Abstract

This study investigates the role of single-step silica nanofluids as additives to increase CO2 absorption in polymeric solutions for proposed oilfield applications. Using pressure decay approach, the study investigates the applicability of single-step silica nanofluids for CO2 absorption in a high pressure–high temperature (HPHT) cell. Various parameters like nanoparticle size (30–120 nm) and concentration (0.1–1 wt%) were investigated to ascertain the absorption performance of the nanofluids and optimization their application in subsurface applications as carrier fluids for CO2. The solutions under observation (deionized water and silica nanofluids) were pressurized under the desired pressure and temperature inside a stirring pot and the decline in pressure was continuously noted. To comprehensively cover the near-reservoir field conditions, the CO2 absorption was investigated in the pressure range of 5–10 MPa and at temperatures of 30–90 °C. While increasing the nanoparticle concentration (from 0.1 to 1 wt%) increased the CO2 absorption (evident by the sharper decline in pressure), increasing the nanoparticle size reduced the absorption capacity of the nanofluids as a lesser volume of decline in pressure was noted. Furthermore, increasing the temperature of the experimental investigation caused a major reduction (12–19%) in the pressure decay. However, it was also observed that higher pressure (> 7.5 MPa) was detrimental for CO2 absorption (due to its supercritical nature). Adding salt (sodium chloride, NaCl) was found to massively lower (up to 33%) while adding surfactant (sodium dodecyl sulfate, SDS) slightly increased the amount of CO2 absorption (in presence of salinity). Based on the observations of this study, the use of single-step silica nanofluids as CO2 carrier fluids is recommended for oilfield conditions where salinity is less than 4 wt%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The inclusion of CO2 in injection water is also responsible for accelerating oil production (Sohrabi et al. 2011). This enhanced oil recovery (EOR) technique, also known as the carbonated water injection (CWI) has been widely reported to increase oil recovery and carbon storage in previous studies (Riazi and Golkari 2016; Seyyedi et al. 2018; Esene et al. 2019). Usually, CO2 has the tendency to preferentially solvate in crude oil (As compared to water) on contact, which reduces the density and viscosity of residual crude oil (CO2-saturated oil usually swells and becomes much less viscous), making it easier for mobilization (Emera and Sarma 2007; Chaturvedi and Sharma 2020). Other factors influencing oil recovery via CWI is reduction of IFT and increased sweep efficiency (Honarvar et al. 2017). Compared to other methods of CO2 EOR like water alternating gas (WAG) injection method which are disadvantaged by the water shielding effect (in which injected water encapsulates the residual oil), CWI increases recovery of oil (Riazi and Golkari 2016). In WAG, the gas injection is performed after water has been injected which reduces the contact area between injected CO2 and crude oil, thereby lowering its efficacy. This is usually not the case with CWI as the injected water is saturated with CO2, increasing its area of contact with crude oil and mobilizing a greater amount of oil (Sohrabi et al. 2012). However, of key importance in the performance on injected CWI in oil recovery is the understanding of the transfer of mass of CO2 among the injected water layers occurring mainly via molecular diffusion with the rate of mass transfer (increments in small quantities) enabling the increase in crude oil mobilization. However, one major drawback of CWI is the slow rate of mass transfer of CO2 between oil and water phases, which reduces the incremental performance of CWI EOR projects, especially in the short term (Foroozesh et al. 2016). This has prompted a need to investigate new methods to establish a viable increase in the rate of mass transfer enhancement for CWI projects (Do and Pinczewski 1993; Tolesorkhi et al. 2018). Other drawbacks of CWI are the relatively low CO2 carrying capacity of water and the lack of any CO2 retention mechanism, which reduces the applicability of CWI to select few reservoirs under constrained operating conditions.(Chaturvedi and Sharma 2020).

