Abstract

Heat losses in solar stills are high, which has led to a decrease in their thermal efficiency. Also, the production of these devices is limited to the presence of the sun, and their production stops during cloudy hours or at night. To solve these problems, in this experimental study, two cascade solar stills are examined under relatively similar conditions for sustainable freshwater production. One of these solar stills is modified with the phase change material and copper fins, and another one is a conventional cascade solar still without using the phase change material and copper fins. Paraffin was selected as a heat storage material to increase the time of desalination of water by the solar still. In addition, the copper fins are used to increase the conduction heat transfer in phase change material and provide better melting and solidification processes. To prolong the water path along the steps, the serpentine water path was considered. The results showed that at sunset hours, desalination efficiency with phase changing material and fins was increased. At 5 pm, the efficiency of the modified device was increased by 29% (on average) as compared to the conventional solar still without using phase changing material and fins. The rate of water production in conventional solar still in midday was higher compared to the modified solar still. However, in the sunset and night hours, the modified solar still has a higher production rate due to heat released from the thermal storage system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is an abundant constituent of the Earth that makes up about 75% of the Earth’s volume (Ajdari and Ameri 2022). It is estimated that the total volume of water on Earth is 1.4 × 109 km3. Most of this water, which accounts for 97% of the world’s total surface water, is the highly salty waters of the seas and oceans. Desalination methods are categorized into two main categories, including thermal and non-thermal methods (AlMallahi et al. 2023; Elgendi et al. 2023a). One of the most reliable and cleanest ways to tackle the shortage of freshwater is solar desalination (Yousef et al. 2019; Mahmoudi et al. 2023). Solar stills are used especially in remote areas due to their ease of use and because there is no need for complex equipment (Jahanpanah et al. 2021; Sharshir et al. 2019).

Here, a literature review of the solar stills especially cascade type is conducted. El-Agouz (2014) experimentally investigated the performance of a modified stepper solar desalination device with a cotton absorber and storage tank. El-Agouz (2014) examined the system with saline and seawater under fixed conditions with black and cotton absorbers during the experiment. Compared to conventional solar still, the water production in modified still with black absorber was increased by 43% and 48% for seawater and saline water, respectively. The increments for modified stills with cotton absorbers are 53% and 47% for sea and saline water, respectively. Also, the daily efficiency of modified solar still increased by 20% compared to conventional solar still. Shmroukh and Ookawara (2020) made a study on a cascade desalination unit with external and internal reflectors. Also, the unit was equipped with copper fins on the surface of cascades. The hourly production of modified still reached 1270 ml/m2. In another study, Naroei et al. (2018) performed a study on a combination of PVT collector and cascade solar still. It was shown that by integrating of PVT system with cascade solar still, the water production increases. In another numerical study, Rashidi et al. (2018) investigated the effects of nanofluids on a cascade solar still. By an optimization analysis, they found that increasing the concentration of nanoparticles from 0 to 5% increased the hourly water production by 22%. In an experiment, Sathish Kumar et al. (2019) tested two single-tilt (with single-basin) solar stills. One still was equipped with square tube blades embedded in the basin and paraffin as a PCM. The daily efficiency for conventional solar still, still with blades, and still with blades and PCM was 23%, 36%, and 44%, respectively. Also, Sathyamurthy et al. (2016) investigated triangular pyramidal solar still with and without PCM. Paraffin was selected as a heat storage material. The solar still production was increased by 20% when the PCM was applied. In a theoretical study, El-Sebaii et al. (2009) developed a model to compare solar stills with and without PCM. They considered stearic acid as the PCM. The use of PCM in summer increased the daily efficiency by 85.3%. Abu-Arabi et al. (2018) modeled a solar still that was connected to an external collector. They showed that using PCM is suitable for producing the freshwater during the night. It increased the overall water production of the device. They also showed that increasing the PCM-to-water mass ratio from 10 to 100% reduced water production by 30%. In an experiment, Sonker et al. (2019) investigated the performance of passive solar still with PCM (including paraffin, stearic acid, and lauric acid). They placed PCMs in cylindrical copper cylinders to increase the contact surface area. They showed that by all three PCMs, water production will increase. The highest water production was obtained by paraffin (due to its higher latent heat capacity). Kantesh (2012) used bitumen as a heat storage material in a solar still in experimental research. He found that solar desalination with bitumen as heat storage materials increased desalination efficiency by only 2%. Tabrizi et al. (2010) examined two cascade-type solar stills (one with a latent heat storage system). The experiment was conducted on cloudy and sunny days. The results showed that on a sunny day, the overall water production for both devices was almost identical. However, on a partially cloudy day, the solar still with a latent heat storage system produced much higher water. Toosi et al. (2021) tested a cascade solar still in four stages. In the first stage, single-step solar still was tested. In the second stage, the cascade solar unit with an external condenser was tested. In the third stage, the cascade solar still with PCM was considered. In the fourth stage, cascade solar still with PCM and external condenser was tested. Compared to the first-stage experiments, the water production in the second, third, and fourth stages was enhanced by 26%, 43%, and 104%, respectively. Elgendi et al. (2023b) reported that the finned absorber has a favorable impact on the solar stills and its efficiency is not general and requires more studies. Elgendi and Atef (2023) focused on the effects of meteorological parameters on the productivity of pyramid solar still by using a machine learning algorithm. They found that the solar still location can be specified based on the four effective parameters.

