999. https://doi.org/10.1016/j.jhazmat.2022.128999

Lin K-YA, Lin J-T, Lin Y-F (2017) Heterogeneous catalytic activation of percarbonate by ferrocene for degradation of toxic amaranth dye in water. J Taiwan Inst Chem Eng 78:144–149. https://doi.org/10.1016/j.jtice.2017.05.017

Lin X, He J, Xu L, Fang Y, Rao G (2020) Degradation of metronidazole by ultrasound-assisted sodium percarbonate activated by ferrous sulfate. Water Pollut Treat 8(3):66–76. https://doi.org/10.12677/wpt.2020.83010

Liu X, He S, Yang Y, Yao B, Tang Y, Luo L, Zhi D, Wan Z, Wang L, Zhou Y (2021) A review on percarbonate-based advanced oxidation processes for remediation of organic compounds in water. Environ Res 200:111371. https://doi.org/10.1016/j.envres.2021.111371

Luo L, Gu C, Li M, Zheng X, Zheng F (2018) Determination of residual 4-nitrobenzaldehyde in chloramphenicol and its pharmaceutical formulation by HPLC with UV/Vis detection after derivatization with 3-nitrophenylhydrazine. J Pharm Biomed Anal 156:307–312. https://doi.org/10.1016/j.jpba.2018.04.024

Ma C, Yu Z, Wei J, Tan C, Yang X, Wang T, Yu G, Zhang C, Li X (2022) Metal-free ultrathin C3N5 photocatalyst coupling sodium percarbonate for efficient sulfamethoxazole degradation. Appl Catal B Environ 319:121951. https://doi.org/10.1016/j.apcatb.2022.121951

Melero JA, Martínez F, Molina R (2008) Effect of ultrasound on the properties of heterogeneous catalysts for sono-Fenton oxidation processes. J Adv Oxid Technol 11(1):75–83. https://doi.org/10.1515/jaots-2008-0109

Meng X, Liu Z, Wang S, Kong F (2021) Synergistic degradation of chloramphenicol by an ultrasound-enhanced Fenton-like sponge iron system. Water 13(24):3561. https://doi.org/10.3390/w13243561

Merouani S, Dehane A, Belghit A, Hamdaoui O, Boussalem NEH, Daif H (2022) Removal of persistent textile dyes from wastewater by Fe(II)/H2O2/H3NOH+ integrated system: process performance and limitations. Environ Sci Adv 1(2):192–207. https://doi.org/10.1039/D2VA00011C

Mohammadi S, Moussavi G, Yaghmaeian K, Giannakis S (2022) Development of a percarbonate-enhanced Vacuum UV process for simultaneous fluoroquinolone antibiotics removal and fecal bacteria inactivation under a continuous flow mode of operation. Chem Eng J 431(2):134064. https://doi.org/10.1016/j.cej.2021.134064

Morales-Morales JA (2017) Synthesis of hematite α-Fe2O3 nano powders by the controlled precipitation method. Cienc Desarro 8(1):99–107. https://doi.org/10.19053/01217488

Neyens E, Baeyens J (2003) A review of classic Fenton’s peroxidation as an advanced oxidation technique. J Hazard Mater 98(1–3):33–50. https://doi.org/10.1016/S0304-3894(02)00282-0

Nguyen LM, Nguyen NTT, Nguyen NTT, Nguyen TT, Nguyen DTC, Tran TV (2022) Occurrence, toxicity and adsorptive removal of the chloramphenicol antibiotic in water: a review. Environ Chem Lett 20(3):1929–1963. https://doi.org/10.1007/s10311-022-01416-x

Oberoi AS, Jia Y, Zhang H, Khanal SK, Lu H (2019) Insights into fate and removal of antibiotics in engineered biological treatment systems: a critical review. Environ Sci Technol 53(13):7234–7264. https://doi.org/10.1021/acs.est.9b01131

Pimentel JAI, Dong C-D, Garcia-Segura S, Abarca RRM, Chen C-W, de Luna MDG (2021) Degradation of tetracycline antibiotics by Fe2+-catalyzed percarbonate oxidation. Sci Total Environ 781:146411. https://doi.org/10.1016/j.scitotenv.2021.146411

