Abstract

One of the major challenges faced by human society is the freshwater crisis and shortage of conventional energy. Solar still is considered as one of the promising sources for the production of freshwater from saline water by desalination method. This paper represents the theoretical and experimental study of tubular solar still with and without fins. In this experimental study, the readings were recorded from 8:00 AM to 6:00 PM. The results of this experiment show that the efficiency of tubular solar still (TSS) with fins and without fins is found as 23.39 and 13.76% respectively. The rate of irreversibility from the basin of TSS with flat is higher than TSS with finned absorber and also the rate of irreversibility from water is significantly reduced by TSS with the finned absorber. The exergy analysis showed the maximum exergy efficiency of about 11.8% from the TSS with fins and about 10.6% from the TSS with a flat absorber.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nearly about 780 million people lack access to water around the world. It is predicted that 50% of the world population will suffer from water scarcity in 2050. To fulfill the necessity, desalination of water can be done. Solar stills can be used to remove salt from the seawater. Solar still desalination is free from pollution and provides a high-quality pure form of water. The setup of this solar still desalination can be used in residential areas to overcome water scarcity in urban areas (Abdelgaied et al. 2020; Attia et al. 2021, 2020; Balachandran et al. 2021; Essa et al. 2020; Kumar et al. 2020; Muthu Manokar et al. 2020a, b; Petela 2003; Sharshir et al. 2020; Velmurugan et al. 2008a; Zurigat & Abu-Arabi 2004). The drawback of solar stills is the low productivity rate and the requirement of constant sunlight for the process to be done. For a single slope and pyramid-shaped solar still, Fath et al. (2003) carried out a thermo-economic analysis. Their study revealed that the performance of traditional solar still was significantly higher than the solar still in the shape of a pyramid. There is an increase of about 30% in the freshwater produced using conventional solar still than pyramid-shaped solar still. Abu-Arabi and Zurigat (2005) performed a simulation on double glass cover cooling with regenerative effect and conventional solar still. Their results revealed that the regenerative effect from double glass cover cooling improved the cumulative yield by 70% than a single slope conventional solar still. Arunkumar et al. (2013) used a concentric tubular solar still and, in addition to that, a parabolic concentrator is attached to focus the incoming solar radiation. Additionally, air- and water-cooling methods were employed to reduce the cover temperature. Through improved cooling of air and water flow, the productivity of water produced was increased from 2050 to 3050 mL/day. With continuous cooling water flow in the concentric tube, the freshwater produced was furthermore increased to 5000 mL/day. Arunkumar et al. (2016) enhanced the productivity of compound parabolic concentrator tubular solar stills. A saline water trough of rectangular shape was designed and fabricated and this trough is attached along with the pyramid type and single slope solar still. The integrated solar still produced an accumulated yield of 7770 mL/day, whereas the single slope solar still produced a maximum cumulative yield of 6460 mL/day. Kabeel et al. (2019) improved the performance of the tubular solar still by controlling the cover cooling and water depth. It is found that lowering the water depth increases the performance, and the productivity of freshwater rate reached a maximum value of 5.85 L/m2. Elashmawy (2019) describes the performance of the high-temperature stand-alone tubular solar still by changing the thickness and surface cooling. By reducing the thickness by 40%, the productivity and efficiency had been enhanced by 21 and 13.35% respectively. Elashmawy (2017) conducted three experiments using tubular solar still namely rectangular