Abstract

Growing concern about the environmental effects of metal mordants and synthetic dyes is encouraging the use of bio-mordants and natural colorants. Cinnamon bark is a rich source of natural colorants such as cinnamaldehyde and tannins. The main purpose of this research was to study and compare the effect of bio-mordants versus metal mordants in terms of colorimetric parameters and color fastness properties of cinnamon bark on wool fibers. Accordingly, some bio-mordants, including date kernel, peppermint, banana peel, and artemisia, as well as some metal mordants like aluminum potassium sulphate and copper sulphate, were studied based on three conventional mordanting methods (pre-, meta-, and post-mordanting). The results indicated that the conjunction of metal mordants and polyphenolic bio-mordants with cinnamon colorants can create different hues and tones of brown. Also, the color produced by cinnamon in wool fibers has poor color fastness and low color strength. Overall, bio-mordants have presented good color properties, making the dyeing process eco-friendly and greener. Among the applied bio-mordants, peppermint has created the best color strength and color fastness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural colorants derived from different parts of plants, insect secretions, and minerals were the only colorants available for dyeing textiles in ancient civilizations. With the discovery of synthetic dyes in 1856, the use of natural colorants declined gradually (Ahsan et al. 2020; Dikshit and Tallapragada 2018). The hazards associated with synthetic dyes, such as allergies, pollution, non-biodegradability, and toxicity, have renewed interest in natural coloring substitutes (Kiumarsi et al. 2017). Natural colorants are compatible with the environment. Also, they have excellent functional properties, such as antioxidant and antifungal (Adeel et al. 2020a). Apart from many advantages, some restrictions have also been detected, such as a lower fastness rating and a low color yield (Haji et al. 2018).

To solve the limitations, in previous research, the use of metal salts as a mordant between dyes and fibers has been suggested. Metal mordants have been traditionally applied to improve color fastness and creation of different shades of the same colorant (Kaur and Sharma 2017). However, residual metals in dyeing effluents, especially heavy metals, can remain in the soil, be absorbed by plants, accumulate in the food chain, and threaten human health and other living organisms (Malviya et al. 2023). In recent years, some researchers have suggested using natural materials as bio-mordants. They investigated the properties of textiles dyed with these types of mordants (Shahmoradi Ghaheh et al. 2021; Tehrani et al. 2023; Adeel et al. 2020b; Hosseinnezhad et al. 2021; Hosseinnezhad et al 2023; Teklemedhin and Gopalakrishnan 2018; Haji et al. 2023). According to many studies, bio-mordants are more eco-friendly and more effective to use than metal mordants. In addition, bio-mordants, such as extracts of pinecone, oak gall, orange peel, aloe vera, pomegranate, and sumac, not only gave new shades but also improved color fastness (Shahmoradi Ghaheh et al. 2021; Tehrani et al. 2023; Adeel et al. 2020b; Hosseinnezhad et al. 2021; Hosseinnezhad et al 2023; Teklemedhin and Gopalakrishnan 2018; Haji et al. 2023).

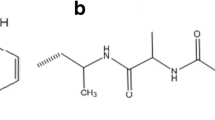

Cinnamomum verum is a small tree that grows naturally in forests in Sri Lanka, Cochin-China, Sumatra, and the Western Ghats of South India (Bakewell-Stone 2022; Al-Salmany and Saleh AL-Rubeii 2020). Cinnamon bark is a hardy species that has been used for thousands of years to enhance taste. Cinnamon bark has a wide range of potential health benefits and can be used in various applications, including food preservation and developing therapeutic interventions for diseases (Nam et al. 2020). Cinnamon bark contains more than 80 aromatic compounds such as flavonol, alkaloids, tannin, saponins, corvalol, terpenes, glycerol, cinnamaldehyde, cinnamyl acetate, nonanal, kaempferol, cinnamic acid, and eugenol (Muhammad and Dewettinck 2017; Gilani and Najafpour 2022; Knauth et al. 2018). Cinnamaldehyde (Fig. 1) and tannin are responsible for the color, which is used to color the matrix (Adeel et al. 2020b; Muhammad and Dewettinck 2017; Knauth et al. 2018). Tannins are colorless, yellow, and light brown. If tannin reacts with metal ions, its color will turn blueish-black. Also, if tannin is exposed to sunlight, it hydrolyzes, and its color turns dark brown (Luftinor and Kurniati 2020).

