Abstract

Urban water pollution has been well controlled by strict management in the past few decades in China. Thus, the central government started to place emphasis on rural water pollution, and increasing number of sewage treatment facilities have been constructed, and currently, they are operating in China. Therefore, thoroughly assessing the operating conditions and the performance of these facilities is important. This article analyzes life cycle assessment and life cycle cost to evaluate the environmental and economic performance of four common technologies to determine how the emerging rural sewage treatment facilities in China are running. The results showed that the plant-adopted anaerobic-anoxic–oxic process was an optimal scheme for lower environmental impact that was also cost-effective. All technologies had similar impacts on eleven environmental categories. Due to cement consumption during the construction phase and electricity consumption during the operation phase, the marine aquatic ecotoxicity potential was the greatest contributor, accounting for approximately 90% of the total potential impact. In addition, this research revealed that electricity consumption during the operation phase was responsible for almost all environmental impact categories, except for eutrophication potential and ozone layer depletion potential categories. Lastly, scenario analysis indicated that reusing treated water and adjusting power structure could be useful measures to promote the sustainable development of rural water environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

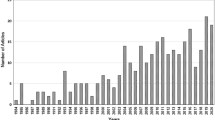

In 2015, China's total annual sewage discharge was 60 billion tons, of which urban sewage was 20 billion tons and rural domestic sewage was 8 billion tons (National Bureau of Statistics of China 2015). During the past decade, the number and the treatment capacity of urban sewage treatment plants increased greatly, and the urban water pollution problem has been solved satisfactorily (Jiang et al. 2020). However, 96% of villages have no drainage channels or sewage treatment systems at present. As such, the problem of rural sewage has gradually become one of the key factors affecting the quality of the regional water environment. To improve the quality of the rural water environment, the central government carries out many rural sewage treatment projects in major rivers, the number of which increased from 763 to 4,810 from 2006 to 2016 (Ministry of Housing and Urban–Rural Development of China 2018). Although the growth rate of China's rural sewage treatment capacity is much higher than that of urban sewage, the performance of rural sewage treatment facilities has been controversial due to unreasonable design and backward management in rural areas.

Scientific and effective performance assessment helps to identify technologies with high-cost effectiveness and to provide guidelines for the design and operation optimization for wastewater treatment projects. Although many studies have addressed the performance evaluation of urban sewage treatment plants, there are few studies on the assessment of emerging rural sewage facilities. Previous studies have mainly compared the sustainability of several treatment projects based on evaluation index systems covering different dimensions (Aulong et al. 2009; Cheng et al. 2020; May et al. 2010; Molinos-Senante et al. 2014). These studies were carried out in a specific area, and the data were not representative. Furthermore, due to the lack of a unified indicator system, it is difficult to arrive at a comparable conclusion.

Life cycle assessment (LCA) is a tool with a universal index system that quantifies the potential environmental impacts of products, processes and systems throughout their life cycle (Finkbeiner et al. 2006). This method has been used to evaluate the performance of wastewater treatment plants since the 1990s, and it was shown to be an ideal evaluating tool in this field (Corominas et al. 2013). Initially, a few studies quantified the environmental burdens of specific sewage treatment cases (Clauson-Kaas et al. 2001; Pasqualino et al. 2009; Venkatesh and Brattebo 2011). Subsequently, several researchers committed to using the LCA to compare and analyze the environmental impacts of a single waste water treatment system under different scenarios, such as determining the best rate for the reuse of water (Tong et al. 2013; Zhang et al. 2010), selecting the best sludge disposal method (Lundin et al. 2004; Xu et al. 2014) and determining the economic and environmental impacts of raising standards (Clauson-Kaas et al. 2004; Mels et al. 1999). With the optimization of traditional technologies and the development of advanced technologies, LCA was used to select the best treatment technology by comparing the environmental impacts of different treatment systems (Dixon et al. 2003; Fuchs et al. 2011; Lundin et al. 2000; Sombekke et al. 1997; Thibodeau et al. 2014). However, these assessments were limited to case studies or the environmental burden comparison of different technologies, which failed to identify the hot issues in the life cycle of these treatment systems. In fact, the construction, operation and end-of-life of treatment facilities consumed enormous energy and materials and produced various waste emissions (Zang et al. 2015). Therefore, it is essential to identify these important issues over the life cycle of the facilities, including the energy, materials and emissions with large contribution. In addition, few studies are targeted at emerging rural sewage treatment technologies at the national level at present.

