Abstract

Photoactive nanomaterials constitute an emerging field in nanotechnology, finding an extensive array of applications spanning diverse areas, including electronics and photovoltaic devices, solar fuel cells, wastewater treatment, etc. Titanium dioxide (TiO2), in its thin-film form, has been exhaustively surveyed as potential photocatalysts for environmental remediation owing to its innocuousness, stability, and photocatalytic characteristics when subjected to ultraviolet (UV) irradiation. However, TiO2 has some shortcomings associated with a large bandgap value of around 3.2 eV, making it less efficient in the visible spectral range. TiO2 is often consolidated with various carbon nanomaterials to overcome this limitation and enhance its efficiency. Graphene, a 2-dimensional allotrope of carbon with a bandgap tuned between 0 and 0.25 eV, exhibits unique properties, making it an attractive candidate to augment the photoactivity of semiconductor (SC) oxides. Encapsulating graphene oxide onto TiO2 nanospheres demonstrates intensified photocatalytic properties and exceptional recyclability for the degeneration of certain dyes, including Rhodamine B. This review encompasses various techniques to synthesize graphene-based TiO2 photoactive composites, emphasizing graphene capsulized hollow titania nanospheres, nanofibers, core/shell, and reduced graphene oxide-TiO2-based nanocomposites. It also consolidates the application of the aforestated nanocomposites for the disintegration of various synthetic dyes, proving efficacious for water decontamination and degradation of chemicals and pharmaceuticals. Furthermore, graphene-based TiO2 nanocomposites used as lithium (Li)-ion batteries manifesting substantial electrochemical performance and solar fuel cells for energy production are discussed here.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Titanium dioxide (titania), an oxide of titanium, is a widely available and cost-efficient photocatalytic material that has acquired tremendous interest over the years owing to its remarkable properties such as innocuousness, eco-compatibility, and greater chemical stability (Václav et al. 2013; Pawar et al. 2018; Moma and Baloyi 2019). TiO2 finds diverse applications, spanning from paint to food coloring, sunscreen, other cosmetics, tattoo pigments, etc. Because of its stable and distinctive photo-physical and photochemical properties, TiO2 serves as an essential material utilized under various areas of solar energy cells, solar fuels, and wastewater purification (Liu et al. 2013; Berberidou et al. 2019). In 1967, Akira Fujishima, a Japanese chemist, discovered the photocatalytic properties of nanosized titanium dioxide under UV irradiation. Following the discovery of photocatalytic properties, TiO2 was employed as a photocatalyst in energy production by dissociating water into hydrogen and oxygen, and the hydrogen thus obtained was utilized as a fuel (Fujishima and Honda 1972). In 1995, TiO2 coated glass exposed to the sunlight led to the progress of glasses that had the capability of keeping themselves free of grime and coatings that eliminate any possibility of surfaces fogging (Hashimoto et al. 2005; Gore et al. 2016a, b, 2019a, 2020, 2021; Bangar et al. 2018; Gore and Kandasubramanian 2018; Pawar et al. 2020; Mayilswamy et al. 2022). By the end of 2008, nanosized TiO2 materials were also incorporated in exterior construction materials (Haider et al. 2017), like paints, to reduce airborne pollutants such as nitrogen oxide. Photo-catalytic attempts have been made to mineralize contaminants in wastewater by converting them into CO2 and H2O (Jochen Winkler 2013; George and Kandasubramanian 2020; Hemanth and Kandasubramanian 2020; Jimmy and Kandasubramanian 2020; Jaya Prakash and Kandasubramanian 2021; Dixit et al. 2022). However, TiO2 suffers from a large bandgap of about 3.2 eV, which allows it to absorb only the UV-photons, i.e., it can utilize a very minimal amount of the total energy in the solar spectrum, which accounts for 3–5% of the total energy thus limiting its application in wastewater purification (Liu et al. 2013; Saxena et al. 2022). It also exhibits rapid recombining of charge carriers resulting in the annihilation of each other, thus affecting titanium dioxide's photocatalytic activity (Nam et al. 2019). Figure 1 illustrates diverse applications of photocatalytic TiO2.

Various properties of distinct crystalline forms of TiO2 (Anatase, rutile, and brookite) are enumerated in Table 1

In order to enhance the efficacy of TiO2 various techniques, including metal/non-metal incorporation, combined with semiconductors having smaller bandgaps, noble metals incorporation, and integration of graphene and graphene oxide are employed. The implementation of such methodologies has improved the overall efficiency of TiO2 nanocomposites. To specify, the production of energy, as discussed earlier, can be increased when TiO2 is doped with carbon.

Graphene is a notable candidate known for its 2-dimensional structure and magnificent properties, including outstanding thermal conductivity, superior mechanical strength, and electron mobility, promoting its versatility to modify the photocatalytic activity of semiconductor oxide. Moreover, graphene's zero bandgap and high electron mobility (which act as a reservoir containing electrons depresses electron–hole pair recombination) serve as a pre-condition for a perfect photosensitizer (Jain and Kandasubramanian 2020). Also, graphene offers a large Brumauer-Emmett-Teller (BET) surface area, providing a favorable scaffold to anchor TiO2 nanoparticles and enhanced adsorption ability for pollutants (Tang et al. 2018; Sun et al. 2020).

Graphene-based oxides and other materials, like drugs, nanocrystals, metal nanoparticles, polymers, and pathogens, find many environmental, energy, and biological applications (Morales-narváez et al. 2017). Graphene and graphene oxides have an optical transmittance of approximately 97.7%, the electrical conductivity of 104 s/cm, and mechanical strength of 1 TPa.

Graphene encapsulated materials are synthesized using several techniques, including chemical vapor deposition, layer-by-layer self-assembly, electrostatic self-assembly, emulsification method, etc. (Morales-narváez et al. 2017).

This review comprehends the fundamental principle involved in photocatalysis, various techniques involved in the synthesis of graphene-based titania nanocomposites, with the implementation of these nanomaterials in saline water treatment, degradation of various chemicals, including synthetic dyes and organic pollutants. The synthesized photoactive nanomaterials discussed here include encapsulated TiO2 core/shell by graphene prepared through self-assembled layer-by-layer stable graphene oxide (GO) nanosheets where the oxygen-containing functional groups are incorporated onto TiO2 nanospheres, wrapped anatase TiO2 by graphene oxide, which is accompanied by one-step graphene oxide reduction and crystallization of TiO2 through hydrothermal treatment, mesoporous hollow TiO2 encapsulated by graphene through unique graphene protected calcination process, reduced-graphene oxide TiO2 nanocomposites through hydrothermal route, and one-dimensional graphene-encapsulated TiO2 nanofibers. Moreover, the application of the aforestated nanocomposites in solar fuel cells and lithium-ion batteries is also explained here.

Fundamentals and preparation methods for graphene-based TiO2 photocatalyst

Basic principle of photocatalysis mechanism.

The photocatalysis mechanism involves photon irradiation of a semiconductor material (having energy greater than or equal to its bandgap) on exposure to sunlight or varied artificial light sources. (Mills and Le Hunte 1997). Titania is contemplated to be one of the quintessential semiconductors used as photocatalytic materials, possessing properties that are efficient for photocatalysis, apart from inactivity when exposed to visible spectrum (Giovannetti et al. 2017). Concisely, the semiconductor photocatalysis mechanism is based on the oxidation and reduction process. When the incident light has bandgap energy equivalent to or higher than that of the semiconductor, agitation of electrons present in the valence band occurs followed by the movement of electrons to the conduction band, thus resulting in the generation of holes in the valence band. The holes oxidize the donor molecule and react with a water molecule (H2O), generating hydroxyl radical (OHˉ). Electrons inside the conduction band further react with oxygen (O2), giving rise to superoxide ions and inducing a redox reaction (Saravanan et al. 2017) given below:-

The crystal structure (Gnanasekaran et al. 2015), morphology (SARAVANAN et al. 2011), and catalyst surface area (Cernuto et al. 2011) are essential factors that determine the photo-mineralization rate of organic compounds through photocatalysis. In addition to this, reaction temperature (Reza et al. 2017), pH (Neppolian et al. 2002), the intensity of the light (Reza et al. 2017), as well as the amount of catalyst (Konstantinou and Albanis 2004) also affects the photocatalytic activity. The interaction of electrons with the surface (TiO2) and electron–hole recombination also affects the photocatalytic process (Giovannetti et al. 2017). Considering these factors for efficient photocatalytic activity, photocatalysis posses' certain advantages and limitations (Saravanan et al. 2017) which are as follows:

Advantages

-

The photocatalysis process involving pollution-free and renewable solar energy provides a better alternative for energy-intensive conventional methods.

-

Conventional techniques generally comprise the transport of pollutants from one stage to another stage, which limits their use. However, harmless products are formed via photocatalysis, making it an effective treatment process.

-

Photocatalysis is preferred due to its mild reaction conditions, less reaction time, required chemical input, and minimum secondary waste production.

Limitations

-

The factors that limit the efficiency of the photocatalysis process include inhibition of interfacial charge transfer, charge-carrier recombination, charge separation, and degradation efficiency when subjected to visible spectrum (Saravanan et al. 2017).

Synthesis of graphene-based titania (GTiO2) nanocomposites

GTiO2 nanocomposites are usually synthesized via two techniques: in-situ crystallization and ex situ hybridization (Giovannetti et al. 2017).

Ex Situ Hybridization.

