Abstract

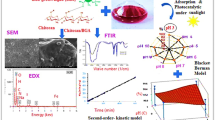

The present work aims to evaluate the removal capacity of Rhodamine B dye (RhB) using nano-porous chitosan (NC) from shrimp shells. NC was characterized by XRD, SEM–EDS, N2 porosimetry, zeta potential (ZP), FTIR, DLS, and zero charge point (pHZCP). Compound central rotational design (CCRD) was used to determine the ideal condition and antimicrobial activity was evaluated against different strains. NC showed characteristic of semi-crystalline material with negative charge surface (around − 21.13 mV), and SBET = 1.12 m2 g−1, Vp = 0.0064 cm3 g−1, Dp = 32.09 nm and pHZCP ≈ 7.98. Kinetic adsorption showed the pseudo first-order model had the best fit, with adsorption capacity (q1) between 3.78 and 64.43 mg g−1 and pseudo first-order kinetic constant (k1) between 0.066 and 0.052 min−1. Sips model best described the equilibrium data, with a maximum adsorption capacity of 505.131 mg g−1. Antimicrobial activity was observed at 0.25 mg mL−1 for different strains. Therefore, NC has potential application in the removal of the dye, combining sustainable development associated with nanotechnology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Contamination of aquatic environments has been the subject of great concern worldwide, mainly because of industrial wastewater with high toxic, bioaccumulative capacity and the presence of recalcitrant compounds (Mandaric et al. 2017; Noorhosseini et al. 2017). For example, it is estimated that around 700,000 tons of dyes wastewater are generated annually, mainly from the textile industries, due to the high consumption of water and organic chemicals in the production process (Bhatia et al. 2017). Moreover, these synthetic dyes are characterized by a complex structure, high molecular weight, greater toxicity, carcinogenic effect, and mutagenicity, indicating a major concern for the environment and human health (Piaskow et al. 2018; Hernández-Montoya et al. 2013; Thue et al. 2018). Among the organic dyes, rhodamine B (RhB) has been used mainly in the dyeing process in the textile industry, due to its ease of solubilization in water, and the washing wastewater containing dye can present concentrations of 20 to 1000 mg L−1 of RhB with high total organic carbon (TOC), high chemical oxygen demand (COD), high concentration of surfactants, high color, in addition to significant toxicity and low pH (Carissimi and Schneider 2010).

Thus, the adsorption process emerges as an alternative for the treatment of dyes wastewater, since it has a series of advantages, such as easy operation, versatility, flexibility, and low-cost alternative materials, such as biosorbents from (agro)industrial residues (Kaur et al. 2016; Peixoto et al. 2013). For example, several types of materials of plant and animal origin have been used as biosorbents for the removal of organic pollutants, such as nutshells, coconut husks, and fibers, rice husks, wood, peat, sludge, and ash (Hadi et al. 2015; Mohan et al. 2008; Figueiredo et al. 2020; Albanio et al. 2021), together with the use of commercial adsorbents such as activated carbon and biochar (Décima et al. 2021; Srivatsav et al. 2020).

Shrimp shells stand out as a precursor of nano-porous chitosan for biosorbent in the removal of the dyes, due to the presence of chemical groups on the biomass surface, such as acetamide groups (from chitin), amines and phosphates from nucleic acids, amino and carboxylic groups (from proteins), and hydroxyl groups from polysaccharides (Metcalf and Eddy 2003). Moreover, contribute to the management of these organic residues, not becoming them an environmental liability (Ferreira et al. 2007).

Nano-porous chitosan has been studied by several researchers as a biosorbent for removing dyes dissolved in aqueous solutions, with a high rate of adsorption in extremely diluted and concentrated solutions, greater selectivity, and affinity for a variety of dyes (Crini and Badot 2007). Moreover, the use of nano-porous chitosan as an antimicrobial agent against a wide range of microorganisms has been studied, according to the molecular weight, viscosity, ionic strength, concentration, pH, temperature, and possible mechanisms of action, aiming to better understand its antibacterial potential (Tavaria et al. 2013).

In this context, the present work aims to evaluate the removal capacity of the rhodamine B (RhB) dye using nano-porous chitosan from shrimp shells, such as biosorbent, through kinetic adsorption. Moreover, the novelty of this manuscript is present applicability of shrimp shells to the preparation of nano-porous chitosan for application as a biosorbent in rhodamine B dye removal, presenting a perspective of reusing this residue, indicating an innovation and/or insight into environmental impacts of waste or wastewater treatment, as well as in wastewater treatment.

Materials and methods

Preparation of shrimp shells

Shrimp shells (Litopenaeus vannamei) were obtained from a local market (Santa Maria – RS, Brazil), and used with chitin precursor for the synthesis of nano-porous chitosan. The preparation of the shells involved the steps of washing, selection, drying, grinding, and sieving, according to the literature (Cavalcanti et al. 2016). Initially, the shells were successively washed with potable water (about 5 times), where all residues were eliminated. After there was the selection (removing viscera or any other unwanted part), drying at 60 °C for 24 h (De Leo model, De Leo Laboratory Equipment, Porto Alegre, Brazil) and shells were ground in ball mills with alumina spheres (Al2O3) (Q298 model, Quimis Equipment, São Paulo, Brazil) for 15 min, at room temperature (25 ± 2 °C), being sieved for uniform particle size (#12).