The CO2 carrying capacity (absorption and retention of CO2) of water can be improved by adding polymers and nanoparticles (NPs). (Haghtalab et al. 2015; Zhang et al. 2018; Chaturvedi et al. 2018, 2019, 2020) Polymers like polyacrylamide (PAM) and nanoparticles (NPs) like SiO2 which are commonly used oil field chemicals emerge as viable alternatives for field applications of CWI. Peyravi et al. (2015) investigated the use of Fe3O4, CNT, SiO2, and Al2O3 nanofluids prepared using distilled for CO2 absorption in a gas–liquid hollow fiber membrane and found that the CO2 absorption rate in water increased by 43.8% for 0.15 wt % Fe3O4, 38.0% for 0.1 wt % CNT, 25.9% for 0.05 wt % SiO2, and 3.0% at 0.05 wt % Al2O3 addition with nanofluid (colloidal suspensions of particles in nanometer range suspended in a base fluid) stability and hydrodynamic diameter of NPs in water being key factors. Separately, Rahmatmand et al. (Rahmatmand et al. 2016) investigated the use of SiO2, Al2O3, CNT, and Fe3O4 NPs for enhanced CO2 absorption in water and amine solutions and observed higher absorption capacity in nanofluids due to higher gas absorption at NP surface. Darvanjooghi et al. (2018) investigated the use of 0.005–0.1 wt% silica NPs of varying sizes (10.6–62 nm) for CO2 absorption in water. Thus, data on the CO2 solubility in water with and without the presence of chemical additives is adequate for polymeric nanofluid systems which are now widely used in the oilfields (Sharma and Sangwai 2017; Kumar and Mandal 2017). However, NPs have the tendency to agglomerate in the presence of salts (which are commonly encountered in reservoirs in form of formation brines) (Al-Anssari et al. 2017; Kumar et al. 2020). This increases their size and renders them less viable for CWI application. Hence, a need emerges to synthesize stable silica nanofluids of controlled size and concentration to improve the applicability of CWI to challenging reservoirs. For this, single-step silica nanofluids emerge as viable candidates due to their superior stability, ease of fabrication, and strong resistance to salt-induced agglomeration (Chaturvedi et al. 2020; Chaturvedi and Sharma 2021). However, no study, investigating the viability of CO2 absorption (using the pressure decay method) in single-step silica nanofluids has been performed at reservoir field pressure and temperature conditions. Also, it has also been observed that some part of the CO2 gas injected during EOR is unable to participate in the oil recovery process due to being trapped in the water/polymeric nanofluids (similar to the water shielding effect observed during WAG). Given the constrained economics of an EOR project, it becomes essential for researchers to carefully evaluate the amount of CO2 needed to maximize oil recovery after ascertaining the amount of CO2 being wasted in other fluids (reservoir brines, injected water, nanofluids). For this, various analytical flow models are used after careful consideration of the rate of CO2 dissolution in the present fluids. There is, however, a severe inadequacy of data related to the diffusion coefficients for commonly used polymeric NP solutions in practical reservoir conditions. Also, given the increasing role played by NPs in the mass transfer applications, assessment of diffusion coefficients in NP solutions must be performed.

One simple method to estimate the diffusion coefficient of a gas is the standard pressure decay method, in which the gas is pressurized to a high pressure and brought in contact with a liquid usually in a PVT cell at predefined isochoric and isothermal conditions (Haghtalab et al. 2015; Haider et al. 2018; Chaturvedi et al. 2018). Mostly, the calculations are performed at equilibrium or quasi-equilibrium conditions with selection of boundary conditions and equilibrium pressure value being important parameters in the determination of diffusivity coefficients, though some recent studies have also applied non-equilibrium boundary conditions in pressure decay tests (Zhang et al. 2000; Rasmussen and Civan 2009; Behzadfar and Hatzikiriakos 2014). However, a significant drawback associated with using equilibrium conditions for calculation is a long time (≈ 6 h), it takes for equilibrium conditions to be achieved which may compromise the results due to gas leakage or errors in the swelling of the liquid. These errors need to be considered and their effects nullified before application of equilibrium conditions for the determination of the diffusion coefficients.

Hence, in this study, the effect of temperature, pressure, and salinity on diffusion coefficients of 0.1–1 wt% silica NP solutions (hereafter referred to as silica nanofluids) prepared in 1000 ppm PAM (silica and PAM are widely used in the oil industry as enhanced oil recovery agents) has been investigated and presented at commonly observed reservoir conditions. The silica nanofluids were synthesized using the Stober sol–gel method from a commercially available precursor solution. The effects investigated include the CO2 absorption in presence of NPs of varying size (30–150 nm), in NPs of varying concentration (0.1–1 wt%), pressure (4–10 MPa), temperature (30–90 °C) and salinity (0–8 wt%). The effect of surfactant treatment on nanofluids and their resultant CO2 absorption was understood by adding surfactant in varying concentration (0–0.4 wt%). Finally, the results and discussion on the diffusion and mass interface transfer coefficients for silica nanofluids of varying concentration (0.1–1 wt%) and under high pressure (4–10 MPa) have been provided.

Materials and methods

Materials

To synthesize the silica nanoparticles, Merck liquid tetraethyl orthosilicate (TEOS, purity 99%) was used as a precursor. Merck liquid ammonia solution (NH4OH, purity 25%), Changshu Hongsheng Fine Chemicals’ ethanol (EtOH, absolute assay 99.9%), and SNAF Floerger’s polyacrylamide (PAM, molecular weight = 10 million Dalton) were also used without purification. SDS, an anionic surfactant with an alkalinity of 5 meq/mL obtained from Sisco Research Lab Pvt. Ltd. in India, was also used in the study. DI water purified with the Millipore® Elix-10 purification apparatus was used in all experiments. All of the aqueous formulations used in this study were prepared with DI water. After carefully weighing the solutes with a highly accurate analytical weighing balance, all solutions were prepared. All chemicals were used exactly as instructed and have previously been reported in studies.

Preparation of nanofluid

The nanofluid synthesis and characterization has been reported in detail, in previous studies (Chaturvedi et al. 2021, 2021).

