Abstract

The main focus of the work is to determine the performance efficiency of water-%CuO nanofluids and water at varied flow rate of 0.035 lit/sec, 0.045 lit/sec, and 0.065 lit/sec in an evacuated tube collector integrated with an heat exchanger. A heat exchanger made of copper tube connected to a horizontal pipe for collection of heat from a vertical tube, and a vertical copper tube for collection of heat from an evacuated tube collector for solar radiation were used in the investigation. Water showed no absorption, a low thermal capacity when it was not suitable for high thermal application for improvement in performance, the base fluid with colloidal dispersion of %vol CuO nanofluids in the force convection mode. The evacuated tube collector produced the highest efficiency of water −0.3% vol CuO nanofluids at flow rate 0.035 lit/sec compared to 0.1% and 0.2% vol of CuO nanofluids at flow rate of 0.045, 0.065 lit/sec and water. A comparison to the water CuO nanofluids with the highest effective concentration showed a greater increase in thermal efficiency.The performance of theworking fluid performances was examined for parameters like exit temperature, specific heat, thermal conductivity, energy productivity, and efficiency utilizing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Energy is one of the vital and needed necessities of life. There is a significant reliance on conservative energy sources for energy production for sustaining our lives in the present situation. The cost of fossil fuel sources of vigor cost is seen increasing at a fast rate. Hence, change to in the renewable form of energy is necessary. Renewable energy sector has a predictable task in the sustainable growth capability. The needs of the present and future generation for meeting their requirements are extensive, considering the energy crisis arising from the development of solar energy-based systems. Evacuated tube collector (ETC) has been on use for more than 20 years. However, it has not recently presented any severe competition to flat plate collectors, as it minimizes convective, radiation, and emissivity heat loss of the absorber surface, ETC is made of double-coated vacuum tubes. An issue with the design of ETC is the difficulty of continually extracting heat from a long thin absorber vacuum tube.

Sabiha et al. (2015a, 2015b, 2015c) in their latest ETC studies have indicated the collector’s enormous potential for energy-producing industries and research organizations. Kumar and Yadav (2015) compared three solar water heaters at 220° and 450° inclination of the collector tube and separated the hot and cold fluids inside the tube. The temperature fluctuations of the first system compared to other systems were 30°C and 20°C, respectively. The temperatures in the second and the third at 450° inclination of the collector tube were 240°C and 210°C, respectively more than the first. Yadav et al. (2017) investigated the increase in solar still coupled with ETC and saw it providency the highest daily yield (4.24 kg/m2/day) among all active solar stills. A double-layer wick solar still coupled with ETC provided 114% higher distillate yield than a simple solar still. Kumar and Chinnapandian (2018) did investigationwere related to forced type ETC with absorber plate thatproduced much energy. The air temperature distinctionattributed to flow rate (FR) at 0.027 lit/sec was reduced from 107.6 to 67.7°C between 12.00 and 1.00P.M with an absorber plate. The exit temperature of ETC with absorber plate was 13.6% more than that without it. Wang et al. (2017) found a novel evacuated receiver helping a reduction in total heat loss when the working temperature exceeded 296°C. The percentage reduction in heat loss was 19.1% at higher working temperatures of 480°C. Patel and Patel (2013) found the out performance of ETC over flat plate collectors due to lower convection losses, which they demonstrated using computational fluid dynamics and experimental analysis methods. Kalbande et al. (2016) looked at the use of electricity in a hot water system. However, calculations showed the presence of more than 266 L of hot water per kilowatt-hour of electricity, enough for a maximum of 14 students. Capacity shortage of 760 L was found for 38 students. According to Hlaing and Soe (2012) more sun radiation was required for reaching the maximum temperature of hot water and the ETC collectors were seen as more efficient than heat pipes and flat plate collectors. According to Thomas et al. (2014), the performance of the FR rate, incoming solar radiation, and temperature difference between the intake and output are all factors in tubular collectors. Collectors with a concave reflector were effectively diverted into the copper tube’s focal point, speedy heating up of water. Kadyan (2018) analyzed the ETC with heat pipe CFD modeling and observed an increase in the pressure drop, velocity, FR, heat transfer coefficient by increasing the inlet at different FR (0.047 and 0.167 kg/s) and different temperatures. Rashak et al. (2016) saw the maximum efficiency around the system as 51% and the coefficient of heat loss as 1.81 W/m2K. The results obtained from the tests were used for further designing and improvements in the evacuated collectors for any location globally and specific applications. Sharma and Pathak (2016) observed the influence of parameter variables like solar intensity, wind velocity, tilt angle and receiver numbers, concluding that the maximum productivity was achieved when the horizontal angle of ETC was 15°C with the use of for ETC’s. Arora et al. (2011) found the ETC to be more productive than other FPC, helping achievement of a maximum temperature between 170 and 180°C. Ayompe et al. (2011) conducted tests on a parallel evacuated tube made of the transparent form of the outer tube for absorbtion of solar energy. The inner tube was coated with a specific absorption coating with nominal reflective property. The heat was absorbed and stored by the tubes in the inner vacuum tube for elimination of conductive and convective heat loss. The experimented on a flat plate collector and an ETC under various settings for obtaining monitor energy efficiency. The results showed ETC performance far better than the FPC, for example, performance, energy consumption, thermal conductivity, heat transfer coefficient, and energy conservation.

