Abstract

As industry is the world’s leading carbon emitter, promoting industrial carbon reduction is of key significance to carbon peak and carbon neutrality. Using a data-driven method, based on the collection and processing of relevant data from statistical yearbooks and others, we analyze the efficiency and amount of carbon emission of each industrial sector after processing multi-dimensional data by the improved IPCC EF method of calculating carbon emissions. In addition, we adopt the LMDI decomposition method for data modeling to measure the contribution of energy efficiency, industrial structure, GDP per capita, and population size to carbon emission changes, to identify targets for industrial carbon reduction, and to propose a targeted optimization path for carbon emission. We show how the method is implemented by taking the statistics of Anhui Province from 2010 to 2019 as an example and advises on an optimization path for carbon emission in Anhui Province. This study is of both theoretical and practical significance as it provides theoretical and methodological support for the low-carbon development of the regional industry, and provides a reference for other countries and regions to explore the path of low-carbon and environment-friendly green transformation and upgrading.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Intergovernmental Panel on Climate Change (IPCC 2014) is 95% certain that with the development of human society since the industrial revolution, the increase in greenhouse gas emissions is the direct cause of global warming. Global warming has caused and is causing a range of climate and environmental changes, including sea-level rise (Kirikkaleli and Sowah 2021), changes in the hydrosphere cycle (Kundzewicz 2008; Zhang et al. 2021a), ocean acidification (Iida et al. 2021), and increased frequency and intensity of extreme weather events (Zang et al. 2021; Naderi 2020), especially in regions that are more sensitive and vulnerable to climate change (Schneider et al. 2007; Gleick et al. 2010). As a result of global warming, climate change is affecting human production and life (Guo et al. 2021), such that reducing carbon emissions is a fundamental task for environmental protection and human survival and development (Shi et al. 2017). To mitigate and address global warming and control greenhouse gas emissions, many countries and international organizations have set avoiding an increase of less than 2 °C in global temperature (compared to that before the industrial revolution) as the goal of greenhouse gas emission reduction (Jiang and Fu 2012; Meinshausen et al. 2009; Allen et al. 2009). As the world’s largest carbon emitter, China has made an active commitment to combat climate change (Lin et al. 2021; Xi 2020). Industry has long been a driver behind China’s rapid economic growth and is also a major carbon emitter among all industries (Jin and Han 2021). As a result, encouraging industrial carbon peak is of key significance and a pressing issue for China as a whole to achieve peak carbon emissions (Lin et al. 2021; Yang et al. 2021a). The main tasks of carbon reduction at present also include understanding the current status of carbon emission, strengthening the management of total carbon emissions, and promoting the target setting of carbon control in key industries and regions.

Promoted carbon reduction will require firstly calculating the amount and identifying the sources of carbon emission, and secondly determining carbon efficiency and analyzing the factors behind carbon emission changes (Yang et al. 2021b). Regarding the calculation method of carbon emissions, two types of systems have been developed to calculate carbon emissions: top-down and bottom-up. The IPCC (2006) Guidelines for National Greenhouse Gas Inventories is a typical top-down system (Kalt et al. 2016; Schueler et al. 2018; Shan et al. 2017) and a widely used tool to calculate carbon emissions by setting an emission factor (EF) for each fuel and multiplying it by the fuel consumption. This system uses EF calculation to compile greenhouse gas inventories applicable to countries and regions, and provides default values for emission factors, which is widely used for its ease to calculate and obtain basic data. Peng et al. (2020) used this method to calculate the carbon dioxide generated by energy consumption during China’s construction of asphalt pavement. Gai et al. (2018) calculated the carbon emissions of thermal power plants by using the emission factor method. However, the calorific value and carbon content of raw coal in China are 40% lower than the recommended statistical value, so this method will result in the overestimation of China’s total carbon dioxide emissions (Liu et al. 2015). The bottom-up accounting system is formed based on the carbon emissions of enterprise products or projects, of which the representative one is life cycle assessment (LCA). Bi et al. (2022) used LCA to discuss the carbon emission of 378 wind farms and described the regional distribution of carbon emission of wind farms in the whole life cycle. Ma et al. (2021) used LCA to compare the carbon emissions of machine tools with different materials in their life cycle. However, this accounting system focuses on examining carbon emissions of specific products or enterprises. Therefore, it has limitations in measuring regional and sectoral carbon emissions. In addition, Fu et al. (2021) used the Greenhouse Gases Observing Satellite to estimate industrial carbon emissions at the city level, providing a new method for estimating carbon emissions.

Researches on carbon efficiency mainly lie in three aspects. First, measurement indicators and methods of carbon efficiency. Kaya and Yokobori (1997) first proposed the concept of carbon production efficiency, and then scholars proposed from different perspectives measurement indicators of carbon efficiency, such as carbonization index and carbon emission intensity (Mielnik and Goldemberg 1999; Wang et al. 2020a). Most of these indicators are single-factor measurements expressed by the ratio of total carbon emissions to a certain factor. However, carbon efficiency is the joint result of multiple factors such as energy consumption and economic development and it has the characteristics of all factors, so it is more scientific to consider a comprehensive indicator including related factors (Ramanathan. 2002). Based on this idea, some scholars take into account fixed capital, labor force, GDP, carbon emissions, etc. to determine the measurement indicators of carbon efficiency (Gao et al. 2020; Zhou et al. 2010). Data envelopment analysis (DEA) based on the all-factor idea is an important method to studying carbon efficiency. For example, based on the all-factor framework of energy efficiency, Yu and Chao (2012) used directional distance function and data envelopment analysis to estimate the energy efficiency and CO2 emission reduction potential of China’s industry from 2000 to 2009. Li et al. (2021) combined DEA with the Malmquist productivity index (MPI) to assess the carbon efficiency of 30 provincial regions in China from 2009 to 2015. Huang et al. (2021) used DEA to calculate the energy use efficiency of each province in China from the perspective of environmental constraints. Kong and He (2020) used the super efficiency DEA to measure and analyze the carbon efficiency of the Silk Road Economic Belt. Zhu et al. (2020a) estimated the carbon emission efficiency (CEE) of China’s energy-intensive industries at the provincial level through the three-stage DEA and analyzed the time–space distribution and influencing factors of CEE through spatial autocorrelation analysis and the Tobit model. Second, the measurement of carbon efficiency of different industrial sectors. Some scholars have studied the carbon efficiency of China’s manufacturing industry (Han et al. 2021; Li and Cheng 2020; An et al. 2021), and some scholars have also studied the carbon efficiency of some specific industries such as the petrochemical industry (Keivani et al. 2021), thermal power industry (Zhu et al. 2020b; Jiang et al. 2019a), and transportation industry from a micro-industry perspective. Third, the research on the influencing factors of carbon efficiency (Yu et al. 2021). Most scholars consider economic development (Zhang et al. 2021b; Khan et al. 2019), energy consumption (Salari et al. 2021; Chen et al. 2021), technology (Xie et al. 2021; Jiao et al. 2020), industrial structure (Zhang and Xu 2022), and trade (Naz et al. 2019) as important factors influencing carbon efficiency (Lu and Li 2020; Dalai et al. 2017).