In this paper, a solar distillation unit with serpentine water paths over cascade steps is investigated experimentally. The unit operates with paraffin (PCM) and copper fins. The first novel feature of the present study is the consideration of the serpentine path for water on the steps of the solar still. The serpentine movement of water on the steps makes the water path longer and thus the water stays on the steps for more time. As a result, the water has enough time to receive solar radiation and be warmed for evaporation. Using the phase change material as a thermal storage medium in the solar still is the second novel feature of the present work. During the day, the heat losses in the solar desalination units are very high, which decreases the productivity rate and efficiency of solar still. In this study, this heat loss is reduced as much as possible by using PCM. The stored heat within the PCM is used for the continuation of the operation of the solar still during those times in which solar irradiation is not available or its intensity is low (Elgendi et al. 2023c). As another novelty of this study, the copper fins are placed inside the phase change material to improve the conduction heat transfer. Copper fins have high thermal conductivity and provide a more effective surface for heat transfer in phase change materials. As a result, the heat can be spread better inside the phase change material and better solidification and melting processes can be achieved. Such a combination has not been tested in the previous works. This study aims to investigate the feasibility and efficiency of such solar stills.

Experimental setup

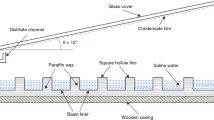

Cascade solar still

Figure 1 shows a view of the cascade solar still. In this type of solar still, the minimum water depth is maintained. Water depth in solar stills can inversely affect their productivity (Elgendi et al. 2022; Elgendi and Selim 2022). The previous studies suggested that a decrease in brine depth increases productivity due to higher temperatures in the basin. To build the device, all aspects should be considered. The construction of the device begins with the design and construction of steps. Since the steps of solar still are permanently exposed to moisture and heat, the issue of rust and corrosion is also important to consider. Galvanized sheets are resistant to corrosion and rust because of the protective layer on them. Also, the low price and formability of the galvanized sheets compared to other metals made it an ideal option for constructing the steps in this work. For this purpose, 11 steps and a terminal pond were considered for collecting hot water. The steps with lengths of 50 cm, height of 3.5 cm, and floor of 5 cm are considered. It is proved that the optimum slope of the glass cover of solar still should be equal to the latitude of the desired location (Yakup and Malik 2001). The city of Semnan is located at a latitude of 35 degrees in Iran. As a result, the slope of the glass cover is considered to be 35 degrees. The evaporation surface area of 0.275 m2 is considered. A 1-cm rim was also considered to prevent water from overflowing from the upper steps to the lower ones. Also, to prolong the water path along the steps and to maintain the lowest water depth inside the steps, a 1-cm gap at the end of the steps was considered to provide the serpentine path for the water on the steps. The schematic of the water movement on the steps considered in this study is illustrated in Fig. 2. It should be noted that the serpentine movement of water on the steps made the water path longer and thus made the water stay on the steps longer. As a result, the water has enough time to receive solar radiation for evaporation. Also, for better absorption of solar radiation, a black layer was applied across the steps.