With the development of the life cycle approach, life cycle costing (LCC) has been used to assess the sustainability of the treatment system (Rossi et al. 2020). LCC is a method to evaluate the costs of products, processes and systems through the life span (Petit-Boix et al. 2017; Reich 2020). LCA limits the introduction of other assessment indicators except for environmental dimensions. According to previous studies, if the two methods have the same scope and basic assumption, LCC can effectively supplement the LCA results to achieve sustainability assessments (Di Maria et al. 2020; Hoogmartens et al. 2014). Therefore, it is common to combine LCC and LCA to evaluate the environmental load and the cost benefits of processing systems.

In this context, this paper combined LCA and LCC to assess the environmental and economic integrated loads of four kinds of emerging rural sewage treatment facilities in China. All samples were selected from the biggest demonstration area, truly reflecting the overall level of rural sewage treatment in China. The purpose of this study was (1) to assess emerging rural sewage treatment technologies in rural areas of China and to answer which one is the best; and (2) to provide targeted suggestions based on the identification and analysis of hot issues, including construction materials replacement, tail water reuse and power structure adjustment. As the largest developing country, these results could provide scientific suggestions for policy decision managers to promote the improvement of water pollution in rural areas in China and to guide other developing countries in the effective treatment of rural sewage.

Methodology

Life cycle assessment

This study used 681 rural sewage treatment facilities in Wuxi as the evaluation object. As one of the first demonstration rural areas to build rural sewage treatment stations, more than 40% of China’s running facilities are operated in Wuxi, including four typical technologies, namely anaerobic-anoxic–oxic process (AAO), membrane bio-reactor process (MBR), sequencing batch reactor process (SBR) and (iv) bio-trickling filter (BTF). Therefore, these samples can best represent the current performance of China’s rural sewage treatment facilities. The characteristics of waste water and treated water for each facility are shown in Table S1.

According to ISO 14040 (Klüppel 2005; Lewandowska et al. 2011), LCA assessment consists of four parts, namely, definition of goal and scope, inventory analysis, life cycle impact assessment and interpretation of results.

Functional unit

As most of the LCA of wastewater treatment in developing countries used 100 m3 as the functional unit (Li et al. 2013; Gallego-Schmid and Tarpani 2019), this research also used 100 m3 as the functional unit for comparison with other studies. All materials, energy consumption, emissions, waste disposal and economic costs were based on this functional unit.

Definition of goal and scope

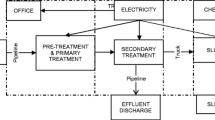

The purpose of this study was to analyze the environmental load of sewage treatment projects throughout the whole life cycle, providing optimization suggestions for the construction and operation of sewage treatment facilities in rural China. According to the existing studies, the environmental impacts of treatment systems mainly came from the construction and the operation phases (Song et al. 2019). Thus, the impact of the end-of-life phase was not considered in this article. The treatment facilities produced little sludge every day, so the environmental impacts of sludge treatment were also excluded. The system boundaries of the four sewage treatment technologies are shown in Fig. 1. Due to the differences in the effluent quality of the four treatment technologies, the discharge of the effluent water was considered in the LCA.

Inventory analysis

To decrease the scale effect, this study selected four facilities with the same treatment capacity. According to the division the of life cycle phrases of rural sewage treatment facilities, data covering three aspects of resource consumption, energy consumption and pollutant discharge were collected. The background data of the raw materials production and transportation in the construction stage were from the Ecoinvent database (version 3.6) and GaBi education database (version 9.1). It was assumed that building materials were transported by diesel trucks (20 t), with an average transportation distance of 50 km. The other inventory data were obtained from field studies, engineering design reports and staff interview. As for the water quality statistical data of the operation stage, the monthly average in 2017 was taken as the benchmark. Table 1 shows the detailed inventory of the four technologies. In this study, as waste water was the object of treatment, the pollutants in the wastewater, such as COD, NH3-N, TP and TN, were regarded as the input of LCA. Therefore, the input of the waste water can bring a negative environmental burden on some impact categories. For example, the input of TP can reduce the value of the EP category.

