Abstract

Developing a novel, simple, and cost-effective analytical technique with high enrichment capacity and selectivity is crucial for environmental monitoring and remediation. Metal–organic frameworks (MOFs) are porous coordination polymers that are self-assembly synthesized from organic linkers and inorganic metal ions/metal clusters. Magnetic metal–organic framework (MMOF) composites are promising candidate among the new-generation sorbent materials available for magnetic solid-phase extraction (MSPE) of environmental contaminants due to their superparamagnetism properties, high crystallinity, permanent porosity, ultrahigh specific surface area, adaptable pore shape/sizes, tunable functionality, designable framework topology, rapid and ultrahigh adsorption capacity, and reusability. In this review, we focus on recent scientific progress in the removal of heavy metal ions present in contaminated aquatic system by using MMOF composites. Different types of MMOFs, their synthetic approaches, and various properties that are harnessed for removal of heavy metal ions from contaminated water are discussed briefly. Adsorption mechanisms involved, adsorption capacity, and regeneration of the MMOF sorbents as well as recovery of heavy metal ions adsorbed that are reported in the last ten years have been discussed in this review. Moreover, particular prospects, challenges, and opportunities in future development of MMOFs towards their greener synthetic approaches for their practical industrial applications have critically been considered in this review.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The world’s aquatic systems are continuously being threatened by the continuous explosion of world population together with urbanization as well as industrial and agricultural revolution (Crini and Lichtfouse 2019). It is a mandatory requirement to have access to clean water for proper survival and development of living beings. Serious health issues to humans and other living organisms caused by chemical risk factors in aqueous environments have been increased in recent years (Crini et al. 2019). The types of pollutants discharged to the aqueous media, their quantities, and difficulties in detection as well as removal have been a major concern for both researchers and environmental organizations all over the world. Most of the heavy metal ions including lead (Pb), arsenic (As), mercury (Hg), cadmium (Cd), and chromium (Cr), inorganic acids, oxycations/oxyanions, and inorganic anions, organic contaminants including agricultural products, organic industrial wastes, organic dyes, pharmaceuticals, and personal care products discharged to water streams are ubiquitous source of water contamination (Mon et al. 2018; Rashid et al. 2021).

Heavy metal ions have versatile applications in different industrial activities including metal planting, mining, chemical and power generation companies, electronic device manufacturing, painting, and plumbing and thereby introduced to the water bodies through industrial effluents (Zargoosh et al. 2013). High-grade toxicity, potential bioaccumulation in the living cells, and non-biodegradability of the existing heavy metal ions even in trace amount have been continuously exerting atrocious impact on living organism by entering into the food chain and food webs (Almomani et al. 2020). Long-term exposure of these toxic heavy metal ions even in ppb level can cause progressive adverse effects to the living organisms by deteriorating the central nervous system, kidney, brain, lungs, etc. (Shams et al. 2016). As stated by the International Agency for Research on Cancer (IARC) and United State Environmental Protection Agency (U.S. EPA), the heavy metals like arsenic (Rahaman et al. 2021), cadmium (Sharma et al. 2015), mercury (Zahir et al. 2005), lead (Hall 1972), and chromium (Tsenget al. 2019) are categorized as either probable or known carcinogenic elements on the basis of their experimental and epidemiological studies (Pratush et al. 2018). In this context, reduction or elimination of existing heavy metal ions from coastal and inland contaminated water is garnering attention worldwide among the scientists (Ledezma et al. 2021; Bhateria and Singh 2019; Wen et al. 2018).

Existing technologies for removal of heavy metal ions

Till now several technologies are demonstrated for removal and recovery of heavy metal ions with different degree of success including membrane filtration (Zhang et al. 2018; Zhao et al. 2022; Peng and Guo 2020; Yang et al. 2020a, b, c), coagulation/flocculation (Sun et al. 2021; Liang et al. 2014; Nguyena et al. 2021), advanced oxidation processes (Zhang et al. 2022a, b, c, d; Kim et al. 2018; Ikhlaq et al. 2022; Mahtab et al. 2021), chemical precipitation (Mavhungu et al. 2021), adsorption (Chaudhry et al. 2022; Sharma et al. 2021; Lata and Samadder 2016), nanotechnologies (Bhat et al. 2022; Lai et al. 2022; Rani et al. 2021; Wadhawan et al. 2020), and biological processes (Singh et al. 2022; Bhatt et al. 2022; Pazdzior et al. 2019). Although these currently used conventional technologies for wastewater monitoring and remediation have their own advantages, they suffer some inconveniences such as high installation and maintenance cost, generation of secondary contaminants, complicated and prolonged processing time, and poor accuracy and are incapable of eliminating the entire waste of contaminated water (De Gisi et al. 2016; Martini 2021; Yahya et al. 2018).

Among all the methods available for wastewater treatment, adsorption technique with organic or inorganic porous materials has been established as the most reliable and competitive one due to its simplicity, high efficiency, and cost-effectiveness (Soylak et al. 2021; Burakov et al. 2018). However, the challenging task for practical application is to discover a highly efficient and cost-effective adsorbent. In this perspective, different types of adsorbents such as mesoporous clays (Marangu et al. 2022; Yadav et al. 2019), mesoporous silica (Han et al. 2018; Yaftian et al. 2019a, b; Yaftian et al. 2018, 2016, 2018), zeolites (Ugwu et al. 2022; Irannajad and Haghighi 2021; Zhang et al. 2022a, b, c, d), nanoporous materials (Ghani et al. 2021; Phukan and Chetia 2016; Liu et al. 2020), nanofibers (Wirzal et al. 2020; Doan et al. 2021), carbon-based materials (Mahesh et al. 2022; Ugwu and Agunwamba 2020; Wong et al. 2018), and biopolymers (Pillay et al. 2021; Liu et al. 2022a; Sarode et al. 2019) have extensively been studied and employed to remove heavy metal ions from water ecosystem to a considerable extent.

However, inconveniences related to the conventional sorbent materials include lack of synthetic procedures to develop recoverable adsorbents with tailorable structures/pores, precise control on adsorption kinetics, high capacity, and selectivity of contaminants (Al-Othman et al. 2021). Thus, addressing novel approaches for complete removal of heavy metal ions from aqueous environments with very high efficiency, high specificity, high selectivity, and high sensitivity has become a priority research topic among the chemists in order to restore a sustainable balance in the ecosystem (Chai et al. 2021; Zhu et al. 2019).

Metal organic frameworks (MOFs)

MOFs also known as porous coordination polymers (PCPs) are organic–inorganic hybrid crystalline materials having fascinatingly diverse properties with highly ordered frameworks of pores in which inorganic nodes (e.g., transition metal ions, alkali and alkaline earth metal ions, and rare earth metal ions/metal clusters) and organic linkers (e.g., carboxylate derivatives, Schiff bases, and pyridyl and ether derivatives) are linked together by coordinate bonds to assemble infinite network structures (Yuan et al. 2018a, b; Khan et al. 2013). Unique structural characteristics in MOFs can be achieved by tuning the building blocks of the frameworks to obtain novel MOFs according to their specified applications. Due to their high crystallinity, permanent porosity, ultrahigh surface area, adaptable pore shape/sizes, tunable functionality, and designable framework topology, MOFs exhibit ever-expanding application scopes in chemistry (Rasheed et al. 2022; Raptopoulou 2021; Kumar et al. 2020; Yang and Gates 2019). MOFs and MOF composites have been extensively studied over the last few years, and researchers have explored their versatile applications in diverse fields including heterogeneous catalysis (Rostamnia and Taghavi 2022a, b; Rostamnia et al. 2020, 2016; Liu et al. 2021; Hu et al. 2018; Cheng et al. 2021a, b; Kaushal et al. 2021; Remya and Kurian 2019), green catalysis (Rostamnia and Alamgholiloo 2018), gas storage and separation (Ghanbari et al. 2020; Lin et al. 2019), sensing (Rasheed and Rizwan 2022; Lv et al. 2022; Safarifard et al. 2020; Soni et al. 2019; Cui et al. 2019), biomedical applications including drug loading and delivery (Wei et al. 2022; Hashemi et al. 2019), enzyme immobilization (Karami et al. 2022; Sheta et al. 2018), luminescence (Zhang et al. 2022a, b, c, d; Xiao et al. 2022), photocatalytic dye adsorption/degradation (Oladoye et al. 2021; Ghosh et al. 2019), removal of environmental pollutants (Rajendran et al. 2022; Saboor et al. 2021; Zhao et al. 2015a, b), proton conduction (Ye Y et al. 2020), and as super capacitors (Byun et al. 2022; Jiao et al. 2017). Zhou et al. in their review article cover different types of Fe-based MOFs in photo-Fenton process for the removal of various organic pollutants (Zhou et al. 2022). In comparison to other MOFs, Fe-MOFs nicely couple with Fenton reagents and show excellent photocatalytic activities. MOF composites have been successfully utilized for the removal of antibiotics from aquatic samples via adsorption and photocatalysis (Yu et al. 2021a, b; Cao et al. 2022; Du et al. 2022; Yu et al. 2021a, b).

Recently, metal single atom catalysts (SACs) supported on MOFs have emerged applications in photocatalytic energy conversions including hydrogen formation reaction and CO2 reduction owing to their synergistic effects in enhancing photocatalytic activities (Cheng et al. 2022a, b). Water-resistant zirconium-based MOF, UiO-66, with excellent mechanochemical and hydrothermal stability has been modified by functionalization of organic linkers, choosing perfect metal nodes, identifying foreign metal, defect engineering, sensitization of dyes, and combination of semiconductors for various photocatalytic applications including the removal of organic pollutants, reduction of Cr(VI), hydrogen generation, and CO2 reduction (Cheng et al. 2022a, b). Uniform encapsulation of polyoxometalate (POM) in long-range ordered structure of MOFs (POM@MOF) has gained wide interests as a promising visible light induced photocatalysts for degradation of organic pollutants, photocatalytic water splitting, selective oxidation of organics, and reduction of CO2 due to their synergistically improved charge transfer and electron redox transformation (Cheng 2021a).

