Abstract

This paper shows the comparison of the various conventional technologies used for desalination and the advantages of using renewable energy such as solar and geothermal in place of them. The comparative analyses of the various techniques using geothermal and solar have been included. The efficiency, productivity rate, cost, etc. have been compared. Productivity of multi-effect distillation—thermal vapor compression (MED-TVC) is 75–80 m3/h of freshwater. In comparison to other techniques, electricity generation is high in multi-effect distillation—thermal vapor compression (MED-TVC). It has been observed that renewable energy gives the cheapest solution to the water desalination problems. Despite of having many flaws, RO is considered to be one of the efficient technologies for the seawater desalination. The study shows that solar still is relatively cheaper and more efficient than all the other techniques used. The efficiency of the solar still ranges between 22 and 34%, and in the best conditions, the efficiency also reaches 40% producing 5–7 l/m2/day. The knowledge of the various technologies discussed can be studied, and then further study on the renewable desalination technologies can be carried out. In the future, this technology is going to play an important role as many researches are going on in this field. The geothermal future is going to play an important role in energy production. The efficiency of the desalination system using solar and geothermal energy has higher efficiency and productivity rate than other older techniques and which can be further increased by modification in the system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is one of the fundamental substances for the existence of life. Though it covers three fourths of the Earth’s surface, there is a shortage of drinking water. Availability of water is boon and scarcity is a curse (Fotouhi and Kresic 2010). Seawater desalination supplies 97 million m3 of freshwater daily to more than 300 million people worldwide. Almost 70% of the global water demand is from the agricultural sector, and the rest is from the industrial and agricultural sectors (Martínez-Alvarez et al. 2018). The shortage of potable water is one of the major concerns in most developing countries including India. Around 2.5% of the Earth’s water is occupied by freshwater which satisfies the potable water needs of humans and other living beings, and the rest of the Earth’s water is seawater which is around 97.5%. Ten thousand of oil per year is required to produce freshwater per day. Around one third of the world’s population lives in countries that have insufficient resources of freshwater. It is very necessary to minimize the deficiency in countries with a shortage of freshwater. To minimize this, a large number of efforts is to be put on. The feed water for the desalination plant is mainly seawater or brackish water (Mechell and Lesikar 2021). The salinity of the seawater ranges from 35,000 to 45,000 ppm while the salinity of drinking water should be between 500 and 1000 ppm. The total dissolved salts in water should be less than 500 ppm (Thu 2010).

It becomes necessary to put efforts to desalinate the seawater and to make it potable. Also, the sources of freshwater are limited and the population using freshwater is increasing day by day (Gude, 2018). So, it becomes necessary to increase the quantity of freshwater. Due to such requirements, desalination of saline water becomes very much necessary. The seawater is available so much in quantity but cannot be used for any purpose and remains unused. Therefore, there must be a technique or technology, which can be used to make this saline water into potable water using desalination techniques. The installed capacity of the desalination plant has reached about 128 million (Cherif and Belhadj 2018). The minimum calculated energy required for desalination is 0.706 kWh. Desalinating the seawater reduces its salt content, brings down the ppm of the water, adds minerals to it, and makes it useful for living beings (Petrovic et al. 2018). The minimum calculated energy required for desalination is 0.706 kWh.

There are various types of desalination techniques used nowadays. Some of them are solar desalination, geothermal desalination, vapor compression desalination, multi-stage flash desalination, etc. The most used desalination technique in remote arid areas is the evaporation-condensation process (Alkaisi et al. 2017). Out of all renewable sources, solar energy is available in abundance on the Earth and so it has a large potential as desalination. Use of solar desalination gives more eco-friendly and also solves the water scarcity problem. Further solar energy can be converted to various other forms, and so, it gives a wide variety of choices. Mostly small-scale solar desalination plant is desirable to produce potable water (Alnaimat et al. 2018). Solar desalination consists of a solar flat plate collector, evacuated tube, concentrating solar troughs, and solar pond. Solar desalination plays an important role in rural areas having low infrastructure and without connection to a grid. The solar desalination process can be of two types direct and indirect. In direct type, the solar energy is directly absorbed by saline water while in the indirect technique, the solar energy is first absorbed by a solar collector and then is transferred to saline water. The major technologies used for solar desalination are membrane technology and thermal desalination technology (Tzen et al. 2012). Environmental impacts are considerably less than other technologies. The unfertile land which cannot be used for agriculture can be used for establishing the solar desalination plant. Waste products of the solar desalination process (i.e., brine) can be further utilized in other types of industries and that decreases environmental hazards. Solar desalination has its benefit as simple in construction. This type of process also has low maintenance requirements.

Another technique used nowadays is desalination by geothermal technique. Geothermal energy is mostly available in countries such as Japan, Iceland, the USA, and China. Geothermal desalination provides the solution to global clean water desalination (Awerbuch et al. 2017). Geothermal energy ensures stable and reliable energy for desalination. The primary and most important heat source for geothermal is magma (Palmer 2003). In addition to this, the isotopes of uranium, thorium, and potassium also play an important role and are a secondary source of heat. The thermal energy of around 1.3 × 1027 J can be estimated at the depth of 10 km and the same can be obtained by burning 3 × 1017 barrels of oil. The hydrothermal reservoir at the depth of 10 km is sufficient enough to supply all mankind’s power needs and that too for several million years. We can have 300 °C temperature at the depth of 10 km as the temperature of the Earth goes on increasing 30 °C/km of depth. Geothermal resources can be classified according to the type of rocks and the temperature available. The resources where the temperature is below 150 °C are used for heating and cooling directly which is used by almost 72 countries in the world while the resource where the temperature is above 150 °C is used for electricity and power generation which is used by the 24 countries in the world. The temperature range varies between 20 and 300 °C. The most important use of the geothermal resource is its direct application where its heat is directly used. Some of the major applications are heat pumps, heating of a building, raising plants in a greenhouse, drying crops, etc. (Semancik and Lizak 1986). High-enthalpy geothermal energy can be directly transmitted to reverse osmosis units (Jimenez et al. 2016). The combination of renewable energy such as geothermal with desalination plays a very important role in increasing the water supply in the regions where water is scarce. The main advantage of this hybrid technology is that it is pollution-free. This hybrid technology also overcomes the price rise of fuels. When geothermal energy is passed over thermoelectric generator, it produces the freshwater at the rate of 22,072 m3/day. Geothermal energy with a desalination unit is used to heat the saline water, and this saline water is further treated to obtain the potable water (Prajapati et al. 2021). Low-enthalpy geothermal energy can be used for desalination purposes. The installation cost of geothermal desalination is very high (Goosen et al. 2010).