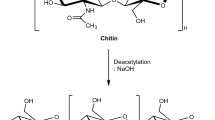

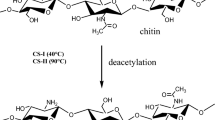

Preparation of nano-porous chitosan

The production process of nano-porous chitosan was carried out from the alkaline deacetylation of chitin, using concentrated alkaline solution (NaOH, 42.1% v/v) at 130 ± 2 °C under magnetic stirring (50 rpm/90 min). Afterward, nano-porous chitosan obtained by deacetylation reaction was purified using 40% v/v glacial acetic acid (CH3COOH, Hexis, P.A.), being centrifuged (6000 rpm/30 min) to remove the undissolved material. The total precipitation of nano-porous chitosan occurred by adding sodium hydroxide (NaOH, Synth, and P.A.) and neutralizing it until pH ≈ 7.0. The chitosan suspension was centrifuged to separate the supernatant, followed by calcined (400 °C/2 h) in a furnace (EDG Equipment’s, model EDG3-PS, São Paulo, Brazil) with a heating rate of 10 °C min−1, milled and sieved for uniform particle size (1.68 mm). Moreover, it is noteworthy that for the preparation of nano-porous chitosan a new methodology was used, based on the top-down method, through abrasion with heat treatment, promoting changes to the nanoscale structure and with specific properties. The collected material was labeled as NC.

Nano-porous chitosan characterization

X-ray diffraction was used to identify crystalline phases and crystallite sizes using the Scherrer Eq. (1), in a Bruker D2 Advance diffractometer (MA, USA), with a copper tube (Kα-Cu = 0.15418 nm), in the range of 2θ from 5 to 70° (increment of 0.05°/s) and acceleration voltage and applied current of 30 kV and 30 mA, respectively.

where: D (nm) is the crystallite size; K is a dimensionless shape factor constant (has a typical value of about 0.9); λ is the wavelength of electromagnetic radiation (λ = 0.15418 nm); Ɵ is the peak position (°) and β is the full width at half maximum (FWHM).

Scanning electron microscopy with energy dispersive spectroscopy (SEM–EDS) was used to evaluate the morphological characteristics and identification of the elemental composition using a Pheno X-ray energy dispersive spectrometer, model PROX 2020 (ThermoFischer Scientific, Massachusetts, USA), operating at 15 kV and the magnification of the 380 × .

N2 adsorption–desorption was used to determine the specific surface area and porosity (diameter and pore volume) in the Gemini VII 2375 Surface Area Analyzer Micrometrics® (Norcross, USA) equipment. Surface specific area (SBET) was determined by the Brunauer–Emmett–Teller Equation (BET method), in the range of P Po−1 = 0.05 to 0.35, while the pore diameter and pore volume by the Barret-Joyner Equation-Halenda (BJH method) (Thommes et al. 2015).

Zeta potential (ZP) was used to determine the surface charge by electrophoretic light scattering method (PALS) in the Nanobrook Omni equipment (Brookhaven Instruments Corporation, NY, USA). For the analyses, 1.5 mL of the sample was dispersed in distilled water and added onto the zetasizer cell (Zetasizer Nano ZSP) at a spreading angle of 15° at room temperature (25 ± 2 °C), where all measurements were in triplicate.

Zero charge point (pHZCP) was determined using the methodology with 11 points at different pH (2–12), according to the literature (Postai et al. 2016). Therefore, 0.1 g of nano-porous chitosan was added in a solution with RhB at different pH (2, 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12), where this initial pH was adjusted with HCl (Sigma-Aldrich, PA) and NaOH (Sigma-Aldrich, PA), both at 1.0 mol L−1. The final pH was measured after 24 h at 120 rpm of rotation and room temperature (25 ± 2 °C).

FTIR was used to identify the functional group and to determine the degree of deacetylation (DD) (Cervera et al. 2004) using a Perkin Elmer spectrometer (Spectrum One model, Shelton, USA) at transmittance mode operation at a range of 4000 to 450 cm−1, with 4 cm−1 resolution and 32 runs, according to the Eq. (2).

where: DD (%) is the degree of deacetylation; AC=O is the absorbance of the C = O group and A-OH is the absorbance of the -OH group.

Nano-porous chitosan molecular weight was determined using the viscosimetric method (HAAKE Viscotester 550 from Thermo Scientific, Victoria, Australia). Thus, the reduced viscosity was determined using the Equation of Huggins, after this was converted into molar mass using the MarkHouwink-Sakurada Equation (Eq. 3) (Zhang and Neau 2001):

where: η is the intrinsic viscosity (mL g−1), MW is the molecular weight (Da), K = 1.81 × 10−3 mL g−1 and a = 0.93.

Dynamic light scattering (DLS) was used to evaluate the diameter of the nano-porous chitosan using NanoBrook Omni equipment (Brookhaven Instrument Corporation, NY, USA) equipped with a red laser diode (35 mV, λ = 640 nm) at a detection angle of 90°. Moreover, the procedure was carried out in triplicates by using BIC Dynamic Light Scattering Particles Sizing Software, version 1.2.1.0 (USA).

