Abstract

The International Maritime Organization (IMO) has concerned significant care to the reduction of ship emissions and improvement of energy efficiency through operational measures. One of those measures is ship speed reduction, which is classified as a short-term measure; in which the speed is reduced below its designed value. The present paper aims at evaluating the potential energy efficiency, and environmental and economic benefits because of applying speed reduction measures. The research methodology depends on establishing a simple mathematical model for technical, environmental, and economical aspects because of this concept. As a case study, container ships from different categories in a range of 2500–15,000 twenty-foot equivalent units (TEU) are investigated. The results show that a 2500 TEU ship can comply with the energy efficiency existing ship index (EEXI) by reducing the service speed to 19 knots. While for the bigger ships, the service speed must be 21.5 knots or below. Furthermore, the operational carbon intensity indicator (CII) has been evaluated for the case studies and found that the CII rating will keep its score between A and C levels if the service speed is equal to or below 19.5 knots. Moreover, the annual profit margin of the ship will be calculated based on applying speed reduction measures. Based on the economical results, the annual profit margin value, and its corresponding optimum speed change with the size of the vessel and the applicable status of carbon taxes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ships consider the most important means of international transportation as it transports more than 90% of global trade (Michail and Melas 2020). Partners in the maritime field are seeking supporting the maritime sector to achieve the blue economy concept (Kim et al. 2020; Papanikolaou 2020). On the other hand, the technical and commercial development in the marine sector contributed significantly to the deterioration of the maritime environment (Mallouppas and Yfantis 2021). The decline appeared because of ships’ emissions (Bullock et al. 2020); therefore, as a step to eliminate this effect, the International Maritime Organization (IMO) prompted to issue the corresponding regulations through the International Convention of Marine Pollution prevention MARPOL 73/78 (Serra and Fancello 2020; Elkafas and Shouman 2022). UNCTAD (UNCTAD 2022) announced that millions of tons of fuel are consumed by ships annually, which is converted into harmful emissions after burning, these emissions include nitrogen oxide (NOx), sulfur dioxide (SOx), carbon monoxide (CO), carbon dioxide (CO2), particle matter (PM), and hydrocarbon (HC). Among the previous emission types, CO2 consider the most effective pollutant in the increment of greenhouse gas (GHG) emissions from shipping. Statistics state that voyage-based international shipping is responsible for approximately 2% of global CO2 emissions (IMO 2021a) and approximately 2.8% of annual GHG on a CO2 equivalent basis (Sui et al. 2020).

In 2018, IMO published several strategies for the reduction of GHG emissions with the goal of reducing them by at least 40% by 2030 compared to 2008 levels (IMO 2021a). Moreover, IMO approved those new ships constructed after 2016 must comply with IMO tier III regulation which stated that NOx emission rates must be reduced by 80% compared to its value at tier I. IMO restricted the maximum content of Sulphur in the marine fuel to be 0.5% instead of 3.5% after 1 January 2020, while the ships that navigate in the emission control areas (ECA), its limit is 0.1% (Rivarolo et al. 2021).

The first strategy represented in the reliance on renewable energy (Nuchturee et al. 2020), where wind and solar energy appeared as forms for providing the energy needed to contribute to the ship’s power (Yuan et al. 2020) or using innovative power systems like fuel cell systems powered by hydrogen (Rivarolo et al. 2018; Elkafas et al. 2022a). The second policy represented dependence on alternative fuels rather than traditional fuels to obtain the necessary ship powering (Rivarolo et al. 2020; Elkafas et al. 2021b, 2022b). The third option is represented in the attempt of ships designers, and shipbuilders to construct ships with low resistance, which reduces fuel consumption (Lindstad and Bø 2018; Elkafas et al. 2019; Jia 2021). The fourth strategy demonstrates the use of exhaust gas treatment technologies, such as filters for P.M, seawater scrubber system for SOx and selective catalytic reduction (SCR) for NOx emissions (Winnes et al. 2020). The latest strategy represents the optimal operation of the ship, and one of those ways is to reach the best operational speed for the ship (Elkafas and Shouman 2021). Among the abovementioned strategies, the present paper will highlight the optimal operation of the ship, with respect to ship speed reduction; to achieve the target of both IMO and ship operators.

The concept of ship speed control is not new in the maritime transportation literature and a considerable number of research is still dealing with it as an attractive and baffling control measure. The speed control of ships depends on many factors such as trade growth/recession, fuel cost, freight rate, and others. Psaraftis (2016) reveals that speed control includes many concepts, mainly (i) speed slow steaming, (ii) speed reduction, and (iii) speed optimization, and the specific meaning of each category is still a point of contention among IMO parties.

