Abstract

Globally escalating ethanol demand necessitates the use of hybrid technologies integrating first- and second-generation biofuel feedstocks for achieving the futuristic targets of gasoline replacement with bioethanol. In present study, an optimized two-step sequential pre-treatment (first dilute alkali, then dilute acid) of Pine forest litter (PFL) was developed. Furthermore, the saccharification of pre-treated PFL was optimized through Response Surface Methodology using Box-Behnken Design, wherein 0.558 g/g of reducing sugar was released under the optimized conditions (12.5% w/v of biomass loading, 10 FPU/g of PFL enzyme loading, 0.15% v/v Tween-80 and 48 h incubation time). Moreover, during hydrolysate fermentation using Saccharomyces cerevisiae NCIM 3288 strain, 22.51 ± 1.02 g/L ethanol was produced. Remarkably, hydrophobic resin (XAD-4) treatment of PFL hydrolysate, significantly removed inhibitors (Furfural, 5-hydroxymethylfurfural and phenolics) and increased ethanol production to 27.38 ± 1.18 g/L. Furthermore, during fermentation of molasses supplemented PFL hydrolysate (total initial sugar: 100 ± 3.27 g/L), a maximum of 46.02 ± 2.08 g/L ethanol was produced with 0.482 g/g yield and 1.92 g/l/h productivity. These findings indicated that the integration of molasses to lignocellulosic hydrolysate, would be a promising hybrid technology for industrial ethanol production within existing bio-refinery infrastructure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The worldwide demand for alternative energy sources has created an opportunity for scientists to develop a cost-effective and environmentally sustainable process (Darvishi and Abolhasan Moghaddami 2019). Because of its potential to strengthen the Earth's environment by lowering greenhouse gas emissions, lignocellulosic biomass is an ideal solution for a renewable alternative to fossil fuels (Pandey et al. 2019). Pine forest litter (PFL) has been identified as one of the most abundant renewable forest-based feedstock resources for lignocellulosic ethanol production (Pandey and Negi 2015).

The lignocellulosic ethanol production process consists of three stages: pre-treatment, enzymatic hydrolysis, and fermentation. Pre-treatment of biomass is a critical step in the breakdown of the lignin-carbohydrate complex network structures, which increases lignocellulose porosity and cellulose accessibility to enzymes in hydrolysis (Singh and Bishnoi 2012; Saini et al. 2020; Pandey et al. 2022). The alkaline pre-treatment essentially removes the lignin from lignocellulosic biomass without affecting the other components, alters the crystallinity in biomass (Chandel et al. 2022; Ceaser et al. 2023), and breaks the lignin-carbohydrate bonds (Salehian and Karimi 2013; Galbe and Wallberg 2019). During diluted acid pre-treatment, mainly hemicelluloses are transformed into monomeric fermentable sugars, furfural and 5-Hydroxymethylfurfural (HMF) (Gupta et al. 2012). In the Lower Himalayan regions of India, chirr pine (Pinus roxburghii) trees are one of the most common biomass sources, and because their litter creates serious forest fires in the summer, they would make an abundant and cost-effective feedstock for ethanol production (Cotana et al. 2014; Pandey and Negi 2015).

Various fermentation inhibitors, such as furfural, HMF, Phenolics, and acetic acid, are formed during the pre-treatment step, causing interference with microbial metabolism by causing cellular and molecular damage to them and significantly affecting ethanol production (Wallace-Salinas and Gorwa-Grauslund 2013). Most industrial yeasts, including S. cerevisiae, are susceptible to pre-treatment derived inhibitors (Ask et al. 2013; Coz et al. 2016). To facilitate the yeast fermentation process, a suitable detoxifying agent such as lime and ion exchange resin were added to the hydrolysate prior to fermentation (Tian et al. 2011). AmberliteTM XAD-4, a polystyrene-divinylbenzene resin lacking functional groups, exhibits adsorption of phenols from aqueous solutions under acidic conditions, wherein molecular phenol species prevail. However, under alkaline conditions, adsorption sharply decreases due to the dominance of negatively-charged phenol species (Ku and Lee 2000).

Molasses as non-crystallizable by-products of sugar mills after sugar crystallization, contains about 40–50% of total sugars (sucrose, fructose and glucose) are preferred substrate for 1G ethanol production worldwide (Joannis-Cassan et al. 2014; Fan et al. 2018; Wu et al. 2020). India produces ~ 2.3 billion litres of ethanol using ∼8.00 metric tons of molasses from about 330 distilleries (Brar et al. 2019). Currently, in India about 800 million litres of ethanol is in use as 5% blending (E5) in petrol. However, to meet the 20% blending (E20) mandate of Ministry of Petroleum and Natural Gas (MoPNG), India there is huge challenge of molasses availability as feedstock (Brar et al. 2019). Another challenge in the molasses fermentation is the need of huge amount of water for its dilution to 15–20% sugar content to make it fermentable for fermenting microorganism (Wu et al. 2020). Most molasses to ethanol production studies showed the 10–12% v/v ethanol production using wild type yeast strain (Arshad et al. 2017; Wu et al. 2020). However, fermenting microorganisms faces many constraints during fermentation such as high temperature, high sugar concentration, high ethanol concentration, pre-treatment generated inhibitors and lack of pentose fermentation machinery. These constraints inhibits the growth and fermentation performances of microorganisms (Selim et al. 2018; Pandey et al. 2019).

Therefore, to cope up with the future ethanol blending mandate, it is essential to explore some new hybrid technologies and find alternative approaches, other than existing first generation (1G) and second-generation (2G) approaches. The hybrid technology, including integrated fermentation of 1G substrate (molasses) and 2G substrate (lignocellulosic hydrolysate) together, was termed as BOLT-ON technology in a previous study (Brar et al. 2019; Pandey et al. 2022).