The existing research results have laid a good foundation for carbon reduction. However, the measurement of carbon emissions, research objects, and research depth can be further improved.

-

(1)

Most existing research is carried out mainly by combining industrial and socio-economic statistical data. In this way, the research object is often not well balanced in spatial scale and industrial precision. Meanwhile, related data on regional industrial carbon emission cannot be fully mined and the potential of regional industrial and socio-economic data for carbon reduction cannot be fully realized.

-

(2)

The IPCC measurement method usually defaults the energy conversion rate to 1, without taking into account the fact that when CO2 is emitted, industrial enterprises will adopt certain processes to recover a fixed portion of CO2, which means that the carbon emissions calculated by this method are more than the actual emissions. At the same time, due to the differences in regional resource endowment, the measurement method of carbon emissions, when applied, should consider specific regions.

-

(3)

In the calculation of carbon emissions, current studies have not fully taken into account the strong regional characteristics of energy consumed by industrial production, such as heat generation and carbon oxidation rate. So the calculated carbon emissions may deviate from the actual emissions. The carbon reduction policy formulated based on carbon emissions is bound to be insufficient in regional pertinence.

To solve the above challenges, based on industrial sector-related statistics, this paper improves the existing measurement methods of carbon emissions to measure and analyze the spatio-temporal evolution characteristics of carbon emissions and carbon efficiency of regional industrial sectors and key industries, and uses the Logarithmic Mean Divisia Index (LMDI) model to analyze the contribution rates of each factor to carbon emissions. Based on this, a regional optimization path for carbon emission is proposed, which is of both theoretical and practical significance. Theoretical significance: (1) this study enriches and improves the measurement method of carbon emissions, evaluates more objectively the carbon emissions and carbon emission intensity of different industrial sectors and regions through data analysis, and thus provides a research foundation for proposing a targeted optimization path of carbon reduction. It offers methodological support for relevant researchers. (2) This paper uses the LMDI model to construct a model of influencing factors and analyze the contribution rates and the mechanism of influencing factors to carbon emission changes. Practical significance: (1) this paper can help the government and industry practitioners acquire a comprehensive and objective understanding of industrial carbon emission, discover the key factors affecting carbon emission, and seek effective paths for carbon reduction. (2) This paper is significant to promote the green transformation and upgrading of regional industry, encourage the balanced growth between the economy and environment of regional industry, and advance environmental protection and ecological conservation.

Method

This part introduces the measurement of regional industrial carbon emissions and carbon efficiency and the identification of influencing factors, which mainly describes the methods and strategies for data collection, processing, modeling, analysis, and application.

Research process

The industrialization has made significant contributions to socio-economic growth; however, industrial development also results in increased energy consumption and carbon emissions. Carbon reduction has become a focus of attention and research for scholars, industrial practitioners, and policymakers, and is a major issue to be addressed for sustainable development. Based on a comprehensive collection of regional industrial sub-sectors’ energy consumption and output value, this paper establishes an improved method to measure regional carbon emissions and carbon emission intensity; the LMDI is used to analyze the contribution rates of each factor to carbon emission changes. The research process is shown in Fig. 1.

Data collection and processing

The research collects data from industrial sectors of Anhui Province on the physical volume of consumption of 14 types of energy including coal, coke, crude oil, gasoline, kerosene, diesel, fuel oil, and natural gas, and on the industrial output value, which spans from 2010 to 2019. The data are from China Energy Statistical Yearbooks, Anhui Statistical Yearbooks, and statistical yearbooks of Anhui municipalities. In the data collation, two sectors with missing data (professional and auxiliary activities for mining; metal products, machinery, and equipment repair industry) are excluded. Besides, in the statistics before 2012, the rubber products industry and plastic products industry are merged as rubber and plastic products industry, and the automobile manufacturing industry and the manufacturing industry of railroad, ship, aerospace, and other transportation equipment are merged as transportation equipment manufacturing industry. The carbon emissions of the remaining 36 industrial sectors are measured and analyzed (see Table 1). Because of the changes in administrative divisions in Anhui Province during the research period, data of relevant areas are collected by counties, and the regional data are rectified on this basis.

Data model

Improve the measurement method of carbon emissions

This paper adopts the carbon emission coefficient method proposed by IPCC 2006 to measure carbon emissions from industrial sectors in Anhui Province. This IPCC-proposed method, however, defaults the energy conversion rate to 1, which does not fully take into account that when CO2 is emitted, industrial enterprises will adopt certain processes to recover a fixed part of CO2. As a result, the carbon emissions calculated by this method are more than the actual emissions. For example, Anhui Jinmei Jinlongyuan Chemical Co., Ltd. makes special industrial-grade and food-grade CO2 via recycling and purifying, while reducing CO2 emissions by 50,000 tons per year, a decrease of 83.3%. To estimate carbon emissions more accurately, the formula of the IPCC method is improved in this paper. See Formula 1.

Ci is the total carbon emissions of industry i; Cij is the carbon emissions of energy j in industry i; Eij is the total consumption of energy j in industry i; Hj is the carbon emission coefficient of energy j; Ki is the carbon oxidation rate; and Ri is the carbon sequestration coefficient. Based on the availability of data, this paper selects 14 types of energy, including coal, cleaned fine coal, other cleaned coal, coal products, coke, crude oil, gasoline, diesel, natural gas, and bioenergy, for calculation. The carbon emission coefficients defined by IPCC are based on calorific values. Since different energy sources have different calorific values, and different countries or regions have different calorific values for the same type of energy, the carbon emission coefficients used in this paper take the calorific values of different energy sources in China as the benchmark for calculation, i.e., the average low heating value (LHV) of different types of energy given in China Energy Statistical Yearbook. The calculation method is shown in Formula 2.

In Formula 2, Hj is the carbon emission coefficient of energy j, Hkj is the carbon emission coefficient of energy j given by IPCC in kg C/GJ, and Lj is the average LHV of energy j in GJ. Carbon emission coefficients and carbon oxidation rate and carbon sequestration coefficient are shown in Table 2, where the carbon oxidation and sequestration rates are cited from references Zhao (2012) and Wang (2017), respectively.