CO2 absorption studies

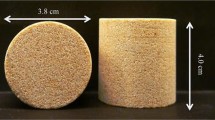

The CO2 absorption studies were performed using a custom designed setup manufactured by D-Cam Engineering, India. A schematic of the set-up has been provided as Fig. 1. A cylindric tube measuring 5.1 cm in length and 5 cm in diameter served as the setup. On one end of the cylinder, near the inlet, a thermocouple and a pressure gauge (DiGi Gauge TX-430; range 0–65 bar; accuracy 0.25%) were mounted. Before use, the entire cell was evacuated with a vacuum pump using an electrical heating jacket (Swastik Electrical, India) to maintain a constant temperature. All of the experiments described in this article were conducted using a custom-built apparatus that could be disassembled into the main components of a cylindrical high-pressure stainless steel cell with maximum pressure and temperature ratings of 30 MPa and 250 °C, respectively. In order to absorb CO2 in the solutions, the prevalent pressure decay method was utilized (Haider et al. 2018; Chaturvedi et al. 2021). The pressure decay method entails keeping the volume and temperature of the solution constant while injecting high-pressure gas, which is continuously monitored. Using a pressure decrease versus time graph, the diffusion coefficients are computed (as the gas continues to solvate in the fluid). Previous research has defined the methodology for CO2 gas absorption in detail (Chaturvedi et al. 2018, 2019). However, for the sake of brevity and reader convenience, only a brief description of the process is provided here. First, the cell was meticulously cleaned and vacuumed to remove any remaining impurities. After measuring the desired volume of nanofluid with precision, it was introduced into the cell. Afterward, the cell was vacuumed and resealed. Then, CO2 was introduced gradually into the cell until the desired pressure was reached. The pressure drop was meticulously recorded using a pressure transducer, and the temperature was maintained by enclosing the cell in a temperature control box.

Results and discussion

In this section, initially the discussion on the stability of the nanofluids would be provided which will be followed by the discussions on the CO2 absorption observed in the nanofluids of varying NP size (30–150 nm) and concentration (0.1–1 wt%). Then, the effect of pressure (4–10 MPa) and temperature (30–90 °C) would be investigated on the silica nanofluids followed by evaluating the role of salinity (NaCl, 0–8 wt%) on CO2 absorption. Then, the effect of surfactant (SDS) addition (0–0.4 wt%) on CO2 absorption in presence of salinity (NaCl, 4 wt%) has been investigated. Finally, the diffusion coefficients and interface mass transfer of the CO2 in the nanofluids under various high pressure (4–10 MPa) and NP concentration (0.1–1 wt%) has been discussed.

Stability of single-step silica nanofluids

The nanofluids were measured using the particle size analyzer to establish the particle size and zeta-potential of the samples. The observations of these analysis have been provided in Table 1. The synthesized NPs exhibited a NP size between 30 and 150 nm, indicating great size control while the zeta-potential was found to be between − 32 and − 36 mV, indicating superior stability of the nanofluids (Setia et al. 2013). The NP concentration was determined by evaporating the nanofluid in an oven at a set temperature of 200 °C. The residual solution was washed carefully with ethanol and water to remove any impurities and then measured using a weighing balance. While past studies have assumed 100% or high conversion of precursor (TEOS) to SiO2, in this study, less than 40% of the precursor was converted into SiO2 with remaining TEOS not participating in the reaction, due to the lack of time given to the experiment for adequate conversion. When the nanofluid solutions were measured again after 2 weeks, no appreciable change was observed in the values of the particle size or the zeta-potential, indicating the superior stability of the single-step silica nanofluids.

Pressure decay studies in water and silica nanofluids

Conventionally, CO2 absorption with time increases and it is calculated with the help of an ideal gas equation (PV = nRT) for which the values of pressure have been reported in this work. In several previous studies (Chaturvedi et al. 2018, 2021; Chaturvedi and Sharma 2020; Haghtalab et al. 2015), CO2 absorption has been demonstrated in detail for colloidal and aqueous solutions. These studies have reported CO2 absorption in form of molality. However, a researcher may want to explore the diffusion and diffusivity of CO2 in the solution. In that case, observing pressure decay as a function of time enables researchers to optimize the process by analyzing CO2 absorption in form of diffusion coefficient. Furthermore, the data also allow to analyze mass transfer processes (viz., grazing effect and Brownian motion) taking place in the nanofluid. Initially, the pressure decay studies were carried out in water to ascertain the validity of the experimental setup and provide a base value for future measurements. The CO2 was pressurized and left in the cell for 8 h to ensure that equilibrium conditions were reached. Once the fall in pressure had stopped and it did not show any change, the remaining gas in the cell was vented out and the solution taken out for observation.

The CO2 absorbed in the solution S1 was photographed and the images indicated a high dispersion of CO2 bubbles throughout the body of the nanofluid. Given the predominately physical nature of CO2 absorption in water-based solutions (Haghtalab et al. 2015), the CO2 bubbles remain suspended inside the body of the fluid while some bubbles settled on the base of the vessel or stuck to its sides. The average size of the CO2 bubbles inside the solution was 43 μm. Left undisturbed, the CO2 bubbles gradually agglomerated and escaped into the air in 6–7 h, indicating the superior retention of CO2 inside silica nanofluids, also discussed in past study (Chaturvedi et al. 2018).