Chemical structure of the cinnamaldehyde (Knauth et al. 2018)

The presence of colorant structures in cinnamon bark has made some researchers use this substance as a natural colorant in fiber dyeing, especially natural fibers. Adeel and co-authors (Adeel et al. 2020b, 2021) used cinnamon bark as a natural colorant for dyeing silk and wool fibers. They concluded that the use of microwave treatment is a very favorable method for the isolation of dye molecules from cinnamon bark under specified conditions. Shahidi and co-authors (Shahidi et al. 2021) investigated the effect of turmeric, cinnamon, and saffron on the transmittance, UV protection, and antibacterial properties of cotton fabrics. Kusstianti and Surya focused on using cinnamon bark as a source of natural colorants for hair dyeing (Kusstianti et al. 2017; Surya et al. 2021). A review of the above research shows that limited studies have been done on the coloring properties of cinnamon bark.

Considering the importance of colored wool fibers in handwoven carpets and preventing the damage of synthetic dyes and heavy metals (metal mordants), in this research, the color and fastness properties of wool fibers dyed with cinnamon bark as a natural colorant and natural substance as a bio-mordant were investigated. To evaluate the impact of the used bio-mordants, the colorimetric and fastness properties of wool fibers dyed with these mordants were compared with those of metal mordants. The colorimetric characteristics of the dyed samples, including CIELAB and color strength, were measured using a reflectance spectrophotometer. Also, the washing and light fastness of the dyed samples were evaluated and compared using the ISO standard.

Materials and methods

Materials

One hundred percent pure semi-worsted wool yarn (200 tex/twofold and 100 TPM) used for dyeing was supplied by an Iranian company. Aluminum potassium sulphate (KAl(SO4)2), copper sulphate (CuSO4), acetic acid (CH3COOH), and ethanol (C2H6O) were purchased from Merck Co. (Germany).

Small pieces of cinnamon bark and bio-mordants such as date kernel, peppermint, banana peel, and artemisia were provided from the local market in Iran. Cinnamon bark, date kernel, peppermint, and banana peel were washed several times with distilled water to remove the dust particles and dried thoroughly. Then, the dried pieces were pulverized using an industrial milling machine.

Dye extraction procedures

The extraction of dye from cinnamon bark was done using the boiling method. Dye extraction was done in an 80% water/20% ethanol solvent in the Soxhlet apparatus at 60°C for 90 min. Subsequently, the solution was completely filtered using a Whatman filter No. 42. Based on previous studies; ethanol was used as a solvent in the extraction process because this chemical was more effective than water. It should be noted that ethanol is not harmful to the environment (Wong et al. 2014).

Dyeing procedure

Before starting the dyeing or mordanting procedure, wool fibers were immersed in an aqueous solution of non-ionic detergent (2 mL/L of Lissapol NC) for 30 min at a temperature of 60°C to remove dirt and swelling. After that, the cleaned fibers were washed thoroughly with tap water.

The wool fibers were mordanted by two metal salts, aluminum potassium sulphate (Al) and copper sulphate (Cu), and four bio-mordants, including date kernel, peppermint, banana peel, and artemisia. Three different mordanting processes have been used, which were: pre-, meta-, and post-mordanting methods. In the pre-mordanting method, the wool fibers were initially mordanted with the metal and bio-mordants in a concentration of 10% owf (copper sulphate in a concentration of 5% owf). Afterward, the mordanted samples were rinsed with water, squeezed, and then dyed with 50% owf of the extracted cinnamon bark. In the mordanting and dyeing steps, the substrate was immersed in the extracted cinnamon bark or mordant bath contained with 4% owf of acetic acid; the temperature was raised to 80°C and kept in that condition for 45 min. The meta-mordanting method was carried out by adding the mordant and the dye to the wool fibers. The post-mordanting method began with dyeing the wool fibers by adding the extracted cinnamon bark to the substance bath. After that, the wool fibers were rinsed with water, squeezed, and then mordanted as mentioned above. In the meta- and post-mordanting methods, the concentration of material and dyeing procedure was precisely carried out as mentioned in the pre-mordanting method.

