Abstract

Developing a use for the inedible parts of citrus, mainly peel, would have great environmental and economic benefits worldwide. Astaxanthin is a value-added fine chemical that affects fish pigmentation and has recently been used in healthcare products for humans, resulting in an increased demand. This study aimed to produce astaxanthin from a citrus, ponkan, peel extract using the yeast Xanthophyllomyces dendrorhous, which has the ability to use both pentose and hexose. Feeding on only ponkan peel extract enhanced X. dendrorhous growth and the concomitant astaxanthin production. Additionally, we determined that pectin and its arabinose content were the main substrate and sole carbon source, respectively, for X. dendrorhous growth and astaxanthin production. Thus, ponkan peel extract could become a valuable resource for X. dendrorhous–based astaxanthin production. Using citrus peel extract for microbial fermentation will allow the development of processes that produce value-added chemicals from agricultural byproducts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The waste products from food industries are attractive biomass resources for biorefining, which uses consolidated (integrated) biotechnology techniques to generate various chemicals from biomass resources as part of a bioeconomy (Hasunuma et al. 2013; Kondo et al. 2013; Lin et al. 2013; Sherwood 2020). Agricultural food residues are attractive resources for bioproduction (Ben-Othman et al. 2020). In particular, the inedible parts of crops, vegetables, and fruits are valuable biomass resources for food biorefining, because they are more easily degraded by microbial cell factories than hard biomass, such as lignocellulosic biomass. Among these, citrus peel is a promising bioresource for microbial fermentation (Sharma et al. 2017; Protzko et al. 2018).

Citrus is a popular fruit worldwide. However, almost half a citrus fruit is inedible, consisting mostly of peel and pressed pulp (seeds and segment membranes) (Marin et al. 2007; Patsalou et al. 2019; Wilkins 2009). These solid residues are referred to as “citrus wastes” and constitute an estimated 15 million tons/year worldwide (Marin et al. 2007). Some are used to produce animal feeds, but this is not a cost-effective strategy, so the solid residues are mainly disposed of in landfills, causing severe economic and environmental problems (Tripodo et al. 2004; Patsalou et al. 2019). Because citrus fruits are mainly processed for juice extraction in food factories (Lohrasbi et al. 2010; Koutinas et al. 2016), the use of the residue in microbial fermentation has been studied (Joglekar et al. 2019). The peel is also suitable for the production of particular value-added fine chemicals for food industries, using zero-emission processes.

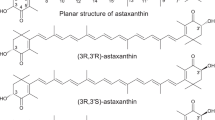

Carotenoids are value-added fine chemicals that are widely distributed in nature. Carotenoids belong to the terpene (isoprenoid) class of natural compounds (Muntendam et al. 2009) and are exclusively synthesized by plants and microorganisms (Vachali et al. 2012; Mata-Gómez et al. 2014; Gervasi et al. 2020; Villegas-Méndez et al. 2019; Korumilli et al. 2020). In particular, astaxanthin (3,3′-dihydroxy-β,β-carotene-4,4′-dione; C40H52O4) is used in fine chemical industries, such as food, pharmaceuticals, and cosmetics, because of its red pigmentation and antioxidant properties (Rodríguez-Sáiz et al. 2009; Hara et al. 2014a). For safety reasons, astaxanthin must be produced with bioprocesses, not chemical processes, especially in the food and cosmetic industries. Therefore, viable natural astaxanthin producers have been investigated, including bacteria, yeasts, algae, and shrimp (Han et al. 2013). At present, Haematococcus pluvialis is used industrially as an astaxanthin producer because it has higher astaxanthin content. However, its production of astaxanthin is very much slower than the chemical reaction used to produce synthetic astaxanthin. Therefore, we investigated a red yeast, Phaffia rhodozyma (sexual form, Xanthophyllomyces dendrorhous), because it has been identified as a promising candidate microorganism with which to maximize the production of the carotenoid astaxanthin in a process faster than that based on H. pluvialis (Visser et al. 2003; Schmidt et al. 2011; Melillo et al. 2013; Barredo et al. 2017; Kothari et al. 2019). X. dendrorhous has the ability to use various biomass resources, including agro-industrial waste (Villegas-Méndez et al. 2019; Gervasi et al. 2020), because it can hydrolyze both hexose and pentose (Rodríguez-Sáiz et al. 2010; Mata-Gómez et al. 2014).