Impact assessment

Life cycle impact assessment (LCIA) is a key aspect of LCA. It classifies and relates inventory data to the corresponding potential environmental impacts, representing the same impacts as the single indicator. As one of the most widely used LCA methods in the field (Gallego-Schmid and Tarpani 2019; Guinee 2001), CML 2001 was selected as the evaluation model. CML 2001 implements human health, ecosystem quality and resource scarcity as the three key protection areas. The interpretation of LCA studies can be conducted at the midpoint level or the endpoint level through characterization factors, which indicate the environmental impact per unit of stressor (e.g., per kg of emission released). Through specific characterization factors, different environmental mechanisms can be assigned to 11 common and comparable impact categories at the midpoint level, including global warming potential (GWP 100 years), acidification potential (AP), eutrophication potential (EP), ozone layer depletion potential (ODP), abiotic depletion potential fossil (ADPF), abiotic depletion potential elements (ADPE), freshwater aquatic ecotoxicity potential (FAETP), human toxicity potential (HTP), marine aquatic ecotoxicity potential (MAETP), photochemical ozone creation potential (POCP) and terrestrial ecotoxicity potential (TETP).

Interpretation of results

LCA interpretation is the last step of LCA, which analyzes the inventory data and the impact assessment results based on the evaluation goal and scope. The target recommendations are then provided to minimize the environmental impacts of the systems.

Life cycle costing (LCC)

LCC evaluates the economic costs of the system sharing the same scope and assumptions of LCA. The price was based on the current market of sewage treatment industry in China (Commission NDaR 2017).

Results and discussion

LCIA mid-point results

Table 2 lists the detailed characteristic mid-point results of the four rural sewage treatment technologies. By contrast, MBR technology had the worst performance, with eight categories, namely, GWP, AP, EP, ODP, ADPF, MAETP, POCP and TETP being the highest among the four sewage treatment projects. The environmental burden of SBR was close to that of BTF, and the AAO technology had the lowest environmental impact value. Overall, the MBR technology had the most significant impact value in the three categories of AP, ADPF and MAETP. For AP and ADPF, the main reason was the use of fiberglass-reinforced plastic (FRP) material in construction phase. Using FRP as the building material for the MBR technology caused 57.04% and 51.96% of the environmental burden in AP and ADPF, whose life cycle environmental burden has been demonstrated by Jiang (2018) to be worse than that of steel materials used by other three technologies. For MAETP, the use of FRP and the relatively high electricity consumption accounted for 19.38% and 79.24% of the environmental burden, respectively.

To compare and analyze the impacts of the different mid-point categories, this study normalized the characteristic values. The standard values for the impact categories were based on the global per capita environmental impacts in 2016. The detailed data are listed in Table 3. The comparison of the normalized midpoint values of MBR, SBR, AAO and BTF technologies is shown in Fig. 2. The four sewage treatment technologies had similar influences on all environmental categories: the sum impacts of the five categories for MAETP, HTP, GWP, AP and ADPF were considerable, accounting for nearly 90% of the total environmental impacts. Specifically, MAETP had the greatest (approximately 77%) total environmental impact. In comparison, the remaining six environmental categories were negligible. Tong et al. (2013) and Hancock et al. (2012) also arrived at a similar conclusion.

Hotspot analysis

To further interpret the results, inventory and contribution analyses were conducted. Figure 3 illustrates the contribution of the construction and operation phases to eleven impact categories. For the five indicators (MAETP, HTP, GWP, AP and ADPF) with greater environmental impacts in SBR, AAO and BTF technologies, the environmental burdens mainly came from the operation phase. Due to the use of FRP, the construction phase of the MBR technology had a higher proportion of total environmental impacts than the other three technologies where steel was used as building material. According to Jiang (2018), over the life cycle, the environmental impact of rural sewage treatment facilities with FRP as the main building material was 15.2% higher than that of facilities with steel as the main building material. Therefore, steel is more environmentally friendly than FRP.

The contributions of the main subprocesses for the five main categories of each technology are presented in Fig. 4. The results revealed that electricity consumption was the decisive contributor. The source of the electricity consumed a large amount of non-renewable energy and discharged harmful substances (e.g., greenhouse gases, sulfur dioxide), which has been reported in previous studies (Li et al. 2013; Polruang et al. 2018; Sastre et al. 2015). In addition to the electricity consumption, the production and consumption of FRP also contributed greatly to the environmental impact for MBR technology. By contrast, other subprocesses generated negligible environmental loads.