Colorimetric characteristics

Color changes of the wool fibers in terms of L*, a*, and b* values and color strength (K/S) were obtained using an YS6010 benchtop reflectance spectrophotometer (illuminant D65, 10° standard observer). The color change between the un-mordanted (control) and mordanted dyed samples was calculated using Eq. (1).

where, ΔL = L*mordanted – L*un-mordanted, Δa = a*mordanted – a*un-mordanted, and Δb = b*mordanted – b*un-mordanted.

The color strength (K/S) and relative color strength (\({(\frac{{\text{K}}}{{\text{S}}})}_{{\text{R}}}\)) values were assessed using Eq. (2) (Kubelka–Munk equation) and Eq. (3).

where, R, \({(\frac{{\text{K}}}{{\text{S}}})}_{{\text{m}}}\) and \({(\frac{{\text{K}}}{{\text{S}}})}_{{\text{um}}}\) are the decimal fraction of the reflectance, color strength of the mordanted, and color strength of the control dyed samples, respectively.

Color fastness

The wash and light fastness of all samples were tested according to ISO standard methods. The determination of wash color fastness was done according to the ISO 105-C06 (A1S):2010 test method. The evaluation of color change was done using ISO 105-A02:1993 and a gray scale (scores from 1 to 5). Light color fastness was evaluated by exposing the dyed fibers to sunlight using the ISO 105-B02:2014 standard and blue scale (scores from 1 to 8).

Results and discussion

Effect of mordant type and mordanting procedures on the reflection factor

The color intensity of the dyed samples, with the pre-, meta-, and post-mordanting methods, was measured and compared using reflective spectroscopy in the range of 400–700 nm. As can be seen in Fig. 2a–c, in all dyeing methods, the reflection factor of all the samples in the range of 400 to 700 nm has an increasing trend. In all samples, the least reflection is obtained at the wavelength of 400 nm, which is related to the yellow color. This result is in agreement with the results obtained by Shahidi and co-authors (Shahidi et al. 2021) in the dyeing of cotton fabric with cinnamon bark extract.

The reflection graphs in the range of 400 to 700 nm for samples dyed by the pre-, meta-, and post-mordanting methods are different. In the pre-mordanting method, the reflection factor of all samples (except the Al sample) is less than or equal to the control sample. Therefore, in the pre-mordanting method, using bio-mordant was effective in increasing the dye absorption. In the meta-mordanting method, the reflection factor of the Al and Artemisia samples is greater than that of the control samples. Also, the Cu sample has a lower reflection factor than the control sample. Other samples have the same reflection factor as the control sample. In the post-mordanting method, the reflection factor of all samples (except the Cu sample) is greater than or equal to the control sample. This means that in the post-mordanting method, the absorbed dye by the mordanted samples is less than or equal to the control sample. For this reason, in the post-mordanting method, where the wool fiber is dyed initially and then the dyed fiber is placed in the mordant solution, due to the poor bonding of the dye to the fiber, some dyes leave the surface of the fiber and enter the mordant solution. It should be mentioned that in all the dyeing methods, the samples dyed with bio-mordant had a less or equal reflection factor compared to the Al sample. However, their reflection factor was significantly greater than that of the Cu sample. So, using the mentioned natural mordant, it is possible to obtain shades close to the dyed sample with Al mordant.

Effect of mordant on color hue changes and colorimetric parameters

Some research indicated that the cinnamon extracts contain cinnamaldehyde and tannin as the most important compounds that cause color. The carbonyl (C = O) and hydroxyl (–OH) groups placed in the structure of cinnamaldehyde and tannin (See Fig. 1) may be a response to complex formation with various mordants, producing different hues on the wool fibers (Adeel et al. 2020b, 2021; Shahidi et al. 2021). This result is confirmed by the digital images of dyed wool samples in Figs. 3, 4, 5. As can be seen, the conjunction of metal mordant and polyphenolic bio-mordants with cinnamon colorants can create different hues and tones of brown (light brown, reddish brown, and dark brown).