Formula 1 calculates carbon emissions of regional industrial sub-sectors. In order to measure the regional carbon efficiency, this paper adopts the indicator of carbon emission intensity, i.e., carbon emissions per 10,000 yuan of GDP, in tons per 10,000 yuan.

LMDI data modeling

As a common analytical tool in the field of energy economics, the index decomposition method decomposes aggregate changes into the incremental contributions of multiple dependent variable indicators based on different weight values (Ang 2004). The LMDI approach has become the most widely used index decomposition method due to its advantages of complete decomposition, no residuals, and allowing zero-valued data (Ang et al. 1998). In this paper, the LMDI decomposition method is used as the basis for building a data model to measure the contribution of different influencing factors to carbon emission changes (see Formula 3).

In Formula 3, Ci is the carbon emissions of sector i, Ei is the total energy consumption of sector i; Ui = Ei/Gi, which represents the energy consumption per unit of industrial output value in sector i, i.e., energy use efficiency. Si = Gi/G, which represents the share of industrial output value of sector i in total industrial output value, i.e., industrial structure. P = G/P, i.e., per capita GDP. I is the population size. From this, the changes in industrial carbon emissions in period t relative to the base period (period 0) can be decomposed as follows.

In Formula (4) is the industrial carbon emissions in period t and is the industrial carbon emissions in the base period; ΔCH, ΔCU, ΔCS, CP, and ΔCI represent the contribution rates to carbon emission changes by carbon emission coefficient, energy use efficiency, industrial structure, industrial output per capita, and total population, respectively. Among them, the carbon emission coefficient H of each energy source is relatively stable, so its influence on carbon emission changes can be ignored, i.e., ΔCH = 0.

For the contribution rates of each of the above influencing factors to carbon emission changes, the formula is as follows.

Meanwhile, the indicator of the contribution rate is calculated by Formula 6. The indicator can help compare the differences in the contribution of the influencing factors among different types of industries because it excludes the differences in the volume of carbon emissions of each industry. In this study, the LMDI formula is used for data modeling to decompose the factors behind the year-by-year carbon emission changes of various regional industrial sectors, and the contribution rates of each influencing factor are calculated.

Data application

In this paper, a method of carbon emission measurement and factor analysis is proposed to optimize the regional industrial carbon emissions by taking for example the research on carbon emission measurement and the low-carbon path of regional industry. The specific application of the method is shown in Fig. 2.

The first step collects various data such as regional industrial energy consumption and output value and processes the data. The second step improves the IPCC EF method by considering the regional resource endowment and the actual industrial carbon emissions to measure the regional carbon emissions and carbon efficiency. It can effectively distinguish the carbon emissions and carbon emission intensity of different regions and industrial sectors, and screen out regions and sectors that need to be focused on. In order to further analyze the influencing factors of carbon emission changes, based on the calculation of carbon emissions, the study uses LMDI to build a model to analyze the contribution rate of influencing factors to the changes in regional carbon emission. The third step, based on the measurement of regional industrial carbon emissions, carbon emission efficiency, and major influencing factors, puts forward policy suggestions for regional low-carbon paths.

Case study

Case study background

Anhui Province is located in East China, between 114°54′E-119°37′E and 29°41′N-34°38′N, with a total area of 140,100,000 km2. The terrain consists of plains, hills, and mountains, gradually rising from north to south. The land north of the Huaihe River is flat, which is the southern part of North China Plain and an important grain producer in Anhui. Between the Huaihe River and the Yangtze River are the Jianghuai hills. South of the Yangtze River is the low hilly area of southern Anhui (see Fig. 3), which accounts for 44.25% of the total area of Anhui. Anhui in the transition area between the warm temperate zone and the subtropical zone has four distinct seasons, a mild climate, and moderate rainfall.

Anhui is an important part of the Yangtze River Delta for it is a strategic hub in China’s economic growth and joins several major economic sectors in China. In 2019, Anhui, with a permanent population of 63.659 million, had a total output value of 3,711.398 billion yuan, of which the industrial output value was 1,145.485 billion yuan, accounting for 30.86% of Anhui’s total. The total industrial output value and its proportion in the province’s total output value respectively ranked 11th and 16th among the 31 provincial administrative regions in mainland China. As a big energy consumer in central China, China has seen a fast increase in industrial energy consumption since 2004. According to Anhui Statistical Yearbooks, the total energy consumption of the province increased from 94.14 million tons of standard coal in 2010 to 138.7 million tons in 2019, with an average growth rate of about 4.4%, which ranked 14th among provinces and regions in mainland China. From 2010 to 2019, the average share of industrial energy consumption in Anhui is 69%. It is estimated that the annual average of industrial carbon emissions in Anhui reached a huge amount of 110 million tons in the past 10 years. Therefore, this paper chooses Anhui Province as the research object of carbon emission measurement and low-carbon path optimization of regional industry. In this context, a comparative analysis of carbon emissions and carbon intensity in Anhui and Anhui cities is important for carbon reduction and the formulation of energy policies and the 14th Five-Year Plan.

Results

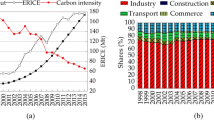

Analysis of industrial energy consumption structure in Anhui Province

Anhui is rich in coal. Its cities of Huainan and Huaibei are important coal bases in China, which are responsible for stably and reliably supplying energy to Anhui Province and even the Yangtze River Delta, which greatly affects the energy production and consumption structure of Anhui. From 2010 to 2019, the total industrial consumption of fossil and biological energy in Anhui was 1.515 billion tons of standard coal, with an average annual consumption of 152 million tons of standard coal, accounting for 66% of Anhui’s total energy consumption (see Fig. 4). Among the industrial energy consumption, the average annual consumption of raw coal was equivalent to 118 million tons of standard coal, and its total in the past 10 years was 1.179 billion tons, ranking first in all kinds of energy, accounting for 78% of the total consumption of fossil and biological energy for industrial use in Anhui, which, combined with cleaned fine coal and coke, reached as high as 92%. This indicates clearly a coal-based energy consumption structure, and the use of clean energy needs to be strengthened (see Fig. 4). Coal-based fossil energy has long dominated Anhui’s energy structure, which means that a very big challenge lies ahead to achieve the carbon reduction target. In order to achieve the low-carbon transformation of energy structure under carbon reduction, it is necessary to accelerate the adjustment of the primary energy structure and significantly increase the proportion of clean energy consumption.