Figure 5 shows the key substances contributing to the five categories of the four technologies. For the GWP category, carbon dioxide (CO2) emitted into the atmosphere was the most important contributor. In addition, Fig. 5a shows that the methane released into the air had a certain impact on GWP. Currently, approximately 70% of China's electricity comes from coal power generation (Yu 2018). Compared with other clean energy, thermal power emits higher levels of carbon dioxide, methane and other greenhouse gases, resulting in high GWP values. For the impact category of AP, sulfur dioxide (SO2) was the primary substance, followed by nitrogen oxides (NOx) (Fig. 5b). Figure 5c identifies that the discharge of arsenic (As) and nickel (Ni) was the greatest contributor to the HTP category. Figure 5d presents that HF was the dominant contributor to MAETP for the MBR technology (50%), and the secondary impact substance was beryllium (Be), which accounted for 22%. However, for SBR, AAO and BTF technologies, Be was the main contributor to the MAETP (43%), followed by nickel (Ni) (25%). The dominance of Be and Ni is mainly caused by the discharge to surface water and groundwater during thermal power production. HF had no significant influence on the MAETP. For the ADPF category (Fig. 3e), coal consumption was the major contributor, and the consumption of crude oil, natural gas and other energy sources also contributed to ADPF to a certain extent.

According to the inventory and hotspot analysis, the consumption of energy and building materials generated almost 100% to the environmental impacts of each technology. Therefore, MBR and SBR with higher energy consumption had worse performance among the four technologies. The electricity consumption of the operation phase contributed the most to the five environmental impact categories, so that the AAO process with the lowest operating energy consumption performed the best compared to the other three technologies.

Sensitivity analysis

Sensitivity analysis of key subprocesses to each technology was carried out, with a variation of 10%. The corresponding changes of the potential environmental impacts are shown in Table 4.

Electricity consumption influenced most environmental categories, which was the most sensitive factor of the five main categories of GWP, AP, ADPF, HTP and MAETP. The sensitivity ranged from 4.34% to 9.43%. In other words, reducing electricity consumption was crucial to decreasing the potential environmental loads for all the treatment facilities. ADPE was not affected much by the change of electricity. In fact, many researchers have proposed that clean and renewable energy, such as hydropower and wind power generation, could significantly reduce the environmental impacts of water management systems (Jeong et al. 2018; Kobayashi et al. 2020; Li et al. 2019). Therefore, optimizing the energy structure for China's rural areas that are dominated by thermal power generation will bring huge environmental incomes. On the other hand, reducing the consumption of FRP remarkably decreased the influence on GWP, ADPE and ADPF categories. The variation of cement had the highest impact on ODP and ADPE categories, and the sensitivity ranged from 9.91% to 10.37%. Therefore, using more environmentally friendly building materials in the construction phase, such as the steel plate mentioned earlier, should be the future direction for managers to consider.

LCC analysis

According to the results of LCIA, the AAO technology had the least impacts on the environment. To determine whether this technology was economically superior, the present worth (PW) method (Kamble et al. 2019) was used to compare the life cycle costs of the four technologies. The uniform present worth factor (UPWF) was used to calculate the present worth of O&M costs spent every year. The following equation is the formula used to calculate UPWF and PW:

where i and T represent the interest rate and the economic life, respectively. In this study, economic life was defined as 50 years (consistent with the life cycle of the facilities), and the interest rate was taken as 12%. Capital costs included any related items during the construction. Operational and maintenance costs took into account labor requirements, electricity consumption and equipment maintenance.

The cost data and results of LCC for the four technologies are presented in Table 5. The highest PW value (28.1824) occurred in the BTF technology due to the highest land requirement compared to the other technologies. The PW value of the AAO (17.6866) technology was slightly higher than that of MBR (17.1667). For the operation phase, the unit cost value of AAO, BTF, MBR and SBR was 2.24, 2.19, 2.00 and 2.09 CNY/m3, respectively, which were approximately the average values of China’s current rural sewage treatment costs (1.38 CNY/m3 to 3.02 CNY/m3) (Guan 2020).

According to Castillo et al. (2016), the cost inputs can be offset by the reduction of environmental damage. Therefore, the AAO technology, with the lowest environmental impacts, has been widely implemented in rural areas recently. The lowest PW value occurred in the SBR (16.1741) technology, but the annual compliance rate of pollutant removal by the SBR process was only 83%. The quality of the effluent under the AAO process was usually better than upgraded SBR process (Singh et al. 2017). Thus, in the context of gradually tightening emission standards, the AAO technology may be the best choice to achieve the trade-off between pollutant removal and cost inputs when traditional and other technologies cannot meet the demand. However, it should be noted that the cost of the AAO technology in the operation phase was slightly higher than the other technologies. Such a burden was due to the demand of electricity. In addition, with the continuous improvement of the technology and the equipment, the difficulty of operation and management will also increase. The introduction of technical personnel will also be a challenge to the backward rural areas.