The results from Leaper (2019) conclude that a 10% speed reduction could reduce the total energy used in shipping by around 40%. Also, the associated reduction in overall ship strike risk has higher uncertainty but could be around 50%. Andersson et al. (2020) in their research paper showed that as the speed is reduced by 30%, fuel savings vary from 2 to 45% depending on ship type, size, and weather conditions. Taskar and Andersen (2020) studies the effect of weather conditions on the strategy of speed control by using a simple methodology and detailed modeling of resistance components and engine propulsion power. Furthermore, the effect of navigation time on the selection of the optimum ship speed has been studied in Li et al. (2020), with the calculation of operating costs including the fuel consumption at different ship speeds. The results showed an inverse relationship between the navigation time and the studied parameters such as fuel consumption and operating costs. Additionally, the study of Dong and Tae-Woo Lee (2020) investigates the effect of emission control areas (ECAs) and slow steaming technique on reducing SOx emissions from container ships, and the results confirmed that the integration between ECAs and the slow steaming led to more reduction in SOx with reducing the profit loss. Xia et al. (2021) proposed a new emission reduction method, called ship scheduling with speed reduction (SSSR). The research displayed that the emissions of ships in port can be reduced by 8.0–11.9% and the traffic efficiency can be improved by 3.8–6.2%. Moreover, the relationship between ship trim, fuel consumption, and the ship speed has been investigated by Elkafas (2022); the results revealed that the bow trim increases the fuel consumption at different ship speeds while the stern trim decreases the fuel consumption.

On the other hand, some research papers highlighted the drawback of the speed reduction concept with reference to the ship’s performance and economy. Lee et al. (2013) explained that to maintain the same service frequency, the speed reduction strategy required extra vessels to substitute the loss of time and the corresponding loss of cargo transport. Frouws (2016) studied the harmful emissions of Ro-Ro cargo carriers, and the results implied that from the societal point of view, a speed reduction from above 25% is nondefendable. Gusti and Semin (2017) tested the effect of the speed reduction concept on one of the sea-going ships, using actual data, they concluded that sailing with a speed reduction of more than 10% will affect negatively of engine performance.

The abovementioned literature shows that there is a gap in the applicability of the ship speed reduction concept onboard ships. Therefore, it proves that the strategy of ship speed reduction still needs more and more studies to address the effect of this measure on ships, performance such as ship fuel consumption and ship profit and its effect on the energy efficiency indicators.

The aim of the paper is to comprehensively assess the speed reduction measure from environmental, energy efficiency, and economical point of view. The environmental assessment will be done by evaluating the effect of speed reduction measures on carbon intensity. Energy efficiency will be studied based on the recent IMO framework to improve energy efficiency in the short term. Furthermore, the paper will introduce the expected optimal service speed to achieve the optimal operation of the ship from an economical point of view by evaluating the annual profit margin. Nowadays, container ships share a considerable percentage of goods transportation between the various ports worldwide. Therefore, container ships from different categories and capacities have been selected as case studies to be investigated.

Environmental and economic assessment methodology

Power and fuel consumption estimation method

Predicting the total resistance of the ship is one of the main practical problems in marine hydrodynamics. Due to high cost, uncertainty, and severely increased time of full-scale measurements in experimental tanks, predicting the total resistance by using MAXSURF program or empirical formulas like Holtrop method (Jasak et al. 2019) is a suitable way to find the propulsion power at different speeds.

The service allowance is used for the determination of the installed main engine power, which means that it shall be determined based on the expected service area. Harvald (1983) suggests service allowances between range 15–35% and its value will be relatively lower for large ships compared to small ships. The effective power can be calculated by multiplying the total resistance and the corresponding speed. Then, the main engine’s output power (Pp) can be calculated by dividing the effective power by the total propulsion system efficiency which can be calculated by using the procedure which discussed by Breslin and Anderson (1994).

Power plays a role in how much fuel is consumed with changes in speed. Thus, derivation of a direct relationship between fuel consumption (FC) and main engine’s output power, which can be obtained using the basic equations of power, and fuel, as displayed in Eq. (1) (Elkafas and Shouman 2021):

where PME, s is the main engine’s output power at the simulated service speed (Vs); SFCs is the specific fuel consumption at the selected power load measured in t/kWh, and D is the sailing distance between the departure and arrival ports estimated in nautical miles. In this way, the yearly fuel saving amount resulted from speed reduction measure (∆Ftotal) estimated in t/year can be evaluated as displayed in Eq. (2) depending on the expected number of round trips per year (NT) and the amount of fuel saving (Elkafas and Shouman 2021).

where FC0 and FCs are the fuel consumption per one round trip at the design service speed, and the simulated service speed, respectively.

Environment and energy efficiency assessment method

The IMO has introduced two new approaches (technical and operational) to reduce the carbon intensity onboard ships already in service. The technical approach is the Energy efficiency existing ship index (EEXI) which is a crucial technical measure and gives a particular figure to the energy efficiency onboard the ship. For each existing ship, there are two parameters of EEXI, the required and the attained (IMO 2022a). The attained EEXI must be lower than or equal to the required EEXI to achieve the minimum energy efficiency standards as recommended from IMO. The required EEXI is based on the baseline value of energy efficiency design index (EEDI) after applying a reduction factor as displayed in Eq. (3) (Elkafas et al. 2021a).

Equation 3 has two constants (a and c), their values depend on the type of ship as recommended from IMO (IMO 2013), while X depends on the ship size as shown in Table 1 (IMO 2020; Rutherford et al. 2020).

The attained EEXI depends on the design specifications of the ship such as the main engine power, specific fuel consumption, fuel type, capacity, and the reference speed. To calculate its value, the formula in Eq. (4) can be used (IMO 2022a).

Attained EEXI value is related to energy efficiency level of the main engine (ME) and auxiliary engine (AE) as shown in Eq. (4) (IMO 2022a). Where MCR is the maximum continuous rating of the installed main engine, the capacity is taken as 70% of DWT as recommended from IMO for container ships and CF is the transformation between fuel type and carbon dioxide which equals to 3.114 and 3.206 for fuel oil and marine diesel oil, respectively (Rehmatulla et al. 2017; Tran 2017). The reference speed (VR) can be calculated as discussed in (IMO 2022a).