Among all the industrialized and non-industrialized organic and inorganic adsorbents available for removal of heavy metal ions, MOFs are developed to gain the advantages of both inorganic and organic components (Li et al. 2014; Shahid et al. 2022; Xu et al. 2021; Kaushal et al. 2020). Even though several research works have been carried out on development and applications of MOFs, industrialization of MOFs has been limited due to their instability in water (Qin et al. 2021; Meteku et al. 2020). Moreover, challenge in recovery of MOF-based adsorbents from the mixture of solution after their application is another severe drawback (Baskar et al. 2022).

Magnetic nanoparticles (MNPs)

MNPs are typically an emerging class of nanomaterials (solid particles with dimensions ranges between 1 and 100 nm) that exhibit extraordinary chemical, mechanical, and thermal properties along with substantially different and marvelous magnetic properties as compared to conventional micro and mesomaterials (Zhou et al. 2020). Along with excellent surface effect and fascinating magnetic properties, they exhibit outstanding optical, electrical, and catalytic properties as well and offer wide opportunities in chemical synthesis (Chutia and Chetia 2018, 2019, 2020), biomedical applications (Devi et al. 2014; Mohammed et al. 2016), environmental remediation, and sensing (Jiang et al. 2018). However, high surface energy of metallic MNPs thermodynamically destabilizes them and exerts a potential tendency to get aggregate which adversely affect their applications.

Magnetic metal–organic frameworks (MMOFs)

To countervail the deficiencies of both MOFs and MNPs, MNPs (MnFe2O4, Fe3O4, α-Fe2O3, γ-Fe2O3, CoFe2O4, NiFe2O4, CuFe2O4, and ZnFe2O4) can either be immobilized into MOF structures or employed as metal source for building an MOF structure and thereby tuning the magnetic properties of NPs in the MOFs, resulting in an auspicious magnetic composite material in which MOFs serve as a host for the functional guest MNPs (magnetic metal–organic framework, MMOFs) (Ricco et al. 2013; Hu et al. 2013). Consequently, MMOF composites have synergistically enhanced properties including increased surface area, higher adsorption ability, easier functionality, and facile as well as rapid recyclability with an external magnet. The synergistic properties are significantly different from those of individual constituting components and offer promising applications in the removal of heavy metal ions from the aqueous system (Liu et al. 2022c; Peng et al. 2022).

Purpose of the review

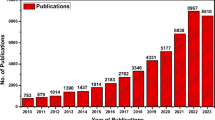

Over the last decade, development in the synthesis and applications of MMOF composites in the adsorption of toxic heavy metal ions has widely been reported all over the world (Abdel-Magied et al. 2022; Abdollahi et al. 2022). Several reviews have summarized the fundamentals of MMOF composites and their selected applications in environmental monitoring and remediation by catalysis and adsorption (Moussavi et al. 2022; Gao et al. 2019; Zhao et al. 2019). To the best of our knowledge, comprehensive reviews on this subject matter are not so far focused. However, most of the recent developments in this area from the last three years have not been covered by their articles. In this review, we summarize different synthetic strategies adopted by the researchers for the preparation of MMOF composites, various structural properties that are harnessed for removal of heavy metal ions from contaminated water, and recent applications in removal of toxic heavy metal ions from wastewater with their adsorption capacities as well as limit of detections and their stability and reusability. Finally, future perspectives of MMOF composites in mitigating global environmental pollution are presented. Moreover, particular prospects and challenges in further development of MMOFs towards greener synthetic approaches for their industrial applications have critically been considered in this review.

Classification of MMOF composites

Several authors have adapted different criteria to elaborate the classification of MMOF composites including the type of guest molecule, nature of the MOF structures, and the synthetic approaches depending on the dynamic interactions between MOFs and MNPs (Li and Huo 2015; Espallargas and Coronado 2018). However, it is crucial to understand the synthetic strategies applied for designing various types of MMOF composites according to their specific applications and desired synergistic properties (Yadav et al. 2021). In this review, for more simplicity, MMOF composites have been categorized into two broad classes based on their composition and their synthetic strategies: (a) simple MMOF composites which are solely constructed by MOFs and MNPs and (b) complex MMOF composites which are usually multifunctional composites that are constructed by MNPs, MOFs, and a third component (Fig. 1).

Simple MMOF composites

As mentioned earlier, simple MMOF composites are generally made up of two components: the magnetic component (MNPs) and the framework structure (MOF). The magnetic components are most commonly the oxides of Fe (Fe3O4, α-Fe2O3, and γ-Fe2O3) or the ferrites of Co and Ni (CoFe2O4, NiFe2O4, etc.) (Far et al. 2022; Saemian et al. 2019; Zheng et al. 2020). Fabrication processes available for devising simple MMOF composites are quite simplistic involving the encapsulation of MNPs within the MOF structure or the deposition of MNPs on the MOF structure. Till date, several synthetic approaches have been successfully reported to get simple MMOF composites which are deliberately designed towards their specific applications.

Direct mixing, encapsulation, and embedding are the most frequently employed synthetic strategies in developing simple MMOF composites.

Direct mixing strategy for preparing MMOF composites

The mixing method is the simplest technique for generating simple MMOF composites in which separately synthesized MNPs and pre-synthesized MOFs are mixed together in a suitable solvent under sonication to avoid aggregation. MNPs are firmly fixed on the surface of the MOFs by electrostatic interactions (Nadar et al. 2018). In this strategy, neither the surface of MNPs is modified by utilizing functionalizing agents nor are polymer coatings employed to provoke the growth of MOFs over MNPs (Huo and Yan 2012).

For instance, the mixing approach for developing simple MMOF composite was demonstrated very well by Liu and his coworkers in which MIL-100(Fe) was prepared by using trimesic acid as organic linker and iron(III) nitrate nonahydrate (Fe(NO3)3·9H2O) as metal source in a Teflon-lined steel autoclave at 200 °C for 8 h. Magnetic MOF composite Fe3O4/MIL-100(Fe) was fabricated by simply mixing the pre-synthesized MIL-100(Fe), ferric chloride crystals, and anhydrous sodium acetate with ethylene glycol in an autoclave for 10 h at 200 °C. Fe3O4/MIL-100(Fe) composite obtained was collected, washed, and dried under vacuum and was demonstrated as a stable, durable, and reusable adsorbent for rapid extraction and separation of Rhodamine B dye from water (Liu et al. 2016).

Yadav et al. recently prepared a novel magnetically retrievable MMOF catalyst CoFe2O4/Mn-BDc by using a solvothermal synthetic route, which is involved in the mixing of manganese dichloride tetrahydrate (MnCl2·2H2O) and 1,4-benzene dicarboxylic acid (1,4-BDC) organic linker and resulting solution was stirred for 10 min. The solution was directly mixed with pre synthesized CoFe2O4 MNPs in 1:4 ratio of DMF:methanol under ultrasonication and then transferred to an autoclave to heat at 120 °C for 10 h (Fig. 2). The synthesized CoFe2O4/Mn-BDc catalyst was found to exhibit high catalytic activity in click coupling reaction to afford several biologically and pharmaceutically significant 1,4-disubstituted 1,2,3-triazoles with a satisfactory yield (Yadav et al. 2020).

Utilizing the aforementioned synthetic approach, several research groups have synthesized Fe3O4/MIL-53(Fe), NH2-MIL-88B(Fe)/Fe3O4, MOF-199/Fe3O4, etc. and successfully explored their efficacy in the field of catalysis, sensing, environmental monitoring, and remediation (Cao et al. 2016; Zhang et al. 2015; Samui et al. 2016).

Encapsulation strategy for preparing MMOF composites

Another synthetic technique often utilized for designing simple MMOF composites is encapsulation in which the outer surface of the magnetic nanostructures (i.e., MNPs or fibers) are pre-treated with an interface material such as a polymer, silica, or a carbonaceous layer possessing high compatibility towards the fabrication of MOF, thereby generating a magnetic core–shell architecture. The affinity of the MOF shell towards the magnetic part was increased by the polymer shell consisting plenteous functional groups and hydrophilic sites and the magnetic core component that allowed the nucleation and controlled growth of a particular type of MOF. Remarkable examples have been reported in which the surface of magnetic nanostructures is modified by effectively encapsulating within silica (Huo and Yan 2012; Luo et al. 2019), chitosan (Chowdhuri et al. 2016), polyacrylic acid (PAA) (Jin et al. 2015), polydopamine (PDA) (Zhou et al. 2015), polyvinylpyrrolidone (PVP) (Xu et al. 2016), etc. to facilitate a controlled growth of MOF layers.

It is worth to mention here that very recently Yang and his group developed a facile synthetic route for attaining a novel MMOF composite, Fe3O4@SiO2@Zr-MOF, with 2-aminoterephthalic acid as the organic linker and Zr as the metal node and demonstrated it as a potential adsorbent for adsorptive removal of salicylic acid and acetylsalicylic acid from aqueous solution. The elementary step of the abovementioned synthetic protocol involves the encapsulation of pre-synthesized Fe3O4 MNPs within a coating of silica utilizing tetraethyl orthosilicate (TEOS). Fe3O4@SiO2@Zr-MOF magnetic composite was obtained by ultrasonic dispersion of silica-coated MNPs (Fe3O4@SiO2) with ZrCl4 salt in DMF followed by addition of separately prepared DMF solution of 2-aminoterephthalic acid under continuous mechanical stirring for 6 h at 120 °C (Fig. 3). The silica coating stabilized the magnetic Fe3O4 core and essentially controlled the growth of Zr-MOF on the surface of Fe3O4 due to chelating interactions existing between Zr4+ ions of the MOF and –OH groups of silica layer (Yang et al. 2018).