The possibility of producing astaxanthin using X. dendrorhous from the residue of the edible part of citrus has already been studied (Wu et al. 2010; Korumilli et al. 2020). Here, the inedible remains of a ponkan (Citrus poonensis) peel extract were tested as a possible bioresource for the direct production of astaxanthin using X. dendrorhous without the addition of other nutrients. We demonstrated that the ponkan peel extract contains not only a carbon source, but also a nitrogen source, minerals, and other activation factors required for the growth of X. dendrorhous and production of astaxanthin.

Materials and methods

Strain and media

Xanthophyllomyces dendrorhous (NBRC 10129) was used as an astaxanthin-producing yeast in this study. It was cultured in minimal synthetic defined (SD) medium (6.7 g/L yeast nitrogen base [YNB] without amino acids and 20 g/L d-glucose) or rich yeast–malt (YM) medium (5 g/L tryptone, 3 g/L yeast extract, 3 g/L malt extract, and 10 g/L d-glucose) as the base medium. In this study, “Shimizu Ota” ponkan fruit harvested within a year in Shizuoka, Japan, were used as model citrus. Ponkan peel was dried at 50–55 °C for 72 h and stored at 4 °C until use. The dried ponkan peel was crushed with a food processor and then a beads cell disruptor (Shake Master Neo, BMS, Tokyo, Japan) and added to each base medium. First, various concentrations of ponkan peel were added to SD medium to determine the most effective ponkan peel concentrations for X. dendrorhous growth and astaxanthin production. Second, media were prepared by adding the selected most effective ponkan peel concentration for X. dendrorhous astaxanthin production to the base media. SP, DP, and SDP media were made of the ponkan peel to 6.7 g/L YNB solution as the nitrogen/mineral source, 20 g/L d-glucose solution as the carbon source, and SD medium (6.7 g/L YNB solution + 20 g/L d-glucose), respectively. SPec medium was made by adding 12.5 g/L pectin, a major carbon source in citrus peels, to a 6.7 g/L YNB solution. Next, to explore the carbon sources of pectin in ponkan peels for X. dendrorhous growth and astaxanthin production, a medium containing total sugars was prepared by adding natural ratio of the top four pectic sugars. Furthermore, four kinds of media were prepared by adding sugar mixtures in which one of the four main sugars was omitted to a 6.7 g/L YNB solution. Finally, the ponkan peel was evaluated as a single substrate compared to SD and YM medium. Throughout all experiments performed in this study, the media containing ponkan peel were autoclaved (121 °C, 0.2 MPa, 20 min) and the solid residue was removed by centrifugation at 10,600×g for 10 min at 4 °C. Yeast and malt extracts were purchased from Becton Dickinson (Sparks, MD, USA). Other chemicals were obtained from Nacalai Tesque (Kyoto, Japan) or FUJIFILM Wako Pure Chemical (Osaka, Japan). Pectin from citrus (FUJIFILM Wako Pure Chemical1) was used to test the pectin in this study. The specification of this reagent included: maximum loss of 15.0% on drying at 105 °C; 3.5–8.5% methoxy group (calculated on dried basis); and 50.0–80.0% galacturonic acid (calculated on dried basis). The estimated molecular weight of the pectin was 50,000–360,000 kDa.

Cultivation and astaxanthin production of the X. dendrorhous strain

The X. dendrorhous strain was grown on a plate containing YM medium agar at 22 °C for 3 days. Some colonies were inoculated into 5 mL liquid YM medium in a 20-mL baffled Erlenmeyer flask and cultivated at 22 °C with agitation at 250 rpm for 24 h. Each culture was inoculated into 10 mL of the appropriate medium (described above) in a 50-mL baffled Erlenmeyer flask to achieve initial OD600 values of 0.15 without pH adjustment. Cells were then grown at 22 °C with agitation at 250 rpm for 72 h.

Astaxanthin extraction and measurement

Extraction and measurement methods for astaxanthin were carried out using previously described conditions (Hara et al. 2014b; Yamamoto et al. 2016). The cell concentration was measured at OD600 using a Gene Quant 1300 spectrometer (GE Healthcare Life Sciences, Buckinghamshire, UK) after culturing for the appropriate time. The OD600 value was converted to a cell concentration (gDCW/L) by multiplication with the conversion factor 0.144 (gDCW/L/OD600). To measure the intracellular astaxanthin content of X. dendrorhous, harvested cells were suspended in 1 mL acetone. The cells in acetone were broken using Shake Master NEO and 0.6-mm diameter zirconia beads. The resulting cell extract was centrifuged at 8000×g for 10 min at 4 °C, and the supernatant was then diluted with an appropriate volume of acetone to adjust its concentration to cover the range of the following high-performance liquid chromatography assay.