The scarcity of potable water is a major problem nowadays. Also, the decreasing level of groundwater is a major concern. In some areas of the world, there is no means to obtain potable water. Even though 97% of the area is surrounded by water this problem persists. The main problem with this is the salt available in the seawater. The salty water can be directly taken into use for drinking purposes. Many different types of processes has to be carried to make this water use for a different purpose. Various conventional methods were used earlier and are also used nowadays, but they are so expensive and also some of them are not eco-friendly. The largest installed desalination technique is reverse osmosis (Sadhwani Alonso and Melián-Martel 2018). The main aim is to provide more pure and healthy potable water by using renewable resources. Renewable resources are available free of cost, and they are also not going to extinct in the future and also they are eco-friendly. The concepts enlightened here are using low enthalpy geothermal energy and solar energy for the desalination purpose. The aim is to make potable water or useful water available to regions where water is scarce at a very low cost and highly efficient manner.

Classification of conventional techniques for desalination

There are various techniques used for the desalination of seawater. Some of them are conventional and some are modern techniques. There is very much scarcity of fresh water and so the desalination techniques play a very important role. In recent decades, the installed capacity of desalination plants has increased tremendously which has reached about 128 m3/day. For centuries, desalination is carried out to obtain fresh potable water.

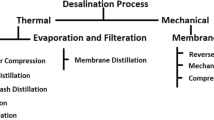

The classification of conventional desalination technologies are shown in Fig. 1.

Desalination techniques are as follows:

-

1.

Membrane technology:

-

Reverse osmosis (RO)

-

Forward osmosis (FO)

-

Electrodialysis (ED)

-

2.

Chemical techniques:

-

2.

-

Ion exchange (I.EX)

-

Gas hydrate (G.HYD)

-

Liquid-liquid extraction (LLE)

-

3.

Adsorption techniques:

-

3.

Membrane technology

The first most important and widely used conventional desalination technology is membrane technology. In membrane technology, a membrane of a thin sheet of material which is generally cellulose acetate is used to separate contaminants and foreign particles from water. Membranes works on the principle of separation of the particles due to their size and charge (Youssef et al. 2014). The commonly used membrane technologies are reverse osmosis, forward osmosis, and electrodialysis (Nagy 2019).

RO

Reverse osmosis is a very old technology and is being used since the 1960s. It uses the membrane barrier for the separation of salt particles from saline water. Reverse osmosis also consumes less energy than the distillation process used for water purification (Menningmann 2011). Reverse osmosis requires an osmotic membrane. The function of the osmotic membrane is that it does not allow the salt to pass through it at the rate at which it allows the water to pass through it (Kim et al. 2013). Reverse osmosis is also known as a semi-permeable membrane because it allows only some constituents to pass through it while holding others. To separate unwanted dissolved particles (solutes), this process only requires pressurized feed water and does not require any heating or phase change (Shatat and Riffat 2014). Generally, the Ro plant consists of five main components such as saline water supply line, high-pressure pump, pretreatment, posttreatment system, and membrane separation.

FO

Forward osmosis uses osmotic pressure difference created between semipermeable membranes which separate two solutions having different amounts of concentration (Cath et al. 2006). The type of forwarding osmosis membrane is asymmetric. It uses a very thin and selective layer of the membrane. For mechanical stability, it uses one support layer of the membrane (Tiraferri et al. 2013). The membrane of the dense polymer matrix is used in forwarding osmosis. The main components of forwarding osmosis techniques are pump, pipes, valves, and feed stream pretreatment system. The integration of both namely forward osmosis and backward osmosis is also used nowadays for water desalination.

ED

Electrodialysis technique is the combination of two processes namely dialysis and electrolysis (Scarazzato et al. 2020). ED is generally a membrane process in which under the influence of an electric potential the ions are transported through a semi-permeable membrane. The membranes can be selected as cation or anion that decides the flow of ions through the membrane. ED provides better control over the product quality as compared to thermal and pressure-based desalination techniques (Karimi et al. 2018). ED is less economical than reverse osmosis and ultrafiltration (Xu and Huang, 2008).

Chemical techniques

The second important technique used for desalination is the chemical technique. In this type of technique, certain types of chemicals are dissolved in the saline water to carry out the desalination process. The various types of chemical techniques are ion exchange, gas hydrate, and liquid–liquid exchange.

I.EX

It is a process in which from liquid phase the ions are interchanged with ions which are electrostatically bounded to the groups contained inside a solid matrix. It was observed that ion exchange can be considered as a reversible chemical process. The ion exchange plays an important role in modifying the zeolite characteristics. Ion exchange is the most utilized technique to reduce the polluting cations from wastewater (Cobzaru and Inglezakis 2015).

G.HYD

Gas hydrates are one of the important techniques for water treatment of seawater. The desalination using gas hydrate is a physical process that separates the solid particles from liquid. The materials used for gas hydrates are methane and ethane (Khan et al. 2019). By measuring the conductivity of the dissociated hydrates the efficiency of salt removal can be determined (Khan et al. 2019).

LLE

LLE is a process to differentiate the compounds based on their relative solubility in the mixture of two different liquids (Mandal et al. 2015). The principle of liquid–liquid extraction is that the sample which has to be tested is made to get separated between two solvents in which the sample and matrix have different solubility. The major benefit of this type of technique is the wide availability of the solvents and also at low costs.