A facile solvothermal route for fabrication of a novel MMOF composite, Fe3O4@MIL-101(Fe), was successfully illustrated by Yue et al. wherein PVP-coated Fe3O4 MNPs were ultrasonically mixed with DMF solution containing MOF salts, i.e., terephthalic acid and FeCl3·3H2O under 110 °C for 20 h. In the abovementioned protocol, the PVP-coated Fe3O4 MNPs are encapsulated within the MIL-101(Fe) nanostructure to yield crystalline Fe3O4@MIL-101(Fe) composite which was demonstrated as a stable and recyclable heterogeneous catalyst for the removal of azo dye such as Acid Orange-7 from environmental wastewater (Yue et al. 2016).

In the last decade, following the similar trend, various research groups have developed Fe3O4@SiO2UiO-67, Fe3O4@PDA@[Cu3(btc)2], Fe3O4@PVP-PEI@MOF-PBA, etc. MMOF composites and illustrated their successful applications in enzyme immobilization, protein capture and release, organic as well as inorganic contaminant removal from environmental samples, etc. (Zhang et al. 2019; Zhao et al. 2015a, b; Yang et al. 2017).

Embedding strategy for preparing MMOF composites

The embedding approach is another important synthetic methodology frequently employed for devising simple MMOF composite. In this approach, pre-synthesized magnetic nanostructures (particles, fibers) are first directly dispersed into the MOF precursor solution comprising the organic linker, inorganic metal salt, and suitable solvent or mixture of solvents. Generally, by employing hydrothermal or solvothermal strategy, MNPs are allowed to get automatically embedded within the pores of MOF matrix without functionalizing or coating the surface of MNPs (Meteku et al. 2020; Ricco et al. 2013).

Very recently, Yadollahi et al. fabricated a novel MMOF composite, CoFe2O4/TMU-17-NH2, via an embedding approach. Firstly, CoFe2O4 MNPs were synthesized by a co-precipitation method (Fig. 4). The synthesized CoFe2O4 MNPs were directly dispersed into a DMF solution containing 2-amino-1,4-benzenedicarboxylic acid, 1,4-bis(4-pyridyl)-2,3-diaza-2,3-butadiene, and Zn(NO3)2·6H2O and allowed to get embedded within the pores of in situ-synthesized TMU-17-NH2 matrix in an autoclave under 90 °C in 3 days (Yadollahi et al. 2021).

They explored the catalytic activity of the magnetic nanocomposite material CoFe2O4/TMU-17-NH2 and established it as an easily recoverable and reusable acid catalyst for synthesis of several dihydropyrimidine derivatives via one pot solvent free multicomponent reaction of aromatic aldehyde, urea or thiourea, and 1,3-diketone.

Saikia and his coworkers followed a quite astounding protocol for embedding Fe3O4 MNPs into MIL-101(Cr) matrix by adding FeCl2·4H2O and FeCl3 salts into an aqueous solution of MIL-101(Cr) under vigorous stirring for 1 h to fabricate Fe3O4@MIL-101(Cr) magnetic hybrid composite. The massive surface area of MIL-101(Cr) allows fantabulous dispersion as well as incorporation of MNPs on its surface. Fe3O4@MIL-101(Cr) composite was demonstrated as a very efficient catalyst for oxidation of benzyl alcohol to benzaldehyde under solvent-free condition and was recycled up to three catalytic cycles (Saikia et al. 2015).

Till date, embedding technique has successfully been utilized by several research groups to develop simple MMOF composites, e.g., hollow magnetic Fe3O4@NH2-MIL-101(Fe), magnetic Mg-MOF-74, and magnetic MIL-101-SO3H, whose efficacy has been explored in several prospering applications (Li et al. 2016a, b, c; Boroujeni et al. 2016).

Complex MMOF composites

As mentioned earlier, complex MMOF composites are generally made up of magnetic component (magnetic fibers or MNPs), MOF structure, and most essentially third component(s) such as noble metals, graphene oxide (GO), carbon nanotubes (CNT), carbon dots (CD), or polymers which synergistically improve the formation of the composites. These supporting agents are chosen on the basis of desired properties for their intended applications (Nirumand et al. 2018; Ke et al. 2015). In a similar manner to those of simple MMOF composites, most commonly employed magnetic components are the oxides of Fe (Fe3O4, α-Fe2O3, and γ-Fe2O3) or the ferrites of Co, Ni, etc. (Yin et al. 2019).

A layer-by-layer synthetic methodology is best suited for devising complex core–shell heterostructure where magnetic component is the core and the MOF is the shell. For synthesizing complex core–shell heterostructures, the surface of magnetic core is decorated with certain appropriate functional groups which facilitates a controlled growth of MOF structure resulting in the core–shell MMOF composite (Zhang et al. 2014).

For instance, Ke et al. (2015) reported a complex core shell MMOF composite Au-Fe3O4@MIL-100(Fe) via a layer-by-layer strategy. In the synthetic process, pre-synthesized Au nanoparticles were immobilized on the surface of L-cysteine-functionalized Fe3O4 MNPs using ascorbic acid to obtain Au-Fe3O4. Magnetic Au-Fe3O4 was then functionalized with mercaptoacetic acid (MAA) which facilitates layer-by-layer growth of MIL-100(Fe) shell around Au-Fe3O4 magnetic core (Ke et al. 2015).

Duo and his coworkers designed a fusiform-like MMOF composite, Fe3O4-NH2@MOF-235, by employing a two-step solvothermal strategy. In the first step, amine-functionalized Fe3O4 MNPs, i.e., Fe3O4-NH2, were obtained by the addition of ferric chloride, 1,6-hexanediamine, and ethylene glycol (Fig. 5). The amine-decorated MNPs were dispersed into a DMF solution containing MOF precursors, i.e., terephthalic acid organic linker and FeCl3·6H2O metal source under a solvothermal condition which allows the -NH2 groups to get chelated with Fe3+ metal ions on the surface of Fe3O4 MNPs and then the chelated Fe3+ ions further bind with terephthalic acid forming the core to yield Fe3O4-NH2@MOF-235 composite (Duo et al. 2019).

Tao et al. reported a time-efficient and productive solvent-free strategy for designing magnetic PCN-250 composite exhibiting outstanding CO2 capture capacity in which citric acid-decorated Fe3O4 MNPs were prepared and blended with 3,3′,5,5′-azobenzene tetracarboxylic acid organic linkers and Fe2Co(μ3-O)(CH3COO)6 metal clusters with a vortex mixer and then transferred to an alternating magnetic field of strength 39 mT. The MNPs in the resulting powder reaction mixture acted as “nanoheaters” and the magnetic induction heat generated mPCN-250 composite after continuous heating of 1.5 h (Tao et al. 2019).

Sepehrmansourie and his group reported a novel MOF-based core–shell nanomagnetic composite Fe3O4@Co(BDC)-NH2 and a range of novel fused pyridines and 1,4-dihydropyridines with pyrazole and pyrimidine moieties were synthesized by using the nanomagnetic composite as an efficient and recyclable catalyst. A simple sonication strategy was employed for the synthesis of Fe3O4@Co(BDC)-NH2. 45.0 mM solution of Co(NO3)2·6H2O and 45.0 mM of H2BDC-NH2 in DMF were prepared separately. Then, a mixture of pre-synthesized carboxylic acid-functionalized Fe3O4 MNPs (Fe3O4@CH2CO2H) and DMF solution of Co(NO3)2·6H2O were sonicated. The sonicated mixture was separated by an external magnet and washed with DMF. To that magnetic mixture DMF solution of H2BDC-NH2 was added and sonicated for 45 min to obtain Fe3O4@Co(BDC)-NH2 MMOF composites (Sepehrmansourie et al. 2021).

Another synthetic strategy for the synthesis of MMOF composite catalyst (Fe3O4@MIL-101(Cr)-N(CH2PO3)2) was reported by the same group for the synthesis of pyrazolo [3,4-b] pyridines as convenient medicine by condensation reaction of aldehydes, 3-(cyanoacetyl)indole and 5-(1H-Indol-3-yl)-2H-pyrazol-3-ylamine. MIL-101(Cr)-NH2 and phosphoric acid-functionalized MIL-101(Cr)-NH2, i.e., MIL-101(Cr)-N(CH2PO3H2)2, were synthesized by employing their previously reported simple solvothermal rout (Fig. 6). Then, a mixture of Fe3O4 MNPs and MIL-101(Cr)-N(CH2PO3H2)2 was dispersed in toluene at 80 °C for 12 h. After cooling the reaction mixture, the nanoporous MMOF composite (Fe3O4@MIL-101(Cr)-N(CH2PO3)2) was collected by an external bar magnet, washed with ethanol, and dried before catalytic application (Sepehrmansourie et al. 2022).