The astaxanthin concentration was determined using a high-performance liquid chromatography system (Shimadzu, Kyoto, Japan) equipped with a Develosil ODS-HG-5 column (Nomura Chemical, Aichi, Japan). The operation was performed at 25 °C, with acetonitrile/methanol/2-propanol (85/10/5 (v/v/v)) as the mobile phase at a flow rate of 0.8 mL/min, and the detection was performed at 471 nm with an SPD-20A UV detector (Shimadzu).

Analysis of total carbon and nitrogen

Total carbon and nitrogen in the media were measured with TC equipped with TN (Shimadzu) using culture samples diluted with the appropriate volume of distilled water after the cells were removed by centrifugation at 8000×g for 5 min at 4 °C.

Data and statistical analysis

Data are presented as the mean values ± standard deviations (SD) of three independent experiments. The cell concentrations, astaxanthin concentrations, and other data were compared with one-way analysis of variance (ANOVA). Significant differences (p ≤ 0.05) between samples cultured in the different media were calculated with two-tailed Student’s t test.

Results and discussion

Effects of ponkan peel extract’s addition on X. dendrorhous cultivation

There have been no reports on astaxanthin production by X. dendrorhous from ponkan peel extract. Thus, in this study, the effects of ponkan peel extract on X. dendrorhous cell growth were first investigated. From 0 to 50 g/L of ponkan peel extract was added to the minimal SD medium to cultivate X. dendrorhous, and after cultivation for 72 h, cell concentrations (gDCW/L) were compared (Fig. 1). Their increase was correlated with the amount of ponkan peel extract added, indicating that the ponkan peel extract enhanced X. dendrorhous growth in the minimal SD medium. In contrast, the addition of 10 g/L ponkan peel extract decreased the cell concentration compared with the control, which contained no ponkan peel extract. This result indicated that the ponkan peel extract also contains compounds that are inhibitory to X. dendrorhous growth in minimal SD medium; however, the inhibitory effect was less than the promotive effects at the high ponkan peel extract concentration. Citrus peel oil (Singh et al. 2020) and phenolic acids (Xu et al. 2008; Rafiq et al. 2018) are candidate inhibitors of X. dendrorhous growth. It has also been reported that ponkan peel contains higher amounts of phenolic acids than other citrus peels (Wang et al. 2007). In contrast, astaxanthin production increased as the amount of ponkan peel added to the SD medium increased (Fig. 1). The most appropriate concentration of ponkan peel for astaxanthin production was around 40 g/L. However, the addition of 50 g/L ponkan peel produced less astaxanthin than the addition of 40 g/L ponkan peel, indicating that intracellular astaxanthin production is inhibited by high concentrations of ponkan peel.

Effects of the addition of ponkan peel extract on X. dendrorhous cell growth (light gray bars) and astaxanthin (ASX) production (dark gray bars) in SD medium after culture for 72 h. Columns marked by the same letters on the individual error bars indicate no significant difference (p > 0.05); those with different letters indicate significant difference (p < 0.05)

Evaluation of ponkan peel extract as a source of nutrients for X. dendrorhous growth and astaxanthin production

To evaluate ponkan peel extract’s potential as a source of carbon, nitrogen, and minerals for X. dendrorhous growth and astaxanthin production, d-glucose and YNB in the SD medium, which are carbon and nitrogen/mineral sources, respectively, were replaced with ponkan peel extract (Fig. 2(a, b)). As shown in Fig. 2(a), a comparison of time courses of cell concentrations in SP, SD, and 20 g/L d-glucose + 40 g/L ponkan peel extract (DP) media revealed that the cell growth rates during the initial 48 h were SD = SP > DP. In contrast, the order of cell concentration at 72 h was SD < SP < DP. The addition of 40 g/L ponkan peel extract to the SD medium (SDP) did not change the rate of the cell growth within 24 h compared with the SD medium, although the cell concentration at 72 h was higher than that in the SD medium and as same as that in the SP medium. Thus, ponkan peel extract rather than d-glucose increased the final cell concentration, although it had less effect than d-glucose on the growth rate during the growth phase. Growth in SP, SD, and DP media indicates that ponkan peel extract can replace d-glucose as the carbon source and YNB as the nitrogen/mineral source, respectively. This presented the possibility that ponkan peel extract on its own could act as a medium for X. dendrorhous. Therefore, we tested a medium that contained 40 g/L ponkan peel extract alone (P medium) to cultivate X. dendrorhous (Fig. 2(a)). Surprisingly, the P medium showed the same rate of increased cell growth as the DP medium during the initial 48 h of cultivation, although at 72 h, the cell concentration in the P medium was lower than that in the DP medium and higher than that in the SD medium. These results indicate that ponkan peel extract has the potential to supply the required nutrients, including carbon, nitrogen, and other minerals, for X. dendrorhous growth.