The CIE indexes of the wool fiber dyed with cinnamon bark in the presence of chemical and bio-mordants and different mordanting methods are given in Tables 1, 2, 3. It can be seen that various mordants could cause the difference in the saturation (C*), hue color (h°), and CIELab values.

The brightness results show that in all dyeing methods, when dyeing of the wool fibers was done with cinnamon through Cu mordant, which yielded deeper shades of brown color, the L* value was 12 to 15% less than the dyed sample without mordant. Also, when the wool fiber was dyed using Al mordant, the L* value was 3–9% greater than the control sample. Regarding the pre- and meta-mordanting methods, except for the peppermint sample (in the pre-mordanting) and the artemisia sample (in the meta-mordanting), other dyed samples with bio-mordant had the same brightness as the control sample. In the pre-mordanting method, the brightness of the peppermint sample was 5% less, and in the meta-mordanting method, the brightness of the artemisia sample was 8% greater than the control sample. Regarding the post-mordanting methods, the brightness values were utterly different from those of the pre- and meta-mordanting methods. In this method, the bio-mordants created more brightness (about 5–8%) in the dyed samples than the control sample. In the post-mordanting method, the dyed samples with bio-mordants (especially the artemisia sample) had a higher brightness than the Al sample.

Although, color coordinates of all the bio-mordanted and metallic mordanted wool fibers dyed with pre-, meta-, and post-mordanting methods were situated in the red-yellow quadrant of CIELab color space, as given in Figs. 3, 4, 5, but the effect of using various mordants on the amount of red and yellow parameters in dyed wool samples was different. The colorimetric coordinate results of the pre- and meta-mordanted samples indicated that immersion of the wool fiber in bio-mordant solution, except banana peel in the pre-mordanting and artemisia in the meta-mordanting method, did not cause much color change in the wool samples. In contrast, Al and especially Cu solutions (chemical solutions) caused up to 48% less redness and up to 15% less yellowness. Banana peel solution in the pre-mordanting method and artemisia solution in the meta-mordanting method made 8 and 12% less redness in the dyed wool fibers, respectively. In the post-mordanting method, using chemical and bio-mordant solutions caused less redness and yellowness in the wool samples. In this method, after the Cu solution, peppermint and banana peel caused the most changes in the redness and yellowness parameters, respectively.

The effect of metallic and bio-mordants, as well as mordanting procedures, on the K/S of wool fiber dyed with cinnamon bark is represented in Fig. 6. The K/S values were calculated at the maximum absorbance wavelength (400 nm). The results indicated that in all mordanting methods, the Cu sample had the highest color strength. The color strength of this sample in the pre-, meta-, and post-mordanting methods is up to 35, 36, and 50% more than the dyed samples with bio-mordants, respectively. Compared to other mordants, copper ions can create a stronger bond with functional groups in wool fibers. Also, the large size of the polyphenolic compounds in bio-mordants and their connection with cinnamaldehyde or tannin structures creates a large complex of colorant and mordant. Due to the large size of the created complex, the accumulation and precipitation increase, and as a result, the absorbed colorant decreases (Vankar 2007).

Regarding the pre- and meta-mordanting methods, the Al sample had the least color strength compared to other dyed samples. In these methods, the color strength of the Al sample was 15 to 36% lower than the dyed samples with bio-mordant. In the post-mordanting method, the color strength of the Al sample was equal to or lower than the dyed sample with bio-mordant.

The relative color strength of the bio-mordant samples, as presented in Tables 1, 2, 3, showed that in the pre-mordanting method, peppermint, banana peel, and artemisia increased the color strength of the dyed wool fiber. Also, in the meta-mordanting method, peppermint improves the color strength of the dyed sample. In the post-mordanting method, using bio-mordant has no effect on improving the color strength. In all dyeing methods, the peppermint sample showed higher color depth/color strength values compared to the other bio-mordants, owing to the presence of high amounts of polyphenolic compounds (Mahboubi and Kazempour 2014).