Babaee et al. developed a nanocomposite (MIL-101(Cr)-N(CH2PO3H2)2) based on MIL-101(Cr)-NH2 MOF with phosphorus acidic functional groups. The synthesized nanoporous MOF composite acted as a multifunctional heterogeneous catalyst for one-pot synthesis of N-amino-2-pyridone and pyrano[2,3-c]pyrazole derivatives. MIL-101(Cr)-NH2 was obtained from an equimolar mixture of 2-aminoterephthalic acid and Cr(NO3)3·9(H2O) in the presence of NaOH by heating it in a Teflon-lined autoclave at 150 °C for 12 h. MIL-101(Cr)-NH2 with phosphoric acidic arms (MIL-101(Cr)-N(CH2PO3H2)2) was obtained by refluxing MIL-101(Cr)-NH2, formaldehyde, phosphorus acid, p-toluenesulfonic acid, and ethanol (Fig. 6). The amount of phosphorus present in MIL-101(Cr)-N(CH2PO3H2)2 was found to be 4.56% (Babaee et al. 2020).

Recently, Alamgholiloo et al. demonstrated a highly economic and novel synthetic strategy to fabricate a complex ternary MMOF nanocomposite (Fe3O4/Cu-BDC/GO) in which Fe3O4 MNPs with open metal site Cu BDC MOF were allowed to grow simultaneously on GO sheets. It was the first ever reported ternary nanocomposite employed as an excellently reusable and efficient catalyst for the aerobic oxidation of alcohols to carbonyls in presence of a stable nitroxide radicals, [2,2,6,6-tetramethylpiperidine-N-oxyl] (TEMPO) as a cocatalyst. The synergistic interactions between Fe3O4 MNPs and GO as well as active copper in open metal sites of Cu-BDC frameworks synergistically enhanced the catalytic activity of the ternary MMOF-based nanocomposites (Alamgholiloo et al. 2020).

Alamgholiloo and his group in another report demonstrated a novel green solvothermal strategy to fabricate a ternary nanocomposite GO/CuBDC-Fe3O4 for fast degradation of ciprofloxacin antibiotics. Microporous Cu-BDC MOF was fabricated by employing a solvothermal route using terephthalic acid as organic linker and copper nitrate trihydrate as metal salts in the presence of polyvinyl alcohol as modulating agent. Exfoliated GO was used as a platform for the growth of Cu-BDC MOF and magnetic Fe3O4 NPs with the aim to create a PMS (peroxymonosulfate) activator. The maximum degradation rate for ciprofloxacin using the new ternary MMOF composite was found to be 98.5% within 24 min with rate constant 0.191 min−1 (Alamgholiloo et al. 2021).

Structural characteristics of MMOF composites

MMOF composites exhibit fascinating synergistic physical properties including ultrahigh surface area, high porosity, and outstanding magnetic property that are exploited in environmental monitoring and remediation (Li and Huo 2015).

Surface area

Surface area is one of the most important synergistic physical properties of MMOF composites that are crucial in environmental monitoring and remediation. Most of the environmental contaminants including organic and inorganic pollutants are eliminated from environmental samples through the adsorption process. The extent of adsorption depends on the available surface area on the sorbent materials. MOF, which is a major component of MMOF composites, is well known for its ultrahigh specific surface area that is highly desirable in many potential applications (Mohammed et al. 2016). Moreover, adsorption can be improved by introducing functional groups to the surface and pores of MMOF sorbents according to their intended application which significantly provides active sites for enhanced adsorption. Farha et al. reported two novel MOFs (NU-109 and NU-110) which exhibited record-breaking specific BET surface area of approximately 7000 m2g−1. Furthermore, theoretical upper limit for the MOF surface area was investigated and a substantially greater hypothetical surface area (14,600 m2g−1) was observed (2.7 American football fields could be covered by only 1 gm of the material) (Farha et al. 2012).

Each component in MMOF composites has synergistic impact on specific surface area. Recently, Mahmoodi and his group reported MOF-based magnetic adsorbent ZIF-8/CoFe2O4/GO (ZCG) composites with different amounts of CoFe2O4/GO (25 mg CoFe2O4/GO for ZCG-25 and 50 mg CoFe2O4/GO for ZCG-50) for the removal of pollutants from water. The specific surface area was determined according to the Brunauer–Emmett–Teller (BET) method and was found to possess an excellent BET surface area of 1543 m2/g and 2490 m2/g for ZCG-25 and ZCG-50, respectively. The BET surface of magnetic component was recorded to be 52 m2/g and that of GO was 46 m2/g. However, introduction of ZIF-8 synergistically enhanced the BET surface area of the entire composite to an outstanding value of 2490 m2/g. Combination of ZIF-8 synergistically enhanced the BET surface area of the entire composite than the single components (Mahmoodi et al. 2019a,b). Far and his coworkers synthesized a MOF (UiO-66) with record-breaking BET surface area of 1215 m2/g. Although BET surface area of pristine MOFs decreased from 1215 m2/g to 507 m2/g on incorporation of MNPs into UiO-66 structures, there was significant increase in the specific BET surface area of Fe3O4 MNPs from 11 to 507 m2/g. On further coating with PPI dendrimer, the BET surface area was lowered down to a value 120 m2/g. However, PPI dendrimer functionalization showed a positive impact on adsorption of anionic dyes (DR31 and AB92) due to the introduction of abundant functional groups to the nanoadsorbents which provided active sites for adsorption (Far et al. 2020).

Magnetic properties

Magnetism, the paramount property for recyclability, is an important characteristic of MMOF composites by virtue of which the sorbent material can be recycled efficiently by using an external magnetic field after usage Ease of recycling and regeneration of adsorbents is an important concern from the industrial and “green chemistry” point of view (Gao et al. 2019). MNP is a major component of MMOF composites that is introduced either to the surface or to the pores of MOFs. They not only affect the properties of specific surface area and adsorption capacity of the sorbent but also impart magnetism in it. Thus, introduction of MNPs to MOFs makes the composite economic and less laborious. The MMOF composites can be recycled, regenerated, and reused repeatedly until the magnetic property and adsorption capacity remain intact (Yang et al. 2020a, b, c; Shao et al. 2019).

Recently, Mousavi and his coworkers reported a novel MMOF composite, MIL-101(Cr)/Fe3O4@SiO2@2-ATP, for the separation/pre-concentration of trace amount silver metal present in aqueous system. To explore magnetic characteristics of the individual components and the entire composite, a Vibrating Sample Magnetometer (VSM) was used for each. MOF and other non-magnetic components present in the composite reduce the magnetic property of the composites. As shown in Fig. 7, the magnetization saturation value of Fe3O4 (MNPs) kept reducing on addition of extra components from 67 emu/g to 41 emu/g for Fe3O4@SiO2@2-ATP and finally to 26 emu/g for the entire composite, MIL-101(Cr)/Fe3O4@SiO2@2-ATP. The obtained plots and values show that although the magnetization saturation value of the composite MIL-101(Cr)/Fe3O4@SiO2@2-ATP is lesser than that of sole MNPs, the material is superparamagnetic and can be magnetically isolated by employing an external magnetic field (Mousavi et al. 2021).

Reproduced from reference Mousavi et al. 2021 with permission from The Royal Society of Chemist

VSM curves of Fe3O4 MNPs, Fe3O4@SiO2@2-ATP MNPs, and MIL-101(Cr)/Fe3O4@SiO2@2-ATP MMOF composite.

Huang and his group reported the synthesis and characterization of novel MMOF composites Fe3O4@SiO2@HKUST-1 and Bi-I-functionalized Fe3O4@SiO2@HKUST-1 utilized for selective and efficient removal of Hg2+ ion from environmental water samples. The magnetic property of the composites was established by VSM study and their corresponding hysteresis curves are shown in Fig. 8.

Reproduced from Reference Huang et al. 2015 with permission from The Royal Society of Chemistry

VSM magnetization curves Fe3O4@SiO2, Fe3O4@SiO2@Cu(OH)2, Fe3O4@SiO2@HKUST-1, and Bi-I-functionalized Fe3O4@SiO2@HKUST-1; and images before and after magnetic separation under an external magnetic field.

The saturation magnetization of Fe3O4@SiO2, Fe3O4@SiO2@Cu(OH)2, Fe3O4@SiO2@HKUST-1, and Bi-I-functionalized Fe3O4@SiO2@HKUST-1 is 39, 22, 13, and 8 emu/g, respectively. It clearly reveals that after addition of extra components to the MNPs, the magnetic property of resultant composites formed in each step decreases. However, all the composites are superparamagnetic and can be sufficiently separated easily with an external bar magnet (Huang et al. 2015).

Farhadi and his coworkers reported a novel magnetically retrievable nanoporous adsorbent P2W18O62@Fe3O4/MIL-101 (Cr) for ultrafast treatment of organic pollutants present in aqueous solutions. The magnetic properties of the Fe3O4, Fe3O4/MIL-101 (Cr), and P2W18O62@Fe3O4/MIL-101 (Cr) were determined by VSM, and the magnetic hysteresis loops depicted are as shown in Fig. 9A.

A Magnetic hysteresis loop of (a) Fe3O4, (b) Fe3O4/MIL-101 (Cr), and (c) P2W18O62@Fe3O4/MIL-101 (Cr) at room temperature. The inset shows the behavior of the nanohybrid under an external magnetic field. B Recyclability of the P2W18O62@Fe3O4/MIL-101 (Cr) hybrid nanomaterial in the removal of MB dye.

All the samples were found to be superparamagnetic, and the saturation magnetizations values of the pure Fe3O4, Fe3O4/MIL101 (Cr), and P2W18O62@Fe3O4/MIL101 (Cr) were found to be 72, 35, and 25 emu/g, respectively. The saturation magnetization value of the magnetic P2W18O62@Fe3O4/MIL101 (Cr) composite was found to be decreased by approximately 70% as compared with pure Fe3O4, which was attributed to the less magnetic source component (Fe3O4) present per gram in the composite sample. However, easy magnetic separation of the adsorbent material from aqueous suspension was satisfied by the saturation magnetization value of the composite. The adsorption capacity of the adsorbent for removing pollutants (methylene blue and Rhodamine B) was found to remain intact in every three consecutive adsorption cycles (Fig. 9B) with a maximum adsorption capacity of 98% (Farhadi and Jarrah 2018).

