Abstract

Under the guidance of carbon peak and carbon neutral targets, the industrial structure transformation is vital for carbon emissions reduction in China. However, there is a rebound effect of carbon emissions during the industrial structure transformation. Resource dependence and technological progress have significant impacts on industrial structure transformation and its carbon reduction effect. This paper explores how industrial structure transformation under resource dependence causes the rebound effect from a technological progress perspective. The key results indicate that (1) resource dependence distorts the carbon emissions reduction effect of industrial structure transformation; (2) with the development of technology, the industrial structure upgrading under resource dependence could cause an increase on carbon emissions at the beginning, but the increase would be weakened subsequently, displaying a two-stage feature; (3) the industrial structure rationalization under resource dependence reduces carbon emissions at first, but the reduction would be weakened as the technology develops, then industrial structure’s rationalization shows an insignificant impact on carbon emissions, and finally reduces carbon emissions again, presenting a four-stage characteristic; (4) environmental protection technology can correct the distortion effect of resource dependence on the industrial structure rationalization and amplify the industrial structure rationalization’s reduction effects on carbon emissions; (5) with the development of energy-saving technology, industrial structure rationalization has a paradoxical impact on carbon emissions, the industrial structure rationalization first reduces, then increases, and finally reduces carbon emissions, indicating an inverted “N” relationship. Finally, policy recommendations for carbon emissions reduction are proposed from the perspective of industrial structure transformation and technological progress.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Relying on extensive economic growth in the past, China has become the second-largest economy in the world. And China has also been the world’s largest emitter of CO2; the emissions levels continue to increase (Ma et al. 2019; Sun et al. 2020). Due to the excessive CO2 emissions, global warming, glaciers retreating, and sea levels rising, a series of natural environmental problems have emerged, posing a severe threat to human survival and the sustainable development of society and the economy (Aljerf and Choukaife 2016). Facing increasing pressure from the international community, since September 2020, General Secretary Xi Jinping has made seven solemn promises to the world that China will achieve a “Carbon peak” by 2030 and “Carbon neutral” by 2060. Under the guidance of carbon peak and carbon neutral targets, reducing CO2 emissions and realizing a low-carbon economy become critical measures for China to cope with the challenges of global climate change (Wang et al. 2012; Xu and Lin 2016; Shi et al. 2021a, b).

Industrial structure transformation is the main path to reducing carbon emissions (Huang et al. 2021; Chuai and Feng 2019; Liu et al. 2020; Dong et al. 2021). With the industrial structure transformation, the proportion and relationship of different industrial sectors are optimized, improving resource utilization efficiency, and thus reducing carbon emissions (Zhang and Deng, 2010; Zhou et al. 2013a, 2013b; Shao et al. 2016a, b; Li and Lin 2017). Transformation of the industrial structure can be characterized as the industrial structure upgrading and industrial structure rationalization (Kuang and Tang 2015; Cheng et al. 2018).

Industrial structure upgrading (ISU) refers to the transition from the low-value-added, low-efficiency industries to the high-value-added, high-efficiency, and low-consumption industries (Pipkin and Fuentes 2017; Zhu et al. 2019). The primary and secondary industries have consumed large amounts of energy and produced considerable amounts of pollutants for a long time (Yu and Liu 2020), and the tertiary industry represented by the modern service industry has high input–output performance with less environmental pollution and energy consumption, which plays an important role in emissions reduction and improvement in carbon emissions efficiency (Wang et al. 2019b), so the proportion of the tertiary industry’s added value and the secondary industry’s added value is used to measure the upgrading of industrial structure; the higher the value, the higher level of industrial structure upgrading. Rationalization of the industrial structure (ISR) reflects the collaborative development capabilities of different industries and the allocation efficiency of production factors among different industries; the higher the degree of industrial structure rationalization, the higher the structural transformation ability, the higher the efficiency of resources utilization (Sun and Ye, 2012), with the carbon emissions efficiency improved (Zhang and Deng 2010; Li et al. 2015; Shao et al. 2016a, b; Li et al. 2017a, b; Yuan and Zhu 2018; Wang et al. 2019b). Following the study of Gan et al. (2011) and Zhu et al. (2019), the reciprocal of the Theil index is used to measure the industrial structure rationalization in this paper.

However, there is a contradiction between industrial structure transformation (upgrading and rationalization) and carbon emissions reduction (Zhao et al. 2022). Figure 1 shows the transformation of the industrial structure and the trend of CO2 emissions. From 2010 to 2017, it is evident that with the transformation of the industrial structure, CO2 emissions first decreased and then increased, showing a rebound phenomenon. Therefore, optimizing the industrial structure may not always favor carbon emissions reduction. The rebound effect of carbon emissions in the process of industrial structure transformation may directly affect the result of CO2 emissions reduction (Li 2021).

The effect of industrial structure transformation on CO2 emissions has been discussed in much research. The factors that affect CO2 emissions have been decomposed in many studies, showing that the industrial structure is an essential factor affecting CO2 emissions (Obas and Anthony 2006; Wei et al. 2009; Adom et al. 2012; Guo et al. 2012). Subsequently, some scholars began to explore the relationship between industrial structure changes and CO2 emissions, where linear and nonlinear assumptions are still the focus of debate. The linear assumption states that the optimizing industrial structure can significantly reduce CO2 emissions (Chebbi and Boujelbene 2008; Zhang et al. 2011; Zhang et al. 2014; Li et al. 2017a, b). The nonlinear assumption considers phased effect characteristics of industrial structure transformation on CO2 emissions. Li et al. (2019) used a threshold model to analyze the relationship between CO2 and the industrial structure in China, and they found that the industrial structure would have different reduction effects on CO2 emissions in different economic development stages. Song et al. (2018) studied China’s provincial sample from 2005 to 2015 and found an inverted U-shaped relationship between industrial structure rationalization and CO2 emissions. Wei and Zhang (2020) employed a panel smooth transition regression (PSTR) model to investigate the effects of the industrial structure upgrading on China’s CO2 emissions from 1997 to 2015, and there is a nonlinear relationship between industrial structure and CO2 emission. Therefore, an analysis of the impacts of industrial structure transformation is critical to reducing carbon emissions, and phase characteristics of industrial structure transformation on CO2 emissions should be considered (Wei 2020).

The reduction effect of industrial structure transformation on carbon emissions is largely affected by resource dependence (Sun and Ye 2012; Chen et al. 2019a, b; Li et al. 2019). Resource dependence is an important factor determining the initial regional industry structure; regions with abundant natural resources tend to give priority to the development of resource-based industries (Shao and Yang, 2014; Li et al. 2019; Wang et al. 2019b). And the resource-dependent industries attracted more physical and human capital investment, which further has a squeezing effect on other industries (Gylfason and Zoega 2006), showing “crowding-out effects” on industries with low energy consumption and “lock-in effects” on industries with high energy consumption (Sun and Ye 2012). Therefore, resource dependence can hinder the diversification of industries and affect the reduction effect of industrial structure transformation on carbon emission (Li et al. 2019; Wu et al. 2021). The over-reliance on the resource is the source of “resource cures”Footnote 1; for the regions with high-level resource dependence, it is very difficult to develop alternative low-carbon industries and change the industrial structure to reduce carbon emissions (Li et al. 2019).

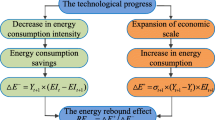

But some empirical findings suggest that the “resource curse” is not a universal law; some resource-abundant countries such as Australia and Norway show that resource-based regions can also develop in green low-carbon ways. It is because the direction and speed of industrial restructuring under resource dependence are different in different stages of technological development (Baldwin et al. 2005; Chang 2015). Along with technological development, the leading industry tends to gradually transform from labor- to capital-intensive, then technology-intensive; the demand structure and the supply structure are stimulated to change (Teece 1996; Simpson, 1999; Chen and Lee 2020), which leads to improvement in the region’s energy efficiency and energy structure (Liu 2009; Sharma 2011; Li et al. 2017a, b), indirectly (Cheng et al. 2018), thus reducing carbon emission. However, some research has also proved that technological progress might cause more fossil energy to replace labor and capital investment in production activities (Yang et al. 2017; Sun et al. 2017; Cheng et al. 2018), easing the reduction of industrial structure transformation on carbon emissions (Sharma 2011; Liu and Xie, 2013). All of these indicate that the direction and the speed of the “structural emissions reduction” effect are changed under the influence of resource dependence, and the extent of change depends on the extent of technological progress; that is, technological progress may have a nonlinear threshold effect on industrial structure transformation’s carbon reduction effect under resource dependence.