In this process, pre-synthesized titania NPs are mixed with graphene dispersion (Pastrana-Martínez et al. 2012; Giovannetti et al. 2017). However, TiO2 NPs, graphene sheets are pre-functionalized by carbon–carbon coupling (covalent) or π-π stacking reaction (non-covalent), thereby improving the quality of GTiO2 nanocomposites [17,26]. (He et al. 2010; Giovannetti et al. 2017).

In Situ Crystallization

In this technique, reduced-graphene oxide (rGO) or GO is used as an initial material owing to the presence of O2 contained functional moieties on its surface. Successive reduction of graphene oxide promotes the direct interaction between graphene and SC nanocrystals (Giovannetti et al. 2017). Due to this reason, various methods could be applied to fabricate GTiO2 nanocrystals, including mixing, sol–gel, electrochemical deposition, hydrothermal and solvothermal methods, microwave, photo-assisted reduction, combustion, and self-assembly approach. These methods are briefly discussed below.

Mixing Method

Mechanical mixing is a process that is widely used due to its controllable reaction conditions and simplicity. To produce enough contact between the original materials, the method necessitates mixing TiO2 and G/GO by further sonication and agitation. Further, the prepared material is centrifuged, washed, and dried to achieve the required TiO2/GO NCs (nanocomposites). The method improves light adsorption ability and electron–hole charge separation, which improves photocatalytic activity (Gao et al. 2014; Thakur and Kandasubramanian 2019; Sharma et al. 2021).

Sol–gel method

The sol–gel technique can be incorporated to obtain the best chemical interaction and a vigorous mixing between GO and TiO2. It is a process that transforms the liquid precursor into a sol which moderately forms a gel-like network structure. This method involves hydrolysis of a TiO2 precursor (commonly titanium-alkoxide), followed by condensation in the presence of graphene and graphene oxide. The overall process does not require an elevated temperature or pressure and is preferred owing to its controllability, reliability, and economic cost (Hamadanian et al. 2017). The dispersion between TiO2 and GO provides relatively stable oxo- and hydroxo-bonds between the two materials, eventually leading towards the formation of sol and then in gel-like networks on further adding GO. The prepared gel is dried and calcinated (Tayel et al. 2018).

Hydrothermal and solvothermal method

In the hydrothermal method, TiO2 NPs (titania nanoparticles) are loaded onto the GO sheet in an aqueous solution form, ultrasonicated, and autoclaved at 120–200℃ for 6–24 h using a Teflon-lined stainless autoclave (Gu et al. 2014). The overall reaction is conducted under controlled pressure and temperature. Researches on photocatalytic nanomaterials revealing high absorptivity of dyes and light absorption range are investigated, obtained by one-step hydrothermal reactions (Zhang et al. 2010a; Giovannetti et al. 2017; Nguyen et al. 2019). The solvothermal method is relatively the same in comparison with the hydrothermal process; besides, a non-aqueous solvent is considered (Tayel et al. 2018). Due to the nanocomposites' better shape, size, and crystallinity control, the solvothermal method is preferred over the hydrothermal method (Tayel et al. 2018).

Electrodeposition

TiO2 NPs can be electrolytically deposited on the graphene surface at a lower temperature through the aqueous solution containing TiO2 (Giovannetti et al. 2017).

Microwave-assisted strategy

TiO2 NPs of controlled size and shape can be uniformly distributed on the graphene sheet due to their binding nature via in situ microwave or microwave-assisted strategy (Giovannetti et al. 2017). Microwave-assisted synthesis of rutile/anatase titania NPs capsulized within N- doped modified graphene sheets for future applications in sodium-ion batteries was reported (Wang et al. 2021).

Photoreduction

Several other methods are investigated, such as fabrication of TiO2-rGO (titania reduced graphene oxide nanocomposites) carried out through the photoreduction of graphene oxide nanosheets (GONSs) in a simple titanium dioxide and graphene oxide, ethanol system, which demonstrates an eco-friendly strategy for TiO2-rGO hybrid preparation (Giovannetti et al. 2017; Pu et al. 2017).

Table 2 offers a glimpse of different synthesis techniques employed in the fabrication of various graphene-based titanium dioxide nanocomposites.

Graphene encapsulated hollow TiO2 nanospheres

Recently, several initiatives have been taken to fabricate and examine the photoactivity of various graphene encapsulated TiO2 nanospheres. The activity of graphene-wrapped TiO2 nanospheres by photocatalytic degradation of methylene blue (MB) under visible light exposure was examined by Park et al. (Zhang et al. 2013). Apart from this, researchers fabricated a robust hollow nanosphere comprising alternating graphene and negatively charged titania nanosheets that displayed high photocatalytic activity for carbon-dioxide conversion to fuels that could be renewed (Zhang et al. 2013). However, these works suffer from low surface area and the large size of TiO2 nanospheres.

This fabrication method forms graphene encapsulated hollow TiO2 core/shell with a large surface area. The first step of this synthesis process includes the deposition of the TiO2 layer onto the SiO2 nanosphere, which is achieved by mixing prepared silica nanosphere with titanium tert-butoxide (TBOT) in ethanol with temperature raised to 85℃ and stirred at 900 rpm for 100 min under refluxing condition. The dried TSNSs were collected, and finally, 3-aminopropyl-trimethoxy-silane (APTMS) was added to obtain amine-modified TSNSs (TiO2-SiO2 nanospheres). In the second step, GO is prepared using the modified hummers method and dispersed in water. Meanwhile, amine-modified TSNPs were also dispersed in water. Subsequently, the prepared graphene oxide is mixed with amine-modified TSNP suspension via vigorous stirring, and the so prepared material is labeled as GOTS NSs (GO-coated TiO2-SiO2 nanospheres) (see Fig. 4). The final step includes the calcination of the prepared GOTS NSs at 800℃ for 3 h. Eventually, chemical etching of SiO2 in a 2 M NaOH solution at 70℃ for 12 h is accomplished, GTNSs are obtained via centrifugation, washed, and dried overnight (see Fig. 2).

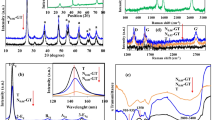

Figure 3 represents the physical characterization of GOTS NSs.

Physical characterization—SEM and TEM images of GOTS NSs (above) and GT NSs (below). Reprinted with permission from (Zhang et al. 2013). Copyright 2013, Royal Society of Chemistry

The Rhodamine-B (Rh-B) degeneration determines the as-prepared sample's photoactivity under ultraviolet light irradiation in an aqueous solution. In contrast, the bandgap of GTNSs is determined to be 3.2 eV (Zhang et al. 2013).

Graphene encapsulated TiO2 core/shell

Recently, there have been limited works known for the functioning of graphene-TiO2 nanoparticle composites. Anchoring is one of the known methods used to fabricate these hybrid materials. However, it limits its application because small TiO2 particles agglomerate, leading to a surface area reduction of both graphene and TiO2, whereas separation of phases occurs during cyclic utilization, thus affecting photocatalytic disintegration of organic pollutants in water (Liu et al. 2013). Park and his co-workers fabricated graphene-coated anatase TiO2 nanoparticles using the one-step hydrothermal reduction of GO followed by crystallization of TiO2. The prepared sample exhibits substantial photoactivity due to effective contact between graphene oxide and titanium dioxide. Figure 4 represents various steps involved in fabricating G-coated TiO2 core/shell hybrid nanostructures. The preparation method is usually a 3-step process in which TiO2 nanoparticles are first treated using 3-aminopropyl-trimethoxysilane (APTMs). This pre-treatment is necessary to obtain an amine-modified TiO2 nanoparticle surface. In the initial step, GO is obtained through the modified hummers method. In the second step, spherical monodispersed titania particles are prepared by controlled hydrolysis of tetrabutyl-titanate (TBOT) in C2H5OH. Eventually, TiO2 core/shell spheres are encapsulated with GO via uncomplicated and pure chemical bonding reactions involving dehydration condensation mechanisms devoid of any modifying agents (Liu et al. 2013).

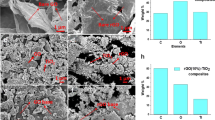

The physical characterization of the prepared photoactive nanomaterial is done using SEM, which depicts the sample’s morphology. SEM analysis revealed a rough surface morphology for the pure TiO2 microsphere possessing a diameter of 850 nm. In contrast, the surface of GO encapsulated TiO2 core/shell structure had wrinkled morphology confirming that GO-sheet had successfully combined to TiO2 microsphere via pure chemical bond reactions (Liu et al. 2013). Further, to obtain more information about the structure, products are probed using TEM, which depicts that the core diameter of TiO2 is around 800 nm and the thickness of GO- sheet coated onto the core is around 5–10 nm. The bandgap of the prepared material is analyzed to be around 2.54 eV which is lesser compared to pure titania (3.18 eV), signifying that the prepared material could be excited on exposure to visible light.

Furthermore, the photocatalytic property was examined for the photoactive degeneration of Rh-B in an aqueous medium at room temperature. A change in the absorption spectra on ultraviolet and visible light exposure for different time intervals was ascertained (Liu et al., 2013). The sample exhibited excellent photocatalytic activity, indicated by the photodegradation time corresponding to 25 min and 130 min when exposed under ultraviolet and visible light, respectively. The prepared sample also displayed a red-shift in the bandgap by about 425 nm (Liu et al. 2013).

The aforestated composite microspheres also demonstrated excellent recyclability as they were easy to separate from the solution owing to their weight and size. They could effectively degrade Rh-B under UV-light without any remarkable deviation even after 5 recycling cycles, thus serving as an effective and recyclable photocatalyst (Liu et al. 2013).

Reduced graphene oxide-titanium dioxide (RGO-TIO2)-based nanocomposites.