The comparison of the color strength results in Fig. 6 shows that the dyeing method is an influential factor in the color strength of samples dyed with bio-mordants. Among the samples dyed with bio-mordants, changing the dyeing method has been most effective on the peppermint sample’s color strength. This sample’s color strength in the pre-mordanting method was 14% and 32% greater than the meta- and post-mordanting methods, respectively.

In the samples dyed with date kernels and banana peel, changing the dyeing method had less effect on the color strength. The date kernel and banana peel sample’s color strength in the pre-mordanting method was up to 6% higher than the meta-mordanting method. Also, the artemisia sample’s color strength in the pre-mordanting method is up to 24% higher than that of other methods. According to the results of works on dyeing using cinnamon bark, the interaction of the dye with the mordant is better than the interaction of the dye with the fiber (Adeel et al. 2020b, 2021). Therefore, in the post-mordanting procedure, where the wool fiber is dyed initially and then the dyed wool fiber is placed in the mordant solution, due to the poor bonding of the dye to the fiber, some dye leaves the surface of the fiber and enters the mordant solution, so the color strength of the sample decreases. In the meta-mordanting method, the colorant and mordant are present together in the dyeing bath. This allows for the possibility of the colorant and mordant forming a complex before they are absorbed by the fibers. However, the size of the colorant-mordant complex can be relatively large, which can hinder its ability to enter the fibers effectively. This can lead to a decreased intensity or depth of color in the dyed samples. In the pre-mordanting method, first, the wool fiber is mordanted, and next, the mordanted fiber enters the dye bath. Since the interaction of the natural mordants with the wool fibers is appropriate, as is the interaction of cinnamaldehyde with the mordant, much dye is absorbed by the fibers, and the color strength increases.

Washing and light color fastness

The color fastness of natural colorants depends on their chemical structure and the type and extent of interaction developed between fiber, mordant, and colorant (Wanyama et al. 2010). Mordanting with metal salts is an old technique for developing fastness properties by strongly bonding dye with fiber through additional bonding, like coordination covalent (Yusuf et al. 2017). The other tool is the application of plants (especially waste of agricultural products) as bio-mordants, which involves the formation of additional interactions by using functional groups with colorants and fibers (Shahmoradi Ghaheh et al. 2021; Tehrani et al. 2023). The major constituents of used bio-mordants and the proposed structure of colorant-metal and fiber, as well as colorant, bio-mordant, and fiber, have been provided in Fig. 7. As can be seen, the presence of hydroxyl (–OH) groups in the structure of date kernel powder (Al-Farsi and Lee 2011; Maqsood et al. 2020), peppermint (Mahboubi and Kazempour 2014; Kaur and Kaur 2023), banana peel (Zaini et al. 2022), and artemisia (Ekiert et al. 2022) promises to improve the color fastness of cinnamon-dyed wool fiber. These groups connect with hydroxyl (OH), carboxyl (COOH), and amino (NH2-) groups in wool fiber as well as with carbonyl (C = O) groups in cinnamaldehyde (the dye found in cinnamon bark) via extra H-bonding. This additional bond also adds value to coloration with enhanced fastness ratings.

The results related to the washing and light fastness of dyed wool fibers using metal and bio-mordants with pre-, meta-, and post-mordanting methods are given in Tables 1, 2, 3. It can be seen that the control sample did not have proper washing (3–4) and light (3–4) fastness. This sample, due to its unfixed dye, had a low wash fastness (Adeel et al. 2020b, 2021). Using chemical and bio-mordants in all mordanting techniques has improved color fastness. Most of the dyed samples with natural and metal mordants had acceptable washing (4–5° and more) and light (5° and more) fastness. The used bio-mordants contain polyphenolic components and release gallic acid as a UV absorber or antioxidant material, improving light fastness (Souissi et al. 2018).

Comparing the fastness results of the dyed samples with metal and bio-mordant shows that the performance of the used bio-mordant was equal to or better than the metal ones. Among the applied bio-mordants, peppermint and artemisia have created the best washing (4–5 and 5) and light (5, 5–6 and 6) fastness.