In present study, an optimized two-step sequential dilute alkali and acid pre-treatment (DAAP) technology was developed for PFL, followed by the statistical optimization of enzymatic saccharification by Response surface methodology (RSM). The obtained DAAP-PFL hydrolysate was detoxified by a hydrophobic resin (AmberliteTM XAD-4 resin) and subsequently fermented to ethanol using S. cerevisiae NCIM3288 strain. Mass balance equation was generated using obtained results for overall lignocellulosic to ethanol production. Furthermore, DAAP-PFL hydrolysate was supplemented with molasses and mixed fermentation was evaluated for high titre ethanol production.

Materials and methods

Feedstock collection and compositional analysis

Pine Forest Litters (PFL), the lignocellulosic feedstock used in this study, was collected in sterile bags from Ranikhet District, Uttaranchal, India and dried at 50 ± 2 °C for 72 h. The dried PFL was milled and homogenized to a particle size of less than 1.0 mm. The composition of the native and dilute alkali and acid pretreated DAAP-PFL (Table 1) was analyzed adopting the National Renewable Energy Laboratory's (NREL) Laboratory Analysis Protocol (Meehnian et al. 2016).

Dilute alkali and dilute acid pre-treatment (DAAP) of PFL

PFL was first pretreated with 1.0% NaOH at 121 °C and 15 lb pressure for 45 min. Subsequently, the pH of solid residual PFL was adjusted to 7.0 with 1.0 N HCl and washed with tap water to eliminate the contaminations of salt, lignin and/or its derivatives, residual alkali etc. The neutralized sample was dried at 50 ± 2 °C to remove moisture. Next, dilute alkali pretreated PFL was pretreated a second time with dilute acid. During dilute acid pre-treatment of alkali pretreated PFL, the effects of different process parameters, including acid concentration (H2SO4: 0.5, 1.0, 1.5, 2.0 and 2.5% v/v), biomass concentration (5, 10, 15, & 20% w/v), and incubation time (15, 30, 45, 60, and 75 min), were investigated and optimized by “one parameter at a time” approach. An experiment under similar conditions with native PFL (without dilute alkali pre-treatment) served as the control in this experiment.

Enzymatic saccharification of pretreated PFL

The crude cellulase enzyme (enzyme activity: 5.09 FPU/ml) was produced under solid state fermentation as per previous studies using locally isolated fungal strain (Pandey et al. 2016). At 10% w/v biomass loading, DAAP-PFL was hydrolyzed in 250 ml stoppered conical flasks with crude cellulase in a 50 mM citrate buffer (pH 4.8). The experiments were carried out for 48 h at 50 °C and 150 rpm with 20 FPU/g enzyme loading and 0.1% w/v Tween-80 loading. The reaction mixture was supplemented with 0.3% w/v sodium azide to check for microbial contamination. After 48 h, the samples were centrifuged at 10,000 rpm for 10 min to collect the hydrolysate. The reducing sugar composition in the hydrolyzate was determined using the 2, 5-dinitrosalicylic acid method (Miller et al. 1959). All of these experiments were performed in technical triplicates and data presented are average values.

Optimization of enzymatic saccharification of pretreated PFL by RSM

Statistical optimization is essential to observe the interactive effect of parameters on the response along with individual parameters effect (Ezeilo et al. 2017; Kumar et al. 2022). The effect of four independent variables for enzymatic saccharification, including biomass loading (10–12.5% w/w), enzyme loading (5–15 FPU/g), surfactant concentration (0.1–0.2% w/w), and incubation time (36–60 h), as well as their interactions with various combinations of variables, were investigated and mathematically optimized by RSM using a Box-Behnken factorial design (BBD).

BBD with four factors and three levels of -1 (lower), 0 (middle), and + 1 (higher) (Table 2) was used for optimization, with three replicates at the centre point, and a total of 27 runs were performed (Table 3). Minitab 16 was used for the experimental design, data analysis, quadratic model construction, and generation of response surface contour plots (Minitab Inc., USA).

Table 3 illustrates the trial setup for the Box-Behnken design. Response surface graphs were used to analyze the variable’s' optimal values for the highest degree of response in order to comprehend the impact of the individual and combined effects of the four variables. Analysis of variance (ANOVA) was used to evaluate the statistical parameters, and three additional runs using the BBD-optimal conditions were used to validate the model (Table 4).

Hydrophobic resin mediated detoxification of DAAP-PFL hydrolysate

A polymeric hydrophobic resin Amberlite™ XAD-4 was procured from Sigma-Aldrich (St. Louis, MO). The DAAP-PFL hydrolysate was detoxified by treatment with polymeric hydrophobic resin XAD-4. The pH of hydrolysate was adjusted to 2.5 by using 1.0 N H2SO4. Initially, the resin was activated by sequential washing with milliQ water, 25% iso-propyl alcohol, 50% iso-propyl alcohol, 100% iso-propyl alcohol and milliQ water, respectively. The activated XAD-4 was mixed with hydrolyzate (5% w/v) in batch mode in the 250 ml Erlenmeyer flask containing 100 ml hydrolysate (pH = 2.5). The experiment was performed at 120 rpm and 30 °C for 2 h. After treatment hydrolysate was filtered, resin was separated and regenerated by using acetone (25 ml/g of XAD-4) for their reuse. The detoxified hydrolysate was analyzed for reducing sugar by 2,5-dinitrosalicylic acid method (Miller et al. 1959), furfural by ethanol hydrochloric acid-aniline method (Pandey and Negi 2015) and phenolic compounds by Folin Ciocalteu Mehod (Blainski et al. 2013).

