Abstract

This study investigated the impacts of a drying process under low temperature and reduced pressure (non-thermal drying) on the final dehydrated products characteristics. This process is based on the retention of water on molecular sieves with a good selectivity against these molecules. In this study, drying experiments of 7mm thick apple slices (AS) were performed and compared to apple slices pretreated by freezing. It was concluded that the dehydrated apple slices were depleted of the maximum amount of water after 12 hours of drying, with a final water content equal to 12 ± 1.75%, whereas after freezing pretreatment, a decrease in drying time to 7 hours was observed, as well as a decrease in water content to 10 ± 0.5%. This explains the effect of freezing pretreatment on accelerating water transfer. In addition, a convective drying was performed on the apple slices at 60°C, which allows comparison with the slices dried by our non-thermal drying process. In order to characterize the obtained fruits, characteristic analyses such as water activity (Aw), color, texture (hardness), and dimensions (diameter and thickness) were performed before and after each drying experiment. Thus, continuous measurements of temperature, humidity, and pressure, within the enclosure, were determined during the experiments using a wireless sensor system controlled by a programming Arduino. Finally, mathematical modeling by various models (Newton, Page, Midilli, etc.) was performed to determine the most suitable model describing the non-thermal and convective drying of apple slices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fruits and vegetables occupied a large part of the daily human diet thanks to their nutritional values (sugar, polyphenol, carotenoid, vitamin C, vitamin E, etc.) and their beneficial effect on health as an antioxidant an anti-inflammatory (Blasa et al. 2010). They have been used for several years in various food products (yogurts, cookies, baby flour, jams, marmalades, cream desserts, etc.), as well as in the pharmaceutical and cosmetic field (Saadoudi Mouni 2019).

In the world, it has been found that all types of vegetables are present in the market throughout the year, while the majority of fruits has a seasonal production; i.e., their consumption is limited to the harvest season, and their storage in fresh form can lead to contamination by pathogens such as molds, bacteria, yeasts, etc. For this reason, it was necessary to find a suitable method of conservation of these fruits without risking the loss of their nutritional value.

In prehistoric times, human dried food in the sun to support him in the periods between seasons, which is the oldest technique of food preservation. But after several studies of this method, many disadvantages have appeared like the loss of vitamins, polyphenols, and sugars. Thus, many efforts have been made during the last century to develop new techniques and equipment for dehydration to eliminate as much water as possible from the fruits which is the major component of biological cells (80% of its mass) and responsible for its development, but with the conservation of nutritional value. This promotes the stability of the cells during the required storage period.

Several researchers have studied different drying methods to dehydrate fruits. There are two types of techniques such as thermal drying like natural convective drying (Chin, Siew, and Soon 2015), microwave drying (Xu et al. 2021), and forced convective drying (Naderinezhad et al. 2016; Moussaoui et al. 2021) and a non-thermal drying like lyophilization (Lammerskitten et al. 2019), osmotic dehydration (Khoualdia, B. Ben-ali and Hannach 2020), and pulsed electric field (PEF) drying (Ben-Ali. 2018; Yu et al. 2020). Each of them is adapted to a particular situation according to the properties of the raw material, the physical characteristics of the finished product, and the operating costs. The dehydration techniques can be classified based on different criteria: according to the mechanism of heat transfer involved in the process and according to the temperature and pressure of operation. In our work, we adopt the classification based on the physical changes (evaporation, sublimation, or without phase change) that water undergoes during the dehydration process, i.e., with phase change where water is removed by evaporation.

This article focuses on the preservation of fruits using a non-thermal drying method to reduce the water content and avoid any risk of evaporation of the nutritional properties of the vegetable products (vitamins, proteins, zinc, etc.). The fruit used is the “apple” which is the fourth most important and most consumed fruit in the world. It is a berry containing seeds and consists of two to five carpels, surrounded by a fleshy envelope (Musacchi and Serra 2018). It has health benefits, high-fiber content, and phenolic compounds that are found in high quantities in its flesh and skin. It contains more than 80% water, and the rest is rich in sugar, vitamin, and minerals (NECIB and MOUSSAOUI 2019). Many studies have recently shown that apple consumption is inversely related to the risk of developing asthma, diabetes, certain cancers (colon), and certain cardiovascular diseases (Verdu 2014). Convective drying was realized as a thermal dehydration on apple slices in order to compare to the apple slices dried by a novel process using non-thermal drying in terms of characteristics and final characteristics such as water content and water activities of dried products.