The results, as shown in Tables 1, 2, 3, show that the mordanting technique had a significant effect on the washing and light fastness of the samples dyed with bio-mordants. Among the mordanting methods, using the post-mordanting method has created the best washing (5) and light fastness (6). Also, the samples dyed using the meta-mordanting method, had less washing (4) and light (4–5) fastness than the pre-mordanting method. In the meta-mordanting method, there is a competition between the mordant and the dye to connect the ligands in the wool fibers. So, some dyes may be connected to the fibers without an intermediary (mordant). Also, in this case, there is a possibility of forming a dye-mordant complex in the dyeing bath. So, the complex formation prevents the entry of dyes into the fibers, as well as the absorption of mordant and dye is done on the surface of wool fiber (more than other methods). Due to the lack of a proper connection, the washing fastness has decreased.

Conclusions

In this research, the colorimetric and fastness parameters of wool fibers dyed with cinnamon bark extracts in the presence of metal and bio-mordants, as well as with different mordanting procedures, were studied and compared. The results showed that:

-

In all dyeing methods, the reflection factor of all the samples in the range of 400 to 700 nm has an increasing trend. In all samples, the least reflection is obtained at the wavelength of 400 nm, which is related to the yellow color.

-

Changing the type of mordant and the dyeing procedure caused a limited change in the value of colorimetric parameters in the dyed samples. Using metallic and bio-mordant could create light brown, dark brown, and reddish brown colors.

-

In all mordanting methods, the dyed sample with Cu mordant had the highest color strength. Also, the dyed sample with peppermint showed higher color strength compared to other bio-mordants owing to the presence of higher amounts of polyphenolic compounds.

-

The samples dyed with cinnamon bark in the presence of metal and bio-mordants had appropriate color fastness to washing and light. Among the tested bio-mordants, peppermint and artemisia have created the best washing and light fastness.

-

Using different dyeing methods led to different color strengths and fastness in the dyed sample with bio-mordants. Samples dyed by applying the pre-mordanting method had higher color strength compared to the other two methods. Also, post-mordanting has created the best washing and light fastness.

Data availability

The data sets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Adeel S, Habib N, Arif S, Rehman F, Azeem M, Batool F, Amin N (2020b) Microwave-assisted eco-dyeing of bio mordanted silk fabric using cinnamon bark (Cinnamomum verum) based yellow natural dye. Sustain Chem Pharm 17:100306. https://doi.org/10.1016/J.SCP.2020.100306

Adeel S, Habib N, Batool F, Amin N, Ahmad T, Arif S, Hussaan T (2021) Environmental friendly exploration of cinnamon bark (Cinnamomum verum) based yellow natural dye for green coloration of bio-mordanted wool fabric. Env Prog Sustain Energy 41(4):13794. https://doi.org/10.1002/ep.13794

Adeel S, Salman M, Zahoor AF, Usama M, Amin N (2020a) An insight into herbal based natural dyes: isolation and applications. In: Recycling from waste in fashion and textiles: a sustainable and circular economic approach. Wiley 423–456. https://doi.org/10.1002/9781119620532.ch19

Ahsan R, Masood A, Sherwani R, Khushbakhat H (2020) Extraction and application of natural dyes on natural fibers: an eco-friendly perspective. Rev Educ Adm Law 3(1): 63–75. https://doi.org/10.47067/real.v3i1.22

Al-Farsi MA, Lee CY (2011) Usage of date (Phoenix dactylifera L.) seeds in human health and animal feed. In Nuts and seeds in health and disease prevention. Academic Press, 447–452. https://doi.org/10.1016/B978-0-12-375688-6.10053-2

Al-Salmany ASM, Saleh AL-Rubeii AM (2020) Effect of cinnamon and turmeric nanoparticles extract in quality characteristics of ground beef during freeze storage. Plant Arch 20(1):350–356

Bakewell-Stone P (2022) Cinnamomum verum (cinnamon). CABI Compendium. https://doi.org/10.1079/cabicompendium.13573