The above reviews suggest that most existing research on carbon emission and industrial structure transformation is concentrated in two areas. One is the finding that industrial structure is an essential factor affecting carbon emissions. The other is the study of the relationship between industrial structure and carbon emissions, and the conclusions can be divided into nonlinear and linear relationship assumptions. Few scholars have explored the influencing factors of the phased changes of the industrial structure on carbon emissions and further explored the mechanism behind how industrial structure transformation caused carbon emissions to rebound in the specific stage.

Exploring the mechanism and causes of carbon emissions rebound due to industrial structure transformation helps decision-makers formulate more effective and accurate industrial structure transformation policies to reach China’s carbon emissions reduction targets. Furthermore, the industrial structure is inextricably linked to resource dependence, and the degree of dependence affects the emissions reduction effect of structural transformation. Moreover, technological innovation may have different biasing effects on the industrial structure, thereby affecting the emissions reduction effect of the industrial structure (Shi et al. 2021a, b). Therefore, it is necessary to identify the stage characteristics of the industrial structure’s effect on carbon emissions and analyze the impact mechanism of technological progress on the industrial structure’s carbon emissions reduction effect while considering the impact of resource dependence on the industrial structure. The contribution of this research is as follows: (1) exploring the distortion effect of resource dependence on the CO2 emissions reduction effect of industrial structure transformation; (2) analyzing how technological progress affects the industrial structure’s carbon emissions reduction effect under resource dependence; and (3) examining the paradox CO2 emissions effects of the industrial structure transformation under resource dependence due to the heterogeneous technological progress (Fig. 2).

The following Sect. 2 presents the variables description and model specification. Section 3 provides the research results. Section 4 draws research conclusions and provides policy recommendations.

Model construction and variable selection

Model construction

Ehrlich (1971) and Holdren (1974) proposed the IPAT model. This model is widely used to evaluate the impact of population, economy, and technology on the environment. Subsequently, Dietz and Rosa (1994) extended the model and established a stochastic STIRPAT model to account for the shortage that the environmental pressure changes in equal proportion to each influencing factor. The equation is expressed as follows:

where I, P, A, and T respectively represent environmental impact, population size, affluence, and technological progress; a, b, c, and d are the parameters to be estimated; e is a random perturbation term. By using natural logarithm, the above equation becomes as follows:

Most previous studies have improved (3) to conduct empirical research (Poumanivong and Kaneko 2010; Liddle 2013). In these empirical studies, I is measured by CO2 emissions, denoted by CO2, P represents the total population, denoted by Pop, and A is measured by GDP per capita, denoted by GDPpc. About T, Bongaarts (1992) believes that different economic structures can show different levels of technology; in previous studies, some scholars used industrial structure upgrading as an agent variable of technology T (Zhang et al. 2012). Industrial structure transformation can be expressed as industrial structure upgrading and industrial structure rationalization (Han et al. 2021; Yuan and Zhu 2018). In this paper, industrial structure rationalization (ISR) and industrial structure upgrading (ISU) are used as technology proxy variables T respectively to study the carbon emissions reduction effect of industrial structure transformation. The benchmark model based on panel data can be derived as follows:

Since resource dependence (R) is an important factor that affects the carbon emissions reduction effect of industrial structure transformation, it is introduced as a cross term in the benchmark model:

The emissions reduction effect of industrial structure transformation under resource dependence varies in the different stages of technological development; we use INV to express the level of technological development and use Hansen’s (1999) panel threshold model to expand models (6) and (7). The threshold model only estimates the intrinsic parameters of each group, improving the accuracy of estimation. Its specific model is as follows:

where I(•) is an indicator function, showing the relationship between the threshold variable INV and the threshold values r and r; when the threshold condition in parentheses is satisfied, the value is 1; otherwise, it is 0. Models (8) and (9) can respectively measure the impact of industrial structure transformation in the different stages of technological development on carbon emissions reduction effects under resource dependence. The above model only assumes a threshold; that is, the influence of variables on carbon emissions will be divided into two different mechanisms. However, it is also possible to have multiple thresholds. Assuming that the thresholds are r1 < r2, r1' < r2' in the case of double thresholds, that is, there are three kinds of influence mechanisms, the model can be modified as follows:

To further explore the impact of technological development on the industrial structure transformation’s carbon emissions effect, threshold models are constructed with energy-saving technology (ES) and environmental protection technology (EP) as threshold variables, respectively. The specific mechanism of carbon emissions rebound effect caused by industrial structure transformation under resource dependence is analyzed from the perspective of technological progress. A single threshold model is given here, and a multi-threshold model is similar (IS in the model indicates ISR or ISU, r3′ and r3′ are threshold values):

Variable selection

According to the data’s availability and validity, this paper selected panel data covering 30 provinces in China (excluding Tibet, Hong Kong, Macao, and Taiwan) from 2004 to 2019. All the original data came from the China Statistical Yearbook, China Industrial Statistical Yearbook, and the China Economic Information Center (CEIC) database. And the carbon emission data is from China Emission Accounts Datasets (CEADs).

Transformation of industrial structure

The upgrading of industrial structures refers to the process in which the focus of the industrial structure gradually shifts from agriculture to industry and then to the service industry, which is reflected in the changes in the proportion of national income, employment, and output value among various industrial sectors (Aljerf 2018a, b). Previous studies have mostly measured the degree of industrial upgrading from two perspectives. Some scholars use the added value of the service industry as a proportion of GDP to indicate the upgrading of the industrial structure (Zhong et al. 2019). Others believe that in the information age, with the relatively low proportion of agriculture and stable growth rate, the growth rate of the service industry output value is faster than that of the industrial output value, which is an essential manifestation of industrial structure upgrading (Gan et al. 2011; Han et al. 2021; Cheng et al. 2018). Therefore, this paper uses the proportion of the tertiary industry’s added value and that of the secondary industry to measure the industrial structure upgrading (ISU).

Rationalization of the industrial structure reflects the reasonable allocation of production factors among different industries, which can measure the structural transformation ability and effectively utilize resources among industries to a certain extent (Zhao et al. 2017). The higher the industrial structure rationalization, the higher the efficiency of resource utilization and the fewer carbon emissions (Zhang and Deng 2010; Li et al. 2015; Shao et al. 2016a, b; Li et al. 2017a, b; Yuan and Zhu 2018). Industrial structure rationalization is usually measured by the reciprocal of the Theil index (Gan et al. 2011; Zhou et al. 2013a, b; Cheng et al. 2018):

where Y represents the total output value, L represents the total number of employed people, Yi represents the output value of industry i, and Li represents the number of employed people in industry i. When Yi/Y and Li/L are the same, it means that the marginal output of the labor force in each industrial sector is the same, which means that the resources in each industrial sector have been optimally allocated. Currently, the industrial structure is balanced, and the industrial structure is the most reasonable. However, under normal circumstances, especially in developing countries, the industrial structure usually cannot reach an equilibrium; when 1/ISR is equal to 0, the industrial structure is the ideal state, and the larger the 1/ISR, the more unreasonable the industrial structure is. For the consistency of description, we use the reciprocal of the index to measure the industrial structure rationalization; that is, the greater the ISR value, the more reasonable the industrial structure.