Materials and methods

Material

The fruit studied is the apple. It was purchased from a local market in Gabes (Tunisia). All the apples have almost a similar size. They were washed, wiped, and kept in a refrigerator at 4°C until use. Before realizing the experiment, the apples were left in the open air until they reached room temperature and were then cut into slices of about 7 ± 1 mm in size. We worked on 2 types of samples for non-thermal drying which are fresh apple slices and apple slices frozen at −18°C. We compared the results with apple slices dehydrated by convective drying at 60°C.

Methods

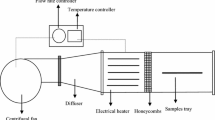

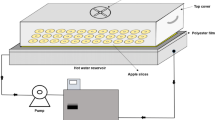

The experimental apparatus is presented by Fig. 1. It consists of a cylindrical enclosure connected to a vacuum pump. A valve, between the two, is used to break the vacuum before stopping the experiment. The enclosure contains trays, some containing the products to be dried (fruits, vegetables, etc.), and others used to place the molecular sieves (4Å). The trays containing the products and the molecular sieves are placed alternately. The molecular sieves adsorb the water vapor (3Å) removed from the products.

At the beginning, we put the vegetable products to be dried on the trays, and the other trays contain the molecular sieves; then we close the enclosure and start the pump. After one hour each, the pump is stopped, and the products are removed to measure their weight. When the weight becomes constant after successive measurements, then the products are completely dried. To study the drying kinetics, a curve that represents the water content WC (%) as a function of the drying time is plotted. Each experiment is repeated 3 times to confirm the reproducibility of the drying process.

Molecular sieves have the capacity to adsorb 10% of their weight in water (Habani and Adda 2019), so a regeneration should be done after its saturation. It is carried out in an oven at a temperature of 200°C during 2 hours in order to eliminate all the adsorbed water and to allow the reuse of molecular sieves in another drying cycle (Gao et al. 2020).

Thus, a three-parameter wireless sensor is placed within the enclosure to determine the temperature (°C), humidity (%), and pressure (mbar) during drying. The sensor data are collected using a programming, Raspberry Pi. Convective drying experiments at 60°C were realized also using “Food Dehydrator model SDA 350 A2” with the aim to compare the results of the convective and a non-thermal drying process.

To plot the kinetics curves of non-thermal drying and convective drying, the water loss was calculated by a normalized equation (1) (NWL) expressed in (%):

Then, it was assumed that the normalized initial amount of water found in the fruit is 100%, so we calculated the Normalized Water Content (NWC) in (%) by this equation (2):

where NWL is the normalized water lost (%), mi is the initial mass of the fruit before drying (g), mt is the mass of the fruit at time “t” (g), and NWC is the normalized water content.

The initial and final moisture content (MC) of the fruit was measured using an “Infrared Moisture Analyzer MA35M-000230V1” on a wet basis according to the device reference.

The water activity (Aw) of fruits is measured by “Water Activity Meter WA-160 A” before and after drying. It is determined the amount of free water found in the product which can cause the appearance of yeast and bacteria that prevents the storage of vegetable products in the long term.

The color analysis of the fruits before and after drying was performed by the “Color Analyzer Digital Precise LAB Color Meter Tester” which consists of a light source. The CieLab coordinates: L∗ (whiteness or brightness), a∗ (redness or greenness), and b∗ (yellowish or bluish), are determined.

The texture of food is an organoleptic quality. This property consists of two characteristics: crispness and hardness. In our study, we are determining the hardness only of the AS before and after drying using “GY-3 penetrometer.”

Finally, the dimensions of the apple slices (AS) are determined. Using a “caliper,” a measurement of the diameter and the thickness of the apple slices is carried out in order to examine the shape of the disc of apple slices before and after drying.

Modeling parameters

In our study, 5 models are used which are Newton (N), Page (P), Modified-Page (M-P), Henderson-Pabis (H-P), and Midilli et al..(Menges and Ertekin 2006; L.C. Hawa et al. 2020a; La Choviya Hawa et al. 2020b) The NWC calculation expression of each model is shown in Table 1.