Porosity

MMOFs possess record-breaking porosity as its major constituent; MOFs are extrinsically sophisticated materials with abundant pores. Pores of the material allow the incorporation of guest molecules into its structure in order to achieve different functionalities. The energy released upon the interactions of adsorbents with the pores is the main driving force for this adsorption phenomenon which strongly depends on adsorbate-adsorbent interaction strength. Adsorption is generally influenced by orientation and structural geometry of the pores and pore functionality as well as adsorbate-adsorbent analogy. Adsorption can be maximized by increasing the pores/adsorption sites. Generally, large cavities offer easy incorporation of guest molecules (Zhao et al. 2020). The flexibility and high porosity of MOFs facilitate guest molecules to diffuse into the MOF-bulk structure, and the pore shape/size controls the selectivity over the guests that may be adsorbed. Most of the reported MMOF composites possess microporous structures (pore diameter less than 2 nm) that are advantageous for absorbing small guest molecules including small organic molecules, small coordination complexes, and gas molecules. Cage-like structures of mesoporous or macroporous (pore diameter 2–50 nm) MMOF composites are highly desired for penetration of larger guest molecules such as biomolecules. Volume of the pores depends on cross-linking density which can be increased by employing slim ligands. Elongated organic linkers are generally employed to increase the pore size through isoreticular expansion (Yuan et al. 2017). Far and his group reported a magnetic metal–organic framework functionalized with PPI dendrimer (Fe3O4@MOF@PPI) for sustainable wastewater treatment. The pore size distribution was determined according to the Barrett-Joyner-Halenda (BJH) method and was found to be dramatically increased from 0.014 to 0.58 cm3/g after coating a layer of MOF (UiO-66) on Fe3O4 MNPs. On magnetization, no significant changes in the pore size were observed for the pristine UiO-66 MOFs which was recorded to be 0.54 cm3/g. However, pore volume was somehow decreased on dendrimer coating to a value 0.25 cm3/g (Far et al. 2020).

Adsorption mechanism

MMOF composites have been successfully applied as adsorbents for the removal of various heavy metal ions from aqueous medium. In many reports, adsorption/removal of heavy metals was reported as a success story (Hasan and Jhung 2015; Howarth et al. 2015; Li et al. 2016a, b, c). MMOF composites possess many types of organic linkers and have structural and morphological differences. The interaction sites involved in the adsorption mechanism can either be the linkers as well as the metal or clusters. As per reports, interaction mechanism involved in the adsorption of heavy metal ions by MMOF composites may be physical base adsorption such as van der Waals interactions, electrostatic adsorption, hydrogen bonding, π–π conjugation, Lewis acid–base interaction, chelation, or by complexation (Manousi N et al. 2019). In order to improve the selectivity and/or adsorptive capability, pre-/post-synthetic functionalization of the linkers, with various groups such as amino, hydroxyl, carboxylic acid, amide, and thiol, is a well-known and successive strategy. Functionalization of the MMOF frameworks increases the number of N-, O-, or S-containing groups that enhance the adsorption efficiency and selectivity of the targeted metal ions. Lewis acid–base interactions are one of the most common mechanisms for the adsorption of metal ions by MMOF composites (Vu et al. 2015). O-, N-, and S-containing groups present in the linkers act as Lewis bases and metal ions act as Lewis acids. pH of the sample plays the most significant role that influences the kinetics and adsorption process. Organic ligands rich in N, O, and S can bind with metal ions via host–guest complexation (Kobielska et al. 2018). At lower pH value, O, N, and S atoms get protonated and hence adsorption cannot occur due to the repulsive forces between positively charged adsorption sites and the metal cation [53]. However, on increasing the pH of metal ions containing aqueous samples, deprotonation of the donor atoms takes place. This enables the sorption of the targeted analytes by complex formation between the donor atoms of the adsorbent and the metal ions (Jamali et al. 2016; Hassanpour et al. 2015).

Adsorption of metal ions with MMOF composite via complexation can be improved by the chelation mechanism (Fang et al. 2010). Adsorption capacity of MMOF adsorbents can be enhanced by functionalization of the composite with groups that facilitate the formation of chelating complexes with the metal ions.

For instance, Wang et al., for the first time, reported a reliable and highly selective dithizone-functionalized magnetic sorbent, Fe3O4/Cu3(BTC)2-H2Dz, for magnetic solid phase extraction and determination of Pb(II) ion from environmental water sample (Wang et al. 2013). BET surface area and pore volume of the composite were determined by N2 adsorption–desorption isotherm which showed that BET surface area of the composite (753.58 m2g−1) was decreased than the pristine MOF (933.37 m2g−1) and pore volume was found to be decreased from 0.62 cm3g−1 to 0.51 cm3g−1 on incorporation of MNPs. However, under the optimized conditions of pH, sample volume, sorbent quantity, and concentration as well as coexisting interfering ions, the maximum Pb(II) uptake was found to be 1.67 mg g−1 determined by ETAAS (Electrothermal Atomic Adsorption Spectrometry) with a very low limit of detection 0.0046 μg L−1.

Highly selective chelating agents under controlled experimental conditions may allow various pre-concentration processes that can be carried out for the extraction of lead. Dithizone (Dz, 1,5-diphenylcarbazone) is a commonly used chelating agent that can form highly stable Pb complex via –SH and –NH functional groups. Efficient extraction of Pb can be attributed to the formation of a penta-heterocycle chelating complex between Pb(II) ion and dithizone molecules in the sorbent (Fig. 10A). At lower pH value, protonation of the binding sites of the chelating molecules takes place and hence adsorption cannot occur. With increase in pH up to an optimum value, adsorption capacity increases but further increase in pH may cause hydrolysis resulting in the precipitation of target analytes.

Reproduced from Reference Wang et al. 2013 with permission from The Royal Society of Chemistry

Schematic representation for A adsorption mechanism of Pb(II) on Fe3O4/Cu3(BTC)2-H2Dz composite and B their corresponding VSM magnetization curves (a) VSM magnetization curves for Fe3O4 and (b) VSM magnetization curves for Fe3O4/Cu3(BTC)2-H2Dz.

Magnetic properties of Fe3O4/Cu3(BTC)2-H2Dz composite were characterized by hysteresis curves by means of VSM. VSM magnetization curves of Fe3O4/Cu3(BTC)2 and Fe3O4/Cu3(BTC)2-H2Dz at room temperature are shown in Fig. 10B. The saturation magnetization value for Fe3O4/Cu3(BTC)2 was measured to be 5.48 emu g−1 whereas for Fe3O4/Cu3(BTC)2-H2Dz it was 4.91 emu g−1. The decrease in magnetic strength of Fe3O4/Cu3(BTC)2-H2Dz as compared to that of Fe3O4/Cu3(BTC)2 was attributed to the presence of the nonmagnetic H2Dz. However, the MMOF sorbent was still sufficiently magnetic for easy separation with a bar magnet.

In case of physical adsorption, various interactions between the adsorbent and targeted adsorbates may be responsible for the higher adsorption capacity of MMOF composites. The presence of particular functional groups and the net charge on the framework have significant impact on the extent of physical adsorption [61]. The electrostatic interactions between anionic adsorption sites of the adsorbent framework and the cationic adsorbates are the most extensively reported mechanism of adsorption (Rahimi and Mohaghegh 2015). In the MMOF composites, pore size can range from micropores to mesopores. MMOF composites possessing different pore sizes allow adsorption of heavy metal ions with spatial arrangements. The diffusion of the targeted metal ions toward the active sites of the MMOF adsorbent is also an important aspect, and hence the size, volume, and geometry of the pores have paramount significance (Jian et al. 2014).

In many cases, more than one interaction mechanism can be explained for the high adsorptive capacity of MMOFs. For instance, Huang et al. reported a cost-effective and green strategy to develop aluminum metal-based, amino-functionalized MMOF composites (MFC-N-X) by varying the ratio of disodium salt of 2-amionterephthalic acid (NH2-Na2BDC) and terephthalic acid (Na2BDC) ligands (Fig. 11). The nanoscale MFCs were found to possess large pore volume, high surface area, and excellent magnetic response as well as good water and thermal stability. MFC-N-100 with 100% NH2-Na2BDC organic ligand was demonstrated as a fascinating adsorbent for removal of As(V) from different water samples with a high removal efficiency of 71 mg g−1 (Huang et al. 2018a, b).

Under pH > 2.2, As(V) mainly exists in anionic forms, i.e., H2AsO4− (2.2 < pH < 7.0), HAsO42− (7.0 < pH < 11.5), and AsO43− (pH > 11.5) (Mohan and Pittman 2007). There exists an electrostatic repulsion between the negatively charged MFC-N-100 composite and anionic As(V) species above pH 8. However, above pH 8, a quantitative adsorption of As(V) was observed indicating the existence of other mechanisms rather than electrostatic interactions contributing to the adsorption of anionic target As(V) species on MFC-N-100 composite. Hence, the FT-IR analysis of MFC-N-100 composite loaded with As(V) species was performed and the peak at 1237 cm−1 verified the appearance of As-O–Al bond, indicating an interaction existing between target As(V) species and hydroxyl groups of octahedral AlO4(OH)2. Adsorption of As(V) onto MFC-N-100 was further established by elemental mapping images. Moreover, XPS analysis of MFC-N-100 done before and after As(V) loading confirmed the formation of arsenic complexes via the formation of Al-O-As bonds. Further, involvement of -NH2 groups in adsorption of As(V) was established by shifting of binding energy for N 1 s by an amount ~ 0.5 eV toward high binding energy after the adsorption of As(V) (Li et al. 2018). Hence, the adsorption of As(V) on the MMOF composite MFC-N-100 is based on the As-O–Al interactions as well as electrostatic interactions between H2AsO4− and NH2 functional groups (Fig. 12).