Rohana H, Hager-Cohen A, Azrad M, Peretz A (2023) Trend of changes in chloramphenicol resistance during the years 2017–2020: a retrospective report from Israel. Antibiotics 12(2):196. https://doi.org/10.3390/antibiotics12020196

Sukhatskiy YV, Znak ZO, Zin OI (2020) Cavitation and its combinations with other advanced oxidation processes in phenol wastewater treatment: a review. Voprosy Khimii i Khimicheskoi Tekhnologii 4:16–30. https://doi.org/10.32434/0321-4095-2020-131-4-16-30

Sukhatskiy Y, Znak Z, Zin O, Chupinskyi D (2021) Ultrasonic cavitation in wastewater treatment from azo dye methyl orange. Chem Chem Technol 15(2):284–290. https://doi.org/10.23939/chcht15.02.284

Sukhatskiy Y, Sozanskyi M, Shepida M, Znak Z, Gogate PR (2022) Decolorization of an aqueous solution of methylene blue using a combination of ultrasound and peroxate process. Sep Purif Technol 288:120651. https://doi.org/10.1016/j.seppur.2022.120651

Sukhatskiy Y, Shepida M, Sozanskyi M, Znak Z, Gogate PR (2023) Periodate-based advanced oxidation processes for wastewater treatment: a review. Sep Purif Technol 304:122305. https://doi.org/10.1016/j.seppur.2022.122305

Sun K, Shi Y, Xu W, Potter N, Li Z, Zhu J (2017) Modification of clays and zeolites by ionic liquids for the uptake of chloramphenicol from water. Chem Eng J 313:336–344. https://doi.org/10.1016/j.cej.2016.12.083

Tang S, Yuan D, Rao Y, Li M, Shi G, Gu J, Zhang T (2019a) Percarbonate promoted antibiotic decomposition in dielectric barrier discharge plasma. J Hazard Mater 366:669–676. https://doi.org/10.1016/j.jhazmat.2018.12.056

Tang P, Jiang W, Lu S, Zhang X, Xue Y, Qiu Z, Sui Q (2019b) Enhanced degradation of carbon tetrachloride by sodium percarbonate activated with ferrous ion in the presence of ethyl alcohol. Environ Technol 40(3):356–364. https://doi.org/10.1080/09593330.2017.1393012

Thomas N, Dionysiou DD, Pillai SC (2021) Heterogeneous Fenton catalysts: a review of recent advances. J Hazard Mater 404:124082. https://doi.org/10.1016/j.jhazmat.2020.124082

Tokumura M, Znad HT, Kawase Y (2006) Modeling of an external light irradiation slurry photoreactor: UV light or sunlight-photoassisted Fenton discoloration of azo-dye Orange II with natural mineral tourmaline powder. Chem Eng Sci 61(19):6361–6371. https://doi.org/10.1016/j.ces.2006.05.038

Wang JL, Xu LJ (2012) Advanced oxidation processes for wastewater treatment: formation of hydroxyl radical and application. Crit Rev Environ Sci Technol 42:251–325. https://doi.org/10.1080/10643389.2010.507698

Wang C, Yu G, Chen H, Wang J (2021) Degradation of norfloxacin by hydroxylamine enhanced fenton system: kinetics, mechanism and degradation pathway. Chemosphere 270:129408. https://doi.org/10.1016/j.chemosphere.2020.129408

Wu D, Liu Y, Zhang Z, Ma L, Zhang Y (2015) Pyrite-enhanced degradation of chloramphenicol by low concentrations of H2O2. Water Sci Technol 72(2):180–186. https://doi.org/10.2166/wst.2015.202

Wu Y, Yue Q, Ren Z, Gao B (2018) Immobilization of nanoscale zero-valent iron particles (nZVI) with synthesized activated carbon for the adsorption and degradation of Chloramphenicol (CAP). J Mol Liq 262:19–28. https://doi.org/10.1016/j.molliq.2018.04.032

Xiong Q, Hu LX, Liu YS, Wang TT, Ying GG (2019) New insight into the toxic effects of chloramphenicol and roxithromycin to algae using FTIR spectroscopy. Aquat Toxicol 207:197–207. https://doi.org/10.1016/j.aquatox.2018.12.017

Xu X-R, Li X-Z (2010) Degradation of azo dye Orange G in aqueous solutions by persulfate with ferrous ion. Sep Purif Technol 72(1):105–111. https://doi.org/10.1016/j.seppur.2010.01.012