The equation constants of all the models are determined, as well as the squared error (RMSE), the correlation coefficient (R2), and the reduced mean square 𝜒2 of the variance which are calculated by the following equations (3, 4, and 5):

where NWCexp is the values of the experimental normalized water content, NWCtheo is the values of the theoretical normalized water content, n is the number of experimental observations, and p is the number of constants in the model.

Results and discussions

Kinetic study of the dehydration of apple slices

To further confirm the advantages of non-thermal drying, experiments were conducted on the apple slices.

The kinetics of non-thermal drying of fresh and frozen AS is observed in Fig. 2. Figure 2a represents the NWL (%) as a function of time with decreasing curves, while Fig. 2b represents the NWC (%) as a function of time with increasing curves. All the curves are composed of three phases, the first one is characterized by a fast kinetics which lasts 3 hours for fresh AS and 2 hours for frozen AS, then a slow phase which lasts 8 hours (fresh AS) and 3 hours (frozen AS), and this phase is followed by a stability of NWL and NWC which lasts 3 hours (fresh AS) and 2 hours (frozen AS). The values of NWL and NWC of the 3 phases for fresh AS are 49.47% and 50.53%, 83.44% and 16.55%, and 85.15% and 14.87%, and those for frozen AS are 53.93% and 46.07%, 80.35% and 19.65%, and 83.81% and 16.18% for the 3 phases, respectively.

On the other hand, convective drying is carried out in order to compare their results with the results of non-thermal drying. Figure 3 shows the kinetics of dehydration of fresh AS by non-thermal and convective drying. Figure 3a represents the NWL (%) as a function of time with decreasing plots, and Fig. 3b represents the NWC (%) as a function of time with increasing plots. Similarly, all the curves are divided into three phases, the first is characterized by a fast kinetics that lasts 3 hours for non-thermal drying and 4 hours for convective drying, then a slow phase that lasts 8 hours (non-thermal) and 4 hours (convective), and a stability of NWL and NWC is reached that lasts 3 hours for both types of drying. The values of NWL and NWC of the 3 phases for the non-thermal drying are 49.47% and 50.53%, 83.44% and 16.55%, and 85.15% and 14.87%, and those for the convective drying are 65.08% and 34.92%, 82.02% and 17.98%, and 82.75% and 17.24%, for the 3 phases respectively. These two curves allow us to conclude that the time needed to dehydrate fresh AS by non-thermal drying is 12 hours and 7 hours for frozen AS, while the time needed for convective drying is 8 hours.

To validate the reproducibility of the drying process, other continuous non-thermal drying experiments were performed (Fig.4), which are given final NWC between 15.33% and 18.81% after 14h of drying; however, NWC of 24.76% was obtained after 10 hours of drying. Yaldiz et al. studied thin film solar drying of grapes and found a final water content of 16% for 55 hours (Yaldiz, Osman. Ertekin, Can. Uzun 2001), which confirms that our process is faster in terms of time and more cost effective, and X. Li et al. studied instant controlled pressure-drop (DIC) drying of apple slices and found that the water content is reduced up to 15.2% (Li et al. 2021). Also, comparing to our results for frozen AS, Peng et al. found that pretreatment by freezing at a temperature (−18 and −40°C) corresponding to freezing times of 84.2 and 45 min and beneficial for obtaining a crisp texture (Peng et al. 2018).

Concerning the measurement of initial and final MC, Table 2 summarizes the MC values of fresh AS before and after drying. A decrease in MC from 82.45 ± 2 to 11.45 ± 3.04 % is observed after 14 hours of non-thermal drying, whereas MC is reduced from 76.98% to 28.4% for 10 hours drying. These results affirm that a drying time between 14 hours and 10 hours leads to good dehydration. An optimal drying time of 12 hours is considered in the following work. Kroehnke et al. studied the drying by osmotic dehydration of kiwi slices. They found the lowest MC with the osmotic agent “erythritol” with a value of 42.47 ± 0.33 % after 105 min (Kroehnke et al. 2021). Similarly, Braga et al. studied the drying of pineapple-mint powder by atomization and found a MC equal to 7% (Braga et al. 2020).