Effects of the 40 g/L ponkan peel extract on time course of X. dendrorhous cell growth (a) and, cell mass and astaxanthin (ASX) production after culture for 72 h (b). Light and dark gray bars represent the concentration of cell and ASX, respectively. Columns marked by the same letters on the individual error bars indicate no significant difference (p > 0.05); those with different letters indicate a significant difference (p < 0.05)

It has been reported that 87.1% of citrus peel is a carbohydrate and the major (37.3%) carbon source is pectin, which is mainly contained in the cell walls (Wang et al. 2007; Yapo et al. 2007). Therefore, we used YNB + 40 g/L ponkan peel extract (SP) medium or YNB + 12.5 g/L pectin (SPec) medium to grow X. dendrorhous (Fig. 2(a, b)) and produce astaxanthin (Fig. 2(b)). The X. dendrorhous cell concentration after cultivation in SPec medium for only 24 h reached 2.0 gDCW/L; however, no further cell growth was observed at later time points (Fig. 2(a)). This value was higher than the value when grown in SD medium for 24 h. This result indicates that pectin is more quickly used as a resource for cell growth during the growth phase compared with d-glucose. The higher cell concentration in SPec medium than in SP medium at 24 h indicates that pectin, which was eliminated from ponkan peel by the crushing and autoclaving pretreatment, was completely consumed by cell growth after less than 24 h. On the contrary, the lack of growth from 24 to 72 h in SPec medium demonstrated that the pectin in SPec medium was exhausted after less than 24 h. Thus, the continuous increase in cell growth beyond the cell concentration of 2.0 gDCW/L observed in the SP medium (Fig. 2(a)) indicates that nutrients other than pectin were utilized for cell growth. However, the cell concentration in SD medium reached 2.4 gDCW/L, which was similar to the value achieved in the SPec medium. Thus, 12.5 g/L pectin corresponds to 20 g/L d-glucose as a carbon source.

The astaxanthin concentration in the X. dendrorhous cells after culture for 72 h was measured (Fig. 2(b)), and showed that the astaxanthin production increased with time, and correlated almost perfectly with the cell concentration. This indicates that astaxanthin biosynthesis in X. dendrorhous is yeast growth dependent.

Exploring the carbon sources in ponkan peel used for X. dendrorhous growth

Next, we investigated the main carbon source in pectin. d-Galacturonic acid was a candidate because it is the major chemical in the main carbon chain of pectin. However, X. dendrorhous cell growth was not observed in medium containing YNB + 12.5 g/L d-galacturonic acid, even though the pH was adjusted to 7.0 (data not shown). This result indicated that chemicals other than d-galacturonic acid in the pectin of ponkan peel extract act as the carbon sources for X. dendrorhous growth. Therefore, we evaluated the top four most abundant sugars in the pectin of ponkan peel extract as the carbon source for X. dendrorhous growth (Table 1).

The pectins extracted from various citrus fruits contain 12.3–58.5% arabinose, 15.1–47.5% galactose, 3.8–14.9% glucose, and 1.8–45.9% rhamnose (Kawabata and Sawayama 1975) as the four most abundant neutral sugars, together with other minor sugars, such as mannose and xylose (Pourbafrani et al. 2010; Schmitz et al. 2019). In this study, we used the proportions of sugars in the mandarin (48.4% arabinose, 29.8% galactose, 14.9% glucose, and 6.8% rhamnose as the four most abundant neutral sugars, and 0.1% other sugars) as reported by Kawabata and Sawayama (1975) for the experiment shown in Table 1. We prepared four kinds of sugar mixtures in which one of the four main sugars was omitted, as shown in Table 1. Then, X. dendrorhous was cultured in each medium containing each sugar mixture and YNB solution for 72 h. The largest decrease in cell concentration compared with the other medium occurred in the medium lacking arabinose. This result indicated that arabinose is the major carbon source in pectin for X. dendrorhous growth. Interestingly, the absence of rhamnose resulted in an increase in cell concentration compared with the medium containing the four main sugars (Table 1). This result indicated that the rhamnose contained in ponkan peel extract could act as an inhibitor of X. dendrorhous cell growth, as shown in Fig. 1.