On the other hand, the operational approach to reduce the carbon intensity onboard ships is the calculation of the annual operational carbon intensity indicator (CII) and its associated rating. The CII evaluates the level of reduction required to confirm continuous enhancement of carbon intensity within an exact rating level. Similar to EEXI, there are required and attained parameters that must be calculated for each ship. The attained annual operational CII is calculated as shown in Eq. (5) (IMO 2022b) by dividing the social cost of shipping activity (annual CO2 emissions) by the social benefit of shipping activity (total transport work = the product of deadweight and the total distance travelled in a year).

The attained CII must be compared with the required CII to obtain the energy efficiency rating. There is a reference line for CII calculated by IMO in 2019 as a function of the capacity of the different ship types above 5000 GT and operating internationally. But the 2019 reference line must be reduced over years to achieve 2030 IMO target in accordance with regulation 28 of MARPOL Annex VI. The reduction factors (Z%) from year 2023 to 2030 are described in IMO (2021b); therefore, the required CII can be calculated as shown in Eq. (6) (IMO 2022c).

where b and d are factors calculated by median regression fits of the data collected by IMO in 2019, their values depend on the ship type (e.g., b = 1984 and d = 0.489 for container ships) (IMO 2022c). Based on the attained CII, a ranking level (A, B, C, D, and E) can be assigned to the ship as A is considered the best rating while E is the worst rating. There are four boundaries that separate the ranking levels (A–E) from each other called superior, lower, upper, and inferior boundaries which can be calculated by multiplying the required CII by fixed factors that differ from one ship type to another (e.g., for container ships, superior boundary = 0.83×CIIrequired, lower boundary = 0.94×CIIrequired, upper boundary = 1.07×CIIrequired, and inferior boundary = 1.19×CIIrequired) (IMO 2022d).

Economic assessment method

The economy issue plays a role in the maritime field in general and most of shipping companies care to achieve the maximum annual profit to continue in the maritime market. Therefore, the aim of this subsection is to discuss how to find the maximum annual profit margin and the corresponding optimal speed. The annual profit margin because of speed reduction can be predicted by subtracting the annual costs from the annual income. Firstly, the annual income depends on the freight rates, loading capacity, and the number of round trips corresponding to each simulated ship speed. For container ships, it is assumed that the ship departed from the departure port loaded with 90% of its maximum capacity, while on the return trip, the ship is loaded with a reduced capacity depending on exist of empty containers onboard (Goicoechea and Abadie 2021). Therefore, the annual income corresponding to the simulated ship speed (AIs, j) is calculated as shown in Eq. (7).

where TEUj is the ship size in twenty-foot equivalent units, LC is the loading capacity on the return trip, and FRdt is the freight rate measured in $/TEU in the departed port while FRrt is the freight rate of the return trip. On the other hand, the annual costs depend on fuel consumption, fuel price, carbon taxes, port costs, and other costs such as canal tolls. By taking these factors into consideration, the annual costs corresponding to each simulated speed can be calculated as displayed in Eq. (8).

where FP is the fuel price measured in $/t, CP is the carbon price measured in $/t CO2, PC is the port costs measured in $ for loading and unloading operations, and CT is the canal tolls measured in US $.

Description of case study and navigational route

The container ship type was chosen as a case study to investigate the impact of speed reduction measure because container ships travel long distances annually and produce much higher carbon dioxide emissions than other types of ships. The current paper studies four different categories of container ships: feeder ships, Panamax, post-Panamax, and ultra-large container vessel (ULCV); their specifications are described in Table 2.

For the current study, the navigational route linking Western Asia with southern Europe was chosen, starting from Jebel Ali port in the United Arab Emirates until reaching Vado Ligure port in Italy. The navigational path passes through the Arabian sea and the Gulf of Aden, Gulf of Aden, Red Sea, Gulf of Suez, and the Mediterranean Sea. Therefore, the distance covered by the ship from Jebel Ali port to Vado Ligure port is 7795 nautical miles as shown in Fig. 1, while the distance covered from Vado Ligure port to Jebel Ali port is estimated to be 4548 nautical miles.

The sailing time depends on the characteristics of the navigational route, weather conditions, and particularly the ship’s speed. While the port time depends mainly on the ship size and is affected by the operational efficiency at the seaports, therefore, the average port time reported by Park and Suh (2019) has been used in this study. In the study of Park and Suh (2019), the average port time includes the waiting time for berthing allocation and the berthing time for loading and unloading operations and its value increases with the increase in container ship size as shown in Fig. 2.

Due to the complex nature of container shipping, the freight rate has been affected by the COVID-19 pandemic which can be figured by the dramatic rise from 2019 till the end of 2021. Although freight rates have fallen starting from the first quarter of 2022, they are still above the pre-pandemic levels (UNCTAD 2022). As the shipping price changes day by day based on many factors, therefore, in this study, reliance was made on recent rates from two different sources (Drewry 2023; S&PGlobal 2023) and take the average. The applied freight rate for shipping from Asia to Europe is assumed to be 1248 $/TEU and in the opposite direction is to be 345 $/TEU.