To prevent heat loss and increase the efficiency of the system, behind the steps of the modified solar still, where the PCM tank is located, it was completely insulated using layers of glass wool and foam. As a result, PCM could transfer heat to the steps more completely.

Phase change material

Thermal energy can be stored during the day and used at night and during periods of lack of solar energy by using PCMs as the latent storage materials. The findings also show that latent storage materials can store more heat than sensible storage materials (Shalaby et al. 2016). For this purpose, under the steps of the modified solar still, a tank was considered for placing PCM for storage of the solar thermal energy. The PCM considered for testing should be appropriate for the climate conditions of that region to ensure the melting and freezing processes are carried out well. For this reason, paraffin was chosen as a thermal storage material. It should be mentioned that paraffin wax is a non-toxic and economically accessible substance, and the findings have shown that for desalination processes, paraffin has shown more suitable performance than other materials and has all the properties of a desirable PCM (Chauhan et al. 2022). The thermophysical properties of solid paraffin wax are shown in Table 1 (Sathyamurthy et al. 2022). To fill the tank with solid paraffin wax, it should be first in liquid form. As a result, the solid paraffin wax was melted. A view of the melting solid paraffin is shown in Fig. 3.

Heat transfer fins

The thermal conductivity of paraffin is low. For better conduction heat transfer between the PCM and steps of the solar still, fins can be used. Fins also intensify the PCM thermal response. The fins used in this study are made of copper, which has good thermal conductivity. Fins are installed on the back of the steps in such a way that they are immersed in PCM. The positions of the fins are shown in Fig. 4. In each step, eight copper tubes with a length of 1 cm were installed to complete the heat transfer from all locations.

Both modified solar still (MSS) with PCM and fins and conventional solar still (CSS) without PCM and fins have a glass container with transparent walls. In the last step of both solar stills, an outlet was provided to remove saline hot water. In addition, an outlet was also considered in a section of the container to remove the produced freshwater. To stabilize the device, a wooden base was designed and built that can change the angle of the device.

Methodology

This experiment was tested on the campus of Semnan University in Semnan for 4 days (2 days for MSS and 2 days for CSS). The geographical coordinates of Semnan are 35° 34′ N and 53° 23′ E. These four days were at the end of spring, including 30/5/2023, 31/5/2023, 10/6/2023, and 11/6/2023. The experiments were carried out from 8 am to 9 pm. The solar still was oriented southward. Every hour, important parameters, such as solar radiation, input and output water temperatures, glass surface temperature, humidity, and freshwater produced, were recorded by measuring devices.

Theoretical investigation

In this section, the theory of the device is analyzed.

Efficiency

The efficiency of solar still is calculated by the following formula (Attia et al. 2021; Kabeel 2009):

In this formula, ṁ is the amount of freshwater produced in kg, L is the latent heat of the water in kJ/kg, I is the solar radiation in W/m2, and A is the surface area of evaporating zone in solar still.

Exergy efficiency

Exergy is a term of second law of thermodynamics and is the maximum useful work when reaching thermodynamic equilibrium with environment (Kumar and Prakash 2022). Exergy efficiency is defined as the rate of the output exergy to the input exergy, which is calculated as follows (Kumar and Prakash 2022; Sharbatiyan et al. 2023):

In this formula, the output exergy is calculated as follows (Kabeel 2009; Sharbatiyan et al. 2023):

In this formula, Ta shows the ambient temperature and Tw is the water temperature.

The total energy input to the device is equal to the amount of radiation received through the device, which can be calculated using the following formulas (Kabeel 2009; Sharbatiyan et al. 2023):

In this formula, Ta is the ambient temperature, Ts is the sun temperature, I is solar radiation in W/m2, and A is the surface area of evaporating zone in the solar still. The sun’s temperature is 6000 K.

4.3. Uncertainty analysis

In this study, the uncertainty of all measured parameters is of type B, which is defined as follows (Rahbar and Esfahani 2012; Rashidi et al. 2017):

where U is the uncertainties or errors of the device and a is the precision of the measuring device. The uncertainty of measuring devices is also presented in Table 2.

Also, the highest calculated uncertainty for efficiency in all experiments is calculated to be 0.0564.