Recent advances in wastewater treatment (Siong et al. 2018; Kusiak-Nejman and Morawski 2019) and reuse require a highly chemically stable material, typically titanium dioxide, with a low environmental impact (Andreozzi et al. 2018). Heterogenous TiO2-based photocatalysis has higher potential in degrading persistent organic pollutants (POPs) (Ayalew et al. 2012; Gonte and Balasubramanian 2012, 2016; Bhalara et al. 2014, 2015a, b; Rule et al. 2014; Gonte et al. 2014; Sharma and Balasubramanian 2015; Sharma et al. 2016; Gupta et al. 2016; Raj et al. 2017; Gore et al. 2017, 2018, 2019c, b; Palaniappan et al. 2018; Thakur and Kandasubramanian 2019; Rajhans et al. 2019; Sharma and Kandasubramanian 2020; Rastogi et al. 2020; Gautam et al. 2020) and compounds that have the endurance towards biological treatment (Schneider et al. 2014; Andreozzi et al. 2018). However, due to its low absorption capability for aquaphobic contaminants and reduced efficiency resulting from photogenerated electron–hole pair recombination, TiO2 lags in water treatment applications. The addition of graphitic materials to TiO2 is being investigated to alleviate the shortcomings associated with utilizing titanium dioxide in wastewater treatment. These methods have improved the photocatalytic effectiveness of pristine titanium dioxide due to charge carrier mobility and the resultant increase in the surface area (Andreozzi et al. 2018).

The preparation method for rGO/TiO2-P25 involves the synthesis of GO from graphite using the modified hummers method. The prepared GO is dispersed in MilliQ water and formamide and stirred. The mixture is ultrasonicated using the ultrasonic processor at 180 W, 24,000 Hz for 60 min, and TiO2-P25 is further added. After mixing, the sample is incorporated in the Teflon-lined autoclave reactor, which is hydrothermally treated. The solids thus achieved are filtered, washed, and finally dried (Andreozzi et al. 2018). Figure 5 represents the preparation method for rGO-TiO2 nanocomposite.

For the removal of high aqua-phobic contaminants (i.e., aromatics) due to the hydrophobic behavior of the carbonic phase, the rGO-TiO2 nanocomposite is found to be more efficacious. However, on the other end, acetic acid is barely degraded.

Table 3 represents the total pore volume (TPV) and the specific surface area (SSA) along with total organic carbon (TOC) removal for different compositions of rGO-TiO2-P25, respectively.

Graphene encapsulated TiO2 nanofibers

Recent graphene encapsulated materials focus on improved electrical conductivity and high-rate performance. In this fabrication process, anatase TiO2 nanofibers are fabricated initially via electrospinning (Li et al. 2017a). Figure 6 depicts the schematic representation of various steps involved in preparing graphene-encapsulated TiO2 nanofibers. Generally, electrospinning refers to a voltage-driven process where fibers of a few microns are formulated from a polymer solution (nanoScience Instruments) https://www.nanoscience.com/techniques/electrospin/. Typically, for synthesizing anatase TiO2 nanofiber process, a solution of polyvinylpyrrolidone dissolved in a mixture of ethanol and acetic acid is stirred. Tetrabutyl-titanate (Ti(OBu)4) is further included in the prepared mixture, and then the sample is transferred to a plastic syringe attached with a stainless-steel needle. The sample is ejected from the needle with 20 kV of the voltage applied. The electrospun materials are collected onto a piece of aluminum foil, dried, and calcinated. The next step involves the encapsulation of synthesized negatively-charged GO onto the prepared positively-charged TiO2 nanofibers. The final product is formed after the reduction of GO and is incorporated as an electrode for rechargeable batteries possessing outstanding regenerative stability and high-rate performance.

G/TiO2 nanocomposites: photocatalysts for water treatment application

Classification and disintegration of various dyes

Dyes are colored substances usually soluble in water and are chemically bonded to the substrate to which they are applied. The different color of dyes results from the selective absorption of different wavelengths of light (Giovannetti et al. 2017). They can be categorized into two types, namely natural dyes—obtained from plant-based sources (like barks, leaves, roots, lichen, and fungi) and synthetic dyes—usually human-made (from petrochemicals).

Typically, dyes are categorized based on their chemical properties and solubility. Their chemical structure comprises a chromophore, a covalent-unsaturated group responsible for color production. On the other hand, it also comprises an autochrome and the chromophore, influencing the solubility of water (Giovannetti et al. 2017).

Dyes can be mainly categorized as acidic, basic, direct or substantive, mordant, reactive, dispersive, azonic, and sulfur dyes based on their uses. Food dyes are another class describing the roles of dyes usually classified as food additives. Figure 7 illustrates some common forms of dyes along with their applications.

However, the production by textile, printing, and paper industries and the substantial use of these dyes result in wastewater which is considered a potential source of pollution of water reservoirs (see Fig. 8). These dyes affect waterways and have a severe impact on the environment, and hence the degradation of these dyes becomes necessary. GTiO2 nanocomposite is considered a possible material used to adsorb harmful chemicals and is individually tested to degrade these eco-unfriendly dyes from aqueous environments (Giovannetti et al. 2017). Table 4 enlists various photoactive materials used to degrade organic dyes (Methylene blue, Methyl orange, Rhodamine B) along with various specifications, including dye concentration (mg/L), catalyst quantity (mg/L), irradiation source, wavelength (nm), power (W), percent degradation, and irradiation time (hr).

-

a.

Methylene blue (C16H18ClN3S)

Methylthioninium chloride, commercially known as MB, is commonly used as a dye and medicament. As a medicament, it was predominantly utilized for treating methemoglobinemia, a state caused by an increased level of methemoglobin in the blood, particularly for methemoglobin levels greater than 30%. It was previously used to treat urinary tract infection and cyanide poisoning; however, it is no longer endorsed due to its common side-effects, including red blood cell (RBC) breakdown, serotonin syndrome, vomiting, suffocation, and high blood pressure. Moreover, as a dye, it is actively used in textile industries and broadly employed as a cationic water-soluble dye for dyeing – paper, timber, silk, cotton, and plastics. However, the evacuation of dyes from these industries causes severe environmental damage, usually in aqueous environments. Therefore, treatment for removing methylene blue from the ecosystem is obligatory.

Researches on photocatalytic materials such as GTiO2 nanocomposites have been carried out, and these nanomaterials possess higher photocatalytic activity in the methylene blue degradation test. Recently, photo-assisted oxidation of methylene blue by anatase/rutile TiO2 microsphere-rGO nanocomposites have been reported. Also, experiments on graphene-supported mesoporous titania nanosheets have been carried out using the template as liquid-phase exfoliated graphene and intermediate as graphene-silica. The formed GTiO2 Ns exhibited increased photocatalytic activity of TiO2, resulting in complete decolorization of the dye when irradiated under ultraviolet light (Zhang et al. 2017) (see Table 4).

Methylene blue degradation can be explained by considering a simple TiO2/G porous nanocomposite system prepared through the sol–gel method. Light irradiation on the TiO2/G surface results in the excitation of electrons from the valance band (VB) to the conduction band (CB), thereby resulting in the formation of holes (\({h}^{+}\)) in the VB and a photoexcited electron (\({e}^{-}\)) in CB. The formed hole and electron pair tend to recombine; however, due to the conductive electronic behavior of graphene sheets, the photoexcited electron tends to transfer towards the graphene sheet. The photoexcited electron in the CB reacts with an O2 molecule (reduction reaction) and gives rise to a superoxide radical anion (•O2‾), which directly degrades MB, while photoinduced hole either reacts with water forming hydroxyl radicals or directly oxidizes MB (Yang et al. 2016) (see Fig. 9).

The adsorption ability of the catalyst exhibits a vital role in the photocatalytic activity of the sample. For instance, the given specimen exhibited an adsorption capacity higher than P25.

The photocatalytic performance of TiO2/G porous nanocomposite for the degradation MB is studied using ion chromatography (separates ion and polar molecules based on their affinity). As a result, MB degraded to form partial Cl‾, SO42‾, and \({\mathrm{NH}}_{4}^{+}\) (Yang et al. 2016). Moreover, scrutinizing the kinetics of the sample follows the first-order Langmuir Hinshelwood model having a degradation rate constant value, k, 0.0208/min, which is approximately 6.5 times more than that of P25 (k = 0.0032/min). Further tests were carried out on the performance of the composite after three repeated cycles, and it was concluded that the catalytic performance of the composite remains invariable (Yang et al. 2016).

The fabrication and photocatalytic activity of TiO2-exfoliated Graphite Oxide composite in MB degradation under UV light irradiation was demonstrated by Vanessa and co-workers. Similar work has been reported by Suave and his co-workers using TiO2-ozonated graphene nanocomposites (Suave et al. 2017). The results showed 100% degradation of the dye under ambient conditions. In 2016, Verma and co-workers fabricated rGO-TiO2 by utilizing mixed-phase titania (with appropriate anatase/rutile ratio) via the ex situ hydrothermal method. They used a low anatase/rutile ratio to make the nanocomposite photoactive under the visible region. The group studied its photocatalytic performance over mixed-phase TiO2 in methylene blue degradation (Verma et al. 2017).

Graphene-based TiO2 nanocomposites as photocatalysts can be used for the photodegradation of MB (Khan et al. 2019; Kurniawan et al. 2020) and have proven to be substantial in wastewater treatment. In another study, photocatalytic degradation of MB through titanium dioxide nanocomposites with (001) exposed facet constituting graphene oxide acquired from coconut shell was reported. TiO2 was subjected to amendments in order to augment its photocatalytic characteristics through the exposure of its (001) crystal facet face. The fabricated materials demonstrated good performance when irradiated under the visual spectrum, resulting in degradation rates of around 51.30% for MB for a reaction time of one hour. This amelioration in photo degradability could be attributed to enhanced reactivity towards free radicals produced and GO that facilitated separation of charges (Yunarti et al. 2022).