Nanoparticle: experimental approach

Chaudhary et al. (2017) found the device employing Al2O3 as the working fluid within the heat pipe a significant heat absorption capacity in the effectiveness of heat of nanofluids in solar water heaters with ETC was seen as better than that of traditional heaters. They also looked at the impact of FRover the condenser and inclination angle on ETC output. Mujawar and Shaikh (2016) did a work with focus on the enhancement of nanofluids filled heat pipe ETC in a forced convection mode compared to traditional ETC. An increase in the tilt angle from 20° to 30° caused a decrease in heat rate oftransport, both the outcomes of the experiments revealed an increase inthe solar collector instantaneous performance. The study of Kang et al. (2019) was based on CuO nanofluids efficiency of the ETC. The solar tubes efficiency was found as above 420 kg/s-m2 with a FR of 598 kg/s-m2. The output of asolar collector with a maximum output of 40 nm-CuO was 69.1%. Nanofluids of 80 nm-CuO improved by 2.0%. The use of CuO nanofluids could help improvement in efficiency compared to water under wide-operating conditions. In addition, Lu et al. (2011c) worked in the CuO/deionized water nanofluids used for increasing performance in an evacuated tube solar collector. The result showed a 30% increase in the heat transfer coefficient relative to evaporator deionized water, while the mass concentration was 1.2% at the highest rise in heat temperature. Al-Mashat and Hasan (2013) improved the performance of the ETC collector using Al2O3/water nanofluids and by adjusting the tilt angle position collector. They found the best tilt angle for ETC was 41% and an improvement of 28.4% with 1% and 6.8% with 0.6, 0.3% concentration of Al2O3/water nanofluids in collector efficiency with no sensible effect. Hussain et al. (2015) used ZrO2/water or Ag/water nanofluids in their investigation of the collector’s performance. They saw a rise in the solar collector’s efficiency compared to water in both nanofluids, especially at high inlet temperatures. The collector’s performance with Ag/water nanofluids, on the other hand, was superior to that with ZrO2/water nanofluids. When heat from the collector went through 20% of nanoparticles such Al2O3, TiO2, SiO2, and CuO dissolved in base fluid, which enhanced thermal conductivity, there was a rose in the efficiency to a maximum value of 62.8%, according to Kim et al. (2016). Xiong et al. (2021c) studied the migration of Ag-Al2O3 hybrid nanoparticles based on by Brownian motion and thermophoresis processes. The results demonstrated the use of hybrid nanofluids and large concentrations of nanoparticles causing a decrease in heat transfer rate and a marginal rise in temperature, conductivity ratio, radiation parameter, porosity coefficient in the higher level. Izadi et al. (2013b) performed an experiment on the effectiveness of nanofluids for a change in Reynolds number and the pressure resulting from a change in the Brinkman number. Izadi et al. (2015) focused on the modeling of effective thermal conductivity and viscosity of carbon-structured nanofluids with interactive effects of temperature and weight percentages of multiwall, single wall, and nanoporous carbon nanotubes. Shehzad et al. (2021b) made assessement of the Buongiorno theory of nanomaterials and found the problem of Brownian movement and thermophoresis having an impact on the flow model. Variable thermal conductivity of the energy equation was solved using the Cattaneo-Christov heat diffusion theory, while that in the complex nonlinear system was solved using the Runge-Kutta-Fehlberg technique. Sajjadi et al. (2021) investigated the natural convection flow in copper/water nanofluids filling a porous cavity with periodic temperature distribution using the lattice Boltzmann method with a growth in the Rayleigh number grows, there was an increase in the effect of the Darcy number on the rate of heat transfer increases, raising the average Nusselt number by a maximum of 12% to 61%. Izadi and Assad (2021) reviewed homogeneous dispersion of nanoparticles represented by nanofluids (nanometer-sized particles in the base fluid). The fluids in which the nanoparticles were suspended dramatically improved in thermal conductivity and heat transfer. Lanjwani et al. (2021) reported concentration of nanoparticles causing a decrease in Schmidt number and increases in Brownian movement, with increase in the convective heat transfer parameter when the suction of the magnetic parameters was increased with unsteadiness parameter. Parameters of the drag force, skin-friction factor, rate of mass, and heat transfer were also discussed. Shahrestani et al. (2021) investigated the natural convection of a nanofluid inside a partitioned circular enclosure in the presence of a flexible (movable) wall. The findings showed the amount of stresses exerted by the fluid directly having effect on the quantum of deformation in the plate. Xiong et al. (2021b) saw significant enhancements in the thermal and optical performance of solar thermal energy systems with the employment of hybrid nanofluids. The thermal efficiency of the nanoparticles was seen as directly proportional to the fraction value of the conventional fluids. They worked on the fluid force requirements and stability limits of fluids. Delouei et al. (2019) have reported on the impact of nanofluid turbulent flows on ultrasonic vibration, pressure drop, and heat transfer enhancement with a rise in both Reynolds number and inlet temperature found helpful for future research on the development of vibrating heat exchanger (HX). Shehzad et al. (2021a) showed the vertical alignment of the fins increased the thermal performance of nanofluids more than the horizontal arrangement of the fins and also mode of heat transfer of adjacent fins and HX. Huu-Quan et al. (2021) indicated the performance of double-pipe HX covered by flat inner pipes with nanofluids which compared at low and high Reynolds numbers. Izadi et al. (2013a) looked into nanofluids flowing in an inner annulus having influence on the performance. The problems of dimensionless axial velocity and temperature were solved using the finite volume method, and also variations in the convective heat transfer coefficient of the walls depending on the Richardson number ratio of the inner and outer tube. Mehryan et al. (2020b). studied the simulation model of a displacement flexible wall interaction with an interior natural convection flow in a trapezoidal container .The results showed an increase in the Rayleigh number of enclosures resulting in increased cavity wall inclination angle heat transfer with no impact on strains caused by partitions. In particular, a square cavity had a 15% higher rate of heat transfer than a trapezoidal cavity with side walls at a 30° angle. Yan et al. (2020) worked on the heat conductivity, viscosity parameter, temperature, and heat exchange parameters of CuO nanofluids in a porous chamber with an elliptical tilted heater. The Runge-Kutta-Fehlberg approach was used by Ramesh et al. (2020) for the development of dimensionless nonlinear ordinary differential equations over the axisymmetric Darcy-Forchheimer and energy flow of hybrid nanoliquid across a thin moving needle. Mehryan et al. (2020a) investigated the impact of two magnetic sources on the flow of melting and heat transfer within a cavity. The presence of two non-uniform convection fluxes had an effect on the heat absorption of the PCM-filled container. Izadi et al. (2020b) determined the precise fusion temperature of melting a magneto-ferro phase transition material in a hollow located between the rights and left insulated walls. The melting rate increased when the pair of sources was placed close to the insulated cold wall. Izadi et al. (2020a) did computational inquiry on H2O/Al2O3 nanoliquids and water-based copper/aluminum oxide hybrid nanofluids (water/Al2O3-CuO) in a horizontal isosceles triangle enclosure with porous media. The results seen demonstrateda rise in the temperature with an increase in the Darcy number increases due to the severity of the instabilities in the flow motion with the distribution of isotherms and streamlines becoming totally asymmetric. Izadi et al. (2014) made statistical analyzsis of the laminar mixed convection of an Al2O3/water nanofluids flow in a chamber with a sliding upper wall from right to left flow and found achievement of a total heat transfer reaching its maximum value and its two eddies at a low heat transfer rate. Xiong et al. (2021a) found nanofluids as superior to traditional fluids for a variety of applications including heat transmission. Compared to metal-based nanofluids, non-metallic based nanofluids could be more beneficial for improving the efficiency of solar collectors. Very few experimental studies are seen on ETC efficiency enhancement with water nanofluids are seen in literature of different FR. This research examined the performance of water-% 0.1vol CuO, % 0.2vol CuO, and % 0.3vol CuO nanofluids and water at varied FR of 0.035 0.045, and 0.065 lit/sec in the ETC with an integrated HX.