As the navigation route cross the Suez Canal, the canal tolls must be applied, therefore, the grand total costs can be estimated by using the Suez Canal tool online calculator (SuezCanal 2022). The calculator is based on the specified data of the container ship such as the Suez Canal Net Tonnage (SCNT) and gross tonnage (GT), maximum draft, maximum beam, and the direction (north or south). Consequently, the Suez Canal tolls used in the study are presented in Table 3 after entering the specific data of the container ships in the online calculator and using the recent tariffs. Due to the limitation of the current investigation, the annual costs are limited to the fuel costs, carbon taxes, Suez Canal tolls, and port loading/unloading charges. These costs have been selected to be included because they are affected directly by the speed reduction measure.

Results and discussions

Speed reduction effect on fuel consumption

The ship fuel consumption is related to the rated engine power at the corresponding ship speed; therefore, the first step in the assessment is to find the rated engine power required at various ship speeds. The rated power can be predicted by using the empirical formula as mentioned in the “Environmental and economic assessment methodology” section. Consequently, the rated engine power of different container ship categories is graphically shown in Fig. 3 versus the corresponding ship speed.

The ship at the design sailing speed might be propelled by using a low-speed marine diesel engine. Therefore, the relation between main engine’s power, specific fuel consumption, and engine speed can be calculated based on the available online source in MAN (2020). It is noted that the specific fuel consumption (SFC) diminishes to its low level at the half load of main engine, then go up again.

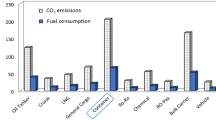

The results of the total fuel consumption per round trip corresponding to reduced service speed can be calculated based on Eq. (1). Consequently, Fig. 4 shows the fuel consumption at different ship speeds (plotted in dash line) and shows that a decrease in the ship’s service speed leads to a decrease in the value of fuel consumption because it depends mainly on the power required to propel the ship. Furthermore, Fig. 4 shows the fuel saving amount per one round trip (plotted in solid line) by using speed reduction measure for different container ships categories which obtained by using the formula in Eq. (2).

By using the speed reduction approach, the quantity of fuel is saved by a noticeable percentage as shown in Fig. 4. When the service speed is reduced by 13% (speed = 20 knots), the fuel consumption will be reduced by 37%, 30%, 29.7%, and 29% for container ships with capacity of 2500, 5000, 10,000, and 15,000 TEU, respectively, and thus will reduce the operation price of the container ships.

Environmental and energy efficiency assessment of speed reduction measure

The environmental and energy efficiency assessment can be accomplished by applying the recommendations from IMO to cut down the CO2 emissions onboard ships by using a technical approach as discussed in the “Environmental and economic assessment methodology” section through the evaluation of EEXI and an operational approach through using CII.

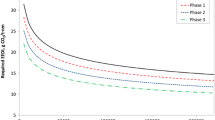

The first step in the EEXI modelling is the calculation of the restrictive limit imposed by IMO as displayed in Eq. (3). The required EEXI value has different values based on the container ship size and the reduction factor applied as shown in Fig. 5. As displayed in Fig. 5, the reference baseline is presented in dash lines while the required EEXI is presented in solid lines, and the reduction factors are clear at the boundaries of container ship capacities as discussed in Table 1. Based on the results, the required EEXI is 17.78, 13.21, 10.87, and 8.53 gCO2/t-nm for the studied container ships CS1, CS2, CS3, and CS4, respectively.

Ship speed reduction by a significant percentage reduces the main engine power, auxiliary engine power, and fuel consumption as discussed before. So, the energy efficiency level can be determined based on the EEXI value which can be calculated by Eq. (4). The results of attained EEXI corresponding to each container ship are shown in Fig. 5 with different colors for the different ship speeds.

For CS1 with a capacity of 2500 TEU, the results show that service speed equal to or below 19 knots fulfils the IMO rules as the attained EEXI (17.34 gCO2/t nm) is below the required value as presented in Fig. 5. The results also show that the larger the capacity of the container ship, the more service speed can be reached and satisfies the required EEXI as shown in the results of CS2–CS4. Therefore, container ships with capacities of 5000, 10,000, and 15,000 TEU can attain EEXI approval by using a service speed equal to or below 21.5 knots, 22 knots, and 21.5 knots, respectively. For all container ship cases, sailing at 19 knots or below satisfies the operational EEXI and complies with IMO rules.

The operational approach to reduce the carbon intensity onboard ship has been assessed by using the CII approach as discussed in the “Environmental and economic assessment methodology” section. Similar to EEXI, the CII has a restrictive limit and attained value which must be calculated for each case study. The required CII has been calculated based on the capacity of the case study and the reduction factor corresponding to the applied year from 2019 to 2030 as recommended by IMO. By applying Eq. (6), the required CII is calculated over years as presented by a black curve in Fig. 6 a, b, c, and d for CS1, CS2, CS3, and CS4, respectively. By multiplying the required CII at each year by the fixed factors presented at the end of the “Environment and energy efficiency assessment method” section, the carbon intensity rating can be determined as shown in Fig. 6. The rating levels are discussed in different colors to facilitate the assignment of CII ratings for ships.

To investigate the effect of speed reduction on operational CII rating, it is important to determine the annual attained CII as displayed in Eq. (5); therefore, the attained CII in 2023 is calculated corresponding to each service speed and was plotted as a point in Fig. 6. The IMO recommendations stated that rating levels of D and E have lower carbon intensity ratings than other rating scales because this rating will be slightly worse year by year if the ship keeps its CII score, for that reason, the assessment of the rating scale in the current study will be limited to scale rating from A to C.