Scenario analysis

Treated sewage reuse scenario

The properly treated wastewater can be reused for various purposes to achieve environmental benefits and reduce the costs of rural water pollution treatment (Mo and Zhang 2013). At present, the nitrogen and phosphorus in treated rural sewage meets the “Water Quality Standards for Farmland Irrigation,” which is an ideal nutrition source for rural farmlands, gardens, orchards and green spaces. Therefore, this section set up a scenario of using treated sewage for agricultural irrigation to explore the environmental benefits of sewage reuse. Figure 6 shows the improvement of the EP category after effluent reuse. The EP values of the four technologies were reduced by 57.30%, 18.85%, 14.02% and 74.19%, respectively. As for the other environmental categories, the changes brought about by effluent reuse were not significant. This measure reduced the equipment investments and subsequent operation and maintenance costs for nitrogen and phosphorus removal. On the other hand, the cost of these four technologies to treat sewage was between 2.00 CNY/m3 and 2.24 CNY/m3. Since the cost of irrigation water is between 0.9 CNY/m3 and 1.7 CNY/m3 (Commission NDaR 2017), using the treated sewage can save approximately 40.2% to 85.0% of the cost. Therefore, water reuse not only can save water and improve the rural water environment but also reduce costs to a certain degree. In Conclusion, reuse is seen as one of the important outlets for rural sewage in the future, which is consistent with the conclusion of Reznik et al. (2017) and Lyu et al. (2016).

Power structure adjustment scenario

In the previous assessment, the power source was assumed to be 100% thermal power, whose impact values accounted for more than 50% in most major categories. In fact, only 70.99% of the national electricity was generated by thermal power, while 18.59% and 10.42% electricity was generated by hydropower and other power, respectively (Yu 2018). Therefore, two scenarios where hydropower and wind power replace thermal power were proposed to quantify the environmental benefits of clean energy. To compare the environmental burden with the original scenario, the characteristics of waste water and treated water remained unchanged (Table S1). The changes of the potential environmental impacts for the four rural sewage treatment technologies are shown in Fig. 7.

Based on the comparison of the three power generation scenarios, the thermal power generation had the greatest potential environmental impact, followed by wind power generation, and hydropower power generation had the least potential environmental impact. When hydro- and wind power replaced thermal power, minor environmental benefits for EP occurred in the four sewage treatment projects because this category was mainly contributed by the residual nutrients such as nitrogen and phosphorus remaining in the effluent. For categories of GWP, AP, ADPF, FAETP, HTP, MAETP, POCP and TETP, power replacement brought significant improvement, with a range of 40% to 100%. Therefore, adjusting the power structure by appropriately increasing the proportion of hydropower and wind generation can effectively reduce the environmental impact. However, since the price of hydropower and wind power in Wuxi is 0.18 CNY/kWh and 0.30 CNY/kWh higher than thermal power, respectively, the power replacement of hydropower and wind power will increase the unit cost of treated water. For hydropower, the unit cost of AAO, BTF, MBR, SBR technology will increase by 5.87%, 6.67%, 7.10% and 7.22%, respectively. For wind power, the unit cost of AAO, BTF, MBR, SBR technologies will increase by 9.78%, 11.11%, 11.84% and 12.04%, respectively.

In addition, it is difficult to quickly adjust China's power structure in the short term. Hydropower and wind power are also unable to achieve huge price cuts. The government should formulate relevant policies to support the promotion of renewable power. At present, decision makers may also need to pay attention to the sewage treatment mode. Generally, the in situ treatment mode can reduce the cost of the pipe network construction, and the centralized processing mode can reduce the energy and resource consumption in the operation phase (Guan 2020). Decision makers should consider the local situation in rural areas and identify a more environmentally friendly treatment mode.