Advanced computational techniques such as density functional theory (DFT) and molecular dynamics (MD) and sophisticated analytical techniques such as X-ray absorption fine structure (XAFS) and resonant anomalous X-ray reflectivity (RAXR) provide sufficient information and make it possible to understand the in-depth adsorption mechanism.

Applications of MMOF composites in removal of heavy metal ions

With rapid development of industries and agricultures, contamination of environmental water by heavy metal ions has become increasingly a severe issue. Heavy metal ions are non-biodegradable and highly biotoxic. Enrichment of heavy metal ions in humans and other organisms via food chain or drinking water can harm normal metabolism and is the greatest threat to human health (Sud et al. 2008; Fu and Wang 2011). Removal of toxic heavy metals by traditional adsorption materials, e.g., metal oxides, activated carbon, zeolite, porous organic polymers, and molecular or ion imprinted polymers, has several limitations owing to their lower specific surface areas, insufficient thermal and chemical stability, poor adsorption performance, poor reusability, and tedious as well as laborious separation process (Zare et al. 2018; Da’na. 2017). In recent years, MSPE done by nanoparticles, nanocomposites, sponges, foam, and beads has been recognized for its easy operation, regenerability, and high efficiency for adsorption of hazardous environmental contaminants including heavy metal ions (Zhang et al. 2022a, b, c, d; Ricardo et al. 2020). MMOF composites have a number of advantages as compared with other conventional adsorbents used for wastewater remediation. These include their multiple types, simple synthetic processes, tunable functionalities, adaptable pore sizes, large specific surface areas, easy recyclability, efficient reusability, and saturated or unsaturated central metal sites. Physicochemical properties of heavy metals can be met by designing the structurally advanced MOFs. MMOF composites successfully replace the conventional adsorbent materials mentioned above for rapid and selective removal of heavy metals from aqueous samples with their outstanding structural characteristics and good adsorption performance. Consequently, MMOF composites have pulled enormous research interest for the removal of toxic pollutants including heavy metal ions from environmental samples via adsorption (Sarker et al. 2017).

Bagheri and his group for the first time introduced a novel MMOF composite (Fe3O4-pyridine)/Cu3(BTC)2 by taking pyridine-functionalized Fe3O4 NPs as the magnetic component, Cu(II) ions as the metal node, and trimesic acid as the organic linker, utilizing a facile solvothermal route. The (Fe3O4-pyridine)/Cu3(BTC)2 composite was demonstrated as a magnetic sorbent material for rapid extraction of highly toxic and carcinogenic Pd(II) ions from various matrixes including environmental water sample with a maximum sorption capacity 105.1 mg g−1 in an optimum pH value 6.9. The limit of detection for Pd(II) ion was found to be 0.37 ng mL−1 without being interfered by other counter ions such as Na+, K+, Ca2+, Al3+, Ag+, Cu2+, Fe3+, Cd2+, Pb2+, Mn2+, and Zn2+. For desorption of Pd(II) ions, Pd(II) ions adsorbed on MMOF sorbent was eluted with 6 mL of 0.01 M NaOH in 9.5 K2SO4 solution as an eluent with recoveries of Pd(II) ions in the range between 96.8% and 102% and the desorption amount was determined by FAAS (flame atomic absorption spectrometry). Other acidic eluting solvents such as HCl and HNO3 were found to decompose the MMOF structures (Bagheri et al. 2012).

Following the same trend, Taghizadeh et al. fabricated a novel MMOF hybrid composite, by immobilizing [Cu3(BTC)2(H2O)3]n MOF with dithizone-functionalized Fe3O4 MNPs employing a simple solvothermal strategy. The synthesized Fe3O4-DHz@HKUST-1 composite was found to be a reproducible adsorbent for fast selective solid phase extraction of Zn(II), Ni(II), Pb(II), and Cd(II) ions from aqueous sample with limit of detection 1.2, 0.98, 0.39, and 0.12 ng mL−1, respectively. Selectivity of the new solid phase towards the heavy metal ions is promoted by the dithizone group presented in the sorbent material. The maximum adsorption capacities in optimum conditions were found to be 206, 98, 104, and 188 mg g−1 for Zn(II), Ni(II), Pb(II), and Cd(II) ions, respectively. Based on Box–Behnken design (BBD), concentration and volume of the eluent were found to have positive and significant impacts on effective recovery of the heavy metal ions while elution time showed a positive but non-significant impact. Several eluents (e.g., HNO3, HCl, NaOH, KCl, K2SO4, and thiourea solution and their mixtures) were examined for desorption process keeping other factors constant (extraction time 13 min, dosage of the magnetic adsorbent 25 mg, pH 6.4, elution time 20 min, and eluent volume 5 mL). Decomposition of the framework structure of MMOF nanocomposite was found to occur with NaOH, HCl, and HNO3 eluents. However, the best quantitative recovery of the metal ions was obtained with 7.8 mL of a 0.9 M thiourea in 0.01 M NaOH solution as an eluent. The clear solution containing the eluted heavy metal ions was introduced to FAAS, and the amount of each ion eluted was calculated (Taghizadeh et al. 2013).

Sohrabi and his coworkers developed a novel MMOF hybrid adsorbent material Fe3O4-pyridine@HKUST-1 from pyridine-functionalized Fe3O4 MNPs and Cu3(BTC)2 MOF following a facile solvothermal synthetic route for rapid and selective extraction of trace amount of Cd(II) and Pb(II) ions from aqueous media with a very low limit of detection (0.2 ng mL−1 for Cd(II) and 1.1 ng mL−1 for Pb(II)) and high enrichment capacity of 190 mg g−1 for both the adsorbents. The new solid phase was found to be highly selective towards Cd(II) and Pb(II) ions due to the presence of pyridine groups in the sorbent. Mechanism for the adsorption of Cd(II) and Pb(II) ions was illustrated as shown in Fig. 13.

The adsorption capacity of Cd(II) and Pb(II) ions by the MMOF sorbent was found to be increased with the increase in pH and the sorbent amount. pH of solution, extraction time, and doses of MMOF were found to have a positive and significant impact on the extraction efficiency. Factors affecting the desorption process were optimized (pH value 6.3 extraction time: 14 min; doses of MMOF sorbent: 30 mg; eluent volume: 5 mL; elution time, 25 min). Eluents such as HCl, NaOH, HNO3, K2SO4, KCl, and EDTA solution and their mixtures were examined as the desorption solvent, and the best quantitative recovery of metal ions was achieved with 0.01 M NaOH in EDTA solution without any structural decomposition (Sohrabi et al. 2013).

Xiong and his coworkers (Xiong et al. 2015) prepared a bifunctional porous magnetic γ-Fe3O4/C@HKUST-1 composite via two simple steps; the first step involves the microwave-assisted high-temperature strategy to prepare highly porous Fe3O4/C magnetic composite from starch via an ionothermal method followed by liquid-phase epitaxial growth of HKUST-1 onto the magnetic composite (Fig. 14). The unique functional groups like –OH and –NH2 on γ-Fe3O4/C were utilized as the support to promote the direct growth of HKUST-1 via the stepwise liquid-phase epitaxy process. Fe3O4/C@HKUST-1 composite was demonstrated as an efficient adsorbent for removal of Cr(VI) ion from aqueous solutions with a very high adsorption capacity 101.4 mg.g−1. pH played a significant role on adsorption and reduction of Cr(VI). The highest adsorption capacity was obtained at pH 3.0, and the lowest adsorption capacity was obtained at pH 9.0 indicating a sorption mechanism that involves in surface complexation or bonding. Desorption of Cr(VI) and regeneration of γ-Fe3O4/C@HKUST-1 composite were successfully achieved by using 0.01 M NaOH solution. The adsorption capacity of the MMOF composite for removing Cr(VI) was decreased by 10% in 5th cycle as compared within the 1st cycle showing better regenerability and recyclability of the adsorbent.

Reproduced from Reference Xiong et al. 2015 with permission from The Royal Society of Chemistry

a Schematic representation for synthesis of γ-Fe3O4/C@HKUST-1 composite and b their corresponding VSM magnetization curves showing separation of samples from solutions under external magnetic field.

Ricco et al. successfully designed a series of magnetic framework composite materials using aluminum-based MOFs, MIL-53, and Fe3O4 MNPs via an embedding methodology. A series of amino-functionalized MIL-53 MOF were prepared by varying the load of 2-amino terephthalic acid (aBDC) with terephthalic acid from 0%, 50%, and 100% to obtain MIL-53(Al@0aBDC), MIL-53(Al@50aBDC), and MIL-53(Al@100aBDC), respectively. The fully functionalized system, i.e., MIL-53(Al@100aBDC), which resulted from 100% load of 2-aminoterephthalic acid as the starting ligand was found to show superior performance in the removal of Pb(II) ion from contaminated water which was confirmed by density functional theory calculations (DFT) (Fig. 15). A record-breaking lead uptake capability of 492.4 mg/g was achieved with the adsorbent. Increase in Pb(II) uptake with increasing amount of amino group during the synthetic procedure can be attributed to the coordination of N atoms present in the framework structure to the metal ions. To further explore the adsorbent-adsorbate interaction, Langmuir and Freundlich models were considered and the Freundlich model was found to fit slightly better, suggesting a homogeneous uptake of lead cations throughout the entire framework. Desorption of Pb(II) was done by exposing the composite to magnetic heating at 43 °C, and nearly 50% of the lead was released within 2 h. Leaching study showed maximum Al leakage under acidic conditions, where due to acid degradation Al was lost up to 15% (Ricco et al. 2015).