Preparation of nanofluids

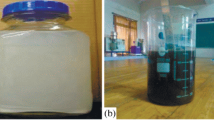

Chakraborty and Panigrahi (2020) stated the stability of a nanofluid affects its thermophysical characteristics, including its viscosity and heat conductivity. The performance of numerous heat transfer applications is enhanced by a suspension of nanoparticles (dimension less than 100 nm) in a basefluid. The stability of nanofluids is affected by factors such as high temperature, pressure, composition, salinity, external magnetic field, and shear rate. Hybrid nanofluid, quantum dot, and stabilization approach methods used for an increase in the stability of nanofluids as one of the methods of nanofluids preparation as described. This nanopowder CuO was purchased from SWASCO Laboratories in Mumbai and its average particle wih size of 40nm was mixed in distilled water with a calculated proportion. The mixture was stirred well for proper mixing of the nanopowder. Encapsulation of water, various % vol CuO nanofluids following the preparation is shown in Fig. 1. A differential calorimeter was employed for evoluation of the CuO nanofluids’ thermal conductivity and specific heat (model: DSC 3000, Perkin ElMER, and USA).

CuO nanofluids’ thermal conductivity and specific heat

The thermal conductivity increased due to an increased percentage of nanofluids due to Brown’s movements between particles causing increase in the activity of nanofluids, and increased efficiency in heat transfer. Fewer heat losses than the solar collector wereseen due to the smaller parameter with a loss of heat. The solar collector had small heat loss parameters in a wide range of operating circumstances, maintaining high thermal efficiency. Heat gain and modest thermal loss parameter were found in a high-efficiency solar collector. The thermal conductivity of three volumes of water-CuO nanofluids was measured as 0.1, 0.2, and 0.3 vol% within the 10–100°C range, as shown in Fig. 2a. The thermal conductivity of CuO nanofluids was substantially higher than that of water, with conductivity increasing with increasing volume fraction and temperature. Fluctuations in solar radiation throughout the day, with a minimum in the morning, a high around 1 P.M., and a decrease subsequently helped making an increase in thermal conductivity with temperature useful for collectors. As a result, CuO nanofluids could absorb more heat released by the heat pipe while passing through the collector’s manifold when compared to water. The specific heat of water—0.1, 0.2, and 0.3 vol % CuO is presented in Fig. 2b. CuO nanofluids were measured within the temperature range of 10–100°C, for every 5°C increase.

Experimental setup

The object of the experimental observation is to enhance the heat transfer of ETC using of CuO-water nanofluid as a working fluid. The proposed systemconsisted of set of evacuated tubes.with outerdiameter (OD), inner diameter (ID), and lengh were 0.08, 0.04, and 2.5 m respectively. The surface area of each set of ETC was as 4.8 m2. One end of the ETC was connected with the supported of a HX consist of manifold and a frame supported in the other end. The photoview of experiment setup as shown in Fig. 3a, heat exchanger are mounted inside the manifold as shown in Fig. 3b. Figure 4 shows the schematic representation of the experimental set-up.

In order to return internal fluid to the hot absorber, the ETC heat pipe was mounted at a minimal inclination angle of 25°. Consequently, the collector tilt angle was set to 30°. The internal HX and the storage tank contained a pump that circulates working fluid through the flow control value. A tank with a capacity of 80 L with 20 ETC was installed on the solar system for the absorbtion of the collector’s heat. The channel of the manifold was made of a Hollow rectangular channel with 0.40 m, 0.20 m, and 5.4 m, respectively for outer, inner, and long sides. The external tube was transparent to allow for negligible reflection of light rays, but a unique selective (Al-N/Al) internal coating with high sun ray absorption and low reflecting properties was applied to the tube. In this process, the working fluid entering the copper tube, absorbed heat from the ETC tube, and collected the heat during the heat exchange process. The experimental setup was installed for the detection of the ETC thermal efficiency through the measurement of devices for measurement at the tank’s entry and exit points and the ambience.