Compound central rotational design (CCRD)

To determine the ideal conditions of the process, preliminary adsorption tests were carried out, evaluating the variables of biosorbent concentration (nano-porous chitosan) and the pH, having as a variable depending on the RhB removal (%R). Thus, an experimental design of the central composite rotational design (CCRD) type was used, using the Statistic software version 10.0 (StatSoft Inc., USA), with 2 variables (k), coded levels of − α, − 1, 0, + 1, + α, and axial spacing of 1.41 (2 k/4), totaling 11 tests ((nano-porous chitosan) = 0.88–5.12 g L−1 and pH = 5.4–9.6). Moreover, the time of 180 min, a magnetic stirring of 150 rpm, and the room temperature of 25 ± 2 °C were fixed for all tests.

Adsorption tests

The adsorption tests were carried out in a batch process, with the RhB solution and nano-porous chitosan. Thus, aliquots (5 mL) were collected at predetermined times (0, 5, 15, 30, 45, 60, 75, 90, 120, 150, and 180 min), filtered (0.22 μm filter, millex GP), centrifuged (10,000 rpm for 10 min) and analyzed in a spectrophotometer (Cary 100Scan, UV–Vis Spectrophotometers, USA) at the characteristic wavelength of RhB (λ = 553 nm). In addition, the concentration of nano-porous chitosan and pH of the reaction medium was varied in the range of 0.88–5.12 g L−1 and 5.4–9.6, respectively, being adjusted using NaOH solutions (0.1 mol L−1) and HCl (0.1 mol L−1). Equations (4) and (5) present the percentage of RhB removal and maximum adsorption capacity, respectively.

where: C0 and Ct (mg L−1) are the initial and final options of RhB, respectively, V (L) is the solution volume and m (g) is the mass of biosorbent (nano-porous chitosan).

Kinetic adsorption

The kinetic adsorption of the RhB dye using nano-porous chitosan was evaluated using pseudo first-order (PFO) (Sadegh et al. 2015), pseudo second-order (PSO) (Zhang et al. 2014), and intraparticle diffusion (Wu et al. 2001) models, according to the Eqs. (6)–(8), respectively. Thus, adsorption capacity (qt) versus time (t) curves were used, with an initial concentration of RhB ranging from 20 to 400 mg L−1 and using the ideal condition by CCRD 22 ((NC) = 4.5 g L−1 and pH ≈ 9.0).

where: q1 is the theoretical value of the adsorption capacity obtained through the pseudo first-order model (mg g−1); k1 is the pseudo first-order kinetic constant (min−1); q2 is the theoretical value of the adsorption capacity obtained through the pseudo second-order model (mg g−1); k2 is the pseudo second-order kinetic constant (g mg−1 min−1); kd is the intraparticle diffusion rate (mg g−1 min−0,5); t is the agitation time (min) and q is the amount absorbed per mass of adsorbent (mg g−1).

Adsorption equilibrium isotherms

The adsorption equilibrium was analyzed using the Langmuir, Freundlich, and Sips models, according to the Eqs. (9)–(11), respectively (Langmuir 1918; Freundlich 1906; Sips 1948).

where qm is the maximum adsorption capacity (mg g−1); KL is the Langmuir constant (L mg−1); Ce is the equilibrium concentration (mg L−1); KF is the Freundlich constant ((mg g−−1) (mg L−1)−1/n); 1/n is the heterogeneity factor; ks is the Sips constant (L mg−1) and m heterogeneity factor.

Antimicrobial activity

Antimicrobial activity was evaluated against the strains of Klebsiella pneumoniae ATCC 700,603, Escherichia coli ATCC 25,922, Pseudomonas aeruginosa ATCC 27,853, and Staphylococcus aureus ATCC 25,923 to investigate the antimicrobial activity of NC against these strains. Minimum inhibitory concentration (MIC) was determined by the microdilution method using 96-well plates, following the guidelines recommended by BrCAST (2018) in triplicate. Suspensions of the microorganisms under analysis were prepared in Mueller–Hinton broth (MHB) cations adjusted and regulated at 0.5 McFarland scale (1.5 × 106 CFU mL−1), with bacterial inoculate diluted 1:20 v/v. Serial dilutions of the compounds (0.5–0.00097 mg mL−1 for nano-porous chitosan) were carried out in 100 μL of MHB, then 10 μL of bacterial inoculate was added to the wells. Plates were incubated for 18–24 h at 37 ± 2 °C in a bacteriological incubator. After the incubation time, the analysis of the plates was carried out by adding 20 μL of triphenyl tetrazolium chloride (10 mg mL−1) to each well, and the plates were incubated again for 2 h at 37 ± 2 °C in a bacteriological incubator. After this time, plates were analyzed visually, where the change of color from colorless to red represented bacterial growth, and MIC was determined as the lower concentration of the compound that presented no visible bacterial growth. For comparison purposes, a commercial chitosan power was used with a deacetylation degree of 80% and molecular weight of 700 kDa from Sigma-Aldrich (São Paulo-SP, Brazil). Figure 1 shows the representation of the nano-porous chitosan dilution at culture media as well as microorganisms distribution in 96-well plates with the NC sample, where concentrations for 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 columns are 0.5; 0.25; 0.125; 0.0625; 0.03125; 0.01562; 0.00781; 0,0039; 0.00195; and 0.00097 mg mL−1, respectively.