-

b.

Methyl orange (C14H14N3NaO3S)

Methyl orange is an anionic azo-dye that has a diverse spectrum of applications in pharmaceuticals, textiles, paper, printing, and research fields (Ai et al. 2011). Azo dyes do not readily degrade, leading to environmental pollution, especially in watercourses (Rumky 2013). Various wastewater treatment methods have been developed, amongst which adsorption techniques are more significant due to their pollutant removal efficiency (Rumky 2013). Researches such as rGO- anatase/rutile mixed-phase TiO2 nanofibers (MPTNFs) (Lavanya et al. 2017) synthesized by electrospinning technique were conducted to upgrade the photocatalytic activity for methyl orange (MO) degradation (Giovannetti et al. 2017). G-pasted TiO2 (Xu et al. 2016) spheres were also prepared, introducing better interfaces between G and TiO2 than GTiO2Ns composites and demonstrating higher photocatalytic activity under ultraviolet light irradiation (Giovannetti et al. 2017). Electron transfer, reaction rate, electronic interaction, interfacial distance, surface area, and light irradiation time affect graphene-based titania's photoactivity in the disintegration of methyl orange in the aqueous solution.

Methyl orange degradation could be further analyzed by investigating the reaction mixture for different time intervals by LC–MS (liquid chromatography-mass spectrometry) (Sheikh et al. 2016). Degradation of MO is considered to take place in three different ways—azo and ring bond cleavage (leading to the formation of intermediate having a mass-to-charge ratio (m/z) value: 156), successive ring demethylation, and addition of hydroxy groups (leading to the generation of intermediates with m/z values: 290 and 320) and demethylation and removal of sulfur dioxide (SO2) from the ring (leading to the generation of intermediates having m/z values: 306, 276 and 240). The final intermediates so formed consist of m/z values: 319, 260, 258, 234, 211, 100, 79, and 59, which are further fragmented to give high molecular weight intermediates with m/z values—322, 292, and 225. The other low molecular weight intermediates mineralized into CO2, H2O, and NO3‾ (Sheikh et al. 2016).

Based on Eqs. (1), (2), and (3), the degradation reactions associated with MO are as follows:

Lavanya and co-workers fabricated rGO wrapped with TiO2 nanofibers via electrospinning technique (Lavanya et al. 2014). They fabricated a photocatalyst that exhibited efficient photodegradation of methyl orange (96%) when irradiated under ultraviolet light with 365 nm emission wavelength and 20 W power. The group compared the photocatalytic activity of the fabricated sample to bare titanium oxide nanofibers, which were only 46% efficient. In 2015, Han and co-workers fabricated a novel graphene/titanate nanostructure via the hydrothermal method (Han et al. 2015). The developed flocculent-like TiO2/graphene nanocomposite has proven an efficient candidate for pollution removal and hydrogen production. The group reported the decomposition of MO through these flocculent-like nanocomposites and compared the results with the flocculent-like TiO2 and raw TiO2 at different time intervals.

Lin et al. fabricated GO/TiO2 photocatalytic composites through the hydrothermal technique and further investigated the degradation and adsorption parameters of MO. When subjected to UV irradiation, the prepared composites exhibited degradation and adsorption rates of around 85.62% for 4 h. The photocatalyst degradation occurred through the following mechanism: (i) adsorption of methyl orange moieties by the as-prepared composite photocatalyst; (ii) photodegradation of methyl orange on the surface of graphene oxide through chemical means (Lin et al. 2020a).

-

iii.

Rhodamine-B (C28H31ClN2O3):

Rhodamine-B is a soluble-basic-fluorescent dye that finds extensive application as a dyeing agent in textile industries. For instance, rhodamine-B is utilized for dyeing several products, including paper, straw, silk, cotton, leather, and bamboo (Giovannetti et al. 2017). It is also broadly used for photochemical, analytical, and biological staining purposes. However, these industries and scientific laboratories emit wastewater contaminated with Rh-B. Dye imparts color to the water, which is undesirable to photosynthetic aquatic life and water consumers. Therefore, contaminated effluent water becomes a severe issue in the environment (Shakir et al. 2010).

Researchers reported various studies on graphene-based TiO2 nanomaterials for the photodegradation of Rh-B. For instance, rGO-TiO2 nanocomposite using electrospinning and hydrothermal reaction methods were fabricated whose photocatalytic properties associated with Rh-B photodegradation were analyzed when exposed to xenon-light irradiation. Furthermore, flowerlike TiO2-rGO were also synthesized (FTS-G), in which TiO2 was characterized as possessing a porous structure and a high specific area, and rGO was prepared devoid of a potent reducing agent. The resultant nanocomposite was evaluated under solar-light irradiation, reducing-GO quantity as an essential factor for photocatalytic activity. Precursors employed, surface area, and interfacial contact were other prominent factors associated with photocatalytic activities for the photodegradation of Rh-B.

For further investigation of formed intermediates, ultra-high-performance liquid chromatography-mass spectrometry (UHPLC-MS) was performed on a heated electrospray ionization mode. As soon as Rh-B was mixed in an aqueous solution, Cl‾ dissociated and led to the formation of \({\mathrm{C}}_{28}{\mathrm{H}}_{31}{\mathrm{N}}_{2}{\mathrm{O}}_{3}^{+}\), having an m/z value 443.2329 (Ariyanti et al. 2017). Further, according to previous studies, Rh-B degradation was carried out via two mechanisms: N-demethylation and conjugate structure destruction. The oxidized intermediates formed after these processes include Formyl benzoate (m/z: 149), N-ethyl-N’-ethylrhodamine (m/z: 387), N, N-diethylrhodamine (m/z: 415), benzoic acid (m/z: 121) N-containing derivatives (m/z: 165–167). Further, pH analysis resulted in reducing the solution's alkalinity level, indicating that OH‾ assisted in demethylation and other mechanisms (such as chromophore cleavage, ring-opening, and mineralization), leading to the formation of smaller molecular intermediates having m/z values between 100–200 (Natarajan et al. 2011; Ariyanti et al. 2017). The further mineralization results in the generation of low molecular weight intermediates: H2O, CO2, NO3‾, \({\mathrm{NH}}_{4}^{+}\).

The catalytic chemical vapor deposition method was utilized to synthesize graphene/TiO2 core–shell nanocomposites (Biris et al. 2016). The photocatalytic performance is calculated by measuring the rate of degradation of Rh-B on irradiation with ultraviolet light (15 W, 365 nm). Furthermore, Wang et al. (2015) fabricated TiO2/rGO nanotubes using the hydrothermal method and demonstrated its photocatalytic activity in Rh-B degradation under ultraviolet light irradiation (Liu et al. 2016). The resultant photocatalyst (100 mg/L) exhibited 100% efficiency in the deterioration of the dye (10 mg/L) after irradiating it for 33 min.

-

iv.

Others dyes

-

v.

Rhodamine-6G (C28H31N2O3Cl)

Rhodamine-6G is a reddish-purple dye that is highly soluble and non-volatile. It is actively employed as a tracer to determine the direction, flow rate, and liquid transportation. This is primarily used in biotechnological applications, including fluorescence correlation spectroscopy, flow cytometry, and fluorescence microscopy. However, these dyes are poisonous and carcinogenic (Rajoriya et al. 2017) to living organisms and are responsible for causing eye, skin, and respiratory system irritations (Giovannetti et al. 2017). For photocatalytic degradation of Rh-6G, in-situ preparation of rGO-TiO2 “dyad hybrid” (Pu et al. 2017) is attained, and the resultant material shows enhanced photo-energy adsorption. The material, thus, leads to an effective degradation of Rh-6G and exhibits a photodegradation rate that is three folds the rate as produced by commercial TiO2 (P-25) nanoparticles (Giovannetti et al. 2017).

To begin with the degradation mechanism of Rh-6G, the attachment of cationic Rh-6G with rGO surface is initiated through the following three approaches: electrostatic attraction, π-conjugate system, and high specific surface area. The •OH radicals formed from the photocatalytic phenomenon (as discussed previously) target the Rh-6G molecules and convert them into CO2, H2O, and some other smaller molecules that are desorbed eventually by TiO2 and graphene surface and sequentially recovering the active sites.

-

Reactive Black 5 (C26H21N5Na4O19S6)

Reactive Black 5 belongs to the family of azo dyes and contains 2 azo groups. They are immensely used as dyeing agents in textile industries. For photodegradation of these dyes, various types of GTiO2 nanocomposites were prepared (Dai et al. 2016). Different types of TiO2 shapes, nanotubes, nanoparticles and nanosheets were combined with graphene and further investigated. Therefore, these materials displayed superior photocatalytic activity compared to P-25, and, amongst them, GTiO2 nanosheets showed the highest photoactivity than other photocatalysts (Dai et al. 2016; Giovannetti et al. 2017). TiO2 nanotubes, combined with graphene nanocomposites fabricated using hydrothermal methods (Liang et al. 2015), also show an enhanced photocatalytic efficiency for RB5 (Giovannetti et al. 2017).

The photodegradation of RB5 with 40% graphene-loaded titanium dioxide was further studied under GC–MS (gas chromatography-mass spectrometry) and took place in 5 steps. The EWE (electron-withdrawing effect) (Zhang et al. 2015) –SO2(CH2)nSO4Na and –SO3Na causes the C–S bonds to break first, thereby initiating photodegradation.