trough with a black cloth, half-cylindrical trough without cloth, and parabolic concentrator solar tracking system-integrated half-cylindrical trough without cloth. The daily yield is about 4.71, 3.6, and 3.53 L/m2 day. Panchal (2015) has proved that the combined application of both black granite gravel and vacuum tubes increased the double basin solar still (DBSS) freshwater productivity to 65% and the application of vacuum tubes alone in DBSS enhanced the freshwater productivity by 56%. Panchal and Thakkar (2016) had validated the thermal and experimental analysis carried out on solar still directly coupled with evacuated tubes during summer and winter climatic conditions. They concluded that the introduction of evacuated tubes and polyurethane foam-type insulation material to the experimental model enhanced the distillate output and also helps in reducing heat loss. Rahbar et al. (2015) proposed new correlations to predict the freshwater produced and heat transfer coefficient of a tubular solar still (TSS) using a computational fluid dynamic simulation (CFD) and theoretical approach. From the characteristic curve of their study, it can be concluded that on lower cover temperature and higher water temperature, the yield from TSS was higher. Sarhaddi et al. (2017) carried out experiments on a weir cascade solar still by incorporating phase change material (PCM) energy storage to estimate the energy and exergy under clear sky conditions and semi-cloudy conditions. From the results of exergy and energy analysis, it has been summarized that the still with PCM is preferred for semi-cloudy days and still without PCM is suitable for sunny days. Experiments conducted on a typical sunny day with a clear sky revealed that the exergy efficiency of solar still without PCM was slightly lower than semi-cloudy days, whereas the energy efficiency was reduced using PCM during semi-cloudy conditions as it affects the melting process of PCM beneath the basin. Shanmugan et al. (2018) conducted experiments to study the yield enhancement of solar still by incorporating nanoparticles and PCM in the basin of the still model. The distillate yield of single basin solar still (SB-SS) with wick material by nanoparticles as FWCW and PCM is 4.120 and 7.460 kg/m2 day. Sharshir et al. (2016) studied the performance of a continuous solar desalination model comprised of an humidification–dehumidification (HDH) unit and solar still (SS) with an evacuated solar water heater unit. The experimental study shows that the distillate productivity of the SS with exit warm water from HDH is 242% higher than the concentrated solar still (CSS) system and there is a 39% rise in the gain output ratio. The effect of forced convection on cover cooling of pyramid solar still was experimentally carried out by Taamneh and Taamneh (2012). A small DC-powered fan was used to cool the entire cover surface. Experimental results revealed that an improvement in daily freshwater yield of about 2.99 L/day (25%) is achieved using forced convection which is higher compared to free convection still. Bhaskar and Rai (2018) investigated the productivity and exergy analysis of tubular solar still operated in active and passive mode individually. This study showed that the daily freshwater yield of the TSS in active mode is 52% more than the passive mode and also the TSS with fan had exergy efficiency of about 133% higher than the TSS in passive mode. Xie et al. (2016) have designed and constructed a novel conceptual design of low-temperature multi-effect desalination system that comprises an array of tubular solar still capable of producing freshwater independently to investigate the performance affecting the following parameters: vacuum pressures, heating conditions, and evaporation temperatures. Panchal and Mohan (2017) presented a cost-effective optimized solar still model with its different approaches of augmenting the productivity of solar still by adding some modifications such as fins, increasing the number of effects, and adding energy-absorbing materials inside the basin.