The MC of frozen AS gives a value equal to 10.51% beyond 7 hours of dehydration. The drying time of AS without pretreatment by freezing is 12 hours to reach a MC of 15%. This result proves the efficiency of freezing on the drying time and the product quality verified by the water activity measurement. This reduction in MC agrees with previous work on freeze-dried apple slices studied by Lammerskitten et al., who found that pulsed electric field (PEF) applied prior to lyophilization reduced the drying time (Lammerskitten et al. 2019).

Regarding the convection drying curve, a decrease in MC from 79.14% to 5.39% was observed. Similar results are shown with Hawa et al. They found that convective drying of cabya fruit decreased the moisture content by 9% without pretreatment (La Choviya Hawa et al. 2020a).

From these experiments, it was concluded that freezing as a pretreatment, before non-thermal drying, decreased the drying time to half of that without pretreatment and thus lowered the moisture content; it does not affect the fruit wall; i.e., it does not present negative symptoms such as burning or excessive shrinkage that affect the quality or shape of the final product. Concerning the convective drying and the non-thermal drying, it can be seen that the convective drying time is shorter than the non-thermal drying. The quality of the final dried product by this last method is the best.

Control and regulation

Figure 5 represents the sensor results of pressure (mbar), humidity (%), and temperature (°C) at a time “t” of the experiment. We observed, during the experiment, a stability of the pressure at a value of about 5.5±0.5 mbar, while the humidity decreased from 82% to 7.44%, which confirms that the water removed from the plant products is well adsorbed by the molecular sieves. This remarkable decrease in humidity is accompanied by a slight increase in temperature from 22.53°C to 25.6°C, which may be related to the degree of temperature outside the room where our device is placed (the ambient temperature of the laboratory) and to the adsorption of water by the molecular sieves is exothermic.

Characteristic analysis

The Aw of fresh AS (Table 3) before drying is equal to 0.9 ± 0.02; after 14 hours of non-thermal drying it decreased to 0.49 ± 0.09, which does not lead to the development of any type of bacteria. An Aw equal to 0.65 after drying of 10 hours which is not sufficient to ensure the conservation of these products for a long time, because this value is responsible for the growth of xerophiles. Concerning frozen AS, the water activity obtained is 0.5 after 7 hours of non-thermal drying. Similarly, next to 11 hours of convective drying, the Aw is reduced to 0.53. The last two results are good values for the long-term preservation of these fruits. These results are in agreement with the results of other research on apple slices dried by PEF, studied by A. Lammerskitten et al., who found a value of Aw equal to 0.75 (Lammerskitten et al. 2019) as well as the work of M. Rascón et al. who dried banana slices by lyophilization with a pretreatment by DO and found an Aw equal to 0.327 (Rascón et al. 2018). The non-thermal drying applies an important decrease of the free water of the fruits which gives a very reduced water activity (Aw) (≤0.65), which allows us to preserve these fruits in the long term.

Color is considered an essential quality attribute for dried food products, especially for ready-to-eat vegetable products. In our study, Hunter’s values for fresh AS samples were brightness L* = 64.9 ± 5, coordinate a*= 1.6 ± 0.9, and coordinate b* = 24.5 ± 2 (Table 3). All AS values after drying showed a significant decrease in the brightness value (L*), while the a* and b* values of the dried samples increased compared to those of the fresh AS. Similarly for the convective dried AS, a slight decrease of L* to 46.11 and an increase in a* to 17.29 and b* to 47.23 are shown. The reduction of L* is also reported after drying of goji berries (Yu et al. 2020), which was caused by browning reactions due to the presence of oxygen and oxidative stress of free radicals during the drying process. These results are comparable to the microwave drying study of lemon slices studied by Xu et al., where they found a slight decrease in L* from 92.73 to 88.01 and a slight increase in a* from 1.02 to 3.82 and b* from 9.45 to 15.61 (Xu et al. 2021). Concerning the frozen AS, freezing has no influence on the decrease of the luminosity L* (to 33.42) or the increase of the coordinates a* (to 14.95) and b* (to 25.38) after thermal drying. The non-thermal drying gives dry fruits, with a color near the witness (fresh fruits) or slightly different but acceptable by the consumers.