Measuring instrument

A PT100 resistive temperature device showed changes in resistance can be measured at intervals up to 450°C with a resolution of 0.1°C. It was made of copper, nickel, or nickel-iron metallic elements or alloys. The indoor humidity monitor of AcuRite 613 made facilitated reading the temperature and moisture were monitored on a daily basis. The FR of water or waste oil was measured at the beginning of the experiment by using a water spark–type flow meter. The measuring range of the instrument was 1 to 30 lit/sec, and its revolution was 0.001 lit/sec. A 10-channel data logger was used for storage and processing of data from the sensors. For measurement of the global radiation, we used TES 133R, the solar meter. Using a pressure sensor can measure the difference between the pressures by an anemometer called the PROVA (AV M-07) for measurement of the wind speed. All data was then transmitted through an interface cable from the data logger to the computer. Several calibrations were performed for the entire system to ensure data accuracy. All the instruments used were calibrated according to the standards used in this experiment.

Efficiency calculations

The performance test for the collector was carried out in a stable state. The temperatures for input and outlet at various FR were measured (0.035, 0.045, and 0.065 L per second). Hematian and Bakhtiari (2015) have defined the collector’s thermal performance as the proportion of useful heat gain to solar radiation incident. The following equations were used for finding the efficiency of the collector.

where QG is the gained valuable heat by the ETC (W) and Q is the ETC-absorbed solar incident radiation. m is the collector’s rate of flow in (kg/s), CP is at constant pressure specific heat in (J/kg °C).T1, T2 is the storage tank’s inlet and outlet temperature. Iβ is the amount of solar radiation with precision ± 10 W/m2 and resolution of 0.1 W/m2 measured by solar meter. AC is the ETC area, V is the speed of the water-CuO nanofluid flow measured in 0.1 m/s accuracy, S is eclipsed area of tubes in m2, N is the number of tubes, D is the outer diameter of ETC, and L is the length of the ETC.

Uncertainty analysis

The most vulnerable parameter of distillate water is the experimental error, determined in terms of % uncertainty for both the internal and external surface of ETC. Nakra and Chaudhry (2003) evaluated the following uncertainty equation (U) used to solve in the ETC .

where σ is the standard deviation as follows:

where (Xi − X) is the deviation from the mean N and N0, number of set and number of observation in each set , respectively

where Ui is the internal uncertainty equation for the ETC. The observed yield (distilled water) values were deemed to be within the % uncertainty.

Comparison of the experiment research

Lu et al. (2011b) measured the efficiency of the ETC tube using particles of the size of 50 nm at 0.8–1.5% CuO/water volume concentration. The result demonstrated an increase in heat transferrate and mass concentration of CuO nanofluids increase. Sabiha et al. (2015a, 2015b, 2015c) experimented on SWCNT/water on ETC at vol % 1–2, 0.05, 0.1, 0.2 as a working fluid at rate of flows 0.008, 0.017, 0.025 lit/sec. The result showed an improvement in energy efficiency in terms of increased concentration of FR. The collective performance was greater during the cloudy than sunny days than in water at the same FR. Using 0.03, 0.06% vol CuO/water nanofluids, Ghaderian and Sidik (2017) experimented on ETC. They saw a linear rise in the coefficient of heat transfer in relation to water in the concentration in the volume of nanofluids. Increase in their average output temperature within this concentration range was approximately 14%. With 0.03, 0.06% vol Al2O3/water nanofluids at a FR of 20–60 l/h. The result showed a 58.65% improvement in the efficiencyof the collector at 0.06 %vol of nanofluids relative to water. Mahendran et al. (2012b) tested TiO2/water with a 30–50 nm concentration at a FR of 2.0, 2.7, 3.0, 3.5 L/min at ETC with 0.3 % vol. The result showed a 19.0% increasein the temperatureof the nanofluidsover water and a 16.07% increase in its corresponding overall performance. At a rate of flow 0.015, 0.00125 kg/s, Chougule et al. (2012) experimented on ETC using 10–12% vol of CNT/water nanofluids. The result showed the good performance of nanofluids even at a low concentration of 0.015%. The performance was also economical. At 50°C tilt angles, both working fluids and their improved solar heat pipe average efficiency at 500°C tilt angles provided better results. In solar collectors, the performance of nanofluids in terms of outlet temperature,the highest CuO nanofluid temperature of 345°C with concentrations of 0.03 and 0.06% showed an increase of approximately 14% of the average temperature output (Table 1).

Earlier studies show enhancement in thesolar collector’s efficiencyby 5–17% through the use of nanofluids. Literature shows very few techniques found useful in experimental research on how ETC performance can be improved in various ways with the use of the test method. High conductivity of experimental and psychological tests of ETC discharge using CuO nanofluids was found ineffective. As a result, the performance of the ETC was investigated using a CuO nanofluids test process, the concentration of CuO nanofluids, and the FR of the working fluid in this study. Thermal effectiveness of the ETC when using CuO nanofluids has been compared with that of water.

Results and discussion

The system resolution was developed with the intention of analyzing the mean value of the parameters in ETC. In the month of May 2020, the study was conducted at 23.8° N llatitude, 72° E longitude as the traditional Indian summer. Measurements were made for 30 days, and the environmental temperature varied from 28 to 38°C during the period. Results of the nanofluids FR and concentration were seen.

The construction of the evacuated tube included internal passages integrated with copper tube which absorbed heat from outer tubes (borosilicate aluminum glass). One end was connected to the HX and other end to the frame support. The performance of ETC was measured from water-%vol CuO of nanofluids at different FR from the storage tank is circulation through a HX, and its corresponding temperature of inner and outer tube was measured. Thermal insulation was also used for preventation of convection losses. The inner and outer tubes were separated considering high vacuum conditions maintained, thus increased the efficiency of energy conversion while lowering convection and conduction heat losses and assisting in atmospheric pressure resistance. The exterior coating applied to the tube had the effect of absorbing solar radiation, and as a result, the electromagnetic wave had the ability to reach the required temperature, so the inner coppertube in the HX reached a higher temperature. The study was carried out at FR of 0.035, 0.045, and 0.065 lit/sec. The experimental system consisted of HX, pump, flow metre, manifold channel, ETC, and storage tank. Additionally, the performance of the ETC was used in the estimation of the output temperature, sun intensity, and FR of the water-vol% CuO nanofluids.

