Abstract

Evaluating carbon emission performance of the construction industry is a significant prerequisite for developing regional carbon mitigation plans. Taking environmental and technical heterogeneities into account, this paper employed a meta-frontier method to measure the carbon emission efficiency, carbon mitigation potential, and costs of the construction sector in different regions of China from 2005 to 2016. The empirical results show that substantial disparities in carbon emission efficiency exist in the construction industry. The total carbon mitigation potential of this sector was 206.76 million tons, with the Lower Yellow river area accounting for the largest proportion at 27%. Meanwhile, the carbon mitigation costs of this sector increased from 584.94 to 1273.30 yuan/ton during 2005–2016. The highest mitigation costs occur in the Lower Yangtze River area and the South Coastal area, indicating it was more costly in these areas to conduct additional carbon emissions mitigation. The results could facilitate the policy formulation on regional-oriented carbon emissions mitigation of the construction industry in China.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the growing threat of global climate warming and environmental degradation, undertaking effective measures to mitigate carbon emissions is a shared responsibility of the global community (Shuai et al. 2017). As the world’s most important contributor to carbon emissions, China has been actively participating in carbon mitigation campaign (Yang et al. 2018). During the 2015 Paris Climate Change Conference, China committed to cut down its carbon intensity by 60–65% by 2030 based on the 2005 level.

As a significant industry for economic development, the construction industry in China exerts an important effect on carbon emissions generation (Du et al. 2019a). It generated 1.4 billion tons of carbon emissions in 2016, making it responsible for 15% of the national carbon emissions (Zhang et al. 2019). As China is still undergoing rapid urbanization and industrialization, there is huge demand for construction projects, which will lead to increased carbon emissions (Huang et al. 2018). The Intergovernmental Panel on Climate Change (2007) reported that the construction industry could realize a carbon emissions reduction of 6 billion tons by 2030, implying that there is large carbon reduction potential in this sector. Accurately assessing carbon emission efficiency and mitigation costs of the construction sector is the key step to evaluate its production technology and carbon mitigation potential, which can help this sector to explore a low-carbon development path (Liu et al. 2016). Moreover, China has launched the national carbon trading market in 2017, evaluating the carbon mitigation costs could provide valuable information on the operating rules of the trading market (He 2015).

In previous studies, only a few researches have considered the effect of heterogeneities of production technology on the carbon emission performance (Song et al. 2019). Due to distinct resource endowments and economic infrastructure development, production technology varies greatly in different regions (Li et al. 2019). And it will cause deviations in outcomes if the heterogeneities are neglected in empirical experiments (Xian et al. 2018; Zhang and Wang, 2015). Therefore, taking the regional environmental and technical heterogeneities into consideration, this study introduced the meta-frontier analysis to comprehensively explore the carbon emission efficiency, mitigation potential, and costs of the construction industry in China during 2005–2016. This study could help the policymakers to develop regional-oriented carbon mitigation strategies.

The rest of this paper is structured as follows. The next section reviews the previous studies. The “Methodology and data” section introduced the methodology used to estimate carbon emission performance. The results are presented in the “Results” section. The “Discussion” section discusses the main results. The “Conclusion and policy implication” section presents the key conclusions and policy implications of this study.

Literature review

Over the past few decades, studies focused on the carbon emission efficiency, and carbon mitigation characteristics of various sectors have sprung up, including thermal power sector (Murty et al. 2007), metallurgical sector (Lin and Xu 2018), transportation sector (Wang and He 2017), and industrial sector (Zhou et al. 2015). However, researches concentrating on the carbon emissions of the construction industry are relatively limited; the major studies of this sector have focused on calculation (Huang et al. 2018; Zhang and Wang 2017) and driving factor analysis (Lu et al. 2016; Shi et al. 2017). Based on the groundwork of previous research, Chen et al. (2019) compared the energy and carbon emission efficiency of the construction industry in China and found a stable trend during 2003–2016. Wang et al. (2018) first estimated carbon abatement costs of the construction industry in China. To sum up, relatively less attention has been given to a comprehensive exploration of carbon emission efficiency, mitigation potential, and costs of the construction industry in China.