For CS1 with 2500 TEU, the CII rating levels are varied between B and E as shown in Fig. 6a. By applying the IMO recommendations, the best service speed that fulfils the operational CII are ranged from 18 to 19.5 knots which corresponds to a rating scale B and C. If the CS1 ship keeps the same attained CII by using 19.5, and 19 knots as a service speed, the operational CII rating will be converted to D by 2025, and 2027, respectively. It is considered that sailing at a service speed equal to 18 or 18.5 knots is the best speed from an operational CII perspective as its value will fulfil the IMO recommendations until 2030 assuming the attained CII value has remained constant over the years.

The same discussion will be done for other container ships, for CS2 with 5000 TEU, the CII rating is investigated in Fig. 6b. Its operational CII rating scores deviated from A to C by increasing the service speed from 18 to 21.5 knots, and the first three speeds are located in the A rating level. By assuming a constant attained CII over the years until 2030, the rating score will be changed to D by 2024, 2027, 2028, and 2030 for the service speeds of 21.5, 21, 20.5, and 20 knots, respectively. By using this hypothesis, sailing at 19.5 knots or below is considered better from a carbon intensity point of view.

For the container ship that accommodates 10,000 TEU onboard, its operational CII chart is shown in Fig. 6c. The operational CII assigns the A rating score by using 18 knots as a service speed, while it assigns the B rating by using 18.5–19.5 knots and the C rating by using 20–20.5 knots. The rating label for sailing by a speed equal to 20.5 knots will be converted to D level by 2025 while the label of 20 knots will be changed by 2027.

The last case study (CS4) has been shown in Fig. 6d, starting from a service speed of 21.5 knots, the CII rating is located at D and E rating levels. If the vessel keeps its emission score constant for the range of speed between 21 and 20 knots, the rating level will be transformed to a D rating by 2024, 2026, and 2027, respectively. Therefore, the service speed of 18–19.5 knots is considered the best option in terms of operational CII.

The previous results indicate that choosing to reduce speed as one of the mechanisms to reach lower emissions rates from ships will depend mainly on several elements such as the number of annual trips, the ship capacity, and the fuel consumption. By combining the results of the operational CII ratings from CS2, CS3, and CS4 ships, it is found that the CII rating will keep its score between A and C levels if the service speed is equal to or below 19.5 knots.

Economic assessment results

By applying the methodology discussed in the “Economic assessment method” section on the selected container ships, the annual costs and profit can be calculated. It is noted that speed reduction has a direct impact on fuel consumption, number of round trips per year, CO2 emissions, number of port calls, and number of crossing the Suez Canal. Therefore, all these parameters have been designed at Eq. (8) for the calculation of the annual costs. To simplify the calculations, some assumptions are considered: (i) the fright rate per container unit is assumed to be fixed throughout the year; (ii) the fuel price is assumed to be fixed at 638 and 605 USD$ in Europe and Asia per metric tons, respectively, based on the recent prices of VLSFO (Ship&Bunker 2022); (iii) the CO2 emission taxes is based on European Union Emissions Trading System (EU ETS) (Lagouvardou and Psaraftis 2022).

The annual profit margin for each container ship by applying different speeds is calculated as shown in Fig. 7, and the optimum speed (the speed corresponding to the highest annual profit margin) is highlighted by a red circle. The economic analysis has studied the effect of using 100% of carbon emissions emitted through the year, 50% of carbon emissions and the last case without using CO2 taxes to figure out its impact with speed reduction measure. For the first container ship (CS1), the annual profit margin reduces with the increment in ship speed as shown in Fig. 7a for the three cases of CO2 emission taxes. Particularly, by using 100% CO2 emissions, the annual profit margin drops under zero when increasing ship speed over 22 knots. For 2500 TEU, the optimum speed is 18 knots for all cases with or without CO2 taxes.

For CS2 which accommodates 5000 TEU, the annual profit margin at different speeds is discussed in Fig. 7b. The results showed that reducing the emissions that can be considered from 100 to 50% leads to an increase in annual profit margin and an increase in the optimum speed from 18 to 18.5 knots. While the results showed that not using carbon taxes leads to an increase in the optimum speed that achieves the highest profitability from 18–18.5 knots into 20.5 knots.

The results of the post-Panamax ship (CS3) indicate that the increase in the speed of the vessel has a proportional effect on the annual profit margin until the optimum speed is reached and then decreases again as shown in Fig. 7c. By making a comparison between the results of applying 100% and 50% of carbon emissions, the optimum speed is increased from 19.5 to 20.5 with an achievement of a profit difference of around 5.5 million between the two scenarios. It is also found that in the scenario of no carbon taxes, the optimum speed is 21 knots with an achievement of a profit of around 11.7 million over the 100% emission scenario.

As described in Fig. 7d, the annual profit margin for CS4 increases with the removal of carbon taxes for all simulated speeds. For the scenarios of applying 100% and 50% carbon emissions, the speed reduction measure has a beneficial impact on the annual profit margin until reaching to the optimum speed at 21 knots and then the margin goes down again. While the removal of carbon taxes leads to an increase in the optimum speed to 23 knots which achieves the highest profitability.