Resource dependence

The transformation of the industrial structure is restricted by regional dependence on resources (Li et al. 2019; Wang et al. 2019b), which reflects the resource constraints in the choice of industrial structure in different regions and demonstrates the principle of comparative advantage in economic development. It is believed that the extractive industry’s investment level depends entirely on the availability of natural resources; thus, the level of investment in the mining industry should be used to measure resource dependence (Xu and Wang 2006a, b). We argue that in addition to mining, agriculture, forestry, animal husbandry, and fishery also need natural resources for their production. Therefore, we selected the total fixed-asset investment of agriculture, forestry, animal husbandry, and fishery and extractive industries as the proportion of the total fixed-asset investment of the whole society to accurately reflect the degree of resource dependence in each region to the greatest extent as Yuan and Xie (2014).

Technological progress

According to the previous literature, the ratio between the internal expenditures on technological research and GDP in the unit is selected as the technological progress variable (Lutz et al. 2005; Wang et al. 2019a). To further explore the impact of technological progress on the carbon emissions reduction effect of industrial structure transformation, this study divides technological progress into energy-saving and environmental protection technological progress (Wang et al. 2019b).

Environmental protection technology mainly includes renewable and new energy technologies and other low-carbon technologies (He et al. 2018). The efficacy of environmental protection technology refers to the technical level and processing efficiency of dealing with the carbon emissions that have been generated with the economy developing (O’Reilly 2000). In this paper, carbon emissions per GDP unit in each region represent the efficacy of environmental protection technologies (EP) (Zhang and Li 2015; Wang et al. 2019b). The larger the value, the lower the efficacy of environmental technology; on the contrary, the smaller the value, the higher the efficacy of environmental technology.

Energy-saving technological progress can improve energy efficiency; that is, technological progress can bring about more output with the same or less energy input (Weizsäcker et al. 1998; Cheng et al. 2021); in this paper, energy consumption per GDP is used to measure the efficacy of energy-saving technology (ES) (Zhang and Li 2015; Wang et al. 2019b; Yi et al. 2020). However, efficient energy technologies can enable consumers to obtain the same amount of energy at a lower cost; thus, consumers may consume more energy while reducing their financial pressure, increasing carbon emissions (Brookes 1992; He et al. 2018).

Results and discussion

Impact of resource dependence on the carbon emissions reduction effect of industrial structure transformation

Before conducting empirical analysis, the collinearity test should be performed on the panel data to ensure the models’ accuracy. The specific results are presented in Table 1.

Table 1 shows that the explanatory variable variance inflation factor (VIF) value is in the range of (0,10) and is much lower than 10, indicating that there is no multicollinearity between the variables, and the measurement model can be accurately constructed.

According to (4), (5), (6), (7), basic panel models 1–4 were constructed to study the impact of industrial structure transformation on carbon emissions. Through the Hausman test, we found that the fixed effect model should be used. The estimated results are displayed in Table 2.

The results of models 1 and 2 show that the rationalization and upgrading of the industrial structure have a noticeable promotion effect on carbon emissions reduction; population and economic development have a noticeable promotion effect on carbon emissions. The resource dependence is introduced into models 3 and 4 as the cross-term, and the coefficients of cross-terms are 4.8624 (significant) and − 0.2604 (insignificant), respectively. Thus, resource dependence distorts the carbon emissions reduction effect of industrial structure upgrading and rationalization (Li et al. 2019). Under the influence of resource dependence, the carbon emissions reduction effect of the industrial structure upgrading is transformed into the increasing effect, and the carbon emissions reduction effect of industrial structure rationalization turned insignificant under this condition. The higher the dependence of resources, the higher the priority development of resource-based industries; human and material capital is locked in the resource industry, which causes a “crowding out” effect on other industries and results in the “resource curse.” Thus, in areas dominated by industries that strongly depend on natural resources, resource dependence can weaken industrial structure rationalization’s carbon emissions reduction effect, as well as lead to the carbon emissions increasing effect of industrial structure upgrading.

Impact of technological progress on the carbon emissions reduction effect of industrial structure transformation under resource dependence

The above analysis shows that resource dependence has a certain distorting impact on the emissions reduction effect of industrial structure transformation. To explore whether technological progress can reduce the distortion effect of resource dependence, this section uses the panel threshold model to study the impacts of technological progress on the carbon emissions reduction effect of industrial structure transformation under resource dependence.

Panel threshold regression of industrial structure upgrading

Before the threshold model is established, likelihood ratio (LR) statistics are used to test the significance of the threshold effect, that is, whether technological progress will bring heterogeneity of industrial structure effect on carbon emissions reduction (Li and Zhou 2021). If there is such a nonlinear threshold effect, the number of thresholds should be further determined according to whether the model has double or triple thresholds.

The test results of the threshold panel model for upgrading the industrial structure are shown in Table 3. When industrial structure upgrading is the critical variable, the single threshold’s p value is 0.003; thus, the null hypothesis is rejected at the 5% level, and there is a single threshold effect. However, there is not enough evidence to prove the existence of the second threshold. Therefore, we build a single-threshold model with technological innovation as the threshold variable and resource-dependent industrial structure advancement as the core explanatory variable. We further estimate the parameters in the model.

According to the results in Table 4, the single threshold value in the model for upgrading industrial structure under resource dependence is 1.1313, which means technological innovation expenditure accounts for 1.1313% of the GDP. Table 5 provides the estimation results, showing that the upgrading of the industrial structure under resource dependence has different effects on carbon emissions at different technological development stages. With the development of technology, the carbon emissions coefficient of industrial structure transformation under resource dependence changed from 4.5819 (significant) to 1.9845 (significant).

When technological innovation expenditures account for less than 1.1313% of the GDP, technological innovation cannot offset the distorting effect of resource dependence on the carbon emissions reduction effect of the industrial structure upgrading, making the industrial structure’s upgrading present the increasing effect of carbon emissions; for every 1% increase in the degree of industrial structure upgrading, carbon emissions increase by 4.5819%; that is, the industrial structure upgrading leads to increased carbon emissions. However, when technological innovation exceeds the threshold (technological innovation expenditures account for more than 1.1313% of the GDP), for every 1% increase in the degree of industrial structure upgrading, carbon emissions increase by 1.9845%, and the increasing effect of industrial structure upgrading on carbon emissions has been weakened. The technological progress offsets the distorting effect of resource dependence on the carbon emissions reduction effect brought by the industrial structure’s upgrading.

Technological progress can increase the carbon emissions reduction effect of industrial structure upgrading and offset the distortion effect of resource dependence on industrial structure upgrading, which verifies that technological progress can reduce the dependence of human production activities on natural resources (Liu et al. 2021). Simultaneously, technological progress promotes the transition of industrial structure from labor-intensive to capital- and technology-intensive industrial structures. Changes in the supply structure promote upgrading the industrial structure (Dosi 1990), thereby enhancing the industrial structure upgrading’s carbon emissions reduction effects.

Panel threshold regression of industrial structure rationalization

The panel threshold model’s test results for the rationalization of the industrial structure are shown in Table 6, which proves that the panel threshold regression model is suitable. The p values of the first and second thresholds are 0.000, respectively, indicating that there exist triple thresholds.

According to the threshold values given in Table 7, the technology innovation threshold values of the threshold model for the rationalization of the industrial structure under the influence of technological progress on the emissions reduction effect are 0.6566, 0.9569, and 1.2524. Table 8 gives the estimation results. It can be observed that with the development of technology, the carbon emissions reduction effect of industrial structure rationalization under resource dependence changes from − 2.0056 to − 1.0965, and 0.7765 (insignificant), then to − 0.7026.