Carbon emission efficiency, mitigation potential, and costs can be derived from the directional output distance function (DODF) introduced by Färe et al. (2005). There are non-parametric and parametric methods to evaluate the value of the DODF. The most well-received method among the former is data envelopment analysis (DEA), while the latter often utilizes the quadratic function form. The DEA method is widely employed to evaluate environmental efficiency and production growth (Boussemart et al. 2017; Wang and Feng 2015). However, the DEA model is not twice differentiable, and the increase in undesirable outputs may bring about a decrease in emission inefficiency, which would be inconsistent with reality (Zhou et al. 2014). Unlike DEA, the parametric approach has the advantage of quadratic differentiability and can provide specific function to estimate the mitigation costs (Färe et al. 2005). Matsushita and Yamane (2012) employed a quadratic DODF model to evaluated carbon mitigation costs in Japan. Peng et al. (2018) calculated the carbon abatement potential and costs in the thermal power industry of China based on a parametric quadratic DODF and found that the Middle Yellow River area has the greatest potential for carbon mitigation. Therefore, this paper choses the quadratic DODF to assess carbon emission efficiency, carbon mitigation potential, and costs of the construction industry in China.

Due to distinct resource endowments and economic infrastructure development, different production technology can be found in the construction sector across different regions of China (Li et al. 2018). To take the production technology heterogeneities into consideration, Oh (2010) introduced the meta-frontier Malmquist-Luenberger index incorporating group heterogeneities to calculate productivity growth and its decomposed factors, applying it to 46 countries. Lin et al. (2013) then expanded the examination to 70 countries to capture the green productivity of the whole world. Wang et al. (2020) constructed a three-level meta-frontier model to measure carbon emission efficiency in China and found that eastern China is the most efficient area. In this study, the meta-frontier method is introduced into the carbon emission performance analysis of China’s construction industry, in an effort to help the policymakers to develop scientific and reasonable carbon mitigation strategies.

Methodology and data

Methodology

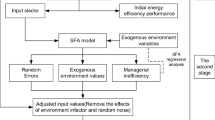

The procedures for analyzing carbon emission performance consist of three steps: first, develop the DODF to represent production technology; then, employ a parametric quadratic function to measure the parameters needed for estimation; finally, based on the estimated parameters and empirical data, assess the carbon emission inefficiency, carbon mitigation potential, and costs.

Directional output distance function

The environmental production technology illuminates a joint production process where desirable outputs \( y\in {R}_{+}^M \) and undesirable outputs \( b\in {R}_{+}^N \) are produced simultaneously given certain inputs \( x\in {R}_{+}^J \) (Färe et al. 2005). Specifically, this study implemented a meta-frontier analysis to assess the production performance of decision-making units (DMUs) in different regions. That is, dividing all the DMUs into k groups (k = 1, 2,..., K) based on the geographic features and technical conditions, then the group frontiers representing regional leading production technology are constructed, and the meta-frontier of all regions can be built by enveloping all the group frontiers. Thus, the group output possibility sets can be defined as:

The output possibility sets reflect certain assumptions, including closed and compact sets, weak disposability and null-jointness of outputs, and strong disposability of inputs and desirable outputs (Zhou et al. 2015). Consequently, the meta-output possibility sets consist of all k groups and can be described as follows:

To simultaneously seek the expansion of desirable output and contraction of undesirable output, this study applied the DODF to clarify the production technology. The group DODF, whose value represents the group carbon emission inefficiency, can be specified as follows:

Similarly, the meta-DODF, whose value represents the meta-carbon emission inefficiency is described as follows:

where the directional vector of outputs is denoted as \( g=\left({g}_y,-{g}_b\right)\in {R}_{+}^M\times {R}_{+}^N \) to ensure the direction of simultaneously proportional change on outputs. βkand βrefer to the value of the group and meta- DODF, respectively; both describe the proportion of a DMU increase in gross domestic product (GDP) and decrease in carbon emissions. As shown in Fig. 1, assuming that point A is a combination of outputs given the inputs x of a DMU in group 2. The value of a group DODF is represented by line segment AB, indicating the emission inefficiency of the DMU compared with the group frontier. Similarly, the value of the meta-DODF is represented by line segment AC. This means that if the DMU is working with the full efficiency of all production units across groups, it will reach the point ′(b − βgb, y + βgy), where the meta-emission inefficiency is equal to zero.

If all the emission inefficiency is eliminated, the carbon mitigation potential \( \Delta {b}_h^t \) can be calculated by the following:

where \( \overrightarrow{D}\left({x}_h^t,{y}_h^t,{b}_h^t;{g}_y,-{g}_b\right) \) represents the value of the meta-DODF and b indicates the absolute value of undesirable outputs.

The carbon mitigation cost is the opportunity cost of a DMU that must pay to achieve one more unit of carbon mitigation. Once the production frontier is captured, according to the duality relation between the DODF and revenue function (Rødseth 2013), the value of undesirable output can be derived from Eq. (6).

where p is the price of desirable output and q is the price of undesirable output.

