Abstract

Many alternative fuel technologies have been studied for the transport sector to increase its sustainability while reducing costs, greenhouse gases (GHG), and air pollution emissions. Nevertheless, conventional diesel is still the predominant fuel for heavy-duty trucks. Road freight transport consumes 25% of the world’s energy and is responsible for emissions with local health impacts and the global greenhouse effect. In this context, this paper reviewed items from 2015 to 2020 to analyze the technologies available for the road freight transport regarding pollutant and GHG emissions. Results are presented in two parts: first quantitatively, quantitative data was extracted from reviewed papers and statistically treated and, second, qualitatively through a comparative chart, which shows the impact on air pollutants from the use of a different type of fuels. In general, papers are mostly concerned with particulate matter (PM), carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC) emissions due to its impact on public health, with a low number of papers covering GHG emissions. The trade-off between different fuels and how this process can impact emissions, sometimes increasing or decreasing specific pollutants, is discussed. According to the analyzed papers, the main characteristics that affect the pollutant emissions are, in general, the fuel oxygen content and the combustion chamber temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Road freight transport contributes significantly to the global economy and directly affects national economies’ efficiency (Nowakowska-grunt et al. 2019). Fossil fuels drive the sector, and diesel oil is still the most used energy carrier in heavy-duty trucks (Qu et al. 2016). Some advantages of this type of transport compared with others (rail, air, water) include low cost, reduced transit times, and increase reliability, while disadvantages cover traffic congestion and air pollutants (Lee and Yoo 2016). According to IEA (2019), CO2 emissions generated by trucks and buses have increased 2.2% yearly. The combination of using fossil sources and high distances traveled annually contribute to the increase of air pollution and GHG emissions, directly impacting human health and the environment.

To reduce emissions to meet standards, improve efficiency, and find cheaper ways to transport goods, the heavy-duty transport profile has been changing over the years (Alam et al. 2015; Qu et al. 2016). To attain the Sustainable Development Scenarios (SDS) and the Nationally Determined Contributions (NDC), many countries have been creating different policies to support strategies in the transport sector (Brotherton et al. 2016; Gallo 2016; Wu et al. 2016; Zhang et al. 2019).

For instance, India has established new fuel economy standards for trucks and buses in 2018. In 2019, monitoring and reporting emissions and fuel consumption became mandatory in the European Union. In the same year, China and Japan updated the fuel efficiency standards and started to increase trucks and buses’ efficiency. Brazil, Mexico, and South Korea are also in different phases of heavy-duty vehicle emissions standards (IEA 2019).

Similarly, the scientific community has been studying and evaluating the use of different types of fuel technologies to be used in road freight transport. Sustainability research on road transport ranges from health impacts (Miller and Xu 2018; Wong et al. 2019), fuels (Ammenberg et al. 2018; Mulholland et al. 2018; Zhang et al. 2019; Wang et al. 2020; Zhao et al. 2020), climate change (Colin et al. 2016; Campbell et al. 2018; He et al. 2018, 2020), and the use of different sources to improve economic feasibility (Nocera and Cavallaro 2016; Connolly 2017; Sen et al. 2019).

Renewable fuels have been studied in several countries, such as the case of biodiesel from different feedstock, i.e., sunflower oil, canola oil, waste cooking oil, cottonseed, and pomegranate seed (Li et al. 2015; Thang et al. 2016; Qasim et al. 2017; Nantha Gopal et al. 2018; Tüccar and Uludamar 2018). More alternative energy carriers such as hydrogen (Hora and Agarwal 2015; Park et al. 2017), renewable diesel (Singh et al. 2015b), biogas (Shafiei et al. 2015), and natural gas (Mersky et al. 2016; Rudolph 2016; Xing et al. 2016; Quiros et al. 2017; Song et al. 2017; da Silva et al. 2018) have also been studied to evaluate pollutant emissions and impacts on heavy-duty engine characteristics.

Nonetheless, the considerable number of studies shows different results in terms, mainly, of emissions and energy consumption even when considering the same fuel, imposing a growing discussion on the need to explore more this issue in the transportation sector. To summarize all the information in the literature, reviews are made mostly focusing on one topic from the wide range of options that deal with transport complexity. In the last 5 years, however, there has not been a review focused on fuels for heavy-duty road transport, one of the motivations to start this paper. Table S1 shows a summary of these reviews.

Although recent reviews such as Osorio-Tejada et al. (2017), Thiruvengadam et al. (2018), Chen et al. (2019), and Kluschke et al. (2019) have focused on heavy-duty transport, their objectives vary and are not as comprehensive as this study. Osorio-Tejada et al. (2017), Thiruvengadam et al. (2018), and Chen et al. (2019) aimed to summarize the benefits and drawbacks of natural gas trucks with attention to thermal efficiency, pollutant emissions (hydrocarbons, carbon monoxide, particulate matter, and nitrogen oxide), technical, environmental, economic aspects (Osorio-Tejada et al. 2017), and engine technology (Thiruvengadam et al. 2018). Their reviews, however, did not provide a thorough assemble of available options, and since the authors only deal with natural gas, their results do not necessarily present the best options for the transport sector.

Moreover, Kluschke et al. (2019) draw essential findings from their review, focusing on market diffusion studies of alternative fuels and powertrains in heavy-duty vehicles. First, most studies forecast that alternative fuel powertrains in heavy-duty will diffuse into the market to a maximum of 30% by 2050, which implies that today’s market environment is already fostering the transition towards alternative options. In climate protection scenarios, alternative fuel powertrains dominate the CO2 emission reduction actions, with all studies forecasting a market diffusion of more than 40%. The authors also highlight the high technological uncertainty for the sector. They point out differences concerning electric vehicles, with some studies considering battery vehicles and other only fuel cell vehicles, which result in distinct conclusions regarding the most competitive technology since the infrastructure costs, for example, are not considered in all studies.

During the literature review process, another focus observed is the comparison of transport modal, as is done in Fan et al. (2018), who highlight the importance of considering air pollutants in optimization studies and evaluating air pollutants’ source in sea and road transport. Ramani et al. (2019) also compare modals in the Canadian transport sector, focusing on land and marine transport. Both reviews bring essential insights into the benefits of modal change and also its drawbacks. Finally, a review related to passenger vehicles was done by Hänggi et al. (2019). The authors used their review as input for analysis to compare various synthetic fuels applied to passenger vehicles and the energy conversion steps in the fuel’s life cycle of hydrogen, methane, methanol, dimethyl ether, and diesel.

Ultimately, previous works have tackled different transport sectors regarding GHG, pollutant emissions, economic factors, and vehicle/engine performance. However, considering the sector and technologies for road freight transport, no other study has coherently acquired information on GHG and pollutant emissions for a comprehensive set of alternative fuels. Thus, this review aimed at collecting GHG and pollutant emission factors for the most studied alternative fuels in the literature for internal combustion engines.