Comparative analysis of total carbon emissions and carbon emission intensity by sub-sectors

After Formula 1 calculations, the industrial sectors in Anhui are divided into four categories according to their annual average carbon emissions and carbon emission intensity ranging from 2010 to 2019 (see Fig. 5, Table 1). The first category represents high carbon emissions and carbon emission intensity. Among the industrial sectors in Anhui in the last decade, the sector of production and supply of electric and heat power ranks first in terms of carbon emissions and carbon emission intensity. The carbon emissions were 35.13 million tons per year, accounting for 32% of the total carbon emissions in Anhui, and the carbon emission intensity is 7.35 tons per 10,000 yuan GDP. Followed are the sector of coal mining and washing and the sector of smelting and pressing of ferrous metals, respectively. The average annual carbon emissions of these three sectors totaled 71.205 million tons, accounting for 64.86% of the total industrial carbon emissions in Anhui. The total carbon emissions of the 11 sectors in the first category were 99.44 million tons, accounting for 90.57% of the total industrial carbon emissions (see Table 3). The second category includes 7 sectors such as chemical fiber manufacturing, which has lower carbon emissions and higher carbon emission intensity. The total annual average carbon emissions of this category were 1.95 million tons, but its average carbon emission intensity was 0.74, higher than the average of industrial sectors (see Fig. 5, Table 3). It shows that although the total carbon emissions of some sectors are relatively not high, they still have a high carbon emission intensity because their output value is low. The water production and supply sector, for example, is a public service sector with strong social attributes, which aims to provide low-priced public necessities to society. The government must take into account affordability, production costs, and policy preferences to promote water conservation when setting the price of water. Therefore, it is difficult for the water production and supply sector to make the desired profit and instead requires financial subsidies from the government to ensure normal operations.

The third category includes seven sectors such as electrical machinery and equipment manufacturing. This category has high carbon emissions and low carbon emission intensity. It shows that although the third category has high carbon emissions, its output value is also high, so it has low carbon emission intensity. The fourth category includes 11 sectors such as pharmaceutical manufacturing, with total carbon emissions of 1.99 million tons, accounting for only 1.81% of the total industrial emissions (see Fig. 5, Table 3). The above four categories of industrial sectors reflect the great difference in carbon emissions among industrial sectors in Anhui Province. In the context of carbon peaking and carbon neutrality, it is more important to focus on industries with high total carbon emissions, i.e., the first and third industrial sectors (Table 3).

Comparative analysis of industrial carbon emissions and carbon intensity in 16 regions of Anhui Province

Due to the differences in the natural environment, resource endowment, development history, total population, and city positioning, industrial development varies across Anhui, resulting in huge differences in energy consumption and carbon emissions in different regions. Between 2010 and 2019, among cities in Anhui, Ma’anshan ranked first with an annual average of 14.94 million tons of total carbon emissions, followed by Huaibei and Huainan, with 14.67 million tons and 13.84 million tons, respectively. The three together emitted 43.45 million tons, accounting for 48.22% of the province. Huangshan and Lu’an are rich in tourism resources because of the mountains in their territories, respectively, the Huangshan Mountains and the Dabie Mountains. In order to protect the beautiful natural environment, the two regions have corresponding policies to restrict the development of energy-intensive and high-polluting industrial enterprises, respectively, so the two regions have the least total industrial carbon emissions (see Fig. 6A).

Carbon emissions in Ma’anshan, Huainan, and Hefei have increased more significantly. Between 2010 and 2019, only five regions in Anhui—Anqing, Bozhou, Huaibei, Suzhou, and Tongling—had different degrees of carbon emission reduction in recent years (see Fig. 6B). The highest carbon emissions of Huaibei and Suzhou were in 2018 in the last 10 years; Anqing, Bozhou, and Tongling had their highest carbon emissions in 2017. When the changes in carbon emissions only in the last 5 years are measured, Tongling, Huaibei, and Suzhou have decreased more significantly. Especially Tongling for Tongling’s carbon emissions in 2019 decreased by 40.03% from 2015. Under the increasingly stringent carbon emission constraint, it may mean that these five regions have reached a carbon peak and will witness carbon emission reduction in the future. Of course, this is subject to further verification in the coming years.

The 2019 industrial carbon emission intensity in Anhui varied greatly among regions. Huaibei, Huainan, Ma’anshan, Tongling, Chizhou, and Suzhou ranked in the top six (see Fig. 7A). The carbon emission intensities of Huaibei, Huainan, and Ma’anshan were 4.02, 3.86, and 2.51 tons per 10,000 yuan GDP, respectively, reflecting the low energy use efficiency in these regions. Huainan and Huaibei are among China’s 13 major coal bases, which produce coal not only to meet the demand in Anhui province but also to supply the Yangtze River Delta, playing an important role in ensuring a safe and efficient energy supply in these areas. Ma’anshan is a large steel production base in Anhui, with a steel output of 19.03 million tons in 2019. The steel industry is a typical energy-intensive industry that consumes large amounts of energy during production. Traditional industries in Tongling, Chizhou, and Suzhou account for a high proportion, and the energy consumption is large, but the output value is limited, so the carbon emission intensity is relatively high. In 2019, Huangshan City had the lowest carbon emission intensity of 0.22 tons per 10,000 yuan GDP, followed by Chuzhou and Bozhou with 0.33 and 0.46, respectively. Huangshan, a World Natural and Cultural Heritage Site and a World Geopark, is known for its rich natural and humanistic landscape and excellent tourism management. Huangshan City, with well-developed tourism as its leading industry, restricts the development of energy-intensive industries in order to protect the development of its tourism and therefore has the lowest carbon emission intensity.

See Fig. 7B for the changes in carbon emission intensity by region in Anhui in the last decade. The highest carbon emission intensity in Anhui in the past 10 years is in Huaibei with an average of 3.59 tons per 10,000 yuan GDP, followed by Huainan with an average of 3.35. Ma’anshan ranks third with 2.08 tons per 10,000 yuan GDP. Huangshan City, Hefei, and Lu’an have the lowest carbon emission intensities with 0.17, 0.37, and 0.38 per 10,000 yuan GDP, respectively. Huainan, Ma’anshan, Huaibei, Tongling, etc. had different increases in carbon emission intensity, among which Huainan is more obvious. Suzhou, Fuyang, Bengbu, Hefei, Xuancheng, Chuzhou, and Anqing have different decreases in carbon emission intensity (see Fig. 7B).

It reflects that most regions in Anhui have an obvious improvement in carbon efficiency. However, the carbon emission intensity remains high in regions with rich resource endowments, and carbon emission reduction will still face greater pressure in the long run.