Economic analysis

The details of economic analysis are presented in this section (Rahbar and Esfahani 2012; Rashidi et al. 2017). The first factor examined in the economic analysis is FAC, which shows the annual cost of solar still and is calculated by:

In this formula, CRF is defined as the capital return factor. P is the cost of capital. CRF is also calculated by

where i is the interest rate related to bank loans (for Iran, this amount is equal to 20%) and n is the lifetime of the device, which is considered 10 years in this study. The value of the device at the end of its useful life is expressed by the ASV factor and is calculated as follows:

In this regard, S is the scrap value of the device and SSF is expressed as a factor of depreciation of the device and is calculated by

The annual maintenance cost of the device is expressed by the AMC factor, which can be calculated from the following formula:

Therefore, according to the obtained values, the total annual cost of the device is

As a result, it is possible to calculate the production cost of each liter of freshwater, which is represented by CPL

where M shows the average annual production rate of the device.

Results and discussion

In this section, all the results obtained from this experiment will be analyzed. Weather conditions have an important effect on the performance of solar stills (Al-Hinai et al. 2002). Figure 5 shows the hourly solar radiation intensity for 4 days of experiments, including 30/5/2023, 31/5/2023, 10/6/2023, and 11/6/2023. SS in this figure is the abbreviation of solar still. The general trend of solar radiation intensity is similar with a slight difference between 12 am and 3 pm for all days. The highest amount of solar radiation intensity related to the day of 30/5/2023 at 11 am is 950 W/m2. The maximum solar radiation intensity occurs between 11 and 12 am for all 4 days of experiments. Also, the average solar radiation intensity for 30/5/2023, 31/5/2023, 10/6/2023, and 11/6/2023 was equal to 570 W/m2, 571 W/m2, 627 W/m2, and 654 W/m2, respectively.

Figure 6 also shows the hourly ambient temperature for 4 days of the experiments. The trend of the hourly ambient temperature for 30/5/2023, 31/5/2023, and 11/6/2023 is the same with slight differences in some hours of the day. However, the trend of the hourly environment temperature for 10/6/2023 is different. Even though the average amount of solar radiation is the highest for 10/6/2023 compared to other days, the lowest ambient temperature occurs on this day. The reason can be the amount of humidity shown in Fig. 7, in which the highest amount of humidity was recorded on 11/6/2023. The wind speed, density, etc. can also affect the hourly environment temperature. The humidity for 30/5/2023, 31/5/2023, and 11/6/2023 has a relatively similar trend, and in the middle of the day, the average humidity is between 14 and 20%. On 10/6/2023, the humidity has the highest amount compared to other days. It is 42% at the beginning of the experiment and then started to drop gently to about 34%.

The hourly temperature of salt water at the output of solar still for 4 days of the experiments is shown in Fig. 8. The highest temperature of 54 °C was recorded for saltwater during these four days on 31/5/2023, when the solar still modified with PCM and fins was tested. It should be mentioned that the modified solar still with PCM and fins was tested on 31/5/2023 and 11/6/2023. The trend of saltwater temperature for days of 30/5/2023, 31/5/2023, and 11/6/2023 is similar with a relatively small difference until 3 pm. For the days of 31/5/2023 and 11/6/2023 when the MSS with PCM and fins was tested, the average temperature at the beginning of the day was lower than that of 30/5/2023 in which the CSS without PCM and fins was tested. This may be due to the storage of solar thermal energy in the PCM. However, for the afternoon hours (e.g., after 3 pm), the downward slope of the saltwater temperature of the CSS without PCM and fins on 30/5/2023 is more than that of the other days and the downward trend has become more intense. The decreasing trend has a lower slope on the days on which the modified still with PCM and fins is tested. The average saltwater temperature in the last hours of the day for the MSS with PCM and fins is higher than that of saltwater in the CSS without PCM and fins. This is due to the discharge of thermal energy from the PCM. However, for the day of 10/6/2023, according to the environmental conditions, the process was the same as the other days, but with a lower range, and at the final hours of the test, due to the high humidity and the speed of the wind, the outlet saltwater experienced a large temperature drop.