In the absence of the above groups, the ERE (electron releasing effect) (Zhang et al. 2015) of NH2 and OH converts the naphthalene ring into EWG, which leads to \({\mathrm{N}}_{=}\mathrm{N}\) bond cleavage.

Further, the strong EWE of NO2 triggers the cleavage of the C–N bond and oxidation of the C–H bond afterward. The cleavage of naphthalene and benzene rings forms certain oxalic acid, formic acid, and acetic acid intermediates.

Finally, the mineralization of the by-products formed resulted in the generation of CO2 and H2O (Zhang et al. 2015).

-

Acid orange 7 (C16H11N2NaO4S)

Acid orange 7 or 2-naphthol orange, an azo dye, is a non-biodegradable dye commonly used for dyeing wool. Dyeing/textile industries must treat their wastewater containing these acidic dyes before decomposing it into the natural environment, as these dyes have chronic toxicity and carcinogenicity. Graphene-based TiO2 nanocomposites show practical photo activities for disintegrating AO7 under solar-light irradiation (Giovannetti et al. 2017). Adsorption of the sample could be explained thoroughly by taking irradiation time into account, which characterizes the complete disappearance of AO7 after 60 min, and the golden yellow color of the solution turns colorless. GTiO2 could effectively degrade 99% of AO7 dye from the aqueous solution.

Moreover, the GTiO2 (G- 0.3 wt.%) catalyst displayed higher photocatalytic performance than P25. Therefore, the degradation efficiency was approximately twice that of bare TiO2. Reusability, which is considered an essential property of the sample, was further analyzed. The results after the third cycle showed 92% degradation of the dye within 60 min (Posa et al. 2016).

Degradation of chemicals and pharmaceuticals

According to the sources, approximately 2.5 billion people lack a clean water supply. The number will increase twice by the year 2025. Recent studies have substantiated that industries and chemical laboratories are not the only sources for water contamination. Domestic wastewater containing a small amount of chemicals, e.g., caffeine and pharmaceuticals, also contributed to groundwater contamination.

Enhanced degradation of caffeine and carbamazepine was reported through reusable magnetic TiO2/G nanocomposite (Tayel et al. 2018). For instance, effective removal of carbamazepine from water by utilizing microwave-hydrothermally produced TiO2/G nanoparticles and hydrothermally produced TiO2/G aerogels under UV-light irradiation were reported (Amalraj Appavoo et al. 2014). Aromatic pharmaceuticals, such as ibuprofen anti-inflammatory and sulfamethoxazole antibacterial, have substantially been photodegraded by utilizing TiO2/G nanocomposite irradiated under the ultraviolet light source.

In another study, GO/TiO2 composites employed for the efficient degeneration of dichloroacetic acid (DCA) from effluents were reported. These photocatalytic composites were fabricated through different processing techniques: mechanical, hydrothermal, and solvothermal methods with the proportion of GO/TiO2 varying from 1 to 10 wt%. GO/TiO2 composite (5 wt%) prepared by hydrothermal method exhibited superior photocatalytic efficacy in contrast compared to fabricated counterparts possessing 87.1% degradation yield and 2.6 folds greater rate of degradation compared to pure titania (Ribao et al. 2018).

Lin et al. explored the photocatalytic degradation of isopropanol through rGO/TiO2 composites when exposed to simulative sunlight. The aforestated composites were fabricated through the hydrothermal technique with the proportion of isopropanol spanning from 20 to 100 ppm. P25rGO (0.01%) (i.e., loading of GO into titania composites: 0.01 wt%) composite demonstrated supreme isopropanol removal of around 92.24% at an isopropanol proportion of 20 ppm. Optimum loading of rGO served to entrap electrons, thus inhibiting electron–hole recombination. Moreover, it was observed that an acidic environment was propitious for photodegradation of isopropanol owing to conditions conducive for the generation of O2− and OH· (Lin et al. 2020b). Several researchers have reported the synthesis of rGO/TiO2 nanocomposites for enhanced photocatalytic degradation and efficient removal of various organic compounds, including nicotine (Maiti et al. 2020), phenol (Fan et al. 2021), triclosan (Kaur et al. 2020), and phenol-4-sulfonic acid (Shen et al. 2021).

Drugs possessing low biodegradability and high toxicity contaminate water bodies and have an adverse impact on marine life. For instance, Diphenhydramine, an anti-histaminic drug (Tayel et al. 2018), a widely found product in fish liver, mainly detected in the United States, is a highly toxic drug that causes damage to aquatic plants, fishes, and invertebrates. Therefore, the photodegradation of such drugs becomes a priority, and hence, the treatment of these drugs is necessary. According to researches, Diphenhydramine could be photo-degraded using TiO2/GO and TiO2/G nanocomposites leading to the deduction that TiO2/G exhibited a lower rate of degradation than TiO2/GO nanocomposites when irradiated under visible and ultraviolet light. Moreover, effective photodegradation of pesticide residues, mainly alachlor, atrazine, isoproturon, and diuron, were carried out (Pastrana-Martínez et al. 2014).

Saline water treatment

Saline water holds a higher concentration of dissolved salts. It consists of insoluble particles, including suspended solids, debris, marine organisms, etc., and soluble particles like dissolved solids, including ions of minerals (like calcium, magnesium, chloride, etc.). As per the US geological survey, seawater has recorded a salt concentration of 35,000 ppm, equal to 0.035 kg of salt per 0.001 Kl of water.

Usually, mixing the saline water with hydrocarbons during the crude oil and natural gas extraction gives rise to saline-produced water (SPW). In general, saline-produced water can be treated as a by-product resulting from the combination of saline water and oil and gas. Due to the ecotoxicological effects and depleting water resources, treating the saline-produced water is necessary, especially in oil-producing countries. Typically, physio-chemical and biological processes are employed conventionally for the saline-produced water treatment (Fakhru'l-Razi et al. 2009; Andreozzi et al. 2018). High chemical costs and a considerable amount of sludge formation limit the application of physio-chemical technologies. Recently, various types of research have been carried out for saline-produced water treatment through photocatalytic processes. Significantly, titania coupled with rGO has shown more significant activity than pure titania nanomaterials for lowering the total organic carbon content of SPW. However, due to the very high concentration of Cl‾, it is challenging to treat saline water through photocatalytic techniques. Moreover, biological processes are proved to be successful for degrading acetic acid, which is barely degraded using photocatalytic technologies.

Other applications

Lithium-ion batteries

In the 1970s, M Stanley Whittingham presented a rechargeable battery class and termed it the lithium-ion battery (LIB). These secondary lithium-ion batteries are used in various stationery and portable devices such as automobiles, electronics, aerospace, etc. They have gained popularity mainly because of their durable power output, high energy density, and stable life cycle. Typically, a Lithium-ion battery comprises a cathode (positive electrode) and an anode (negative electrode) partitioned by a nanoporous or microporous polymer separator soaked into an electrolyte solution (Fig. 10).

Usually, the cathode is made up of a chemical compound, either lithium cobalt oxide (LiCoO2) (Wang 1996) or lithium iron phosphate (LiFePO4) (Hassoun et al. 2014), and the anode comprises graphite (an allotrope of carbon). However, commercially used graphite suffers from specific barriers for several applications. A high charging rate would raise serious concerns due to low lithium insertion potential and dendritic lithium deposition on the electrode's surface. Poor rate performance obstructs the fabrication and implementation of these Li batteries. TiO2 replaced the graphite electrode because of its low volume change, natural abundance, and high safety performance. However, TiO2 was also unsuccessful due to the poor Li-ion and electron transfer, low conductivity, and aggregation tendency, affecting the electrochemical particle performance. Furthermore, one-dimensional morphology—such as nanofibers (Gao et al. 2019), nanotubes (de las Casas and Li 2012; Fang et al. 2019), and nanowires (Peng et al. 2008), is an alternative practice to boost the electrochemical performance of these batteries due to their high surface area to volume ratio.

However, the aforementioned approach seemed impractical in specific applications due to lower electron conductivity and diffusion of Li-ion. Researchers have reported credential usage of graphene-coated TiO2 composite materials as anode for lithium-ion batteries having significant electrochemical performance (Ma et al. 2019; Xin et al. 2019; Fu et al. 2019; A.D.R. Madhusanka 2020). A practical technique to fabricate such graphene encapsulated TiO2 nanofibers is discussed in the previous section.

Solar fuel cells

Increasing energy crises and environmental contamination have called out for a search and the need for renewable and eco-friendly methods for energy generation. Hydrogen (H2) is considered a potential alternative for energy storage (Zhang et al. 2019) and production due to its pollution-free behavior and excellent storage capacity. TiO2 being a nanoparticle and due to its thin-film nature, could be effectively used as a semiconductor oxide for energy production. The process involves a simple breakdown of water into elemental constituents, i.e., oxygen and hydrogen, and the hydrogen thus obtained is used as a fuel. However, the efficiency of these fuel cells is comparatively lower even after utilizing the thin film and nanoparticle morphology of TiO2. The photocatalytic activity of titania can be enhanced by doping it with carbon-based material, effectively graphene (Bellamkonda et al. 2019; Sampath and Sellappa 2020).