The effect of humid air present in the tubular enclosure on heat and mass transfer was experimentally studied by Ahsan and Fukuhara (2010). Other similar configuration of solar still includes improving the exposure area by attaching hollow and solid fins. In addition to the fins, additional materials such as wick material, PCM, ethanol, and solar pond can further increase freshwater. A parametric study on the pyramid and single slope solar still was carried out by Fath et al. (2003) and Arun Kumar et al. (2013) added some new cooling techniques and structures were adapted to solar still which resulted in a better production rate of freshwater. Pin fins with an external condenser were introduced in solar still to enhance productivity. Manokar and Winston (2017) experimented on acrylic solar still with pin fins. From the detailed literature review, it is found that only a few research work had been done on this area. The main novelty of the present manuscript is to analyze the exergy and energy of tubular solar still to enhance the yield. Through this study, the exergy efficiency increased by 2% and thermal efficiency increased by 7% when compared with without fins. The proposed model provided new outputs for the tubular solar still. Finally, it is concluded that the daily and hourly production of the tubular solar still can be accurately predicted.

Experimental setup and procedure

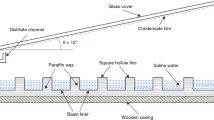

The schematic diagram and experimental test rig photograph of TSS with fins (left) and the TSS without fins (right) are depicted in Fig. 1. This experimental setup consists of a transparent tube made up of glass, a steel rectangular water basin called a trough, and a calibrated flask to collect the freshwater produced. The glass tube allows the penetration of solar irradiance from any direction which helps in augmenting the evaporation process in this desalination system. The trough containing saline water is placed in the transparent glass tube. The trough is coated in black color in order to reduce the reflection of solar irradiance by absorbing all the solar irradiance transmitted through the outer transparent glass tube. Solar thermal heat produced by solar radiation is absorbed by the saline water in the trough. As a result of heating, the saline water gets heated and evaporated. The evaporated water vapor gets condensed on the inner surface of the glass tube due to the release of latent heat of evaporation. The condensed water flows down by the effect of gravity and is collected at the bottom of the tube as freshwater. Two experimental models of TSS in which one of the models having fins attached with trough and another without fins in the trough are used and a comparative experimental study between the two models is carried out. Fins used in the trough help in boosting the desalination process because of the increased surface area of the absorber and enhanced greenhouse effect within the still. The range, error, accuracy, and type of instruments used in the present experimental study are tabulated in Table 1.

Results and discussion

The experimental data recorded such as solar radiation, ambient temperature, cover, basin, and water temperature from the modified tubular solar still using flat and finned absorber are presented in this section with a detailed discussion. Using the empirical correlations, the instantaneous thermal and exergy efficiencies are determined. In addition, the predicted yield is correlated to the experimental results obtained from the study. Furthermore, a comparison of different solar still using fins and phase change materials were made to justify the present experimental investigation.

Thermal analysis

In this section, a comparative interpretation between the theoretical and experimental study of TSS with and without fins is carried out. The hourly variation of operating parameters for TSS with and without fins including solar intensity, glass temperature, basin temperature, water temperature, and ambient temperature are plotted in Figs. 2 and 3. The maximum solar intensity of about 963.7 W/m2 was attained at midday and its starts decreasing gradually. While solar intensity starts decreasing during the evening, the temperatures of TSS’s glass, basin, and water start increasing around the evening. The TSS integrated with fins reacts faster and higher to solar intensity than the TSS without fins. The distillate output rate of any solar still is determined by the temperature of the water inside still and the performance of still is also dependent upon many factors such as air temperature inside still (the cavity between the basin and glass cover area), lower glass cover temperature, absorber plate temperature, and the surface area of the absorber.

Figure 2 shows the solar intensity of TSS without fins measured starting from 8:00 AM to 6:00 PM. Solar intensity ranges from 150 to 1000 W/m2. At the beginning of the day, the solar intensity is about 270 W/m2 and the temperature is about 20 °C. The ambient, basin, water, and glass temperatures are about 31 °C, 31 °C, 29 °C, and 28 °C, respectively, and their solar intensity is about 400–450 W/m2. Solar intensity reaches as high as 963.7 W/m2 at noon time and the ambient temperature is about 37.5 °C. The ambient, water, and glass temperature reach its peak at around 15:00 hours and then gradually decreases. Also, the solar intensity drops to 150 W/m2 around 6:00 hours.

Figure 3 shows the solar intensity of TSS with fins. The ambient temperature is lower due to lower solar intensity in the daytime. Thus, the basin, water, and glass temperatures remain lower. The ambient temperature increases from 9:00 hours to 12:00 hours, while the ambient temperature reaches its maximum value of 37.5 °C around 12:00 PM. The solar intensity increases and reaches a maximum value of 963.7 W/m2 during noon. The basin and water temperatures attain their maximum temperature around 59 and57 °C at 2:00 PM. The glass temperature reaches a maximum value of 51 °C at 15:00 hours. In the peak solar radiation period, the ambient temperature decreases to 31.2 °C, so the solar intensity also decreases and reaches a lower value of 150 W/m2. Thus, the basin, water, and glass temperatures also decrease.

The experimental and theoretical results on hourly freshwater production from TSS using flat and finned absorber is plotted in Fig. 4. It is seen from Fig. 4 that using a flat absorber, the hourly freshwater produced is lower as compared to the finned absorber. There is a gradual increase in the yield from the sunrise and the maximum is reached during the peak solar intensity.