The glass surface temperature diagram shown in Fig. 9 is subject to environmental factors. At the beginning of the day, for all 4 days of the experiment, glass surface temperature has taken an increasing trend by absorbing solar thermal energy, and then, at the end of the day, by decreasing the intensity of solar radiation, it has taken a downward trend. The trend for the day of 10/6/2023 is slightly lower due to environmental factors, even though the solar radiation is relatively the same as the other test days.

Figure 10 illustrates the difference between the outlet water temperature and the glass surface temperature. This temperature difference for 3 days of the experiment, i.e., 30/5/2023, 31/5/2023, and 11/6/2023, starts with relatively small values at the beginning of the day. Due to the increase in the outlet water temperature, this difference reaches its maximum value in the middle of the day. After that, this difference decreases in the last hours of the day. For the day of 10/6/2023, a similar trend occurs with for lower temperature differences.

Figure 11 illustrates the graph of the hourly water production rate for four test days from 9 am to 9 pm. At the beginning of the day, the production of water increased on the days when the CSS without PCM and fins was tested. On the first 2 days (i.e., 30/5/2023 and 31/5/2023), the CSS without PCM and fins and the MSS with PCM and fins were tested, respectively. It was observed that until 4 pm, the CSS has a higher average production of freshwater than the MSS. The average water production rate for the CSS from 9 am to 4 pm is 25% higher as compared with the MSS. This is due to the storage of a part of solar thermal energy in PCM in the MSS, which decreases the production of freshwater. In the afternoon hours, from 5 to 9 pm, it can be seen that the average production rate of MSS with PCM and fins increases compared to the CSS without PCM and fins. The production rate increases up to 121.5% by using the MSS from 5 to 9 pm. This is caused by the discharge of thermal energy from PCM to the solar still. The increase in production at night by the MSS was able to partially compensate for the lack of water production during the day for this solar still. For the second 2 days, i.e., 10/6/2023 and 10/6/2023, when the CSS without PCM and fins and the MSS with PCM and fins, respectively, were tested, the process was similar to the first 2 days. The CSS was able to produce more water than other days during the daytime hours even with the average lower ambient temperature. This shows the importance of environmental conditions in the operation of solar still. The production of MSS with PCM and fins decreased by 35.5% from 9 am to 4 pm compared to the CSS without PCM and fin, but from 5 to 9 pm, the production of MSS increased by 101.5% compared to the CSS for the second 2 days.

Figure 12 shows the trend of efficiency of both MSS and CSS for 4 days of the experiment. The average efficiency for the CSS without PCM and fins is higher during the daytime hours. However, the trend of efficiency is different at the end of the day and night, and due to the discharge of thermal energy from PCM, the efficiency of MSS with PCM and fins has increased in these hours. Considering the production of more freshwater by the MSS in these hours, this trend can be justified. At 5 pm, for the first 2 days, the efficiency of MSS with PCM and fins increased by 37% compared to the CSS, and this value was equal to 21% for the second 2 days.

Figure 13 shows the exergy efficiency for the 4 days of the experiment. These changes in the diagram are related to environmental conditions and vary according to these conditions. The exergy efficiency has been an increasing trend at the beginning of the day for all 4 days of the experiment. In the afternoon, the trend of exergy efficiency for the CSS without PCM and fins is decreasing, but this trend for the MSS with PCM and fins is increasing with a mild slope. This can be justified due to the continuation of the desalination process of MSS with PCM and fin in these hours.

Table 3 shows the economic analysis results for both MSS and CSS. As shown, the production cost of each liter of fresh water for the CSS without PCM and fins is equal to 0.0074 $/l/m2 and this amount for the MSS with PCM and fins is equal to 0.0129 $/l/m2.

Different analyses were done on the quality of the inlet and outlet waters of the solar stills. The results of these analyses are presented in Table 4. As can be seen, the quality level of the outlet water has reached a standard level and the hardness has decreased to a great extent. The total dissolved solids (TDS) in water have reached 73 mg/l.

Finally, it should be mentioned that during the day, the heat losses in the solar desalination units are very high. It is possible to reduce this heat loss by using phase change materials (PCMs). The stored heat within the PCM can be used for the continuation of the operation of the desalination units at night or when solar irradiation is not available.