The value of drop in pressure as a function of time have been provided for water and the silica nanofluids in Fig. 2. In water, the pressure fell from 5 to 2.65 MPa, indicating the solubility of CO2 in water. Usually, this solubility is defined in terms of molality (i.e., no. of moles of CO2 absorbed in a kg. of solvent) which is calculated using the ideal gas equation (Haghtalab et al. 2015; Chaturvedi et al. 2018). Within water, the following reactions take place.

Here, l and g denote liquid and gas phases, respectively. The final equilibrium is established between dissolved CO2 and H2CO3, also referred as carbonic acid (a weak acid formed by the interaction of CO2 and water).

However, these processes involving the formation of carbonic acid are highly kinetically slow, and it has been shown that a minimal amount of dissolved CO2 undergoes transition to H2CO3, with the bulk of CO2 staying in solution as solvated molecular CO2. Then, the solutions S1–S3 (nanofluids with similar particle size but increasing concentration) were used for CO2 absorption. While the final value of pressure in S1 (0.1 wt% NPs) was 2.41 MPa (higher than water), increasing silica concentration from 0.1 to 0.5 wt% (i.e., S2) yielded a pressure value of 2.22 MPa (Fig. 2(a)) while in nanofluid with maximum concentration (1 wt%), the lowest value of pressure recorded was 2 MPa (Fig. 2(a)), indicating that higher NP concentration is much more viable for enhanced CO2 absorption. This increase may be attributed to the Brownian motion of NPs in the solution which rapidly disintegrate the larger gas bubbles (which are more prone to phase separation and escape) into smaller bubbles which more easily entrapped and retained inside the fluid (Chaturvedi et al. 2018; Rezakazemi et al. 2019).

Then, the CO2 absorption was performed in silica nanofluid solutions S1, S4, and S5 where the NP concentration remained similar (≈0.1 wt%), the size of NPs in the solution increased from 36 (S1) to 142 nm (S5). These observations have been provided in Fig. 2(b). Increasing NP size (from 36 to 84 nm, i.e., in S4), the least value of pressure drop recorded was 2.56 MPa while in the silica solution with largest NPs (i.e., S5 with 142 nm NPs), the lowest value of pressure was 2.59 MPa. Also, in the previous study, it has been found that compared to NPs of smaller size for single-step silica nanofluids (Chaturvedi and Sharma 2021), larger size NPs are more prone to agglomeration (even in the absence of external factors) which reduces their incremental effect on CO2 absorption and mass transfer enhancement.

Role of pressure on CO2 absorption

The pressure decay tests were then repeated for nanofluid S1 at varying pressures (5–10 MPa) to establish the role of pressure on the CO2 absorption. These observations have been provided in Fig. 3. While the lowest value of pressure recorded for S1 at 5 MPa was 2.41 MPa, increasing the confining pressure from 5 to 7.5 MPa, yielded a pressure value of 5.62 MPa, indicating that high pressure was not well suited for increasing the absorption of CO2 in silica nanofluids. Finally, when the observations were repeated at 10 MPa, the lowest value of pressure was 8.2 MPa, indicating very low solubility of CO2 in solution. This fall in CO2 solubility at higher pressures may be explained by their tendency to reduce the micro-convections caused due to the Brownian motion of the NPs in the system, reducing the CO2 absorption capacity significantly at high pressures (Krishnamurthy et al. 2006; Nagy et al. 2007). This causes a reduction in the movement of gas molecules from the interface of the liquid to its body, causing a reduction in the mass transfer (Tolesorkhi et al. 2018).

Role of temperature on CO2 absorption

Then, the effect of temperature (as most oilfields have a higher temperature than 60–90 °C) on the CO2 absorption in silica nanofluid S1 was investigated and has been reported in Fig. 4. The temperatures investigated were 30–90 °C. A temperature higher than 90 °C was not taken as PAM has the tendency to majorly degrade at higher temperatures which would render the nanofluid less viable for high temperatures (Uranta et al. 2019; Chaturvedi and Sharma 2021). At 60 °C, the lowest value of pressure recorded was 2.6 MPa while at 90 °C, the lowest value of pressure was 2.97 MPa. Hence, increasing the temperature reduced the amount of CO2 absorption in the silica nanofluid. The fall in CO2 absorption on increasing temperature is due to the increase in kinetic energy which causes an increase in motion of gas molecules and leads to their premature escape (Chaturvedi et al. 2018). This is especially true for most water-soluble gases.

Role of salinity and surfactant addition on CO2 absorption in silica nanofluids

Salt-induced agglomeration is one of the main constraints before nanofluid use in oilfield applications. NPs tend to agglomerate in the presence of salt, forming large clusters which are detrimental for mass transfer and flow applications (Al-Anssari et al. 2017). Also, salt has been found to reduce the CO2 absorption of water in previous studies (Chaturvedi et al. 2021). The phenomena known as “salting-out” in which dissolved salt ions occupy the interstitial spaces between water layers and reduce the CO2 absorption capacity of water has been observed in past studies (Carvalho et al. 2015; Messabeb et al. 2017). A similar trend was observed in the absorption of CO2 in water solutions (with varying salinity between 0 and 8 wt% NaCl) in this study. From the data presented in Fig. 5(a), it can be observed that inducing 2 wt% NaCl, majorly reduced the CO2 absorption by reducing the pressure drop to just 3.22 MPa (in pure water, it was 2.65 MPa). Further increasing the salt concentration also minimized pressure fall to 3.58 MPa (4 wt% NaCl) and 3.64 MPa (8 wt% NaCl), indicting the high loss of solubility of CO2 in the presence of salts.