Adsorption techniques

The main components of the adsorption technique used for desalination are:

-

(a)

Pumps

-

(b)

Evaporator beds

-

(c)

Adsorption and desorption reaction beds

-

(d)

Condenser

-

(e)

Facilities for pretreatment (Shahzad et al. 2018)

The adsorption process works on the principle of absorbing the water vapor on the surface of adsorbent (such as silica gel, zeolite, and activated carbon) by van der Waal’s force or polar bonding force. Adsorption based technology has the capacity to convert the feed water having high salinity to low salinity water and with low running cost of 0.2$/m3 (Youssef et al. 2014).

Limitation of conventional desalination techniques

The main disadvantage of conventional desalination technologies is the energy requirement and also cost is increasing day by day. The by-products of the desalination process which are chemicals such as like chlorine, hydrochloric acid etc. should be treated well before disposal as they are an environmental concern. The disposal of the brine directly into the ocean is also the major drawback of conventional techniques. Due to brine disposal and chemical disposal, marine life is directly affected. The chemicals used earlier in the conventional techniques are harmful to human health. The energy is depleting day by day, and therefore, the conventional techniques using nonrenewable energy become drawback.

Solar desalination

For many years, renewable energy has played an important part in the production of energy resources. The cost of nonrenewable energy is also increasing with the energy demand. So, it becomes necessary to make much and much use of renewable energies such as solar, wind, etc. With the increase in population the scarcity of potable water is also increasing. So, if we link renewable energy to overcome this issue it would be a great benefit for society. Such a technology developed is called desalination using solar energy. Solar desalination provides a better way to produce potable water at the minimum cost and zero environmental problems. Generally, desalination is the process of separating the salt particles and the unwanted minerals present in the saline water or brackish water to make it potable. In recent times, there are various technologies in solar desalination such as membrane technique, solar still, solar pond, multi-flash distillation, electrodialysis, and chemical techniques. The major benefit of the desalination plant is that it provides drinking water in excess. It is very much useful in countries where the scarcity of freshwater is a major concern. Further, the desalinated water meets all the quality index of the potable water, and thus, it reduces the pressure on the freshwater sources. It not only provides potable water but also this desalinated water can be used in an agricultural field. In arid regions where the farmers did not have direct access to irrigation water, this technology plays an important role such as in countries of Africa. The main disadvantage of solar desalination is weather conditions. The required solar energy might not be available for more than 8 months. Further, it requires a large amount of energy. Gallons of seawater are required to produce fresh water at a time. It is advantageous and disadvantageous at the same time. If this technology is used in hybrid mode, it overcomes its all limitations and pays well to the society.

Altarawneh et al. (2020) carried out the study of solar desalination under concentrated solar flux and reduced pressure conditions in man, Jordan. The main objective was to study the performance of parabolic trough collectors (PTC) under reduced pressure. Results showed that under reduced pressure the efficiency increases up to 58% than normal or atmospheric pressure. Due to this, the productivity of PTC increases and reaches about 2.9 l/h. It was observed that the reduced pressure experiment increases productivity by 397%.

Chauhan et al. (2021) carried out a comprehensive review of direct solar desalination techniques at IIT BHU, Varanasi, India. Day by day, the demand for freshwater is increasing with the increase in population. They suggested the use of solar energy to produce freshwater. It was found that the cost of the RO plant is 33% lesser than the other conventional techniques. The study reviewed the various techniques of desalination such as solar still. There is a direct effect on the cost as we change the desalination technique.

Chen et al. (2020) experimented with the use of direct spray in solar desalination in Makkah, Saudi Arabia. the research presented the use of low-temperature spray technology in combination with solar desalination. The proposed design was able to give an output near to the water supply of 20 kg/day and which further can be increased by some modifications. When the area of the collector is 360 m2, the annual productivity becomes maximum with the feed flow rate of 1.7 kg/s and the diameter of the storage tank to be 1.9 m. The cost due to this technology decreases up to $1.29/m3 and which is much lesser than the thermal desalination technique.

Mayere (2011) experimented on solar power desalination at the University of Nottingham. The system using humidification/dehumidification is more efficient than other conventional techniques. The main aim was to provide potable water to the one billion populations. Both theoretical and experimental analysis were carried out, and it was found that potable water output up to 20 kg/h and having COP value of 3 can be produced. It was found that the system can be manufactured by low-cost plastics rather than costlier and toxic metals.

Shatat et al. (2016) experimented on an innovative psychometric solar-powered water desalination system at the University of Nottingham. The capital cost and the running cost of the desalination system are lowered by advancements in technology. They used evacuated tube collectors instead of solar concentrator collectors. Synthetic brackish water was used for the study. They found that at a temperature ranging between 55 and 60 °C, 6 kg/h of clean water is produced. It was observed that when the temperature is increased the quality of the water also increases. This type of system can be a great asset in the countries like Africa, Middle East, and Asia.

Mitra et al. (2014) studied solar desalination using an adsorption technique at IIT Madras and IISC Bangalore. They wanted to make the desalination process easily available. The use of renewable energy as an energy source for desalination by replacing simple techniques with solar-driven adsorption desalination systems. Conventional desalination processes have more operating costs. Further, this system utilizes low-grade heat from the nonconventional type of collectors. It was observed that by increasing the quality of the condenser and evaporator the quality of the adsorption technique can be increased.

Dastjerdi and Citation (2020) suggested the integrated solar membrane-based desalination with wastewater treatment. The main aim of the study was to estimate the performance of the system and to find the optimum physical behavior of the solar and desalination system. The proposed design successfully removes all foreign materials from the wastewater. The production of potable water increases up to 37% when engaged with a cooling unit.

Aburideh et al. (2012) and Arunkumar et al. (2012) carried out a similar study on solar desalination using solar still at Tiara, Algeria, and Coimbatore, India, respectively. It was found that the efficiency of the solar still directly depends upon its inclination angle of the cover. The cover angle may be 15°, 25°, 35°, 45°, and 55°. The maximum efficiency was found when the angle was in the range of 23°–35°. The average field of distilled water obtained by this water was found to be 3–4 l/m2/day.

El-Aziz et al. (2013) and Ghermandi and Messalem (2009) have done their research on solar desalination using the RO technology at El Arich valley and Abu Dhabi, respectively. The cost was found to be in the range of $3–7/m3, and the daily production was found to be as maximum as 150 m3. The power required for the production was 11.25 kW in the case of Andrea’s study and was 86 kW in the case of Saitou’s study.