Parametric quadratic directional output distance function

To evaluate the value of the DODF, it has to specify a function form. This study employed a parametric quadratic function form because it has the advantage of twice differentiability and satisfies the translation property, which facilitates the calculation of carbon mitigation costs (Peng et al. 2018; Zhou et al. 2014). Additionally, to simultaneously credit the maximum increase of desirable output and decrease of undesirable output, this study chose (gy, −gb) = (1, −1) as the directional vector (Färe et al. 1993). Therefore, the parametric quadratic DODF can be characterized as Eq. (7):

where t is the time trend, t = 1, 2, …, T, h denotes the hth DMU, x, y and b refer to the inputs, desirable output and undesirable output respectively, c0 is the constant,\( {d}_n,{c}_1,{c}_2,{c}_{n{n}^{\prime }},\alpha, \beta, {\delta}_n,{\gamma}_n,\mu \) stands for the estimated parameters.

Supposing that there are Sk DMUs in group k, the parameters of the group parametric quadratic DODF can be estimated by solving the minimization linear programming problem (Aigner and Chu 1968; Zhang et al. 2014):

The purpose of the objective function is to minimize the sum of the deviations of the estimated group DODF value from the group production frontier. The first constraint means that all the observed values of the group DODF are non-negative under feasible input vectors. The second constraint states the null-jointness property of outputs, which indicates that without undesirable output, the output sets are infeasible. The third to fifth constraints impose monotonicity on outputs and inputs, respectively. The sixth constraint specifies symmetry and translation properties.

The meta-production frontier is the envelope of all the group frontiers. It can be constructed by minimizing the absolute sum of deviations between meta-DODF and group DODF (Battese et al. 2004; Lin and Zhao 2016). That is, besides all the constraints of the group DODF, the value of the meta-DODF must be larger than those of the group DODF. Therefore, the meta-parametric quadratic DODF linear programming problem can be interpreted as Eq. (9). The linear programming problems can be solved by MATLAB R2019.

Data

Regional division

To estimate the group and meta- frontiers, respectively, all the DMUs have to be divided into different groups based on certain criterions. According to the Development Research Center of the State Council of the People’s Republic of China (DRC), the division of regions requires comprehensively evaluation of geographic features, economic conditions, and resource endowments. Therefore, this study divided China into eight areas on the basis of the overall district developing plan promulgated by the DRC (Wang and He 2017; Du et al. 2019b). The detailed classification is shown in Table 1.

Variable selection

This paper employed panel data for the construction industry covering 30 provinces and regions of China from 2005 to 2016. Due to inconsistent statistical caliber and lack of data, Hong Kong, Macao, Taiwan, and Tibet are not included in this study. According to the corresponding relationship between inputs and outputs (Färe et al. 2005; Lin and Xu 2018), this study employed capital stock (K), labor force (L), and energy consumption (E) of the construction industry as inputs, GDP (y) as the desirable output, and carbon emissions (b) as the undesirable output.

-

1

Capital stock is estimated using the widely accepted perpetual inventory method (Du et al. 2017; Zhang et al. 2012). The formula is as follow:

where Kt and Kt-1 refer to the capital stock of the construction industry in year t and year t-1, respectively. δt represents the economic depreciation rate of year t, and It is the fixed asset investment in year t, which have to be deflated to constant the 2000 price to eliminate the effect of price. The unit of capital stock is 108 yuan.

-

2.

Labor force corresponds to the year-end employed persons for the building industry in the China Statistical Yearbook. The unit of labor force is 104 people.

-

3

Energy consumption of the construction industry can be acquired from the National Bureau of Statistics of China and have been converted to standard coal equivalent. The unit of energy consumption is 104 tce.

-

4

GDP of the construction industry is considered as the desirable output in this study and is obtained from the National Bureau of Statistics of China. It has to be deflated to the 2000 constant price. The unit of GDP is 108 yuan.

-

5

Carbon emissions generated from the construction industry are the undesirable output. The data of carbon emissions cannot be directly acquired from the China Statistical Yearbook or the National Statistical Bureau. The study calculated the carbon emissions of this sector based on IPCC (2006).

where Ei denotes the energy consumption of the building industry, NCVi represents the net calorific value, CEFi refers to the carbon emission coefficient, COFi is the carbon oxidation factor of energy i, and 44/12 is the conversion coefficient of carbon to CO2.

To avoid the convergence of the evaluation model, each input and output variable must be normalized by dividing the raw data by their mean values before estimation (Boyd et al. 2002; Färe et al. 2005). The statistical description of input and output variables in eight areas of China are shown in Appendix Table 2.