It is also seen that the experimental and theoretical yields are in agreement in both cases. From Fig. 4, it is clear that the theoretical distillate yield is always greater than the experimental distillate yield from the TSS. The maximum theoretical freshwater yield value achieved by the TSS with fins is 0.67 kg/m2 and by the TSS without fins is 0.58 kg/m2. The maximum experimental freshwater yield value achieved by the TSS with fins is 0.65 kg/m2 and by the TSS without fins is 0.55 kg/m2 which shows that the fins present in the TSS will naturally augment the freshwater yield due to the enhanced surface area of the absorber. These fins increased the rate of absorption of heat in the basin due to the increased surface area in the basin by the water. The presence of fins in the basin furthermore distributes the heat throughout the water to augment the rate of evaporation from the surface of the water. With a simultaneous increase in the rate of evaporation inside the enclosure, the amount of water produced from the solar still is increased.

Figures 5 and 6 show the results of predicted and measured yield of TSS without and with fins on the absorber respectively. The predicted yield from solar still is measured using Eqs. (1) to (3). It can be seen that the experimental yield produced from the TSS is in good agreement with the predicted yield with a confidence level of 95%.

The hourly yield from the tubular solar still under both cases can be mathematically expressed as [43],

The influential parameter for determining the yield of freshwater from solar still are the partial difference in pressure, evaporative heat transfer coefficient, temperature difference, and convective heat transfer coefficient as mathematically expressed in Eqs. (2) and (3).

Mathematically, the EHTC is estimated as (Shukla and Sorayan 2005),

Similarly, the convective heat transfer coefficient (CHTC) is mathematically expressed as (Shukla and Sorayan 2005),

Energy efficiency

The instantaneous hourly changes in thermal efficiency of the TSS using flat absorber and finned absorber are plotted in Fig. 7. The instantaneous thermal efficiency of the solar still is calculated using Eq. (4).

From the graph, it can be noted that the efficiency of the solar still without fins reaches the peak value during midday and gradually falls around evening. The thermal efficiency of the TSS having fins also reaches the maximum value during the midday same as the solar still without fans but the TSS with fins maintains the thermal efficiency for a significant time period in the evening of that experiment day. The peak value of thermal efficiency for solar still without fins reached approximately 36.65%, whereas for the solar still with fins, it attains a peak value of about 43.13%. Hence, the usage of fins in the TSS has a remarkable effect on freshwater production and also helps in boosting the vapor to be entrapped inside the tubular enclosure.

Rate of irreversibility from water, glass, and basin

The rate of the irreversibility of water, glass, and basin using finned absorber and flat absorber is mathematically expressed in Eqs. (5–7). The total rate of irreversibility is the summation of the destruction of exergy and loss of exergy.

The rate of irreversibility from glass is mathematically given as (Sarhaddi et al. 2017),

The rate of irreversibility from water is mathematically given as (Sarhaddi et al. 2017),

The rate of irreversibility from the basin is mathematically given as (Sarhaddi et al. 2017),

Figure 8a, b shows the variations of the irreversibility of water, glass, and basin of water, glass, and basin of TSS using a flat and finned absorber. It is clear that the irreversibility of the basin is higher in both cases and the lower irreversibility occurs on water and glass. Also, increased solar intensity falling on the solar still increased the irreversibility of each component. The average irreversibility rates of water, glass, and basin using a flat absorber are found as 26.45, 29.45, and 457.2 W respectively, whereas for a finned absorber, they were found as 24.6, 29.02, and 448.8 W respectively. It is observed that the irreversibility rate of the finned absorber is reduced as compared to that of solar still using a flat absorber. Also, from Fig. 8a, b, it is depicted that the irreversibility rate of water and glass were closer till reaching the peak solar intensity. From the previous literature (Sarhaddi et al. 2017), it is found that the irreversibility of solar still can be reduced by modifying the design of the absorber plate.