Factor decomposition of carbon emissions in industrial sectors in Anhui Province

Based on the above classifications, the LMDI formula is used to decompose factors behind the year-by-year carbon emission changes of the four categories of industrial sectors (with 2010 as the base period), and the contribution rates of each influencing factor are measured. The results are shown in Fig. 8. Among the influencing factors, the effect of per capita GDP growth is the most important factor behind the carbon emission increase, and its contribution rates to carbon emissions of the four categories are relatively high, especially for the second and third categories, and the contribution rates grew rapidly in 2019 compared to 2018. The factor of population size can help increase carbon emissions of the four categories, but its contribution rates are relatively low. The factor of energy use efficiency contributes negatively to the carbon emissions of the four categories, and it contributes more to the reduction of carbon emissions, which is an important factor to slow down the growth of carbon emissions. The effect of industrial structural change contributes negatively to the carbon emissions of the first category but negatively to the other three categories with a higher contribution rate to the fourth category. It shows that industrial structural optimization and adjustment can effectively reduce the carbon emissions of industrial sectors with high carbon emissions and high carbon emission intensity, but at the same time, this adjustment will increase this factor’s contribution rates to carbon emissions of the remaining three categories, especially the fourth category.

Suggestions on an optimization path for carbon emission and policy

Existing studies consider industrial energy consumption as the main source of current greenhouse gas emissions. In this context, it is of great significance to measure the carbon emissions and carbon intensity of industrial sectors and regions in Anhui Province and analyze the influencing factors for the formulation of relevant policies to achieve green, low-carbon development in Anhui Province. Based on the above research, we can draw the following three conclusions:

Firstly, the three industrial sectors with the highest carbon emissions and carbon intensity in Anhui Province in the past 10 years include the production and supply of electric and heat power, coal mining and washing, and smelting and pressing of ferrous metals, which together account for 64.86% of the total industrial carbon emissions in Anhui. Secondly, the regions with the highest carbon emissions in Anhui Province in the past 10 years are the resource-based cities of Huainan, Huaibei, and Ma’anshan. Their carbon emission intensities have a decreasing trend in different degrees, which indicates that the carbon efficiency of Anhui has improved. Finally, the factors influencing the industrial carbon emissions in Anhui are mainly energy use efficiency, industrial structure, economic scale, and population size. Energy use efficiency can significantly curb carbon emissions, while industrial structural optimization and adjustment only curb carbon emissions of the industrial sectors with high carbon emissions and high carbon intensity.

Based on the above findings, this research provides the following suggestions for the low-carbon industrial development of Anhui Province.

First, industrial structural changes are closely related to carbon emissions from energy use (Jiang et al. 2019b), and industrial structural upgrading is beneficial to carbon reduction and sustainable development (Dong et al. 2020). The analysis shows that the optimization and adjustment of industrial structure will effectively restrain carbon emissions of the industrial sectors with high carbon emissions and high carbon emission intensity. Resource-based cities in Anhui Province with high carbon emissions, such as Ma’anshan, Huainan, and Huaibei, should focus on achieving carbon peak and carbon neutrality, and accelerate structural transformation and energy saving in the future development to reduce carbon emissions. For example, the output value of the first category of industrial sectors in Tongling decreased by 13.33% in 2019 compared to 2015. Tongling’s carbon emissions decreased by 40.03% in 2019 compared to 2015, effectively controlling carbon emissions through industrial structural upgrading and adjustment.

Second, improve energy use efficiency in key industries. Analysis shows that the improvement of energy use efficiency will effectively curb carbon emissions. Therefore, the government should encourage technological progress and innovation by increasing investment in science and technology, establishing an effective institutional environment to protect technological innovation, and increasing financial investment in energy-saving technologies, thus giving play to technological advances in improving energy use efficiency. For example, Ma Steel Group in Ma’anshan has properly controlled coal consumption through the technical transformation of the large blast furnace. The company’s overall energy consumption per ton of steel decreased from 601 kg of standard coal in 2015 to 560.76 kg of standard coal in 2020, effectively curbing carbon emissions.

Third, strengthen policy guidance. Low-carbon development has become an increasingly important strategy in China, and different policies can cause an increase or decrease in China’s carbon emissions, so policies will play a leading role in carbon reduction (Song and Zhou 2021; Deng et al. 2017). Anhui should gradually introduce various policies to support low-carbon governance in industry, including laws and regulations, industrial standards, and fiscal and taxation tools. The policy tool should gradually include things from environmental protection, energy conservation, new energy, and renewable energy to circular economy development and industrial structural adjustment to build a tool that supports low-carbon industrial development. A stricter regulatory system should be established to ensure the effective implementation of low-carbon policies, measures, and standards. Anhui has developed a series of policy documents on carbon peaking and carbon neutrality, such as Guidelines on Strengthening the Prevention and Control of Ecological and Environmental Sources of Projects with High Energy Consumption and High Emissions formulated by the Department of Ecology and Environment of Anhui Province.

Fourth, develop technologies for carbon capture, utilization, and storage. Analysis shows that the sector of production and supply of electric and heat power in Anhui Province is the industry with the highest carbon emissions and highest carbon intensity, so its carbon emission problem should be actively addressed. In terms of carbon capture, biological carbon fixation is considered an effective and economical means (Wang et al. 2020b). The hilly and mountainous areas of Anhui account for 44.25% of the province’s total area. Anhui has a forest coverage of 30.22%, higher than the national average, which has a strong carbon fixation capacity. In order to improve the carbon sink capacity of the ecosystem, Anhui plans to complete the afforestation of 1.4 million mu during the 14th Five-Year Plan, which will further contribute to carbon peak and carbon neutrality.

Discussion and suggestions on management practices

Compared with existing studies (Zhao et al. 2022; Peng et al. 2020), this study has the following advantages: first, the research on carbon emission measurement and the low-carbon path of regional industry firstly improves the measurement method of regional industrial carbon emissions based on the IPCC EF method, takes carbon emission intensity as the carbon emission efficiency index, measures the regional industrial carbon emission and carbon emission intensity, and divides the regional industrial sectors into four categories, which are the categories with high carbon emission and high carbon emission intensity, low carbon emission and high carbon emission intensity, high carbon emission and low carbon emission intensity, and low carbon emission and low carbon emission intensity. This calculation method is more accurate based on regional energy consumption characteristics. Secondly, the research uses the LMDI decomposition method to quantitatively measure the contribution rates of each factor to the carbon emissions of the four categories of industrial sectors. This method can effectively identify the carbon emissions and carbon emission intensity of different industrial sectors as well as their influencing factors, in order to explore the target of carbon reduction. Third, based on the accurate calculation of regional industrial carbon emissions and carbon emission intensity and the analysis of the influencing factors of carbon emission changes, the research provides local governments with targeted policy suggestions.

