Abstract

Practical and energy-efficient carbon dioxide (CO2) conversion to value-added and fuel-graded products and transitioning from fossil fuels are promising ways to cope with climate change and to enable the circular economy. The carbon circular economy aims to capture, utilize, and minimize CO2 emissions as much as possible. To cope with the thermodynamic stability and highly endothermic nature of CO2 conversion via conventional thermochemical process, the potential application of non-thermal plasma (NTP) with the catalyst, i.e., the hybrid plasma catalysis process to achieve the synergistic effects, in most cases, seems to promise alternatives under non-equilibrium conditions. This review focuses on the NTP fundamentals and comparison with conventional technologies. A critical review has been conducted on the CO2 reduction with water (H2O), methane (CH4) reduction with CO2 to syngas (CO + H2), CO2 dissociation to carbon monoxide (CO), CO2 hydrogenation, CO2 conversion to organic acids, and one-step CO2–CH4 reforming to the liquid chemicals. Finally, future challenges are discussed comprehensively, indicating that plasma catalysis has immense investigative areas.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Plasma technology for CO2 conversion

Global climate change is considered an exponentially rising risk to the environment and human beings (Loenders et al. 2023, Zhang et al. 2022). It has been estimated that global warming has increased the earth’s temperature since the pre-industrial period by 1.5 °C, leading to irreversible changes and adverse effects on nature. Considering these alarming facts, it is necessary to put efforts into decreasing greenhouse gas emissions, mainly CO2 and CH4, which are reaching atmospheric concentrations of about 416 ppm and 1910 ppb, respectively (Cooley et al. 2022, Wang et al. 2023a). These figures indicate that CO2 and CH4 have increased by 19% and 173% since the pre-industrial era, respectively (Houghton et al. 2001). Besides, it is well known that society is much more dependent on fossil fuel combustion to gain energy, leading to considerable greenhouse gas emissions. Therefore, finding a potential solution for both problems is necessary, i.e., cutting greenhouse gas emissions and transitioning from fossil fuels to renewable and fuel-graded products, enabling the CO2 circular economy (Goeppert et al. 2014, Tcvetkov et al. 2019, Tebbiche et al. 2021). Although conventional thermal catalysis can fill the bill, the nature of the CO2 conversion reaction, i.e., highly endothermic (900–1273 K) for shifting the thermal equilibrium, makes it less energy efficient (Aramouni et al. 2018, Pakhare and Spivey 2014, Sun et al. 2023).

In thermochemical conversion processes, the higher thermal stability of the CO2 molecules demands much higher energy to break the double bonds in the CO2 molecule (O=C=O), making it less effective (Ashford and Tu 2017). Overcoming this issue by applying non-thermal plasma (NTP) is an innovative process to overcome the CO2 molecule activation challenges and convert it into various value-added and fuel-graded products. The reason is that the NTP can enable the reaction to proceed, which is thermodynamically unfavorable under ambient reaction conditions. Usually, the NTP performs at atmospheric pressure, low temperature, and non-equilibrium conditions and still achieves much higher conversion than the thermochemical conversion processes. Typically, the NTP produces energetic electrons having an average temperature (1 to 10 eV) possessing a high capability of CO2 molecule activation by ionization, followed by excitation, and finally, dissociation, leading to the development of an avalanche of reactive species, which include the ions, excited atoms, radicals, and molecules which can trigger the chemical reaction into forward direction (Bogaerts and Neyts 2018, Mehta et al. 2019, Tu and Whitehead 2012, Tu et al. 2019, Zeng et al. 2018). The significant benefit of NTP technology is the ease of installation, compactness, flexibility, and the considerable potential of integration with other technologies for effective and energy-efficient conversion of CO2 to value-added and fuel-graded products (George et al. 2021).

The major obstacle in the pathway of the NTP technology is the improvement of energy efficiency, which could be accomplished by combining the catalyst and transforming the plasma process to the hybrid plasma catalysis process, creating synergy, and providing enough room for the excited species for catalyst surface interaction and subsequently lose their excitation energies and relax before reaction. However, the knowledge available for the plasma catalysis process to effectively and efficiently convert CO2 to value-added and fuel-graded products and, most importantly, for the complex interactions between plasma, catalyst, and reactive species is minimal (Fridman 2008).

This review paper comprehensively focuses on plasma and plasma catalysis technologies, their fundamental physicochemical properties; integration in reactors with different configurations; and possible interactions between complex plasma, catalyst, and reactive species. In addition, the general mechanism of the plasma-only process for CO2 activation by ionization, excitation, and dissociation is also discussed, along with current developments and future challenges in plasma catalysis for different CO2 conversion routes.

Comparison of plasma with conventional CO2 conversion approaches

Comparison has been summarized in Table 1 for all traditional and conventional CO2 conversion technologies and the plasma-only and plasma-catalysis technologies. Overall, it has been found that the conventional thermochemical conversion of CO2 assisted by catalysts cannot split CO2; however, it can be effectively implemented to dry reforming methane (DRM) and the hydrogenation of CO2. At the same time, data for CO2 reduction in H2O is not available for the catalyst-assisted thermochemical conversion approach. Compared to the catalyst-assisted thermochemical conversion approach, all other novel approaches successfully achieved CO2 reduction in H2O, and the electrochemical and solar-assisted thermochemical conversion approaches can also successfully split the CO2. Interestingly, the literature generally does not report the CH4 and hydrogen (H2) combination. Although plasma-chemical technology is the only technology discussed here that can be successfully applied to all four significant areas of CO2 conversion research, including DRM, CO2 hydrogenation, CO2 splitting, and CO2 reduction in H2O, CO2 reduction in H2O is not investigated in the plasma-catalysis system but only in the plasma-only system. In all four CO2 conversion routes, DRM and CO2 splitting are considered the two most important routes and have already been demonstrated to achieve 90–95% and 60% energy efficiency with the plasma-only treatment, respectively. Even though the one-step synthesis of value-added liquid products from CO2 conversion in the plasma-catalysis mode has been proved by preliminary research, more research is still needed to improve the process. CO2 reduction with H2O, also known as the “artificial photosynthesis,” is the least mature technology and requires significant research to improve. It is admitted that a clear priority should be given to plasma catalysis owing to its several key benefits, including flexibility, versatility, and low operation cost, as compared in Fig. 1.

Different types of plasmas

The CO2 conversion process employs various types of plasma, as described in this section: dielectric barrier discharge, radiofrequency inductively coupled plasma, atmospheric pressure glow discharges, gliding arc plasma, corona discharge, and microwave plasma. A table detailing their operational characteristics is provided in the following section (Table 2).

Dielectric barrier discharge (DBD) can be formed by employing the electrical field linking two electrodes as a non-uniform discharge with an alternating (AC) current with at least one electrode covered with a dielectric barrier. Different arrangements of the two electrodes could be made to minimize the gas bypassing the plasma area by keeping both electrodes parallel. However, a cylindrical configuration is more appropriate for greenhouse gas conversion applications. The advantage of DBD is that it can operate near ambient pressure and temperature. Due to its simple design, it can be easily upgraded for commercialization. In the case of DBD, the conversion efficiency of CO2 is appropriate; however, the energy efficiency is 2–10% less than that of other plasmas (Bogaerts and Centi 2020, Okubo et al. 2018, Ong et al. 2022, Puliyalil et al. 2018, Yamasaki et al. 2020).

Gliding arc plasma can work at ambient pressure and be produced by applying electricity between two electrodes with flat diverging. Initially, an arc is formed at the inter-electrode with the shortest distance. After that, the arc glides along with the surfaces of the diverging electrode, leading from the small to longer distances between the electrodes in the direction of gas flow until it extinguishes. The process of arc formation is then repeatedly reformed immediately at the initial sport. It has comparatively better energy efficiency even at ambient pressure with a range of 43–60% splitting CO2 and DRM conversion of 18% and 8–16%, respectively. The short residence time of the gas to be treated is a significant constraint of the traditional gliding arc plasma; however, the residence time can be increased with modifications in design (Bogaerts and Snoeckx 2019, Nunnally et al. 2011, Puliyalil et al. 2018, Ramakers et al. 2017).

As the name implies, atmospheric pressure glow discharge is operatable at ambient pressure with advantages over other plasmas, such as higher electron density and proper plasma temperature. The plasma of the discharge is luminous or glowing. It is formed by employing voltage ranging between a few hundred and a few kilovolts between two electrodes with a ballast circuit to minimize the transition of glow to arc. It has been reported that by using atmospheric pressure glow discharges with an input power of 23 W, the CH4 and CO2 conversion of 61% and 50% can be achieved, respectively (Arumugam et al. 2018, Ghorbanzadeh et al. 2009, Li et al. 2019, Tao et al. 2011).

Corona discharge is a non-uniform discharge with a lower current density that can be produced at ambient pressure. It usually involves two different electrodes, including a plate with a low curvature and a sharp tip with a high curvature. In such arrangements, when high voltage is implemented between such two different electrodes, an electric breakdown near the sharp tip with high curvature leads to plasma formation in the drift region. In the reported work, it has been demonstrated that by using the corona discharge with 46.3 W of discharge power, the conversion of CH4 and CO2 was 62.4% and 47.8%, respectively (Nguyen et al. 2015, Schutze et al. 1998, Tao et al. 2011, Yang 2002).