Conclusion

This study conducted an integrated assessment of four typical rural sewage treatment technologies in China from environmental and economic perspectives. The AAO process was seen as the best choice because of efficient removal of contaminants and low economic costs. According to LCA results, five categories, namely, MAETP, HTP, GWP, AP and ADPF, were the main sources of environmental burdens, accounted for nearly 90% of the total environmental impacts. Hotspot analyses revealed the environmental impacts mainly came from the energy consumption of operation phase. For each technology, optimizing power structure from thermal power to hydropower or wind power will bring more than 50% environmental incomes. Using steel to replace FRP as main building materials in the construction phase could also reduce the environmental loads. What’s more, reuse of tail water can obtain both economic and environmental benefits.

Through analyzing the key contributions and hot issues during the life cycle, this study helps the governmental administrator and operating managers select out the state of art of emerging rural sewage treatment facilities from both economic and environmental dimensions in rural areas of China. LCA and LCC results provide the targeted suggestions for the sustainable development of rural water environment, including FRP materials replacement, reuse of tail water and power structure adjustment. In addition, considering assessment results are affected by other factors such as system boundary, treatment capacity and discharge standards, further research should be conducted to make up for the blank database in this field.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Aulong S, Bouzit M, Doerfliger N (2009) Cost-effectiveness analysis of water management measures in two River Basins of Jordan and Lebanon. Water Resour Manag 23:731–753

Castillo A, Porro J, Garrido-Baserba M et al (2016) Validation of a decision support tool for wastewater treatment selection. J Environ Manage 184:409–418. https://doi.org/10.1016/j.jenvman.2016.09.087

Cheng P, Jin Q, Jiang H, Hua M, Ye Z (2020) Efficiency assessment of rural domestic sewage treatment facilities by a slacked-based DEA model. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.122111

Clauson-Kaas J, Poulsen TS, Jacobsen BN, Guildal T, Wenzel H (2001) Environmental accounting – a decision support tool in WWTP operation and management. Water Sci Technol 44:25–30

Clauson-Kaas J, Poulsen TS, Neergaard-Jacobsen B, Guildal T, Thirsing C (2004) Economic and environmental optimization of phosphorus removal. Water Sci Technol 50:243–248

Commission NDaR (2017) China Price Yearbook. China Price Association, Beijing

Corominas L, Foley J, Guest JS, Hospido A, Larsen HF, Morera S, Shaw A (2013) Life cycle assessment applied to wastewater treatment: State of the art. Water Res 47:5480–5492. https://doi.org/10.1016/j.watres.2013.06.049

Di Maria A, Eyckmans J, Van Acker K (2020) Use of LCA and LCC to help decision-making between downcycling versus recycling of construction and demolition waste. Advances in Construction and Demolition Waste Recycling pp 537–558. https://doi.org/10.1016/b978-0-12-819055-5.00026-7

Dixon AM, Simon M, Burkitt T (2003) Assessing the environmental impact of two options for small-scale wastewater treatment: comparing a reedbed and an aerated biological filter using a life cycle approach. Ecol Eng 20:297–308

Finkbeiner M, Inaba A, Tan RBH, Christiansen K, Kluppel HJ (2006) The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int J Life Cycle Ass 11:80–85. https://doi.org/10.1065/lca2006.02.002

Fuchs VJ, Mihelcic JR, Gierke JS (2011) Life cycle assessment of vertical and horizontal flow constructed wetlands for wastewater treatment considering nitrogen and carbon greenhouse gas emissions. Water Res 45:2073–2081. https://doi.org/10.1016/j.watres.2010.12.021

Gallego-Schmid A, Tarpani RRZ (2019) Life cycle assessment of wastewater treatment in developing countries: A review. Water Res 153:63–79. https://doi.org/10.1016/j.watres.2019.01.010

Guan R (2020) LCA-LCC integrted analysis of rural sewage treatment model. Shanghai Jiao Tong University, China (In Chinese)

Guinee J (2001) Handbook on life cycle assessment - Operational guide to the ISO standards. Int J Life Cycle Ass 6:255–255. https://doi.org/10.1007/Bf02978784

Hancock NT, Black ND, Cath TY (2012) A comparative life cycle assessment of hybrid osmotic dilution desalination and established seawater desalination and wastewater reclamation processes. Water Res 46:1145–1154. https://doi.org/10.1016/j.watres.2011.12.004

Hoogmartens R, Van Passel S, Van Acker K, Dubois M (2014) Bridging the gap between LCA, LCC and CBA as sustainability assessment tools. Environ Impact Assess Rev 48:27–33. https://doi.org/10.1016/j.eiar.2014.05.001