Based on the results generated, the annual profit margin value and its corresponding optimum speed change with the size of the vessel and the applicable status of carbon taxes. For example, the speed reduction effect has an economic benefit in the annual margin of CS1 as the optimum profit has been generated by using the lowest ship speed. On the other hand, the larger the container ship, the greater the optimum speed whether or not 100% carbon emissions are used. For example, the optimum speed is equal to 18, 19.5, and 21 knots for 5000 TEU, 10,000 TEU, and 15,000 TEU, respectively, when applying 100% carbon emissions. While the optimum speed is equal to 20.5, 21, and 23 knots without applying carbon taxes.

Conclusions

IMO identifies many measures for the reduction of ship emissions and improvement of energy efficiency through technical and operational viewpoint. One of the effective short-term operational measures (speed reduction method) is presented in this paper. The main conclusions from the assessment of speed reduction measures on the container ships as a case study are as follows:

-

1.

From environmental perspective, the carbon intensity onboard ship has been assessed by using the CII approach. The results revealed that the value of CII depends on the number of annual trips, the ship capacity, and the fuel consumption. For a container ship with a capacity of 2500 TEU, the best carbon intensity rating score is accomplished by using a service speed equal to 18 or 18.5 knots as its value will fulfil the IMO recommendations until 2030. While the bigger container ships have the best rating score if the service speed is equal to or below 19.5 knots.

-

2.

From an energy efficiency perspective, the required EEXI has been calculated for different container ship capacities. Therefore, the attained EEXI of the four studied container ships is compared with the required value to select the optimum speed that complies with the IMO requirements. The results show that service speed must be equal to or below 19 knots, 21.5 knots, 22 knots, and 21.5 knots to fulfil the IMO rules for container ships with capacities of 5000, 10,000, and 15,000 TEU, respectively.

-

3.

From the point of economic view, the paper highlighted that there is an economic benefit as a result of speed reduction, but it depends on the ship size and the applicable status of carbon taxes. The results show that the larger the container ship, the greater the optimum speed whether or not 100% carbon emissions are used. However, the optimum speed of a feeder container ship is selected to be 18 knots in any scenario as it produces the highest annual profit margin.

The previous conclusions indicate that choosing to reduce speed as one of the mechanisms to reach lower emissions rates from ships will depend mainly on several elements. The crucial factors include the ship size, the number of annual round trips, and the carbon emission scenario. The optimum speed varies from ship to ship and from one perspective to another. For example, the optimum speed for a feeder ship from an economical perspective is different from the optimum one for a post-Panamax ship from an energy efficiency perspective.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- AE:

-

Auxiliary engine

- CII:

-

Carbon intensity indicator

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- CS:

-

Container ship

- DWT:

-

Deadweight

- EEDI:

-

Energy efficiency design index

- EEXI:

-

Energy efficiency existing ship index

- EU-ETS:

-

European Union Emissions Trading System

- FC:

-

Fuel consumption

- GHG:

-

Greenhouse gases

- GT:

-

Gross tonnage

- HC:

-

Hydrocarbon

- IMO:

-

International Maritime Organization

- MCR:

-

Maximum continuous rating

- ME:

-

Main engine

- NOx:

-

Nitrogen oxide

- PM:

-

Particle matter

- SFC:

-

Specific fuel consumption

- SSSR:

-

Ship scheduling with speed reduction

- SOx:

-

Sulfur dioxide

- TEU:

-

Twenty-foot equivalent unit

- ULCV:

-

Ultra-large container vessel

- UNCTAD:

-

United Nations Conference on Trade and Development

- AC:

-

Annual costs

- AI:

-

Annual income

- CP:

-

Carbon costs [$/t CO2]

- CT:

-

Canal tolls [$]

- CF :

-

Conversion factor between fuel and carbon dioxide

- D:

-

Sailing distance [nm]

- FP:

-

Fuel price [$/t]

- FR:

-

Freight rate [$/TEU]

- LC:

-

Loading capacity

- NT:

-

Number of round trips per year

- PC:

-

Port costs for loading and unloading operations [$]

- PME :

-

Main engine’s output power [kW]

- V R :

-

Reference speed [knots]

- Vs :

-

Specific sailing speed [knots]

- X:

-

Reduction rate

- Z:

-

Reduction factors from year 2023 to 2030 for CII

References

Andersson K, Brynolf S, Hansson J, Grahn M (2020) Criteria and decision support for a sustainable choice of alternative marine fuels. Sustainability 12(9):3623. https://doi.org/10.3390/su12093623

Breslin JB, Anderson P (1994) Hydrodynamics of ship propellers. Cambridge University Press, Cambridge, UK

Bullock S, Mason J, Broderick J, Larkin A (2020) Shipping and the Paris climate agreement: a focus on committed emissions. BMC Energy 2:1–16. https://doi.org/10.1186/s42500-020-00015-2

Dong G, Tae-Woo Lee P (2020) Environmental effects of emission control areas and reduced speed zones on container ship operation. J Clean Prod 274:122582. https://doi.org/10.1016/j.jclepro.2020.122582

Drewry (2023) Spot freight rates by major route. Supply chain advisors https://www.drewry.co.uk/supply-chain-advisors/supply-chain-expertise/world-container-index-assessed-by-drewry. Accessed 28 Feb 2023

Elkafas AG (2022) Advanced operational measure for reducing fuel consumption onboard ships. Environ Sci Pollut Res 29(60):90509–90519. https://doi.org/10.1007/s11356-022-22116-7