This paper is organized as follows. Section 2 shows the methodology used to develop the review. Section 3 presents the pieces of evidence found through this methodology. Section 4 shows the results and discussions, and the limitations of this review are presented in Section 5. Conclusions and final remarks with crucial points are finally drawn in Section 6.

Methodology

Considering the need to diversify the energy matrix by increasing alternative fuel participation in the transport sector, this study proposes a review to identify and evaluate road freight transport alternative fuel technologies. This section presents the review methodology, which covers the scope, search strategy, eligibility criteria used to select papers, and the methodology used to extract data and analyze the review results.

This study’s scope is the analysis of engine performance and pollutant/GHG emissions for different alternative fuel technologies considering the operation phase. To address this subject, the following research questions were proposed below:

-

i.

What is the current situation of fuels used in the road freight transport sector in the world?

-

ii.

What fuels have been used/studied around the world?

-

iii.

What are their characteristics, advantages, and disadvantages?

-

iv.

Which fuels could have low emissions (pollutant/GHG)?

This review looked for relevant studies inside two databases, Scopus and Web of Science, to answer the above questions. Different searches were performed using the following keywords: alternative fuel, natural gas, hydrogen, heavy-duty vehicle, truck, commercial vehicle, freight, air pollution, and GHG emission. Searches were held on May 15, 2019. Only papers published in English and the period from 2015 to 2020 were considered. Duplicates papers were removed.

Through the search performed using databases previously mentioned, 2462 papers were identified. After duplicates removal, the total decreased to 834, and the studies were screened by titles and abstracts according to the scope of this study. After a full-text review, 42 papers were used in this study. According to the quality criterion applied to the searched items, papers without introduction, methodology, and results in the abstract were not considered.

This review focused only on scientific and peer-reviewed journals. The eligibility criteria used to include or exclude some paper are listed below:

-

Papers published and fully available in previously cited scientific databases were included.

-

Recent works published from 2015 to 2020 on peer-review journals were included, until de date the search was conducted.

-

Environmental issues regarding alternative fuels for the freight transport sector were included.

-

Review studies were excluded.

-

Only quantitative studies were included (simulation or experimental).

-

Only tank-to-wheel (TTW) analysis was considered.

To normalize the emission units used in the papers, a general conversion from ppm to g/kWh for heavy-duty vehicles was used according to Pilusa et al. (2012). Figure 1 shows the review steps.

Evidence found

Considering all papers selected by title/abstract and that could be downloaded, 79% of the papers worked with alternative fuels, 13% studied the impacts of emissions with a different focus, 5% discussed sustainability and economic issues in the transport sector, and 3% covered other areas beyond the scope of this paper such as industry, construction, and policy.

Figure 2 shows the growth rate of the latest articles researching alternative fuels for the analyzed period. Diesel was included since many studies used it to compare the performance and emissions to other fuels. It is possible to note that natural gas and electricity most appeared in the studies, representing around 45% of the papers published in the period. Another alternative fuel that has been studied is biodiesel from plants and waste, which will be discussed below.

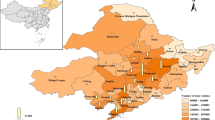

As previously shown in Fig. 1, 42 papers were selected and included in this work after full-text review. General characterization of the evidence found from the review is shown in Figure S1, S2, and S3 (displayed at the supplementary material) with information on geographical scope, main keywords found in papers, and types of fuels. Figure S1 presents the geographical scope of the published papers selected through the review. From the total of 42 selected papers, 6% were made in Canada, 8% in Turkey, 11% in the USA, 10% in India, and 13% in China. Other papers are divided among other countries, with one found in South America and none in Africa.

The selected papers presented as the main discussion focus the pollutants emissions. As is possible to see in Figure S2, by counting words, “Natural gas vehicles,” “HCNG” (Hydrogen enriched Compressive Natural Gas), Diesel engine, Diesel, “Biodiesel,” “Emissions,” “Alternative fuels,” and “Greenhouse gases” were the keywords that presented the highest frequency. This result is aligned with the type of corpus analyzed since all of them were about testing engine technologies, fuels, and checking emissions. Other keywords relate to fuel types (biodiesel sources, electricity, hydrogen, and others) and types of used methodologies (life cycle analysis and well-to-wheel).

Regarding the types of fuels analyzed in the selected body, as it is possible to see in Figure S3 (left), most of the papers were discussing biodiesel emissions (23,4%), followed by different kinds of fuel blends (22.1%), CNG with 20.8%, and LNG with 10.4% of the total reviewed papers. Other fuels appeared in the selected papers, such as hydrogen, electricity, biomass to liquid, biogas, and ethanol. Nevertheless, it is essential to note the broad range of feedstock in biodiesel production, such as waste, palm oil, and microalgae (see Figure S3, right, for more examples). This clarification is necessary because the resulting emission factor from each biodiesel type is considerably different due to some specific fuel characteristics such as heating value and viscosity, as discussed in the results section.

Results and discussions

Emission factor versus fuel technologies

From the literature review, it was observed two ways of analyzing pollutant emissions. The first one is based on primary data collection through bench dynamometer and real-life condition simulation experiments. The second way covers paper with models that use pollutant emission factors as input data. It is important to remember that this review’s data corresponds only to the operation phase’s emissions.

Another critical point to mention is that each study found in the review uses specific engines, which drive different emissions. As previously mentioned, there is a wide range of results regarding pollutant emissions due to several reasons discussed during this section.

In general, the literature corpus presented emissions of nitrogen oxides (NOx), hydrocarbon (HC), carbon monoxide (CO), and carbon dioxide (CO2), which will be discussed separately. However, particulate matter (PM) was also analyzed, but fewer publications and fewer options. Only four studies were found evaluating PM in a general way since some papers prioritize PM10 or PM2.5. Sulfur oxides (SOX) emissions were not included since only one study covered this issue. Table S3 shows the emission factors in this review, considering all types of fuels and pollutants analyzed.

To evaluate the emission factor for each pollutant, a box plot was created in Figs. 3, 4, 5, 6, and 7, which represents the variation of observed data showing the maximum, minimum, and median values; outliers; and upper and lower quartiles. In the next topics, the results will be discussed for each pollutant.

Particulate matter (PM)

Figure 3 shows the results of PM emissions for the only five fuels analyzed in the selected papers: diesel (D), biodiesel (B), renewable dieselFootnote 1 (RD), liquefied natural gas (LNG), and compressive natural gas (CNG). Black points represent outliers. Considering an overview, renewable diesel and biodiesel (from Jatropha curcas oil) presented the highest values, although both have only one value from the same paper (Singh et al. 2015b).