When these observations were repeated for S1 nanofluid, 2 wt% NaCl yielded a lowest pressure value of 2.73 MPa while increasing salt content caused the pressure to fall to 2.86 and 3.01 MPa from 5 MPa for 4 wt% and 8 wt% NaCl, respectively. The presented results may be better explained by observing the average particle size of NPs in the nanofluids after adding salt (Table 2). Increasing salt concentration caused agglomeration (evident from the increase in particle size, Table 2) and destabilized the solutions (zeta-potential, Table 2) which lowered the efficacy of nanofluids for CO2 absorption. Especially in the presence of 8 wt% NaCl, the silica NP size was in the high 1600 s (nm) which indicated that NPs had lost their nature and their applicability for mass transfer applications reduced immensely. These results indicate that salt-induced agglomeration is serious concern for nanofluids and is detrimental for the use in carbon storage applications in saline reservoirs.

However, several studies have indicated the viability of using anionic surfactants to increase the stability of silica nanofluids in the presence of salt (Al-Anssari et al. 2017; Kumar et al. 2020). One such commonly used surfactant is sodium dodecyl sulfate (SDS) which is also used for multiple oil field applications like foam formation, gas hydrate investigations, IFT reduction and wettability alteration (Kumar and Mandal 2016; Thoutam et al. 2019; Mofrad and Dehaghani 2020). When, used for nanofluid stabilization, the surfactants form a layer on the NPs, increasing their resistance to salt-induced agglomeration (Chaturvedi and Sharma 2021). Thus, to S1 nanofluid, surfactant SDS was added in minute quantities (0.1–0.3 wt%) and then salt (4 wt% NaCl) was added to the solution before CO2 absorption. 4 wt% NaCl was chosen because (1) 8 wt% NaCl severely destabilizes the nanofluid and (2) it is relatively common oil field salinity (Kumar et al. 2020). Adding surfactants was able to restore the nanofluid like nature of S1, evident by the control in particle size and zeta-potential (Table 3). However, the inclusion of surfactant provided additional steric stability to dispersed nanoparticles and nanofluid exhibited enough resistance against agglomeration when salt is introduced in the system (Al-Ansari et al. 2017, Kumar et al., 2020). Therefore, when salt was introduced, the particles of smaller size were evident in surfactant treated nanofluid. However, the results of CO2 absorption were different from the norm (Fig. 6). While adding 0.1 and 0.2 wt% SDS yielded a lowest pressure value of 2.73 and 2.82 MPa, respectively, adding 0.3 wt% SDS further lowered CO2 absorption by allowing pressure to fall to only 3 MPa (Fig. 6). This reduction in CO2 absorption in presence of SDS is yet unexplained and requires a comprehensive study of its own.

Mathematical modeling of D and k

Given the special interest that numerous CO2 sequestration projects have espoused in the recent times, it has become of special interest that the thermophysical properties of the fluid systems used for carbon storage be investigated. The diffusion of gases in multi-component mixtures is one of the least well studied aspects and is found to be highly dependent on the composition of the solvent, the temperature and the pressure (Cadogan et al. 2014). Also, of particular interest are the interface mass transfer coefficients which is the measure of the diffusion rate constants directly dependent on the rate and area of mass transfer along the change in concentration as the driving force in the diffusion of a gas inside a solvent. Hence, in this work, the diffusion (D) and interface mass transfer (k) of CO2 in silica nanofluids was investigated. Using equations and methodology reported in previous studies (Tolesorkhi et al. 2018), a commonly used mathematical optimization software was used to determine the optimum values of k and D under operating conditions (pressure 4–10 MPa and NP concentration 0.1–1 wt%).

The dimensionless gas concentration, distance, and time are defined as follows:

where C, Co, and C∗ denote initial, instantaneous, and equilibrium gas concentration in liquid phase, respectively. L and X are liquid region length and distance from gas–liquid interface, respectively. D is gas–liquid diffusion coefficient and t represents time.

Fick’s law for the diffusion problem is as follows:

The dimensionless mass-accumulation function, QD(tD) in liquid phase is defined as follows:

Also, the definition of QD(tD) in gas phase is as follows:

The final pressure measurement is used as a reference point. P0, P, P*, and PR are the initial, instantaneous, equilibrium, and reference pressures of the gas phase, respectively. Z0, Z, Z*, and ZR are the initial, immediate, equilibrium, and reference gas compressibility factors, respectively. The short-time approximation can compute parameters properly for brief time periods, but it is invalid for longer time durations. Moreover, long-time approximation is correct for long periods but not for short durations. However, there is a region of overlap in intermediate time where both propositions are correct. The selection between small- and large-time approximations is contingent on dimensionless time, tD.