Elkafas AG, Shouman MR (2021) Assessment of energy efficiency and ship emissions from speed reduction measures on a medium sized container ship. Trans R Inst Nav Archit A: Int J Marit Eng 163:121–132. https://doi.org/10.5750/ijme.v163iA3.805

Elkafas AG, Shouman MR (2022) A study of the performance of ship diesel-electric propulsion systems from an environmental, energy efficiency, and economic perspective. Mar Technol Soc J 56:52–58. https://doi.org/10.4031/MTSJ.56.1.3

Elkafas AG, Elgohary MM, Zeid AE (2019) Numerical study on the hydrodynamic drag force of a container ship model. Alexandria Eng J 58:849–859. https://doi.org/10.1016/j.aej.2019.07.004

Elkafas AG, Elgohary MM, Shouman MR (2021a) Numerical analysis of economic and environmental benefits of marine fuel conversion from diesel oil to natural gas for container ships. Environ Sci Pollut Res 28:15210–15222. https://doi.org/10.1007/s11356-020-11639-6

Elkafas AG, Khalil M, Shouman MR, Elgohary MM (2021b) Environmental protection and energy efficiency improvement by using natural gas fuel in maritime transportation. Environ Sci Pollut Res 28(43):60585–60596. https://doi.org/10.1007/s11356-021-14859-6

Elkafas AG, Rivarolo M, Gadducci E et al (2022a) Fuel cell systems for maritime: a review of research development, commercial products, applications, and perspectives. Processes 11:97. https://doi.org/10.3390/pr11010097

Elkafas AG, Rivarolo M, Massardo AF (2022b) Assessment of alternative marine fuels from environmental, technical, and economic perspectives onboard ultra large container ship. Trans R Inst Nav Archit A: Int J Marit Eng 164:125–134. https://doi.org/10.5750/ijme.v164iA2.768

Frouws K (2016) Is reducing speed the right mitigating action to limit harmful emissions of seagoing RoRo cargo carriers? J ship trade 1:1–12. https://doi.org/10.1186/s41072-016-0014-2

Goicoechea N, Abadie LM (2021) Optimal slow steaming speed for container ships under the EU emission trading system. Energies (Basel) 14(22):7487. https://doi.org/10.3390/en14227487

Gusti AP, .Semin (2017) Speed optimization model for reducing fuel consumption based on shipping log data. World Acad Sci Eng Technol J Mech Mechatron 11:359–362

Harvald SA (1983) Resistance and Propulsion of Ships. Wiley

IMO (2013) Resolution MEPC.231(65): 2013 Guidelines for calculation of reference lines for use with the energy efficiency design index (EEDI). IMO

IMO (2020) Report of the seventh meeting of the Intersessional Working Group on Reduction of GHG Emissions from Ships (ISWG-GHG 7). No. MEPC 75/WP.3. IMO

IMO (2021a) Fourth IMO greenhouse gas study. International Maritime Organization, pp 197–212

IMO (2021b) Resolution MEPC.338(76): Guidelines on the operational carbon intensity reduction factors relative to reference lines. IMO

IMO (2022a) Resolution MEPC.350(78): Guidelines on the method of calculation of the attained energy efficiency existing ship index (EEXI). IMO

IMO (2022b) Resolution MEPC.352(78): Guidelines on operational carbon intensity indicators and the calculation methods. IMO

IMO (2022c) Resolution MEPC.353(78): Guidelines on the reference lines for use with operational carbon intensity indicators. IMO

IMO (2022d) Resolution MEPC.354(78): Guidelines on the operational carbon intensity Rating of ships. IMO

Jasak H, Vukčević V, Gatin I, Lalović I (2019) CFD validation and grid sensitivity studies of full scale ship self propulsion. Int J Nav Archit Ocean Eng 11:33–43. https://doi.org/10.1016/j.ijnaoe.2017.12.004

Jia Z (2021) Influencing factors and optimization of ship energy efficiency under the background of climate change. IOP Conf Ser Earth Environ Sci 647:1. https://doi.org/10.1088/1755-1315/647/1/012178

Kim M, Joung T-H, Jeong B, Park H-S (2020) Autonomous shipping and its impact on regulations, technologies, and industries. J Int Marit Saf Environ Aff Shipp 4:17–25. https://doi.org/10.1080/25725084.2020.1779427

Lagouvardou S, Psaraftis HN (2022) Implications of the EU Emissions Trading System (ETS) on European container routes: A carbon leakage case study. Maritime Transport Research 3:100059. https://doi.org/10.1016/j.martra.2022.100059

Leaper R (2019) The role of slower vessel speeds in reducing greenhouse gas emissions, underwater noise and collision risk to whales. Front Mar Sci 6:505. https://doi.org/10.3389/fmars.2019.00505

Lee C-Y, Lee H, Zhang J (2013) The impact of slow ocean steaming on delivery reliability and fuel consumption. Transp Res E Logist Transp Rev 76:176–190. https://doi.org/10.2139/ssrn.2060105

Li X, Sun B, Guo C et al (2020) Speed optimization of a container ship on a given route considering voluntary speed loss and emissions. Appl Ocean Res 94:101995. https://doi.org/10.1016/j.apor.2019.101995

Lindstad E, Bø TI (2018) Potential power setups, fuels and hull designs capable of satisfying future EEDI requirements. Transp Res D Transp Environ 63:276–290. https://doi.org/10.1016/j.trd.2018.06.001