Exergy efficiency

The exergy efficiency of the solar still is mathematically expressed as follows (Petla 2003; Hepbasli 2008):

The exergy output is mathematically expressed as (Petla 2003; Hepbasli 2008),

where

hfg = Latent heat of vaporization (kJ/kg)

Tw = Water temperature (K)

The exergy input is mathematically expressed as (Petla 2003; Hepbasli 2008),

where

Tsun = temperature of sun (Tsun = 6000 K)

Ta = ambient temperature (K)

The exergy efficiency of the solar still increases with respect to time and the amount of solar radiation falling on the system. It is seen that the exergy efficiency of both the solar still increases as the solar radiation increased and reaching the maximum of 11.8 and 10.6% for finned and flat absorbers respectively. During the start of the experiment till reaching the maximum solar intensity, the exergy efficiency of finned absorber TSS produced exergy efficiency (Fig. 9).

Conclusions

This paper represents the study of the performance of TSS with and without fins and from the results, it has been clear that the usage of fins in TSS augmented the distillate yield experimentally and theoretically. The findings of the experimental and theoretical study show that the fins integrated with the basin of TSS augmented the performance and thermal efficiency higher than the TSS without fins. The distillate yield of TSS with fins is experimentally and theoretically higher than the TSS without fins. A cumulative distillate gain of 53.08% implying an hourly thermal efficiency gain of 69.9% is recorded for the TSS with fins compared with the TSS without fins. Table 2 describes the different yields achieved by different research works done in TSS. According to the table, the maximum yield of about 5.85 L/m2 was achieved by Kabeel et al. (2019) with tubular solar still with cover cooling and a minimum yield of about 0.81 kg freshwater was produced in the experimental study with evacuated tube collector (ETC)-integrated solar still by Panchal and Thakkar (2016). A maximum distillate yield of about 2.93 L/day is achieved by the TSS with fins in this experiment and also by attaching fins, the exergy efficiency of solar still also improved. The use of fins in the basin of TSS enhanced the amount of heat absorbed by the absorber due to an increase in the surface area of the absorber plate which in turn results in higher freshwater production compared to the TSS without fins. The rate of irreversibility is slightly reduced from the TSS using finned absorber as compared to the flat absorber. Similarly, by attaching fins in the absorber plate, the exergy efficiency is improved from the solar still as compared to solar still with a flat absorber.

Abbreviations

- TSS:

-

Tubular solar still

- DBSS:

-

Double basin solar still

- SB-SS:

-

Single basin solar still

- DC:

-

Direct current

- EHTC:

-

Evaporative heat transfer coefficient

- CHTC:

-

Convective heat transfer coefficient

- ETC:

-

Evacuated tube collector

- HDH:

-

Humidification–dehumidification

- CFD:

-

Computational fluid dynamic simulation

- CSS:

-

Concentrated solar still

- PCM:

-

Phase change material

- T :

-

Ambient temperature (K)

- T sun :

-

Temperature of sun (K)

- A :

-

Area (m2)

- U b :

-

Overall heat transfer coefficient (W/m2 K)

- I (t):

-

Solar intensity (W/m2)

- I r,g :

-

Rate of irreversibility from glass

- h fg :

-

Latent heat of vaporization (kJ/kg)

- E in :

-

Exergy input (W/m2)

- E out :

-

Exergy output (W/m2)

- E evap :

-

Exergy associated with the heat transfer through evaporation

- E sun :

-

Solar exergy

- τ :

-

Transmissivity

- α :

-

Absorptivity

- η :

-

Efficiency

- a:

-

Ambient

- w:

-

Water

- b:

-

Basin

- g:

-

Glass

References

Abdelgaied M, Kabeel AE, Sathyamurthy R (2020) Improving the performance of solar powered membrane distillation systems using the thermal energy storage mediums and the evaporative cooler. Renew Energy 157:1046–1052

Abu-Arabi M, Zurigat Y (2005) Year-round comparative study of three types of solar desalination units. Desalination 172(2):137–143

Ahsan A, Fukuhara T (2010) Mass and heat transfer model of tubular solar still. Sol Energy 84(7):1147–1156

Alaian WM, Elnegiry EA, Hamed AM (2016) Experimental investigation on the performance of solar still augmented with pin-finned wick. Desalination 379:10–15

Appadurai M, Velmurugan V (2015) Performance analysis of fin type solar still integrated with fin type mini solar pond. Sustain Energy Technol Assess 9:30–36