These advantages can measure regional industrial carbon emissions and carbon efficiency more accurately and analyze the factors affecting the changes in regional industrial carbon emissions, which provide a basis for local governments to formulate relevant policies according to local conditions, thus promoting the low-carbon development of the regional industry to achieve the established goals of carbon peak and carbon neutrality. Based on the results, the research draws the following conclusions.

First, to promote low-carbon development of the regional industry, priority should be given to the development and implementation of carbon-peak and carbon-neutrality policies, including laws and regulations, industrial standards, and green GDP accounting. A strict management system for low-carbon industrial development should be introduced, and incentives should be strengthened. Strengthening policy guidance can effectively drive regional industrial carbon reduction.

Second, to promote the low-carbon development of regional industry, attention should be given to the development of technological input. Technology input is the basis of the low-carbon development of the regional industry. Technical research and investment in regional industrial transformation and upgrading, carbon capture and storage, and green energy development and utilization should be strengthened. This will make the low-carbon development of regional industry possible.

Conclusions

Industry is the world’s leading emitter, so promoting industrial carbon reduction is of key significance to achieve carbon peak and carbon neutrality. To this end, this research proposes a method for research on carbon emission measurement and the low-carbon path of regional industry. First, the research improves the IPCC EF method to accurately measure the regional carbon emissions and carbon efficiency by considering regional resource endowment and actual industrial carbon emissions. Next, the research divides regional industries into four categories based on regional industrial carbon emissions and carbon emission intensity. Finally, the research uses LMDI to analyze the contribution rates of influencing factors to regional carbon emission changes so as to accurately determine the optimization target of the low-carbon path.

The main innovation points of this research are as follows: (1) it improves the carbon emission calculation method based on the IPCC EF method and provides quantitative support for the study of an optimization path for regional carbon emission; (2) it proposes a method to analyze the factors affecting the changes of regional industrial carbon emissions based on objective data related to industrial economy, population, and resources; and (3) it proposes targeted policy suggestions for low-carbon development of regional industry on this basis. This research result not only provides quantifiable and practical solutions for low-carbon optimization in Anhui Province but also provides a reference for other countries or regions to explore new paths for carbon reduction.

However, the LMDI decomposition method may lead to contradictory conclusions when different influencing factors are selected for the same target variable to be decomposed. It is also prone to the incomplete selection of factors due to its inherent limitations, and thus cannot analyze all relevant influencing factors in their entirety. In addition, due to the long period and a large amount of data, the calculation results of some specific values may have small deviations, but they do not affect the conclusions of this paper. In the future, we will focus on the analysis of factors influencing carbon emissions and explore relevant analytical methods. We will also study the data-driven measurement and evaluation method of regional carbon emissions in-depth to provide more accurate support for carbon emission control and optimization.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Allen MR, Frame DJ, Huntingford C, Jones CD, Lowe J, Meinshausen M, Meinshausen N (2009) Warming caused by cumulative carbon emissions towards the trillionth tonne. Nature 458(7242):1163–1166. https://doi.org/10.1038/nature08019

An Y, Zhou D, Yu J, Shi X, Wang Q (2021) Carbon emission reduction characteristics for China’s manufacturing firms: implications for formulating carbon policies. J Environ Manage 284(4):112055. https://doi.org/10.1016/j.jenvman.2021.112055

Ang BW (2004) Decomposition analysis for policymaking in energy: which is the preferred method? Energy Policy 32(9):1131–1139. https://doi.org/10.1016/S0301-4215(03)00076-4

Ang BW, Zhang FQ, Choi KH (1998) Factorizing changes in energy and environmental indicators through decomposition. Energy 23(6):489–495. https://doi.org/10.1016/S0360-5442(98)00016-4

Bi X, Yang J, Yang S (2022) LCA-based regional distribution and transference of carbon emissions from wind farms in China. Energies 15(1):198. https://doi.org/10.3390/en15010198

Chen L, Li X, Yang Y, Wang M (2021) Analyzing the features of energy consumption and carbon emissions in the Upper Yangtze River Economic Zone. Greenhouse Gases: Science and Technology 0:1–17. https://doi.org/10.1002/ghg.2067

Dalai MA, Wenli WU, Dong Z (2017) Industrial carbon emission performance and its influencing factors in China: based on an empirical study of spatial panel data model. China Econ Stud 01:121–135. https://doi.org/10.19365/j.issn1000-4181.2017.01.11 ((in Chinese))

Deng X, Gibson J, Wang P (2017) Relationship between landscape diversity and crop production: a case study in the Hebei Province of China based on multisource data integration. J Clean Prod 142:985–992. https://doi.org/10.1016/j.jclepro.2016.03.174

Dong J, He J, Li X, Mou X, Dong Z (2020) The effect of industrial structure change on carbon dioxide emissions: a cross-country panel analysis. J Syst Sci Inf 8(1):1–16. https://doi.org/10.21078/JSSI-2020-001-16

Fu Y, Sun W, Zhao Y, Han Y, Gao Y (2021) Exploring spatiotemporal variation characteristics of China’s industrial carbon emissions on the basis of multi-source data. Environ Sci Pollut Res 28(30). https://doi.org/10.1016/j.resconrec.2017.10.036

Gai ZJ, Zhao JG, Zhang G (2018) Typical calculation and analysis of carbon emissions in thermal power plants. Iop Conference 128. https://doi.org/10.1088/1755-1315/128/1/012176

Gao P, Yue S, Chen H (2020) Carbon emission efficiency of China’s industry sectors: from the perspective of embodied carbon emissions. J Clean Prod 283(1):124655. https://doi.org/10.1016/j.jclepro.2020.124655

Gleick PH, Adams RM, Amasino RM, Anders E, Anderson DJ (2010) Climate change and the integrity of science. Science 328(5979):689–690. https://doi.org/10.1126/science.328.5979.689

Guo F, Meng S, Sun R (2021) The evolution characteristics and influence factors of carbon productivity in China’s industrial sector: from the perspective of embodied carbon emissions. Environ Sci Pollut Res 28:50611–50622. https://doi.org/10.1007/s11356-021-14271-0

Han Y, Jin B, Qi X, Zhou H (2021) Influential factors and spatiotemporal characteristics of carbon intensity on industrial sectors in China. Int J Environ Res Public Health 18(6):2914. https://doi.org/10.3390/ijerph18062914

Huang G, Pan W, Hu C, Pan WL, Dai WQ (2021) Energy utilization efficiency of China considering carbon emissions-based on provincial panel data. Sustainability 13(2):877. https://doi.org/10.3390/su13020877