Radiofrequency inductively coupled plasma can be formed into the plasma chamber by employing the electromagnetic field or, more precisely, radio frequency field, and the radio frequency field can be produced using the radio frequency power through the dielectric window to the planar coil. Compared to other types of plasmas, the radiofrequency inductively coupled plasma has less than 50% energy efficiency, which could be significantly decreased at higher power, e.g., > 100 kW (Hopwood 1992, Kwak et al. 2015, Okumura 2010, Wang et al. 2017a).

Microwave plasma can be formed by implementing microwave power to a gas-filled quartz tube, and the gas temperature can be easily raised to > 3000 K at (sub)ambient pressure with energy efficiency up to 40% comparatively higher at atmospheric pressure and normal flow conditions. However, this energy efficiency can be increased to 90% with a CO2 conversion between 10 and 20% under specific operational conditions such as the supersonic/subsonic gas flow and reduced pressure. The catalyst cannot be investigated quickly for the higher gas temperature in microwave plasma. Still, it can be placed after the plasma reactor, also known as the “post-plasma catalysis,” although only a few studies have been reported (Azizov et al. 1983, Fridman 2008, Hong et al. 2006, Hrycak et al. 2014, Jasiński et al. 2013, Legasov et al. 1978, Mizeraczyk et al. 2014, Tao et al. 2011).

Plasma-catalysis reactor configurations

It is well known that a series of parameters are involved in the plasma-only process (Fig. 2) for effective and energy-efficient conversion of CO2 to the value-added products, including the specific energy input (SEI), composition of the feed gas, feed gas flow rate, discharge power, dielectric material, electrode configuration, discharge length/gap, and discharge frequency and type (George et al. 2021). However, coupling the plasma with the catalyst provides cooperative effects as the plasma-produced species can interact at the surface of the catalyst due to the interactive behavior of plasma and catalyst (Tu et al. 2011, Tu and Whitehead 2012, Whitehead 2016, 2019). There are two significant configurations in plasma catalysis, known as the in-plasma and the post-plasma catalysis, represented as IPC and PPC, respectively, as shown in Fig. 2.

Schematic illustrations of the reactor configurations for a plasma-only, b IPC, and c PPC. Reprinted from the reference (Ollegott et al. 2020) with the permission of Wiley

The IPC-configured reactor (Fig. 2) is based on a single-step procedure where a catalyst is placed in the plasma discharge region to enable to produce the short- and long-lived reactive species by the NTP to immediately interact with the surface of the catalyst with the plasma zone, leading to enhancement of CO2 conversion and the targeted product selectivities. The IPC-configured reactor facilitates energy efficiency as the required energy to produce the short-lived species is often wasted either in the plasma-only or the PPC-configured reactor. In the IPC-configured reactor, the catalyst is either partially or fully packed into the plasma discharge region, and such packing configuration also affects the discharge properties. Due to the potential impacts of plasma on the catalyst, as discussed in the preceding sections, the NTP can synthesize and modify the catalyst to improve its performance and stability, a key driver towards commercialization (Di et al. 2019, Tu et al. 2013, Wang et al. 2018b, Witvrouwen et al. 2012).

The PPC-configured reactor (Fig. 2) facilitates the two-stage reactions where the gas-phase reaction occurs in the plasma region, followed by the second stage at the catalyst’s surface. In this case, as the catalyst is not within the plasma discharge region, the catalyst bed is heated thermally to promote the reaction at the catalyst’s surface. One of the disadvantages of the PPC-configured reactor is that as it is placed outside the plasma discharge region, only long-lived species and end-products can travel from the plasma region to the catalyst surface to interact with the catalyst surface for the reaction (Bo et al. 2020, Neyts et al. 2015). The short-lived species are the vibrationally excited species with 1–10 nanoseconds of short lifetimes at atmospheric pressure and seem difficult to survive while transitioning from the plasma region to the catalyst region. Hence, the PPC-configured reactor appears not feasible for efficient CO2 conversion due to the lack of short-lived species conversion to targeted products.

Current developments in NTP-assisted CO2 conversion

CO2 reduction with 0H2O

Chen et al. (2015) reported the concurrent CO2 and H2 dissociation using a surface wave sustained discharge in a pulse regime to investigate the potential impact of various process parameters, comprising the CO2/H2O feed flow rate ratio and SEI on the energy efficiency and conversion by identifying and quantifying the product streams using gas chromatography. It has been found that the H2 and carbon monoxide (CO) formation in the same gas mixture can be carried out at the optimum SEI value of 1.6 eV/molecule. Further, this process is favored by the low feed flow rates and maximum energy efficiency. It has been found that the lower SEI and CO2 with an excess amount behave as a “physical catalyst” for H2O, leading to the formation of H2.

In contrast, the higher SEI and feed flow rates significantly reduced the H2 yield, suggesting that the CO formation consumes H2, thus facilitating the reverse direction of WGSR. The optimal emission spectroscopy (OES) results revealed that the lower gas temperature favored the higher dissociation rate. Hoeben et al. (2015) investigated that the CO2 conversion with H2O to produce CH4 was observed using a pulsed corona discharge at a higher density using a CO2 flow over the H2O film, which results in the formation of CH4 under mild reaction conditions. It was interesting to know that the CO2 and H2O dissociation using plasma induces the CO2 or CO hydrogenation chemistry over the NiCr wire materials, which behave as catalysts superior to low-alloy steel.

CH4 reforming with CO2 to syngas

Nearly two decades ago, Huang et al. (2000) reported the reformation of CO2–CH4 by a glow discharge plasma using and without using micro-arc formation with a Y-type reactor. The process seems effective for converting the mixture of CO2 and CH4 into syngas (CO and H2) as a dominant product with a minor amount of hydrocarbons also identified. Interactions between the different species and arms were observed even when only reactants were excited. With micro-arc formation, the CO selectivity was enhanced, and the process became more energy efficient than the one without micro-arc formation. However, they found that the conventional catalytic methods have better energy efficiency than the plasma-only process to convert CO2 and CH4 mixture to produce syngas. In another similar work (Li et al. 2002), the product distribution generated from the CO2 and CH4 mixture was investigated with the impact of the discharge gap width, feed gas composition, and post-glow zone effects. From the feed gas composition effect, the gaseous and liquid hydrocarbons increased with an enhancement in the feed concentration of CH4. At the same time, the CO selectivity was found to be directly proportional to the feed concentration of CO2. The CO2–CH4 conversion is enhanced at a shorter discharge gap, favoring the synthesis of liquid-phase hydrocarbons and organic acids.

For this reason, an atomic economic reaction was identified to produce acetic acid directly from CO2–CH4. In addition, the higher discharge gap resulted in the synthesis of methanol (CH3OH) and ethanol (C2H5OH). Most liquid-phase hydrocarbons identified in this work were highly chained, with olefins about 5.5 wt.%.

For the first time, Patiño et al. (2005a) investigated the application of radio frequency in the plasma-based to convert the CH4 and CO2 mixture to syngas with a conversion achieved similar to the other processes, which was further enhanced by increasing the radio frequency power and feed gas pressure. The reforming of CH4 was investigated by injecting steam, CO2, and oxygen (O2) separately for reaction with CH4, and it was found that the steam plasma was the most effective. In contrast, the O2 plasma was the most oxidant. Higher power and higher H2O–CH4 feed flow rates resulted in CO2-free syngas. In contrast, lower feed flow rates at the power of 50 W produced CO2–CO-free H2, indicating their potential for clean H2 production for fuel cell applications. This way, an H2 to CO ratio of up to 16 could be produced at certain reaction conditions.

Qi et al. (2006) found that it could be a potential option to produce syngas from CO2 and CH4 reforming using an abnormal glow plasma due to its unique energy density and the temperature profile in the discharge space. With an enhancement in either the energy density with temperature in the discharge space or power, the CO2 and CH4 conversion increased without any potential impact on the CO and H2 selectivity, possibly because the electron’s energy distribution did not change during the discharges. A competing reaction between the oxygen, carbon, molecules, and hydrogen radical atoms could increase the H2 to CO ratio, which can be achieved by increasing the CH4/CO2 feed ratio. However, this strategy could lead to carbon deposition on electrodes, which can be avoided by adding oxygen to the reaction system.

Goujard et al. (2009) investigated the synthesis of hydrocarbons and syngas from biogas (excessive CH4, CH4/CO2 = 1.5) using NTP, where the CH4 and CO2 conversion depended on the discharge power despite the variation in frequency or voltage at room temperature. In contrast, the excessive CO2 was favorable for higher CH4 and higher conversion of CO2, leading to higher CO selectivity. Conversely, the higher CH4 concentration favored hydrocarbon synthesis, and higher CO2 concentration increased the selectivity towards CO. The results showed that temperature significantly influenced selectivity with higher CO selectivity at elevated temperatures, i.e., 873 K. These results could be elaborated by considering the reaction between the active oxygen species and the carbon formed from the CH4 cracking. In this regard, the catalyst facilitates CO2 activation and favors the higher CO selectivity in a hybrid plasma system compared to a plasma-only system at 773 K. More detailed, the catalyst’s metallic nickel (Ni) species behaved as a radical trap. At the same time, the La2O3-based basic sites activated the CO2 immediately as the catalyst was incorporated with the discharge plasma.