Jeong H, Broesicke OA, Drew B, Crittenden JC (2018) Life cycle assessment of small-scale greywater reclamation systems combined with conventional centralized water systems for the City of Atlanta, Georgia. J Clean Prod 174:333–342. https://doi.org/10.1016/j.jclepro.2017.10.193

Jiang H (2018) Life cycle analysis of rural sewage facilities in suzhou. Suzhou university of science and technology, China (in Chinese)

Jiang H, Hua M, Zhang J, Cheng P, Ye Z, Huang M, Jin Q (2020) Sustainability efficiency assessment of wastewater treatment plants in China: A data envelopment analysis based on cluster benchmarking. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.118729

Kamble S, Singh A, Kazmi A, Starkl M (2019) Environmental and economic performance evaluation of municipal wastewater treatment plants in India: a life cycle approach. Water Sci Technol 79:1102–1112. https://doi.org/10.2166/wst.2019.110

Klüppel H-J (2005) The Revision of ISO Standards 14040–3 - ISO 14040: Environmental management- Life cycle assessment-Principles and framework - ISO 14044: Environmental management-Life cycle assessment-Requirements and guidelines. Int J Life Cycle. https://doi.org/10.1065/lca2005.03.001

Kobayashi Y, Ashbolt NJ, Davies EGR, Liu Y (2020) Life cycle assessment of decentralized greywater treatment systems with reuse at different scales in cold regions. Environ Int. https://doi.org/10.1016/j.envint.2019.105215

Lewandowska A, Matuszak-Flejszman A, Joachimiak K, Ciroth A (2011) Environmental life cycle assessment (LCA) as a tool for identification and assessment of environmental aspects in environmental management systems (EMS). Int J Life Cycle Ass 16:178–186

Li Y, Luo XY, Huang XW, Wang DW, Zhang WL (2013) Life Cycle Assessment of a municipal wastewater treatment plant: a case study in Suzhou, China. J Clean Prod 57:221–227. https://doi.org/10.1016/j.jclepro.2013.05.035

Li Y et al (2019) Life cycle assessment of advanced wastewater treatment processes: Involving 126 pharmaceuticals and personal care products in life cycle inventory. J Environ Manage 238:442–450. https://doi.org/10.1016/j.jenvman.2019.01.118

Lundin M, Bengtsson M, Molander S (2000) Life cycle assessment of wastewater systems: Influence of system boundaries and scale on calculated environmental loads. Environ Sci Technol 34:180–186. https://doi.org/10.1021/es990003f

Lundin M, Olofsson M, Pettersson GJ, Zetterlund H (2004) Environmental and economic assessment of sewage sludge handling options. Resour Conserv Recy 41:255–278

Lyu SD, Chen WP, Zhang WL, Fan YP, Jiao WT (2016) Wastewater reclamation and reuse in China: Opportunities and challenges. J Environ Sci 39:86–96. https://doi.org/10.1016/j.jes.2015.11.012

May et al (2010) Effectiveness of wastewater management in rural areas of developing countries: a case of Al-Chouf Caza in Lebanon. Environ Monit Assess 161:61–69

Mels AR, van Nieuwenhuijzen AF, van der Graaf JHJM, Klapwijk B, de Koning J, Rulkens WH (1999) Sustainability criteria as a tool in the development of new sewage treatment methods. Water Sci Technol 39:243–250. https://doi.org/10.1016/S0273-1223(99)00108-0

Ministry of Housing and Urban-Rural Development of China (2018) China Urban Construction Statistical Yearbook. China Statistics Press, Beijing

Mo W, Zhang Q (2013) Energy-nutrients-water nexus: Integrated resource recovery in municipal wastewater treatment plants. J Environ Manag 127:255–267. https://doi.org/10.1016/j.jenvman.2013.05.007

Molinos-Senante M, Gomez T, Garrido-Baserba M, Caballero R, Sala-Garrido R (2014) Assessing the sustainability of small wastewater treatment systems: A composite indicator approach. Sci Total Environ 497–498:607–617

National Bureau of Statistics of China (2015) China's annual discharge of major pollutants in wastewater. https://data.stats.gov.cn/index.htm. Accessed 26 Nov 2021

Pasqualino JC, Meneses M, Abella M, Castells F (2009) LCA as a decision support tool for the environmental improvement of the operation of a municipal wastewater treatment plant. Environ Sci Technol 43:3300–3307. https://doi.org/10.1021/es802056r