Comparison of solar radiation of ETC

For each test, identical sun radiation and ambient temperature were used as experimental data for accessment of and comparision between the effects of various FR across a number of days. The primary determinant of ETC performance is the solar radiation intensity, which changes hourly as seen in the Fig. 5. In this experiment, the initial and maximum solar radiation readings were about 585 W/m2 and 890 W/m2, respectively. The thermal gradient seen was more at noon due to increased sun radiation and the surrounding temperature. ETC efficiency was at its highest for each rate of flow water-vol% CuO.

When the outflow occurred in the region, there was a slight increase in the temperature from the initial low temperature, higher relative humidity, and comparable inflow. Achievement of sufficient melting and stability of the water-vol% CuO nanofluids inside the collection tubes was a challenging role with increasing after every hour as the temperature inside the ETC exceeded 70°C. During normal operation, the temperature inside the tubes rose until it reached its maximum stable value. The outcome revealed a rise in temperature from 12 to 1 P.M., followed by a slight increase in value due to sunlight, increase in as well as % vol CuO-water nanofluids sufficient melting and stability of the heat storage and its happen high heat loss through collector tubes but the overall efficiency of the collector was increased.

At 9.00am, the radiation intensity was 685 W/m2, and it progressively grew until 1 pm, when it reached a maximum of 890 W/m2. After that, the radiation intensity gradually reduced. As solar radiation rises, more heat is absorbed by the ETC absorber tube, which is then transferred into the HX, raising the temperature to a maximum of 95°C. According to Arora et al. (2011), the increased overall effectiveness of parallel ETC is primarily dependent on solar energy absorption. To prevent convective and conductive heat loss, the tubes in the inner vacuum tube absorbed the heat and stored them.

Comparison of outlet temperature of ETC

ETC surrounding tubes improved heat conductivity and convective heat transfer capacitydue to Brownian motion–induced convection of nanoparticles. Brownian motion is incapable of operating under static conditions and has an outstanding effect when used in an evacuated collector system due to the fact that nanofluids flow in tubes. The Brownian motion method of cluster formation uses clusters of nanotubes for transfer of large energy, enhancing the performance of the collector. There was an increase in the rate of heat transfer of nanofluids depending on the size of the nanoparticles. As a result, concentration of CuO nanofluids exhibited better thermal properties..

Figure 6 shows the experimental outlet temperature of ETC with variations over time at water-vol % CuO at FRof 0.035, 0.045, and 0.065 lit/sec. At a rate of 0.035 lit/sec, the outlet temperature of ETC using water-0.3vol% CuO, water-0.2vol% CuO, and water-0.1vol % CuO nanofluids reached 95°C, 93.5°C, and 91.8°C, respectively, and water temperature exceeded 90°C. Under the same circumstances, at the flow of 0.045 lit/sec, decreases in the temperature were 93.5°C, 92°C, 90.3°C, and 88.4°C and, at the rate of 0.065 lit/sec decreases in the temperature were 92.1°C, 90.6°C, 88.9°C, and 87°C correspondingly. When ETC used water-0.3vol % CuO nanofluids at a FR of 0.035 lit/sec, the outlet temperature was superior to 0.045, 0.065 lit/sec.

The amount of thermal energy transmitted and increase in heat absorbed when a concentration of water-0.3vol% CuO nanofluids were used as a working medium. Compared to water-vol% CuO nanofluids, this improved the solar collector’s thermal efficiency resulting in less external heat loss. Earlier studies the absorption of a larger amount of heat at a low rate while releasing less amount of radiant heat loss compared to a high FR. Therefore, at a FR of 0.035 lit/sec compared to 0.045, 0.065lit/sec absorbed more energy. At 1–2 P.M., more energy was absorbed at water-0.3vol%. CuO nanofluids at a FR of 0.035 lit/sec due to high intensity of radiation, less humidity ratio, and environment loss being small. A heat loss factor ((Ti-Ta)/G was employed in the analyze of the solar collector’s thermal efficiency due to alterations having a substantial impact on it. Furthermore, the optimum efficiency of the solar collector was at Ti = Ta, and when the heat loss factor increased, the efficiency declined.

Comparison of efficiency of ETC

Analysis of the efficiency of the ETC collector in terms of operating temperature and concentration of water-CuO nanofluids showed an increase in the temperature of the nanofluidsfrom 5 to 7°C with a different FR. A linear increase in thermal conductivity of CuO nanofluids was seen with a higher percentage of nanofluids and at a operating temperature, the system’s linearity improvedUnder all operating conditions, the ETC using CuO nanofluids with 40 nm-sized nanoparticles was reasonably compact and effective. Figure 7 shows the ETC collector efficiency with water-0.3vol%, water-0.2vol%, water-0.1vol% nanofluids and water as a working fluid at FR of 0.035 lit/sec, 0.045 lit/sec, and 0.065 lit/sec. The overall performance of a solar collector using water-0.3vol% CuO nanofluids was better than water-0.2vol%, water-0.1vol% CuO nanofluids, and water under the same operating conditions.