Texture is one of the major sensory quality attributes affecting consumer acceptance of foods (Ikoko and Kuri 2007). According to the values measured for the hardness of fresh AS (8 ±0.32 kg/cm2) (Table 3), a slight increase in this value is observed after non-thermal drying, which becomes about 8.45 ± 1.05 kg/cm2. After drying of the frozen AS, an increase is also observed to give a value equal to 9.5 kg/cm2. Similarly for convective drying, the hardness gives a value of 10.4 kg/cm2. In comparison with other researches, an increase in hardness is observed in the results of the study of Li et al., on the dehydration of apple cubes by DIC from a value equal to 69 ± 17 N before drying to a value of 104 ± 24 N after drying, and a decrease in this magnitude was reported after drying with hot air in the same study and by the same team, and they found that the hardness decreases from 69 ± 17 N to 11 ± 1 N (Li et al. 2020). The non-thermal drying produces fruit that is slightly rigid than fresh fruit, and this slight hardness does not have a negative effect on teeth.

The dimensions (diameter and thickness) of the AS before and after drying were determined (Table 3). A slight decrease in the values of the diameter of the dried AS (50 ± 1.5 mm) is observed after an initial value of 53 ± 0.5 mm, in parallel with a strong reduction of the thickness which is reduced from 7 ± 0.2 mm for the fresh AS to a value of about 1.5 ± 1.3 mm (AS dried without pretreatment). Similarly for convective dried AS, the diameter is decreased to 4.3 mm accompanied with a reduction in thickness to 43.7 mm. However, for frozen SA, a slight decrease in thickness and diameter is observed after 7 hours of drying. We can conclude, after dehydration of the AS, that there is a shrinkage in the thickness of the dried samples to give thinner slices. A study by Hawa et al., on drying by forced convection solar dryer on cabya fruits, shows a reduction in length by 75% and diameter by 68% (La Choviya Hawa et al. 2020b).

Modeling

The NWC curves of AS dried by a non-thermal and convective drying were regressed against 5 models to obtain the best fitting of the experimental data. Each model was evaluated on the basis of three statistical parameters: R2, χ2, and RMSE. Tables 4 and 5 summarize the model constants (k, n, a, and b) and the statistical parameters of the AS dried by non-thermal and convective drying, respectively.

A curve plot was performed after calculating the NWC of each model, as shown in Fig. 6a, b, which represents the variation of NWC as a function of time of the experimental and theoretical values of the models. It can be seen that the model of Midilli et al. is the best adequate model with the highest R2 (0.9989 and 0.9981) value and the lowest 𝜒2 (0.00009 and 0.00019) and RMSE (0.00006 and 0.01148) for the AS samples without pretreatment after a non-thermal drying and convective drying, respectively.

Similar to our results, Hawa et al. studied cabya fruit drying by sun drying. They found that the Midilli et al. model is the most adequate model for the drying curve (L.C. Hawa et al. 2020a). Also, Xu et al. found that the Midilli et al. model could accurately describe the drying kinetics of finger citron slices under HR20%, 40% ,and 60% drying by microwave hot air drying (Xu et al. 2021).

Conclusion

Considering its nutritional value and its richness in antioxidant substances, the apple represents an important potential market at the national and international level. In spite of its nutritional value, the absence of adequate techniques of conservation limits the exploitation of this fruit to the harvest season. For this reason, this work is focused on the drying of apple slices to better preserve them with a reduction of the water activity in the product by using a non-thermal dehydration process.

This drying method allows a consistent reduction of the water content in the AS at low temperature. The application of a pretreatment could improve the material transfer and consequently reduce the processing time. For that, the impact of freezing as a pretreatment on the performance of this process was studied. The freezing allowed to accelerate the kinetics of water transfer and therefore reduce the drying time from 12 hours to 7 hours. In order to characterize the AS, analyses such as water activity, color, texture (hardness), and dimensions (diameter and thickness) were performed on the dried fruits using different devices. The non-thermal drying takes a long time and can reach 40 hours for other fruits or vegetables, than convective drying, but gives us a good quality final product such as an acceptable color, a natural taste, and a soft texture.

Among the five proposed drying kinetics models, the Midilli et al. model is selected as the most adequate model to describe both non-thermal and convective drying of AS.

Data availability

The data used in this study are available from the corresponding author upon request.