Reproduced from Reference Ricco et al. 2015 with permission from The Royal Society of Chemistry

DFT optimized locations and binding energies (B.E.) of lead atom in a MIL-53(Al) and b MIL-53(Al)-NH2 calculated using DFT-D2 method. The distances shown are in angstroms. Color code: C, grey; H, white; N, blue; Al, pink; Pb, orange.

Huang and his group (Huang et al. 2015) reported a green strategy for facile self-template-assisted synthesis of a designable core–shell MMOF composite, Fe3O4@SiO2@HKUST-1 (Fig. 16). The thickness of the MMOF shell can be adjusted by varying the quantity of metal precursor. Moreover, they employed a facile coordination based post-synthetic approach to generate a thermally and chemically stable bismuthiol-functionalized magnetic composite, Bi-I-functionalized-Fe3O4@SiO2@HKUST-1, which was demonstrated as an excellent adsorbent for fast and selective (99%) removal of Hg(II) ions in environmental water with a high adsorption capacity of 264 mg g−1 in the presence of other competing ions, e.g., Cr3+, Mn2+, Co2+, Ni2+, Zn2+, Pb2+, and Cd2+. About 99% mercury ions were found to be adsorbed within 10 min, indicating that the Bi-I-functionalized-Fe3O4@SiO2@HKUST-1 exhibited a fast adsorption dynamics for the removal of mercury from water. Excellent adsorption capacity of Bi-I-functionalized-Fe3O4@SiO2@HKUST-1 towards Hg2+ in a wide pH range was ascribed to the strong interaction between mercury species and -SH functional group. PXRD patterns obtained for MMOFs after loading Hg2+ ions within the pH range 3–10 were in accordance with those of the synthesized MMOFs before spiking into the aqueous solution, suggesting a good chemical stability of Bi-I-functionalized Fe3O4@SiO2@HKUST-1 in aqueous solution. For release of mercury, several eluents, e.g., HCl, HNO3, NaOH, and thiourea solution and their mixtures, were tested as the desorption solvent. However, elution of Hg2+ from the adsorbent was found to be difficult due to strong binding forces of -SH with Hg2+, and hence, the utilized MMOF adsorbent was disposable. Although a considerable recovery was obtained with diluted NaOH (0.01 M) solution without any structural damage of the employed adsorbent, it may cause the hydrolysis of Bi-I.

Reproduced from Reference Huang et al. 2015 with permission from The Royal Society of Chemistry

Schematic representation for synthesis of Fe3O4@SiO2@HKUST-1 composite.

MSPE was done under different pH to investigate the leaching of Cu2+ from the prepared Fe3O4@SiO2@HKUST-1 and Bi-I-functionalized Fe3O4@SiO2@HKUST-1 sorbents, and Cu2+ concentration in the aqueous solution was determined by ICP-OES. Better chemical stability of Bi-I-functionalized Fe3O4@SiO2@HKUST-1 than Fe3O4@SiO2@HKUST-1 was suggested by the percentage of Cu2+ release in acidic condition (at pH 3) which is lesser in the case of Bi-I-functionalized Fe3O4@SiO2@HKUST-1 (20%) compared to that of Fe3O4@SiO2@HKUST-1 (27%).

A selective recyclable and regenerable MMOF-based adsorbent, Fe3O4@MIL-101, for removal of As(III) and As(V) ions from surface as well as ground water was successfully demonstrated by K observed by Folens and his group with excellent adsorption capacities of 121.5 and 80 mg g−1, respectively. The magnetic nanocomposite material was synthesized by encapsulating Fe3O4-engineered nanoparticles (ENPs) within MIL-101(Cr) framework structure. No significant leaching of Cr and Fe and the retained crystallinity of the magnetic framework structure after adsorption and desorption process indicates the higher stability of the magnetic adsorbent material. To examine the chemical stability of Fe3O4@MIL-101(Cr), leaching of Cr and Fe as well as the crystallinity was explored after the adsorption–desorption process. Leaching of 0.3% Cr3+ ions and (0.2 ± 0.10) % Fe2+/3+ ions was confirmed by ICP-OES measurements after a contact time of 24 h. Preservation of crystal structure of the MMOF composite after the desorption processes was further confirmed by XRPD measurements. NaH2PO4 was selected as eluent for the efficient release of As(III) (56.5%) and As(V) (71.1%) which offers efficient exchange of the arsenic ions owing to their tetrahedral chemical structure that resembles the phosphate ion (Folens et al. 2016).

Moradi et al. reported a highly water stable and nontoxic MMOF composite, Fe3O4@MOF-235(Fe)-OSO3H, by loading sulfonated MOF, MOF-235(Fe)-OSO3H, onto mercaptoacetic acid-functionalized Fe3O4 MNPs, utilizing a simple solvothermal strategy (Fig. 17). The MOF-235(Fe)-OSO3H composite was utilized as a reusable adsorbent for magnetic solid phase extraction of Cd(II) ion present in environmental water sample with limit of detection 0.04 μg L−1 and enrichment value 195.0 in the presence of other competing ions such as Al3+, Ca2+, Mg2+, K+, Mn2+, Fe2+, Fe3+, Cu2+, Zn2+, Pb2+, Cl−, CO32−, and SO42− (Moradi et al. 2016). The pH value played a significant role in adsorption of Cd(II) ions due to the influences of pH on the surface properties of the MMOF as well as the ionic form of the Cd(II) ions in solution. Depending on the pH of solution, cadmium exists in various ionic forms including Cd2+, Cd(OH)+, Cd(OH)2, Cd(OH)3−, and Cd(OH)42− in aqueous medium. Over the pH range 2.0–8.0, cadmium predominantly exists in Cd2+ form. At pH value greater than 2.0, the surface of MMOF sorbent gets negatively charged providing affinity for electrostatic interactions between the sorbent and cationic cadmium species. Experimental data were well fitted to Langmuir isotherm suggesting homogenous monolayer adsorption of cadmium ion onto the sorbents. No significant structural change was observed up to ten adsorption–desorption cycles indicating excellent stability and recyclability. 1 mL of 0.5 M EDTA solution was selected as the best eluent for the desorption of Cd(II) ions.

Reproduced from Reference Moradi et al. 2016 with permission from The Royal Society of Chemistry

Schematic representation for adsorption of Cd(II) on Fe3O4@MOF-235(Fe)-OSO3H composites and separation of samples from solutions under external magnetic field.

Yang et al. fabricated a highly porous and beautifully organized core–shell magnetic adsorbent material Fe3O4@MIL-100(Fe), using citrate-functionalized Fe3O4 MNPs as the crystal seed that facilitated the in situ growth of MIL-100(Fe) shell on its surface via a facile hydrothermal approach. It was the first MMOF composite appraised to remove Cr(VI) ion from aqueous media. Higher extraction yield was obtained at lower pH value (pH < 3.7) due to the increased electrostatic interaction between the positively charged surface of Fe3O4@MIL-100(Fe) and CrO42− ion in acidic solution. Overall optimization study revealed that the magnetic adsorbent material exhibited a maximum adsorption capacity of 18 mg g−1 at pH value 2 in 120-min time of duration with 4 mg dose of the magnetic adsorbent (Yang et al. 2016).

Safari et al. developed a synthetic approach for fabricating two pillar MOFs: TMU-8 with azine groups in the middle of pillar ligand [4-bpdb (1,4-bis(4-pyridyl)-2,3-diaza-1,3-butadiene)] and TMU-9 with 4,4′-bipyridine (4,4′-bipy) pillar ligand. Lewis basic azine-functionalized pores of TMU-8 were found to exhibit more extraction efficiency for heavy metal ions as compared to that of TMU-9 which do not contain any azine group. TMU-8 was chosen as an effective adsorbent for the extraction and pre-concentration of trace amounts of some heavy-metal ions including Cr(III), Mn(II), Co(II), Ni(II), Cu(II), Pb(II), and Cd(II) ions from contaminated aqueous system. TMU-8 was fabricated with magnetic component (Fe3O4) by employing two strategies—in situ synthesis of magnetic nanocomposites and core shell. Results showed that magnetic Fe3O4@TMU-8 composite synthesized via core–shell strategy provides more binding sites for the adsorption of heavy metal ions and magnetic proprieties.

Magnetic solid-phase extraction of heavy metal ions was done by adding 10 mg of sorbent (Fe3O4@TMU-8) to 185 mL of spiked sample solution at a pH of 10. After adsorption, Fe3O4@TMU-8 was by using an external magnet. For pre-concentration, 500 μL of 0.5 M HNO3 solution was added as eluent to desorb the metal ions from the adsorbent surface by fierce vortex and was determined by ICP-AES (inductively coupled plasma-atomic emission spectroscopy) technique (Safari et al. 2017).