The results found from the systematic review were presented in Fig. 3, which shows that, in a general way, compared to diesel, the PM emission factor could be higher by using biodiesel and renewable diesel and lower using CNG and LNG. Although RD and biodiesel presented the highest values on average, Singh et al. (2015b) evaluated the use of both fuels in a compression ignition engine and compared the results to conventional diesel through an experimental bench test. All fuels were used purely, without any kind of blend. The authors found a reduction of PM emissions using both fuels compared to diesel (0.077 g/kWh), but biodiesel (0.044 g/kWh) presented a reduction of around 43%. The authors explained the reduction using biodiesel due to oxygen content, contributing to better and more efficient combustion.

On the other hand, renewable diesel presented a PM emission factor of 0.056 g/kWh. This reduction is due to the higher cetane renewable diesel numberFootnote 2 than the conventional diesel, contributing to a shorter ignition delay, resulting in better combustion stability and hence less particulate matter.

Regarding LNG and CNG, information comes from tank-to-wheel simulations. Yuan et al. (2018) used emission factors to compare LNG with diesel fuels in different vehicle types, including heavy-duty. Their life cycles were assessed based on the Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) model database for both fuels and LNG emissions are lower than diesel around ten times. Cai et al. (2017) assessed greenhouse gases and pollutant emissions through life cycle assessment using EPA’s Motor Vehicle Emission Simulator (MOVES) model, in which PM emissions from CNG and LNG were found to be around 17 to 34% lower than diesel, respectively. It is possible to note that, in general, the PM emission factor from LNG corresponds to the lowest value compared to diesel, CNG, RD, and biodiesel. These results show that LNG and CNG can contribute to the PM reductions, which impacts the air quality and human health improvement. It is important to remember that the exposition to high particulate matter concentrations can cause different health effects, which include respiratory, allergic, and cardiovascular diseases (Saldiva et al. 1994; Miller and Xu 2018; Kihal-Talantikite et al. 2019).

Although biodiesel and renewable diesel presented lower results than conventional diesel, other studies showed PM emission factors with different values. Stettler et al. (2016) tested different configurations for dual fuel diesel and natural gas heavy goods vehicles, and the values found for the vehicles powering only by diesel were in the range from 0.006 to 0.015 g/kWh, which are lower than biodiesel and RD presented by Singh et al. (2015b).

Nitrogen oxides (NOx)

Regarding nitrogen oxides (NOx) emissions from alternative fuels, Fig. 4 presents the emission factor for each fuel. Ten papers evaluated this pollutant in different types of fuel. NOx formation mainly depends on the combustion temperature, oxygen content, and residence time (Heywood 2018) and, in general, temperatures above 1800 K favor NOx generation (Cowart et al. 2008). On average, the use of CNG and hydrogen presented the highest emission factors.

Hora and Agarwal (2015) compared pure CNG with hydrogen-enriched CNG and found that the introduction of hydrogen, which has higher lower heating value than CNG (Table S2 shows fuel properties), contributes to an increase in the temperature, favoring a higher emission compared to the pure CNG, as can be seen in Fig. 4.

Diesel-biodiesel-alcohol blends presented the NOx emission factor with the highest variability in the results. Emiroğlu and Şen (2018) evaluated the effect of adding cottonseed biodiesel and different types of alcohol (ethanol, methanol, and butanol) to diesel fuel and compared to pure diesel, considering emissions and performance in a compressive ignition engine. NOx emissions were found for biodiesel-alcohol-diesel blends, which were 7 to 18% higher than conventional diesel, depending on the engine load.

The low cetane number and high oxygen contents on alcohols and biodiesel contribute to an increase in the combustion temperature, which leads to a higher NOx emission factor in all blends (John Heywood 2018). The same situation was expected to the blends diesel-alcohol (Pan et al. 2015; Muthaiyan and Gomathinayagam 2016) and diesel-biodiesel (Baltacioglu et al. 2016; Liu et al. 2016; Al-lwayzy and Yusaf 2017; Çelebi et al. 2017; Qasim et al. 2017; Emiroğlu and Şen 2018; Yusop et al. 2018; Sathiyamoorthi et al. 2019).

However, in the study presented by Muthaiyan and Gomathinayagam (2016), NOx emissions were reduced with the addiction of propanol to diesel due to the higher heat of vaporization of propanol, which is responsible for creating a cooling effect, producing a lower combustion temperature and, consequently, 8 to 15% lower NOx emissions with propanol-diesel blend than conventional diesel, depending on the propanol proportion. Yang et al. (2015) also found NOx reductions for diesel-biodiesel-butanol blends by 15 to 32% compared to pure diesel. Butanol increases the heat of vaporization, reducing the combustion temperatures and NOx emissions, although this trend is especially pronounced for the high concentration of biodiesel in blends from 20 to 40%. In biodiesel-diesel blends without some type of alcohol, NOx emissions increased in the range of 1.77 to 13.8%.

Other biomass-based pathways as biomass to liquid (BTL), diesel-biodiesel-hydrogen blends, and biodiesel from waste oil presented the lowest NOx emissions range, as shown in Fig. 4. It is important to note that BTL is synthetic and a second-generation biofuel, which can be produced from any portion of biomass (Heracleou and Lappas 2011). On the other hand, Ogunkoya and Fang (2015) compared the use of biodiesel from waste oil and biomass to liquid to conventional diesel, where, except for higher engine loads, both alternative fuels presented higher NOx emissions than diesel. Biodiesel and biomass to liquid presented NOx emissions around 27% and 33%, respectively, higher than conventional diesel on average loads. Baltacioglu et al. (2016) evaluated the use of hydrogen and hydroxy-enriched biodiesel, and both options increase NOx emissions due to higher heating values. The authors also pointed out the environmental problem of hydrogen, which increases NOx emissions when used in internal combustion engines.

Yusop et al. (2018) also highlight the trade-off between NOx and PM emissions since both depend on temperature. PM emissions are formed at the diffusion flame boundary in higher temperatures, and these temperature values favor NOx formation. Thus, an increase in the temperature caused by a fuel additive, for example, can contribute to a decrease in PM emissions and an increase in NOx emissions.

Hydrocarbon (HC)

Regarding HC emissions, some factors contribute to the increase in emissions seen in Fig. 5: incomplete combustion, low temperature in the chamber, loose sealing in the cylinder and piston, and also due to lubricating oil in the combustion phase (Paykani et al. 2015; Heywood 2018). Engines powered by hydrogen-diesel and diesel-alcohol blends presented the highest HC emission factor. Emiroğlu and Şen (2018) also evaluated the addition of alcohols in biodiesel-diesel blends, and the cooling effect promoted by alcohol (in this case, ethanol, methanol, and butanol), reducing the combustion chamber temperature, which contributes to an increase HC emissions. The authors found an increase of 7 to 13% in HC emissions using biodiesel-diesel blends and around 18% using biodiesel-alcohol-diesel blends. Pan et al. (2015) analyzed the effects of methanol-diesel blends on emissions and performance. According to the authors, HC emissions increase until 80% with methanol proportion in any intake temperature, being more visible in low temperatures (from 20 to 60°C), representing the highest emissions compared to other fuels. Factors such as the longer ignition delay and higher evaporation heat due to hydrogen contribute to these HC emission changes.