Results

Group and meta-carbon emission inefficiency

The value of group DODF represents group carbon emission inefficiency, which could reflect the disparities of production technology inside each area. The change trends of the group emission inefficiency for the eight areas are different (see Fig. 2). The group emission inefficiency in the Middle Yellow River area and the South Coastal area decreased during the study period, while those in the Northeast area and the Middle and Upper Yangtze River areas increased slightly. However, the changes in the Lower Yellow River area, the Lower Yangtze River area, and the Northwest area are not clear. The Lower Yangtze River area and the Lower Yellow River area have relatively lower average value of group emission inefficiency, indicating that DMUs inside these areas have similar production technology. In contrast, the production technology within the Middle Yellow River area varies greatly with the highest mean value of group emission inefficiency at 0.122.

The meta-carbon emission inefficiency is applied for comparison of production technology across the eight areas. As shown in Fig. 3, the Northeast area has the most efficient production technology among the eight areas, followed by the Lower Yangtze River area and the South Coastal area. The most inefficient areas are the Lower Yellow River area and the Northwest area, where the average values of the meta-emission inefficiency are 0.67 and 0.62, respectively. To be specific, the meta-emission inefficiency in the Lower Yellow River area showed a substantial decrease from 0.75 in 2005 to 0.53 in 2016, which means that the inputs and outputs of the DMUs in this area are becoming more acceptable. However, the changes in the Yangtze River areas are not significant. The values of the meta-emission inefficiency in the Lower Yangtze River area varies from 0.22 to 0.32, while those of the Upper and Middle Yangtze River areas are distributed around approximately 0.54 during the sample period. The emission inefficiency in the Northeast area and South Coastal area increases slightly and fluctuates during 2005–2016. Overall, the average value of the meta-DODF is 0.47, which indicates that the carbon emission inefficiency of the construction industry in China is 47% from 2005 to 2016.

Figure 4 illustrates the regional carbon mitigation potential of the construction industry from 2005 to 2016. If all the carbon emission inefficiency was eliminated, the national carbon emissions mitigation in the construction industry was expected to reach 206.76 million tons, accounting for approximately 47% of total carbon emissions. The overall carbon mitigation potential shows an ascending trend and peaks in 2013 at 22.10 million tons. The Lower Yellow River area shows the greatest potential for carbon mitigation. It is expected to reduce its carbon emissions by 55.94 million tons, which accounts for 27% of the total carbon mitigation potential in the construction industry. The percentages of carbon mitigation in the Middle Yangtze River area, the Upper Yangtze River area, and the Middle Yellow River area are approximately 17%, 13%, and 12%, respectively, which ranking second through fourth. In general, the four regions mentioned above are responsible for more than 70% of the total carbon mitigation potential. However, the percentage of carbon mitigation potential is less than 10% in the other areas, indicating that the DMUs in the Lower Yellow River area, the Middle Yellow River area, and the Middle and Upper Yangtze River areas play a vital role in carbon emissions mitigation in the construction industry.

Carbon mitigation costs

Carbon mitigation costs reflect the economic interests that must be foregone to reduce carbon emissions under certain production technology. The carbon mitigation costs in eight areas of the construction industry were estimated based on Eq. (6) and were classified into three categories. As shown in Fig. 5, significant spatial cluster features exist, and the mitigation costs increase from northwest to southeast. In particular, the areas with higher mitigation costs are mainly located in the coastal areas of China (the Northeast area, the Lower Yangtze River area and the South Coastal area), where the average carbon mitigation costs are all above 1000 yuan/ton. The Middle Yellow River area and the Upper and Middle Yangtze River areas are in the second tier, where the mitigation costs vary from 600 yuan/ton to 1000 yuan/ton. The Northwest area and the Lower Yellow River area show the lowest carbon mitigation costs, all being under 600 yuan/ton.

From a temporal point of view (see Fig. 6), an almost increasing trend in carbon mitigation costs is observed in the eight areas during the sample period. The national carbon mitigation costs increased from 584.94 yuan/ton in 2005 to 1273.30 yuan/ton in 2016. Specifically, the carbon mitigation costs in the Lower Yangtze River area have the highest growing speed with an expansion of 587.21 yuan/ton to 1698.80 yuan/ton. Following this, the mean growth rates of the mitigation costs in the Lower Yellow River area and the South Coastal area are 5.90 and 5.11%, respectively. Similarly, the mitigation costs in other areas show slow but steady growth trends during the sample period. The lowest mitigation costs occur in the Northwest area and the Lower Yellow River area, where the average mitigation costs are 568.61 yuan/ton and 590.70 yuan/ton, indicating that there are great opportunities for the DMUs in these areas to achieve more carbon reduction under relatively lower economic costs.