Arunkumar T, Jayaprakash R, Ahsan A, Denkenberger D, Okundamiya MS (2013) Effect of water and air flow on concentric tubular solar water desalting system. Appl Energy 103:109–115

Arunkumar T, Velraj R, Denkenberger DC, Sathyamurthy R, Kumar KV, Ahsan A (2016) Productivity enhancements of compound parabolic concentrator tubular solar stills. Renew Energy 88:391–400

Attia MEH, Driss Z, Abdelgaied M, Manokar AM, Sathyamurthy R, Hussein AK (2021) Performance evaluation of modified solar still using aluminum foil sheet as absorber cover–a comparative study. J Test Eval 49(5)

Attia MEH, Driss Z, Manokar AM, Sathyamurthy R (2020) Effect of aluminum balls on the productivity of solar distillate. Journal of Energy Storage 30:101466

Balachandran GB, David PW, Rajendran G, Ali MNA, Radhakrishnan V, Balamurugan R, Athikesavan M, Sathyamurthy R (2021) Investigation of performance enhancement of solar still incorporated with Gallus gallus domesticus cascara as sensible heat storage material. Environ Sci Poll Res 28:611–624

Bhaskar N, Rai AK (2018) Thermal investigation of a tubular solar still. Technology 9(1):356–362

Elashmawy M (2017) An experimental investigation of a parabolic concentrator solar tracking system integrated with a tubular solar still. Desalination 411:1–8

Elashmawy M (2019) Effect of surface cooling and tube thickness on the performance of a high temperature standalone tubular solar still. Appl Therm Eng 156:276–286

El-Sebaii AA, El-Naggar M (2017) Year round performance and cost analysis of a finned single basin solar still. Appl Therm Eng 110:787–794

El-Sebaii AA, Ramadan MRI, Aboul-Enein S, El-Naggar M (2015) Effect of fin configuration parameters on single basin solar still performance. Desalination 365:15–24

Essa FA, Elsheikh AH, Algazzar AA, Sathyamurthy R, Ali MKA, Abd Elaziz M, Salman KH (2020) Eco-friendly coffee-based colloid for performance augmentation of solar stills. Process Saf Environ Prot 136:259–267

Fath HE, El-Samanoudy M, Fahmy K, Hassabou A (2003) Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 159(1):69–79

Hepbasli A (2008) A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renew Sust Energ Rev 12(3):593–661

Jani HK, Modi KV (2018) Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol Energy 179(December):186–194

Kabeel AE, Sharshir SW, Abdelaziz GB, Halim MA, Swidan A (2019) Improving performance of tubular solar still by controlling the water depth and cover cooling. J Clean Prod 233:848–856

Kumar SA, Kumar PSM, Sathyamurthy R, Manokar AM (2020) A study of life cycle conversion efficiency and CO2 role in the pyramid shape solar stills–Comparative analysis. Groundw Sustain Dev 11:100413

Manokar AM, Winston DP (2017) Experimental analysis of single basin single slope finned acrylic solar still. Mater Today Proc 4(8):7234–7239

Muthu Manokar A, Prince Winston D (2017) Comparative study of finned acrylic solar still and galvanised iron solar still. Mater Today Proc 4(8):8323–8327

Muthu Manokar A, Vimala M, Prince Winston D, Rajendran DR, Sathyamurthy R, Kabeel AE (2020a) Year around distilled water production, energy, and economic analysis of solar stills—a comparative study. Heat Transfer 49(6):3651–3662

Muthu Manokar A, Vimala M, Prince Winston D, Rajendran DR, Sathyamurthy R, Kabeel AE (2020b) A comparative study of 3E (energy, exergy, and economy) analysis of various solar stills. Heat Transfer 49(8):4394–4409

Omara ZM, Hamed MH, Kabeel AE (2011) Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 277(1–3):281–287

Panchal HN (2015) Enhancement of distillate output of double basin solar still with vacuum tubes. Journal of King Saud University-Engineering Sciences 27(2):170–175

Panchal HN, Thakkar H (2016) Theoretical and experimental validation of evacuated tubes directly coupled with solar still. Therm Eng 63(11):825–831