Huang and his coworkers reported a facile solvent-assisted ligand exchange (SALE) strategy to obtain Zr-MOF composite (MFC-S), in which terephthalate ligand present in UIO-66 was replaced with flexible mercaptoacetic acid ligand in aqueous solvent under mild reaction condition (Fig. 18). The porosity, crystallinity, and supermagnetic properties of mercapto-functionalized Zr-MOF were maintained well during the process of SALE. The MFC-S was found to exhibit higher stability and enhanced adsorption capacity of 282 mg g−1 towards the removal of Hg(II) ions from environmental water sample (Huang et al. 2016). A mixture of 0.1 M HCl with 0.1% thiourea was used as eluent for regeneration of the adsorbents at pH 1.8. Regenerated MFC-S was reused for the removal of target contaminants, and the adsorption capacity was found to remain intact up to 5 cycles. To examine the leaching of Zr4+ from the MFC-S, magnetic solid phase extraction was done under different pH and ICP-OES result showed that less than 0.5% of the total Zr4+ was present in the supernatant. PXRD patterns of the MFC-S after 5 adsorption/elution cycles of Hg2+ suggested excellent chemical stability of the synthesized sorbent. Moreover, high specific surface areas (571 m2 g−1) of the employed MFC-S after the 5th cycle were established by N2 adsorption–desorption isotherms. Furthermore, unchanged morphology and core–shell structure of prepared MFC-S after 5 adsorption/elution cycles of Hg2+ were supported by TEM investigation.

Reproduced from Reference Huang et al. 2016 with permission from The Royal Society of Chemist

a Schematic representation for synthesis of MFCs and b their corresponding VSM magnetization curves showing separation of samples from solutions under external magnetic field; c recyclability test.

Naeimi et al. synthesized [Cu3(BTC)2] (HKUST-1) MOFs impregnated with potassium nickel hexacyanoferrate (KNiFC) to obtain MOF/KNiFC. Further, it was magnetized with Fe3O4 MNPs to obtain MOF/Fe3O4/KNiFC composite. MOF/KNiFC and MOF/Fe3O4/KNiFC were utilized as adsorbent for efficient removal of hazardous Cs(I) radionuclide present in wastewater in the presence of other background ions like Na(I) and K(I) with adsorption capacities 153.0 and 109.0 mg g−1, respectively. Lower adsorption capacity of MOF/Fe3O4/KNiFC than MOF/KNiFC may be attributed to the addition of magnetic component (Fe3O4) to MOF/KNiFC which had no significant effect on the adsorption of Cs+. However, the presence of Fe3O4 facilitated magnetic separation of the used sorbent from the solution. Adsorption mechanism was ascribed by the exchange of K+ in KNiFC with Cs+ in solution. At higher pH value, deprotonation of the adsorbents surface occurs which facilitates electrostatic interactions between the adsorbent surface and ingoing cation. At lower pH, hydronium ions compete with Cs+ for the exchange sites lowering the uptake. Experimental data for adsorption was found to fit better with Langmuir model suggesting homogeneous monolayer adsorption of Cs+ ions on the surface of MOF/Fe3O4/KNiFC without any interactions between the adsorbed ions. Decrease in adsorptive capability with increase in the dose of adsorbents was attributed to the concentration of Cs+ which was not enough to occupy all the sites available for adsorption and to the surplus adsorption sites remained unemployed. For regeneration, 25 mL of 1 M HNO3 solution was added to 0.1 g of the sorbent and kept for 24 h. Negligible concentration of iron in the supernatant indicated that Fe3O4 was perfectly protected against acidic conditions. The adsorption-regeneration process was repeated up to five cycles. Incomplete Cs+ desorption and leaching of KNiFC from the adsorbent surface lower the adsorption capacity of the magnetic sorbent after regeneration. 70% and 80% of initial adsorption capacity of MOF/Fe3O4/KNiFC and MOF/ KNiFC were retained up to five adsorption-regeneration cycles (Naeimi and Faghihian 2017).

A step-by-step assembly strategy was reported by Ke et al. (2017) for fabrication of a novel core–shell MMOF composite with Fe3O4 MNPs as the magnetic core and porous Cu3(BTC)2 MOF as shell which was further thiol-functionalized by a facile post-synthetic modification approach to obtain thiol-functionalized Fe3O4@Cu3(BTC)2 composite (Fig. 19). The thiol-functionalized magnetic adsorbent was demonstrated as an efficient recyclable adsorbent for almost complete removal of highly toxic Pb(II) and Hg(II) ions from wastewater containing mixed heavy metal ions with maximum adsorption capacities of 348.43 and 215.05 mg g−1, respectively. Excellent adsorption capacity of thiol-functionalized Fe3O4@Cu3(btc)2 toward Pb2+ and Hg2+ ions over a wide pH range was ascribed by the strong interaction between the thiol group and the analyte ions. For desorption, the Fe3O4@Cu3(btc)2 sorbent with adsorbed Pb2+ and Hg2+ ions was collected by an external magnet from the mixture, washed three times with 5 mL 0.01 M NaOH solution, and sonicated. Adsorption capacity of regenerated thiol-functionalized Fe3O4@Cu3(btc)2 was tested with the same initial conditions, and no significant losses in the adsorption capacity for Hg2+ ion and only minute changes in the adsorption capacity for Pb2+ ion were observed up to four adsorption-regeneration cycles which indicated excellent long-term stability of the magnetic core–shell microspheres (Ke et al. 2017).

Yang et al. developed a highly stable magnetic core–shell nanocomposite CoFe2O4@MIL-100(Fe), for rapid and effective removal of both As(III) and As(V) from contaminated water with maximum removal capacities 143.6 mg g−1 and 114.8 mg g−1, respectively. Adsorption kinetics, adsorption isotherms, and thermodynamics of iAs on CoFe2O4@MIL-100(Fe) were examined to illustrate the adsorption mechanism of iAs. Both Langmuir and Freundlich models were studied for the adsorption of iAs on CoFe2O4@MIL-100(Fe) to propose the adsorption mechanism. The Langmuir model fitted better with the adsorption of As(V) on CoFe2O4@MIL-100(Fe) suggesting a homogeneous monolayer adsorption process. Adsorption of As(III) was appropriately fitted with the Freundlich isotherm model indicating heterogeneous multilayer adsorption which was attributed to H-bonding between H3AsO3 molecules. However, an inner-sphere complex mechanism was attributed to the adsorption of both As(III) and As(V) to form the Fe–O-As microstructure via hydroxyl exchange with the deprotonated arsenite and arsenate. CoFe2O4@MIL-100(Fe) sorbent with adsorbed As(V) or As(III) was added to 5 mL of ultrapure water, ultrasonicated, and centrifuged at high speed. Higher concentration (22.3 mg L−1) of As(III) in the supernatant than that of As(V) (1.1 mg L−1) indicated weak adsorption of As(III) on the absorbent. High chemical stability, fast adsorption kinetics, high adsorption capacity, wide pH range, and capability of tolerating interfering ions of the adsorbent facilitated it to be validated by two different wastewater treatment processes for simultaneous removal of iAs; one is a simple filtration strategy and another one is batch magnetic separation strategy (Yang and Yin 2017).

For the first time, Min and his group reported an expedient and powerful method for fast and efficient removal of UO2+2 ion from aqueous solution with an unprecedented maximum adsorption capacity of 523.5 mg g−1 by utilizing Fe3O4@ZIF-8 nanocomposite. Adsorption mechanism of UO22+ ions on Fe3O4@ZIF-8 was ascribed by coordination between Zn atoms of the framework and UO22+ ions as well as the hydrogen bonding. For desorption, U-absorbed sorbent was eluted by 0.1 M Na2CO3 solution and the desorption percentage was found to be 77%. PXRD patterns of samples after adsorption and desorption of UO22+ suggested excellent chemical stability of the nanocomposite. Moreover, the magnetic sorbent possessed extraordinary selectivity toward lanthanides over actinides. Excellently high porosity, outstanding thermal and chemical stability of ZIF-8, and possibilities of easy and fast magnetic separation established it as a fantabulous adsorbent for wastewater treatment (Min et al. 2017).

It is worth to mention here that Zhu and his coworkers fascinatingly designed a core-double-shell magnetic polydopamine@ZIF-8 nanocomposite (MP@ZIF-8) with supermagnetic Fe3O4 NPs as the magnetic core, polydopamine (PDA) as the inner shell, and porous ZIF-8 structures as the outer shell by employing a facile and green synthetic route. The PDA shell not only provides colloidal stability to the MNPs but also prevents them from undergoing corrosion. The MP@ZIF-8 composite was used to achieve a high adsorption capacity of 136.56 mg g−1 in the removal of Cr(VI) ions from Cr-contaminated aqueous media as well as partial reduction of highly toxic Cr(VI) ions to low toxic Cr(III) ions. Along with adsorption, Cr(VI) ions were in situ reduced to Cr(III) ions and enabled to get immobilized on the adsorbent via the reduction of N containing groups on ZIF-8 and PDA. Adsorption of Cr(VI) is not an ordinary and single process mechanism but occurs in multisteps—(i) adsorption of water molecules on ZIF-8 in aqueous solution (pH = 5.0) producing active sites including protonated N atoms groups and the Zn − OH sites, (ii) adsorption of Cr(VI) at active sites and their partial reduction to Cr(III) by the groups containing nitrogen atoms on ZIF-8, (iii) retarded diffusion of Cr(VI) to PDA and reduction of Cr(VI) into lesser toxic Cr(III) by amine groups, and (iv) chelation of Cr(III) onto imino groups, as well as chemical bonding between Cr(VI) with the hydroxyl groups on PDA. After adsorption of Cr(VI), the sorbent with adsorbed metal was immersed in 6 mL 0.05 M NaOH solution, agitated for 12 h, centrifuged and washed multiple times with Milli-Q water for regeneration, and reused up to five adsorption–desorption cycles. A slight decrease in Cr(VI) removal efficiency was observed after regeneration in the fifth cycle. The slight decreases in uptake efficiency were attributed to the incomplete desorption of adsorbate from the surface of the sorbent (Zhu et al. 2017).