Tu and Whitehead (2014) reported a hybrid plasma-catalysis process to produce clean fuel and value-added products by reforming the CO2–CH4 mixture using an AC gliding arc reactor. It has been found that using the DBD reactor for CO2–CH4 reforming produced a wide range of hydrocarbons, while using the AC gliding arc plasma resulted in much cleaner fuel, and of course, syngas was the dominant product. It could be attributed to the high electron density generated by AC gliding arc plasma, which may cause a change in the reaction pathway. But this postulate needs further investigation. The optical emission spectra identified various species, including Al, CH, C2, O, CO, Hα, and Hβ. Compared to the hydrocarbons and syngas, a series of varying carbon nanomaterials were also formed, which included the spherical carbon nanoparticles, amorphous carbon, and multi-walled carbon nanotubes, indicating that this hybrid process could open new doors to synthesizing carbon nanomaterials in more sustainable and energy-efficient ways.

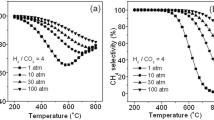

In another work, Zeng et al. (2015) reported the potential impacts of the hybrid plasma catalysis system on the CO2–CH4 reforming using the alumina-supported metal (Co, Mn, Cu, and Ni) catalysts using a coaxial DBD reactor. It has been observed that with the plasma-only mode, the CO2–CH4 conversion to syngas was strongly influenced by the feed ratio, not the feed flow rate; however, combining the Ni and Mn supported on alumina catalyst with plasma by packing into the discharge gap demonstrated a synergistic effect on the conversion of CH4–CO2 to syngas. Still, the CO2 conversion was not affected by the catalyst presence. The conversion was almost independent of the textural characteristics of the employed catalyst (Fig. 3).

Effect of catalysts and textural properties on the CO2–CH4 reforming to syngas and other value-added products in plasma-only and plasma-catalysis systems. Reprinted from the reference (Zeng et al. 2015) with the permission of Elsevier

Snoeckx et al. (2015) reported the CH4–CO2 reforming to syngas using the DBD plasma to identify the most promising parameter among the residence time, power, frequency, and gas mixture composition to determine the most effective and energy-efficient condition from the commercialization point of view. They optimized the abovementioned parameters and obtained the energy efficiency and maximal conversion, which were found to be 8.5% and 84%, respectively. In general, they found that the higher concentration of CO2 favored energy efficiency and higher conversion; however, with an enhancement in the SEI, which accounted for both residence time and power, the results revealed only an enhancement of the conversion with a slight decline in the energy efficiency. Among the different parameters investigated, the most complicated effect came from the frequency. The product of the residence time and frequency, which indicated the total counts of filaments undergone by the gas molecules while passing via the reactor, was a decisive factor. It has been found that the higher counts of micro-discharge filaments with less energy per filament resulted in higher energy efficiency and conversion.

Another similar work was reported by Nguyen et al. (2015) for reforming CO2–CH4 to syngas using the corona discharge plasma with CO and H2 as dominant products. Among different process parameters, such as the total feed flow rate, applied peak voltage, CO2/CH4 ratio, and pulse frequency, the pulse frequency and CO2/CH4 ratio were the most significant parameters. Overall, it has been found that a decrease in the total feed flow rate with an enhancement in the pulse frequency and peak voltage resulted in a higher conversion of CO2/CH4. In addition, the CO selectivity decreased more than that of H2 with the increased CO2/CH4 ratio. With a rise in the applied peak voltage up to 10 kV, the CO and H2 selectivity increased and then decreased upon further increasing the applied peak voltage. In contrast, the CO and H2 selectivity was not influenced by the variation in the pulse frequency or total feed flow rate.

Scapinello et al. (2016) reported CO2–CH4 reforming to syngas using a pulsed (NRP) discharge plasma (nanosecond repetitively) and reached a series of observations and conclusions. They found that the utilization of NRP discharge plasma demonstrated the highest performance, with an increased CH4 and CO2 conversion as a function of SEI. Due to the competing production of carbon powder and water, the selectivity towards syngas was decreased. To improve energy efficiency, water formation should be reduced with a thorough understanding of the water formation mechanism in this process.

Lu et al. (2017) reported CO2–CH4 reforming to syngas with a cooperative effect of the plasma with a catalyst supported on the graphitic carbon nitride (g-C3N4) using a DBD reactor. In the case of the plasma-only system, the overall reaction was affected by the overall feed flow rate, CH4/CO2 ratio, and input power, indicating an increased conversion of CO2 and CH4 with a rise in the input power and a decline in the total feed flow rate. However, the syngas selectivity was probably reduced due to coke formation at elevated energy levels. In the case of a hybrid plasma-catalysis system, the conversion of CO2 and CH4, as well as the syngas yields, was higher because of the synergistic effect of the plasma and the catalyst (Fig. 4). By increasing the mass ratio of TiO2, the reaction probability between the catalyst and the higher energy electrons was reduced due to the adsorption of higher energy electrons.

(Left): effect of the CH4/CO2 ratio on the syngas and other product yields in the plasma-only system. (Right): effect of power and catalyst on the CH4/CO2 reforming conversion in the plasma-catalysis system. Reprinted from the reference (Lu et al. 2017) with the permission of Springer

Yap et al. (2018) investigated CO2–CH4 reforming to syngas under NTP, with the catalyst (La2O3/Al2O3) filling the entire zone of discharge in helium gas. It has been observed that the presence of helium in the feed gas favored the higher CO2/CH4 conversion, probably due to the transfer of energy from the activated helium species to the reactant molecules and decreasing the carbon deposition. Overall, helium utilization was not found to be favorable in terms of energy efficiency.

Khoja et al. (2018) investigated a Ni/γ-Al2O3-MgO catalyst in the packed-bed DBD plasma reactor for CO2–CH4 reforming to syngas and additional value-added products. Performance was compared with the plasma-only system. It has been found that Ni/γ-Al2O3-MgO resulted in low-carbon deposition compared to Ni/MgO and Ni/γ-Al2O3, probably because of the higher metal dispersion, high Lewis’s basicity, and surface faceting (Fig. 5). The lowest carbon deposit was observed with the equimolar formation of CO and H2. This lower carbon formation was due to suppressing the carbon gasification and reversing the water gas shift reaction (RWGS). In addition, the higher H2 production was credited with suppressing the recombination of H and CH3 species to form CH4.

Effect of the different catalysts on the (left) CH4/CO2 reforming conversion (X) and selectivity (S), (right) H2/CO ratio, and energy efficiency (EE). Reprinted from the reference (Khoja et al. 2018) with the permission of Elsevier

A detailed reaction mechanistic pathway was proposed for the hybrid plasma-catalyst system to produce syngas and other value-added products through CO2–CH4 reforming. The proposed mechanism was believed to follow the Langmuir-Hinshelwood-Hougen-Watson (LHHW) mechanism with the activation of CH4 on the Ni-based active sites, and the deposited C* may go to the process of gasification on MgO (Fig. 6). According to the proposed mechanistic pathway, the dissociation, or the activation of CH4 as well as the CO2, is initiated by the plasma, followed by the elemental and intermediate adsorption composed of C, O, H, and oxy-carbonates on the support surface active sites. The surface-adsorbed species form the desired product in the presence of a catalyst and plasma (Akbari et al. 2017, Messaoudi et al. 2018).

A proposed reaction mechanism for the CO2–CH4 reforming over the Ni/γ-Al2O3-MgO catalyst in the presence of plasma. Reprinted from the reference Khoja et al. (2018) with the permission of Elsevier

Ray et al. (2018) deployed the DBD plasma reactor with the catalyst to investigate the potential effects on CO2–CH4 reforming to syngas, and it has been found that incorporating the catalyst into the DBD reactor favored an enhancement in the conversion of CH4. The conversion efficiency of CH4 was observed to be in the order of Ni-Mn/γ-Al2O3 > Ni/γ-Al2O3 > DBD, with the bimetallic catalyst showing the highest CH4 conversion probably due to its resistance towards carbon formation. Similar trends were observed for the CO2 conversion, i.e., Ni-Mn/γ-Al2O3 > Ni/γ-Al2O3 > DBD.

Zeng et al. (2018) investigated CO2–CH4 reforming to syngas in three different modes: the plasma-only, catalyst-only (Ni/Al2O3 at 160 °C), and plasma-catalyst mode, to explore the potential effects in a DBD reactor (Fig. 7). The hybrid plasma-catalysis mode demonstrated higher CH4 conversion, H2 production, and energy efficiency than the plasma-only and catalyst-only (Ni/Al2O3) modes at 160 °C. Comparing the promoted catalysts with the catalyst (Ni/Al2O3) showed that the promoted catalysts (Ni/Al2O3 catalyst modified with K–, Mg–, and Ce–) had higher CH4 conversion performance attributed to their enhanced acidic active sites as the acidic active sites are responsible for activating CH4. Compared with thermochemical conversion, it has been found that these promoters have adverse effects on CH4 conversion. Interestingly, the promoters demonstrated a different behavior in plasma and thermochemical conditions, indicating that their behavior was temperature-dependent regarding carbon deposition and the conversion of CH4. Among the promoted catalysts, the Mg-promoted catalyst significantly enhanced the H2/CO molar ratio, probably due to the weak CO2 affinity to the catalyst’s surface.