Fermentation of DAAP-PFL enzymatic hydrolysate

Using detoxified and un-detoxified DAAP-PFL enzymatic hydrolysate, fermentation experiments were carried out in 250 ml airtight rubber-corked Erlenmeyer flasks. Cells of S. cerevisiae NCIM3288 (procured from National collection of industrial microorganisms, Pune, India) were grown in yeast extract peptone dextrose (YEPD) broth at 30 °C under shaking at 200 rpm for overnight to obtain seed inoculum. For fermentation, 100 ml of hydrolysate (pH 5.5) was mixed with 0.5% w/v urea, inoculated with above grown seed inoculums (5% v/v) and incubated at 30 °C for 24 h at 150 rpm. 1.0 ml of sample was centrifuged at 10,000 rpm for 10 min and the supernatant was analyzed for ethanol concentration by dichromate method at 600 nm (Vaid et al. 2017).

Mass balance equation generation

To analyze overall mass balance, mass balance analysis of each step involved in ethanol production such as DAAP, saccharification, detoxification and fermentation was carried out. Carbon (C), Hydrogen (H), Nitrogen (N) and Oxygen (O) composition analysis of the solid and liquid components of the different steps of each process were analysed by CHNS Element Analyser (Thermo Finnigan, USA). The obtained compositions of C, H, N and O were utilized to calculate mole fractions of elements in solid/liquid input and output of each step to generate mass balance equation.

Mixed fermentation of DAAP-PFL hydrolysate and molasses (BOLT-ON process)

DAAP-PFL hydrolysate was supplemented with molasses to adjust the final sugar concentration of 100 g/L in the fermentation medium (pH 5.5). For fermentation, 100 ml of fermentation medium (mixture of hydrolysate and molasses with total initial sugar of 100 g/l) was mixed with 0.5% g/L urea, inoculated with above grown seed inoculums (5% v/v) and incubated at 30 °C for 24 h at 150 rpm. 1.0 ml of sample was centrifuged at 10,000 rpm for 10 min and the supernatant was analyzed for ethanol concentration by dichromate method at 600 nm (Joshi et al. 2019). All the fermentation experiments were carried out in rubber-corked airtight 250 ml Erlenmeyer flasks.

Results and discussion

Optimization of pre-treatment process for PFL

Presence of lignin sheathing along with sugars (cellulose and hemicellulose) in lignocellulosic biomass (LCB) is one of the major challenge during sugar accessibility towards saccharification step in 2G bioethanol production (Pandey and Negi 2015; Rezania et al. 2020). This challenge necessitate to find an efficient pre-treatment process with high lignin removal potential for increasing the availability of sugars to saccharifying enzymes during saccharification. Henceforth, to achieve maximum lignin removal and saccharification, we performed a sequential two-step dilute alkali and dilute acid Pre-treatment (DAAP) in this study. Initially, PFL underwent a dilute alkali pre-treatment step using a 1.0% w/v NaOH, wherein effective breakdown of the recalcitrant lignin outer layer occurred. Alkali treatment removes lignin from lignocellulose by deacetylation of lignin’s side acetyl group and decreases lignin content in lignocellulosic biomass (Wang et al. 2019). Subsequently, the alkali-pretreated PFL was subjected to the dilute acid pre-treatment and the process was optimized for attaining the maximum deconstruction of lignocellulosic network to increase accessibility of complex sugars (cellulose and hemicellulose) for enzymatic saccharification. A maximum 0.248 g/g total reducing sugar yield was obtained under optimum dilute acid pre-treatment conditions (1.5% v/v H2SO4, 10% w/v biomass loading and 45 min incubation time). The possible reason for the release of reducing sugar during dilute acid pre-treatment of alkali treated PFL was attributed to the affinity of acid toward solubilization of hemicelluloses fraction of biomass (Arora and Carrier 2015). In previous study also, release of reducing sugar was reported during dilute acid pre-treatment of sugarcane tops (Sindhu et al. 2011), which supported our findings.

Compositional analysis of native and pretreated PFL

Determination of major lignocellulosic structural components (cellulose, hemicellulose and lignin) before and after pre-treatment is essential for analyzing the effect of pre-treatment on lignocellulosic materials breakdown (Dharmaraja et al. 2023). Therefore, the compositional analysis of native and pretreated PFL was performed for structural carbohydrates and lignin content (Table 1). The analysis revealed that the native PFL consisted of 31.45 ± 1.78% cellulose, 20.78 ± 1.02% hemicelluloses, and 31.48 ± 1.14% total lignin. The pretreated biomass showed cellulose, hemicellulose and total lignin content of 41.25 ± 1.82%, 8.72 ± 0.35% and 11.39 ± 0.46%, respectively (Table 1). Notably, compositional analysis revealed the breakdown of lignin and hemicellulose by 63.81 ± 2.78% w/w and 58.04 ± 2.45% w/w, respectively during DAAP. However, in pretreated biomass cellulose content was found to be increased by 31.79 ± 1.21% w/w. The plausible reason for this decreased lignin and hemicellulose, and increased cellulose could be the breakdown of intermolecular cross-linkages and increased cavitation in the biomass (Sharma et al. 2023). Similarly, increased cellulose content and decreased lignin and hemicellulose content were reported in previous studies for pre-treatment of Rice straw (Kumari and Singh 2022) and sugarcane tops (Sindhu et al. 2011), these supported our results. The total material (sum of cellulose, hemicelluloses and lignin content) loss in pretreated biomass was found to be 22.35 ± 1.09% (Table 1). Total material loss during the dilute acid pre-treatment of sorghum stover was reported previously also (Akanksha et al. 2016), which supported our findings. Taken together, these results revealed the breakdown of complex lignocellulose network during DAAP leading to release of lignin and partial hydrolysis of complex sugars.