Hosseini and Ahmadi (2017) studied the impacts of the replacement and addition of hydrogen to diesel in different percentages. The replacement showed higher HC emissions than the addition since the indicated efficiency is reduced, and the absence of oxygen leads to incomplete combustion and could increase 98% of HC emissions when 70% of diesel is replaced by hydrogen.

Banerjee et al. (2016) also analyzed diesel/biodiesel/hydrogen blends, leading to an increase of 85% in HC emissions compared to pure biodiesel and pure diesel. According to the authors, the oxygen content is responsible for improving combustion efficiency. Compared to pure diesel, pure biodiesel can reduce HC emissions from 51.8 to 75.4%, depending on the load. For biodiesel, the same emission behavior was found in other studies using blends with biodiesel from seed oil and waste (Ogunkoya and Fang 2015; Sathiyamoorthi et al. 2019).

Qasim et al. (2017) evaluated the use of biodiesel from canola oil and diesel blends. HC emissions decreased for all biodiesel blends, justified by the high oxygen content in biodiesel fuel. Contrastingly, biodiesel’s viscosity and density from canola oil (Table S2) are higher than from cottonseed oil presented by Emiroğlu and Şen (2018), which could lead to the same situation with problems during the atomization fuel and combustion phase. This situation was not raised or discussed by Qasim et al. (2017).

Considering spark ignition engines, Yuan et al. (2018) presented one of the highest HC emission factors. Grigoratos et al. (2016) also confirmed the increased HC emissions from CNG compared to conventional diesel fuel. The authors tested a prototype with a variable valve actuator for a heavy-duty compressed gas engine under transient and real conditions for bench and dynamometer analysis and suggested that more CH4 escaped unburned in this type of engine.

Regarding CNG, the fuel enriched by hydrogen presented lower emission factors than pure CNG. According to the experimental results obtained by Hora and Agarwal (2015), the addition of hydrogen to CNG could reduce from 10 to 30% of the HC emissions which contributes to improving the combustion efficiency, reducing the quenching gap, and facilitating the combustion, also in the crevices where there is trapped fuel.

Carbon monoxide (CO)

Considering the carbon monoxide (CO), it is formed mainly according to the air/fuel ratio, leading to a fuel-rich or lean (Heywood 2018). Figure 6 shows the resulting CO emission factors evaluated. Among the fuels studied, diesel enriched by hydrogen presented the highest values for CO emissions. The replacement of hydrogen leads to a lack of oxygen, late start of combustion, decrease in the chamber temperature, and, consequently, incomplete combustion. The addition of hydrogen deteriorates the diesel diffusion in the chamber and could increase around 90% of CO emissions when the percentage of hydrogen corresponds to 70% (Hosseini and Ahmadi 2017).

Other blends, however, cause a reduction of CO emissions. For example, adding propanol improves the combustion due to oxygen, reducing until 70% of CO emissions, depending on the propanol concentrations and engine load (Muthaiyan and Gomathinayagam 2016). On the other hand, CO emissions could increase around 80 to 90% with methanol-diesel blends depending on the methanol concentration and intake charge temperature. This increase in CO emissions could be explained due to the reduced temperature caused by methanol, given the low heating value (Pan et al. 2015).

Regarding biodiesel from seed oil, according to the studies analyzed (Banerjee et al. 2016; Al-lwayzy and Yusaf 2017; Çelebi et al. 2017; Qasim et al. 2017; Emiroğlu and Şen 2018; Tüccar and Uludamar 2018), this fuel pure and blends with diesel can cause, in general, a reduction around 60% of CO emissions, depending on the engine load, compared to pure diesel mainly due to the oxygen content. According to Yang et al. (2015) and Sathiyamoorthi et al. (2019), CO formation is inversely proportional to the percentual biodiesel used in the mixtures. The addition of alcohols such as methanol and ethanol increases the blend’s oxygen content, contributing to reductions in CO emissions (Yang et al. 2015; Banerjee et al. 2016; Emiroğlu and Şen 2018).

Regarding CNG, the average found for CO emission factor was less than 1 g/kWh. The study presented by Grigoratos et al. (2016) found results from 0.05 to 1 g/kWh, depending on the cycle, which is related to engine speed and oxygen content in the combustion chamber. Hora and Agarwal (2015) evaluated hydrogen-enriched compressed natural gas, showing that due to low quenching distances, lower carbon-to-hydrogen ratio, and flammability limits increased, hydrogen can promote better combustion, reducing CO emissions around 30% depending on the hydrogen concentration and engine load.

Carbon dioxide (CO2)

Concerning carbon dioxide (CO2), its formation is related to a complete combustion process (John Heywood 2018). Higher CO2 emissions than CO emissions in the engine exhaust indicate quality and fuel efficiency combustion (Hora and Agarwal 2015). Figure 7 shows different fuels and respective CO2 emissions during the operation phase. On average, studies (Hora and Agarwal 2015; Grigoratos et al. 2016) showed that CNG presented higher CO2 emissions than other fuels.

However, the emission factor range is still high, with values from 171 to 1119 g/kWh. In the study presented by Grigoratos et al. (2016), results from CO2 emissions for CNG were from 585 to 1119 g/kWh, but the values depended on the type of driving cycle used, which was considered urban, rural, and motorway. Stettler et al. (2016) also tested heavy-duty vehicles in different cycles, and the range found for CNG was from 171 to 434 g/kWh. Cai et al. (2017) used emission factors as input data for a life cycle assessment for both CNG and LNG.

In overview, studies showed that biodiesel from seed oil (Baltacioglu et al. 2016; Çelebi et al. 2017) and biodiesel from different waste sources (Ogunkoya and Fang 2015; Adam et al. 2017) could contribute to an increase in CO2 emissions since there is a reduction of CO emissions in engine exhaust due to the oxygen content, which contributes for better combustion.

On the other hand, results by Al-lwayzy and Yusaf (2017) showed different trends, and a reduction in both pollutants—CO (14 to 38%) and CO2 (15 to 30%) depending on the concentration of biodiesel—was observed with the use of pure microalgae biodiesel and blends, but this fact was not well explained. Baltacioglu et al. (2016) also evaluated the introduction of hydrogen in a biodiesel-diesel blend, which resulted in a reduction of around 22% of CO2 emissions. Biomass to liquid presented lower CO and CO2 emissions (around 5%, depending on the engine load) than pure diesel and pure biodiesel from waste cooking oil.