Evaluation of ponkan peel extract for astaxanthin production by X. dendrorhous

The potential of ponkan peel extract alone, or in the SD or YM medium, to act as a resource for astaxanthin production by X. dendrorhous was evaluated after cultivation for 72 h (Table 2). The ponkan peel extract (40 g/L) alone resulted in the production of 0.92 mg/L of astaxanthin. The addition of ponkan peel extract to SD medium enhanced astaxanthin production by 1.7-fold (1.22 mg/L) compared with SD medium (0.71 mg/L). Furthermore, the addition of ponkan peel extract to YM medium also enhanced astaxanthin production by 1.9-fold (2.05 mg/L) compared with YM medium (1.06 mg/L). Thus, the astaxanthin production in both media was increased owing to the increase in X. dendrorhous cell growth caused by the ponkan peel extract (Table 2).

The enhancement of X. dendrorhous cell growth by the addition of ponkan peel extract to not only the SD medium but also the YM medium indicated that ponkan peel extract contains a growth enhancer compound(s) for X. dendrorhous. This insight from the results shown in Tables 1 and 2 indicates that arabinose is a candidate growth enhancer of X. dendrorhous. This indicates the great antioxidant production potential of X. dendrorhous, which has the ability to use not only hexose but also pentose monosaccharides, such as arabinose.

Astaxanthin production by X. dendrorhous from only ponkan peel extract

As shown in Table 2, the ponkan peel extract diluted into distilled water (DW) to adjust to 40 g/L has the ability to support X. dendrorhous growth and astaxanthin production. The X. dendrorhous cell and astaxanthin concentrations at 72 h in the P medium containing 40 g/L ponkan peel extract were lower than those in the DP medium (Fig. 2(b)). These results indicate that in the medium containing only 40 g/L ponkan peel extract, the carbon source is the limiting factor for X. dendrorhous growth. To determine the most appropriate concentration of ponkan peel extract for astaxanthin production by X. dendrorhous, we measured cell and astaxanthin concentrations after cultivation for 72 h in the medium including only ponkan peel extract at different concentrations (Fig. 3). As shown in Fig. 3, the drastic increase in the cell concentration was correlated with the ponkan peel extract’s concentration when it was less than 120 g/L, but the cell concentration decreased at concentrations greater than 160 g/L. Thus, the optimum ponkan peel extract concentration for cell growth was 120 g/L. However, as shown in Fig. 3, the increase in astaxanthin production was generally correlated with the ponkan peel extract’s concentration when it was less than 80 g/L, but production decreased at concentrations greater than 120 g/L (Fig. 3). In particular, a ponkan peel extract concentration greater than 160 g/L resulted in a drastic decrease in astaxanthin production. The optimum ponkan peel extract concentration for astaxanthin production was 80 g/L.

Effects of the addition of only ponkan peel extract on X. dendrorhous cell growth (light gray bars) and astaxanthin (ASX) production (dark gray bars) after culture for 72 h. Columns marked by the same letters on the individual error bars indicate no significant difference (p > 0.05); those with different letters indicate a significant difference (p < 0.05). n.d.: not detected

One reason for the drastic decrease in astaxanthin production at a ponkan peel extract concentration greater than 160 g/L would be a decrease in cell growth. However, this was insufficient because the rate of decrease in cell growth was not large compared with the decrease in astaxanthin production. Another important reason is the inhibitory effects of chemicals contained in ponkan peel extract on astaxanthin synthesis in X. dendrorhous. Another reason is the Crabtree effect, which is the phenomenon in which respiration decreases in the presence of high concentrations of carbon sources. X. dendrorhous is a Crabtree-positive yeast and its astaxanthin production correlates positively with its respiration (Reynders et al. 1997; Yamane et al. 1997; Alcaíno et al. 2016).

Thus, using ponkan peel extract on its own, with no additional nutrients, to produce astaxanthin from X. dendrorhous has economic and environmental advantages; however, using the correct ponkan peel extract concentration is important for establishing efficient industrial astaxanthin production processes.