Iida Y, Takatani Y, Kojima A, Ishii M (2021) Global trends of ocean CO2 sink and ocean acidification: an observation-based reconstruction of surface ocean inorganic carbon variables. J Oceanogr 77:323–358. https://doi.org/10.1007/s10872-020-00571-5

IPCC (2014) Summary for policymakers. Climate change 2014: impacts adaptation and vulnerability. Part A: global and sectoral aspects. Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change CB Field, VR Barros, DJ Dokken, et al, Eds, Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, 34 pp. https://doi.org/10.1074/jbc.M110.100735

Jiang DB, Fu YH (2012) Climate change over China with a 2°C global warming. Chinese Journal of Atmospheric Sciences 36 (2): 234–246. ((in Chinese))

Jiang Y, Peng L, Zhao S, Liu L, Management S. O, University J (2019a) Carbon emission efficiency of China provincial thermal power industry based on spatial measurement. Journal of Shandong University of Finance and Economics. ((in Chinese))

Jiang T, Huang S, Yang J (2019b) Structural carbon emissions from industry and energy systems in China: an input-output analysis. J Clean Product 240(Dec.10):118116.1–118116.13. https://doi.org/10.1016/j.jclepro.2019b.118116

Jiao J, Chen C, Bai Y (2020) Is green technology vertical spillovers more significant in mitigating carbon intensity? Evidence from Chinese industries. J. Clean. Prod 257. https://doi.org/10.1016/j.jclepro.2020.120354

Jin B, Han Y (2021) Influencing factors and decoupling analysis of carbon emissions in China’s manufacturing industry. Environ Sci Pollut Res 28:64719–64738. https://doi.org/10.1007/s11356-021-15548-0

Kalt G, Höher M, Lauk C, Schipfer F, Kranzl L (2016) Carbon accounting of material substitution with biomass: case studies for Austria investigated with IPCC default and alternative approaches. Environ Sci Policy 64:155–163. https://doi.org/10.1016/j.envsci.2016.06.022

Kaya Y, Yokobori K (1997) Environment, energy and economy: strategies for sustainability. United Nations. University Press, New York, pp 56–59

Keivani E, Abbaspour M, Abedi Z, Ahmadian M (2021) Promotion of low-carbon economy through efficiency analysis: a case study of a petrochemical plant. Int J Environ Res 15:45–55. https://doi.org/10.1007/s41742-020-00282-1

Khan MK, Teng JZ, Khan MI (2019) Effect of energy consumption and economic growth on carbon dioxide emissions in Pakistan with dynamic ARDL simulations approach. Environ Sci Pollut Res 26:23480–23490. https://doi.org/10.1007/s11356-019-05640-x

Kirikkaleli D, Sowah JK (2021) Time-frequency dependency of temperature and sea level: a global perspective. Environ Sci Pollut Res (6). https://doi.org/10.1007/s11356-021-14846-x

Kong Y, He W (2020) The path analysis of carbon emission reduction: a case study of the Silk Road Economic Belt. Environ Eng Res 25(1):71–79. https://doi.org/10.4491/eer.2018.379

Kundzewicz ZW (2008) Climate change impacts on the hydrological cycle. Ecohydrol Hydrobiol 8(2):195–203. https://doi.org/10.2478/v10104-009-0015-y

Li J, Cheng Z (2020) Study on total-factor carbon emission efficiency of China’s manufacturing industry when considering technology heterogeneity. J Clean Prod 260(2):121021. https://doi.org/10.1016/j.jclepro.2020.121021

Li Y, Hou W, Zhu W, Liang L (2021) Provincial carbon emission performance analysis in China based on a Malmquist data envelopment analysis approach with fixed-sum undesirable outputs. Ann Oper Res 304:233–261. https://doi.org/10.1007/s10479-021-04062-8

Lin X, Bian Yu, Wang Dai (2021) Spatiotemporal evolution characteristics and influencing factors of industrial carbon emission efficiency in Beijing-Tianjin-Hebei region. Econ Geogr 41(6):187–195. ((in Chinese))

Liu Z, Guan D, Wei W, Davis SJ, Ciais P, Bai J, Peng S, Zhang Q, Hubacek K, Marland G, Andres RJ, Crawford BD, Lin J, Zhao H, Hong C, Boden TA, Feng K, Peters GP, Xi F, Liu J, Li Y, Zhao Y, Zeng N, He K (2015) Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 524:335–338. https://doi.org/10.1038/nature14677

Lu Y, Li M (2020) Industrial carbon emission efficiency in the Yangtze River Economic Belt and its influencing factors. International Journal of Design & Nature and Ecodynamics 15(1) :25–32. https://doi.org/10.18280/ijdne.150104

Ma Y, Li F, Wang L, Wang G, Kong L (2021) Life cycle carbon emission assessments and comparisons of cast iron and resin mineral composite machine tool bed in China. Int J Adv Manuf Technol 113:1143–1152. https://doi.org/10.1007/s00170-021-06656-9

Meinshausen M, Meinshausen N, Hare W, Raper SCB, Frieler K, Knutti R, Frame DJ, Allen MR (2009) Greenhouse-gas emission targets for limiting global warming to 2 °C. Nature 458:1158–1162. https://doi.org/10.1038/nature08017

Mielnik O, Goldemberg J (1999) Communication the evolution of the“Carbonization Index”in developing countries. Energy Polic 27(5):307–308. https://doi.org/10.1016/S0301-4215(99)00018-X

Naderi M (2020) Extreme climate events under global warming in northern Fars Province southern Iran. Theor Appl Climatol 142:1221–1243. https://doi.org/10.1007/s00704-020-03362-6

Naz S, Sultan R, Zaman K, Aldakhil AM, Nassani AA, Abro MMQ (2019) Moderating and mediating role of renewable energy consumption FDI inflows and economic growth on carbon dioxide emissions: evidence from robust least square estimator. Environ Sci Pollut Res 26(3):2806–2819. https://doi.org/10.1007/s11356-018-3837-6

Peng B, Tong X, Cao S, Li W, Xu G (2020) Carbon emission calculation method and low-carbon technology for use in expressway construction. Sustainability 12(8):3219. https://doi.org/10.3390/su12083219

Ramanathan R (2002) Combining indicators of energy consumption and CO2 emissions: across country comparison. Int J Global Energy Issues 17(3):214–227. https://doi.org/10.1504/IJGEI.2002.000941

Salari M, Javid RJ (2021) Noghanibehambari H (2021) The nexus between CO2 emissions energy consumption and economic growth in the U.S. Econ Anal Policy 69:182–194. https://doi.org/10.1016/j.eap.2020.12.007