Comparative chart

To summarize the results, Table 1 shows each paper, alternative fuels analyzed, and their impacts on pollutant emissions, compared to the baseline fuel, which, in general, is the conventional diesel. Furthermore, in their majority, the papers analyzed proposed blending conventional diesel with another alternative fuel to its environmental performance. Other emission reduction measures pointed out by the authors were the use of filters (Adam et al. 2017), hybridization (Holmer and Eriksson 2017a), hydrogen enrichment (Abbasian-Hosseini et al. 2015; Hora and Agarwal 2015; Baltacioglu et al. 2016), and preheating of air intake (Pan et al. 2015)

It is important to note that there were a low number of papers that covered GHG emissions. Papers such as Hosseini and Ahmadi (2017) and Stettler et al. (2016) evaluate GHG in experimental studies, but the first deals with CO2 and not CO2 equivalent, which is the global unit for greenhouse gases. This fact can cause some misunderstanding with concepts and what was evaluated. On the other hand, Stettler et al. (2016) showed the results for both (CO2 and CO2e) and concluded that CNG contributes to increasing GHG emissions, mainly because of methane emissions, which has a higher global warming potential. Thus, sometimes, the fuel can decrease other emissions and contribute to improving local air pollution, but fuels based on methane can elevate CO2 equivalent in terms of global warming.

In general, studies analyzed biodiesel (from seed or waste oil) impacts and found a decrease in hydrocarbon concomitant with an increase in NOx emissions (Hora and Agarwal 2015; Pan et al. 2015; Singh et al. 2015a; Holmer and Eriksson 2017b; Qasim et al. 2017; Yusop et al. 2018; Sathiyamoorthi et al. 2019).

Some authors reported an increase (Adam et al. 2017; Qasim et al. 2017) or decrease (Hora and Agarwal 2015; Singh et al. 2015a; Sathiyamoorthi et al. 2019) in CO emissions with the use of blends and pure biodiesel. Emiroğlu and Şen (2018) found an increase in NOx, HC, and CO emissions due to biodiesel’s introduction, which has a higher viscosity, impacting the atomization process and the combustion process. Regarding particulate matter emissions, a low number of papers analyzed this pollutant. A decrease in PM emissions using alcohol-biodiesel-diesel and biodiesel-diesel (Singh et al. 2015a) blends was observed, mainly due to oxygen content, which leads to better combustion, reducing soot formation.

Several characteristics contribute to the pollutant formation and were commented on by many authors and are summarized as follows: CO2 emissions are affected mainly due to engine speed, temperature, and oxygen content (Adam et al. 2017; Al-lwayzy and Yusaf 2017). An increase in the combustion temperature leads to complete combustion and higher efficiency, contributing to increasing CO2 emissions. On the other hand, CO emissions result from incomplete combustion, affected mainly by the oxygen content (Al-lwayzy and Yusaf 2017; Çelebi et al. 2017; Qasim et al. 2017). A rich-fuel mixture has more fuel to burn, and the combustion can run out before burning all the fuel, which contributes to an increase in CO emissions.

Some author cited other characteristics that contribute to an increase in carbon monoxide, such as temperature (Pan et al. 2015; Yang et al. 2015; Hosseini and Ahmadi 2017; Smajla et al. 2019), engine speed (Adam et al. 2017; Al-lwayzy and Yusaf 2017; Nantha Gopal et al. 2018), viscosity (Adam et al. 2017), lower heating value (Yang et al. 2015), and fuel proportion (Nantha Gopal et al. 2018). HC emissions are impacted mainly due to oxygen content (Liu et al. 2016; Nantha Gopal et al. 2018; Sathiyamoorthi et al. 2019), temperature (Hosseini and Ahmadi 2017; Wang et al. 2019), fuel quality (Singh et al. 2015a, b), lubrification oil layer in the cylinder and piston (Hosseini and Ahmadi 2017), and ignition delay (Pan et al. 2015). NOx emissions are directly associated with combustion temperature, which is a characteristic of all studies.

However, other characteristics such as the residence time (Baltacioglu et al. 2016; Adam et al. 2017; Sathiyamoorthi et al. 2019), ignition delay (Adam et al. 2017; Nantha Gopal et al. 2018), and cetane number (Al-lwayzy and Yusaf 2017) are not entirely explored and should have more attention. To summarize the main issues highlighted in the studies, Fig. 8 was build according to the characteristics cited in the studies as the responsible for the effects on the increase or decrease emissions considering pollutant analyzed.

Limitations

During the review, some limitations were found for analyzing all the results together. First, the number of papers regarding the type of fuels, technologies, and emissions results is not the same. It means that there are papers that evaluate CO, PM, and NOx but do not analyze HC, for example. This situation makes it difficult to compare different sources and their impacts.

Second, there was a problem with the units used in the papers; because of the lack of uniformity, there was a need to convert them to enable the emission factor evaluation/comparison. In this regard, it is essential to note that these conversions are approximations and can, sometimes, escape from reality.

Third, although the principles of compression ignition engine technologies are the same, each paper performed the study in a different engine and always has different results. This paper also considered different technologies such as compression ignition and spark ignition engines, which have different operating and specific results. Nevertheless, this paper aims to analyze, in a general way, the emissions results from different alternative fuel technologies and identify which ones could be better to help reduce emissions in the transport sector. Therefore, this comparison is feasible.

Conclusions and final remarks

The review enabled an overview of different fuel technologies studied over the last 5 years in the academy and their impacts on air pollution. For the internal combustion technologies available, the review showed no best options to, concomitantly, reduce GHG and pollutant emissions.

For CO2, one of the GHGs, the biomass options such as BTL and seed oil biodiesel are the most capable of reducing emissions by around 60%, depending on the type of fuel, engine load, and speed. However, on the pollutants side, the trade-off between their emissions makes it difficult to pinpoint one single best. For example, LNG shows the lowest PM emissions (34% lower than diesel), and LNG is not the most applicable to reduce CO emissions. This is also true for biodiesel, in which performance will depend on the feedstock. While seed oil and residues biodiesel have similar HC emissions behavior, CO2 and CO emissions from biodiesel from waste cooking oil are considerably around 20% and 40% higher than biodiesel from seed oil.

Nonetheless, the papers reviewed show that to guarantee continuous improvements and focus on reducing pollutants, future research on engines should tackle the temperature of the engine and oxygen content of the fuels, which are the most cited influential aspects of fuel combustion on emissions.