An overview of CO2–CH4 reforming with the effect of plasma and catalysts and promoted catalysts on CO2 and CH4 conversion, CO, C2–C4 alkanes, and H2 yield together with energy efficiency and catalyst stability. Reprinted from the reference Zeng et al. (2018) with the permission of Elsevier

In contrast, the K-promoted catalyst demonstrated the overall best performance in CO2–CH4 conversion and the yields of C2–C4 alkanes, CO, and H2 together with energy efficiency. Promoted catalysts also favored carbon deposition in the hybrid plasma-catalysis process. However, the total quantity of deposited carbon was still lower than in the high-temperature thermochemical reforming of CO2/CH4. The thermogravimetric analysis (TGA) revealed that the spent catalyst has carbon deposition in the reactive carbon-based species, which can be easily oxidized by O and CO2 to maintain the catalyst stability during the reaction.

CO2 dissociation to CO

Mei et al. (2014) reported a plasma catalysis system for CO2 conversion into O2 and CO in a DBD cylindrical-shaped reactor using and/or without the packing materials. The aim was to investigate the potential effects of the materials used as reactor packing, i.e., glass beads and BaTiO3, on the CO2 discharge properties and conversion to CO and O2. At the same discharge power, it has been found that there was an evolution in the CO2 discharge behavior from a typical filamentary discharge with no packing material to a combination of surface discharge with glass beads and barium titanate (BaTiO3) packings and filamentary. Incorporating BaTiO3 into the plasma system improves the energy of electrons and increases the average electric field by 98.49% and 93.78%, respectively, further influencing the plasma-catalysis–based reactions. In addition, it has been found that utilization of the reactor packing materials, i.e., glass beads and BaTiO3, in the discharge gap results in the efficiency enhancement of the DBD reactor for the conversion of CO2, although the CO2 residence time has been reduced due to an increase in the volume of discharge at the identical flow rate of gas. Overall, it has been found that utilization of the reactor packing materials, i.e., glass beads and BaTiO3, significantly improved the conversion of CO2 by 75% and the yield of CO due to variation in the discharge properties (Fig. 8), making it an efficient process compared to CO2 conversion in plasma catalysis with no packing. Furthermore, the electron with a highly energetic state (> 3.0 eV) produced by the discharge could be assistive in activating the photocatalyst (BaTiO3) by an electron-hole pair on to the surface of the catalyst, which further provides a synergistic effect to the CO2 conversion process.

Effect of packing materials on (left) CO selectivity and (right) CO yield. Reprinted from the reference Mei et al. (2014) with the permission of IOP Science Publishing

In another work, Mei and Tu (2017) extended their research to explore the potential different parametric effects on the plasma-catalysis–based transformation of CO2 to O2 as well as the CO. These parameters included the discharge length and frequency, plasma power, electrode gap, CO2 flow rate, dielectric materials thickness, and the reactor design using a DBD coaxial reactor. It has been found that the decomposition of CO2 and the efficiency of the process were not affected noticeably by the discharge frequency. Higher discharge power and/or lower flow rate CO2 feed results in an increased conversion of CO2 than the lower discharge and/or higher CO2 feed flow rate. In this regard, a clear trade-off existed between the conversion of CO2 and the plasma process efficiency. In addition, the decomposition of CO2 and process energy efficiency was positively affected by lowering the thickness of the dielectric material and discharge gap and increasing the discharge length. Regression modeling shows that the flow rate of the CO2 feed and the discharge power are the key drivers for enhancing the conversion of CO2 and the process’s energy efficiency.

Additionally, it has been observed that using aluminum (Al) foil on the outer surface of the electrodes and the screw-type inner electrodes composed of stainless steel (SS) significantly improved the conversion of CO2 and energy efficiency compared to other forms of electrodes. The role of the SS screw-type inner electrode and Al foil was investigated, and it was found that the Al foil contributed to the enlargement of the effective discharge area. In contrast, the SS screw-type electrodes improved the local electric field near the electrode’s sharp edge. Both effects positively enhanced the process of converting CO2 (Fig. 9).

Standardized coefficients for various processing parameters for (left) CO2 conversion and (right) energy efficiency. Reprinted from the reference Mei and Tu (2017) with the permission of Elsevier

Xu et al. (2017) reported the CO2 dissociation in NTP at atmospheric pressure using a reactor packed with BaTiO3 packing to investigate the potential impacts of CO2 dilution with nitrogen (N2) and argon (Ar). The results showed that the packing material composed of BaTiO3 ferroelectric in contact with the electrodes facilitated the conversion of CO2 with higher yield and the process energy efficiency compared to the DBD reactor with and without packing materials using dielectric layer–covered electrodes. Based on their operating conditions, the CO2 dissociation was unaffected and remained constant despite the input energy. Thus, the packing material composed of BaTiO3 ferroelectric, together with the NTP atmospheric pressure system for CO2 dissociation, was found to be a potential and powerful alternative to CO2 utilization compared to thermal catalysis, in terms of energy efficiency, process economics, and scale-up configurations. In addition to the above discussion, the influence of feed CO2 dilution with N2 and Ar showed a positive impact by increasing CO2 conversion by reducing the breakdown voltage at a given energy input for the dissociation of CO2, resulting in a simplifying NTP process design in terms of power supply. O2 and CO were the significant products identified in the process of dissociation of CO2. At the same time, a trace amount of ozone (O3) was also detected (maximum 100 ppm) in the case of pure CO2 and Ar/CO2 systems but was not observed in the case of the N2/CO2 system. It has been found that the higher dilution of the CO2 feed with Ar results in higher production of atomic oxygen that leads to a higher concentration of O3, but at the same time, a temperature rise caused by the higher input of the plasma energy results in O3 dissociation. However, as mentioned above, there was no O3 in the N2/CO2 system, and nitrogen oxides (N2O, NO2, and NO) were identified up to a maximum of 3120 ppm. Based on their proposed mechanism, except for higher plasma energies, the N2O formation is generally favored compared to NOX. In the meantime, the higher contents of N2 facilitate the NO2 conversion to NO and NO conversion to N2.

In another similar study (Yap et al. 2015), the effect of CO2 dilution using and without the helium (He) was explored experimentally in the plasma catalysis CO2 conversion process to CO and O2 using glass balls filled with a non-thermal plasma reactor and two different generator supplies. It has been found that the sinusoidal excitation-based discharge generation was much more effective for dissociating CO2 than the pulsed generator discharge at an equivalent input power. At specific input energy (40 kJ/mole), 7.5% of CO2 conversion was obtained with the pulsed supply while 13.5% with the sinusoidal excitation with a dilution ratio of He/CO2 = 1/1. The kinetic investigations revealed the first-order kinetics, but the rate constant significantly differed in the two generator types. From the mechanistic point of view, the CO2 dilution with He favors the CO2 conversion to CO, particularly in the case of AC sinus activation, which produces mainly species possessing vibrational excitation. However, pure CO2 demonstrated remarkable efficiency in both types of power supply. It has been found that the CO selectivity and the carbon balance were maximal with the He dilution. At the same time, there was an issue with the carbon deposition in the case of a pure CO2 system without dilution. Large cubic and spherical particles with carbon filaments that were several tens of micrometers long were identified. They have demonstrated for the first time that carbon atoms can also be merged into the silica network of the glass under the NTP discharge during the dissociation of the CO2 process, indicating a higher energetic process in plasma. The CO2 conversion remains constant, but the CO selectivity improved by controlling the reactor wall temperature, and the lower temperature favors the higher CO selectivity, indicating that the carbon balance is because of the decomposition of CO on the reactor walls.

Butterworth et al. (2016) reported the potential impacts of the particle size of the two distinct packing materials (BaTiO3 and Al2O3) on CO2 conversion to O2 and CO in the packed bed reactor assisted by plasma catalysis. It has been found that the reduced particle size of the packing materials (180–300 µm) could enhance the conversion of CO2 by 70% and also enhance the incidence of reactor partial discharging and reactor breakdown voltage. The term “partial discharging” represents a decline in the reactor fraction where the plasma formation occurs, usually initiated by insufficient applied electric field strength, subsequently reducing the reactor efficacy. Hence, partial discharging can be prevented by providing excessive electric fields in the reactor consuming voltage. For a fair comparative analysis, it should be noted that the comparison of packing materials should be investigated only when the partial discharge is shallow; otherwise, effective materials for reactor packing might be unconsciously neglected. Peeters and van de Sanden developed Lissajous figures based on the partial discharging equivalent circuit that could be used to quantify partial discharging and reactor burning voltage (Peeters and Sanden 2014). In another work (Paulussen et al. 2010), it has been experimentally revealed that the CO2 feed flow rate is the utmost critical parameter influencing the conversion of CO2 and the yield of CO, which is usually higher at a lower CO2 feed flow rate. Additionally, the influence of temperature directly impacts CO2 conversion, but CO yield is limited.