Discussion

Substantial disparities in carbon emission efficiency exist in the construction industry across different regions of China. The Northwest area and the Lower Yellow River area have the lowest emission efficiency for the construction process, while higher emission efficiency appears in the Northeast area, the Lower Yangtze River area, and the South Coastal area. The results are in line with Guo et al. (2017) and Wu et al. (2019) that significant heterogeneities exist in terms of economic and social development across regions, which have evident effects on the performance of the local construction industry. The Northeast area, the Lower Yangtze River area and the South Coastal area are more developed and economically advanced areas of China, and their production technology is superior to that in other regions. Therefore, cross-regional coordinated carbon emission reduction mechanism should be reinforced to encourage the DMUs in these areas to provide more technology and capital support for the underdeveloped areas. However, the carbon emission inefficiency in the Northeast area rebounded slightly after 2012, which is probably due to the development dilemma of advanced technology. As the most efficient area, it is difficult for the Northeast area to realize further advancement in production technology. And rapid expansion of urbanization in China has brought great pressure on this area with tremendous infrastructure construction projects, which may result in an inefficiency rebound effect. Nevertheless, the DMUs in the Northeast area could achieve further emissions reduction by using renewable and clean energy.

The carbon emission efficiency in each area is negatively correlated with the carbon mitigation potential of the construction industry except for the Northwest area. The Northwest area has the second lowest carbon emission efficiency among eight regions yet only accounts for approximately 5% of the national carbon mitigation potential. The reason is that the construction projects are inadequate in the Northwest area due to the underdeveloped economy and remote location; thus it produces the smallest amounts of carbon emissions on average (see Appendix Table 2). With the lowest carbon emission efficiency and the highest mitigation potential, the Lower Yellow River area, the Middle Yellow River area, and the Middle and Upper Yangtze River areas play prominent roles in carbon emission mitigation in the construction industry. The Middle and Upper Yangtze River areas are located in the hinterland of western China and are more likely to suffer from an underprivileged economy and to have delayed technology updating. This phenomenon is consistent with the situation revealed by He et al. (2018) that, as a result of obsolete production technology, western China is facing great obstacles to fulfilling their carbon mitigation potential. The Lower Yellow River area is composed of Beijing, Tianjin and Hebei, and Shandong provinces, where Hebei and Shandong provinces show the lowest emission efficiency of all 30 administrative districts. Unreasonable resource allocation and poor management of the construction process are the main reasons for the carbon emission inefficiency in these two provinces, which also resulted in the inefficiency of the Lower Yellow River area. Therefore, the DMUs in the Lower Yellow River area and the Middle and Upper Yangtze River areas should construct a more reasonable structure of management, phase out outdated production equipment, and invest more in technology updating to achieve full potential for carbon mitigation.

The carbon mitigation costs of the construction industry in all regions grow rapidly during the study period, especially in 2010, when the Twelfth Five-Year Plan was initially put into effect and the Chinese government announced the target for the construction industry to decrease its energy consumption per unit of added value of construction products by 10%. Since then, investments to update production technologies have been increasing, which led to an obvious rise in carbon mitigation costs. In particular, as the pioneer in industrial innovation and technical promotion, the Lower Yangtze River area shows a rather sharp increasing trend in mitigation costs than other areas. Among this area, Shanghai is one of eight pilot cities implementing carbon emission trading schemes. Advanced production technology and carbon trading policies in this area invigorated the rapid development of its construction industry, leading it to achieve the highest carbon mitigation costs (Lin and Xu 2018). Besides, areas with higher mitigation costs are mainly located in the coastal areas of China, while the costs in western and central China are relatively low, which implies that the carbon trading scheme of the construction industry has broad market prospects. The carbon emission accounting and quota allocation system should be strengthened to promote the carbon trading activities across different regions.

It is noteworthy that the estimated carbon mitigation costs in this study are much higher than those found by Peng et al. (2018) and Zhang et al. (2014). The reason is that this study chose the DODF to represent the production technology of the construction industry, which impose a more “costly” direction of simultaneously expanding GDP and contracting carbon emissions that the government promotes. In addition, Peng et al. (2018) and Zhang et al. (2014) focused on the costs of carbon mitigation at the national level, while this study explored the construction industry. Due to the high dependence on the use of gasoline, diesel, and petroleum, the greenhouse gas emissions generated by the construction industry are higher than other industries. Therefore, it is more challenging for the building sector to conduct additional carbon mitigation. Moreover, the carbon mitigation costs estimated in this study exceed the actual trading price in the current carbon trading market in China, implying that the carbon price in the market does not reflect the real value of carbon emissions. The evaluation of carbon mitigation costs in this study could be a benchmark for the initial carbon trading price. The exchange rate between US dollars and RMB fluctuated from 1:8.07 to 1:6.09 during the sample period; the results could also provide references for the carbon mitigation costs in an international scope.