An advantage of using ponkan peel as a resource for X. dendrorhous growth and astaxanthin production rather than other citrus peels is that it has a higher arabinose content. Table 1 shows that arabinose is the critical sugar for X. dendrorhous growth. Flavonoids and carotenoids are other beneficial compounds and are also present at higher levels in ponkan peel than in other citrus peels (Wang et al. 2007), and these precursor compounds for astaxanthin can be metabolically converted into astaxanthin by X. dendrorhous.

Finally, to evaluate the full kinetics of the best-performing cultures, X. dendrorhous was cultured in medium containing 80 g/L ponkan peel for 96 h. The cell concentration, astaxanthin production, and carbon and nitrogen depletion were measured over time (Fig. 4). Astaxanthin production correlated positively with cell growth and with carbon and nitrogen depletion. These results indicate that ponkan peel supplied not only the carbon source but also the nitrogen source for both cell growth and astaxanthin production. The C/N ratio was constantly around 60 during the time courses, except at 24 h, when it was 96.5, indicating that the initial cell growth consumed nitrogen faster than it consumed carbon. As shown in Fig. 4, the cell concentration and astaxanthin production of wild-type X. dendrorhous reached 11.1 gDCW/L and 1.7 mg/L, respectively, after culture for 72 h with the addition of 80 g/L ponkan peel only. These values are higher and lower, respectively, than those in a previous study of a higher-astaxanthin-producing mutant X. dendrorhous strain on rich YM medium with the addition of 5 g/L ponkan peel, which were 9.1 gDCW/L and 5.2 mg/L, respectively, (Kothari et al. 2019). The higher growth of wild-type X. dendrorhous with astaxanthin production from ponkan peel without the addition of other nutrients in this study compared with the previous study is attributable to the use of ponkan peel and its appropriate concentration. The combination of the mutant strain used in the previous study and ponkan peel in the appropriate concentration determined in the present study would combinatorial increase the astaxanthin production from ponkan peel.

Conclusion

This study revealed the potential of ponkan peel extract alone for producing an antioxidant, astaxanthin, from X. dendrorhous. This indicated that ponkan peel extract contains all the components required to grow X. dendrorhous and produce astaxanthin. In the ponkan peel extract, pectin, particularly its arabinose content, was identified as the core substrate for cell growth with astaxanthin production. Citrus peel extract, when used at its optimal concentration, has the potential to be used as a nutrient source in microbial fermentation for biorefining.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Alcaíno J, Bravo N, Córdova P, Marcoleta AE, Contreras G, Barahona S, Sepúlveda D, Fernández-Lobato M, Baeza M, Cifuentes V (2016) The involvement of Mig1 from Xanthophyllomyces dendrorhous in catabolic repression: an active mechanism contributing to the regulation of carotenoid production. PLoS One 11:e0162838

Barredo JL, García-Estrada C, Kosalkova K, Barreiro C (2017) Biosynthesis of astaxanthin as a main carotenoid in the heterobasidiomycetous yeast Xanthophyllomyces dendrorhous. J Fungi (Basel) 3:44

Ben-Othman S, Jõudu I, Bhat R (2020) Bioactives from agri-food wastes: present insights and future challenges. Molecules. 25:510

Gervasi T, Santini A, Daliu P, Salem AZ, Gervasi C, Pellizzeri AV, Salem ZM, Gervasi C, Pellizzeri V, Barrega L, Pasquale PD, Giacomo D, Cicero N (2020) Astaxanthin production by Xanthophyllomyces dendrorhous growing on a low cost substrate. Agrofor Syst 94:1229–1234

Han D, Li Y, Hu Q (2013) Astaxanthin in microalgae: pathways, functions and biotechnological implications. Algae 28:131–147

Hara KY, Morita T, Endo Y, Mochizuki M, Araki M, Kondo A (2014a) Evaluation and screening of efficient promoters to improve astaxanthin production in Xanthophyllomyces dendrorhous. Appl Microbiol Biotechnol 98:6787–6793

Hara KY, Morita T, Mochizuki M, Yamamoto K, Ogino C, Araki M, Kondo A (2014b) Development of a multi-gene expression system in Xanthophyllomyces dendrorhous. Microb Cell Factories 13:175

Hasunuma T, Okazaki F, Okai N, Hara KY, Ishii J, Kondo A (2013) A review of enzymes and microbes for lignocellulosic biorefinery and the possibility of their application to consolidated bioprocessing technology. Bioresour Technol 135:513–522