Abbreviations

- AS:

-

Apple slices

- NWL:

-

Normalized water lost

- NWC:

-

Normalized water content

- m i :

-

Initial mass

- m t :

-

Mass at time “t”

- MC:

-

Moisture content

- NWC exp :

-

Experimental normalized water content

- NWC theo :

-

Theoretical normalized water content

- n :

-

Number of experimental observations

- p :

-

Number of constants in the model

- A w :

-

Water activity

- R 2 :

-

Coefficient of determination

- 𝜒2 :

-

Reduced mean square of deviation

- RMSE:

-

Root Mean Square Error

- DIC:

-

Détente Instantanée Contrôlé (Instant Controlled Pressure-Drop)

- PEF:

-

Pulsed electric field

- N:

-

Newton

- P:

-

Page

- M-P:

-

Modified-Page

- H-P:

-

Henderson-Pabis

References

Ben-Ali. (2018) Comparison of electric, thermal and combined treatment effect on solid-liquid extraction. Int J Eng Technol 10:44–52. https://doi.org/10.21817/ijet/2018/v10i1/181001022

Blasa M, Gennari L, Angelino D, Ninfali P (2010) Fruit and Vegetable Antioxidants in Health. In: Universitaa Di Urbino ‘Carlo Bo. First. Edit. Elsevier Inc. https://doi.org/10.1016/B978-0-12-374628-3.00003-7

Braga V, Rocha L, Corrêa R, Santana D, Fernanda M (2020) Production and characterization of pineapple-mint juice by spray drying. J Powder Technol 375:409–419. https://doi.org/10.1016/j.powtec.2020.08.012

Chin SK, Siew ES, Soon WL (2015) Drying characteristics and quality evaluation of kiwi slices under hot air natural convective drying method. Int Food Res J 22(6):2188–2195

Gao Y, Bao S, Zhang L, Zhang L (2020) Nitrate removal by using chitosan/zeolite molecular sieves composite at low temperature: characterization, mechanism, and regeneration studies. Desal Water Treat 203:160–171. https://doi.org/10.5004/dwt.2020.26219

Habani O, Adda H (2019) Optimisation de La Régénération de Tamis Moléculaires de La Section Déshydratation Du Complexe GP1 / Z. UNIVERSITAIRE AHMED BEN YAHYA

Hawa LC, Ubaidillah Ubaidillah FN, Afifah NIW, Yosika AN, Maharani DM (2020b) Cabya (Piper Retrofractum Vahl) fruit under open sun drying: drying behavior and modeling of thin layer drying kinetics. J Earth Environ Sci 542:1. https://doi.org/10.1088/1755-1315/542/1/012001

Hawa LC, Ubaidillah U, Mardiyani SA, Laily AN, Yosika NIW, Afifah FN (2020a) Drying kinetics of cabya (Piper Retrofractum Vahl) fruit as affected by hot water blanching under indirect forced convection solar dryer. Solar Energy 214(August 2020):588–598. https://doi.org/10.1016/j.solener.2020.12.004

Ikoko J, Kuri V (2007) Osmotic pre-treatment effect on fat intake reduction and eating quality of deep-fried plantain. Food Chem 102:523–531. https://doi.org/10.1016/j.foodchem.2006.06.008

Khoualdia B, Ben-ali S, Hannach A (2020) Pomegranate arils osmotic dehydration : effect of pre-drying on mass transfer. J Food Sci Technol 57:2129–2138. https://doi.org/10.1007/s13197-020-04248-1

Kroehnke J, Szadzi J, Musielak G, Mierzwa D (2021) Osmotic dehydration and convective drying of kiwifruit (Actinidia Deliciosa) – the influence of ultrasound on process kinetics and product quality. J Ultrason Sonochem 71(September 2020):105377. https://doi.org/10.1016/j.ultsonch.2020.105377

Lammerskitten A, Mykhailyk V, Wiktor A, Toepfl S, Nowacka M, Bialik M, Czyżewski J, Witrowa-Rajchert D, Parniakov O (2019) Impact of pulsed electric fields on physical properties of freeze-dried apple tissue. Innov Food Sci Emerg Technol 57(March):102211. https://doi.org/10.1016/j.ifset.2019.102211