References

Abbasian-Hosseini SA, Liu M, Leming M (2015) Comparison of least-cost and least-pollution equipment fleet configurations using computer simulation. J Manag Eng 31:1–8. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000360

Adam A, Ramlan NA, Jaharudin NF, Hamzah H, Othman MF, Mrwan AAG (2017) Analysis of combustion characteristics, engine performance and exhaust emissions of diesel engine fueled with upgraded waste source fuel. Int J Hydrog Energy 42:17993–18004. https://doi.org/10.1016/j.ijhydene.2017.04.021

Al-lwayzy SH, Yusaf T (2017) Diesel engine performance and exhaust gas emissions using microalgae Chlorella protothecoides biodiesel. Renew Energy 101:690–701. https://doi.org/10.1016/j.renene.2016.09.035

Alam A, Besselink B, Turri V, et al (2015) Heavy-duty vehicle platooning for sustainable freight and efficiency

Ammenberg J, Anderberg S, Lönnqvist T, Grönkvist S, Sandberg T (2018) Biogas in the transport sector—actor and policy analysis focusing on the demand side in the Stockholm region. Resour Conserv Recycl 129:70–80. https://doi.org/10.1016/j.resconrec.2017.10.010

Baltacioglu MK, Arat HT, Özcanli M, Aydin K (2016) Experimental comparison of pure hydrogen and HHO (hydroxy) enriched biodiesel (B10) fuel in a commercial diesel engine. Int J Hydrog Energy 41:8347–8353. https://doi.org/10.1016/j.ijhydene.2015.11.185

Banerjee R, Debbarma B, Roy S, Chakraborti P, Bose PK (2016) An experimental investigation on the potential of hydrogen-biohol synergy in the performance-emission trade-off paradigm of a diesel engine. Int J Hydrog Energy 41:3712–3739. https://doi.org/10.1016/j.ijhydene.2015.12.140

Brotherton T, Gilde A, Tomic J (2016) 2015 e-truck task force: key barriers affecting e-truck adoption, industry and policy implications, and recommendations to move the market forward. World Electr Veh J 8:651–659. https://doi.org/10.3390/wevj8030657

Cai H, Burnham A, Chen R, Wang M (2017) Wells to wheels: environmental implications of natural gas as a transportation fuel. Energy Policy 109:565–578. https://doi.org/10.1016/j.enpol.2017.07.041

Campbell P, Zhang Y, Yan F, Lu Z, Streets D (2018) Impacts of transportation sector emissions on future U.S. air quality in a changing climate. Part I: Projected emissions, simulation design, and model evaluation. Environ Pollut 238:903–917. https://doi.org/10.1016/j.envpol.2018.04.020

Çelebi K, Uludamar E, Tosun E, Yıldızhan Ş, Aydın K, Özcanlı M (2017) Experimental and artificial neural network approach of noise and vibration characteristic of an unmodified diesel engine fuelled with conventional diesel, and biodiesel blends with natural gas addition. Fuel 197:159–173. https://doi.org/10.1016/j.fuel.2017.01.113

Chen H, He J, Zhong X (2019) Engine combustion and emission fuelled with natural gas: a review. J Energy Inst 92:1123–1136. https://doi.org/10.1016/j.joei.2018.06.005

Colin M, Palhol F, Leuxe A (2016) Adaptation of transport infrastructures and networks to climate change. Transp Res Procedia 14:86–95. https://doi.org/10.1016/j.trpro.2016.05.044

Connolly D (2017) Economic viability of electric roads compared to oil and batteries for all forms of road transport. Energy Strateg Rev 18:235–249. https://doi.org/10.1016/j.esr.2017.09.005

da Silva RE, Sobrinho PM, de Souza TM (2018) How can energy prices and subsidies accelerate the integration of electric vehicles in Brazil? An economic analysis. Electr J 31:16–22. https://doi.org/10.1016/j.tej.2018.03.007

Emiroğlu AO, Şen M (2018) Combustion, performance and exhaust emission characterizations of a diesel engine operating with a ternary blend (alcohol-biodiesel-diesel fuel). Appl Therm Eng 133:371–380. https://doi.org/10.1016/j.applthermaleng.2018.01.069

Fan YV, Perry S, Klemeš JJ, Lee CT (2018) A review on air emissions assessment: transportation. J Clean Prod 194:673–684. https://doi.org/10.1016/j.jclepro.2018.05.151

Gallo JB (2016) Electric truck & bus grid integration, opportunities, challenges & recommendations. World Electr Veh J 8:45–56

Grigoratos T, Fontaras G, Martini G, Peletto C (2016) A study of regulated and green house gas emissions from a prototype heavy-duty compressed natural gas engine under transient and real life conditions. Energy 103:340–355. https://doi.org/10.1016/j.energy.2016.02.157

Hänggi S, Elbert P, Bütler T, Cabalzar U, Teske S, Bach C, onder C (2019) A review of synthetic fuels for passenger vehicles. Energy Rep 5:555–569. https://doi.org/10.1016/j.egyr.2019.04.007

He H, Liang X, Wuebbles DJ (2018) Effects of emissions change, climate change and long-range transport on regional modeling of future U.S. particulate matter pollution and speciation. Atmos Environ 179:166–176. https://doi.org/10.1016/j.atmosenv.2018.02.020

He L, Zhang S, Hu J, Li Z, Zheng X, Cao Y, Xu G, Yan M, Wu Y (2020) On-road emission measurements of reactive nitrogen compounds from heavy-duty diesel trucks in China. Environ Pollut 262:114280. https://doi.org/10.1016/j.envpol.2020.114280

Heracleou E; Lappas A (2011) Production of biofuels via Fischer-Tropsch synthesis: biomass-to-liquids. In: Handbook of biofuels production: processes and technologies. p 688

Holmer O, Eriksson L (2017a) Simultaneous reduction of fuel consumption and NO<inf>x</inf> emissions through hybridization of a long haulage truck. IFAC-PapersOnLine 50:8927–8932. https://doi.org/10.1016/j.ifacol.2017.08.1295

Holmer O, Eriksson L (2017b) Simultaneous reduction of fuel consumption and nox emissions through hybridization of a long haulage truck. IFAC-PapersOnLine 50:8927–8932. https://doi.org/10.1016/j.ifacol.2017.08.1295

Hora TS, Agarwal AK (2015) Experimental study of the composition of hydrogen enriched compressed natural gas on engine performance, combustion and emission characteristics. Fuel 160:470–478. https://doi.org/10.1016/j.fuel.2015.07.078

Hosseini SM, Ahmadi R (2017) Performance and emissions characteristics in the combustion of co-fuel diesel-hydrogen in a heavy duty engine. Appl Energy 205:911–925. https://doi.org/10.1016/j.apenergy.2017.08.044

IEA (2019) Tracking Transport. https://www.iea.org/reports/tracking-transport-2019/trucks-and-buses#abstract

J. S. Cowart, E. M. Sink, P. G. Slye, P. A. Caton LJ Hamilton (2008) Performance, efficiency and emissions comparison of diesel fuel and a Fischer-Tropsch synthetic fuel in a CFR single cylinder diesel engine during high load operation. SAE Tech Pap 2008-01-2382 14

Heywood J (2018) Internal combustion engine: fundamentals, 2nd edn.