Joglekar SN, Pathak PD, Mandavgane SA, Kulkarni BD (2019) Process of fruit peel waste biorefinery: a case study of citrus waste biorefinery, its environmental impacts and recommendations. Environ Sci Pollut Res 26:34713–34722

Kawabata A, Sawayama S (1975) Constituent sugars of pectin substances from fruits. J Jpn Soci Food Nutr 28:395–402

Kondo A, Ishii J, Hara KY, Hasunuma T, Matsuda F (2013) Development of microbial cell factories for bio-refinery through synthetic bioengineering. J Biotechnol 163:204–216

Korumilli T, Mishra S, Korukonda JR (2020) Production of astaxanthin by Xanthophyllomyces Dendrorhous on fruit waste extract and optimization of key parameters using Taguchi method. J Biochem Technol 11:25

Kothari D, Lee JH, Chon JW, Seo KH, Kim SK (2019) Improved astaxanthin production by Xanthophyllomyces dendrorhous SK984 with oak leaf extract and inorganic phosphate supplementation. Food Sci Biotechnol 28:1171–1176

Koutinas M, Patsalou M, Stavrinou S, Vyrides I (2016) High temperature alcoholic fermentation of orange peel by the newly isolated thermotolerant Pichia kudriavzevii KVMP10. Lett Appl Microbiol 62:75–83

Lin CSK, Pfaltzgraff LA, Herrero-Davila L, Mubofu EB, Abderrahim S, Clark JH, Koutinas AA, Kopsahelis N, Stamatelatou K, Dickson F, Thankappan S, Mohamed Z, Brocklesby R, Luque R (2013) Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ Sci 6:426–464

Lohrasbi M, Pourbafrani M, Niklasson C, Taherzadeh MJ (2010) Process design and economic analysis of a citrus waste biorefinery with biofuels and limonene as products. Bioresour Technol 101:7382–7388

Marin FR, Soler-Rivas C, Benavente-Garcia O, Castillo J, Perez-Alvarez JA (2007) By-products from different citrus processes as a source of customized functional fibres. Food Chem 100:736–741

Mata-Gómez LC, Montañez JC, Méndez-Zavala A, Aguilar CN (2014) Biotechnological production of carotenoids by yeasts: an overview. Microb Cell Factories 13:12

Melillo E, Setroikromo R, Quax WJ, Kayser O (2013) Production of α-cuprenene in Xanthophyllomyces dendrorhous: a step closer to a potent terpene biofactory. Microb Cell Factories 12:13

Muntendam R, Melillo E, Ryden A, Kayser O (2009) Perspectives and limits of engineering the isoprenoid metabolism in heterologous hosts. Appl Microbiol Biotechnol 84:1003–1009

Patsalou M, Samanides CG, Protopapa E, Stavrinou S, Vyrides I, Koutinas M (2019) A citrus peel waste biorefinery for ethanol and methane production. Molecules 24:2451

Pourbafrani M, Forgács G, Horváth IS, Niklasson C, Taherzadeh MJ (2010) Production of biofuels, limonene and pectin from citrus wastes. Bioresour Technol 101:4246–4250

Protzko RJ, Latimer LN, Martinho Z, Reus E, Seibert T, Benz JP, Dueber JE (2018) Engineering Saccharomyces cerevisiae for co-utilization of D-galacturonic acid and D-glucose from citrus peel waste. Nat Commun 9:5059

Rafiq S, Kaul R, Sofi SA, Bashir N, Nazir F, Nayik GA (2018) Citrus peel as a source of functional ingredient: a review. J Saudi Soc Agric Sci 17:351–358

Reynders M, Rawlings DE, Harrision ST (1997) Demonstration of the Crabtree effect in Phaffia rhodozyma during continuous and fed-batch cultivation. Biotechnol Lett 19:549–552

Rodríguez-Sáiz M, Godio RP, Alvarez V, de la Fuente JL, Martí JF, Barredo JL (2009) The NADP-dependent glutamate dehydrogenase gene from the astaxanthin producer Xanthophyllomyces dendrorhous: use of its promoter for controlled gene expression. Mol Biotechnol 41:165–172

Rodríguez-Sáiz M, de la Fuente JL, Barredo JL (2010) Xanthophyllomyces dendrorhous for the industrial production of astaxanthin. Appl Microbiol Biotechnol 88:645–658