Statistical evaluation of adjusted models

Equilibrium and kinetic parameters were determined according to the fit of the models with the experimental data, using non-linear regression. The calculations were performed using the Statistic 9.1 software (StatSoft, USA), using the Quasi Newton estimation method. The determination coefficient (R2), adjusted determination coefficient (R2adj), mean percentage error (ARE), and error sum of squares (SSE) were used to evaluate the fit quality of the models, according to the Eqs. (12)–(15).

where: yexp is the experimental data, ypred is the predicted value, n is the number of experimental values, and p is the number of parameters according to the model.

Results and discussion

Characterization of the nano-porous chitosan

Figure 2 shows the X-ray pattern diffractogram of the NC prepared from shrimp shells.

According to Fig. 2, nano-porous chitosan diffractogram showed typical peaks of semi-crystalline material, with a broad base around 2θ = 10° (0 2 0) and 2θ = 20° (1 1 0), as determined by the literature (Luo et al. 2011). Moreover, NC has a semi-crystalline profile due to strong intra- and intermolecular interactions, characterized by hydrogen bonds formed between the amine, alcohol, amide, and other functional groups present in the chitosan molecule. These strong interactions provide a certain organization to the crystal structure of chitosan. Furthermore, it was possible to determine an average analyte size of about 35.5 nm, indicating a nanometric scale, confirmed by the literature (Uragami and Tokura 2006).

Figure 3a shows the micrograph of nano-porous chitosan prepared from shrimp shells, indicating a rough and untidy surface with the presence of protuberances and cavities, providing greater porosity and interparticle diffusion of the RhB dye, favoring the process of adsorption, while Fig. 3b shows the chemical composition (% weight) by EDS, indicating the presence of oxygen (51.75%), sodium (32.12%), carbon (13%), and aluminum (3.13%). Therefore, it was possible to verify the predominant forms involving Na and Al are hydroxides and oxides, because of the alkaline deacetylation of chitin used to preparation of nano-porous chitosan (Albanio et al. 2021).

Figure 4 shows the zero charge point (pHZCP) of the NC from shrimp shells, indicating around 7.98, confirmed with the literature (Hosain et al. 2020). Moreover, when the pH is lower than pHZCP, NC surface will be protonated, favoring the adsorption of compounds with negative charges (such as anionic dyes), and a large number of anions will be adsorbed to balance the positive charges. However, when the pH is higher than pHZCP, NC surface will be deprotonated, favoring the adsorption of compounds with positive charges (such as cationic dyes). This process can be explained by the electrostatic attraction between the charge generated on the surface of the adsorbent material and the anionic or cationic group of the solution (Mall et al. 2006). It is noteworthy that the RhB molecule is characterized by presenting a positive charge, due to its cationic nature (Salleh et al. 2011). Thus, the RhB adsorption process will be favored when pH > pHZCP.

Figure 5 shows the N2 adsorption/desorption isotherms of the NC, indicating typical type IV isotherms of mesoporous solids (2 < Dp < 50 nm) with filling in multilayer and the presence of an H3-type hysteresis curve with wedge pores and cones, according to the classification of Brunauer–Deming–Deming–Teller (IUPAC 2015).

NC showed a surface specific area of 1.12 m2 g−1 and pore volume of 0.0064 cm3 g−1 and the pore diameter was 32.09 nm, consistent with that found with the XRD crystallite diameter, according to the literature (Hosseini et al. 2019; Salamat et al. 2019). About the zeta potential, the surface charge was negative (− 21.13 ± 1.57 mV), indicating charge compatibility, favoring attractive forces, since the RhB molecule has cationic characteristics (positive charge) (Debrassi et al. 2011).

Figure 6 shows the FTIR spectrum for NC, where some specific stretching was identified, such as (Sakkayawong et al. 2005) (a) at 860 cm−1 is relative to C-N bonds, and at 2420 cm−1 the stretching of the primary amine; (b) the strong band at wavelength 1440 cm−1 is the typical amino group of chitosan (-NH2); (c) at 1650 cm−1 is the axial deformation relative to the C = O bonds (typical amide I band); and (d) at 3470 cm−1 is the OH stretching vibrations. Moreover, nano-porous chitosan prepared from the shrimp shells showed a molecular weight of 97 ± 8 kDa and a degree of deacetylation of 86.4 ± 0.5%.

Figure 7 shows the particle size distribution of the nano-porous chitosan, indicating a good homogeneity of particle size distribution with the size of a nanoparticle was in the range of 6.63–50.09 nm where the highest fraction of NC was 18.23 nm.

Compound central rotational design (CCRD 22)

To define the ideal condition for the biosorption process for the RhB removal using NC, the experimental design was carried out, using NC concentration and pH as independent variables, and RhB removal (%) as a dependent variable. Thus, the experimental design CCRD 22 was used, containing 11 experiments including triplicate of the central point and the limits defined as maximum and minimum represented coded in Table 3 by − 1.41 and + 1.41, according to Table 1. Figure 7 shows the Pareto graph indicating the standardized effects with a statistical significance of 95% (p < 0.05).