Next, to calculate k, Stokes–Einstein equation was utilized. Here, D represents diffusion coefficient, k represents Boltzmann’s constant, T represents temperature, η stands for dynamic viscosity of system, ξ is correlation length while R is the universal gas constant. These values have been provided in Fig. 7 (for D) and Fig. 8 (for k). In Fig. 7, it can be observed that increasing the NP concentration and pressure, both had a positive impact on the D, though the increase was more pronounced for higher pressures than at higher NP concentrations. From the presented results, it can be also observed that increasing concentration of SiO2 NPs (from 0.1 to 1 wt%) leads to an increment in the interface mass transfer coefficients (Fig. 8). This may be attributed to the increase in no. of silica NPs on the gas–liquid interface which helps in the absorption of CO2. A similar effect is observed when the pressure is increased as pressure is directly linked to adsorption and consequently the interface mass transfer coefficients are found to increase on increasing pressure in the silica nanofluids. The results obtained from this study, indicate the significant role played by NPs (Brownian motion and grazing effect) in enhancing the D and k (Tolesorkhi et al. 2018). Furthermore, in previous, studies and data from this investigation, show that for a nanofluid, an increase in temperature enhances the diffusivity of CO2. However, it decreases the adsorption as well. An increase in temperature also causes reduction in fluid viscosity (Tolesorkhi et al. 2018). It consequently enhances Brownian motion of nanoparticles, which would finally improve the mass transfer rate. The results of this study show that negative impact of temperature on CO2 diffusion is lower than its positive effect on diffusivity, in line with research findings in literature (Tolesorkhi et al. 2018). In presence of salinity, both CO2 diffusion and diffusivity reduce as the presence of salt causes salting-out effect (Chaturvedi et al. 2021, Sharma et al. 2022). On the other hand, surfactant increased CO2 diffusion (due to presence of greater number of void spaces in water lattices).

Conclusion

In this study, the viability of silica nanofluids synthesized via the single-step Stober sol–gel route for enhanced CO2 absorption at high reservoir pressure and temperature conditions was investigated. Initially, the synthesis of silica nanofluids was performed using a precursor, tetraethyl orthosilicate (TEOS) in the presence of ammonium hydroxide and ethanol. The base fluid used in this study was 1000 ppm PAM. The concentration of silica NPs (0.1–1 wt%) suspended in the mixture were carefully controlled by limiting the amount of the precursor (TEOS) between 0.045 and 0.18 M while the NP size (30–120 nm) was controlled by adding varying amounts of ammonium hydroxide (0.28–0.56 M). The fabricated nanofluids displayed excellent stability with no appreciable agglomeration observed even after storage for 2 weeks. The synthesized nanofluids were then investigated for CO2 absorption where it was observed that while increasing NP concentration was found to increase CO2 absorption (evident by a higher fall in the pressure), increasing NP size caused a reduction in CO2 absorption (by up to 6–8%). Also, while the increase in pressure was found to increase CO2 absorption, at higher pressures, CO2 absorption fell significantly. When the pressure was increased from 5 to 10 MPa, the pressure decay reduced, indicating the non-performance of liquid solutions for CO2 absorption at high pressures. Increasing temperature, slightly reduced the CO2 absorption as CO2 is less dispersive in water-based solutions at higher temperatures though the effect of increase in dynamic viscosity of the solution (due to the addition of silica NPs) ensured that the fall in CO2 absorption remained low (between 6 and 18%). In presence of salinity, NP agglomeration resulting in the increase in particle size increase (up to 1600 nm in presence of 8 wt% NaCl) which rendered the silica nanofluids less viable for CO2 absorption with 8 wt% NaCl addition causing the 0.1 wt% silica nanofluid solution to behave like simple water. Adding surfactant was able to mitigate the salt-induced agglomeration to a certain extent (evident from the pressure decay plot), indicating the viability of surfactant addition to nanofluids in presence of high salinity conditions. Finally, the diffusion coefficients and the mass transfer coefficients were obtained for the silica nanofluids using mathematical modeling. As per the obtained results of our experimental studies, the CO2 diffusion and mass transfer coefficients were found to increase with confining pressure and nanofluid concentration. However, the increase was less well pronouncing for higher pressure. Based on the observations in this study, single-step silica nanofluids emerge as viable candidates for use in CO2 absorption due to their superior performance when compared to water and their use in CO2 EOR and storage applications is highly recommended.

Data availability

The authors will make all data sets available on request to readers without any reservations.