When technological innovation is in the first stage (the ratio of technological innovation expenditure to GDP is less than 0.6566%), the effect coefficient of industrial structure rationalization on the carbon emissions under resource dependence is − 2.0056; each 1% increase of the industrial structure rationalization decreases carbon emissions by 2.0056%. When the development of technology is in the second stage (the ratio of technological innovation expenditure to GDP is more than 0.6566% and less than 0.9569%), the effect coefficient of industrial structure rationalization on the carbon emissions under resource dependence is − 1.0965; each 1% increase of the industrial structure rationalization decreases carbon emissions by 1.0965%. In the third stage (the ratio of technological innovation expenditure to GDP is more than 0.9569 and less than 1.2524), the effect coefficient of industrial structure rationalization on the carbon emissions under resource dependence is insignificant. In the fourth stage (the ratio of technological innovation expenditure to GDP is more than 1.2524), the effect coefficient of industrial structure rationalization on the carbon emissions under resource dependence is − 0.7026; each 1% increase of the industrial structure rationalization decreases carbon emissions by 0.7026%.

During the early stages of technological development, technological innovation can reduce the distortion effect caused by resource dependence, the supply and demand structure changes, and the industrial structure’s rationalization is promoted (Zhou et al. 2020); the effect of industrial structure rationalization under resource dependence on carbon emissions under resource dependence shows negative. With the further development of technology, the reduction effect of industrial structure rationalization under resource dependence on carbon emissions weakens, and then the effect of industrial structure rationalization under resource dependence on carbon emissions shows insignificantly positive. When technology develops into the last level, the effect of industrial structure rationalization under resource dependence shows negative again.

Technological progress can promote the rationalization of the industrial structure, optimize the rational allocation of production factors, enable the coordinated development of various industries, and reduce carbon emissions (Li and Wu 1994). Additionally, some researchers believe that technological progress may not only promote energy efficiency, but it can also promote economic growth, leading to a new demand for energy (Solow 1957; Krugman 1994; Liu et al. 2018; Akadiri et al. 2019). Thus, technological progress may increase the energy demand in the process of rationalizing the industrial structure, and it may also lead to an increase in carbon emissions under the combined effect of the distortion effect of resource dependence.

In the first stage of technological development, technological innovation optimizes the rational allocation of production factor, offsetting the distortion effect of resource dependence; the rationalization of the industrial structure shows a significant reduction effect on carbon emissions. When technological innovation develops to the second stage and the third stage, the economy expands to a stage with more significant energy needs, the carbon emission reduction effect of the industrial structure rationalization is weakened at first, and then the increasing effect of the industrial structure rationalization on carbon emissions appears, resulting in a rebound effect of carbon emissions (Yang et al. 2017). When technological innovation further develops to the fourth stage, energy efficiency improves with the increasing marginal productivity of production factors; offsetting the carbon emissions increases the effect of industrial structure rationalization and the distortion of resource dependence, and the carbon reduction effect of the industrial structure rationalization is significant again.

Carbon emissions rebound effect of industrial structure rationalization

Based on the above findings, it can be observed that when technology develops to a certain stage, industrial structure rationalization leads to an increase in carbon emissions. To further analyze this problem, we used energy-saving technology (ES) and environmental protection technology (EP) to replace technological progress (INV) respectively in model (13), while the industrial structure index (IS) in model (13) was represented by industrial structure rationalization (ISR), two threshold models are constructed. Tables 9 and 10 reveal the threshold test results with energy-saving and environmental protection technologies as threshold variables, respectively.

As depicted in Table 9, the energy-saving technology was taken as the threshold variable. The rationalization of the industrial structure under resource dependence was the core explanatory variable. When the threshold effect test is carried out, and the double threshold P of the energy-saving technology is 0.033, there exist double thresholds, and threshold values are 1.03E − 04 and 1.56E − 04.

In Table 10, the threshold variable was the environmental protection technology. The rationalization of the industrial structure under resource dependence was taken as the core explanatory variable. We found that the double threshold P of environmental protection technology was 0.000; thus, there exist double thresholds with values 0.0018 and 0.0091.

Based on the above test results, we have established two threshold regression models to analyze the impact of industrial structure rationalization on carbon emissions with heterogeneous technological progress. Energy-saving and environmental protection technologies are the threshold variables, carbon emissions are explained variables, and the industrial structure’s rationalization under resource dependence is the dependent variable. The estimated results are presented in Table 11.

Taking environmental protection technology as the threshold variable, the industrial structure’s rationalization under resource dependence presents a three-stage mechanism for carbon dioxide emissions (Aljerf 2016). When the environmental protection technology is in the first stage (CO2 emissions per unit of GDP is more than 0.0091), the impact coefficient of the industrial structure rationalization under resource dependence on carbon emissions is 1.7620; for every 1% increase in the industrial structure’s rationalization under resource dependence, carbon emissions will increase by 1.7620%. When the environmental protection technology is in the second stage (CO2 emissions per unit of GDP is less than 0.0091 and more than 0.0018), the impact coefficient of the industrial structure rationalization under resource dependence on carbon emissions is − 0.8186; for every 1% increase in the industrial structure’s rationalization under resource dependence, carbon emissions will decrease by 0.8186%. In the third stage (CO2 emissions per unit of GDP is less than 0.0091), the impact coefficient of the industrial structure rationalization under resource dependence on carbon emissions is − 2.2943; for every 1% increase in the industrial structure’s rationalization under resource dependence, carbon emissions will decrease by 2.2943%.

It can be observed that when the environmental protection technology develops from the first to the second stage, the distortion effect of resource dependence on the industrial structure rationalization was corrected, and it began to have reduction effects on carbon emissions. Subsequently, with its further development (into the third stage), the carbon emissions reduction effect of the industrial structure rationalization under resource dependence is enhanced. The development of environmental protection technology reflects the concept of low carbon in economic development (Li and Xu 2013; Wu 2017). With the progress of environmental protection technology, the flow of resources to the environmental protection industry is promoted, and the resource allocation efficiency of industrial structure rationalization is improved, which further promotes the carbon reduction effect (Zhao et al. 2021).

Taking energy-saving technology as the threshold variable, the industrial structure’s rationalization under resource dependence also presents a three-stage mechanism for carbon emissions. When it is in the first stage (the energy consumption per unit of GDP is more than 1.03E − 04), the impact coefficient of the industrial structure rationalization under resource dependence on carbon emissions is − 1.3454; for every 1% increase in the industrial structure’s rationalization under resource dependence, carbon emissions decrease by 1.3454%. When the energy-saving technology is in the second stage (the energy consumption per unit of GDP is less than 1.56E − 04 and more than 1.03E − 04), the impact coefficient of the industrial structure rationalization under resource dependence on carbon emissions is 0.5434; for every 1% increase in the industrial structure rationalization under resource dependence, carbon emissions increase by 0.5434%. When the energy-saving technology develops into the third stage (the energy consumption per unit of GDP is more than 1.56E − 04), the impact coefficient of the industrial structure rationalization under resource dependence on carbon emissions is − 0.7586; for every 1% increase in the industrial structure rationalization under resource dependence, carbon emissions decrease by 0.7586%.

It can be found that when the energy-saving technology is in the first stage, the distortion effect of resource dependence on industrial structure rationalization is corrected; the industrial structure rationalization under resource dependence shows a reduction effect on carbon emissions. However, when the energy-saving technology develops from the first to the second stage, under the combined impact of resource dependence, the reduction effect of the industrial structure rationalization on carbon emissions turns into the increasing effect. The rebound effect of industrial structure rationalization on carbon emissions emerges. With the energy-saving technologies developing into the last stage, the increasing effect turns the reduction effect. With the development of energy-saving technology, under the combined impact of resource dependence, the industrial structure’s rationalization first reduces carbon emissions, then increases and finally reduces carbon emissions, displaying an inverted “N” shape.

This phenomenon may be related to the cost of energy consumption (Meng et al. 2019). When energy-saving technologies are relatively underdeveloped, with its development, the resource utilization efficiency improves, and increased rationalization of the industrial structure can significantly reduce carbon emissions, and with the further development of such technology, energy consumption costs are further reduced, alternative production factors appear, energy consumption may increase (Dong et al. 2017b; Kim et al. 2018), which can lead to the appearance of carbon emissions rebound effects caused by industrial structure rationalization. When energy-saving technologies are further developed, energy efficiency further improves, the degree of coordination and cooperation between industries is further enhanced, thereby suppressing carbon emissions again.