Kihal-Talantikite W, Legendre P, Le Nouveau P, Deguen S (2019) Premature adult death and equity impact of a reduction of no2, pm10, and pm2.5 levels in Paris—a health impact assessment study conducted at the census block level. Int J Environ Res Public Health 16

Kluschke P, Gnann T, Plötz P, Wietschel M (2019) Market diffusion of alternative fuels and powertrains in heavy-duty vehicles: a literature review. Energy Rep 5:1010–1024. https://doi.org/10.1016/j.egyr.2019.07.017

Knothe G (2010) Biodiesel and renewable diesel: a comparison q. Prog Energy Combust Sci 36:364–373. https://doi.org/10.1016/j.pecs.2009.11.004

Lee M, Yoo S (2016) The role of transportation sectors in the Korean national economy: an input-output analysis. Transp Res Part A 93:13–22. https://doi.org/10.1016/j.tra.2016.08.016

Li Q, Backes F, Wachtmeister G (2015) Application of canola oil operation in a diesel engine with common rail system. Fuel 159:141–149. https://doi.org/10.1016/j.fuel.2015.06.060

Liu J, Wang H, Li Y, Zheng Z, Xue Z, Shang H, Yao M (2016) Effects of diesel/PODE (polyoxymethylene dimethyl ethers) blends on combustion and emission characteristics in a heavy duty diesel engine. Fuel 177:206–216. https://doi.org/10.1016/j.fuel.2016.03.019

Mersky AC, Sprei F, Samaras C, Qian ZS (2016) Effectiveness of incentives on electric vehicle adoption in Norway. Transp Res Part D Transp Environ 46:56–68. https://doi.org/10.1016/j.trd.2016.03.011

Miller L, Xu X (2018) Ambient PM 2.5 human health effects-findings in China and research directions. Atmosphere (Basel) 9:1–16. https://doi.org/10.3390/atmos9110424

Mulholland E, Teter J, Cazzola P, McDonald Z, Ó Gallachóir BP (2018) The long haul towards decarbonising road freight – a global assessment to 2050. Appl Energy 216:678–693. https://doi.org/10.1016/j.apenergy.2018.01.058

Muthaiyan P, Gomathinayagam S (2016) Combustion characteristics of a diesel engine using propanol diesel fuel blends. J Inst Eng Ser C 97:323–329. https://doi.org/10.1007/s40032-016-0229-x

Nantha Gopal K, Ashok B, Senthil Kumar K, Thundil Karuppa Raj R, Denis Ashok S, Varatharajan V, Anand V (2018) Performance analysis and emissions profile of cottonseed oil biodiesel–ethanol blends in a CI engine. Biofuels 9:711–718. https://doi.org/10.1080/17597269.2017.1306679

Nocera S, Cavallaro F (2016) Economic valuation of well-to-wheel CO2emissions from freight transport along the main transalpine corridors. Transp Res Part D Transp Environ 47:222–236. https://doi.org/10.1016/j.trd.2016.06.004

Nowakowska-grunt J, Strzelczyk M, Nowakowska-grunt J, Strzelczyk M (2019) ScienceDirect ScienceDirect The current situation and the directions of changes in road freight The current situation and the directions of changes transport in the European Union in road freight transport in the European Green Cities 2018. Transp Res Procedia 39:350–359. https://doi.org/10.1016/j.trpro.2019.06.037

Ogunkoya D, Fang T (2015) Engine performance, combustion, and emissions study of biomass to liquid fuel in a compression-ignition engine. Energy Convers Manag 95:342–351. https://doi.org/10.1016/j.enconman.2015.02.041

Osorio-Tejada JL, Llera-Sastresa E, Scarpellini S (2017) Liquefied natural gas: could it be a reliable option for road freight transport in the EU? Renew Sust Energ Rev 71:785–795. https://doi.org/10.1016/j.rser.2016.12.104

Pan W, Yao C, Han G, Wei H, Wang Q (2015) The impact of intake air temperature on performance and exhaust emissions of a diesel methanol dual fuel engine. Fuel 162:101–110. https://doi.org/10.1016/j.fuel.2015.08.073

Park CW, Kim CG, Choi Y, Lee SY, Lee SW, Yi UH, Lee JH, Kim TM, Kim DS (2017) Development of hydrogen-compressed natural gas blend engine for heavy duty-vehicles. Int J Automot Technol 18:1061–1066

Paykani A, Kakaee A, Rahnama P, Reitz RD (2015) Effects of diesel injection strategy on natural gas / diesel reactivity controlled compression ignition combustion. Energy 90:814–826. https://doi.org/10.1016/j.energy.2015.07.112

Pilusa TJ, Mollagee MM, Muzenda E (2012) Reduction of vehicle exhaust emissions from diesel engines using the whale concept filter. 994–1006. https://doi.org/10.4209/aaqr.2012.04.0100

Qasim M, Ansari TM, Hussain M (2017) Combustion, performance, and emission evaluation of a diesel engine with biodiesel like fuel blends derived from a mixture of Pakistani waste canola and waste transformer oils. Energies 10. https://doi.org/10.3390/en10071023

Qu Y, Bektas T, Bennell J (2016) Sustainability SI: multimode multicommodity network design model for intermodal freight transportation with transfer and emission costs. 303–329. https://doi.org/10.1007/s11067-014-9227-9

Quiros DC, Smith J, Thiruvengadam A, Huai T, Hu S (2017) Greenhouse gas emissions from heavy-duty natural gas, hybrid, and conventional diesel on-road trucks during freight transport. Atmos Environ 168:36–45. https://doi.org/10.1016/j.atmosenv.2017.08.066

Ramani T, Jaikumar R, Khreis H, Rouleau M, Charman N (2019) Air quality and health impacts of freight modal shifts: review and assessment. Transp Res Rec 2673:153–164. https://doi.org/10.1177/0361198119834008

Rudolph C (2016) How may incentives for electric cars affect purchase decisions? Transp Policy 52:113–120. https://doi.org/10.1016/j.tranpol.2016.07.014

Saldiva PHN, Lichtenfels AJFC, Paiva PSO, Braone IA, Martins MA, Massad E, Pereira JCR, Xavier VP, Singer JM, Bohm GM (1994) Association between air pollution and mortality due to respiratory diseases in children in São Paulo, Brazil: a preliminary report. Environ Res 65:218–225

Sathiyamoorthi R, Sankaranarayanan G, Adhith Kumaar SB et al (2019) Experimental investigation on performance, combustion and emission characteristics of a single cylinder diesel engine fuelled by biodiesel derived from Cymbopogon Martinii. Renew Energy 132:394–415. https://doi.org/10.1016/j.renene.2018.08.001

Sen B, Ercan T, Tatari O, Zheng QP (2019) Robust Pareto optimal approach to sustainable heavy-duty truck fleet composition. Resour Conserv Recycl 146:502–513. https://doi.org/10.1016/j.resconrec.2019.03.042

Shafiei E, Davidsdottir B, Leaver J, Stefansson H, Asgeirsson EI (2015) Comparative analysis of hydrogen, biofuels and electricity transitional pathways to sustainable transport in a renewable-based energy system. Energy 83:614–627. https://doi.org/10.1016/j.energy.2015.02.071