According to Fig. 8, it was possible to verify that the concentration of nano-porous chitosan and the pH showed a positive linear influence on the RhB removal. However, both independent variables indicated a negative quadratic relationship in the RhB removal, and the interaction pH and (NC) did not affect the RhB removal. In addition, Fig. 9 shows the response surfaces where it was possible to verify that the highest percentage of removal of the RhB dye (86.84%) occurred with the concentration of nano-porous chitosan of 4.5 g L−1 and pH of 9.0, indicating the ideal condition.

According to Eq. 16, regression coefficients and statistical parameters of the quadratic model for the response variable (%R), indicated the model was predictive since the calculated F values (Fcal = 66.5) was higher than the standard F-value tabulated (Ftab = 5.05), with R2 = 0.9852, showing that the experimental values referring to the RhB removal and the predicted value were adequate for the model.

Kinetic adsorption

Figure 10 shows the kinetic adsorption of the RhB removal using nano-porous chitosan to the adsorption capacity curves (qt) with time (t), and initial concentration of RhB ranging from 50 to 400 mg L−1 under ideal condition by CCRD ((NC) = 4.5 g L−1 and pH = 9.0).

Table 2 shows the kinetic parameters of RhB uptake with the nano-porous chitosan ((NC) = 4.5 g L−1 and pH = 9) of the PFO (a), PSO (b), and intraparticle diffusion (c) models. respectively.

According to Table 2, it was possible to observe that the PFO kinetic model presented the best fit of the experimental data considering the high values of the coefficient of determination (R2 > 0.99) and adjusted coefficient of determination (R2adj > 0.99), and lower values of ARE, indicating that the limiting stage of the adsorption process is the external diffusion, ideal to fast adsorption process (about 20–30 min) applied for dye removal (Vimonses et al. 2009). The value of the pseudo first-order kinetic constant corresponds to 0.066–0.052 min−1, to 3.783–64.435 mg g−1, and 50–400 mg L−1, respectively. Moreover, it was possible to verify an increase in the adsorption capacity and specific reaction rate as the dye concentration increases, due to the increase in the number of molecules available to be adsorbed on the nano-porous chitosan surface until the saturation of the active sites.

Equilibrium adsorption

To the adsorption equilibrium study, Langmuir, Freundlich, and Sips adsorption isotherm models were used to fit the experimental data, to describe the interaction of adsorbent-adsorbate, according to Fig. 11. Table 3 shows the respective parameters of the models.

According to Fig. 11, the shapes of the curves for RhB dye can be classified as type L1, which the adsorption sites were not fully used, according to Giles classification (Giles et al. 1974). Moreover, the Sips model showed the best statistical indicators (R2, R2adj, ARE, and SSE) and was selected to represent the equilibrium study. The maximum adsorption capacity determined from the Sips model was 505.131 mg g−1 for RhB dye and results were according to the literature (Sugashini et al. 2022; Cheung et al. 2009).

Antimicrobial activity

Nano-porous chitosan showed antimicrobial activity against the four bacterial species tested in the concentration of 0.25 mg mL−1, while the commercial chitosan did not show any antimicrobial effect in the concentration range analyzed, according to Table 4.

The antimicrobial activity can be observed against the four bacteria tested, because nano-porous chitosan has a variety of antibacterial mechanisms (Li and Zhuang 2020) since nano-porous chitosan can bind to bacteria through electrostatic interactions, with cell death occurring rapidly (Raafat et al. 2008). One of the most accepted antibacterial mechanism is that the positive charge of nano-porous chitosan combines with the negative charge on the surface of the bacteria, causing the destruction of the structure and extravasation of intracellular components to occur, leading to cell death (Tan et al. 2013; Jeon et al. 2014). The antimicrobial activity of nano-porous chitosan is mainly due to microbial factors, which involve the species of microorganisms and the target cell (Kong et al. 2010). Moreover, the inhibitory efficiency of nano-porous chitosan on microorganisms is quite variable (Hernandez-Luzardo et al. 2008), where studies report that the antibacterial activity is greater in gram-negative bacteria than in gram-positive ones (Chung et al. 2004), while others point to gram-positive bacteria as being more susceptible (Zhong et al. 2008); and there are still those who did not observe significant differences in the antimicrobial effect on bacteria (Wang et al. 2004). Compared to chitosan in the conventional form, nano-porous chitosan nanoparticles have a greater potential of antibacterial activity because it has a larger surface area of nanomaterial and greater affinity with microbial cells (Ramezani et al. 2015).

Conclusion

In this work, a study was carried out to evaluate the application potential of the nano-porous chitosan biosorbent for the removal of the dye rhodamine B. The micrograph of the nano-porous chitosan showed a surface with certain uniformity and smooth with certain protuberances and cavities, providing greater porosity and interparticle diffusion of the RhB dye, favoring the adsorption process. The pHZCP of NC was around 7.98, and it was observed that when the pH is lower than the pHZCP, the nano-porous chitosan favors the adsorption of negatively charged compounds, and when higher, it favors the adsorption of positive liquid compounds, and this happens through the electrostatic attraction between the charge generated on the surface of the adsorbent material. For an analysis of the crystalline structure (DRX) of nano-porous chitosan, it was possible to verify the typical peaks of a semi-crystalline material. Through N2 porosimetry, NC showed type IV isotherm typical of mesoporous solids and the presence of a hysteresis curve of type H3. Regarding the kinetic studies, the PFO showed the best fit of the experimental data, characteristics for dye adsorption. The maximum adsorption capacity was 505.131 mg g−1, according to the Sips model. About antimicrobial activity, nano-porous chitosan prepared antimicrobial activity against the four bacterial species tested in the concentration of 0.25 mg mL−1, while commercial chitosan did not show any antimicrobial effect under the conditions analyzed (> 0.5 mg mL−1). Thus, considering that despite the few publications involving the biosorbent (NC), the results obtained are promising and reveal a potential for the treatment of wastewater with dyes via adsorption.