Comparison section

In this section, a comparison between the results of the current study with similar ones from other parts of the world is conducted. The results of this comparison can be found in Table 5. It can be observed that the modified stepped solar still in this study has a higher production rate as compared with similar ones for other parts of the world. It should be mentioned that there are some features, which lead to achieving higher productivity by the current modified stepped solar still.

From Table 5, it can be found that the studies conducted about solar stills are limited to Southeast Asia, Middle East, and North Africa regions. It is suggested to use the solar stills in other parts of the world. This increases the share of renewable energy in the desalination process in different regions.

Conclusions

In this experiment, two cascade solar stills with PCM and fins and without PCM and fins were tested. Paraffin was used as the PCM for heat storage. Copper fins were used to enhance the conduction heat transfer rate and provide better solidification and melting processes in the PCM. A special serpentine path design is applied for water flow over the cascade of the solar still. The important results of these experiments are summarized as follows:

-

Environmental factors such as humidity and wind speed can affect the performance and the production of freshwater of the device.

-

The addition of PCM to the solar still reduces the production at the beginning of the day. However, the heat released from the PCM at night was able to compensate for the decrease in production during the day

-

The use of PCM and fins in solar still increased the production between 5 and 9 pm for the first 2 days by 121.5%. This increase was equal to 101.5% for the next 2 days.

-

The efficiency of the MSS with PCM and fins has increased by 37% as compared to the CSS for the first 2 days of the experiment at 5 pm. This increase was 21% for the second 2 days.

-

The production cost of each liter of fresh water for the CSS without PCM and fins is equal to 0.0074 $/l/m2, and this amount for the MSS with PCM and fins is equal to 0.0129 $/l/m2.

-

The water quality has improved significantly and TDS reduced from 960 to 73 mg/l.

Data availability

Data can be made available on request.

Abbreviations

- A :

-

Area (m2)

- AC:

-

Annual cost ($)

- AMC:

-

Annual maintenance cost ($)

- ASV:

-

Annual salvage value ($)

- CPL:

-

Cost per liter ($ l−1)

- CRF:

-

Capital recovery factor

- CSS:

-

Conventional solar still

- EX:

-

Exergy

- FAC:

-

Fixed annual cost ($)

- I ( t ) :

-

Solar irradiation (W m−2)

- L :

-

Latent heat of the water (kJ kg−1)

- ṁ :

-

Freshwater production rate (kg s−1)

- M :

-

Average annual productivity (l)

- MSS:

-

Modified solar still

- n :

-

Life of the still (years)

- P :

-

Capital cost ($)

- PCM:

-

Phase change material

- S :

-

Salvage value ($)

- SFF:

-

Sinking fund factor

- T :

-

Temperature (K)

- TDS:

-

Total dissolved solids

- U :

-

Standard uncertainty

- η :

-

Efficiency

- η EX :

-

Exergy efficiency

References

Abu-Arabi M, Al-harahsheh M, Mousa H, Alzghoul Z (2018) Theoretical investigation of solar desalination with solar still having phase change material and connected to a solar collector. Desalination 448:60–68

Abd Elbar AR, Hassan H (2020) Energy, exergy and environmental assessment of solar still with solar panel enhanced by porous material and saline water preheating. J Clean Prod 20(277):124175

Ajdari H, Ameri A (2022) Performance assessment of an inclined stepped solar still integrated with PCM and CuO/GO nanocomposite as a nanofluid. J Build Eng 49:104090

Al-Hinai H, Al-Nassri MS, Jubran BA (2002) Effect of climatic, design and operational parameters on the yield of a simple solar still. Energy Convers Manag 43(13):1639–1650

AlMallahi MN, Asaad SM, Inayat A, Harby K, Elgendi M (2023) Analysis of solar-powered adsorption desalination systems: current research trends, developments, and future perspectives. Int J Thermofluids 9:100457

Aly WI, Tolba MA, Abdelmagied M (2023) Experimental investigation and performance evaluation of an oval tubular solar still with phase change material. Appl Therm Eng 25(221):119628

Attia ME, Kabeel AE, Bellila A, Manokar AM, Sathyamurthy R, Driss Z, Muthusamy S (2021) A comparative energy and exergy efficiency study of hemispherical and single-slope solar stills. Environ Sci Pollut Res 28:35649–35659

Cappelletti GM (2002) An experiment with a plastic solar still. Desalination 142(3):221–7