Optimization of process parameters for enzymatic saccharification of pretreated PFL by Box-Behnken design (BBD)

For achieving maximum reducing sugar during enzymatic saccharification of DAAP-PFL, the saccharification process was statistically optimized by Response surface methodology (RSM). Box-Behnkken design (BBD) is a tested RSM design for optimization of process to evaluate the individual and interactive effect of each process parameters towards the desired response (Pandey and Negi 2015; Kumar et al. 2022), henceforth we selected BBD design for performing RSM. Reducing sugar yield (RSY) was considered as response of this optimization process. The levels of variables were set to achieve maximum RSY in the selected BBD (Table 2). The experimental design of BBD suggested twenty-seven runs with different combinations of factors and their responses (RSY) was illustrated in Table 3. The effect of each variable individually and their interactive effect to the response (RSY) was evaluated by fitting polynomial quadratic equations. Polynomial equations for the model used were as below:

Where \({\mathrm{X}}_{1}\), \({\mathrm{X}}_{2}\), \({\mathrm{X}}_{3}\) and \({\mathrm{X}}_{4}\) are biomass loading, enzyme loading, surfactant concentration and incubation time, respectively.

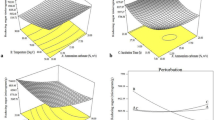

ANOVA (analysis of variance) was conducted to test statistical significance of experimental data. The model was found to be highly significant as evident from the Fisher’s F-test (p = 0.001). The p-value denoting the significance of the coefficients was important in understanding the pattern of mutual interaction between the variables. The goodness of the fit of the model was checked by determining coefficient R2 (96.29), which indicated that 96% of the total variation in enzymatic saccharification yield explained by the model (Table 4). Lack of fit analysis was carried out to measure the failure of used model to represent the data in the experimental domain. Non-significant p-value of lack of fit (p > 0.05) for model indicated that experimental data obtained was in good agreement with the model (Bajar et al. 2020). The surface plots were plotted by using Minitab 16 software and interaction of variables were analyzed for the determination of their optimum level to achieve maximum RSY (Fig. 1a-f).

3D surface plots generated by Minitab Software and Box-Behnken design (BBD). Effect process parameters on saccharification of DAAP-PFL. a biomass loading and enzyme loading, b surfactant concentration and biomass loading, c incubation time and biomass loading, d surfactant concentration and enzyme loading, e incubation time and enzyme loading and f incubation time and surfactant concentration

The developed RSM model predicted the optimum conditions for the enzymatic saccharification of DAAP-PFL as 12.5% w/v biomass loading, 10 FPU/g enzyme loading, 0.15% w/v surfactant loading and 48 h incubation time, wherein release of maximum of 0.558 g/g of RSY was achieved. However, under un-optimized condition (10% w/v biomass loading, 20 FPU/g enzyme loading, 0.1% w/v surfactant loading and 48 h incubation time), RSY was 0.389 g/g. These results displayed that the RSM optimization of the saccharification parameters significantly improved the saccharification yield by 1.43-folds. Similarly, recent studies also demonstrated enhanced saccharification yield after RSM optimization for alkali pretreated jute (Sharma et al. 2023) and acid pretreated cotton stalk (Yildirim et al. 2023).

Moreover, under similar saccharification conditions (12.5% w/v biomass loading, 10 FPU/g enzyme loading, 0.15% w/v surfactant loading and 48 h incubation time), untreated (native) PFL produced 0.091 g/g of RSY. These results showed the 6.46-folds enhanced saccharification yield with DAAP-PFL in comparison to native untreated PFL under RSM optimized conditions. Similarly, previous studies also reported enhanced saccharification with alkali pretreated sugarcane tops (Sindhu et al. 2014) and alkali pretreated jute biomass (Sharma et al. 2023) in comparison to untreated (native) biomass. These reports supported our findings. Taken together, these results indicated the effectiveness of DAAP and RSM optimization for degrading lignin to enhance sugars (cellulose and hemicellulose) availability to saccharifying hydrolytic enzymes and then after finding optimum conditions to hydrolyze these sugars in to fermentable sugars, respectively.

Detoxification of DAAP-PFL hydrolysate

Lignocellulosic hydrolysate contains various pre-treatment generated inhibitors (furfural, 5-HMF and phenolics) along with the fermentable sugars (Jönsson et al. 2013). These inhibitors causes cellular stress to the fermenting microorganisms resulting into their decreased specific growth rate and fermentation performance (Pandey et al. 2019). Therefore, in order to achieve high fermentation performance (yield and productivity) of a yeast strain, it is essential to treat hydrolysate for removal of these inhibitors before fermentation (Jönsson et al. 2013). Henceforth, we treated DAAP-PFL hydrolysate with polymeric hydrophobic resin XAD-4 for its detoxification (removal of inhibitors). At 5% w/v XAD-4 loading, 85.22% furfural, 68.56% 5-Hydroxymethylfurfural (HMF) and 67.78% phenolics were found to be removed with 5.94% sugar loss from the hydrolysate in 2 h (Table 5). Similarly, XAD-4 mediated removal of furfural and HMF (> 70%) with low (< 10%) sugar loss was reported in previous study (Devendra and Pandey 2017) also, which validated our findings. Similarly, in agreement to our findings effectiveness of XAD-4 for adsorption of phenolics was also reported in previous study (Kumar et al. 2020). These findings indicated the effectiveness of the hydrophobic resin XAD-4 as detoxifying agent for the removal of pre-treatment generated inhibitors from hydrolysate for improving fermentation efficiency of yeast.