Availability of data and materials

The data that support the findings of this study are available on request from the corresponding author.

Code availability

Not applicable.

References

Albanio II, Muraro PCL, Da Silva WL (2021) Rhodamine B dye adsorption onto biochar from olive biomass waste. Water Air Soil Poll 232:214–224. https://doi.org/10.1007/s11270-021-05110-6

Bhatia D, Sharma NR, Singh J, Kanwar R (2017) Biological methods for textile dye removal from wastewater : a review. Crit Rev Env Sci Tec 47:1836–1876. https://doi.org/10.1080/10643389.2017.1393263

BrCAST (2018). Brazilian committee on antimicrobial susceptibily testing. Antimicrobial sensitivity test. Disk transmission method . EUCAST. Version 6.0

Carissimi E, Schneider IAH (2010) Treatment and continued use of water in the gemstone industry of Soledade, RS. Technologies for the gems, jewelry and mining. Federal Universit of Rio Grande do Sul, Porto Alegre

Cavalcanti CF, Rocha LKS, Oliveira HML, Queiroz JCF (2016) Chitosan production from shrimp shell fermentation. Rev Bras Prod Agroindustriais 18:503–515

Cervera MF, Heinamaki J, Rasanem M, Maunu SL, Karjalainen M, Acosta OMN, Colarte AI, Yliruusi J (2004) Solid state characterization of chitosan derived from lobster chitin. Carbohyd Polym 58:401–408. https://doi.org/10.1016/j.carbpol.2004.08.017

Cheung WH, Szeto YS, McKay G (2009) Enhancing the adsorption capacities of acid dyes by chitosan nano particles. Bioresource Technol 100:1143–1148. https://doi.org/10.1016/j.biortech.2008.07.071

Chung YC, Su YP, Chen CC, Jia G, Wang HL, Wu JCG, Lin JG (2004) Relationship between antibacterial activity of chitosan and surface characteristics of cell wall. Acta Pharm Sinic 25:932–936

Crini G, Badot PM (2007) Application of chitosan, a natural aminopolysaccharide, for dye removal from aqueous solutions by adsorption processes using batch studies: a review of recent literature. Progr Polym Sci 33:399–447. https://doi.org/10.1016/j.progpolymsci.2007.11.001

Debrassi A, Corrêa AF, Baccarin T, Nedelko N, Ślawska-Waniewska A, Sobczak K, Dłużewski P, Greneche JM, Rodrigues CA (2011) Removal of cationic dye from aqueous solution using N-benzyl-O-carboxymethylchitosan magnetic nanoparticles. Chem Eng J 183:284–293. https://doi.org/10.1016/j.cej.2011.12.078

Décima MA, Marzeddu S, Barchiesi M, Marcantonio CD, Chiavola A, Boni MS (2021) A review on the removal of carbamazepine from aqueous solution by using activated carbon and biochar. Sustainability 13:11760–11809. https://doi.org/10.3390/su132111760

Ferreira JM, Silva FLH, Alsina OLS, Oliveira LSC, Cavalcanti EB, Gomes WC (2007) Study of balance and kinetics of Pb2+ biosorption by Saccharomyces cerevisiae. Quim Nova 30:1188–1193. https://doi.org/10.1590/S0100-40422007000500026

Freundlich H (1906) Over the adsorption in solution. Z Phys Chem 57:358–471

Figueiredo VM, Lourenço JB, Vasconcellos NJS, Da Silva WL (2020) Preparation, characterization and photocatalytic activity of activated charcoal from microalgae for photocatalytic degradation of rhodamine B dye. Cerâmica 66:367–372. https://doi.org/10.1590/0366-69132020663802937

Giles CH, Smith D, Huitson A (1974) A general treatment and classification of the solute adsorption isotherm. I Theoretical J Colloid Interface Sci 47:755–765. https://doi.org/10.1016/0021-9797(74)90252-5

Hadi P, Xu M, Ning C, Lin CSK, Mckay GA (2015) Critical review on preparation, characterization and utilization of sludge-derived activated carbons for wastewater treatment. Chem Eng J 260:895–906. https://doi.org/10.1016/j.cej.2014.08.088

Hernández-Montoya V, Pérez-Cruz MA, Mendoza-Castillo DI, Moreno-Virgena MR, Bonilla-Petriciolet A (2013) Competitive adsorption of dyes and heavy metals on zeolitic structures. J Environ Manage 116:213–221. https://doi.org/10.1016/j.jenvman.2012.12.010

Hernandez-Luzardo AN, Bautista-Banos S, Velazquez-Del Valle MG, Mendez-Montealvo MG, Sanchez-Rivera MM, Bello-Perez LA (2008) Antifungal effects of chitosan with different molecular weights on in vitro development of Rhizopus stolonifer (Ehrenb.:Fr.) Vuill. Carbohyd Polym 73:541–547. https://doi.org/10.1016/j.pestbp.2008.09.001