Fluctuation in the collector’s efficiency were more in the beginning with a reduction over time. However, up to 1–2 P.M., there was a gradual improvement in efficiency. The highest efficiency of 80.2% was attained between 1 and 2 PM using water-0.3vol%. Water-0.2vol% CuO nanofluids at 78.3%, water-0.1vol%. CuO nanofluids were 76.4%, and water was 74.5% at the FR of 0.035 lit/sec, respectively. Under the same conditions, temperature decreases at the FR of 0.045 lit/sec were 78.5%, 76.6%, 74.7%, and 72.8%, while at the rate of flow of 0.06 lit/sec, they were 76.7%, 74.8%, 72.9%, and 71%, respectively. ETC’s performance when using water-vol%, CuO and water as working fluid with FR of 0.045 and 0.065 lit/sec was higher at 0.035 lit/sec due to increase in the thermal conductivity of the nanofluids relative to the concentration of 0.3vol% CuO, and its corresponding the efficiency also higher than 0.2vol% CuO, 0.1vol% CuO and water. Increase in the aggregation stability of scattering and viscosity helped a significant growth in the boundary layer on the surface of the wall with the use of the Brownian motion method of cluster formation with a concentration of water-0.3vol% CuO nanofluids. The value gradually dropped as a result of heat loss from the environment and a reduction in solar radiation intensity. This occurrence showed the heat loss of ETC with water-0.3vol% CuO nanofluids as lower than that of water-0.2vol%, water-0.1vol%, and water by 1.9%, 3.8%, and 5.7%, respectively.

The ETC comparison of different nanofluids provided information on nanoparticle size, fluid flow, tilt angle, concertation of the nanofluid mixed with water, FR of nanofluid, and efficiency. CuO/water, SWCNT/water, Al2O3/water, and TiO2/water were the nanofluids used in the comparison. The greater the volumetric percentage of nanofluids in the water improved efficiency, while a decrease in the FR improved efficiency. Table 2 shows a comparison of efficiency with previous research experiment.

Conclusion

Experiments with FR of 0.035, 0.045, and 0.065 lit/sec and different combinations of working medium of water-vol% CUO nanofluids were performed for the determination of the efficiency of ETC. The conclusions showedan increase in the aggregation stability of scattering and viscosity, assisting a significant growth in the boundary layer on the surface of the wall with the use of the Brownian motion method of cluster formation with a concentration of water-vol% CuO nanofluids which improve the thermal efficiency. The findings of the experimentled to the following conclusions.

-

1.

The outlet temperatures of ETC using water-0.3vol%. CuO nanofluids achieved the highest figures of 95°C, water-0.2vol%. CuO nanofluids at 93.5°C, water-0.1vol%. CuO nanofluids were 91.8°C, and water was 90°C at 0.035 lit/sec flow, respectively. Temperature decrease under similar conditions at theFR of 0.045 lit/sec were 93.5°C, 92°C, 90.3°C, and 88.4°C. At the FR of 0.065 lit/sec, the figures were 92.1°C, 90.6°C, 88.9°Cand 87°C respectively.

-

2.

The outlet temperatures of ETC using water-0.3vol%. CuO nanofluids at a FR of 0.035 lit/sec was more than FR of 0.045, 0.065 lit/sec.

-

3.

The maximum efficiency of the collector was 80.2% with the use of water-0.3vol% CuO nanofluids, water-0.2vol% CuO nanofluids at 78.3%, water-0.1vol%. CuO nanofluids were 76.4%, and water was 74.5% at the FR of 0.035 lit/sec, respectively. With similar conditions and at the FR of 0.045 lit/sec, decreases in the temperature were 78.5%, 76.6%, 74.7%, and 72.8% and a rate of 0.065 lit/sec, decreases in the temperature were 76.7%, 74.8%, 72.9%, and 71% respectively.

-

4.

The efficiency of ETC using water-0.3vol% CuO nanofluids atFR of 0.035 lit/sec was more than water-0.2vol%, water-0.1vol%. CuO nanofluids and water working fluid as well as the flow of 0.045 and 0.065 lit/sec.

-

5.

A significant improvement was seen when water-0.3vol%.CuO nanofluids were used in the ETC, the performance compared to the water-0.2vol%. CuO nanofluids, water-0.1vol%. CuO nanofluids and water.

Future commendation for futhur use

The thermal efficiency of solar collectors utilizing nanofluids as working fluids is the subject of this research. More research is required, however, in the gain of more profound expertise in nanofluids. The inference of thermal conductivity and outlet temperature from nanofluids has been used in this analysis. Particle size, shape, mass concentration, volume concentration, agglomeration, and sedimentation are all parameters of nanoparticles that have a significant impact on the thermal conductivity of nanofluids will need more attention in the future. Apart from that, a study of advanced nanofluid characteristics and how they are used in solar energy–harvesting systems are needed. Enhancement of the efficiency and performance of collectors using nanofluids requires determination of the optimal FR of nanofluids in solar thermal systems.

Data availability

All data are given in the manuscript.

Change history

01 July 2024

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s11356-024-34168-y

Abbreviations

- ETC:

-

evacuated tube collector

- FR:

-

flow rate

- HX:

-

heat exchanger

References

Alim MA, Abdin Z, Saidur R, Hepbasli A, Khairul MA, Rahim NA (2013) Analyses of entropy generation and pressure drop for a conventional flat plate solar collector using different types of metal oxide nanofluids. Energy and Buildings 66:289–296

Al-Mashat SMS, Hasan AA (2013) Evaluation of convective heat transfer and natural circulation in an evacuated tube solar collector. J Eng 19(5):613–628

Arora S, Chitkara S, Udayakumar R, Ali M (2011) Thermal analysis of evacuated solar tube collectors. J Petrol Gas Eng 4(2):74–82

Asirvatham LG, Vishal N, Gangatharan SK, Lal DM (2009) Experimental study on forced convective heat transfer with low volume fraction of CuO/water nanofluid. Energies 2(1):97–119

Ayompe LM, Duffy A, Mc Keever M, Conlon M, McCormack SJ (2011) Comparative field performance study of flat plate and heat pipe evacuated tube collectors (ETCs) for domestic water heating systems in a temperate climate. Energy 36(5):3370–3378