Conclusion and policy implication

Since the construction industry in China plays a pivotal role in carbon mitigation campaigns, this paper estimated regional carbon emission efficiency, carbon mitigation potential, and costs of the construction industry in China from 2005 to 2016 using meta-frontier parametric quadratic direction output distance function. The main conclusions are summarized as follows:

-

1

Substantial disparities in carbon emission efficiency exist in the construction industry across different regions of China. The mean value of emission inefficiency is 0.47, indicating 47% of inefficient production in China’s construction industry. The Lower Yellow River area and Northwest area have the lowest emission efficiency among the eight regions, whereas the Northeast area, the Lower Yangtze River area, and the South Coastal area have higher emission efficiency.

-

2

The carbon emission mitigation potential of the construction industry was 206.76 million tons from 2005 to 2016, which accounts for 47% of the total carbon emissions of this sector. The Lower Yellow River area accounts for 27% of the total mitigation potential, followed by the Middle Yangtze River area, the Upper Yangtze River area, and the Middle Yellow River area.

-

3

The cost to conduct additional carbon emission reduction in the construction sector gradually increases over time. The national carbon mitigation costs increased from 584.94 to 1273.30 yuan/ton during 2005–2016. The Northwest area and the Lower Yellow River area have the lowest carbon mitigation costs with an average value of 568.61 and 590.70 yuan/ton, respectively. The Lower Yangtze River area, the South Coastal area, and the Northeast area have the highest carbon mitigation costs among the eight regions.

On account of the main conclusions, significant heterogeneities of carbon emission performance of the construction industry exist in different regions. Therefore, the policymakers should uphold the “common but differentiated” principle to formulate carbon mitigation schemes based on the regional specific conditions. First, with the lowest carbon emission efficiency, the largest mitigation potential and the lowest mitigation costs, the Lower Yellow River area should be the primary focus of the carbon emissions reduction in China. Stricter emission regulations should be committed in this area to fully utilize its potential of carbon reduction. Areas with relatively advanced production technology, such as the Northeast area and the Lower Yangtze River area, could achieve further emission reduction by using renewable and clean energy. Second, technical communications in the construction sector between different regions should be strengthened, and more capital and technology support should be devoted to underdeveloped areas such as the Northwest area. Phasing out outdated production equipment and improving the resources allocation and management system could also be conducive to the achievement of carbon mitigation targets in these areas. Third, the carbon trading market in the construction industry has great development potential. The government should set up specialized register system and supervision department to explicitly identify the carbon emissions sources of the construction production units and collect the data of energy consumption and estimate the carbon emissions, so as to improve the carbon quota allocation system of the construction sector and facilitate the development of the national carbon trading market.

Future research could further explore the carbon emission performance from the perspective of construction enterprises and capture the influence of carbon trading scheme on carbon emissions.

References

Aigner DJ, Chu SF (1968) On estimating the industry production function. AmEcon Rev 58(4):826–839

Battese GE, Rao DSP, O’Donnell CJ (2004) A metafrontier production function for estimation of technical efficiencies of wheat farmers under different technologies. J Product Anal 3:933–944

Boussemart J, Leleu H, Shen Z (2017) Worldwide carbon shadow prices during 1990–2011. Energy Policy 109:288–296. https://doi.org/10.1016/j.enpol.2017.07.012

Boyd GA, Tolley G, Pang J (2002) Plant level productivity, efficiency, and environmental performance of the container glass industry. Environ Resour Econ 23:29–43. https://doi.org/10.1023/A:1020236517937

Chen J, Xu C, Managi S, Song M (2019) Energy-carbon performance and its changing trend: an example from China’s construction industry. Resour Conserv Recycl 145:379–388. https://doi.org/10.1016/j.resconrec.2019.03.014

Du Q, Li Y, Bai L (2017) The energy rebound effect for the construction industry: empirical evidence from China. Sustain. 9. https://doi.org/10.3390/su9050803

Du Q, Shao L, Zhou J, Huang N, Bao T, Hao C (2019a) Dynamics and scenarios of carbon emissions in China’s construction industry. Sustain Cities Soc 48:101556. https://doi.org/10.1016/j.scs.2019.101556