Hosain ANA, Nemr AE, Sikaily AE, Mahmoud E, Amira MF (2020) Surface modifications of nanochitosan coated magnetic nanoparticles and their applications in Pb(II), Cu(II) and Cd(II) removal. J Environ Chem Eng 8:104316–104329. https://doi.org/10.1016/j.jece.2020.104316

Hosseini SM, Younesi H, Bahramifar N, Mehraban Z (2019) A novel facile synthesis of the amine-functionalized magnetic core coated carboxylated nanochitosan shells as an amphoteric nanobiosupport. Carbohyd Polym 221:174–185. https://doi.org/10.1016/j.carbpol.2019.06.006

IUPAC (2015) International Union of Pure and Applied Chemistry. Pure Appl Chem 87:1051–1069

Jeon SJ, Oh M, Yeo WS, Galvão KN, Jeong KC (2014) Underlying mechanism of antimicrobial activity of chitosan microparticles and implications for the treatment of infectious diseases. J Plos One 9:e92723–e92732. https://doi.org/10.1371/journal.pone.0092723

Kaur K, Mor S, Ravindra K (2016) Removal of chemical oxygen demand from landfill leachate using cow-dung ash as a low-cost adsorbent. J Colloid Interf Sci 469:338–343. https://doi.org/10.1016/j.jcis.2016.02.025

Kong M, Cheng XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–63. https://doi.org/10.1016/j.ijfoodmicro.2010.09.012

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Li J, Zhuang S (2020) Antibacterial activity of chitosan and its derivatives and their interaction mechanism with bacteria: current state and perspectives. Eur Polym J 138:109984–109995. https://doi.org/10.1016/j.eurpolymj.2020.109984

Luo D, Sang L, Wang X, Xu S, Li X (2011) Low temperature, pH-triggered synthesis of collagen-chitosan-hydroxyapatite nanocomposites as potential bone grafting substitutes. Mater Lett 65:2395–2397. https://doi.org/10.1016/j.matlet.2011.05.011

Mall ID, Srivastava DC, Agarwal NK (2006) Removal of Orange-G and methyl violet dyes by adsorption onto bagasse fly ash-kinetic study and equilibrium isotherm analyses. Dyes Pigments 69:210–223. https://doi.org/10.1016/j.dyepig.2005.03.013

Mandaric L, Diamantini E, Stella E, Cano-Paoli K, Valle-Sistac J, Molins-Delgado D, Bellin A, Chiogna G, Majone B, Diaz-Cruz MS, Sabater S, Barcelo D, Petrovic M (2017) Contamination sources and distribution patterns of pharmaceuticals and personal care products in Alpine rivers strongly affected by tourism. Sci Total Environ 590–591:484–494. https://doi.org/10.1016/j.scitotenv.2017.02.185

Metcalf, Eddy (2003) Wastewater engineering: treatment and reuse. McGraw-Hill, New York

Mohan D, Singh KP, Singh VK (2008) Wastewater treatment using low cost activated carbons derived from agricultural byproducts A case study. J Hazard Mater 152:1045–1053. https://doi.org/10.1016/j.jhazmat.2007.07.079

Noorhosseini SA, Allahyari MS, Damalas CA, Moghaddam SS (2017) Public environmental awareness of water pollution from urban growth: the case of Zarjub and Goharrud rivers in Rasht. Iran Sci Total Environ 599–600:2019–2025. https://doi.org/10.1016/j.scitotenv.2019.133595

Peixoto FP, Marinho G, Rodrigues K (2013) Textile Dyes: a Review. Holos 5:98–106

Piaskow K, Świderska-Dąbrowska R, Zarzycki PK (2018) Dye removal from water and wastewater using various physical, chemical, and biological processes. J AOAC Int 10:1371–1384. https://doi.org/10.5740/jaoacint.18-0051

Postai DL, Demarchi CA, Zanatta F, Melo DCC, Rodrigues CA (2016) Adsorption of rhodamine B and methylene blue dyes using waste of seeds of Aleurites Moluccana, a low cost adsorbent. Alexandria Eng J 55:1713–1723. https://doi.org/10.1016/j.aej.2016.03.017

Raafat D, Von Bargen K, Haas A, Sahl HG (2008) Insights into the mode of action of chitosan as an antibacterial compound. Appl Environ Microb 74:3764–3773. https://doi.org/10.1128/AEM.00453-08

Ramezani Z, Zarei M, Raminnejad N (2015) Comparing the effectiveness of chitosan and nanochitosan coatings on the quality of refrigerated silver carp fillets. Food Control 51:43–48. https://doi.org/10.1016/j.foodcont.2014.11.015

Sadegh H, Shahryari-Ghoshekandi R, Agarwal S, Tyagi I, Asif M, Gupta VK (2015) Microwave-assisted removal of malachite green by carboxylate functionalized multi-walled carbon nanotubes: kinetics and equilibrium study. J Mol Liq 206:151–158. https://doi.org/10.1016/j.molliq.2015.02.007

Sakkayawong N, Thiravetyan P, Nakbanpote W (2005) Adsorption mechanism of synthetic reactive dye wastewater by chitosan. J Colloids Interf Sci 286:36–42. https://doi.org/10.1016/j.jcis.2005.01.020