Fermentation of PFL hydrolysate for ethanol production

Fermentation of DAAP-PFL was performed using un-detoxified hydrolysate (with initial sugar: 54.82 ± 2.11 g/l) and XAD-4 detoxified hydrolysate (with initial sugar 51.54 ± 2.39 g/l) with 5% v/v inoculum of overnight YEPD grown S. cerevisiae NCIM3288 cells. After 24 h of fermentation, in un-detoxified hydrolysate 20.15 ± 0.98 g/L ethanol was produced with 0.426 g/g yield and 0.84 g/l/h productivity. However, XAD-4 detoxified hydrolysate showed enhanced ethanol production of 21.68 ± 1.14 g/l with significantly improved yield and productivity of 0.498 g/g and 0.9 g/l/h, respectively (Table 6). Enhanced ethanol production with detoxified hydrolysate is reported in previous study (Xian et al. 2023) also, which supported our results. The observed improved fermentation potential after hydrolysate detoxification was attributed to the exposure of yeast to very less or non-toxic level of the pre-treatment generated inhibitors (furfural, HMF and phenolics) in detoxified hydrolysate resulting in to their healthier growth and fermentation performance (Kim 2018; Pandey et al. 2019).

Mass balance analysis of overall lignocellulosic bioethanol production process

It is necessary to conduct a mass balance analysis to ascertain the viability of the lignocellulose ethanol manufacturing process (Akanksha et al. 2016; Nakanishi et al. 2017). To analyse the lignocellulosic ethanol conversion process rationally, mass balance studies for the dilute alkali and acid pre-treatment (DAAP), saccharification, detoxification, and fermentation processes were carried out. DAAP raised the cellulose content of the PFL by 31.79%, and 72% of the cellulose was hydrolyzed during enzymatic saccharification. During XAD-4 mediated detoxification, 73.85% of inhibitors (furfural, HMF and phenolics) were removed with considerably low sugar loss of 5.94%. Moreover, fermentation of PFL hydrolysate showed fermentation efficiencies of 83.41% with non-detoxified hydrolysate. However, fermentation efficiency was significantly increased to 97.45% during fermentation of XAD-4 resin detoxified hydrolysate.

For generating mass balance equation of the developed lignocellulosic ethanol production process, elemental (C, H, N, and O) analysis was carried out at each steps (pre-treatment, saccharification and fermentations). Further, mole fractions were calculated using elemental analysis data and mass balance equation was generated as following:

-

Step 1: DAAP Pre-treatment of PFL

$${2.66\mathrm C}_{1.6}{\mathrm H}_{2.3}\mathrm O\;(\mathrm S)+55.5{\mathrm H}_2\mathrm O\;(\mathrm l)=0.11{\mathrm C}_6{\mathrm H}_{12}{\mathrm O}_6\;(\mathrm l)+0.049{\mathrm C}_5{\mathrm H}_{10}{\mathrm O}_5\;(\mathrm l)+20.39{\mathrm C}_{1.5}{\mathrm H}_{2.1}\mathrm O\;(\mathrm l)+1.19{\mathrm C}_{3.4}{\mathrm H}_{1.7}\mathrm O\;(\mathrm S)$$(1) -

Step II: Hydrolysis of DAAP-PFL

$$1.19{\mathrm C}_{3.4}{\mathrm H}_{1.7}\mathrm O\;(\mathrm S)+38.88{\mathrm H}_2\mathrm O\;(\mathrm l)=0.29{\mathrm C}_6{\mathrm H}_{12}{\mathrm O}_6\;(\mathrm l)+0.043{\mathrm C}_5{\mathrm H}_{10}{\mathrm O}_5\;(\mathrm l)+10.287{\mathrm C}_{1.3}{\mathrm H}_{4.4}\mathrm O\;(\mathrm l)+0.94{\mathrm C}_{1.4}{\mathrm H}_{3.7}\mathrm O\;(\mathrm S)$$(2) -

Step III: Fermentation of the DAAP-PFL hydrolysate

$$0.29{\mathrm C}_6{\mathrm H}_{12}{\mathrm O}_6\;(\mathrm l)+0.043{\mathrm C}_5{\mathrm H}_{10}{\mathrm O}_5\;(\mathrm l)+10.287{\mathrm C}_{1.3}{\mathrm H}_{4.4}\mathrm O\;(\mathrm l)=0.39{\mathrm C}_2{\mathrm H}_5\mathrm{OH}\;(\mathrm l)+1.99{\mathrm{CO}}_2\;(\mathrm g)+0.11{\mathrm C}_6{\mathrm H}_{12}{\mathrm O}_6\;(\mathrm l)+0.036{\mathrm C}_5{\mathrm H}_{10}{\mathrm O}_5\;(\mathrm l)+7.494{\mathrm C}_{1.2}{\mathrm H}_{4.3}\mathrm O\;(\mathrm l)+{\mathrm{CH}}_{1.75}{\mathrm N}_{0.15}\mathrm O{{}_{0.5}\;(}\mathrm S)$$(3)

Overall Mass balance equation (By summarizing above three equations):

In above equation, S = solid and l = liquid.

The generated equation showed the mole fraction of elements in the reactants and their entire distribution in various solid and liquid outputs of the developed lignocellulosic ethanol production process. To the best of literature survey based information, elemental analysis based mass balance equation is being reported first time in this study.