References

Aggelopoulos CA, Robin M, Vizika O (2011) Interfacial tension between CO2 and brine (NaCl+CaCl2) at elevated pressures and temperatures: the additive effect of different salts. Adv Water Resour 34:505–511

Ahmadi H, Jamialahmadi M, Soulgani BS, et al (2020) Experimental study and modelling on diffusion coefficient of CO2 in water. Fluid Phase Equilib 112584

Al-Anssari S, Arif M, Wang S et al (2017) Stabilising nanofluids in saline environments. J Colloid Interface Sci 508:222–229

Behzadfar E, Hatzikiriakos SG (2014) Diffusivity of CO2 in bitumen: pressure-decay measurements coupled with rheometry. Energy Fuels 28:1304–1311

Bikkina PK, Shoham O, Uppaluri R (2011) Equilibrated interfacial tension data of the CO2-water system at high pressures and moderate temperatures. J Chem Eng Data 56:3725–3733

Cadogan SP, Maitland GC, Trusler JPM (2014) Diffusion coefficients of CO2 and N2 in water at temperatures between 298.15 K and 423.15 K at pressures up to 45 MPa. J Chem Eng Data 59:519–525

Carvalho PJ, Pereira LMC, Gonçalves NPF et al (2015) Carbon dioxide solubility in aqueous solutions of NaCl: measurements and modeling with electrolyte equations of state. Fluid Phase Equilib 388:100–106

Celia MA, Bachu S, Nordbotten JM, Bandilla KW (2015) Status of CO2 storage in deep saline aquifers with emphasis on modeling approaches and practical simulations. Water Resour Res 51:6846–6892

Chaturvedi KR, Kumar R, Trivedi J et al (2018) Stable silica nanofluids of an oilfield polymer for enhanced CO2 absorption for oilfield applications. Energy Fuels 32:12730–12741

Chaturvedi KR, Ravilla D, Kaleem W et al (2021) Impact of low salinity water injection on CO2 storage and oil recovery for improved CO2 utilization. Chem Eng Sci 229:116127

Chaturvedi KR, Sharma T (2020) Carbonated polymeric nanofluids for enhanced oil recovery from sandstone reservoir. J Pet Sci Eng 194:107499. https://doi.org/10.1016/j.petrol.2020.107499

Chaturvedi KR, Sharma T (2021) Rheological analysis and EOR potential of surfactant treated single-step silica nanofluid at high temperature and salinity. J Pet Sci Eng 196:107704

Chaturvedi KR, Trivedi J, Sharma T (2019) Evaluation of polymer-assisted carbonated water injection in sandstone reservoir: absorption kinetics, rheology, and oil recovery results. Energy Fuels 33:5438–5451

Chaturvedi KR, Trivedi J, Sharma T (2020) Single-step silica nanofluid for improved carbon dioxide flow and reduced formation damage in porous media for carbon utilization. Energy 197:117276

Darvanjooghi MHK, Esfahany MN, Esmaeili-Faraj SH (2018) Investigation of the effects of nanoparticle size on CO2 absorption by silica-water nanofluid. Sep Purif Technol 195:208–215

Do HD, Pinczewski WV (1993) Diffusion-controlled swelling of reservoir oil by indirect contact with injection gas. Chem Eng Sci 48:3243–3252

Emera MK, Sarma HK (2007) Prediction of CO2 solubility in oil and the effects on the oil physical properties. Energy Sources, Part A Recover Util Environ Eff 29:1233–1242

Esene C, Rezaei N, Aborig A, Zendehboudi S (2019) Comprehensive review of carbonated water injection for enhanced oil recovery. Fuel 237:1086–1107

Foroozesh J, Jamiolahmady M, Sohrabi M (2016) Mathematical modeling of carbonated water injection for EOR and CO2 storage with a focus on mass transfer kinetics. Fuel 174:325–332

Haghtalab A, Mohammadi M, Fakhroueian Z (2015) Absorption and solubility measurement of CO2 in water-based ZnO and SiO2 nanofluids. Fluid Phase Equilib 392:33–42

Haider MB, Jha D, Marriyappan Sivagnanam B, Kumar R (2018) Thermodynamic and kinetic studies of CO2 capture by glycol and amine-based deep eutectic solvents. J Chem Eng Data 63:2671–2680

Honarvar B, Azdarpour A, Karimi M et al (2017) Experimental investigation of interfacial tension measurement and oil recovery by carbonated water injection: a case study using core samples from an iranian carbonate oil reservoir. Energy Fuels 31:2740–2748

Krishnamurthy S, Bhattacharya P, Phelan PE, Prasher RS (2006) Enhanced mass transport in nanofluids. Nano Lett 6:419–423

Kumar RS, Chaturvedi KR, Iglauer S et al (2020) Impact of anionic surfactant on stability, viscoelastic moduli, and oil recovery of silica nanofluid in saline environment. J Pet Sci Eng 195:107634

Kumar S, Mandal A (2017) A comprehensive review on chemically enhanced water alternating gas/CO2 (CEWAG) injection for enhanced oil recovery. J Pet Sci Eng 157:696–715

Kumar S, Mandal A (2016) Studies on interfacial behavior and wettability change phenomena by ionic and nonionic surfactants in presence of alkalis and salt for enhanced oil recovery. Appl Surf Sci 372:42–51

Messabeb H, Contamine F, Cézac P et al (2017) Experimental measurement of CO2 solubility in aqueous CaCl2 solution at temperature from 323.15 to 423.15 K and pressure up to 20 MPa using the conductometric titration. J Chem Eng Data 62:4228–4234