Therefore, combining Tables 8 and 11, we can infer that in the initial two stages of technological progress, energy-saving technology and environmental protection technologies are in the first stage; under the combined effect of the distortion effect of resource dependence, the carbon emissions effect of the industrial structure rationalization shows negative, and the effect is reduced with the development of technology. Moreover, when the technological innovation develops into the later stage, the energy-saving technology develops to the second stage, and the environmental protection technology may still be in the first stage; thus, the rationalization of the industrial structure increases carbon emissions. And when the technological innovation develops into the last stage, the energy-saving technology develops to the third stage, and the environmental protection technology may be in the second or third stage; the carbon emissions effect of the industrial structure rationalization shows negative again.

Conclusion and policy implications

Based on the panel data of 30 provinces and cities in China from 2004 to 2019, this paper uses the STIRPAT model and panel threshold model to analyze the specific mechanism of carbon emissions rebound effect caused by industrial structure transformation under resource dependence from the perspective of technological progress. This paper’s notable conclusions can be listed as follows: (1) Without considering other influencing factors, industrial structure upgrading and industrial structure rationalization can effectively reduce CO2 emissions. (2) Resource dependence distorts the carbon emissions reduction effect of industrial structure upgrading and rationalization. In this case, the industrial structure upgrading may increase carbon emissions instead. (3) With the development of technology, the carbon emissions’ increasing effect of industrial structure upgrading under resource dependence reduces, showing a two-stage feature. (4) The industrial structure’s rationalization under resource dependence shows a four-stage characteristic with the development of technology. It shows a significant reduction impact on carbon emissions at first; with technology developing into the second stage, the reduction effect of industrial structure’s rationalization on carbon emissions weakens. With the further development of technology, the industrial structure’s rationalization increases carbon emissions, leading to carbon emissions’ rebound effect. And in the last stage of technology development, the industrial structure’s rationalization shows a reduction effect on carbon emissions again. (5) The environmental protection technology can correct the distortion effect of resource dependence on the industrial structure rationalization and further amplify the industrial structure rationalization’s reduction effects on carbon emissions. (6) With the development of energy-saving technology, industrial structure rationalization has a paradoxical impact on carbon emissions, exhibiting an inverted “N” relationship. The early development of energy-saving technology can enhance the carbon emissions reduction effect of the industrial structure rationalization. With energy-saving technology developing furtherly, the increasing effect of industrial structure rationalization under resource dependence on carbon emissions appears, which causes the carbon rebound in the process of industrial structure rationalization. With energy-saving technology progressing to the last stage, the increasing effect of the industrial structure rationalization on carbon emissions turns into the reduction effect again.

The following policy recommendations are based on the above conclusions.

To reduce carbon emissions and realize a low-carbon economy, resource-dependent regions must regard the upgrading of the industrial structure as an essential development strategy in the medium and long term. In the short term, industrial structure’s rational development should also be promoted, avoiding the rebound effect of carbon emissions caused by the transformation of industrial structure, phasing out backward industries, and transforming resource-intensive industries, and upgrading into a technology-intensive industry.

Technological progress should be used to promote the upgrading of industrial structure and to phase out the current coal-based energy dependence. The government should promote research and production, vigorously develop cutting-edge, innovative technologies and high-tech industries, and help enterprises transform, upgrade, and update their equipment and technologies. The government should encourage developing environmental protection technologies, such as developing new energy and renewable energy; strengthening the exploration, development, and utilization of natural gas, coal bed methane, and shale gas; and increasing the proportion of renewable energy and new energy types in the manufacturing industry.

To reduce the rebound effect of emissions caused by energy-saving technology in the process of rationalization of industrial structure, the government should introduce corresponding measures. It should formulate and improve tax policies, such as energy, resource, and environmental taxes, and internalize the environmental cost of energy. The government should also improve the energy price policy and reform the existing energy price mechanism. By controlling the relative changes in energy prices, the substitution effect over input factors can be directed to release the pressure brought by more energy consumption. Adjusting energy prices and energy consumption can effectively limit and control the carbon emissions’ rebound effect. The government can also encourage enterprises to introduce foreign technologies to realize re-innovation.

In addition, it is worth noting that there are many other factors that can effectively promote the rationalization and upgrading of the industrial structure, such as financial development, natural resource utilization efficiency, environmental regulations, technological progress sources, education investment, etc. Such research is of great significance to the industrial structure adjustment; further study can explore the impact of other factors on the carbon emission reduction effect of industrial structure transformation.

Data availability

Not applicable.

Notes

The resource curse, also known as the paradox of plenty, refers to the paradox that countries with an abundance of natural resources (like fossil fuels and certain minerals), tend to have less economic growth, and worse development outcomes than countries with fewer natural resources (Auty and Warhurst, 1993).

References

Adom PK, Bekoe W, Amuakwa-Mensah F, Mensah JT, Botchway E (2012) Carbon dioxide emissions, economic growth, industrial structure, and technical efficiency: empirical evidence from Ghana, Senegal, and Morocco on the causal dynamics. Energy 47(1):314–325

Akadiri SS, Bekunv FV, Taheri E, Akadiri AC (2019) Carbon emissions, energy consumption and economic growth: causality evidence. Int J Energy Technol Policy 15(2–3):320–336

Aljerf L (2016) Reduction of gas emission resulting from thermal ceramic manufacturing processes through development of industrial conditions. Sci J King Faisal Univ 17(1):1–10

Aljerf L (2018a) High-efficiency extraction of bromocresol purple dye and heavy metals as chromium from industrial effluent by adsorption onto a modified surface of zeolite: kinetics and equilibrium study. J Environ Manag 225:120–132

Aljerf L (2018b) Data of thematic analysis of farmer’s use behavior of recycled industrial wastewater. Data Brief 21:240–250

Aljerf L, Choukaife AE (2016) Sustainable development in Damascus University: a survey of internal stakeholder views. J Environ Stud 2(2):1–12

Amp SY (2012) Chusheng Y (2012) Abundant natural resources and industry structure distortion: influence mechanism and multi-dimensional measure. Soc Sci Nanjing 06:1–8

Auty R, Warhurst A (1993) Sustainable development in mineral exporting economies. Resour Policy 19(1):14–29

Baldwin JS, Allen PM, Winder B, Ridgway K (2005) Modelling manufacturing evolution: thoughts on sustainable industrial development. J Clean Prod 13(9):887–902

Bithas K, Kalimeris P (2015) Revisiting the energy-development link: evidence from the 20th century for knowledge-based and developing economies. Springer

Bongaarts J (1992) Population growth and global warming. Popul Dev Rev 299–319

Brookes L (1990) The greenhouse effect: the fallacies in the energy efficiency solution. Energy Policy 18(2):199–201

Brookes N (1992) In vitro evidence for the hole of glutamate in the CNS toxicity of mercury. Toxicology 76(3):245–256

Chang N (2015) Changing industrial structure to reduce carbon dioxide emissions: a Chinese application. J Clean Prod 103:40–48

Chebbi H, Boujelbene Y (2008) CO2 emissions, energy consumption and economic growth in Tunisia (No. 725-2016-49474)

Chen Y, Lee C (2020) Does technological innovation reduce CO2 emissions? Cross-country evidence. J Clean Prod 263:121550

Chen J, Yuan H, Tian X, Zhang Y, Shi F (2019a) What determines the diversity of CO2 emission patterns in the Beijing-Tianjin-Hebei region of China? An analysis focusing on industrial structure change. J Clean Prod 228:1088–1098

Chen X, Chen YE, Chang CP (2019b) The effects of environmental regulation and industrial structure on carbon dioxide emission: a nonlinear investigation. Environ Sci Pollut Res 26(29):30252–30267

Cheng Z, Li L, Liu J (2018) Industrial structure, technical progress and carbon intensity in China’s provinces. Renew Sustain Energy Rev 81:2935–2946

Cheng Z, Liu J (2019) L L (2019) Research on the influence of industrial structure adjustment and technological progress on smog emission reduction. China Soft Sci 01:146–154

Cheng S, Meng L, Xing L. (2021). Energy technological innovation and carbon emissions mitigation: evidence from China. Kybernetes.