Schmidt I, Schewe H, Gassel S, Jin C, Buckingham J, Hümbelin M, Sandmann G, Schrader J (2011) Biotechnological production of astaxanthin with Phaffia rhodozyma/Xanthophyllomyces dendrorhous. Appl Microbiol Biotechnol 89:555–571

Schmitz K, Protzko R, Zhang L, Benz JP (2019) Spotlight on fungal pectin utilization-from phytopathogenicity to molecular recognition and industrial applications. Appl Microbiol Biotechnol 103:2507–2524

Sharma K, Mahato N, Cho MH, Lee YR (2017) Converting citrus wastes into value-added products: economic and environmentally friendly approaches. Nutrition 34:29–46

Sherwood J (2020) The significance of biomass in a circular economy. Bioresour Technol 300:122755

Singh B, Singh JP, Kaur A, Singh N (2020) Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res Int 132:109114

Tripodo MM, Lanuzza F, Micali G, Coppolino R, Nucita F (2004) Citrus waste recovery: a new environmentally friendly procedure to obtain animal feed. Bioresour Technol 91:111–115

Vachali P, Bhosale P, Bernstein PS (2012) Microbial carotenoids. Methods Mol Biol 898:41–59

Villegas-Méndez MÁ, Aguilar-Machado DE, Balagurusamy N, Montañez J, Morales-Oyervides L (2019) Agro-industrial wastes for the synthesis of carotenoids by Xanthophyllomyces dendrorhous: Mesquite pods-based medium design and optimization. Biochem Eng J 150:107260

Visser H, van Ooyen AJ, Verdoes JC (2003) Metabolic engineering of the astaxanthin-biosynthetic pathway of Xanthophyllomyces dendrorhous. FEMS Yeast Res 4:221–231

Wang YC, Chuang YC, Hsu HW (2007) The flavonoid, carotenoid and pectin content in peels of citrus cultivated in Taiwan. Food Chem 106:277–284

Wilkins MR (2009) Effect of orange peel oil on ethanol production by Zymomonas mobilis. Biomass Bioenergy 33:538–541

Wu W, Lu M, Yu L (2010) Citrus residues isolates improve astaxanthin production by Xanthophyllomyces dendrorhous. Z Naturforsch C J Biosci 65:594–598

Xu GH, Chen JC, Liu DH, Zhang YH, Jiang P, Ye XQ (2008) Minerals, phenolic compounds, and antioxidant capacity of citrus peel extract by hot water. J Food Sci 73:C11–C18

Yamamoto K, Hara KY, Morita T, Nishimura A, Sasaki D, Ishii J, Ogino C, Kizaki N, Kondo A (2016) Enhancement of astaxanthin production in Xanthophyllomyces dendrorhous by efficient method for the complete deletion of genes. Microb Cell Factories 15:155

Yamane YI, Higashida K, Nakashimada Y, Kakizono T, Nishio N (1997) Influence of oxygen and glucose on primary metabolism and astaxanthin production by Phaffia rhodozyma in batch and fed-batch cultures: kinetic and stoichiometric analysis. Appl Environ Microbiol 63:4471–4478

Yapo BM, Lerouge P, Thibault JF, Ralet MC (2007) Pectins from citrus peel cell walls contain homogalacturonans homogenous with respect to molar mass, rhamnogalacturonan I and rhamnogalacturonan II. Carbohydr Polym 69:426–435

Acknowledgments

The Xanthophyllomyces dendrorhous (NBRC 10129) strain was obtained from the National Bioresource Center. Citrus (“Shimizu Ota” ponkan) peel was gifted from the Shizuoka Prefectural Agriculture and Forestry Research Institute. We thank Mr. K. Murofushi for his assistance in collecting the experimental data.

Funding

This work was supported by a Grant from Toyo Institute of Food Technology, a Grant-in-Aid for Scientific Research (C) (Number 16K00616), and a JST-Mirai Program Grant (Number JPMJMI17EJ), Japan.

Author information

Authors and Affiliations

Contributions

Y.K. and K.Y.H. conceived the idea and designed the experiments. Y.K. and N.T. performed experiments and data analysis. Y.H-H., H.K., and K.Y.H. wrote the manuscript. K.W. supervised the study. K.Y.H. coordinated the research project. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hara, K.Y., Kageyama, Y., Tanzawa, N. et al. Development of astaxanthin production from citrus peel extract using Xanthophyllomyces dendrorhous. Environ Sci Pollut Res 28, 12640–12647 (2021). https://doi.org/10.1007/s11356-020-11163-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-11163-7