Chauhan VK, Shukla SK, Rathore PK (2022) A systematic review for performance augmentation of solar still with heat storage materials: a state of art. J Energy Storage 47:103578

Cheng WL, Huo YK, Nian YL (2019) Performance of solar still using shape-stabilized PCM: experimental and theoretical investigation. Desalination 1(455):89–99

El-Agouz SA (2014) Experimental investigation of stepped solar still with continuous water circulation. Energy Convers Manage 86:186–193

Elgendi M, Selim MY (2022) Determination of the effect of water depth on the yield of a solar still using an automatic feedwater system. Environ Sci Pollut Res 1:1–9

Elgendi M, Selim MY, Aldhaheri A, Alshehhi W, Almarshoodi H, Alhefeiti A (2022) Design procedures for a passive pyramid solar still with an automatic feed water system. Alex Eng J 61(8):6419–6431

Elgendi M, Atef M (2023) Calculating the impact of meteorological parameters on pyramid solar still yield using machine learning algorithms. Int J Thermofluids 1(18):100341

Elgendi M, Kabeel AE, Essa FA (2023a) Improving the solar still productivity using thermoelectric materials: a review. Alex Eng J 15(65):963–982

Elgendi M, Kabeel AE, Essa FA (2023b) Application of heat sinks inside the pyramid solar distiller: experimental study on distiller performance under various operating conditions. Environ Sci Pollut Res 30(8):21838–21852

Elgendi M, AlHamad IM, Albedwawi W, Alhammadi R, Alzeyoudi F, Alrashdi M (2023c) Determining the appropriate conditions for the drainage process of a solar still. Environ Sci Pollut Res 30(10):25892–25902

El-Sebaii AA, Al-Ghamdi AA, Al-Hazmi FS, Faidah AS (2009) Thermal performance of a single basin solar still with PCM as a storage medium. Appl Energy 86(7–8):1187–1195

Essa FA, Abdullah AS, Alawee WH, Alarjani A, Alqsair UF, Shanmugan S, Omara ZM, Younes MM (2022) Experimental enhancement of tubular solar still performance using rotating cylinder, nanoparticles’ coating, parabolic solar concentrator, and phase change material. Case Stud Therm Eng 1(29):101705

Jahanpanah M, Sadatinejad SJ, Kasaeian A, Jahangir MH, Sarrafha H (2021) Experimental investigation of the effects of low-temperature phase change material on single-slope solar still. Desalination 499:114799

Kabeel AE (2009) Performance of solar still with a concave wick evaporation surface. Energy 34(10):1504–1509

Kabeel AE, Abdelgaied M (2016) Improving the performance of solar still by using PCM as a thermal storage medium under Egyptian conditions. Desalination 1(383):22–28

Kantesh DC (2012) Design of solar still using Phase changing material as a storage medium. Int J Sci Eng Res 3(12):1–6

Kumar M, Yadav C, Manchanda H (2016) Thermal performance of a weir-type cascade solar still: an experimental study. Int J Sci Res Dev 4:339–344

Kumar S, Prakash O (2022) Improving the single-slope solar still performance using solar air heater with phase change materials. Energies 15(21):8013

Mahmoudi A, Bostani M, Rashidi S, Valipour MS (2023) Challenges and opportunities of desalination with renewable energy resources in Middle East countries. Renew Sustain Energy Rev 184:113543

Naroei M, Sarhaddi F, Sobhnamayan F (2018) Efficiency of a photovoltaic thermal stepped solar still: experimental and numerical analysis. Desalination 441:87–95

Radhwan AM (2005) Transient performance of a stepped solar still withbuilt-in latent heat thermal energy storage. Desalination 171(1):61–76

Rahbar N, Esfahani JA (2012) Experimental study of a novel portable solar still by utilizing the heatpipe and thermoelectric module. Desalination 284:55–61

Rajamanickam MR, Ragupathy A (2012) Influence of water depth on internal heat and mass transfer in a double slope solar still. Energy Procedia 1(14):1701–1708

Rashidi S, Bovand M, Rahbar N, Esfahani JA (2018) Steps optimization and productivity enhancement in a nanofluid cascade solar still. Renew Energy 118:536–545