Petit-Boix A et al (2017) Application of life cycle thinking towards sustainable cities: A review. J Clean Prod 166:939–951. https://doi.org/10.1016/j.jclepro.2017.08.030

Polruang S, Sirivithayapakorn S, Talang RPN (2018) A comparative life cycle assessment of municipal wastewater treatment plants in Thailand under variable power schemes and effluent management programs. J Clean Prod 172:635–648. https://doi.org/10.1016/j.jclepro.2017.10.183

Reich MC (2020) Economic assessment of municipal waste management systems–case studies using a combination of life cycle assessment (LCA) and life cycle costing (LCC). J Clean Prod 13:253–263

Reznik A, Feinerman E, Finkelshtain I, Fisher F, Huber-Lee A, Joyce B, Kan I (2017) Economic implications of agricultural reuse of treated wastewater in Israel: A statewide long-term perspective. Ecol Econ 135:222–233. https://doi.org/10.1016/j.ecolecon.2017.01.013

Rossi F, Heleno M, Basosi R, Sinicropi A (2020) Environmental and economic optima of solar home systems design: A combined LCA and LCC approach. Sci Total Environ 744:140569

Sastre CM, González-Arechavala Y, Santos AM (2015) Global warming and energy yield evaluation of Spanish wheat straw electricity generation – A LCA that takes into account parameter uncertainty and variability. Appl Energy 154:900–911. https://doi.org/10.1016/j.apenergy.2015.05.108

Singh NK, Singh RP, Kazmi AA (2017) Environmental impact assessment of a package type IFAS reactor during construction and operational phases: a life cycle approach. Water Sci Technol 75:2246–2256. https://doi.org/10.2166/wst.2017.110

Sombekke HDM, Voorhoeve DK, Hiemstra P (1997) Environmental impact assessment of groundwater treatment with nanofiltration. Desalination 113:293–296. https://doi.org/10.1016/S0011-9164(97)00144-6

Song P, Huang GH, An CJ, Zhang P, Chen XJ, Ren S (2019) Performance analysis and life cycle greenhouse gas emission assessment of an integrated gravitational-flow wastewater treatment system for rural areas. Environ Sci Pollut R 26:25883–25897. https://doi.org/10.1007/s11356-019-05746-2

Thibodeau C, Monette F, Glaus M (2014) Comparison of development scenarios of a black water source-separation sanitation system using life cycle assessment and environmental life cycle costing. Resour Conserv Recy 92:38–54. https://doi.org/10.1016/j.resconrec.2014.08.004

Tong L, Liu X, Liu XW, Yuan ZW, Zhang Q (2013) Life cycle assessment of water reuse systems in an industrial park. J Environ Manage 129:471–478. https://doi.org/10.1016/j.jenvman.2013.08.018

Venkatesh G, Brattebo H (2011) Environmental impact analysis of chemicals and energy consumption in wastewater treatment plants: case study of Oslo, Norway. Water Sci Technol 63:1018–1031. https://doi.org/10.2166/wst.2011.284

Xu CQ, Chen W, Hong JL (2014) Life-cycle environmental and economic assessment of sewage sludge treatment in China. J Clean Prod 67:79–87. https://doi.org/10.1016/j.jclepro.2013.12.002

Yu C (2018) China electric power yearbook 2017. Beijing

Zang Y, Li Y, Wang C, Zhang W, Xiong W (2015) Towards more accurate life cycle assessment of biological wastewater treatment plants: a review. J Clean Prod 107:676–692. https://doi.org/10.1016/j.jclepro.2015.05.060

Zhang QH, Wang XC, Xiong JQ, Chen R, Cao B (2010) Application of life cycle assessment for an evaluation of wastewater treatment and reuse project – Case study of Xi’an, China. Bioresour Technol 101:1421–1425

Acknowledgements

The authors thank Wuxi wastewater treatment authority for providing data collecting help during the preparation of this research.

Funding

This study was supported by Major Science and Technology Program for Water Pollution Control and Treatment from Ministry of Science and Technology of the People’s Republic of China (2017ZX07204001).

Author information

Authors and Affiliations

Contributions

QJ designed the research, reviewed the manuscript, and supervised the revision. PC collected the data, analyzed the results, and drafted the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cheng, P., Jin, Q. Performance evaluation of the emerging rural sewage treatment facilities in China. Environ Sci Pollut Res 29, 51623–51634 (2022). https://doi.org/10.1007/s11356-022-19467-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19467-6