Salamat S, Hadavifar M, Rezaei H (2019) Preparation of nanochitosan-STP from shrimp shell and its application in removing of malachite green from aqueous solutions. J Environ Chem Eng 7:103328–103335. https://doi.org/10.1016/j.jece.2019.103328

Salleh MAM, Mahmoud DK, Karim WAWA, Idris A (2011) Cationic and anionic dye adsorption by agricultural and solid wastes: a comprehensive review. Desalination 280:1–13. https://doi.org/10.1016/j.desal.2011.07.019

Sips R (1948) On the structure of a catalyst surface. J Chem Phys 16:490–495

Srivatsav P, Bhargav BS, Shanmugasundaram V, Arun J, Gopinath KP, Bhatnagar A (2020) Biochar as an eco-friendly and economical adsorbent for the removal of colorants (dyes) from aqueous environment: a Review. Water 12:3561–3587. https://doi.org/10.3390/w12123561

Sugashini S, Gomathi T, Aruna Devi R, Sudha PN, Rambabu K, Banat F (2022) Nanochitosan/carboxymethyl cellulose/TiO2 biocomposite for visible-light-induced photocatalytic degradation of crystal violet dye. Environ Res 204:112047–102055. https://doi.org/10.1016/j.envres.2021.112047

Tan H, Ma R, Lin C, Liu Z, Tang T (2013) Quaternized chitosan as an antimicrobial agent: antimicrobial activity, mechanism of action and biomedical applications in orthopedics. Int J Mol Sci 14:1854–1869. https://doi.org/10.3390/ijms14011854

Tavaria FK, Costa EMC, Pina-Vaz I, Carvalho MF, Pintado MM (2013) Chitosan as a dental biomaterial: state of the art. Braz J Biomed Eng 29:110–120. https://doi.org/10.4322/rbeb.2013.002

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem 87:1051–1069. https://doi.org/10.1515/pac-2014-1117

Thue PS, Sophia C, Lima E, Wamba AGN, De Alencar WS, Dos Reis GS, Rodembusch FS, Dias SLP (2018) Synthesis and characterization of a novel organic-inorganic hybrid clay adsorbent for the removal of acid red 1 and acid green 25 from aqueous solutions. J Clean Prod 171:30–44. https://doi.org/10.1016/j.jclepro.2017.09.278

Uragami T, Tokura S (2006) Material science of chitin and chitosan, 6th edn. Kodansha Ltd., Springer, Japan

Vimonses V, Lei S, Jin B, Chow CWK, Saint C (2009) Kinetic study and equilibrium isotherm analysis of congo red adsorption by clay materials. Chem Eng J 148:354–364. https://doi.org/10.1016/j.cej.2008.09.009

Wang XH, Du YM, Liu H (2004) Preparation, characterization and antimicrobial activity of chitosan-Zn complex. Carbohyd Polym 56:21–26. https://doi.org/10.1016/j.carbpol.2003.11.007

Wu FC, Tseng RL, Juang RS (2001) Kinetic modeling of liquid-phase adsorption of reactive dyes and metal ions on chitosan. Water Res 35:613–618. https://doi.org/10.1016/S0043-1354(00)00307-9

Zhang H, Neau SH (2001) In vitro degradation of chitosan by a commercial enzyme preparation: effect of molecular weight and degree of deacetylation. Biomaterials 22:1653–1658. https://doi.org/10.1016/S0142-9612(00)00326-4

Zhang R, Zhang J, Zhang X, Dou C, Han R (2014) Adsorption of Congo red from aqueous solutions using cationic surfactant modified wheat straw in batch mode: kinetic and equilibrium study. J Taiwan Inst Chem E 45:2578–2583. https://doi.org/10.1016/j.jtice.2014.06.009

Zhong ZM, Xing RG, Liu S, Wang L, Cai SB, Li PC (2008) Synthesis of acyl thiourea derivatives of chitosan and their antimicrobial activities in vitro. Carbohyd Res 343:566–570. https://doi.org/10.1016/j.carres.2007.11.024

Acknowledgements

We thank the Polytechnical School of Chemical Engineering at the University of São Paulo 537 (USP, Brazil – SP) and Franciscan University (UFN, Brazil – RS) for the support and assistance to carry out the present work. This work received financial support from the Foundation for Research of the State of Rio Grande do Sul (FAPERGS–Project 19/2551-0001606-9).

Author information

Authors and Affiliations

Contributions

LDP: Conceptualization, validation, and writing-review and editing. PCLM: Conceptualization and writing-review and editing. GC: Conceptualization and writing-review and editing. BSV: Conceptualization, data curation, and writing-review and editing. GP: Conceptualization, data curation, formal analysis, and writing-review and editing. DCRE: Conceptualization and writing-review and editing. LSF: Conceptualization, validation, and writing-review and editing. WLDS: Conceptualization, data curation, formal analysis, investigation, validation, writing-original draft, and writing-review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

All authors read and approved the final manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Tito Roberto Cadaval Jr

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pompeu, L.D., Muraro, P.C.L., Chuy, G. et al. Adsorption for rhodamine b dye and biological activity of nano-porous chitosan from shrimp shells. Environ Sci Pollut Res 29, 49858–49869 (2022). https://doi.org/10.1007/s11356-022-19259-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19259-y