Du Q, Zhou J, Pan T, Sun Q, Wu M (2019b) Relationship of carbon emissions and economic growth in China’s construction industry. J Clean Prod 220:99–109. https://doi.org/10.1016/j.jclepro.2019.02.123

Färe R, Grosskopf S, Lovell CAK, Yaisawarng S (1993) Derivation of shadow prices for undesirable outputs : a distance function approach. Rev.Econ.Stat. 75:374–380

Färe R, Grosskopf S, Noh D, Weber W (2005) Characteristics of a polluting technology : theory and practice. 126:469–492. https://doi.org/10.1016/j.jeconom.2004.05.010

Guo X, Zhu Q, Lv L, Chu J, Wu J (2017) Efficiency evaluation of regional energy saving and emission reduction in China : a modified slacks-based measure approach. J Clean Prod 140:1313–1321. https://doi.org/10.1016/j.jclepro.2016.10.021

He X (2015) Regional differences in China’s CO2 abatement cost. Energy Policy 80:145–152. https://doi.org/10.1016/j.enpol.2015.01.044

He W, Yang Y, Wang Z, Zhu J (2018) Estimation and allocation of cost savings from collaborative CO2 abatement in China. Energy Econ 72:62–74. https://doi.org/10.1016/j.eneco.2018.03.025

Huang L, Krigsvoll G, Johansen F, Liu Y, Zhang X (2018) Carbon emission of global construction sector. Renew Sust Energ Rev 81:1906–1916. https://doi.org/10.1016/j.rser.2017.06.001

Intergovernmental Panel on Climate Change (IPCC) (2006) IPCC Guidelines for National Greenhouse Gas Inventories

Intergovernmental Panel on Climate Change (IPCC) (2007) IPCC Fourth Assessment Report: Climate Change

Li Y, Wei Y, Shan S, Tao Y (2018) Pathways to a low-carbon economy: estimations on macroeconomic costs and potential of carbon emission abatement in Beijing. J Clean Prod 199:603–615. https://doi.org/10.1016/j.jclepro.2018.07.093

Li Y, Du Q, Lu X, Wu J, Han X (2019) Relationship between the development and CO2 emissions of transport sector in China. Transp Res Part D Transp Environ 74:1–14. https://doi.org/10.1016/j.trd.2019.07.011

Lin B, Xu M (2018) Regional differences on CO2 emission efficiency in metallurgical industry of China. Energy Policy 120:302–311. https://doi.org/10.1016/j.enpol.2018.05.050

Lin B, Zhao H (2016) Technology gap and regional energy efficiency in China’s textile industry: a non-parametric meta-frontier approach. J Clean Prod 137:21–28. https://doi.org/10.1016/j.jclepro.2016.07.055

Lin EYY, Chen PY, Chen CC (2013) Measuring green productivity of country: a generlized metafrontier Malmquist productivity index approach. Energy 55:340–353. https://doi.org/10.1016/j.energy.2013.03.055

Liu Y, Zhao G, Zhao Y (2016) An analysis of Chinese provincial carbon dioxide emission efficiencies based on energy consumption structure. Energy Policy 96:524–533. https://doi.org/10.1016/j.enpol.2016.06.028

Lu Y, Cui P, Li D (2016) Carbon emissions and policies in China’s building and construction industry: evidence from 1994 to 2012. Build Environ 95:94–103. https://doi.org/10.1016/j.buildenv.2015.09.011

Matsushita K, Yamane F (2012) Pollution from the electric power sector in Japan and efficient pollution reduction. Energy Econ 34:1124–1130. https://doi.org/10.1016/j.eneco.2011.09.011

Murty MN, Kumar S, Dhavala KK (2007) Measuring environmental efficiency of industry: a case study of thermal power generation in India. Environ Resour Econ 38:31–50. https://doi.org/10.1007/s10640-006-9055-6

Oh DH (2010) A metafrontier approach for measuring an environmentally sensitive productivity growth index. Energy Econ 32:146–157. https://doi.org/10.1016/j.eneco.2009.07.006

Peng J, Yu BY, Liao H, Wei YM (2018) Marginal abatement costs of CO2 emissions in the thermal power sector: a regional empirical analysis from China. J Clean Prod 171:163–174. https://doi.org/10.1016/j.jclepro.2017.09.242

Rødseth KL (2013) Capturing the least costly way of reducing pollution: a shadow price approach. Ecol Econ 92:16–24. https://doi.org/10.1016/j.ecolecon.2013.04.006

Shi Q, Chen J, Shen L (2017) Driving factors of the changes in the carbon emissions in the Chinese construction industry. J Clean Prod 166:615–627. https://doi.org/10.1016/j.jclepro.2017.08.056