CO2 hydrogenation

Wang et al. (2018a) investigated the hydrogenation of CO2 over the hybrid catalyst-based NTP by considering the different parametric effects, including reactor design, reactant composition, and catalyst effect. Initially, they developed three different types of DBD reactor arrangements depending on the construction materials for the ground electrode and higher voltage electrode known as reactor-I (aluminum foil with stainless steel (SS) rod), reactor-II (water with SS rod covered by the quartz tube), and reactor-III (water with SS rod). Based on the design of different reactors, it has been found that the overall CO2 conversion was quite similar, but the product distribution varied widely. In all reactors, methanol and ethanol were identified as the major oxygenated products, while CO and CH4 were the most significant gaseous products. It has been found that reactor III produced the highest methanol compared to reactors I and II, while reactor I resulted in the highest CO selectivity. The significant increase in the methanol production and selectivity using reactor-III could be directed to the water used as a ground electrode instead of aluminum foil, which successfully maintained the temperature. The CO selectivity in reactor-III was the lowest among the three reactors, possibly due to the highest conversion of CO to methanol. As reactor-II and reactor-III operated at lower temperatures, higher activity was observed with oxygenate formation (CH3OH). CO was the dominant product in reactor-I due to high-temperature operation. Another advantage of reactor-II and reactor-III at lower temperature operation was that they inhibited the further decomposition of CH3OH (Wang et al. 2023b). Reactor III demonstrated the best performance even though high voltage was applied in reactors I and II. The better performance of reactor III was related to the domination of strong filaments, which were much weaker in reactor II. The feed molar ratio with the catalyst was also investigated in their work. It is an admitted fact and observed in their study that the feed molar ratio, i.e., CO2:H2, significantly influences the methanol conversion, concentration, and yield. By increasing the hydrogen ratio over CO2, it has been found that the overall methanol conversion increases with a decrease in the CO selectivity, indicating the forward reaction. In addition to the feed molar ratio, the effect of catalysts was also studied. Two different catalysts, Pt/Al2O3 and Cu/Al2O3, were employed for efficient H2 and CO2 activation, respectively. The results revealed that the Cu/Al2O3 catalyst demonstrated better performance towards methanol production than the Pt/Al2O3 catalyst.

It has been known that molecular adsorption depends on the molecule-catalyst interaction, and it is not supposed to be a spontaneous process. Due to the higher internal energy of CO2 (v), its adsorption is preferred energetically compared to the CO2 in its ground state. However, the plasma characteristics influence the CO2 (v) adsorption, including the electron energy and electric field (Wang et al. 2017b). Based on the previously reported studies on CH4 conversion using the plasma-catalysis system, the efficient adsorption of CH4 (v) species on the Ni metal surface was the origin of the higher CH4 conversion compared to the thermochemical process of steam methane reforming. Quantitatively, the CH4 conversion was 50% and 20% in the plasma-catalysis and thermochemical conversion processes, respectively (Nozaki et al. 2004). Furthermore, it has been found that the CO2 (v) adsorption onto the surface of the catalyst resulted in the dissipation of the CO2 (v) energy to the catalyst, leading to the Auger de-excitation and formation of low-energy electron-hole pairs, which could alter the physical and chemical characteristics of the catalyst, including the electronic structure, to make it more active and trigger the CO2 (ad) to form HOCO (ad) and HCOO (ad). Additionally, the RWGS can also occur at the surface of the catalyst, preceding the production of CO (ad) from CO2 (ad), which could be the possible reason for the enhanced formation of CO when plasma reactors are packed with the catalysts (Porosoff et al. 2016).

Comparing the catalyst performance in the plasma-catalysis mode, it has been found that Cu/γ-Al2O3 demonstrated better performance in terms of synthesis of methanol (yield) than Pt/γ-Al2O3 with almost identical OES CO2/H2 discharge spectra, indicating that the physical and chemical characteristics of the catalysts were more dominant to determine their different reaction performances. It has also been found that the Cu nanoparticle size in Cu/γ-Al2O3 was considerably more significant than the Pt nanoparticle size in Pt/γ-Al2O3. However, better performance for methanol synthesis was observed for Cu/γ-Al2O3 rather than Pt/γ-Al2O3, indicating that the particle size was not the dominant factor in determining the catalyst performance. At the same time, the x-ray diffraction (XRD) analysis of the spent catalyst demonstrated that the Cu in the metallic state was the dominant phase over the catalyst’s surface, a highly active site for the hydrogenation of CO2 to methanol. Compared to the active metal particle size, the oxygen-based intermediates (ΔEo) adsorption energy over the active metal surface was the dominant parameter related to the catalyst performance for the hydrogenation of CO2 to CH3OH. Based on the theoretical investigation, a volcano chart was developed, which showed that the elements located on the volcano top would favor the hydrogenation of CO2 to methanol. Cu is found to be on the top of the volcano, indicating that Cu is the dominant catalyst over Pt and others for CO2 hydrogenation to methanol because it will moderately bind the oxygen-based intermediates at atmospheric pressure (Studt et al. 2014). In another study to investigate the CO2 hydrogenation mechanism over the Pt nanoparticles supported separately on SiO2 and TiO2, it has been found that probably due to the weaker CO2 binding to the catalyst, the Pt nanoparticles could not catalyze the reaction. However, once the CO2 hydrogenation to CO was initiated with the stabilization of CO2, the reaction proceeded via RWGR (Kattel et al. 2016). By using an in situ attenuated total reflection infrared (ATR-IR) spectroscopy, it has been found that the CO2 adsorption leads to the synthesis of carbonate-like species over the Pt/γ-Al2O3 and γ-Al2O3, which are subsequently hydrogenated to produce CO as a final product (Ferri et al. 2002). The abovementioned findings indicated why the Pt/γ-Al2O3 resulted in higher CO selectivity than the Cu/γ-Al2O3 or plasma-only mode.

CO2 to organic acids

Electrochemical reduction of CO2 (ITo et al. 1982) to produce carboxylic acids was investigated a long time ago by using the non-aqueous electrolytes composed of dimethyl sulfoxide (DMSO) as an aprotic solvent with tetraalkylammonium salts over different electrodes such as lead (Pd), indium (In), zinc (Zn), and strontium (Sn). Based on the experimental investigation, it has been found that oxalic acid was the dominant product of the CO2 electrochemical reduction with Pd electrodes. However, other higher carboxylic acids, including the propionic, glycolic, malonic, and n-butyric acids, were produced in addition to the formic acid at substantial concentrations in TEAP or TEABr/DMSO because oxalic, tartaric, and formic acids were found to be the dominant products in the case of TBABr/DMSO, with a negligible amount of other organic acids produced. CO was identified as a dominant product with a low oxalic, formic, malonic, and glycolic acid concentration in the Zn, Sn, and In electrodes. Based on experimental evidence, it has been confirmed that oxalic acid as an intermediate pathway can be used to produce the higher carboxylic acids mentioned above through CO2 cathodic reduction.

Recently, the electrochemical CO2 reduction to produce formate and oxalate facilitated by the solvated electrons produced by the plasma operated at atmospheric pressure was examined (Rumbach et al. 2016). In this work, the optical absorbance measurements were employed to visualize the solvation of free electrons produced by the plasma at atmospheric pressure into the solution to reduce the aqueous CO2 to carboxyl radical anion, i.e., CO2− (aq.). It was found that most of the CO2− (aq.) ions were typically recombined to produce oxalate under basic conditions. In contrast, some of them produced formate following the disproportionation mechanism with the kinetics of this reduction reaction, such as bulk kinetics in radiolysis experimentations. The formate was found to be the dominant species under strongly acidic conditions. Higher concentrations of dissolved CO2 could help improve the process efficiency, but there will be a trade-off between the oxalate and formate yields due to pH. In another similar work (Ihara et al. 1994), the reverse combustion, i.e., the reduction of CO2 in water assisted by plasma, was investigated, and the oxalic acid with hydrogen peroxide (H2O2) was identified as a significant product with low yield with no formation of alcohol or mixture of acids.

One-step CO2–CH4 reforming to liquid chemicals

Wang et al. (2017c) investigated the one-step CO2–CH4 reforming into a series of liquids (CH3COOH, CH3OH, C2H5OH, and C3H6O), with CH3COOH as the dominant product. A trace amount of HCOOH, propanol (C3H8O), and butanol (C4H9OH) were also identified. The gaseous products included H2, CO, and CxHy (where x = 2–4 and y = 2–10). In this reaction, it was found that the catalyst could not trigger the reaction at 30 °C. At the same time, the NTP assisted the unfavorable reaction, i.e., thermodynamics, in proceeding at ambient temperature. It was observed that combining the catalyst with the plasma could help employ the synthesis and distribution of various oxygenates under ambient reaction conditions. CH3COOH was the dominant product, and whatever catalyst was employed for this reaction was followed by CH3OH and C2H5OH. HCOOH was formed only in the case of catalysts supported by noble metals with the highest selectivity over the Pt/γ-Al2O3. The distribution of the gaseous product was not influenced by adding the catalyst into the plasma-only mode, with CO, H2, and C2H6 being dominant gaseous products. In hybrid plasma catalysis mode, the H2 selectivity was found to be enhanced with slightly increased productivity of C2H6 with a weak influence on the enhancement of selectivity for CO and other CxHy (where, x = 2–4 and y = 2–10) except for the catalyst (Cu/γ-Al2O3). The CO2 and CH4 conversion decreased slightly in the hybrid plasma catalysis mode compared to the plasma-only mode. It could be due to the variation in the discharge behavior prompted by the catalyst that has an adverse impact on the reaction. Remarkably, a chemical, C6H12O4 (CAS No. 49653-17-0), was identified on the inner walls of the reactor in the hybrid plasma catalysis mode. The proposed experimental setup directly reformed CO2–CH4 into a series of gaseous and liquid chemicals at ambient reaction conditions, bypassing the syngas formation.