Comparative analysis of different solar desalination techniques are mentioned in Table 1.

Among all the solar desalination techniques, solar still seems to be productive at a very low operating cost. The initial investment of the solar still is also less compared to other technology (Ortiz et al. 2007). The high capital cost is counter-balanced by the low operating cost (Belessiotis et al. 2016). The unused land can be used for the establishment of the plant. The desalination takes place based on condensation and evaporation. The process of the solar still is so simple, at first saline water is pumped into the solar still and is rested under the solar light. The water evaporates and is collected at the dome and is further condensed to get the pure potable water. The efficiency of the solar still ranges between 22 and 34%. In the best conditions, the efficiency can reach up to 40% (Belessiotis et al. 2016). It can produce 5–7 l/m2/day. The simple diagram of solar still is shown in Fig. 2.

Geothermal desalination

With the increase in the population, the demand of the freshwater is constantly increasing. Further, the energy which is used for the production of the freshwater is also high and hence the cost for production increases. In this age of increasing demand of the freshwater and the increasing price rise the use of geothermal energy plays a very important role. In geothermal, the heat of the Earth’s core is used for the desalination purpose. In geothermal, the heat of the core is used to make steam which can be used further for the desalination and also for the power generation. The temperature range available for use is between 150 and 350 °C. The steam obtained by the process is estimated 175–200 °C. Most of the geothermal sites are found to be in the western USA. The geothermal energy can be divided into low-grade and high-grade resources. Mostly high grade is used for power production and lower grade can be used for the desalination. The low-grade geothermal is very useful and is also underused. The simple working process is shown in Fig. 3. The water which has to be desalinated is pumped to the system. The water is then injected inside the core using the injection well. Gaining the heat water evaporates and comes out of the well. Using certain technologies and adding some minerals to it, we can obtain the fresh potable water. The cost for the production is estimated between $1.5 and 2.5/m3.

Chandrasekharam et al. (2019) formulated the research on the basis that the freshwater would be in scarcity in near future at Djibouti. The main objective was to make freshwater available for all the classes of society. To use renewable energy for desalination so that the cost of potable water can be reduced and a self-sustainable society can be created. The data of fossil fuels and renewable energy over the years were analyzed, and the results were compared to analyze the cost for the production of freshwater. It was observed that the geothermal energy required for desalination is 900 × 106 kWh which is far less than the electricity required. The cost for desalination using geothermal energy is US $1.6/m3, which is very less compared to other techniques. The population living in rural can increase their economic status and the poverty level of Djibouti can be reduced by using geothermal energy resources.

Yousefi et al. (2017) evaluated the technology of the desalination using hybrid solar-geothermal desalination at Tehran, Iran. The objective was to overcome the shortage of drinking water by using geothermal desalination techniques. The cost of freshwater production was too high. So, the aim was to tackle the challenges in using renewable energy as an energy source. Geothermal energy has a major benefit over other renewable energy as it can produce energy 24 h/day. This combined hybrid system of solar and geothermal can be used for various purposes such as space heating-cooling. Results showed that this system is flexible and economical. This hybrid technology turns out to be very effective in arid regions. Further, this technology will allow the countries to overcome their shortage of potable water and to produce it at a very low cost.

Turchi et al. (2017) studied the desalination of impaired water at Ormat’s Tuscarora plant in northern Nevada. He showed the integration of geothermal energy with membrane technology. Tests were performed and results were noted. The kind of antifouling coatings which has to be applied and also cost was taken into consideration. The main aim was to make use of the underused geothermal resources for desalination purposes. This technology cost was estimated between $1.4 and 1.6/m3. However, the proposed design was not that cost-effective as compared to nanofiltration. “Hot nanofiltration” can produce high-quality potable water using geothermal brines. This technique may be applicable to reverse osmosis and membrane desalination techniques.

Davies and Orfi (2014) studied the desalination of groundwater sources and technical feasibility of self-powered geothermal desalination at four different locations such as India, Saudi Arabia, Tunisia, and Turkey. The main objective was to carry out the technical feasibility and its study for desalination purposes. The study focused on the organic Rankine cycle which will drive reverse osmosis. The results were compared under ideal, semi-ideal, and real-life assumptions taking four different case studies. Results showed that the recovery rate was around 0.99 when all the four case studies were studied. It showed that the recovery ratio mostly depends upon the source temperature of the geothermal energy source. This study showed the possibility of the self-powered desalination system without using any external source.

Gude (2016) explained the potential of the geothermal resources for desalination using case studies at different locations such as India, Australia, and the USA. The study shows the present scenario of the geothermal resources and their benefits over all the other energy sources. The advantages of geothermal over all the other conventional and nonconventional sources were described and also the future perspective with this technique was studied. It was observed that the cost for desalination was around $1.15/m3 using geothermal while if we use other sources it was found around $4.80/m3.The geothermal energy sources provide an better alternative with zero environmental pollution and also at low cost. The geothermal source is estimated to increase and mainly as a heat source and electricity generation.

Christ et al. (2017) carried out the study and analysis of geothermal energy sources based on its thermos-economic factor using hot sedimentary aquifers for western Australia. The study showed the framework for thermo-economic assessment of sub-surface and surface low-grade energy system components. Additionally, they used to advance technology such as multi-effect desalination. The use of geothermal energy in the areas of Western Australia proved to be very reliable. The estimated cost for the water production was found to be 2.60$/m3.The survey showed that the preheated multi-effect desalination (MED) lies in the economic range. The importance of energy extraction was analyzed in the case of conventional MED, the preheated MED, and the boosted MED. And so the study showed the reduction of the unit cost to upto13%-16%.