Panchal H, Mohan I (2017) Various methods applied to solar still for enhancement of distillate output. Desalination 415:76–89

Panomwan Na Ayuthaya R, Namprakai P, Ampun W (2013) The thermal performance of an ethanol solar still with fin plate to increase productivity. Renew Energy 54:227–234

Petela R (2003) Exergy of undiluted thermal radiation. Sol Energy 74(6):469–488

Rabhi K, Nciri R, Nasri F, Ali C, Ben Bacha H (2017) Experimental performance analysis of a modified single-basin single-slope solar still with pin fins absorber and condenser. Desalination 416(April):86–93

Rahbar N, Esfahani JA, Fotouhi-Bafghi E (2015) Estimation of convective heat transfer coefficient and water-productivity in a tubular solar still–CFD simulation and theoretical analysis. Sol Energy 113:313–323

Rajaseenivasan T, Srithar K (2016) Performance investigation on solar still with circular and square fins in basin with CO2 mitigation and economic analysis. Desalination 380(January):66–74

Sarhaddi F, Tabrizi FF, Zoori HA, Mousavi SAHS (2017) Comparative study of two weir type cascade solar stills with and without PCM storage using energy and exergy analysis. Energy Convers Manag 133:97–109

Shanmugan S, Palani S, Janarthanan B (2018) Productivity enhancement of solar still by PCM and nanoparticles miscellaneous basin absorbing materials. Desalination 433:186–198

Sharshir SW, Eltawil MA, Algazzar AM, Sathyamurthy R, Kandeal AW (2020). Performance enhancement of stepped double slope solar still by using nanoparticles and linen wicks: energy, exergy and economic analysis. Applied Thermal Engineering, 115278

Sharshir SW, Peng G, Yang N, El-Samadony MOA, Kabeel AE (2016) A continuous desalination system using humidification–dehumidification and a solar still with an evacuated solar water heater. Appl Therm Eng 104:734–742

Shukla SK, Sorayan VPS (2005) Thermal modeling of solar stills: an experimental validation. Renew Energy 30(5):683–699

Srivastava PK, Agrawal SK (2013) Winter and summer performance of single sloped basin type solar still integrated with extended porous fins. Desalination 319:73–78

Taamneh Y, Taamneh MM (2012) Performance of pyramid-shaped solar still: experimental study. Desalination 291:65–68

Velmurugan V, Deenadayalan CK, Vinod H, Srithar K (2008a) Desalination of effluent using fin type solar still. Energy 33(11):1719–1727

Velmurugan V, Gopalakrishnan M, Raghu R, Srithar K (2008) Single basin solar still with fin for enhancing productivity. Energy Convers Manag 49(10):2602–2608

Xie G, Sun L, Mo Z, Liu H, Du M (2016) Conceptual design and experimental investigation involving a modular desalination system composed of arrayed tubular solar stills. Appl Energy 179:972–984

Yousef MS, Hassan H, Kodama S, Sekiguchi H (2019) An experimental study on the performance of single slope solar still integrated with a PCM-based pin-finned heat sink. Energy Procedia 156(September):100–104

Zurigat YH, Abu-Arabi MK (2004) Modelling and performance analysis of a regenerative solar desalination unit. Appl Therm Eng 24(7):1061–1072

Availability of data and materials

Not applicable

Author information

Authors and Affiliations

Contributions

Conceptualization, methodology, resources, formal analysis, writing—original draft preparation, review and editing, and supervision and investigation were carried out by Ravishankar Sathyamurthy, Abd Elnaby Kabeel, and Ali Chamkha.

Writing—original draft preparation and review and editing were carried out by Hemanth Arun Kumar, Hariprasath Venkateswaran, Athikesavan Muthu Manokar, Ramani Bharathwaaj, and Sathiyaseelan Vasanthaseelan.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sathyamurthy, R., Kabeel, A.E., Chamkha, A. et al. Exergy and energy analysis of a tubular solar still with and without fins: a comparative theoretical and experimental approach. Environ Sci Pollut Res 29, 6612–6621 (2022). https://doi.org/10.1007/s11356-021-16065-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-16065-w