Challenges and future prospectives

TiO2 is being comprehensively examined owing to its photocatalytic properties for free radical generation disintegrating a diverse spectrum of contaminants in the surroundings. Graphene-based nanomaterials and their counterparts are endowed with versatile properties, including greater surface area, exceptional chemical stability, and electron mobility, owing to which they find a multitude of applications such as pliable electrodes for polymer photovoltaics (Tiwari et al. 2020), hydrogen storage (Jain and Kandasubramanian 2020), fuel cell technology (Yadav et al. 2018), and adsorption of heavy metal ions (Bhalara et al. 2015a). The photocatalytic performance of graphene-based titania composites for photodegradation of organic dyes predominantly depends on various factors, including potent oxidizing agents and pollutants adsorbed, relating to the electron–hole recombination and the electron mean free path and the specific surface area of the photocatalyst, respectively. Various research is being carried out to enhance some of the factors directly affecting the photocatalysts' degradability. To enhance the chemisorption ability of these nanocomposites, significant attention has to be paid towards the chemical contact between graphene and the pollutants.

Some other challenges posed by the graphene-based titania nanocomposites that should be addressed in the design and fabrication of high-performance photocatalytic composites include microstructural analysis and investigation of photocatalytic degradation mechanisms.

Although the aforestated materials are highly beneficial in wastewater decontamination, some specific issues related to the defect densities and agglomeration of graphene networks need to be treated. The agglomeration of graphitic layers diminishes its surface area, consequently reducing surface accessibility and restricting interaction with the contaminants. To regulate other similar technical constraints, researchers are exploring progress in graphene-based nanomaterials incorporated with various functional moieties. Surface modification of graphene with hydrophilic moieties such as ketone, hydroxyl, carboxyl, and epoxy groups are some strategies that augment its dispersion and reduce agglomeration effects (Thakre et al. 2021).

More efforts have to be made for depressing the electron–hole recombination in TiO2 on exposure to ultraviolet light irradiation. Uniform distribution of titania on the graphene surface and an increase in the contact area by optimizing the morphology of graphene and TiO2 can be considered future challenges that should be included in further research. Furthermore, commercialization of the fabricated graphene-based TiO2 nanocomposites on a massive scale at reasonable prices employing regenerable strategies is one of the most fundamental concerns that need to be addressed (Thakre et al. 2021).

The challenges mentioned above in this field can be considered promising for further modifications and innovation in future studies.

Conclusion

This review revolves around the theme of graphene-based \({\mathrm{TiO}}_{2}\) nanocomposites that exhibit superlative photocatalytic activity when exposed to natural or artificial light sources. Being bestowed with several inherent advantages such as high stability, commercial accessibility, and cost-effectiveness, titania can be explicitly employed for environmental remediation towards water treatment and air pollution. However, most photocatalytic materials often have greater band gap energy values and reduced efficacy resulting in reduced surface area and absorption rates. Hence, various approaches for transforming photocatalytic materials to enhance some properties like light absorptivity, photoreactive efficacy have been explored over the years. In this regard, although TiO2 is a widely deployed candidate for photocatalytic applications, it suffers from drawbacks associated with low chemical adsorption, high electron–hole recombination rate, and inactivity towards visible light, and these shortcomings of pure TiO2 can be overcome by incorporating nanomaterials like graphene. The incorporation of graphene leads to a low electron–hole recombination rate and intensified chemisorption owing to its exceptional electron storage ability, higher electron mobility, larger specific surface area, and zero bandgap, thus ameliorating the adsorption and photodegradation rates of different contaminants when subjected to visible radiation.

Furthermore, the G/TiO2 nanocomposites fabricated by diverse processing techniques employed in water decontamination, i.e., for degradation of dyes, chemicals, pharmaceuticals, and saline water, serve as cutting-edge strategies for treating wastewater. It could be deduced that G/TiO2 nanocomposites demonstrated to be more expedient than pure TiO2 and served as effective photocatalytic nanomaterials for organic pollutant degradation. Apart from this, graphene encapsulated TiO2 nanocomposites as anodes in Li-ion batteries exhibited substantial electrochemical performance, and graphene-doped TiO2 materials proved efficient candidates for hydrogen production. The utilization of these enhanced materials and state-of-the-art technologies has proven ideal to various stationery and mobile devices, thus ensuring better and environment-friendly paths in the electronics and biomedical arena.

Data availability

Not Applicable.

References

A.D.R. Madhusanka S (2020) TiO2 Microparticles/Reduced Graphene Oxide Composite as Anode Material for Lithium Ion Battery. Int J Electrochem Sci 2792–2805. https://doi.org/10.20964/2020.03.11

Ai L, Zhang C, Meng L (2011) Adsorption of Methyl Orange from Aqueous Solution on Hydrothermal Synthesized Mg–Al Layered Double Hydroxide. J Chem Eng Data 56:4217–4225. https://doi.org/10.1021/je200743u

Amalraj Appavoo I, Hu J, Huang Y et al (2014) Response surface modeling of Carbamazepine (CBZ) removal by Graphene-P25 nanocomposites/UVA process using central composite design. Water Res 57:270–279. https://doi.org/10.1016/j.watres.2014.03.007

Andreozzi M, Álvarez MG, Contreras S et al (2018) Treatment of saline produced water through photocatalysis using rGO-TiO2 nanocomposites. Catal Today 315:194–204. https://doi.org/10.1016/j.cattod.2018.04.048

Ariyanti D, Maillot M, Gao W (2017) TiO 2 used as photocatalyst for rhodamine B degradation under solar radiation. Int J Mod Phys B 31:1744095. https://doi.org/10.1142/s0217979217440957

Ayalew A, Gonte RR, Balasubramanian K (2012) Development of Polymer Composite Beads for Dye Adsorption. International Journal of Green Nanotechnology 4:440–454. https://doi.org/10.1080/19430892.2012.739480

Baldissarelli VZ, de Souza T, Andrade L et al (2015) Preparation and photocatalytic activity of TiO 2 -exfoliated graphite oxide composite using an ecofriendly graphite oxidation method. Appl Surf Sci 359:868–874. https://doi.org/10.1016/j.apsusc.2015.10.199

Bangar GY, Ghule D, Singh RKP, Kandasubramanian B (2018) Thermally triggered transition of fluid atomized micro- and nanotextured multiscale rough surfaces. Colloids Surf, A 549:212–220. https://doi.org/10.1016/j.colsurfa.2018.03.044

Bellamkonda S, Thangavel N, Hafeez HY et al (2019) Highly active and stable multi-walled carbon nanotubes-graphene-TiO2 nanohybrid: An efficient non-noble metal photocatalyst for water splitting. Catal Today 321–322:120–127. https://doi.org/10.1016/j.cattod.2017.10.023

Berberidou C, Kyzas GZ, Paspaltsis I et al (2019) Photocatalytic disinfection and purification of water employing reduced graphene oxide/TiO 2 composites. J Chem Technol Biotechnol 94:3905–3914. https://doi.org/10.1002/jctb.6188

Bhalara PD, Balasubramanian K, Banerjee BS (2015a) Spider-Web Textured Electrospun Composite of Graphene for Sorption of Hg(II) Ions. Materials Focus 4:154–163. https://doi.org/10.1166/mat.2015.1232

Bhalara PD, Punetha D, Balasubramanian K (2015b) Kinetic and isotherm analysis for selective thorium(IV) retrieval from aqueous environment using eco-friendly cellulose composite. Int J Environ Sci Technol 12:3095–3106. https://doi.org/10.1007/s13762-014-0682-0

Bhalara PD, Punetha D, Balasubramanian K (2014) A review of potential remediation techniques for uranium(VI) ion retrieval from contaminated aqueous environment. J Environ Chem Eng 2:1621–1634. https://doi.org/10.1016/j.jece.2014.06.007

Biris AR, Toloman D, Popa A et al (2016) Synthesis of tunable core–shell nanostructures based on TiO2-graphene architectures and their application in the photodegradation of rhodamine dyes. Physica E 81:326–333. https://doi.org/10.1016/j.physe.2016.03.028

Cernuto G, Masciocchi N, Cervellino A et al (2011) Size and Shape Dependence of the Photocatalytic Activity of TiO 2 Nanocrystals: A Total Scattering Debye Function Study. J Am Chem Soc 133:3114–3119. https://doi.org/10.1021/ja110225n

Dai B, Tao H, Lin Y-J, Chang C-T (2016) Study of Various Nanostructures Titania with Graphene Composites: The Preparation and Photocatalytic Activities. NANO 11:1650106. https://doi.org/10.1142/S179329201650106X

de las Casas C, Li W (2012) A review of application of carbon nanotubes for lithium ion battery anode material. Journal of Power Sources 208:74–85. https://doi.org/10.1016/j.jpowsour.2012.02.013

Dixit F, Zimmermann K, Dutta R, et al (2022) Application of MXenes for water treatment and energy-efficient desalination: A review. Journal of Hazardous Materials 423https://doi.org/10.1016/j.jhazmat.2021.127050

Fakhru’l-Razi A, Pendashteh A, Abdullah LC, et al (2009) Review of technologies for oil and gas produced water treatment. Journal of Hazardous Materials 170:530–551https://doi.org/10.1016/j.jhazmat.2009.05.044

Fan H, Yi G, Zhang Z et al (2021) Binary TiO2/RGO photocatalyst for enhanced degradation of phenol and its application in underground coal gasification wastewater treatment. Opt Mater 120:111482. https://doi.org/10.1016/j.optmat.2021.111482

Fang R, Chen K, Yin L et al (2019) The Regulating Role of Carbon Nanotubes and Graphene in Lithium-Ion and Lithium-Sulfur Batteries. Adv Mater 31:1800863. https://doi.org/10.1002/adma.201800863