Schneider SH, S Semenov, A Patwardhan, I Burton, CHD Magadza, MO ppenheimer, AB Pittock, A Rahman, JB Smith, A Suarez and F Yamin (2007) Assessing key vulnerabilities and the risk from climate change. Climate change 2007: impacts, adaptation and vulnerability. Contribution of Working Group II to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change, ML Parry, OF Canziani, JP Palutikof, PJ van der Linden and CE Hanson, Eds, Cambridge University Press, Cambridge, UK, 779–810

Schueler M, Hansen S, Marten H (2018) Discrimination of milk carbon footprints from diferent dairy farms when using IPCC Tier 1 methodology for calculation of GHG emissions from managed soils. J Clean Prod 177:899–907. https://doi.org/10.1016/j.jclepro.2017.12.227

Shan Y, Guan D, Liu J, Mi Z, Liu Z, Liu J, Schroeder H, Cai B, Chen Y, Shao S, Zhang Q (2017) Methodology and applications of city level CO2 emission accounts in China. J Clean Prod 161:121–1225. https://doi.org/10.1016/j.jclepro.2017.06.075

Shi Q, Chen J, Shen L (2017) Driving factors of the changes in the carbon emissions in the Chinese construction industry. J Clean Prod 166:615–627. https://doi.org/10.1016/j.jclepro.2017.08.056

Song L, Zhou X (2021) How does industrial policy affect manufacturing carbon emission? Evidence from Chinese provincial sub-sectoral data. Environ Sci Pollut Res 28:61608–61622. https://doi.org/10.1007/s11356-021-15107-7

Wang J, Feng L, Palmer PI, Liu Y, Fang SX, Bösch H, O’Dell CW, Tang XP, Yang DX, LiX L, Xia CZ (2020b) Large Chinese land carbon sink estimated from atmospheric carbon dioxide data. Nature 586:720–723. https://doi.org/10.1038/s41586-020-2849-9

Wang F, Sun X, Reiner DM, Wu M (2020a) Changing trends of the elasticity of China’s carbon emission intensity to industry structure and energy efficiency. Energy Econ 86(Feb.) 104679.1–104679.20. https://doi.org/10.1016/j.eneco.2020a.104679

Wang XZ (2017) Carbon emission measurement and analysis of energy consumption. China metrology. 2017(5):49–52. https://doi.org/10.16569/j.cnki.cn11-3720/t.2017.05.016 ((in Chinese))

Xi Jinping. President Xi’s speech at Climate Ambition Summit 2020 (full text). http://www.chinadaily.com.cn/a/202012/13/WS5fd575a2a31024ad0ba9b7ac.html,2020-12-13.

Xie Z, Wu R, Wang S (2021) How technological progress affects the carbon emission efficiency? Evidence from national panel quantile regression. J Clean Prod 307(1):127133. https://doi.org/10.1016/j.jclepro.2021.127133

Yang G, Zhang F, Zhang F, Ma D, Yang Q (2021a) Spatiotemporal changes in efficiency and influencing factors of China’s industrial carbon emissions. Environ Sci Pollut Res 28:36288–36302. https://doi.org/10.1007/s11356-021-13003-8

Yang S, Wang Y, Han R, Chang Y, Sun X (2021b) Spatial heterogeneity of factors influencing CO2 emissions in China’s high-energy-intensive industries. Sustainability 13(15):8304. https://doi.org/10.3390/su13158304

Yu X, Chao Z (2012) Energy efficiency and emissions reduction potential of China’s industrial sector. Chinese Journal of Population Resources and Environment 10(3):30–39. https://doi.org/10.1080/10042857.2012.10685098

Yu Y, Li S, Sun H, Farhad Taghizadeh-Hesary (2021) Energy carbon emission reduction of China’s transportation sector: an input–output approach. Econ Anal Policy 69(C):378–393. https://doi.org/10.1016/j.eap.2020.12.014

Zang N, Zhao J, Yan P, Zhang H, Tang S, Feng G (2021) Interdecadal variations of persistent extreme heat events in eastern China under global warming. Theor Appl Climatol 146:349–364. https://doi.org/10.1007/s00704-021-03723-9

Zhang Y, Xu X (2022) Carbon emission efficiency measurement and influencing factor analysis of nine provinces in the Yellow River basin: based on SBM-DDF model and Tobit-CCD model. Environ Sci Pollut Res 29:1–18. https://doi.org/10.1007/s11356-022-18566-8

Zhang Y, Ye A, You J, Jing X (2021b) Quantification of human and climate contributions to multi-dimensional hydrological alterations: a case study in the Upper Minjiang River China. J Geogr Sci 31:1102–1122. https://doi.org/10.1007/s11442-021-1887-z

Zhang J, Dai Y, Su CW, Kirikkaleli D, Umar M (2021b) Intertemporal change in the effect of economic growth on carbon emission in China. Energy Environ 32. https://doi.org/10.1177/0958305X211008618

Zhao K, Cui X, Zhou Z, Huang P (2022) Impact of uncertainty on regional carbon peak paths: an analysis based on carbon emissions accounting modeling and driving factors. Environ Sci Pollut Res 29:17544–17560. https://doi.org/10.1007/s11356-021-16966-w

Zhao M (2012) Quantitative analysis of the factors influencing CO2 emissions from final energy consumption in Shanghai. China Environmental Science 2012,32(9):1583~1590. ((in Chinese))

Zhou P, Ang BW, Han JY (2010) Total factor carbon emission performance: a Malmquist index analysis. Energy Economics 32(1):194–201. https://doi.org/10.1016/j.eneco.2009.10.003

Zhu J, Sun H, Zhou D, Peng L, Sun C (2020a) Carbon emission efficiency of thermal power in different regions of China and spatial correlations. Mitig Adapt Strat Glob Change 25:1221–1242. https://doi.org/10.1007/s11027-019-09901-5

Zhu R, Zhao R, Sun J, Xiao L, Jiao S, Chuai X, Zhang L, Yang Q (2020a) Temporospatial pattern of carbon emission efficiency of China’s energy-intensive industries and its policy implications. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020b.125507

Funding

This research is supported by a Key Project of Anhui Philosophy and Social Science Planning (AHSKXZX2020D13).

Author information

Authors and Affiliations

Contributions

Conceptualization, X.W.; methodology, X.W. and G.X.; investigation, S.Z.; resources, C.L.; data curation, X.W. and G.X.; writing—original draft preparation, S.Z. and X.W.; writing—review and editing, C.L. and Y.Z.; all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, X., Zhou, S., Xu, G. et al. Research on carbon emission measurement and low-carbon path of regional industry. Environ Sci Pollut Res 29, 90301–90317 (2022). https://doi.org/10.1007/s11356-022-22006-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22006-y