Mallouppas G, Yfantis EA (2021) Decarbonization in Shipping industry: a review of research, technology development, and innovation proposals. J Mar Sci Eng 9:415. https://doi.org/10.3390/jmse9040415

MAN (2020) CEAS engine calculations. MAN Energy solutions https://www.man-es.com/marine/products/planning-tools-and-downloads/ceas-engine-calculations. Accessed 20 Nov 2020

Michail NA, Melas KD (2020) Shipping markets in turmoil: an analysis of the Covid-19 outbreak and its implications. Transp Res Interdiscip Perspect 7:100178. https://doi.org/10.1016/j.trip.2020.100178

Nuchturee C, Li T, Xia H (2020) Energy efficiency of integrated electric propulsion for ships – A review. Renewable Sustainable Energy Rev 134:110145. https://doi.org/10.1016/j.rser.2020.110145

Papanikolaou AD (2020) Review of the design and technology challenges of zero-emission, battery-driven fast marine vehicles. J Mar Sci Eng 8:941. https://doi.org/10.3390/jmse8110941

Park NK, Suh SC (2019) Tendency toward mega containerships and the constraints of container terminals. J Mar Sci Eng 7:131. https://doi.org/10.3390/jmse7050131

Psaraftis HN (2016) Green maritime transportation: market based measures. In: Green Transportation Logistics. Springer International Publishing, pp 267–297

Rehmatulla N, Calleya J, Smith T (2017) The implementation of technical energy efficiency and CO2 emission reduction measures in shipping. Ocean Eng 139:184–197. https://doi.org/10.1016/j.oceaneng.2017.04.029

Rivarolo M, Rattazzi D, Magistri L (2018) Best operative strategy for energy management of a cruise ship employing different distributed generation technologies. Int J Hydrogen Energy 43:23500–23510. https://doi.org/10.1016/j.ijhydene.2018.10.217

Rivarolo M, Rattazzi D, Lamberti T, Magistri L (2020) Clean energy production by PEM fuel cells on tourist ships: A time-dependent analysis. Int J Hydrogen Energy 45:25747–25757. https://doi.org/10.1016/j.ijhydene.2019.12.086

Rivarolo M, Rattazzi D, Magistri L, Massardo AF (2021) Multi-criteria comparison of power generation and fuel storage solutions for maritime application. Energy Convers Manag 244:114506. https://doi.org/10.1016/j.enconman.2021.114506

Rutherford D, Mao X, Comer B (2020) Potential CO2 reductions under the energy efficiency existing ship index, vol 27. International council on clean transportation, p 1

Serra P, Fancello G (2020) Towards the IMO’s GHG goals: a critical overview of the perspectives and challenges of the main options for decarbonizing international shipping. Sustainability (Switzerland) 12:3220. https://doi.org/10.3390/su12083220

Ship&Bunker (2022) World Bunker Prices. Bunker prices https://shipandbunker.com/prices. Accessed 26 Feb 2023

S&PGlobal (2023) Platts Asia-to-Europe container rates. Price Assessment https://www.spglobal.com/commodityinsights/en/our-methodology/price-assessments/shipping/asia-to-europe-container-rates. Accessed 28 Feb 2023

SuezCanal (2022) Vessels tolls calculator. Navigation tolls https://www.suezcanal.gov.eg/English/Navigation/Tolls/Pages/TollsCalculator.aspx. Accessed 28 Feb 2023

Sui C, de Vos P, Stapersma D et al (2020) Fuel consumption and emissions of ocean-going cargo ship with hybrid propulsion and different fuels over voyage. J Mar Sci Eng 8:588. https://doi.org/10.3390/JMSE8080588

Taskar B, Andersen P (2020) Benefit of speed reduction for ships in different weather conditions. Transp Res D Transp Environ 85:102337. https://doi.org/10.1016/j.trd.2020.102337

Tran TA (2017) A research on the energy efficiency operational indicator EEOI calculation tool on M/V NSU JUSTICE of VINIC transportation company, Vietnam. J Ocean Eng Sci 2:55–60. https://doi.org/10.1016/j.joes.2017.01.001

UNCTAD (2022) Review of maritime transport 2022. United Nations

Winnes H, Fridell E, Moldanová J (2020) Effects of marine exhaust gas scrubbers on gas and particle emissions. J Mar Sci Eng 8:299. https://doi.org/10.3390/JMSE8040299

Xia Z, Guo Z, Wang W, Jiang Y (2021) Joint optimization of ship scheduling and speed reduction: a new strategy considering high transport efficiency and low carbon of ships in port. Ocean Eng 233:109224. https://doi.org/10.1016/j.oceaneng.2021.109224

Yuan Y, Wang J, Yan X et al (2020) A review of multi-energy hybrid power system for ships. Renewable Sustainable Energy Rev 132:110081. https://doi.org/10.1016/j.rser.2020.110081

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Ahmed G. Elkafas. The first draft of the manuscript was written by Ahmed G. Elkafas. Massimo Rivarolo and Aristide Massardo were commented and reviewed previous versions of the manuscript. Supervision of the research: Aristide Massardo.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Elkafas, A.G., Rivarolo, M. & Massardo, A.F. Environmental economic analysis of speed reduction measure onboard container ships. Environ Sci Pollut Res 30, 59645–59659 (2023). https://doi.org/10.1007/s11356-023-26745-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-26745-4