Fu Y-X, Dai Y, Pei X-Y et al (2019) TiO2 nanorods anchor on reduced graphene oxide (R-TiO2/rGO) composite as anode for high performance lithium-ion batteries. Appl Surf Sci 497:143553. https://doi.org/10.1016/j.apsusc.2019.143553

Fujishima A, Honda K (1972) Electrochemical Photolysis of Water at a Semiconductor Electrode. Nature 238:37–38. https://doi.org/10.1038/238037a0

Gao P, Li A, Sun DD, Ng WJ (2014) Effects of various TiO2 nanostructures and graphene oxide on photocatalytic activity of TiO2. J Hazard Mater 279:96–104. https://doi.org/10.1016/j.jhazmat.2014.06.061

Gao Y, Yin L, Kim SJ et al (2019) Enhanced lithium storage by ZnFe2O4 nanofibers as anode materials for lithium-ion battery. Electrochim Acta 296:565–574. https://doi.org/10.1016/j.electacta.2018.11.093

Gautam A, Gore PM, Kandasubramanian B (2020) Nanocluster materials in photosynthetic machines. Chem Eng J 385:123951. https://doi.org/10.1016/j.cej.2019.123951

George SM, Kandasubramanian B (2020) Advancements in MXene-Polymer composites for various biomedical applications. Ceram Int 46:8522–8535. https://doi.org/10.1016/j.ceramint.2019.12.257

Giovannetti R, Rommozzi E, Zannotti M, D’Amato CA (2017) Recent Advances in Graphene Based TiO2 Nanocomposites (GTiO2Ns) for Photocatalytic Degradation of Synthetic Dyes. Catalysts 7:305. https://doi.org/10.3390/catal7100305

Gnanasekaran L, Hemamalini R, Ravichandran K (2015) Synthesis and characterization of TiO2 quantum dots for photocatalytic application. J Saudi Chem Soc 19:589–594. https://doi.org/10.1016/j.jscs.2015.05.002

Gonte R, Balasubramanian K (2016) Heavy and toxic metal uptake by mesoporous hypercrosslinked SMA beads: Isotherms and kinetics. J Saudi Chem Soc 20:S579–S590. https://doi.org/10.1016/j.jscs.2013.04.003

Gonte RR, Balasubramanian K (2012) Chemically modified polymer beads for sorption of gold from waste gold solution. J Hazard Mater 217–218:447–451. https://doi.org/10.1016/j.jhazmat.2012.03.020

Gonte RR, Shelar G, Balasubramanian K (2014) Polymer–agro-waste composites for removal of Congo red dye from wastewater: adsorption isotherms and kinetics. Desalin Water Treat 52:7797–7811. https://doi.org/10.1080/19443994.2013.833876

Gopalakrishnan A, Binitha NN, Yaakob Z et al (2016) Excellent photocatalytic activity of titania–graphene nanocomposites prepared by a facile route. J Sol-Gel Sci Technol 80:189–200. https://doi.org/10.1007/s10971-016-4058-4

Gore PM, Balakrishnan S, Kandasubramanian B (2019a) Superhydrophobic corrosion inhibtion polymer coatings. Superhydrophobic Polymer Coatings: Fundamentals, Design, Fabrication, and Applications, 1st edn. Elsevier, Amsterdam, pp 1–22

Gore PM, Dhanshetty M, Kandasubramanian B (2016a) Bionic creation of nano-engineered Janus fabric for selective oil/organic solvent absorption. RSC Adv 6:111250–111260. https://doi.org/10.1039/C6RA24106A

Gore PM, Kandasubramanian B (2018) Heterogeneous wettable cotton based superhydrophobic Janus biofabric engineered with PLA/functionalized-organoclay microfibers for efficient oil-water separation. J Mater Chem A 6:7457–7479. https://doi.org/10.1039/c7ta11260b

Gore PM, Khurana L, Dixit R, Balasubramanian K (2017) Keratin-Nylon 6 engineered microbeads for adsorption of Th (IV) ions from liquid effluents. J Environ Chem Eng 5:5655–5667. https://doi.org/10.1016/j.jece.2017.10.048

Gore PM, Khurana L, Siddique S et al (2018) Ion-imprinted electrospun nanofibers of chitosan/1-butyl-3-methylimidazolium tetrafluoroborate for the dynamic expulsion of thorium (IV) ions from mimicked effluents. Environ Sci Pollut Res 25:3320–3334. https://doi.org/10.1007/s11356-017-0618-6

Gore PM, Naebe M, Wang X, Kandasubramanian B (2020) Silk fibres exhibiting biodegradability & superhydrophobicity for recovery of petroleum oils from oily wastewater. Journal of Hazardous Materials 389https://doi.org/10.1016/j.jhazmat.2019.121823

Gore PM, Naebe M, Wang X, Kandasubramanian B (2021) Nano-fluoro dispersion functionalized superhydrophobic degummed & waste silk fabric for sustained recovery of petroleum oils & organic solvents from wastewater. Journal of Hazardous Materials 127822. https://doi.org/10.1016/j.jhazmat.2021.127822

Gore PM, Naebe M, Wang X, Kandasubramanian B (2019b) Progress in silk materials for integrated water treatments: Fabrication, modification and applications. Chem Eng J 374:437–470. https://doi.org/10.1016/j.cej.2019.05.163

Gore PM, Purushothaman A, Naebe M, et al (2019c) Nanotechnology for Oil-Water Separation. 299–339. https://doi.org/10.1007/978-3-030-02381-2_14

Gore PM, Zachariah S, Gupta P, Balasubramanian K (2016b) Multifunctional nano-engineered and bio-mimicking smart superhydrophobic reticulated ABS/fumed silica composite thin films with heat-sinking applications. RSC Adv 6:105180–105191. https://doi.org/10.1039/c6ra16781k

Gu Y, Xing M, Zhang J (2014) Synthesis and photocatalytic activity of graphene based doped TiO2 nanocomposites. Appl Surf Sci 319:8–15. https://doi.org/10.1016/j.apsusc.2014.04.182

Gupta P, Lapalikar V, Kundu R, Balasubramanian K (2016) Recent Advances in Membrane Based Waste Water Treatment Technology: A Review. Energy and Environment Focus 5:241–267. https://doi.org/10.1166/eef.2016.1227

Haider AJ, AL– Anbari RH, Kadhim GR, Salame CT (2017) Exploring potential Environmental applications of TiO2 Nanoparticles. Energy Procedia 119:332–345. https://doi.org/10.1016/j.egypro.2017.07.117

Hamadanian M, Rostami M, Jabbari V (2017) Graphene-supported C-N–S tridoped TiO2 photo-catalyst with improved band gap and charge transfer properties. J Mater Sci: Mater Electron 28:15637–15646. https://doi.org/10.1007/s10854-017-7452-y

Han W, Ren L, Zhang Z et al (2015) Graphene-supported flocculent-like TiO2 nanostructures for enhanced photoelectrochemical activity and photodegradation performance. Ceram Int 41:7471–7477. https://doi.org/10.1016/j.ceramint.2015.02.068

Hashimoto K, Irie H, Fujishima A (2005) Tio2 Photocatalysis: A Historical Overview and Future Prospects. japenese journal of applied physics 44:8269–8285

Hassoun J, Bonaccorso F, Agostini M et al (2014) An Advanced Lithium-Ion Battery Based on a Graphene Anode and a Lithium Iron Phosphate Cathode. Nano Lett 14:4901–4906. https://doi.org/10.1021/nl502429m

He F, Fan J, Ma D et al (2010) The attachment of Fe3O4 nanoparticles to graphene oxide by covalent bonding. Carbon 48:3139–3144. https://doi.org/10.1016/j.carbon.2010.04.052

Hemanth NR, Kandasubramanian B (2020) Recent advances in 2D MXenes for enhanced cation intercalation in energy harvesting Applications: A review. Chemical Engineering Journal 392. Hemanth NRhttps://doi.org/10.1016/j.cej.2019.123678

Jain V, Kandasubramanian B (2020) Functionalized graphene materials for hydrogen storage. J Mater Sci 55:1865–1903. https://doi.org/10.1007/s10853-019-04150-y

Jaya Prakash N, Kandasubramanian B (2021) Nanocomposites of MXene for industrial applications. Journal of Alloys and Compounds 862. https://doi.org/10.1016/j.jallcom.2020.158547

Jimmy J, Kandasubramanian B (2020) Mxene functionalized polymer composites: Synthesis and applications. European Polymer Journal 122. https://doi.org/10.1016/j.eurpolymj.2019.109367

Jochen Winkler (2013) Titanium Dioxide: Production, Properties and Effective Usage

Kaur H, Dahake R, Maddigapu PR et al (2020) Enhanced photocatalytic degradation of antimicrobial triclosan using rGO–TiO2 composite under natural solar illumination. J Mater Sci: Mater Electron 31:6045–6058. https://doi.org/10.1007/s10854-020-03156-6

Khan SA, Arshad Z, Shahid S et al (2019) Synthesis of TiO2/Graphene oxide nanocomposites for their enhanced photocatalytic activity against methylene blue dye and ciprofloxacin. Compos B Eng 175:107120. https://doi.org/10.1016/j.compositesb.2019.107120

Kim T-W, Park M, Kim HY, Park S-J (2016) Preparation of flower-like TiO 2 sphere/reduced graphene oxide composites for photocatalytic degradation of organic pollutants. J Solid State Chem 239:91–98. https://doi.org/10.1016/j.jssc.2016.04.010

Konstantinou IK, Albanis TA (2004) TiO2-assisted photocatalytic degradation of azo dyes in aqueous solution: kinetic and mechanistic investigations. Appl Catal B 49:1–14. https://doi.org/10.1016/j.apcatb.2003.11.010