Fermentation of molasses supplemented DAAP-PFL hydrolysate

Molasses is a sugar industry generated sugar rich (30–50% w/v) substrate for ethanol production (Mikulski and Kłosowski 2021). In general, lignocellulosic hydrolysate (LH) contains low amount of fermentable sugars, and molasses addition to LH increases the initial fermentable sugars in LH to produce high ethanol titre (Gutiérrez-Rivera et al. 2015). Therefore, in present study we supplemented molasses to un-detoxified and detoxified DAAP-PFL individually (for initial sugar: 100 g/l) and fermentation was carried out using S. cerevisiae NCIM3288 cells. As expected, due to the presence of higher initial sugar, more ethanol was produced in molasses supplemented DAAP-PFL hydrolysate than DAAP-PFL hydrolysate only (Table 6), due to the presence of high initial sugars. In molasses supplemented XAD-4 detoxified DAAP hydrolysate fermentation, a maximum of 46.02 ± 2.08 g/L ethanol was produced with 0.482 g/g yield and 1.92 g/l/h productivity. However, relatively lower ethanol (42.51 ± 2.16 g/L) was produced in fermentation of molasses supplemented un-detoxified hydrolysate with lower yield (0.455 g/g), and productivity (1.77 g/l/h) (Table 6), due to the presence of inhibitors. In previous studies also the enhanced ethanol production is reported during mixed fermentation of lignocellulosic hydrolysate and molasses (Saini et al. 2020; Pandey et al. 2022). These findings validated the effectiveness of XAD-4 mediated detoxification in mixed fermentation as well. Considering these results, it is relevant to supplement molasses in lignocellulosic hydrolysates to produce high titre of ethanol for accomplishing the ethanol-blending target in gasoline in near future.

Conclusion

The dilute alkali and acid pre-treatment (DAAP) of PFL had significantly improved the enzymatic saccharification efficiency by six-folds. The polymeric resin, XAD-4 mediated detoxification drastically removed the major inhibitors such as furfural (85.22%), HMF (68.56%) and phenolics (67.78%) with very low (5.94%) sugar loss. And, therefore ethanol titre, yield and productivity was enhanced after detoxification. In mixed fermentation of molasses supplemented DAAP-hydrolysate (BOLT-ON technology), higher ethanol production demonstrated the superiority of the developed hybrid ethanol production technology over first generation (1G) or second generation (2G) technologies, separately. As a result, the developed bioprocess for BOLT-ON technology would be a promising technology for industrial scale ethanol production in existing bio-refinery infrastructure. To the best our literature analysis, integration of XAD-4 detoxified lignocellulosic hydrolysate and molasses has been reported first time for ethanol production in this study.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Akanksha K, Sukumaran RK, Pandey A, Rao SS, Binod P (2016) Material balance studies for the conversion of sorghum stover to bioethanol. Biomass Bioenerg 85:48–52. https://doi.org/10.1016/J.BIOMBIOE.2015.11.027

Arora A, Carrier DJ (2015) Understanding the Pine dilute acid pre-treatment system for enhanced enzymatic hydrolysis. ACS Sustain Chem Eng 3:2423–2428. https://doi.org/10.1021/acssuschemeng.5b00417

Arshad M, Hussain T, Iqbal M, Abbas M (2017) Enhanced ethanol production at commercial scale from molasses using high gravity technology by mutant S. cerevisiae. Braz J Microbiol 48:403–409. https://doi.org/10.1016/j.bjm.2017.02.003

Ask M, Bettiga M, Mapelli V, Olsson L (2013) The influence of HMF and furfural on redox-balance and energy-state of xylose-utilizing Saccharomyces cerevisiae. Biotechnol Biofuels 6:22. https://doi.org/10.1186/1754-6834-6-22

Bajar S, Singh A, Bishnoi NR (2020) Exploration of low-cost agro-industrial waste substrate for cellulase and xylanase production using Aspergillus heteromorphus. Appl Water Sci 10:153. https://doi.org/10.1007/s13201-020-01236-w

Blainski A, Lopes G, de Mello J (2013) Application and analysis of the folin ciocalteu method for the determination of the total phenolic content from Limonium Brasiliense L. Molecules 18:6852–6865. https://doi.org/10.3390/molecules18066852

Brar KK, Agrawal D, Chadha BS, Lee H (2019) Evaluating novel fungal secretomes for efficient saccharification and fermentation of composite sugars derived from hydrolysate and molasses into ethanol. Bioresour Technol 273:114–121. https://doi.org/10.1016/j.biortech.2018.11.004

Ceaser R, Rosa S, Montané D, Constanti M, Medina F (2023) Optimization of softwood pre-treatment by microwave-assisted deep eutectic solvents at high solids loading. Bioresour Technol 369. https://doi.org/10.1016/j.biortech.2022.128470

Chandel H, Kumar P, Chandel AK, Verma ML (2022) Biotechnological advances in biomass pre-treatment for bio-renewable production through nanotechnological intervention. Biomass Convers Biorefinery 2024. https://doi.org/10.1007/s13399-022-02746-0

Cotana F, Cavalaglio G, Gelosia M, Nicolini A, Coccia V, Petrozzi A (2014) Production of bioethanol in a second generation prototype from Pine Wood chips. Energy Procedia 45:42–51. https://doi.org/10.1016/j.egypro.2014.01.006

Coz A, Llano T, Cifrián E, Viguri J, Maican E, Sixta H (2016) Physico-chemical alternatives in lignocellulosic materials in relation to the kind of component for fermenting purposes. Materials (Basel) 9. https://doi.org/10.3390/MA9070574

Darvishi F, Abolhasan Moghaddami N (2019) Optimization of an industrial medium from molasses for bioethanol production using the Taguchi statistical experimental-design method. Fermentation 5:14. https://doi.org/10.3390/fermentation5010014

Devendra LP, Pandey A (2017) Adsorptive detoxification of fermentation inhibitors in acid pretreated liquor using functionalized polymer designed by molecular simulation. Bioprocess Biosyst Eng. https://doi.org/10.1007/s00449-017-1821-z

Dharmaraja J, Shobana S, Arvindnarayan S, Francis RJ, Jeyakuma RB, Saratale RG, Ashokkumar V, Bhatia SK, Kumar V, Kumar G (2023) Lignocellulosic biomass conversion via greener pre-treatment methods towards biorefinery applications. Bioresour Technol 369. https://doi.org/10.1016/J.BIORTECH.2022.128328