Goosen et al. (2010), Ghaffour et al. (2014) and Turchi et al. (2015) have studied the Multi-effect desalination using geothermal energy at Colorado (US), Wairakei (NZ), and Thuwal (Saudi Arabia) respectively. The study showed that the available geothermal energy is about 11.2MW. With the use of this technology the temperature of the water obtained goes up to 160-190 °C by Craig's study while it is above 250 °C according to the study of Mathews and Thomas. The productivity according to Craig was found around 426m3/day while the research of Mathews showed that the productivity is 75-80 m3/day and the highest productivity was by the study of Thomas and that was 25000 m3/day. The efficiency of the system from Craig’s study was found highest ranging between 40 and 55%. The other two were found less efficient.

Missimer et al. (2016), Salehi et al. (2018), and Gnaifaid and Ozcan (2021) have carried out their study on the geothermal desalination using multi-effect desalination at Tabriz (Iran), Krabuk (Turkey), and Saudi Arabia, respectively. With the use of geothermal as a direct heat source, they also found its use in electricity generation. The temperature of the water was found 2200 °C in the case of Rosen’s study while it was in the range of 150–300 °C in the other two cases. The efficiency of all the three studies was very near and was ranging between 35 and 50%. The cost of the whole setup was estimated at around $17/m3.The comprehensive comparative analysis of different geothermal desalination techniques is mentioned in Table 2.

The cost for geothermal production well is comparatively high. If we combine geothermal energy with desalination technology, we can generate electricity, as well as production of freshwater can be done. We can establish this plant where the geothermal energy temperature range is between 300 and 350 °C. From all the geothermal technologies used for desalination, the most used and reliable one is multi-effect distillation. The multi-effect distillation–thermal vapor compression seawater plant produces the freshwater directly. Above the MED evaporator, the recirculate seawater is sprayed and which results in the evaporation of a fraction of water. The freshwater is then obtained by condensing this evaporated water. In this way, fresh potable water is obtained. Productivity of multi-effect distillation–thermal vapor compression (MED-TVC) is 75–80 m3/h of freshwater. In comparison to other techniques, electricity generation is high in MED-TVC.

Challenges and future scope

Solar still cannot remove microorganisms; it only can separate freshwater from saline water (Mathioulakis et al. 2007). The main challenge is low-energy recovery and the presence of noncondensable gases in the dehumidifier. It reflects in low performance and high cost of water production. Relatively low permeate flux in comparison with pressure-based membrane processes. It is caused by concentration polarization and fouling of the membrane. It causes high cost and high thermal energy consumption. High operating cost when waste heat is not available for the distillation. This system operates at high temperatures which increases corrosion. Desalination plants are very costly to build and operate the plant. Selection of location for the desalination plant is very difficult. High energy is required to operate the desalination plant. Sometimes, it increases the production cost of freshwater. Another disadvantage is the environmental impact. Disposal of salt which is removed from saline water is the major issue. This charge is called brine. Brine can change the salinity of water and lower the amount of oxygen in the water at a disposal site. It causes the death of animals and birds because of the higher level of salt in water at a disposal site. In the desalination process, some chemicals like chlorine, hydrochloric acid, anti-scaling, etc. are used and which are also harmful to the environment. In geothermal water desalination, operation cost is very high and the efficiency of the plant is relatively low.

We should attach the filtration plant with solar still to overcome the challenges faced (Mathioulakis et al. 2007). The pairing of technologies such as MED with thermal collectors will play an important role in the future (Trivedi Hetal and Bhatt 2011). We should supply freshwater streams directly to infiltration plants so that energy is consumed in the process. By following this, usage of this technology in the future can be increased. Improving the design and efficiency of heat exchangers or using a better efficient heat exchanger and can provide a better option for the humidification and dehumidification desalination process. The efficiency of the system can also be increased. Use good quality membrane material is the option to avoid polarization, and it will improve the efficiency of the technologies using membrane can be improved shortly. The membrane technology using electricity are the systems going to be mostly used in the future (Ahmadi et al. 2020). Improve the efficiency of the waste heat recovery system. Because of water desalination plants, we can produce freshwater from saline water. This produced freshwater will increase the overall percentage of fresh water, and it will reduce pressure on natural freshwater resources. To improve the efficiency of geothermal water desalination plant, we must have to improve the efficiency of every important piece of equipment of the plant for example heat exchanger, pump, blower, evaporator, and regenerator. Renewable energy distillation will provide a reliable source, sustainability, and also reduces the carbon footprint (Alkaisi et al. 2017). The use of ocean thermocline energy for the desalination system will prove to be an excellent strategy for producing potable water (Esmaeilion 2020). It is shown that the integration of the power and the gas sector will reduce the overall cost of 1–3% per year (Caldera et al. 2017). Along with the purification of the seawater, the emphasis should be laid on the purification of the brackish water so that the content of freshwater can be increased (Reif and Alhalabi 2015). The efficiency of above 95% can be obtained by using Cu2ZnSnS4 (CZTS)-based photocathode during seawater desalination after testing for almost 500 h. The highly efficient and promising seawater desalination is the combination of redox flow and ion exchange membrane (IEM) (Xu et al. 2020).

Conclusion

In this study, a comprehensive review was conducted. Since many years, fossil fuels have been used to generate power, and these energies are becoming extinct. The use of renewable energy instead of fossil fuels is an alternative. This renewable energy will also be used to produce potable water. One third of the world’s population lives in areas where drinking water is scarce. Furthermore, due to the high ppm of seawater, it cannot be used directly as drinking water. To make it potable, various types of treatment must be performed. Desalination of seawater reduces its saline content, lowers its ppm, and adds some minerals. Seawater reduces its saline content, brings down its ppm, and adds some required minerals. Some of the concluding remarks are listed as follows:

-

Different types of techniques are used nowadays and which are conventional techniques have been studied. It was found that using renewable energy techniques in place of such conventional techniques gives rise to productivity and is much reliable. The cost of the overall production can be minimized, and it is also environment friendly.

-

In renewable sources, solar and geothermal energy has its importance. Various geothermal and solar energy based desalination technologies discussed in this paper.

-

Geothermal energy provides a better alternative to a conventional energy source. The efficiency of the geothermal desalination is found around 30–35%.