Kurniawan TA, Mengting Z, Fu D et al (2020) Functionalizing TiO2 with graphene oxide for enhancing photocatalytic degradation of methylene blue (MB) in contaminated wastewater. J Environ Manage 270:110871. https://doi.org/10.1016/j.jenvman.2020.110871

Kusiak-Nejman E, Morawski AW (2019) TiO2/graphene-based nanocomposites for water treatment: A brief overview of charge carrier transfer, antimicrobial and photocatalytic performance. Appl Catal B 253:179–186. https://doi.org/10.1016/j.apcatb.2019.04.055

Lavanya T, Dutta M, Ramaprabhu S, Satheesh K (2017) Superior photocatalytic performance of graphene wrapped anatase/rutile mixed phase TiO 2 nanofibers synthesized by a simple and facile route. J Environ Chem Eng 5:494–503. https://doi.org/10.1016/j.jece.2016.12.025

Lavanya T, Satheesh K, Dutta M et al (2014) Superior photocatalytic performance of reduced graphene oxide wrapped electrospun anatase mesoporous TiO 2 nanofibers. J Alloy Compd 615:643–650. https://doi.org/10.1016/j.jallcom.2014.05.088

Li D, Guo E, Lu Q et al (2017a) Synthesis of one-dimensional graphene-encapsulated TiO2 nanofibers with enhanced lithium storage capacity for lithium-ion batteries. J Solid State Electrochem 21:2313–2320. https://doi.org/10.1007/s10008-017-3579-2

Li Q, Bian J, Zhang L et al (2014) Synthesis of Carbon Materials-TiO 2 Hybrid Nanostructures and Their Visible-Light Photo-catalytic Activity. ChemPlusChem 79:454–461. https://doi.org/10.1002/cplu.201300380

Li T, Wang T, Qu G et al (2017b) Synthesis and photocatalytic performance of reduced graphene oxide–TiO2 nanocomposites for orange II degradation under UV light irradiation. Environ Sci Pollut Res 24:12416–12425. https://doi.org/10.1007/s11356-017-8927-3

Liang X, Tao H, Zhang Q, Chang C-T (2015) High Performance Photocatalytic Degradation by Graphene/Titanium Nanotubes Under Near Visible Light with Low Energy Irradiation. J Nanosci Nanotechnol 15:4887–4894. https://doi.org/10.1166/jnn.2015.10020

Lin C, Gao Y, Zhang J et al (2020a) GO/TiO 2 composites as a highly active photocatalyst for the degradation of methyl orange. J Mater Res 35:1307–1315. https://doi.org/10.1557/jmr.2020.41

Lin Y-T, Huang C-W, Wang Y-H, Wu JCS (2020b) High Effective Composite RGO/TiO2 Photocatalysts to Degrade Isopropanol Pollutant in Semiconductor Industry. Top Catal 63:1240–1250. https://doi.org/10.1007/s11244-020-01263-6

Liu H, Dong X, Wang X et al (2013) A green and direct synthesis of graphene oxide encapsulated TiO 2 core / shell structures with enhanced photoactivity. Chem Eng J 230:279–285. https://doi.org/10.1016/j.cej.2013.06.092

Liu H, Wang Y, Shi L et al (2016) Utilization of reduced graphene oxide for the enhancement of photocatalytic property of TiO 2 nanotube. Desalin Water Treat 57:13263–13272. https://doi.org/10.1080/19443994.2015.1060172

Liu Y, Zhang D, Shang Y et al (2015) Construction of multifunctional films based on graphene–TiO 2 composite materials for strain sensing and photodegradation. RSC Adv 5:104785–104791. https://doi.org/10.1039/C5RA21364A

Long M, Qin Y, Chen C et al (2013) Origin of Visible Light Photoactivity of Reduced Graphene Oxide/TiO 2 by in Situ Hydrothermal Growth of Undergrown TiO 2 with Graphene Oxide. The Journal of Physical Chemistry C 117:16734–16741. https://doi.org/10.1021/jp4058109

Ma Y, Li Y, Li D et al (2019) Uniformly distributed TiO2 nanorods on reduced graphene oxide composites as anode material for high rate lithium ion batteries. J Alloy Compd 771:885–891. https://doi.org/10.1016/j.jallcom.2018.08.251

Maiti M, Sarkar M, Liu D (2020) Mechanism of nicotine degradation and adsorption by a nano-TiO 2 engineered reduced graphene oxide composite in light variant conditions. Catal Sci Technol 10:2797–2809. https://doi.org/10.1039/D0CY00073F

Martínez-Sánchez C, Montiel-González F, Díaz-Cervantes E, Rodríguez-González V (2019) Unraveling the strength interaction in a TiO2-Graphene photocatalytic nanocomposite synthesized by the microwave hydrothermal method. Mater Sci Semicond Process 101:262–271. https://doi.org/10.1016/j.mssp.2019.06.011

Mayilswamy N, Boney N, Kandasubramanian B (2022) Fabrication and molecular dynamics studies of layer-by-layer polyelectrolytic films. Eur Polymer J 163:110945. https://doi.org/10.1016/j.eurpolymj.2021.110945

Mills A, Le Hunte S (1997) An overview of semiconductor photocatalysis. J Photochem Photobiol, A 108:1–35. https://doi.org/10.1016/S1010-6030(97)00118-4

Moma J, Baloyi J (2019) Modified Titanium Dioxide for Photocatalytic Applications. In: Photocatalysts - Applications and Attributes. IntechOpen

Morales-narváez E, Florio L, Antonio S, et al (2017) Progress in Materials Science Graphene-encapsulated materials : Synthesis , applications and trends. 86:1–24. https://doi.org/10.1016/j.pmatsci.2017.01.001

Morawski AW, Kusiak-Nejman E, Wanag A et al (2017) Photocatalytic degradation of acetic acid in the presence of visible light-active TiO 2 -reduced graphene oxide photocatalysts. Catal Today 280:108–113. https://doi.org/10.1016/j.cattod.2016.05.055

Nam Y, Lim JH, Ko KC, Lee JY (2019) Photocatalytic activity of TiO 2 nanoparticles: a theoretical aspect. Journal of Materials Chemistry A 7:13833–13859. https://doi.org/10.1039/C9TA03385H

Natarajan TS, Thomas M, Natarajan K et al (2011) Study on UV-LED/TiO2 process for degradation of Rhodamine B dye. Chem Eng J 169:126–134. https://doi.org/10.1016/j.cej.2011.02.066

Neppolian B, Choi HC, Sakthivel S et al (2002) Solar light induced and TiO2 assisted degradation of textile dye reactive blue 4. Chemosphere 46:1173–1181. https://doi.org/10.1016/S0045-6535(01)00284-3

Nguyen DCT, Cho KY, Oh W-C (2019) Mesoporous CuO-graphene coating of mesoporous TiO2 for enhanced visible-light photocatalytic activity of organic dyes. Sep Purif Technol 211:646–657. https://doi.org/10.1016/j.seppur.2018.10.009

Palaniappan N, Cole IS, Caballero-Briones F et al (2018) Praseodymium-decorated graphene oxide as a corrosion inhibitor in acidic media for the magnesium AZ31 alloy. RSC Adv 8:34275–34286. https://doi.org/10.1039/C8RA05118F

Pastrana-Martínez LM, Morales-Torres S, Likodimos V et al (2012) Advanced nanostructured photocatalysts based on reduced graphene oxide–TiO2 composites for degradation of diphenhydramine pharmaceutical and methyl orange dye. Appl Catal B 123–124:241–256. https://doi.org/10.1016/j.apcatb.2012.04.045

Pastrana-Martínez LM, Morales-Torres S, Likodimos V et al (2014) Role of oxygen functionalities on the synthesis of photocatalytically active graphene–TiO2 composites. Appl Catal B 158–159:329–340. https://doi.org/10.1016/j.apcatb.2014.04.024

Pawar M, Topcu Sendoğdular S, Gouma P (2018) A Brief Overview of TiO 2 Photocatalyst for Organic Dye Remediation: Case Study of Reaction Mechanisms Involved in Ce-TiO 2 Photocatalysts System. J Nanomater 2018:1–13. https://doi.org/10.1155/2018/5953609

Pawar SS, Baloji Naik R, Rath SK et al (2020) Photoinduced hydrophilicity and self-cleaning characteristics of silicone-modified soya alkyd/TiO2 nanocomposite coating. J Coat Technol Res 17:719–730. https://doi.org/10.1007/s11998-019-00253-y

Peng K, Jie J, Zhang W, Lee S-T (2008) Silicon nanowires for rechargeable lithium-ion battery anodes. Appl Phys Lett 93:033105. https://doi.org/10.1063/1.2929373

Posa VR, Annavaram V, Somala AR (2016) Fabrication of graphene-TiO2 nanocomposite with improved photocatalytic degradation for acid orange 7 dye under solar light irradiation. Bull Mater Sci 39:759–767. https://doi.org/10.1007/s12034-016-1215-x

Pu S, Zhu R, Ma H et al (2017) Facile in-situ design strategy to disperse TiO2 nanoparticles on graphene for the enhanced photocatalytic degradation of rhodamine 6G. Appl Catal B 218:208–219. https://doi.org/10.1016/j.apcatb.2017.06.039

Raj RBA, Gonte RR, Balasubramanian K (2017) Dual functional styrene-maleic acid copolymer beads: Toxic metals adsorbent and hydrogen storage. Enhancing Cleanup of Environmental Pollutants. Springer International Publishing, Cham, pp 255–295