Rashidi S, Esfahani JA, Rahbar N (2017) Partitioning of solar still for performance recovery: experimental and numerical investigations with cost analysis. Sol Energy 153:41–50

Safae MR, Goshayesh HR, Chaer I (2019) Solar still efficiency enhancement by using graphene oxide/paraffin composite. Energies 12(10):2002

Sampathkumar A, Suraparaju SK, Natarajan SK (2023) Enhancement of yield in single slope solar still by composite heat storage material—experimental and thermo-economic assessment. J SolEnergy Eng 145(2):021005

Sathish Kumar TR, Jegadheeswaran S, Chandramohan P (2019) Performance investigation on fin type solar still with paraffin wax as energy storage media. J Therm Anal Calorim 136(1):101–112

Sathyamurthy R, El-Maghlany WM, Attia ME, Kabeel AE, Abdelgaied M, Abdel-Aziz M, Abdullah AS, Vasanthaseelan S (2022) Hemispherical solar distiller performance utilizing hybrid storage media, paraffin wax with nanoparticles: an experimental study. Molecules 27(24):8988

Sathyamurthy R, Nagarajan PK, Vijayakumar D (2016) Experimental validation of fresh water production using triangular pyramid solar still with PCM storage. Int J Eng Res Afr 20:51–58

Shalaby SM, El-Bialy E, El-Sebaii AA (2016) An experimental investigation of a v-corrugated absorber single-basin solar still using PCM. Desalination 398:247–255

Sharbatiyan MH, Rashidi S, Mirhosseini M (2023) Experimental study on the performance of floating solar desalination system with porous absorbent plate. J Taiwan Inst Chem Eng 11:104677

Sharshir SW, Elsheikh AH, Edreis EM, Ali MK, Sathyamurthy R, Kabeel AE, Zang J, Yang NJ (2019) Improving the solar still performance by using thermal energy storage materials: a review of recent developments. Desalin Water Treat 165:1–5

Sharma A, Sachan V (2020) Effect of phase change material on the performance of solar still in winter season. Int J Adv Res Eng Technol (IJARET). 11(5)

Shmroukh AN, Ookawara S (2020) Evaluation of transparent acrylic stepped solar still equipped with internal and external reflectors and copper fins. Therm Sci Eng Prog 18:100518

Sonker VK, Chakraborty JP, Sarkar A, Singh RK (2019) Solar distillation using three different phase change materials stored in a copper cylinder. Energy Rep 5:1532–1542

Tabrizi FF, Dashtban M, Moghaddam H (2010) Experimental investigation of a weir-type cascade solar still with built-in latent heat thermal energy storage system. Desalination 260(1–3):248–253

Toosi SS, Goshayeshi HR, Heris SZ (2021) Experimental investigation of stepped solar still with phase change material and external condenser. J Energy Storage 40:102681

Tuly SS, Sarker MR, Saha S (2019) Experimental investigation of the combined effect of fin, phase change material and external condenser on the yield of solar still. SSRG Int J Mater Sci Eng 6(7):1–5

Velmurugan V, Gopalakrishnan M, Raghu R, Srithar K (2008) Single basin solar still with fin for enhancing productivity. Energy Convers Manag 49(10):2602–8

Velmurugan V, Kumar KN, Haq TN, Srithar K (2009) Performance analysis in stepped solar still for effluent desalination. Energy 34(9):1179–86

Yakup MA, Malik AQ (2001) Optimum tilt angle and orientation for solar collector in Brunei Darussalam. Renew Energy 24(2):223–234

Yousef MS, Hassan H, Kodama S, Sekiguchi H (2019) An experimental study on the performance of single slope solar still integrated with a PCM-based pin-finned heat sink. Energy Procedia 156:100–104

Author information

Authors and Affiliations

Contributions

Methodology: MZ. Writing original draft preparation: MZ. Writing review and editing: SR, RR, GL. Resources: MZ. Supervision: SR, RR, GL.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zarei, M., Rashidi, S., Rafee, R. et al. Sustainable freshwater production using novel cascade solar still with phase change material, serpentine water path, and copper fins. Environ Sci Pollut Res 31, 16928–16939 (2024). https://doi.org/10.1007/s11356-024-32272-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-32272-7