Xu J, Liu X, Cao Z, Bai W, Shi Q, Yang Y (2020a) Fast degradation, large capacity, and high electron efficiency of chloramphenicol removal by different carbon-supported nanoscale zerovalent iron. J Hazard Mater 384:121253. https://doi.org/10.1016/j.jhazmat.2019.121253

Xu J, Wang L, Chen J-B, Xu F, Wang K-Q, Hou Z-F, Huang T-Y (2020b) Degradation of AO7 with magnetic Fe3O4-CuO heterogeneous catalyzed sodium percarbonate system. Environ Sci 41(4):1734–1742. https://doi.org/10.13227/j.hjkx.201908117

Yang F, Zhang Q, Jian H, Wang C, Xing B, Sun H, Hao Y (2020) Effect of biochar-derived dissolved organic matter on adsorption of sulfamethoxazole and chloramphenicol. J Hazard Mater 396:122598. https://doi.org/10.1016/j.jhazmat.2020.122598

Yavorskiy V, Sukhatskiy Y, Znak Z, Mnykh R (2016) Investigations of cavitation processes in different types of emitters using sonochemical analysis. Chem Chem Technol 10(4):507–513. https://doi.org/10.23939/chcht10.04.507

Yavorskyi VT, Znak ZO, Sukhatskyi YV, Mnykh RV (2017) Energy characteristics of treatment of corrosive aqueous media in hydrodynamic cavitators. Mater Sci 52(4):595–600. https://doi.org/10.1007/s11003-017-9995-8

Zhang C, Dong Y, Li B, Li F (2018) Comparative study of three solid oxidants as substitutes of H2O2 used in Fe (III)-oxalate complex mediated Fenton system for photocatalytic elimination of reactive azo dye. J Clean Prod 177:245–253. https://doi.org/10.1016/j.jclepro.2017.12.211

Zhang T, Yang Y, Gao J, Li X, Yu H, Wang N, Du P, Yu R, Li H, Fan X, Zhou Z (2020) Synergistic degradation of chloramphenicol by ultrasound-enhanced nanoscale zero-valent iron/persulfate treatment. Sep Purif Technol 240:116575. https://doi.org/10.1016/j.seppur.2020.116575

Znak Z, Sukhatskiy Y (2016) The brandon method in modelling the cavitation processing of aqueous media. East Eur J Enterp Technol 3:37–42. https://doi.org/10.15587/1729-4061.2016.72539

Znak ZO, Sukhatskiy YV, Zin OI, Khomyak SV, Mnykh RV, Lysenko AV (2018a) The decomposition of the benzene in cavitation fields. Voprosy Khimii i Khimicheskoi Tekhnologii 1:72–77

Znak ZO, Sukhatskiy YV, Mnykh RV, Tkach ZS (2018b) Thermochemical analysis of energetics in the process of water sonolysis in cavitation fields. Voprosy Khimii i Khimicheskoi Tekhnologii 3:64–69

Funding

The work was supported by the Ministry of Education and Science of Ukraine (the scientific research project of young scientists “Advanced oxidation processes, including nanocatalytic, based on cavitation technologies for purification of aqueous media from resistant N-substituted organic compounds,” state registration number 0122U000790).

Author information

Authors and Affiliations

Contributions

Yu. Sukhatskiy: supervision, original draft preparation, conceptualization, funding acquisition. M. Shepida: methodology, investigation, original draft preparation. D. Lysak: methodology, investigation. Z. Znak: supervision, reviewing and editing, project administration. Parag R. Gogate: supervision, reviewing and editing.

Corresponding author

Ethics declarations

Ethical approval

All authors confirm that they adhere to COPE guidelines. We also declare that the work did not involve any humans or animals that might require ethical approvals.

Consent to participate

All authors have given consent to participate in this publication.

Consent for publication

All authors have given consent to publish the work in Environmental Science and Pollution Research.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ricardo A. Torres-Palma

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sukhatskiy, Y., Shepida, M., Lysak, D. et al. Modified sono-Fenton process for oxidative degradation of chloramphenicol. Environ Sci Pollut Res 31, 54559–54573 (2024). https://doi.org/10.1007/s11356-024-34827-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-34827-0