Christoforou CS, Salmon LG, Hannigan MP, Solomon PA, CassTrends GR (2000) In fine particle concentration and chemical composition in southern California. Air Waste Manage 50(1):43–53

Chuai X, Feng J (2019) High resolution carbon emissions simulation and spatial heterogeneity analysis based on big data in Nanjing City, China. Sci Total Environ 686:828–837

Dietz T, Rosa EA (1994) Rethinking the environmental impacts of population, affluence and technology. Hum Ecol Rev 2(1):277–300

Dong F, Yu B, Hadachin T, Dai Y, Wang Y, Zhang S, Long R (2018) Drivers of carbon emission intensity change in China. Resour Conserv Recycl 129:187–201

Dong H, Geng Y, Xi F, Fujita T (2013) Carbon footprint evaluation at industrial park level: a hybrid life cycle assessment approach. Energy Policy 57:298–307

Dong H, Ohnishi S, Fujita T, Geng Y, Fujii M, Dong L (2014) Achieving carbon emission reduction through industrial & urban symbiosis: a case of Kawasaki. Energy 64:277–286

Dong H, Xue M, Xiao Y, Liu Y (2021) Do carbon emissions impact the health of residents? Considering China’s industrialization and urbanization. Sci Total Environ 758: 143688.

Dong K, Sun R, Hochman G, Zeng X, Li H, Jiang H (2017a) Impact of natural gas consumption on CO2 emissions: panel data evidence from China’s provinces. J Clean Prod 162:400–410

Dong KY, Sun RJ, Li H, Jiang HD (2017b) A review of China’s energy consumption structure and outlook based on a long-range energy alternatives modeling tool. Pet Sci 14(1):214–227

Dosi G (1990) Finance, innovation and industrial change. J Econ Behav Organ 13(3):299–319

Du L, Wei C, Cai S (2012) Economic development and carbon dioxide emissions in China: provincial panel data analysis. China Econ Rev 23(2):371–384

Ehrlich L W (1971) Solving the biharmonic equation as coupled finite difference equations. SIAM J Numer Anal 8(2):278–287

Ehrlich PR, Holdren JP (1971) Impact of population growth. Science 171(3977):1212–1217

Englert N (2004) Fine particles and human health—a review of epidemiological studies. Toxicol Lett 149(1–3):235–242

Fan CC (2006) China’s eleventh five-year plan (2006–2010): from “getting rich first” to “common prosperity.” Eurasian Geogr Econ 47(6):708–723

Gan C, Zheng R, Yu D (2011) An empirical study on the effects of industrial structure on economic growth and fluctuations in china. Econ Res J 21(1):85–100

Grossman GM, Krueger AB (1995) Economic growth and the environment. Q J Econ 110(2):353–377

Guo S, Shao L, Chen H, Li Z, Liu J, Xu F, Li J, Han M, Meng J, Chen Z, Li S (2012) Inventory and input–output analysis of CO2 emissions by fossil fuel consumption in Beijing 2007. Eco Inform 12:93–100

Gylfason T, Zoega G (2006) Natural resources and economic growth: The role of investment. World Econ 29(8):1091–1115

Han YH, Huang LX, Wang XB (2015) Is industrial structure upgrading improving ecological civilization——local effect and interregional impact. Soc Sci Abstr 36(12):129–146

Han Y, Zhang F, Huang L, Peng K, Wang X (2021) Does industrial upgrading promote eco-efficiency? ─ A panel space estimation based on Chinese evidence. Energy Policy 154:112286

Hansen B (1999) Threshold effects in non-dynamic panels: Estimation, testing, and inference. J Econ 93(2)345–368

Hansen BE (2000) Sample splitting and threshold estimation. Econometrica 68(3):575–603

Hao Y, Zheng S, Zhao M, Wu H, Guo Y, Li Y (2020) Reexamining the relationships among urbanization, industrial structure, and environmental pollution in China—new evidence using the dynamic threshold panel model. Energy Rep 6:28–39

He N, Li XJ (2018) Enterprise heterogeneity, environmental protection tax and technology innovation——research based on the perspective of taxation and GJreening. Tax Res 000(003):74–80

He B, Zhao D, Zhu J, Darko A, Gou Z (2018) Promoting and implementing urban sustainability in China: An integration of sustainable initiatives at different urban scales. Habitat Int 82:83–93

Holdren J P (1974) Technology, environment, and well-being: some critical choices

Holdren JP, Ehrlich PR (1974) Human population and the global environment. Am Sci 62(3):282

Huang J, Xiang S, Wang Y, Chen X (2021) Energy-saving R&D and carbon intensity in China. Energy Econ 98:105240

Ji L (2018) The impact of technological innovation on the upgrading of China’s manufacturing industry structure: based on the moderating effect of financing constraints. Technoeconomics 11:4

Jia C, Chen S (2018) The Impact of technological innovation on the transformation and upgrading of industrial structure under the new normal: an empirical test based on inter-provincial panel data from 2011 to 2015. Sci Technol Manage Res 38; 409(15): 26–31.

He B, Zhao D, Zhu J, Darko A, Gou Z (2018) Promoting and implementing urban sustainability in China: An integration of sustainable initiatives at different urban scales. Habitat Int 82:83–93

Khazzoom J D (1980) Economic implications of mandated efficiency in standards for household appliances. Energy J 1(4).

Kim SJ, Thornton A, Kara S (2018) Energy flow analysis of an alternative fuel production facility in South Australia. Procedia CIRP 69:288–293

Kuang YP, Tang WT (2015) Time series evolution and regional difference analysis of industrial structure optimization in China. Economist 9:40–47

Li K, Lin B (2017) Economic growth model, structural transformation, and green productivity in China. Appl Energy 187:489–500

Li L, Lei Y, Wu S, He C, Chen J, Yan D (2018) Impacts of city size change and industrial structure change on CO2 emissions in Chinese cities. J Clean Prod 195:831–838

Li W, Wang W, Wang Y, Qin Y (2017a) Industrial structure, technological progress and CO2 emissions in China: analysis based on the STIRPAT framework. Nat Hazards 88(3):1545–1564

Li W, Xu Y (2013) Manufacturing agglomeration, environmental technological efficiency and energy-saving and emission-reduction. Econ Manage 035(009):1–12

Li Y, Wu J (1994) The allocation principle of production factors in the adjustment of industrial structure. Economist 5:61–74

Z Li L Sun Y Geng H Dong J Ren Z Liu X Tian H Yabar HiganoY, 2017b Examining industrial structure changes and corresponding carbon emission reduction effect by combining input-output analysis and social network analysis: a comparison study of China and Japan J Clean Prod 162 61 70

Li, X. (2021). Study on the impact of energy rebound effect on carbon emission reduction at different stages of urbanization in China. Ecol Indic 120, 106983.