-

Desalination system mostly depend on the geothermal and solar energy are becoming more common on the planet. Furthermore, in solar integrated desalination system, maintaining the cost of a solar collector /plate is higher, and the heat flax is not consistent. At the same time, geothermal integrated desalination is not as expensive, and it provides a consistent heat flux. The largest barrier to using geothermal energy to power the desalination system is the geographical area with an excess of heat that is readily available.

At last, in the future, new technical developments in absorption heat pump designs, hybrids with other renewable energy sources, and salt recovery will increase the process’s energy efficiency and process economics.

Data availability

All relevant data and material are presented in the main paper.

References

Aburideh H, Deliou A, Abbad B, Alaoui F, Tassalit D, Tigrine Z (2012) An experimental study of a solar still: application on the sea water desalination of Fouka. Proc Eng 33:475–484. https://doi.org/10.1016/j.proeng.2012.01.1227

Ahmadi E, McLellan B, Mohammadi-Ivatloo B, Tezuka T (2020) The role of renewable energy resources in sustainability of water desalination as a potential fresh-water source: an updated review. Sustainability (Switzerland) 12(13). https://doi.org/10.3390/su12135233

Alkaisi A, Mossad R, Sharifian-Barforoush A (2017) A review of the water desalination systems integrated with renewable energy. Energy Procedia 110(December 2016):268–274. https://doi.org/10.1016/j.egypro.2017.03.138

Alnaimat F, Klausner J, Mathew B, (2018) Solar desalination. IntechOpen. 127–150. https://doi.org/10.5772/intechopen.76981

Altarawneh I, Batiha M, Rawadieh S, Alnaief M, Tarawneh M (2020) Solar desalination under concentrated solar flux and reduced pressure conditions. Sol Energy 206(June):983–996. https://doi.org/10.1016/j.solener.2020.06.058

Arunkumar T, Jayprakash R, Denkenberger D, Ahsan A, Okundamiya MS, Kumar S, Tanka H, Aybar HS (2012) An experimental study on a hemispherical solar still. Desalination 286:342–348

Auti AB (2012) Domestic solar water desalination system. Energy Procedia 14(2011):1774–1779. https://doi.org/10.1016/j.egypro.2011.12.1166

Awerbuch L, Van der Mast V, Canton G (2017) Geothermal desalination potential for clean and affordable new water solutions. Presented at IDA internationaL energy and environment forum creative solutions and innovative strategies for today's water challenges 1–9

Belessiotis V, Kalogirou S, Delyannis E, (2016) Solar distillation - solar stills. Thermal solar desalination. Methods and Systems. https://www.sciencedirect.com/book/9780128096567/thermal-solar-desalination

Caldera U, Bogdanov D, Afanasyeva S, Breyer C (2017) Role of seawater desalination in the management of an integrated water and 100% renewable energy based power sector in Saudi Arabia. Water (Switzerland) 10(1):3. https://doi.org/10.3390/w10010003

Cath TY, Childress AE, Elimelech M (2006) Forward osmosis: principles, applications, and recent developments. J Membr Sci 281(1–2):70–87. https://doi.org/10.1016/j.memsci.2006.05.048

Chandrasekharam D, Lashin A, Al Arifi N, Al-Bassam AM, Varun C (2019) Geothermal energy for desalination to secure food security: case study in Djibouti. Energy Sustain Soc 9(1). https://doi.org/10.1186/s13705-019-0206-3

Chaouachi B (2011) Solar desalination, desalination, trends and technologies, Dr. Michael Schorr (Ed.), InTech, Available from: http://www.intechopen.com/books/desalinationtrends-andtechnologies/solar-desalination

Chauhan VK, Shukla SK, Tirkey JV, Singh Rathore PK (2021) A comprehensive review of direct solar desalination techniques and its advancements. In: In Journal of Cleaner Production, 284th edn. Elsevier Ltd, Oxford. https://doi.org/10.1016/j.jclepro.2020.124719

Chen Q, Alrowais R, Burhan M, Ybyraiymkul D, Shahzad MW, Li Y, Ng KC (2020) A self-sustainable solar desalination system using direct spray technology. Energy 205:118037. https://doi.org/10.1016/j.energy.2020.118037

Cherif H, Belhadj J (2018) Environmental life cycle analysis of water desalination processes. In: Sustainable Desalination Handbook. Elsevier, Amsterdam, pp 527–559. https://doi.org/10.1016/B978-0-12-809240-8.00015-0

Christ A, Rahimi B, Regenauer-Lieb K, Chua HT (2017) Techno-economic analysis of geothermal desalination using hot sedimentary aquifers: a pre-feasibility study for Western Australia. Desalination 404:167–181. https://doi.org/10.1016/j.desal.2016.11.009

Cobzaru C, Inglezakis V (2015) Ion exchange. In: Progress in Filtration and Separation. Elsevier Ltd., Oxford. https://doi.org/10.1016/B978-0-12-384746-1.00010-0

Compain P (2012) Solar energy for water desalination. Proc Eng 46(0):220–227. https://doi.org/10.1016/j.proeng.2012.09.468

Csányi L, Krištof V, Kušnír S, Katin M, Marci M (2010) Geothermal energy. Intensive programme. Renew Energy Sources 21–25

Dastjerdi AS, Citation R (2020) Edith Cowan University. The Grants Register. Palgrave Macmillan, London. 2021, 344–345. https://doi.org/10.1057/978-1-349-95988-4_335

Davies PA, Orfi J (2014) Self-powered desalination of geothermal saline groundwater: Technical feasibility. Water (Switzerland) 6(11):3409–3432. https://doi.org/10.3390/w6113409

Deniz E (2015) Solar-Powered desalination. IntechOpen 89–123. http://dx.doi.org/10.5772/60436

El-Aziz KM, Hamza K, El Morsi M, Nassef AO, Metwalli SM, Saitou K (2013) Optimum solarpowered hdh desalination system for semi-isolated communities. Proceedings of the ASME 2013 Int Des Eng Tech Conf and Comp Inf Eng Conf 1–9

Esmaeilion F (2020) Hybrid renewable energy systems for desalination. In Applied Water Science, 10, 3 edn. Springer International Publishing, Cham. https://doi.org/10.1007/s13201-020-1168-5