Li et al. (2023) reported an experimental study to synthesize H2 and liquid fuels using hybrid plasma catalysis-driven one-step CO2–CH4 reforming using a Fe- and Cu-based active site catalyst supported on 5A zeolite. The process resulted in a one-stage CO2–CH4 mixture co-conversion into liquid chemicals and H2 due to the strong cooperative effect of the Fe/Cu active sites with the externally applied plasma field. In the case of gaseous products such as CO and H2, the selectivity was found to be enhanced (36 to 56.6% for H2 and 50 to 57.6% for CO) with the addition of H2O, which could be related to the improved radical density of OH and H. In the case of liquid fuels such as CH3OH and acetic acid (CH3COOH), a strong cooperative effect between the plasma and the acid/base characteristics of the employed catalyst was observed with varied selectivity of the liquid chemicals. A combined in situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) with OES was used to investigate the role of active sites and the possible mechanistic pathways. It was found that the Cu/5A zeolite with a higher density of acidic sites significantly facilitated the production of different carbonate species, which further played their critical role in the synthesis of CHxO and further CH3OH by the recombination of CHxO with gaseous H2. It was found that the COOH generated from both processes, i.e., recombination of gaseous OH with CO and CO2 protonation, was the key to producing CH3COOH. It was interesting to know that the Cu/5A zeolites (Cu0) with a higher acidic sites density and the Fe/5A zeolites (Fe2+) with a higher density of basic sites favored the formation of CH3OH and CH3COOH, respectively (Fig. 10). In addition to the experimental demonstration, the adsorption energy differences–based density functional theory (DFT) calculations for the O-containing radicals showed crucial interactions with the varied charge transfer between the active sites, i.e., Cu (111) surfaces and the gaseous radicals, thus leading to the formation of targeted products. As discussed in this review, a detailed comparison of the plasma- and plasma-catalysis–based CO2 conversion routes to C1 products is tabulated in Table 3 with experimental setup and reaction conditions.

a Energy density difference for the CH3, COOH, OH radicals with Cu (111) surface; b essential radicals’ density as a function of the time during the five periods for the CO2–CH4–H2O plasma; and c the discriminative formation of CH3OH and CH3COOH over Cu/5A and Fe/5A, respectively, via a synergistic plasma-catalyst effects. Reprinted from the reference Li et al. (2023) with the permission of Elsevier

Conclusions and future recommendations

This review comprehensively analyzed and compared the fundamentals of plasma technology for converting CO2 to fuel-graded and value-added products with other conventional CO2 conversion technologies. A detailed discussion was conducted on the different types of plasma, and their comparisons based on their characteristics, operational conditions, and performance were also reviewed, as well as various configurations of the plasma reactors. Critical discussions on plasma catalysis for CO2 conversion were presented. Some challenges in this field are identified and provided below:

-

CO2 circular economy: CO2 is essential for life on Earth; however, the exponential growth of gases after industrialization has resulted in excessive CO2 in the Earth’s atmosphere. The circular carbon economy is a crucial concept for addressing the issue of excessive CO2 emissions worldwide. A circular carbon economy is a conceptual structure to regulate and minimize emissions. The closed-loop system incorporates the 4Rs: reduce, reuse, recycle, and remove.

-

CO2 reduction in H2O: It is essential to investigate the reaction mechanism and the process parameters that lead to the H2O dissociation in the plasma and the plasma-catalysis systems. Further studies are recommended to determine the vibrational and electron temperatures. For economic feasibility, it is essential to perform real-time optimization of the discharge parameters, including pulse frequency and duration, as it is believed that optimizing these parameters will positively affect energy efficiency. Adding H2O weakens the discharge, so experimental studies are required to investigate the Ar effects in the gas mixture, which could be beneficial to sustain the discharge. To further improve conversion and the energy efficiency of CO2 reduction in the H2O process, the impact of catalysts in plasma should be thoroughly investigated.

-

CH4 reforming with CO2 to syngas: It has been found that the selection of an efficient catalyst to get synergy with the plasma for higher conversion and energy efficiency is still inadequate, and more research is projected to overcome the conventional barriers and make a bridge between the thermal- and plasma-catalysis. It has been established that the metal-supported catalysts are promising candidates in plasma catalysis for the efficient CH4 reforming with CO2 to syngas, and there is room to develop multifunctional metal-supported catalysts such as bimetallic catalysts of monometallic catalysts in combination with some promoters. Such advanced and next-generation catalysts should be developed to achieve multiple targets simultaneously, including energy efficiency, enhanced conversion, selectivity, and a balanced CO/H2 ratio. Investigations on optimization of the discharge effects, input power, and feed flow conditions should be done as they could directly impact the syngas formation, electron density distribution, and conversion/selectivity. Research should be carried out comprehensively to inhibit the carbon deposition observed with higher feed concentrations of CH4 by introducing some oxygen to the system. In terms of energy efficiency, there is a need to find a way to inhibit water formation by understanding the mechanisms of water formation.

-

CO2 dissociation to CO: It has been suggested that the reaction parameters should be optimized to enhance CO2 dissociation in plasma catalysis. These parameters include but are not limited to the dielectric materials, the reactor’s geometrical configurations, the catalyst bed, and input power. To date, it has been demonstrated that using a DBD reactor, the CO2 dissociation is reasonable; however, the energy efficiency is still too low and needs significant improvement for commercialization if the electricity is produced from fossil fuels. However, having electricity from renewable sources might address the energy efficiency issue. Specifically, the effects of the co-reagents, such as CH4 or H2O, which are highly probable for the selective formation of value-added chemicals from CO2 dissociation, should be investigated using plasma catalysis.

-

CO2 hydrogenation: It is evident that the hydrogenation of CO2 to methanol in the plasma-catalysis system depends on a wide range of reactive species, which could initiate more reaction routes for methanol formation. A detailed investigation should be carried out to govern the interaction between the active sites on the catalyst and the reaction intermediates. The final product selectivity cannot be determined without first determining the adsorption energies of the oxygen-based reaction intermediates to the catalyst surface.

-

CO2 to organic acids: More comprehensive research is necessary to deliberate the possible reaction mechanistic pathways of CO2 conversion to organic acids, such as formic, acetic, and oxalic acid, in connection with the plasma-catalysis synergistic effects. In this regard, developing next-generation multifunctional catalysts for CO2 reduction and the coupling of C–C simultaneously is required. The impact of either with or without base use should be investigated regarding product distribution and reaction efficiency.

-

One-step CO2–CH4 reforming to liquid chemicals: Considering the C1 products, such as methanol, the bond energies of C–O (326 kJ/mole) and C–H (416 kJ/mole) in methanol and CH4, respectively, suggest that the methanol is less stable in plasma than CH4, thus pointing to the need for more fundamental research regarding the potential role of CH2O and methanol as reaction intermediates in plasma-catalysis. Developing next-generation selective and efficient catalysts that could produce multi-carbon products from CO2 conversion in plasma catalysis is necessary. Thus, parallel process optimization is required for energy efficiency.

Data availability

Not applicable.