Li L, Lei Y, Zhao L, Li X (2015) Study on the optimization of the industrial structure in a mining economic region: Taking carbon emissions as a restriction. Minerals 5(2):203–220

Li Z, Shao S, Shi X, Sun Y, Zhang X (2019) Structural transformation of manufacturing, natural resource dependence, and carbon emissions reduction: Evidence of a threshold effect from China. J Clean Prod 206:920–927

Li Z, Zhou Q (2021) Research on the spatial effect and threshold effect of industrial structure upgrading on carbon emissions in China. J Water Clim Change 12(8):3886–3898

Liang J, Zheng W, Cai J (2007) The decomposition of energy consumption growth in China: based on input-output model. J Nat Resour 22(6):853–864

Liddle B (2013) Urban density and climate change: a STIRPAT analysis using city-level data. J Transp Geogr 28:22–29

Lin J, Sun X, Jiang Y (2013) Endowment, industrial structure, and appropriate financial structure: a new structural economics perspective. J Econ Policy Reform 16(2):109–122

Liu W, Liu Y, Lin B (2018) Empirical analysis on energy rebound effect from the perspective of technological progress—a case study of China’s transport sector. J Clean Prod 205:1082–1093

Liu Y (2009) Exploring the relationship between urbanization and energy consumption in China using ARDL (autoregressive distributed lag) and FDM (factor decomposition model). Energy 34(11):1846–1854

Liu Y, Chen WM, Wang SY, Wu XL (2021) Sustainable growth from a factor dependence and technological progress perspective: a case study of East China. Discr Dyn Nat Soc 2021.

Liu Z, Ciais P, Deng Z, Lei R, Davis SJ, Feng S (2020) Near-real-time monitoring of global CO 2 emissions reveals the effects of the COVID-19 pandemic. Nat Commun 11(1):1–12

Liu Y, Xie Y (2013) Asymmetric adjustment of the dynamic relationship between energy intensity and urbanization in China. Energy Econ 36:43–54

Lutz C, Meyer B, Nathani C, Schleich J (2005) Endogenous technological change and emissions: the case of the German steel industry. Energy Policy 33(9):1143–1154

Ma X, Wang C, Dong B, Gu G, Chen R, Li Y, Zou H, Zhang W, Li Q (2019) Carbon emissions from energy consumption in China: its measurement and driving factors. Sci Total Environ 648:1411–1420

Meng X, Yu W, Zheng C, Wang D, Cao X (2019) Path analysis of energy-saving technology in Yangtze River basin based on multi-objective and multi-parameter optimisation. J Therm Sci 28(6):1164–1175

Mi Z, Pan S, Yu H, Wei Y (2015) Potential impacts of industrial structure on energy consumption and CO2 emission: a case study of Beijing. J Clean Prod 103:455–462

Min X (2017). The problems of financial support for industrial structure upgrading in Beijing-Tianjin-Hebei region and countermeasures. DEStech Trans Econ Bus Manage

Ministry of Environmental Protection People’s Republic of China. (2018) 2017 China State Environ Bull Beijing.

Obas J, Anthony J (2006) Decomposition analysis of CO2 emission intensity between oil-producing and non-oil-producing sub-Saharan African countries. Energy Policy 34(18):3599–3611

O’Reilly AJ (2000) Waste water treatment process selection: an industrial approach. Process Saf Environ Prot 78(6):454–464

Oosterhaven J, Broersma L (2007) Sector structure and cluster economies: a decomposition of regional labour productivity. Reg Stud 41(5):639–659

Peters A (2005) Particulate matter and heart disease: evidence from epidemiological studies. Toxicol Appl Pharmacol 207(2):477–482

Pipkin S, Fuentes A (2017) Spurred to upgrade: a review of triggers and consequences of industrial upgrading in the global value chain literature. World Dev 98:536–554

Poumanyvong P, Kaneko S (2010) Does urbanization lead to less energy use and lower CO2 emissions? Cross Country Anal Ecol Econ 70(2):434–444

Saunders HD (1992) The Khazzoom-Brookes postulate and neoclassical growth. Energy J 13(4).

Shao S, Liu J, Geng Y, Miao Z, Yang Y (2016a) Uncovering driving factors of carbon emissions from China’s mining sector. Appl Energy 166:220–238

Shao S, Yang L (2014) Natural resource dependence, human capital accumulation, and economic growth: a combined explanation for the resource curse and the resource blessing. Energy Policy 74:632–642

Shao S, Yang L, Gan C, Cao J, Geng Y, Guan D (2016b) Using an extended LMDI model to explore techno-economic drivers of energy-related industrial CO2 emission changes: a case study for Shanghai (China). Renew Sustain Energy Rev 55:516–536

Sharma SS (2011) Determinants of carbon dioxide emissions: empirical evidence from 69 countries. Appl Energy 88(1):376–382

Shi X, Zheng Y, Lei Y, Xue W, Yan G, Liu X, Cai B Tong D, Wang J (2021a) Air quality benefits of achieving carbon neutrality in China. Sci Total Environ 795: 148784.

Shi T, Si S, Chan J, Zhou L (2021b) The carbon emission reduction effect of technological innovation on the transportation industry and its spatial heterogeneity: evidence from China. Atmosphere 12(9):1169

Simpson, R. D. (1999). Technological innovation in natural resource industries, pp 11–44.

Solow RM (1957) Technical change and the aggregate production function. Rev Econ Stat 312–320.

Song Q, Zhou N, Liu T, Siehr S A, Qi Y (2018) Investigation of a “coupling model” of coordination between low-carbon development and urbanization in China. Energy policy 121:346–354

Sun Y, Ye C (2012) Abundant natural resources and industry structure distortion: influence mechanism and multi-dimensional measure. Soc Sci Nanjing 6:1–8

Sun C, Zhang F, Xu M (2017) Investigation of pollution haven hypothesis for China: an ARDL approach with breakpoint unit root tests. J Clean Prod 161:153–164

Sun L, Qin L, Taghizadeh-Hesary F, Zhang J, Mohsin M, Chaudhry IS (2020) Analyzing carbon emission transfer network structure among provinces in China: new evidence from social network analysis[J]. Environ Sci Pollut Res 27(18):23281–23300

Teece D J (1996) Firm organization, industrial structure, and technological innovation. J Econ Behav Organ 31(2):193–224

Tian X, Bai F, Jia J, Liu Y, Shi F (2019) Realizing low-carbon development in a developing and industrializing region: impacts of industrial structure change on CO2 emissions in southwest China. J Environ Manage 233:728–738

Tian X, Chang M, Shi F, Tanikawa H (2014) How does industrial structure change impact carbon dioxide emissions? A comparative analysis focusing on nine provincial regions in China. Environ Sci Policy 37:243–254

Wang J, Zhao T, Wang Y (2016) How to achieve the 2020 and 2030 emissions targets of China: evidence from high, mid, and low energy-consumption industrial sub-sectors. Atmos Environ 145:280–292

Wang H, Chen Z, Wu X, Nie X (2019a) Can a carbon trading system promote the transformation of a low-carbon economy under the framework of the porter hypothesis? —Empirical analysis based on the PSM-DID method. Energy Policy 129:930–938

Wang K, Wu M, Sun Y, Shi X, Sun A, Zhang P (2019b) Resource abundance, industrial structure, and regional carbon emissions efficiency in China. Resour Policy 60:203–214

Wang Q, Wang L (2020) The nonlinear effect of population aging, industrial structure, and urbanization on carbon emissions: a panel threshold regression analysis of 137 countries. J Clean Prod 125381.

Wang R, Wang P (2013) The dynamic relationship between urbanization, industrial structure adjustment and environmental pollution——an empirical analysis based on the VAR model. Ind Technol Econ 01:26–31

Wang W (2014) Research on the dynamic relationship between urbanization, industrial structure and carbon emissions——an empirical analysis based on VAR model. Ecol Econ 30(11):28–35

Wang Z, Yin F, Zhang Y, Zhang X (2012) An empirical research on the influencing factors of regional CO2 emissions: evidence from Beijing city, China. Appl Energy 100:277–284

Wei W, Zhang M (2020) The nonlinear impact of industrial structure on CO2 emissions in China. Appl Econ Lett 27(7):576–579

Wei C. (2020). Climate change and industry structure in China: CO2 emission features. Routledge, pp 159–189.