Mofrad SK, Dehaghani AHS (2020) An experimental investigation into enhancing oil recovery using smart water combined with anionic and cationic surfactants in carbonate reservoir. Energy Rep 6:543–549

Nagy E, Feczkó T, Koroknai B (2007) Enhancement of oxygen mass transfer rate in the presence of nanosized particles. Chem Eng Sci 62:7391–7398

Peyravi A, Keshavarz P, Mowla D (2015) Experimental investigation on the absorption enhancement of CO2 by various nanofluids in hollow fiber membrane contactors. Energy Fuels 29:8135–8142

Rahmatmand B, Keshavarz P, Ayatollahi S (2016) Study of absorption enhancement of CO2 by SiO2, Al2O3, CNT, and Fe3O4 Nanoparticles in water and amine solutions. J Chem Eng Data 61:1378–1387

Rasmussen ML, Civan F (2009) Parameters of gas dissolution in liquids obtained by isothermal pressure decay. AIChE J 55:9–23

Rezakazemi M, Darabi M, Soroush E, Mesbah M (2019) CO2 absorption enhancement by water-based nanofluids of CNT and SiO2 using hollow-fiber membrane contactor. Sep Purif Technol 210:920–926

Riazi M, Golkari A (2016) The influence of spreading coefficient on carbonated water alternating gas injection in a heavy crude oil. Fuel 178:1–9. https://doi.org/10.1016/j.fuel.2016.03.021

Sadhukhan T, Latif IA, Datta SN (2014) Solvation of CO2 in water: effect of RuBP on CO2 concentration in bundle sheath of C4 plants. J Phys Chem B 118:8782–8791

Setia H, Gupta R, Wanchoo RK (2013) Stability of nanofluids. Mater Sci Forum 757:139–149

Seyyedi M, Mahzari P, Sohrabi M (2018) A comparative study of oil compositional variations during CO2 and carbonated water injection scenarios for EOR. J Pet Sci Eng 164:685–695

Sharma T, Sangwai JS (2017) Silica nanofluids in polyacrylamide with and without surfactant: viscosity, surface tension, and interfacial tension with liquid paraffin. J Pet Sci Eng 152:575–585

Sharma T, Joshi A, Jain A, Chaturvedi KR (2022) Enhanced oil recovery and CO2 sequestration potential of Bi-polymer Polyvinylpyrrolidone-Polyvinyl alcohol. J Pet Sci Eng 211:110167

Sohrabi M, Kechut NI, Riazi M et al (2011) Safe storage of CO2 together with improved oil recovery by CO2-enriched water injection. Chem Eng Res Des 89:1865–1872

Sohrabi M, Kechut NI, Riazi M et al (2012) Coreflooding studies to investigate the potential of carbonated water injection as an injection strategy for improved oil recovery and CO2 storage. Transp Porous Media 91:101–121

Thoutam P, Rezaei Gomari S, Chapoy A et al (2019) Study on CO2 hydrate formation kinetics in saline water in the presence of low concentrations of CH4. ACS Omega 4:18210–18218

Tolesorkhi SF, Esmaeilzadeh F, Riazi M (2018) Experimental and theoretical investigation of CO2 mass transfer enhancement of silica nanoparticles in water. Pet Res 3:370–380

Uranta KG, Rezaei Gomari S, Russell P, Hamad F (2019) Application of polymer integration technique for enhancing polyacrylamide (PAM) performance in high temperature and high salinity reservoirs. Heliyon 5:e02113

Wiebe R, Gaddy VL (1940) The solubility of carbon dioxide in water at various temperatures from 12 to 40° and at pressures to 500 atmospheres. Critical Phenomena J Am Chem Soc 62:815–817

Zarghami S, Boukadi F, Al-Wahaibi Y (2017) Diffusion of carbon dioxide in formation water as a result of CO2 enhanced oil recovery and CO2 sequestration. J Pet Explor Prod Technol 7:161–168

Zhang YP, Hyndman CL, Maini BB (2000) Measurement of gas diffusivity in heavy oils. J Pet Sci Eng 25:37–47

Zhang Z, Cai J, Chen F et al (2018) Progress in enhancement of CO2 absorption by nanofluids: a mini review of mechanisms and current status. Renew Energy 118:527–535

Acknowledgements

We thank Rajiv Gandhi Institute of Petroleum Technology, Jais for providing financial and infrastructural support for this study.

Author information

Authors and Affiliations

Contributions

Krishna Raghav Chaturvedi: data curation, investigation, methodology, writing—original draft preparation. Tushar Sharma: conceptualization, visualization, supervision, validation, writing—reviewing and editing, project administration.

Corresponding author

Ethics declarations

Conflict of interest

There declare no competing interests.

Consent to Participate and publish

Both authors confirm their participation in this study, have read the final manuscript and given their consent for the publication of this study.

Additional information

Communicated by Tito Roberto Cadaval Jr.

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chaturvedi, K.R., Sharma, T. Diffusion of CO2 in single-step silica nanofluid for subsurface utilization: an experimental study. Environ Sci Pollut Res 30, 31231–31241 (2023). https://doi.org/10.1007/s11356-022-24402-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-24402-w