Chakraborty S, Panigrahi PK (2020) Stability of nanofluid: a review. Appl Therm Eng 174:115259

Chaudhary Y, Kalamkar B, Patel P, Mali J, Patel P (2017) CFD analysis of evacuated tube heat pipe solar water heater. Int J Lat Technol Eng VI(VS):73–77

Chougule SS, Pise AT, Madane PA (2012) Performance of nanofluid-charged solar water heater by solar tracking system. In IEEE-international conference on advances in engineering, science and management (ICAESM-2012) (pp. 247-253). IEEE

Delouei AA, Sajjadi H, Mohebbi R, Izadi M (2019) Experimental study on inlet turbulent flow under ultrasonic vibration: pressure drop and heat transfer enhancement. Ultrason Sonochem 51:151–159

Ghaderian J, Sidik NAC (2017) An experimental investigation on the effect of Al2O3/distilled water nanofluid on the energy efficiency of evacuated tube solar collector. Int J Heat Mass Transf 108:972–987

Ghaderian J, Sidik NAC, Kasaeian A, Ghaderian S, Okhovat A, Pakzadeh A et al (2017) Performance of copper oxide/distilled water nanofluid in evacuated tube solar collector (ETSC) water heater with internal coil under thermosyphon system circulations. Appl Therm Eng 121:520–536

He Q, Zeng S, Wang S (2015) Experimental investigation on the efficiency of flat-plate solar collectors with nanofluids. Appl Therm Eng 88:165–171

Hematian A, Bakhtiari AA (2015) Efficiency analysis of an air solar flat plate collector in different convection modes. Intl J Green Energy 12(9):881–887

Hlaing S, Soe MM (2012) Design calculation and heat transfer analysis of heat pipe evacuated tube solar collector for water heating. Intl J Sci Eng Technol Res (IJSETR) 1(1):1–5

Hussain HA, Jawad Q, Sultan KF (2015) Experimental analysis on thermal efficiency of evacuated tube solar collector by using nanofluids. Intl J Sustain Green Energy 4(3-1):19–28

Huu-Quan D, Rostami AM, Rad MS, Izadi M, Hajjar A, Xiong Q (2021) 3D numerical investigation of turbulent forced convection in a double-pipe heat exchanger with flat inner pipe. Appl Therm Eng 182:116106

Izadi M, Assad MEH (2021) Use of nanofluids in solar energy systems. In Design and Performance optimization of renewable energy systems (pp. 221-250). Academic Press

Izadi M, Bastani B, Sheremet MA (2020a) Numerical simulation of thermogravitational energy transport of a hybrid nanoliquid within a porous triangular chamber using the two-phase mixture approach. Adv Powder Technol 31(6):2493–2504

Izadi M, Behzadmehr A, Shahmardan MM (2014) Effects of discrete source-sink arrangements on mixed convection in a square cavity filled by nanofluid. Korean J Chem Eng 31(1):12–19

Izadi M, Ghalambaz M, Mehryan SAM (2020b) Location impact of a pair of magnetic sources on melting of a magneto-Ferro phase change substance. Chin J Phys 65:377–388

Izadi M, Shahmardan MM, Behzadmehr A (2013a) Richardson number ratio effect on laminar mixed convection of a nanofluid flow in an annulus. Intl J Comput Meth Eng Sci Mech 14(4):304–316

Izadi M, Shahmardan MM, Rashidi AM (2013b) Study on thermal and hydrodynamic indexes of a nanofluid flow in a micro heat sink. Challenges Nano Micro Scale Sci Technol 1(1):53–63

Izadi M, Shahmardan MM, Behzadmehr A, Rashidi AM, Amrollahi A (2015) Modeling of effective thermal conductivity and viscosity of carbon structured nanofluid. Challenges Nano Micro Scale Sci Technol 3(1):1–13

Kadyan H (2018) Performance analysis of evacuated tube collector. Int J Appl Eng Res 13(13):11344–11348

Kalbande SR, Khambalkar VP, Priyankanayak SD (2016) Development and evaluation solar still integrated with evacuated tubes. Intl J Res Appl 4:99–106

Kang W, Shin Y, Cho H (2019) Experimental investigation on the heat transfer performance of evacuated tube solar collector using CuO nanofluid and water. J Mech Sci Technol 33(3):1477–1485

Kim H, Ham J, Park C, Cho H (2016) Theoretical investigation of the efficiency of a U-tube solar collector using various nanofluids. Energy 94:497–507

Kumar SBS, Chinnapandian M (2018) Experimental study on the thermal efficiency of the forced convection evacuated tube solar air collectors with and without absorber plate. J Ind Pollut Control 34(1):1839–1846

Kumar Y, Yadav A (2015) Thermal performance comparison of evacuated tube solar water heater with different shapes of flow passage in the tube. J Energy Res Environ Technol 2(4–5):8

Lanjwani HB, Chandio MS, Anwar MI, Shehzad SA, Izadi M (2021) Dual solutions of time-dependent magnetohydrodynamic stagnation point boundary layer micropolar nanofluid flow over shrinking/stretching surface. Appl Math Mech 42(7):1013–1028

Lu L, Liu ZH, Xiao HS (2011a) Thermal performance of an open thermosyphon using nanofluids for high-temperature evacuated tubular solar collectors: Part 1: Indoor experiment. Sol Energy 85(2):379–387

Lu L, Liu ZH, Xiao HS (2011b) Thermal performance of an open thermosyphon using nanofluids for high-temperature evacuated tubular solar collectors: Part 1: Indoor experiment. Sol Energy 85(2):379–387

Lu L, Liu ZH, Xiao HS (2011c) Thermal performance of an open thermosyphon using nanofluids for high-temperature evacuated tubular solar collectors: Part 1: Indoor experiment. Sol Energy 85(2):379–387