Wei C, Ni J, Shen M (2009) Empirical analysis of provincial energy efficiency in China. Chin World Econ 17(5):88–103

Wei Y, Fan Y, Han Z, Zou L (2010) Energy economics: modeling and empirical analysis in China. Center for Energy and Environmental Policy Research (CEEP), Beijing Inst Technol

Weizsäcker E, Lovins A, Lovins L (1998) Factor four: doubling wealth-halving resource use: the new report to the Club of Rome. Earthscan

Wu X (2017) Study on the dynamic effect and transmission mechanism of environmental protection technology, energy saving and emission reduction policies on ecological environment quality——numerical analysis based on three-sector DSGE model. China Manage Sci 025(012):88–98

Wu L, Sun L, Qi P, Ren X, Sun X (2021). Energy endowment, industrial structure upgrading, and CO2 emissions in China: revisiting resource curse in the context of carbon emissions. Resour Policy, 74, 102329.

Xie Y, Chen J, Li W (2014) An assessment of PM2.5 related health risks and impaired values of Beijing residents in a consecutive high-level exposure during heavy haze days. Environ Sci 35(1):1–8.

Xie W, Yan T, Xia S, Chen F. (2020). Innovation or introduction? The impact of technological progress sources on industrial green transformation of resource-based cities in China. Frontiers Energy Res 301.

Xu B, Lin B (2016) Reducing carbon dioxide emissions in China’s manufacturing industry: a dynamic vector autoregression approach. J Clean Prod 131:594–606

Xu K, Wang J (2006a) Research on the relationship between natural resource abundance and economic development level. Econ Res 1:78–89

Xu K, Wang J (2006b) Factor endowment, geographical factors and new international division of labor. China Soc Sci 6:65–77

Xu X, Ang B (2013) Index decomposition analysis applied to CO2 emission studies. Ecol Econ 93:313–329

Xu L, Tan J (2020). Financial development, industrial structure and natural resource utilization efficiency in China. Resour Policy, 66, 101642.

Yang Z, Shao S, Yang L, Liu J (2017) Differentiated effects of diversified technological sources on energy-saving technological progress: Empirical evidence from China's industrial sectors. Renew Sust Energ Rev 72:1379–1388

Yi Z (2009) Technical progress, industrial structure transition and their effects on China’s employment. J Quant Tech Econ 5.

Yi M, Wang Y, Sheng M, Sharp B, Zhang Y (2020) Effects of heterogeneous technological progress on haze pollution: Evidence from China. Ecol Econ 169:106533

Yin L, Bo N, Jia J (2019) Location oriented induction: research on the industrial structure upgrade mode in China (in Chinese). Finance Trade Res 2:38–45

Yu Y, Deng Y, Chen F (2018) Impact of population aging and industrial structure on CO2 emissions and emissions trend prediction in China. Atmos Pollut Res 9(3):446–454

Yu D, Gao S, Shen L (2017) The empirical study of the education investment’s influences on the industrial structure rationalization in Hainan province. J Serv Sci Manag 10(5):447–463

Yu Y, Li H (2020) Economic growth, industrial structure and nitrogen oxide emissions reduction and prediction in China. Atmos Pollut Res 11(7):1042–1050

Yuan H, Zhu C (2018) Does the National High-tech Zone promote the transformation and upgrading China’s industrial structure. China Ind Econ 8:60–77

Yuan Y, Xi Q, Sun T, Li G (2016) The impact of industrial structure on regional carbon emissions: an empirical analysis based on multinational data. Geogr Res 35(1):82–94

Yuan Y, Xie R (2014) Research on industrial structure adjustment effect of environmental regulation——an empirical test based on Chinese provincial panel data. China Ind Econ 8:57–69

Zhang C, Zhang C, Lin Y (2012) Panel estimation for urbanization, energy consumption and CO2 emissions: a regional analysis in China. ELSEVIER SCI LTD.

Zhang J, Deng W (2010) Industrial structure change and its eco-environmental influence since the establishment of municipality in Chongqing, China. Procedia Environ Sci 2:517–526

Zhang Q, Crooks R (2011) Environmental strategy for the 12th five-year plan period: what can the People’s Republic of China learn from the 11th five-year plan?.

Zhang W, Li G (2015) Analysis on carbon emission reduction effect of heterogeneous technological progress. Sci Sci Manage of S.& T.

Zhang X, Ren J (2011) The relationship between carbon dioxide emissions and industrial structure adjustment for Shandong province. Energy Procedia 5:1121–1125

Zhang Y, Jiang DC (2014) FDI, Government supervision and water pollution in China——an empirical test based on industrial structure and technological progress decomposition indicators. Econ Q 13(2):491–514

Zhang Y, Zhang J, Yang Z, Li S (2011) Regional differences in the factors that influence China’s energy-related carbon emissions, and potential mitigation strategies. Energy Policy 39(12):7712–7718

Zhang Y, Liu Z, Zhang H, Tan T (2014) The impact of economic growth, industrial structure and urbanization on carbon emission intensity in China. Nat Hazards 73(2):579–595

Zhang Z (2003) Why did the energy intensity China’s industrial sector in the 1990s? The relative importance of structural change and intensity change. Energy Econ 25(6):625–638

Zhao H, Geng Y, Xi F, Liu Z, Dong H (2012) Analysis of CO2 emissions related to sectoral energy consumption in Liaoning Province based on production and consumption perspectives. Res Environ Sci 25(11):1290–1296

Zhao T, Ren X (2013) The empirical research of the causality relationship between CO2 emissions intensity, energy consumption structure, energy intensity and industrial structure in China. In The 19th Int Confer Ind Eng Eng Manage (601–609). Springer, Berlin, Heidelberg.

Zhao X, Zhang X, Shao S (2016) Decoupling CO2 emissions and industrial growth in China over 1993–2013: the role of investment. Energy Econ S0140988316302894.

Zhao J, Jiang Q, Dong X, Dong K, Jiang H. (2022). How does industrial structure adjustment reduce CO2 emissions? Spatial and mediation effects analysis for China. Energy Econ 105, 105704.

Zhao K, Zhang R, Liu H, Wang G, Sun X (2021) Resource endowment, industrial structure, and green development of the Yellow River Basin. Sustainability 13(8):4530

Zhao R, Min N, Geng Y, He Y (2017) Allocation of carbon emissions among industries/sectors: an emissions intensity reduction constrained approach. J Clean Prod 142:3083–3094

Zheng Y, Peng J, Xiao J, Su P, Li S (2020) Industrial structure transformation and provincial heterogeneity characteristics evolution of air pollution: evidence of a threshold effect from China[J]. Atmos Pollut Res 11(3):598–609

Zhou M, Chen Q, Cai YL (2013a) Optimizing the industrial structure of a watershed in association with economic–environmental consideration: an inexact fuzzy multi-objective programming model. J Clean Prod 42:116–131

Zhou X, Song M, Cui L (2020) Driving force for China’s economic development under Industry 4.0 and circular economy: technological innovation or structural change? J Clean Prod 271:122680.

Zhou X, Zhang J, Li J (2013b) Industrial structural transformation and carbon dioxide emissions in China. Energy Policy 57:43–51

Zhu B, Zhang M, Zhou Y, Wang P, Sheng J, He K, Wei Y, Xie R. (2019). Exploring the effect of industrial structure adjustment on interprovincial green development efficiency in China: a novel integrated approach. Energy Policy, 134, 110946.

Funding

The financial support from the National Natural Science Foundation of China (No. 71673257), Chongqing Social Science Planning Doctoral Training Program (No. 2021BS056), Chongqing Social Science Planning Project (2019QNGL35), and the Fundamental Research Funds for the Central Universities (SWU1909750).

Author information

Authors and Affiliations

Contributions

YZ: Data curation, methodology, software, and writing; JX: Conceptualization and supervision; FH: Editing and supervision; TJ: methodology, supervision.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicate.

Consent for publication

Not applicate.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Roula Inglesi-Lotz.

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, Y., Xiao, J., Huang, F. et al. How do resource dependence and technological progress affect carbon emissions reduction effect of industrial structure transformation? Empirical research based on the rebound effect in China. Environ Sci Pollut Res 30, 81823–81838 (2023). https://doi.org/10.1007/s11356-022-20193-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-20193-2