References

Akbari E, Alavi SM, Rezaei M (2017) Synthesis gas production over highly active and stable nanostructured NiMgOAl2O3 catalysts in dry reforming of methane: effects of Ni contents. Fuel 194:171–179

Aramouni NAK, Touma JG, Tarboush BA, Zeaiter J, Ahmad MN (2018) Catalyst design for dry reforming of methane: analysis review. Renewable Sustain Energy Rev 82:2570–2585

Arumugam S, Prince A, Sinha SK (2018) Feedback model of secondary electron emission in DC gas discharge plasmas. Plasma Sci Technol 20:025404

Ashford B, Tu X (2017) Non-thermal plasma technology for the conversion of CO2. Curr Opinion in Green Sustain Chem 3:45–49

Azizov RI, Vakar AK, Zhivotov VK, Krotov MF, Zinovev OA, Potapkin BV, Rusanov AA, Rusanov VD, Fridman AAE (1983) Nonequilibrium plasmachemical process of CO2 decomposition in a supersonic microwave discharge. In: Akademiia Nauk SSSR Doklady, vol 271. pp 94–98

Bo Z, Yang S, Kong J, Zhu J, Wang Y, Yang H, Li X, Yan J, Cen K, Tu X (2020) Solar-enhanced plasma-catalytic oxidation of toluene over a bifunctional graphene fin foam decorated with nanofin-like MnO2. ACS catalysis 10:4420–4432

Bogaerts A, Centi G (2020) Plasma technology for CO2 conversion: a personal perspective on prospects and gaps. Front Energy Res 8:111

Bogaerts A, Neyts EC (2018) Plasma technology: an emerging technology for energy storage. ACS Energy Lett 3:1013–1027

Bogaerts A, Kozák T, Van Laer K, Snoeckx R (2015) Plasma-based conversion of CO 2: current status and future challenges. Faraday Discuss 183:217–232

Bogaerts A, Snoeckx R (2019) Plasma-based CO 2 conversion. An economy based on carbon dioxide and water: potential of large scale carbon dioxide utilization, 287-325

Bongers W, Bouwmeester H, Wolf B, Peeters F, Welzel S, van den Bekerom D, den Harder N, Goede A, Graswinckel M, Groen PW (2017) Plasma-driven dissociation of CO2 for fuel synthesis. Plasma Process Polym 14:1600126

Britun N, Chen G, Silva T, Godfroid T, Delplancke‐Ogletree M‐P, Snyders R (2017) Enhancing the greenhouse gas conversion efficiency in microwave discharges by power modulation. Green chemical processing and synthesis. IntechOpen

Butterworth T, Elder R, Allen R (2016) Effects of particle size on CO2 reduction and discharge characteristics in a packed bed plasma reactor. Chem Eng J 293:55–67

Chen G, Silva T, Georgieva V, Godfroid T, Britun N, Snyders R, Delplancke-Ogletree MP (2015) Simultaneous dissociation of CO2 and H2O to syngas in a surface-wave microwave discharge. Int J Hydrogen Energy 40:3789–3796

Chen G, Snyders R, Britun N (2021) CO2 conversion using catalyst-free and catalyst-assisted plasma-processes: Recent progress and understanding. Journal of CO2 Utilization 49:101557

Cooley S, Schoeman D, Bopp L, Boyd P, Donner S, Ghebrehiwet DY, Ito S-I, Kiessling W, Martinetto P, Ojea E, Racault M-F, Rost B, Skern-Mauritzen M (2022) Oceans and coastal ecosystems and their services. In: Pörtner H-O, Roberts DC, Tignor M, Poloczanska ES, Mintenbeck K, Alegría A, Craig M, Langsdorf S, Löschke S, Möller V, Okem A, Rama B (eds) Climate change 2022: Impacts, adaptation and vulnerability. Contribution of working group II to the sixth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge, UK and New York, NY, USA, pp 379–550. https://doi.org/10.1017/9781009325844.005

Di L, Zhang J, Ma C, Tu X, Zhang X (2019) Atmospheric-pressure dielectric barrier discharge cold plasma for synthesizing high performance Pd/C formic acid dehydrogenation catalyst. Catalysis Today 337:201–207

Ferri D, Bürgi T, Baiker A (2002) Probing boundary sites on a Pt/Al 2 O 3 model catalyst by CO 2 hydrogenation and in situ ATR-IR spectroscopy of catalytic solid–liquid interfaces. Phys Chem Chem Phys 4:2667–2672

Fridman A (2008) Plasma chemistry. Cambridge University Press

George A, Shen B, Craven M, Wang Y, Kang D, Wu C, Tu X (2021) A review of non-thermal plasma technology: a novel solution for CO2 conversion and utilization. Renewable Sustain Energy Rev 135:109702

Ghorbanzadeh A, Lotfalipour R, Rezaei S (2009) Carbon dioxide reforming of methane at near room temperature in low energy pulsed plasma. Int J Hydrogen Energy 34:293–298

Goeppert A, Czaun M, Jones J-P, Prakash GS, Olah GA (2014) Recycling of carbon dioxide to methanol and derived products–closing the loop. Chem Soc Rev 43:7995–8048

Goujard V, Tatibouët J-M, Batiot-Dupeyrat C (2009) Use of a non-thermal plasma for the production of synthesis gas from biogas. Applied Catalysis A: General 353:228–235

Hecimovic A, Mayer M, de Haart L, Gupta S, Kiefer C, Navarrete A, Schulz A, Fantz U (2024) Benchmarking microwave-induced CO2 plasma splitting against electrochemical CO2 reduction for a comparison of promising technologies. J CO2 Utilization 83: 102825

Hoeben W, Van Heesch E, Beckers F, Boekhoven W, Pemen A (2015) Plasma-driven water assisted CO 2 methanation. IEEE Trans Plasma Sci 43:1954–1958

Hong YC, Uhm HS, Chun BJ, Lee SK, Hwang SK, Kim DS (2006) Microwave plasma torch abatement of NF3 and SF6. Physics of Plasmas 13:3

Hopwood J (1992) Review of inductively coupled plasmas for plasma processing. Plasma Sources Science and Technology 1:109

Houghton JT, Ding Y, Griggs DJ, Noguer M, van der Linden PJ, Dai X, Maskell K, Johnson CA (2001) Climate change 2001: the scientific basis, 881. Cambridge university press Cambridge

Hrycak B, Czylkowski D, Miotk R, Dors M, Jasinski M, Mizeraczyk J (2014) Application of atmospheric pressure microwave plasma source for hydrogen production from ethanol. Int J Hydrogen Energy 39:14184–14190

Huang A, Xia G, Wang J, Suib SL, Hayashi Y, Matsumoto H (2000) CO2 reforming of CH4 by atmospheric pressure ac discharge plasmas. J Catalysis 189:349–359

Ihara T, Kiboku M, Iriyama Y (1994) Plasma reduction of CO2 with H2O for the formation of organic compounds. Bull Chem Soc Japan 67:312–314

Ito K, Ikeda S, Iida T, Nomura A (1982) Electrochemical reduction of carbon dioxide dissolved under high pressure III. In Non-aqueous Electrolytes. Denki Kagaku oyobi Kogyo Butsuri Kagaku 50:463–469

Jasiński M, Czylkowski D, Hrycak B, Dors M, Mizeraczyk J (2013) Atmospheric pressure microwave plasma source for hydrogen production. Int J Hydrogen Energy 38:11473–11483

Kattel S, Yan B, Chen JG, Liu P (2016) CO2 hydrogenation on Pt, Pt/SiO2 and Pt/TiO2: importance of synergy between Pt and oxide support. J Catalysis 343:115–126

Khoja AH, Tahir M, Amin NAS (2018) Cold plasma dielectric barrier discharge reactor for dry reforming of methane over Ni/ɤ-Al2O3-MgO nanocomposite. Fuel Processing Technol 178:166–179

Kiruthika M, Shanmugavelayutham G (2020) Characteristics of anodic glow pulsed plasma. Physics Lett A 384:126040

Kutz M (ed) (2011) Applied plastics engineering handbook: processing and materials. William Andrew

Kwak HS, Uhm HS, Hong YC, Choi EH (2015) Disintegration of carbon dioxide molecules in a microwave plasma torch. Sci Rep 5:18436

Legasov VA, Zhivotov VK, Krasheninnikov EG, Kroto MF, Patrushev BI, Rusanov VD, Rykunov GV, Spektor AM, Fridman AA, Shoiin GV (1978) A nonequilibrium plasma-chemical process of CO 2 dissociation in highfrequency and ultrahigh-frequency discharges. In Soviet Physics Doklady 23:44

Li Y, Liu C-J, Eliasson B, Wang Y (2002) Synthesis of oxygenates and higher hydrocarbons directly from methane and carbon dioxide using dielectric-barrier discharges: product distribution. Energy Fuels 16:864–870

Li J, Dou L, Liu Y, Gao Y, Hu X, Yu F, Li J, Zhang S, Shao T (2023) One-step plasma reforming of CO2CH4 into hydrogen and liquid fuels: the roles of Cu and Fe sites on products distribution. Fuel Process Technol 242:107648

Li L, Zhang H, Li X, Kong X, Xu R, Tay K, Tu X (2019) Plasma-assisted CO2 conversion in a gliding arc discharge: improving performance by optimizing the reactor design. JCO2 Utilization 29, 296-303

Li L, Zhang H, Li X, Huang J, Kong X, Xu R, Tu X (2020) Magnetically enhanced gliding arc discharge for CO2 activation. J CO2 Utilization 35: 28-37

Loenders B, Michiels R, Bogaerts A (2023) Is a catalyst always beneficial in plasma catalysis? Insights from the many physical and chemical interactions. J Energy Chem 85:501–533

Lu N, Bao X, Jiang N, Shang K, Li J, Wu Y (2017) Non-thermal plasma-assisted catalytic dry reforming of methane and carbon dioxide over GC 3 N 4-based catalyst. Topics Catalysis 60:855–868

Mehta P, Barboun P, Go DB, Hicks JC, Schneider WF (2019) Catalysis enabled by plasma activation of strong chemical bonds: a review. ACS Energy Lett 4:1115–1133

Mei D, Zhu X, He Y-L, Yan JD, Tu X (2014) Plasma-assisted conversion of CO2 in a dielectric barrier discharge reactor: understanding the effect of packing materials. Plasma Sources Sci Technol 24:015011