Ezeilo UR, Zakaria II, Huyop F, Wahab RA (2017) Enzymatic breakdown of lignocellulosic biomass: the role of glycosyl hydrolases and lytic polysaccharide monooxygenases. Biotechnol Biotechnol Equip:1–16. https://doi.org/10.1080/13102818.2017.1330124

Fan M, Zhang S, Ye G, Zhang H, Xie J (2018) Integrating sugarcane molasses into sequential cellulosic biofuel production based on SSF process of high solid loading. Biotechnol Biofuels 11:1–9. https://doi.org/10.1186/s13068-018-1328-0

Galbe M, Wallberg O (2019) Pre-treatment for biorefineries: a review of common methods for efficient utilisation of lignocellulosic materials. Biotechnol Biofuels 121(12):1–26. https://doi.org/10.1186/S13068-019-1634-1

Gupta R, Kumar S, Gomes J, Kuhad RC (2012) Kinetic study of batch and fed-batch enzymatic saccharification of pretreated substrate and subsequent fermentation to ethanol. Biotechnol Biofuels 5:16. https://doi.org/10.1186/1754-6834-5-16

Gutiérrez-Rivera B, Ortiz-Muñiz B, Gómez-Rodríguez J, Cardenas-Cagal A, Gonzalez JMD, Aguilar-Uscanga MG (2015) Bioethanol production from hydrolyzed sugarcane bagasse supplemented with molasses “B” in a mixed yeast culture. Renew Energy 74:399–405. https://doi.org/10.1016/j.renene.2014.08.030

Joannis-Cassan C, Riess J, Jolibert F, Taillandier P (2014) Optimization of very high gravity fermentation process for ethanol production from industrial sugar beet syrup. Biomass Bioenerg 70:165–173. https://doi.org/10.1016/j.biombioe.2014.07.027

Jönsson LJ, Alriksson B, Nilvebrant NO (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16. https://doi.org/10.1186/1754-6834-6-16

Joshi J, Dhungana P, Prajapati B, Maharjan R, Paudyal P, Yadav M, Mainali M, Yadav AP, Bhattarai T, Sreerama L (2019) Enhancement of ethanol production in electrochemical cell by Saccharomyces cerevisiae (CDBT2) and Wickerhamomyces anomalus (CDBT7). Front Energy Res 7:70. https://doi.org/10.3389/fenrg.2019.00070

Kim D (2018) Physico-chemical conversion of lignocellulose: inhibitor effects and detoxification strategies: a mini review. Molecules 23. https://doi.org/10.3390/molecules23020309

Ku Y, Lee K-C (2000) Removal of phenols from aqueous solution by XAD-4 resin. J Hazard Mater 80:59–68. https://doi.org/10.1016/S0304-3894(00)00275-2

Kumar M, Pandey AK, Kumari S, Wani SA, Jakeer S, Tiwari R, Prasad R, Gaur NA (2022) Secretome produced by a newly isolated Aspergillus flavus strain in engineered medium shows synergy for biomass saccharification with a commercial cellulase. Biomass Convers Biorefinery 12:4745–4757. https://doi.org/10.1007/S13399-020-00935-3/METRICS

Kumar V, Yadav SK, Kumar J, Ahluwalia V (2020) A critical review on current strategies and trends employed for removal of inhibitors and toxic materials generated during biomass pre-treatment. Bioresour Technol 299:122633. https://doi.org/10.1016/J.BIORTECH.2019.122633

Kumari D, Singh R (2022) Rice straw structure changes following green pre-treatment with petha wastewater for economically viable bioethanol production. Sci Rep 12:1–11. https://doi.org/10.1038/s41598-022-14627-7

Meehnian H, Jana AK, Jana MM (2016) Effect of particle size, moisture content, and supplements on selective pre-treatment of cotton stalks by Daedalea flavida and enzymatic saccharification. 3 Biotech 6:235. https://doi.org/10.1007/s13205-016-0548-x

Mikulski D, Kłosowski G (2021) Integration of first- and second-generation bioethanol production from beet molasses and distillery stillage after dilute sulfuric acid pre-treatment. Bioenergy Res:1–12. https://doi.org/10.1007/S12155-021-10260-W/FIGURES/5

Miller GL, Kuila A, Suralikerimath N et al (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Nakanishi SC, Soares LB, Biazi LE, Nascimento VM, Costa AC, Rocha GJM, Ienczak JL (2017) Fermentation strategy for second generation ethanol production from sugarcane bagasse hydrolyzate by Spathaspora passalidarum and Scheffersomyces stipitis. Biotechnol Bioeng 114:2211–2221

Pandey AK, Edgard G, Negi S (2016) Optimization of concomitant production of cellulase and xylanase from Rhizopus oryzae SN5 through EVOP-factorial design technique and application in Sorghum Stover based bioethanol production. Renew Energy 98:51–56. https://doi.org/10.1016/j.renene.2016.05.071

Pandey AK, Kumar M, Kumari S, Kumari P, Yusuf F, Shaik J, Sumera N, Piyush C, Ishita B, Gaur NA (2019) Evaluation of divergent yeast genera for fermentation-associated stresses and identification of a robust sugarcane distillery waste isolate Saccharomyces cerevisiae NGY10 for lignocellulosic ethanol production in SHF and SSF. Biotechnol Biofuels 12:1–23. https://doi.org/10.1186/S13068-019-1379-X/FIGURES/6

Pandey AK, Kumar M, Kumari S, Gaur NA (2022) Integration of acid pre-treated paddy straw hydrolysate to molasses as a diluent enhances ethanol production using a robust Saccharomyces cerevisiae NGY10 strain. Renew Energy 186:790–801. https://doi.org/10.1016/J.RENENE.2022.01.039