Fotouhi F, Kresic N (2010) Springwater treatment. In: Groundwater Hydrology of Springs, 1st edn. Elsevier Inc., Amsterdam. https://doi.org/10.1016/B978-1-85617-502-9.00007-4

Ghaffour N, Lattemann S, Missimer T, Ng KC, Sinha S, Amy G (2014) Renewable energy-driven innovative energy-efficient desalination technologies. Appl Energy 136:1155–1165. https://doi.org/10.1016/j.apenergy.2014.03.033

Ghermandi A, Messalem R (2009) Solar-driven desalination with reverse osmosis: The state of the art. Desalin Water Treat 7(1–3):285–296. https://doi.org/10.5004/dwt.2009.723

Gnaifaid H, Ozcan H (2021) Development and multiobjective optimization of an integrated flash-binary geothermal power plant with reverse osmosis desalination and absorption refrigeration for multi-generation. Geothermics 89(September 2020):101949. https://doi.org/10.1016/j.geothermics.2020.101949

Goosen M, Mahmoudi H, Ghaffour N (2010) Water desalination using geothermal energy. Energies 3(8):1423–1442. https://doi.org/10.3390/en3081423

Gude VG (2016) Geothermal source potential for water desalination - current status and future perspective. Renew Sust Energ Rev 57:1038–1065. https://doi.org/10.1016/j.rser.2015.12.186

Gude VG (2018) Geothermal source for water desalination-challenges and opportunities. In: Renewable Energy Powered Desalination Handbook: Application and Thermodynamics, vol 1. Elsevier Inc. https://doi.org/10.1016/B978-0-12-815244-7.00004-0

Gude VG, Khandan NN (2006) Solar desalination. Southern Illinois University Carbondale OpenSIUC. 1–13

Harrison DG, Mathew K, Ho GE, Kutay C, Mathew K, Ho G (1991) Appropriate technology for aboriginal enterprise development. In: Ho G. ( ed ) Seminar on appropriate technology for remote communities, organised by Newman Campus, Hedland College and Remote Area Dev 49–54

Jiménez HA, Rosa-Urbalejo D, García-Gutiérrez A (2016). Desalination using geothermal energy. GRC Transactions 40:141–146

Karimi L, Ghassemi A, ZamaniSabzi H (2018) Quantitative studies of electrodialysis performance. Desalination 445(June):159–169. https://doi.org/10.1016/j.desal.2018.07.034

Kaviti AK, Ram AS, ArunaKumari A, Hussain S (2020) A brief review on high-performance nano materials in solar desalination. Mater Today: Proc xxxx. https://doi.org/10.1016/j.matpr.2020.09.466

Khaghani A (2013). Dual thermal system for power and fresh water production. https://researchrepository.rmit.edu.au/esploro/outputs/doctoral/Dual-thermal-system-for-power-and-fresh-water-production/9921861234401341#files_and_links

Khan MN, Peters CJ, Koh CA (2019) Desalination using gas hydrates: the role of crystal nucleation, growth and separation. Desalination 468(July):114049. https://doi.org/10.1016/j.desal.2019.06.015

Kim J, Hamza K, El Morsi M, Nassef AO, Metwalli S, Saitou K (2013) Design optimization of a solar-powered reverse osmosis desalination system for small communities. Proceedings of the ASME Design Engineering Technical Conference, 3 A(August). https://doi.org/10.1115/DETC2013-12654

Kolahi MR, Amidpour M, Yari M (2020) Multi-objective metaheuristic optimization of combined flash-binary geothermal and humidification dehumidification desalination systems. Desalination 490(February):114456. https://doi.org/10.1016/j.desal.2020.114456

Li C (2012) Innovative desalination systems using low-grade heat. Thesis, January, 1–211. http://scholarcommons.usf.edu/etd/4126/. Accessed 1 Nov 2022

Mandal SC, Mandal V, Das AK (2015) Extraction of botanicals. Essentials of Botanical Extraction, 63–82. https://doi.org/10.1016/b978-0-12-802325-9.00005-7

Martínez-Alvarez V, González-Ortega MJ, Martin-Gorriz B, Soto-García M, Maestre-Valero JF (2018) Seawater desalination for crop irrigation-current status and perspectives. In Emerging Technologies for Sustainable Desalination Handbook. https://doi.org/10.1016/B978-0-12-815818-0.00014-X

Mathioulakis E, Belessiotis V, Delyannis E (2007) Desalination by using alternative energy: Review and state-of-the-art. Desalination 203(1–3):346–365. https://doi.org/10.1016/j.desal.2006.03.531

Mayere A (2011) Solar powered desalination. PhD thesis, University of Nottingham. Book, 1(1)

Mechell JK, & Lesikar B (2021) Desalination methods for producing drinking water. https://agrilifeextension.tamu.edu/library/water/desalination-methods-for-producing-drinking-water/. Accessed 1 Nov 2022

Menningmann J (2011) reverse osmosis.pdf

Missimer TM, Choon Ng K, Thuw K, WakilShahzad M (2016) Geothermal electricity generation and desalination: an integrated process design to conserve latent heat with operational improvements. Desalin Water Treat 57(48–49):23110–23118. https://doi.org/10.1080/19443994.2016.1144693

Mitra S, Srinivasan K, Kumar P, Murthy SS, Dutta P (2014) Solar driven adsorption desalination system. Energy Procedia 49:2261–2269. https://doi.org/10.1016/j.egypro.2014.03.239

Mohiuddin AKM, Hoda A (2011) Alternative energy. IIUM Press 1–269

Nagy E (2019) Forward osmosis. Basic Equations of Mass Transport Through a Membrane Layer, 2016, 447–456. https://doi.org/10.1016/b978-0-12-813722-2.00017-0

Ortiz JM, Expósito E, Gallud F, García-García V, Montiel V, Aldaz A (2007) Electrodialysis of brackish water powered by photovoltaic energy without batteries: direct connection behaviour. Desalination 208(1–3):89–100. https://doi.org/10.1016/j.desal.2006.05.026

Palmer A (2003) Geothermal energy. Geogr Rev 17(2):2–5. https://doi.org/10.4324/9781315766416-22