Shuai C, Shen L, Jiao L, Wu Y, Tan Y (2017) Identifying key impact factors on carbon emission: evidences from panel and time-series data of 125 countries from 1990 to 2011. Appl Energy 187:310–325. https://doi.org/10.1016/j.apenergy.2016.11.029

Song M, Wang S, Lei L, Zhou L (2019) Environmental efficiency and policy change in China: a new meta-frontier non-radial angle efficiency evaluation approach. Process Saf Environ Prot 121:281–289. https://doi.org/10.1016/j.psep.2018.10.023

Wang Z, Feng C (2015) Sources of production inefficiency and productivity growth in China : a global data envelopment analysis. Energy Econ 49:380–389. https://doi.org/10.1016/j.eneco.2015.03.009

Wang Z, He W (2017) CO2 emissions efficiency and marginal abatement costs of the regional transportation sectors in China. Transp Res Part D Transp Environ. 50:83–97. https://doi.org/10.1016/j.trd.2016.10.004

Wang K, Yang K, Wei Y-M, Zhang C (2018) Shadow prices of direct and overall carbon emissions in China’s construction industry: a parametric directional distance function-based sensitive estimation. Struct Chang Econ Dyn 47:180–193. https://doi.org/10.1016/j.strueco.2018.08.006

Wang Y, Duan F, Ma X, He L (2020) Carbon emissions efficiency in China : key facts from regional and industrial sector. J Clean Prod 206:850–869. https://doi.org/10.1016/j.jclepro.2018.09.185

Wu L, Chen Y, Reza M (2019) Study on the estimation, decomposition and application of China’ s provincial carbon marginal abatement costs. J Clean Prod 207:1007–1022. https://doi.org/10.1016/j.jclepro.2018.10.082

Xian Y, Wang K, Shi X, Zhang C, Wei YM, Huang Z (2018) Carbon emissions intensity reduction target for China’s power industry: an efficiency and productivity perspective. J Clean Prod 197:1022–1034. https://doi.org/10.1016/j.jclepro.2018.06.272

Yang L, Wang KL, Geng JC (2018) China’s regional ecological energy efficiency and energy saving and pollution abatement potentials: an empirical analysis using epsilon-based measure model. J Clean Prod 194:300–308. https://doi.org/10.1016/j.jclepro.2018.05.129

Zhang N, Wang B (2015) A deterministic parametric metafrontier Luenberger indicator for measuring environmentally-sensitive productivity growth: a Korean fossil-fuel power case. Energy Econ 51:88–98. https://doi.org/10.1016/j.eneco.2015.06.003

Zhang X, Wang F (2017) Life-cycle carbon emission assessment and permit allocation methods: a multi-region case study of China’s construction sector. Ecol Indic 72:910–920. https://doi.org/10.1016/j.ecolind.2016.09.023

Zhang XP, Tan YK, Tan QL, Yuan JH (2012) Decomposition of aggregate CO2 emissions within a joint production framework. Energy Econ 34:1088–1097. https://doi.org/10.1016/j.eneco.2011.09.006

Zhang X, Xu Q, Zhang F, Guo Z, Rao R (2014) Exploring shadow prices of carbon emissions at provincial levels in China. Ecol Indic 46:407–414. https://doi.org/10.1016/j.ecolind.2014.07.007

Zhang Y, Yan D, Hu S, Guo SY (2019) Modelling of energy consumption and carbon emission from the building construction sector in China, a process-based LCA approach[J]. Energy Policy 134:110949. https://doi.org/10.1016/j.enpol.2019.110949

Zhou P, Zhou X, Fan LW (2014) On estimating shadow prices of undesirable outputs with efficiency models : a literature review. Appl Energy 130:799–806. https://doi.org/10.1016/j.apenergy.2014.02.049

Zhou X, Fan LW, Zhou P (2015) Marginal CO2 abatement costs : findings from alternative shadow price estimates for Shanghai industrial sectors. Energy Policy 77:109–117. https://doi.org/10.1016/j.enpol.2014.12.009

Funding

The research work was supported by the National Social Science Foundation of China [Grant No. 16CJY028]. The Fundamental Research Funds for the Central Universities [Grant No. 300102238303, 300102239617, 300102230615, 300102230706].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations of interest

The authors declare no conflict of interest.

Additional information

Responsible Editor: Eyup Dogan

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Du, Q., Wu, J., Cai, C. et al. Carbon mitigation by the construction industry in China: a perspective of efficiency and costs. Environ Sci Pollut Res 28, 314–325 (2021). https://doi.org/10.1007/s11356-020-10412-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-10412-z