Dikshit R, Tallapragada P (2018) Comparative study of natural and artificial flavoring agents and dyes. In Natural and artificial flavoring agents and food dyes. Academic Press, 83–111. https://doi.org/10.1016/B978-0-12-811518-3.00003-X

Ekiert H, Klimek-Szczykutowicz M, Rzepiela A, Klin P, Szopa A (2022) Artemisia species with high biological values as a potential source of medicinal and cosmetic raw materials. Molecules 27(19):6427. https://doi.org/10.3390/molecules27196427

Gilani S, Najafpour G (2022) Evaluation of the extraction process parameters on bioactive compounds of cinnamon bark: a comparative study. Process Biochem 114:93–101. https://doi.org/10.1016/j.procbio.2022.01.022

Haji A, Shahmoradi Ghaheh F, Mohammadi L (2023) Dyeing of polyamide 6 fabric with new bio-colorant and bio-mordants. Environ Sci Pollut Res 30:37981–37996. https://doi.org/10.1007/s11356-022-24862-0

Haji A, Qavamnia SS, Nasiriboroumand M (2018) The use of D-optimal design in the optimization of wool dyeing with Juglansregia bark. Ind Textil 69(2): 104–110. https://doi.org/10.35530/IT.069.02.1509

Hosseinnezhad M, Gharanjig K, Jafari R, Imani H (2021) Green dyeing of woolen yarns with weld and madder natural dyes in the presences of biomordant. Prog Color Colorants Coat 14(1):35–45. https://doi.org/10.1080/15440478.2020.1848735

Hosseinnezhad M, Gharanjig K, Adeel S, Nahavandi AM (2023) In quest for improvement of dyeing properties using agriculture waste: utilization of Oleaster as new bio-mordant for wool yarns. Environ Sci Pollut Res 30:12262–122273. https://doi.org/10.1007/s11356-023-30603-8

Kaur J, Kaur K (2023) Peppermint essential oil. Essential oils, extraction, characterization and applications. Academic Press, 103–120. https://doi.org/10.1016/B978-0-323-91740-7.00010-4

Kaur A, Sharma S (2017) Removal of heavy metals from waste water by using various adsorbents- a review. Ind J Sci Techno 10(34): 1–14. https://doi.org/10.17485/ijst/2017/v10i34/117269

Kiumarsi A, Gashti MP, Salehi P, Dayeni M (2017) Extraction of dyes from Delphinium Zalil flowers and dyeing silk yarns. J Text Inst 108(1):66–70. https://doi.org/10.1080/00405000.2016.1153865

Knauth P, López ZL, Acevedo-Hernandez G, Sevilla MTE (2018) Cinnamon essential oil: chemical composition and biological activities, essential oils production, applications and health benefits. Nova Science Publishers, Inc., 215–244

Kusstianti N, Wilujeng BY, Megasari DS (2017) The effects of cinnamon and clove powder compositions on hair coloring. Proceedings of the 1st International Conference on Social, Applied Science and Technology in Home Economics (ICONHOMECS 2017). Atlantis Press, 171–174. https://doi.org/10.2991/iconhomecs-17.2018.41

Luftinor HN, Kurniati AS (2020) Coffee bean skin waste extraction for silk dyeing. Mater Sci Eng 801:1–9. https://doi.org/10.1088/1757-899X/801/1/012075

Mahboubi M, Kazempour N (2014) Chemical composition and antimicrobial activity of peppermint (Mentha piperita L.) Essential oil. Songklanakarin J Sci Technol 36(1): 83–87

Malviya P, Verma AK, Chaurasia AK, Parmar H, Thakur LS, Kumbhkar P, Shah P (2023) Heavy metals contaminants threat to environment: it’s possible treatment. energy, environment, and sustainability. Published in: transportation energy and dynamics. Springer Nature Singapore 323–341

Maqsood S, Adiamo O, Ahmad M, Mudgil P (2020) Bioactive compounds from date fruit and seed as potential nutraceutical and functional food ingredients. Food Chem 308:125522. https://doi.org/10.1016/j.foodchem.2019.125522