Li X, Bi J, Jin X, Li X, Zhao Y, Song Y (2020) Effect of pectin osmosis or degradation on the water migration and texture properties of apple cube dried by instant controlled pressure drop drying (DIC). Food Sci Technol 125(September 2019):109202. https://doi.org/10.1016/j.lwt.2020.109202

Li X, Bi J, Jin X, Lyu J, Wu X, Li B, Li X (2021) Study on the mechanism of volume expansion and texture formation of apple cube dried by instant controlled pressure drop drying ( DIC ). J Food Eng 293(June 2020):110379. https://doi.org/10.1016/j.jfoodeng.2020.110379

Menges HO, Ertekin C (2006) Mathematical modeling of thin layer drying of golden apples. J Food Eng 77(1):119–125. https://doi.org/10.1016/j.jfoodeng.2005.06.049

Mouni S (2019) Caractérisation Biochimique , Conservation et Essais d ’ Élaboration Des Produits Alimentaires à Base Du Fruit de Zizyphus Lotus L. UNIVERSITE BATNA 1 - HADJ LAKHDAR

Moussaoui H, Bahammou Y, Tagnamas Z, Kouhila M, Lamharrar A, Idlimam A (2021) Application of solar drying on the apple peels using an indirect hybrid solar-electrical forced convection dryer. Renew Energy 168:131–140. https://doi.org/10.1016/j.renene.2020.12.046

Musacchi S, Serra S (2018) Apple fruit quality: overview on pre-harvest factors Stefano. J Sci Horticult 234(December):409–430. https://doi.org/10.1016/j.scienta.2017.12.057

Naderinezhad S, Etesami N, Najafabady AP, Falavarjani MG (2016) Mathematical modeling of drying of potato slices in a forced convective dryer based on important parameters. Food Sci Nutr 4(1):110–118. https://doi.org/10.1002/fsn3.258

Necib S, Moussaoui AK (2019) Comparaison Des Propriété Physico-Chimique Du Vinaigre de Pomme et de Datte ( Degla-Beida). Université Echahid Hamma Lakhdar, El Oued

Peng J, Yi J, Bi J, Chen Q, Xinye W, Zhou M, Jia’ning Liu. (2018) Freezing as pretreatment in instant controlled pressure drop (DIC) texturing of dried carrot chips: impact of freezing temperature. LWT Food Sci Technol 89(2):365–373. https://doi.org/10.1016/j.lwt.2017.11.009

Rascón MP, Huerta-vera K, Pascual-pineda LA, Contrera A (2018) Osmotic dehydration assisted impregnation of Lactobacillus rhamnosus in banana and effect of water activity on the storage stability of probiotic in the freeze-dried products-oliva, and E Flores-andrade. LWT Food Sci Technol 92(March):490–496. https://doi.org/10.1016/j.lwt.2018.02.074

Verdu C (2014) Cartographie Génétique Des Composés Phénoliques de La Pomme. Université d’Angers

Xu W, Islam MN, Cao X, Tian J, Zhu G (2021) Effect of relative humidity on drying characteristics of microwave assisted hot air drying and qualities of dried finger citron slices. Food Sci Technol 137(October 2020):110413. https://doi.org/10.1016/j.lwt.2020.110413

Yaldiz O, Ertekin C, Uzun HI (2001) Mathematical modeling of thin layer solar drying of sultana grapes. Energy 26:457–465

Yu F, Li Y, Zhenfeng W, Wang X, Wan N, Yang M (2020) Dehydration of wolfberry fruit using pulsed vacuum drying combined with carboxymethyl cellulose coating pretreatment. Food Sci Technol 134(July):110159. https://doi.org/10.1016/j.lwt.2020.110159

Acknowledgements

The authors are grateful to all research staff that contributed to the data collection required for this study.

Funding

The Ministry of Higher Education and Scientific Research in Tunisia financially supported this work.

Author information

Authors and Affiliations

Contributions

Khouloud Kraiem is responsible for the experiments, data collection, writing, and submission; Samia Ben Ali and Souhir Abdelmoumen are assigned to the supervision and review of the manuscript. All authors read and approved the final manuscript

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

KRAIEM, K., ABDELMOUMEN, S. & BEN-ALI, S. Dehydration study of apple slices by a non-thermal process. Environ Sci Pollut Res 31, 40620–40628 (2024). https://doi.org/10.1007/s11356-023-27517-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-27517-w