Mei D, Tu X (2017) Conversion of CO2 in a cylindrical dielectric barrier discharge reactor: effects of plasma processing parameters and reactor design. J CO2 Utilization 19: 68-78

Messaoudi H, Thomas S, Djaidja A, Slyemi S, Barama A (2018) Study of LaxNiOy and LaxNiOy/MgAl2O4 catalysts in dry reforming of methane. J CO2 Utilization 24: 40-49

Michielsen I, Uytdenhouwen Y, Pype J, Michielsen B, Mertens J, Reniers F, Meynen V, Bogaerts A (2017) CO2 dissociation in a packed bed DBD reactor: first steps towards a better understanding of plasma catalysis. Chem Eng J 326:477–488

Mikoviny T, Kocan M, Matejcik S, Mason N, Skalny J (2003) Experimental study of negative corona discharge in pure carbon dioxide and its mixtures with oxygen. J Phys D: Appl Phys 37:64

Mizeraczyk J, Urashima K, Jasiński M, Dors M (2014) Hydrogen production from gaseous fuels by plasmas—a review. Int J Plasma Environ Sci Technol 8:89–97

Neyts EC, Ostrikov K, Sunkara MK, Bogaerts A (2015) Plasma catalysis: synergistic effects at the nanoscale. Chem Rev 115:13408–13446

Nguyen HH, Nasonova A, Nah IW, Kim K-S (2015) Analysis on CO2 reforming of CH4 by corona discharge process for various process variables. J Industrial Eng Chem 32:58–62

Nguyen SCVT (2009) Hydrogen production in a radio-frequency plasma source operating on water vapor (Doctoral dissertation)

Nozaki T, Muto N, Kadio S, Okazaki K (2004) Dissociation of vibrationally excited methane on Ni catalyst: Part 2. Process diagnostics by emission spectroscopy. Catalysis Today 89:67–74

Nunnally T, Gutsol K, Rabinovich A, Fridman A, Gutsol A, Kemoun A (2011) Dissociation of CO2 in a low current gliding arc plasmatron. J Phys D: Appl Phys 44:274009

Okubo M, Takahashi K, Kamiya S, Kuroki T (2018) High-efficiency carbon dioxide reduction using nonthermal plasma desorption. IEEE Trans Industry Appl 54:6422–6429

Okumura T (2010) Inductively coupled plasma sources and applications. Physics Research International 2010(1):164249

Ollegott K, Wirth P, Oberste-Beulmann C, Awakowicz P, Muhler M (2020) Fundamental properties and applications of dielectric barrier discharges in plasma-catalytic processes at atmospheric pressure. Chemie Ingenieur Technik 92:1542–1558

Ong M, Nomanbhay S, Kusumo F, Show P (2022) Application of microwave plasma technology to convert carbon dioxide (CO2) into high value products: a review. J Clean Production 336:130447

Pakhare D, Spivey J (2014) A review of dry (CO 2) reforming of methane over noble metal catalysts. Chem Soc Rev 43:7813–7837

Park J, Henins I, Herrmann H, Selwyn G (2001) Gas breakdown in an atmospheric pressure radio-frequency capacitive plasma source. J Appl Phys 89:15–19

Patiño P, Perez Y, Caetano M (2005a) Coupling and reforming of methane by means of low pressure radio-frequency plasmas. Fuel 84:2008–2014

Patiño P, Pérez Y, Caetano M (2005b) Coupling and reforming of methane by means of low pressure radio-frequency plasmas. Fuel 84:2008–2014

Paulussen S, Verheyde B, Tu X, De Bie C, Martens T, Petrovic D, Bogaerts A, Sels B (2010) Conversion of carbon dioxide to value-added chemicals in atmospheric pressure dielectric barrier discharges. Plasma Sources Sci Technol 19:034015

Peeters F, Van de Sanden M (2014) The influence of partial surface discharging on the electrical characterization of DBDs. Plasma Sources Sci Technol 24:015016

Porosoff MD, Yan B, Chen JG (2016) Catalytic reduction of CO 2 by H 2 for synthesis of CO, methanol and hydrocarbons: challenges and opportunities. Energy Environ Sci 9:62–73

Puliyalil H, Jurković DL, Dasireddy VD, Likozar B (2018) A review of plasma-assisted catalytic conversion of gaseous carbon dioxide and methane into value-added platform chemicals and fuels. RSC Adv 8:27481–27508

Qi C, Wei D, Xumei T, Hui Y, Xiaoyan D, Yongxiang Y (2006) CO2 reforming of CH4 by atmospheric pressure abnormal glow plasma. Plasma Sci Technol 8:181

Ramakers M, Trenchev G, Heijkers S, Wang W, Bogaerts A (2017) Gliding arc plasmatron: providing an alternative method for carbon dioxide conversion. ChemSusChem 10:2642–2652

Ray D, Reddy PMK, Subrahmanyam C (2018) Ni-Mn/γ-Al2O3 assisted plasma dry reforming of methane. Catalysis Today 309:212–218

Rumbach P, Xu R, Go DB (2016) Electrochemical production of oxalate and formate from CO2 by solvated electrons produced using an atmospheric-pressure plasma. J Electrochem Soc 163:F1157

Scapinello M, Martini LM, Dilecce G, Tosi P (2016) Conversion of CH4/CO2 by a nanosecond repetitively pulsed discharge. J Phys D: Appl Phys 49:075602

Schutze A, Jeong JY, Babayan SE, Park J, Selwyn GS, Hicks RF (1998) The atmospheric-pressure plasma jet: a review and comparison to other plasma sources. IEEE Trans Plasma Sci 26:1685–1694

Snoeckx R, Bogaerts A (2017) Plasma technology–a novel solution for CO 2 conversion? Chem Soc Rev 46:5805–5863

Snoeckx R, Zeng Y, Tu X, Bogaerts A (2015) Plasma-based dry reforming: improving the conversion and energy efficiency in a dielectric barrier discharge. RSC Adv 5:29799–29808

Spencer LF, Gallimore AD (2011) Efficiency of CO 2 dissociation in a radio-frequency discharge. Plasma Chem Plasma Process 31:79–89

Studt F, Sharafutdinov I, Abild-Pedersen F, Elkjær CF, Hummelshøj JS, Dahl S, Chorkendorff I, Nørskov JK (2014) Discovery of a Ni-Ga catalyst for carbon dioxide reduction to methanol. Nature Chem 6:320–324

Sun Y, Liu X, Zhu M, Zhang Z, Chen Z, Wang S, Ji Z, Yang H, Wang X (2023) Non-noble metal single atom-based catalysts for electrochemical reduction of CO2: synthesis approaches and performance evaluation. DeCarbon 2:100018

Tao X, Bai M, Li X, Long H, Shang S, Yin Y, Dai X (2011) CH4–CO2 reforming by plasma–challenges and opportunities. Progress in Energy Combustion Sci 37:113–124

Tcvetkov P, Cherepovitsyn A, Fedoseev S (2019) The changing role of CO2 in the transition to a circular economy: review of carbon sequestration projects. Sustainability 11:5834

Tebbiche I, Mocellin J, Huong LT, Pasquier LC (2021) Circular Economy and carbon capture, utilization, and storage. Biomass, Biofuels, Biochemicals. Elsevier, pp 813–851

Trenchev G, Bogaerts A (2020) Dual-vortex plasmatron: a novel plasma source for CO2 conversion. J CO2 Utilization 39: 101152

Tu X, Whitehead J (2012) Plasma-catalytic dry reforming of methane in an atmospheric dielectric barrier discharge: understanding the synergistic effect at low temperature. Appl Catalysis B: Environ 125:439–448

Tu X, Whitehead JC (2014) Plasma dry reforming of methane in an atmospheric pressure AC gliding arc discharge: co-generation of syngas and carbon nanomaterials. Int J Hydrogen Energy 39:9658–9669

Tu X, Gallon HJ, Twigg MV, Gorry PA, Whitehead JC (2011) Dry reforming of methane over a Ni/Al2O3 catalyst in a coaxial dielectric barrier discharge reactor. J Phys D: Appl Phys 44:274007

Tu X, Gallon H, Whitehead J (2013) Plasma-assisted reduction of a NiO/Al2O3 catalyst in atmospheric pressure H2/Ar dielectric barrier discharge. Catalysis Today 211:120–125

Tu X, Whitehead JC, Nozaki T (2019) Plasma catalysis: fundamentals and applications. Springer

van den Bekerom DC, Linares JP, Verreycken T, Van Veldhuizen EM, Nijdam S, Berden G, Bongers WA, Van De Sanden M, van Rooij GJ (2019) The importance of thermal dissociation in CO2 microwave discharges investigated by power pulsing and rotational Raman scattering. Plasma Sources Sci Technol 28:055015

Wang L, Dinescu G, Deng X, Ionita E-R, Leys C, Nikiforov AY (2017a) Mechanisms of sustaining a radio-frequency atmospheric pressure planar discharge. Plasma Sources Sci Technol 26:075012

Wang L, Yi Y, Guo Y, Zhao Y, Zhang J, Guo H (2017b) Synergy of DBD plasma and Fe-based catalyst in NH3 decomposition: plasma enhancing adsorption step. Plasma Processes Polym 14:1600111