Mahendran M, Lee GC, Sharma KV, Shahrani A, Bakar RA (2012a) Performance of evacuated tube solar collector using water-based titanium oxide nanofluid. J Mech Eng Sci 3:301–310

Mahendran M, Lee GC, Sharma KV, Shahrani A, Bakar RA (2012b) Performance of evacuated tube solar collector using water-based titanium oxide nanofluid. J Mech Eng Sci 3:301–310

Mehryan SAM, Ghalambaz M, Feeoj RK, Hajjar A, Izadi M (2020a) Free convection in a trapezoidal enclosure divided by a flexible partition. Int J Heat Mass Transf 149:119186

Mehryan SAM, Tahmasebi A, Izadi M, Ghalambaz M (2020b) Melting behavior of phase change materials in the presence of a non-uniform magnetic-field due to two variable magnetic sources. Int J Heat Mass Transf 149:119184

Moghadam AJ, Farzane-Gord M, Sajadi M, Hoseyn-Zadeh M (2014) Effects of CuO/water nanofluid on the efficiency of a flat-plate solar collector. Exp Thermal Fluid Sci 58:9–14

Mujawar NH, Shaikh SM (2016) Thermal performance investigation of evacuated tube heat pipe solar collector with nanofluids. Int J Eng Sci Res Technol 5(12):924–837

Nakra BC, Chaudhry KK (2003) Instrumentation, measurement and analysis. Tata McGraw-Hill Education

Patel M, Patel K (2013) A critical review of evacuated tube collector. Intl J Adv Eng Res Studies 2(3):55–56

Ramesh GK, Shehzad SA, Izadi M (2020) Thermal transport of hybrid liquid over thin needle with heat sink/source and Darcy–Forchheimer porous medium aspects. Arab J Sci Eng 45(11):9569–9578

Rashak QA, Ala'a AJ, Khanfoos HN (2016) Improving the productivity of solar still using evacuated tubes. Intl J Energy Environ 7(5):375

Sabiha MA, Saidur R, Hassani S, Said Z, Mekhilef S (2015a) Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers Manag 105:1377–1388

Sabiha MA, Saidur R, Hassani S, Said Z, Mekhilef S (2015b) Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers Manag 105:1377–1388

Sabiha MA, Saidur R, Mekhilef S, Mahian O (2015c) Progress and latest developments of evacuated tube solar collectors. Renew Sust Energ Rev 51:1038–1054

Sajjadi H, Delouei AA, Mohebbi R, Izadi M, Succi S (2021) Natural convection heat transfer in a porous cavity with sinusoidal temperature distribution using Cu/water nanofluid: Double MRT lattice Boltzmann method. Commun Comput Phys 29(1):292–318

Shahrestani AB, Alshuraiaan B, Izadi M (2021) Combined natural convection-FSI inside a circular enclosure divided by a movable barrier. Intl Commun Heat Mass Transf 126:105426

Sharma A, Pathak AK (2016) Evacuated tube solar collector’s importance and innovations in wide range applications. Intl J Sci Technol Adv 2(4):39–44

Shehzad SA, Alshuraiaan B, Kamel MS, Izadi M, Ambreen T (2021a) Influence of fin orientation on the natural convection of aqueous-based nano-encapsulated PCMs in a heat exchanger equipped with wing-like fins. Chem Eng Process Process Intensification 160:108287

Shehzad SA, Mabood F, Rauf A, Izadi M, Abbasi FM (2021b) Rheological features of non-Newtonian nanofluids flows induced by stretchable rotating disk. Phys Scr 96(3):035210

Thomas P, Ajith P, Palayakkodan A, Natarajan M (2014) Experimental analysis of evacuated tubular collectors with plain & concave reflectors. Intl J Eng Sci Res Technol 3(4):852–855

Wang Q, Li J, Yang H, Su K, Hu M, Pei G (2017) Performance analysis on a high-temperature solar evacuated receiver with an inner radiation shield. Energy 139:447–458

Xiong Q, Altnji S, Tayebi T, Izadi M, Hajjar A, Sundén B, Li LK (2021a) A comprehensive review on the application of hybrid nanofluids in solar energy collectors. Sustain Energy Technol Assess 47:101341

Xiong Q, Hajjar A, Alshuraiaan B, Izadi M, Altnji S, Shehzad SA (2021b) State-of-the-art review of nanofluids in solar collectors: a review based on the type of the dispersed nanoparticles. J Clean Prod 310:127528

Xiong Q, Tayebi T, Izadi M, Siddiqui AA, Ambreen T, Li LK (2021c) Numerical analysis of porous flat plate solar collector under thermal radiation and hybrid nanoparticles using two-phase model. Sustain Energy Technol Assess 47:101404

Yadav S, Manchanda H, Kumar M, Kumar R, Scholar R (2017) Stepped and evacuated tube collector coupled solar stills: a comprehensive review. no, 4, 2394-0697

Yan SR, Izadi M, Sheremet MA, Pop I, Oztop HF, Afrand M (2020) Inclined Lorentz force impact on convective-radiative heat exchange of micropolar nanofluid inside a porous enclosure with tilted elliptical heater. Intl Commun Heat Mass Transf 117:104762

Acknowledgements

The authors are appreciative to Kings Engineering College’s Principal and management for their cooperation in completing this research endeavor.

Author information

Authors and Affiliations

Contributions

BabuSasi Kumar Subrananiam: project administration, writing original manuscript and software; Arun Kumar Sugumaran: review and editing: MuthuManokar Athikesavan: formal analysis, review and editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1007/s11356-024-34168-y

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Subrananiam, B.S.K., Sugumaran, A.K. & Athikesavan, M.M. RETRACTED ARTICLE: Improving the performance of novel evacuated tube solar collector by using nanofluids: experimental study. Environ Sci Pollut Res 30, 12728–12740 (2023). https://doi.org/10.1007/s11356-022-22998-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22998-7