Pandey AK, Negi S (2015) Impact of surfactant assisted acid and alkali pre-treatment on lignocellulosic structure of pine foliage and optimization of its saccharification parameters using response surface methodology. Bioresour Technol 192:115–125. https://doi.org/10.1016/J.BIORTECH.2015.04.054

Rezania S, Oryani B, Cho J, Talaiekhozani A, Sabbagh F, Hashemi B, Rupani PF, Mohammadi AK (2020) Different pre-treatment technologies of lignocellulosic biomass for bioethanol production: an overview. Energy 199:117457. https://doi.org/10.1016/J.ENERGY.2020.117457

Saini R, Hegde K, Brar SK, Vezina P (2020) Advanced biofuel production and road to commercialization: an insight into bioconversion potential of Rhodosporidium sp. Biomass Bioenerg 132:105439. https://doi.org/10.1016/j.biombioe.2019.105439

Salehian P, Karimi K (2013) Alkali pre-treatment for improvement of biogas and ethanol production from different waste parts of pine tree. Ind Eng Chem Res 52:972–978. https://doi.org/10.1021/ie302805c

Selim K, El-Ghwas D, Easa S, Abdelwahab Hassan M (2018) Bioethanol a microbial biofuel metabolite; new insights of yeasts metabolic engineering. Fermentation 4:16. https://doi.org/10.3390/fermentation4010016

Sharma L, Alam NM, Roy S, Satya P, Kar J, Ghosh S, Goswami T, Majumdar B (2023) Optimization of alkali pre-treatment and enzymatic saccharification of jute (Corchorus olitorius L.) biomass using response surface methodology. Bioresour Technol 368:128318. https://doi.org/10.1016/J.BIORTECH.2022.128318

Sindhu R, Kuttiraja M, Binod P, Janu KU, Sukumaran RK, Pandey A (2011) Dilute acid pre-treatment and enzymatic saccharification of sugarcane tops for bioethanol production. Bioresour Technol 102:10915–10921. https://doi.org/10.1016/J.BIORTECH.2011.09.066

Sindhu R, Kuttiraja M, Binod P, Sukumaran RK, Pandey A (2014) Physicochemical characterization of alkali pretreated sugarcane tops and optimization of enzymatic saccharification using response surface methodology. Renew Energy 62:362–368. https://doi.org/10.1016/j.renene.2013.07.041

Singh A, Bishnoi NR (2012) Optimization of enzymatic hydrolysis of pretreated rice straw and ethanol production. Appl Microbiol Biotechnol 93:1785–1793. https://doi.org/10.1007/s00253-012-3870-1

Tian S, Zhu J, Yang X (2011) Evaluation of an adapted inhibitor-tolerant yeast strain for ethanol production from combined hydrolysate of softwood. Appl Energy 88:1792–1796. https://doi.org/10.1016/j.apenergy.2010.11.037

Vaid S, Nargotra P, Kumar Bajaj B (2017) Consolidated bioprocessing for biofuel-ethanol production from pine needle biomass. Environ Prog Sustain Energy 37:546–552. https://doi.org/10.1002/ep.12691

Wallace-Salinas V, Gorwa-Grauslund MF (2013) Adaptive evolution of an industrial strain of Saccharomyces cerevisiae for combined tolerance to inhibitors and temperature. Biotechnol Biofuels 6:151. https://doi.org/10.1186/1754-6834-6-151

Wang Z, Dien BS, Rausch KD, Tumbleson ME, Singh V (2019) Improving ethanol yields with deacetylated and two-stage pretreated corn stover and sugarcane bagasse by blending commercial xylose-fermenting and wild type Saccharomyces yeast. Bioresour Technol 282:103–109. https://doi.org/10.1016/J.BIORTECH.2019.02.123

Wu R, Chen D, Cao S, Lu Z, Huang Z, Lu Q, Chen Y, Guan N, Wei Y, Huang R (2020) Enhanced ethanol production from sugarcane molasses by industrially engineered: Saccharomyces cerevisiae via replacement of the PHO4 gene. RSC Adv 10:2267–2276. https://doi.org/10.1039/c9ra08673k

Xian X, Zheng X, Huang J, Qureshi N, Li B, Liu J, Zeng Y, Nichols NN, Lin X (2023) Detoxification of high solid-liquid hydrothermal pretreated sugar cane bagasse by chromatographic adsorption for cellulosic ethanol production. Ind Crops Prod 202:117048. https://doi.org/10.1016/J.INDCROP.2023.117048

Yildirim O, Tunay D, Ozkaya B (2023) Optimization of enzymatic hydrolysis conditions of chemical pretreated cotton stalk using response surface methodology for enhanced bioethanol production yield. Biomass Convers Biorefinery 13:6623–6634. https://doi.org/10.1007/S13399-021-01692-7/METRICS

Funding

The study was funded by Uttar Pradesh Higher Education Council (UPHEC) with reference number vide: No-45/2022/869/Sattar-4–2022/001–70-4099–1-2022, dated 20.04.2022 and C.V. Raman Minor Research Project Scheme of CSJMU, Kanpur with reference number vide: No-CSJMU/CV/12/2022, dated 19/04/2022.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Ajay Kumar Pandey performed conceptualization, material preparation, data analysis and manuscript writing. Sangeeta Negi performed conceptualization, writing and reviewing of the manuscript. Rajesh Yadav performed writing, reviewing and revision of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pandey, A.K., Negi, S. Enhanced ethanol production using hydrophobic resin detoxified Pine forest litter hydrolysate and integrated fermentation process development supplementing molasses. Environ Sci Pollut Res (2023). https://doi.org/10.1007/s11356-023-30185-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11356-023-30185-5