Muhammad DRA, Dewettinck K (2017) Cinnamon and its derivatives as a potential ingredient in functional food-a review.Int J Food Prop 20: 2237–2263https://doi.org/10.1080/10942912.2017.1369102

Nam JW, Phansalkar RS, Lankin DC, McAlpine JB, Leme-Kraus AA, Bedran-Russo AK, Pauli GF (2020) Targeting trimeric and tetrameric proanthocyanidins of Cinnamomum verum bark as bioactives for dental therapies. J Nat Prod 83(11):3287–3297. https://doi.org/10.1021/ACS.JNATPROD.0C00570

Shahidi S, Khoshechin E, Dalal Sharifi S, Mongkholrattanasit R (2021) Investigation of the effect of various natural dyes on UV protection properties and antibacterial activity of cotton fabrics. J Nat Fibers 19(13):1–16. https://doi.org/10.1080/15440478.2021.1944433

Shahmoradi Ghaheh F, Moghaddam MK, Tehrani M (2021) Comparison of the effect of metal mordants and bio-mordants on the colorimetric and antibacterial properties of natural dyes on cotton fabric. Color Technol 137(6):689–698. https://doi.org/10.1111/cote.12569

Souissi M, Guesmi A, Moussa A (2018) Valorization of natural dye extracted from date palm pits (Phoenix dactylifera) for dyeing of cotton fabric. Part 2: Optimization of dyeing process and improvement of colorfastness with biological mordants. J Clean Prod 204:1143–1153. https://doi.org/10.1016/j.jclepro.2018.08.325

Surya A, Deepan T, Alekhya V, Dhanaraju MD (2021) A comparative study of dyeing efficiency and retention capacity of formulated polyherbal hair dye. Int J Recent Sci Res 12(09): 43106–43109. https://doi.org/10.24327/ijrsr.2021.1209.6216

Tehrani M, Shahmoradi Ghaheh F, Tadi Beni Z, Rahimi M (2023) Extracted dyes’ stability as obtained from spent coffee grounds on silk fabrics using eco-friendly mordants. Environ Sci Pollut Res 30(26):68625–68635. https://doi.org/10.1007/s11356-023-27157-0

Teklemedhin TB, Gopalakrishnan LH (2018) Environmental friendly dyeing of silk fabric with natural dye extracted from Cassia singueana plant. J Textile Sci Eng 3:1–6. https://doi.org/10.4172/2165-8064.S3-001

Vankar PS (2007) Handbook on natural dyes for industrial applications. National Institute of Industrial Re

Wanyama PAG, Kiremire BT, Ogwok P, Murumu JS (2010) The effect of different mordants on strength and stability of colour produced from selected dye-yielding plants in Uganda. Int Archive Appl Sci Technol 1(2):81–92

Wong YC, Ahmad-Mudzaqqir MY, Wan-Nurdiyana WA (2014) Extraction of essential oil from cinnamon (Cinnamomum zeylanicum). Oriental J Chem 30(1): 37–47. https://doi.org/10.13005/ojc/300105

Yusuf M, Khan SA, Shabbir M, Mohammad F (2017) Developing a shade range on wool by madder (Rubiacordifolia) root extract with gallnut (Quercusinfectoria) as biomordant. J Nat Fibers 14(4):597–607. https://doi.org/10.1080/15440478.2016.1240641

Zaini HM, Roslan J, Saallah S, Munsu E, Sulaiman NS, Pindi W (2022) Banana peels as a bioactive ingredient and its potential application in the food industry. J Funct Foods 92:105054. https://doi.org/10.1016/j.jff.2022.105054

Funding

This work has been financially supported by the research deputy of Shahrekord University. The grant number was 1GRN36M797.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Majid Tehrani and Taraneh Navayee. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Consent for publication

All authors have read and agreed with the publication of the manuscript upon the acceptance by the journal.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tehrani, M., Navayee, T. Suitability of dyes from cinnamon bark on wool fibers using metal and bio-mordants. Environ Sci Pollut Res 31, 31414–31423 (2024). https://doi.org/10.1007/s11356-024-33381-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-33381-z