Singh D, Singal SK, Garg MO, Maiti P, Mishra S, Ghosh PK (2015a) Transient performance and emission characteristics of a heavy-duty diesel engine fuelled with microalga Chlorella variabilis and Jatropha curcas biodiesels. Energy Convers Manag 106:892–900. https://doi.org/10.1016/j.enconman.2015.10.023

Singh D, Subramanian KA, Singal SK (2015b) Emissions and fuel consumption characteristics of a heavy duty diesel engine fueled with hydroprocessed renewable diesel and biodiesel. Appl Energy 155:440–446. https://doi.org/10.1016/j.apenergy.2015.06.020

Smajla I, Sedlar DK, Drljača B, Jukić L (2019) Fuel switch to LNG in heavy truck traffic. Energies 12. https://doi.org/10.3390/en12030515

Song L, Song H, Lin J, Wang C, Yu M, Huang X, Guan Y, Wang X, du L (2017) PM2.5 emissions from different types of heavy-duty truck: a case study and meta-analysis of the Beijing-Tianjin-Hebei region. Environ Sci Pollut Res 24:11206–11214. https://doi.org/10.1007/s11356-017-8755-5

Stettler MEJ, Midgley WJB, Swanson JJ, Cebon D, Boies AM (2016) Greenhouse gas and noxious emissions from dual fuel diesel and natural gas heavy goods vehicles. Environ Sci Technol 50:2018–2026. https://doi.org/10.1021/acs.est.5b04240

Thang PQ, Muto Y, Maeda Y, Trung NQ, Itano Y, Takenaka N (2016) Increase in ozone due to the use of biodiesel fuel rather than diesel fuel. Environ Pollut 216:400–407. https://doi.org/10.1016/j.envpol.2016.04.102

Thiruvengadam A, Besch M, Padmanaban V, Pradhan S, Demirgok B (2018) Natural gas vehicles in heavy-duty transportation-a review. Energy Policy 122:253–259. https://doi.org/10.1016/j.enpol.2018.07.052

Tsita KG, Pilavachi PA (2017) Decarbonizing the Greek road transport sector using alternative technologies and fuels. Therm Sci Eng Prog 1:15–24. https://doi.org/10.1016/j.tsep.2017.02.003

Tüccar G, Uludamar E (2018) Emission and engine performance analysis of a diesel engine using hydrogen enriched pomegranate seed oil biodiesel. Int J Hydrog Energy 43:18014–18019. https://doi.org/10.1016/j.ijhydene.2017.11.124

Wang L, Shen W, Kim HC, Wallington TJ, Zhang Q, Han W (2020) Life cycle water use of gasoline and electric light-duty vehicles in China. Resour Conserv Recycl 154:104628. https://doi.org/10.1016/j.resconrec.2019.104628

Wang X, Shen Y, Lin Y, Pan J, Zhang Y, Louie PKK, Li M, Fu Q (2019) Atmospheric pollution from ships and its impact on local air quality at a port site in Shanghai. Atmos Chem Phys 19:6315–6330. https://doi.org/10.5194/acp-19-6315-2019

Wong YK, Huang XHH, Cheng YY, Louie PKK, Yu ALC, Tang AWY, Chan DHL, Yu JZ (2019) Estimating contributions of vehicular emissions to PM 2.5 in a roadside environment: a multiple approach study. Sci Total Environ 672:776–788. https://doi.org/10.1016/j.scitotenv.2019.03.463

Wu X, Wu Y, Zhang S, Liu H, Fu L, Hao J (2016) Assessment of vehicle emission programs in China during 1998-2013: achievement, challenges and implications. Environ Pollut 214:556–567. https://doi.org/10.1016/j.envpol.2016.04.042

Xing Y, Song H, Yu M, Wang C, Zhou Y, Liu G, du L (2016) The characteristics of greenhouse gas emissions from heavy-duty trucks in the Beijing-Tianjin-Hebei (BTH) region in China. Atmosphere (Basel) 7:121. https://doi.org/10.3390/atmos7090121

Yang PM, Lin YC, Lin KC, Jhang SR, Chen SC, Wang CC, Lin YC (2015) Comparison of carbonyl compound emissions from a diesel engine generator fueled with blends of n-butanol, biodiesel and diesel. Energy 90:266–273. https://doi.org/10.1016/j.energy.2015.06.070

Yuan JH, Zhou S, Peng TD, Wang GH, Ou XM (2018) Petroleum substitution, greenhouse gas emissions reduction and environmental benefits from the development of natural gas vehicles in China. Pet Sci 15:644–656. https://doi.org/10.1007/s12182-018-0237-y

Yusop AF, Mamat R, Yusaf T et al (2018) Analysis of particulate matter (PM) emissions in diesel engines using palm oil biodiesel blended with diesel fuel. Energies 11. https://doi.org/10.3390/en11051039

Zhang Y, Jiang Y, Rui W, Thompson RG (2019) Analyzing truck fleets’ acceptance of alternative fuel freight vehicles in China. Renew Energy 134:1148–1155. https://doi.org/10.1016/j.renene.2018.09.016

Zhao Y, Damgaard A, Liu S, Chang H, Christensen TH (2020) Bioethanol from corn stover – integrated environmental impacts of alternative biotechnologies. Resour Conserv Recycl 155:104652. https://doi.org/10.1016/j.resconrec.2019.104652

Acknowledgements

The authors gratefully acknowledge the Institute of Energy and Environment, University of São Paulo, and support from SHELL Brazil and FAPESP, through the “Research Centre for Gas Innovation (RCGI) hosted by the University of São Paulo” (FAPESP Grant Proc. 2014/50279-4). Ana Carolina Teixeira thanks especially the current financial support of grant Process 2019/09242-3, São Paulo Research Foundation (Fundação de Amparo à Pesquisa do Estado de São Paulo – FAPESP). Pedro Gerber Machado was funded by CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) grant number 205987/2018-4.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Funding

This study was financially supported by Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) - Grant Process: 2014/50279-4 and 2019/09242-3 and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) - Grant Number 205987/2018-4.

Author information

Authors and Affiliations

Contributions

Ana Carolina Rodrigues Teixeira: conceptualization, methodology, validation, formal analysis, investigation, data curation, writing-original draft, writing-review and editing, and visualization

Pedro Gerber Machado: conceptualization, methodology, validation, formal analysis, investigation, data curation, writing-original draft, and writing-review and editing

Flávia Mendes de Almeida Collaço: conceptualization, methodology, formal analysis, investigation, data curation, writing-original draft, and writing-review and editing

Dominique Mouette: conceptualization, review and editing, and project administration

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 3.70 mb)

Rights and permissions

About this article

Cite this article

Teixeira, A.C.R., Machado, P.G., Collaço, F.M.d. et al. Alternative fuel technologies emissions for road heavy-duty trucks: a review. Environ Sci Pollut Res 28, 20954–20969 (2021). https://doi.org/10.1007/s11356-021-13219-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13219-8