Petrovic A, Delibasic B, Filipovic J, Petrovic A, Lomovic M (2018) Thermoeconomic and environmental optimization of geothermal water desalination plant with ejector refrigeration system. Energy Convers Manag 178(December 2017):65–77. https://doi.org/10.1016/j.enconman.2018.10.035

Prajapati M, Shah M, Soni B, Parikh S, Sircar A, Balchandani S, Thakore S, Tala M (2021) Geothermal-solar integrated groundwater desalination system: Current status and future perspective. Groundw Sustain Dev 12:100506. https://doi.org/10.1016/j.gsd.2020.100506

Quteishat K, Abu-arabi M (2006) Promotion of solar desalination in the MENA region. Middle East Desalination Centre, Muscat, Oman, 1–11. Oman?. http://www.menarec.com.Cndocs/Abu-Arabi.pdf. Accessed 1 Nov 2022

Reif JH, Alhalabi W (2015) Solar-thermal powered desalination: its significant challenges and potential. Renew Sust Energ Rev 48:152–165. https://doi.org/10.1016/j.rser.2015.03.065

Sadhwani Alonso JJ, Melián-Martel N (2018) Environmental regulations-inland and coastal desalination case studies. In: In Sustainable Desalination Handbook: Plant Selection, Design and Implementation. Elsevier Inc, Amsterdam. https://doi.org/10.1016/B978-0-12-809240-8.00010-1

Salehi S, Mahmoudi SMS, Yari M, Rosen MA (2018) Multi-objective optimization of two double-flash geothermal power plants integrated with absorption heat transformation and water desalination. J Clean Prod 195:796–809. https://doi.org/10.1016/j.jclepro.2018.05.234

Scarazzato T, Barros KS, Benvenuti T, Rodrigues MAS, Espinosa DCR, Bernardes AMB, Amado FDR, Pérez-Herranz V (2020) Achievements in electrodialysis processes for wastewater and water treatment. In: In Current Trends and Future Developments on (Bio-) Membranes. Elsevier Inc., Amsterdam. https://doi.org/10.1016/b978-0-12-817378-7.00005-7

Semančík P, Lizák F (1986) Geothermal resources. Intensive Programme, Environmental Impacts of Power Industry, June, 1–6

Shahzad MW, Burhan M, Ang L, Ng KC (2018) Adsorption desalination-principles, process design, and its hybrids for future sustainable desalination. In: In Emerging Technologies for Sustainable Desalination Handbook. Elsevier Inc., Amsterdam. https://doi.org/10.1016/B978-0-12-815818-0.00001-1

Shatat M, Riffat SB (2014) Water desalination technologies utilizing conventional and renewable energy sources. Int J Low-Carbon Technol 9(1):1–19. https://doi.org/10.1093/ijlct/cts025

Shatat M, Riffat S, Gan G (2016) An innovative psychometric solar-powered water desalination system. Int J Low-Carbon Technol 11(2):254–265. https://doi.org/10.1093/ijlct/cts075

Stefano F, Valentina G, Roberto B, Vito L, Riccardo G (2021, 114854) Setting up of a cost-effective continuous desalination plant based on coupling solar and geothermal energy. Desalination 500(October). https://doi.org/10.1016/j.desal.2020.114854

Thu K (2010) Adsorption desalination: Theory & Experiments. Doctoral Thesis. http://scholarbank.nus.edu.sg/handle/10635/17729. Accessed 1 Nov 2022

Tiraferri A, Yip NY, Straub AP, Romero-Vargas Castrillon S, Elimelech M (2013) A method for the simultaneous determination of transport and structural parameters of forward osmosis membranes. J Membr Sci 444:523–538. https://doi.org/10.1016/j.memsci.2013.05.023

Trivedi Hetal K, Bhatt DV (2011) Research Article: Renewable resources used for seawater. Int J Adv Eng Res Stud 1(1):35–41

Turchi CS, Akar S, Cath T, Vanneste J (2015) Use of low-temperature geothermal energy for desalination in the Western United States. November, 1–51

Turchi CS, Sertac A, Tzahi C, Johan V, Emily G (2017) Desalination of impaired water using geothermal energy. United States: Web

Tzen E, Zaragoza G, Alarcón Padilla DC (2012) Solar desalination. Comprehensive. Renew Energy 3(July):529–565. https://doi.org/10.1016/B978-0-08-087872-0.00316-4

Ullah I, Rasul MG (2019) Recent developments in solar thermal desalination technologies: A review. Energies 12(1). https://doi.org/10.3390/en12010119

Xu T, Huang C (2008) Electrodialysis-based separation technologies: a critical review. Seperations. AIChE J 54(12):3147–3159

Xu K, Wang C, Li Z, Wu S, Wang J (2020) Salt mitigation strategies of solar-driven interfacial desalination. Adv Funct Mater 2007855:1–26

Yousefi H, Mortazavi SM, Noorollahi Y, Mortazavi SM, Ranjbaran P (2017). A review of solar-geothermal hybrid systems for water desalination. Middle East Africa North America Asia South America Australia. 1–9

Youssef PG, Al-Dadah RK, Mahmoud SM (2014) Comparative analysis of desalination technologies. Energy Procedia 61:2604–2607. https://doi.org/10.1016/j.egypro.2014.12.258

Acknowledgements

The authors are grateful to Department of Mechanical Engineering, School of Technology and Department of Chemical Engineering, School of Energy Technology, Pandit Deendayal Energy University for the permission to publish this research.

Author information

Authors and Affiliations

Contributions

All the authors make a substantial contribution to this manuscript. PJ, SR, JP, and MS participated in drafting the manuscript. PJ, SR, and JP wrote the main manuscript. All the authors discussed the results and implication on the manuscript at all stages.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent for publication

Not applicable.

Ethics approval and consent to participate

Not applicable.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jha, P., Rajguru, S., Parmar, J. et al. A holistic study on geothermal and solar water desalination system for sustainable development. Environ Sci Pollut Res 30, 90–103 (2023). https://doi.org/10.1007/s11356-022-22987-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22987-w