Abstract

The present study investigated the effect of thermo-chemical pretreatment on the enhancement of enzymatic digestibility of olive mill stones (OMS), as well as its possible valorisation via bioconversion of the generated free sugars to alcohols. Specifically, the influence of parameters such as reaction time, temperature, type and concentration of dilute acids and/or bases, was assessed during the thermo-chemical pretreatment. The hydrolysates and the solids remaining after pretreatment, as well as the whole pretreated slurries, were further evaluated as potential substrates for the simultaneous production of ethanol and xylitol via fermentation with the yeast Pachysolen tannophilus. The digestibility and overall saccharification of OMS were considerably enhanced in all cases, with the maximum enzymatic digestibility observed for dilute sodium hydroxide (almost 4-fold) which also yielded the highest total saccharification yield (91% of the total OMS carbohydrates). Ethanol and xylitol yields from the untreated OMS were 28 g/kg OMS and 25 g/kg OMS, respectively, and were both significantly enhanced by pretreatment. The highest ethanol yield was 79 g/kg OMS and was achieved by the alkali pretreatment and separate fermentation of hydrolysates and solids, whereas the highest xylitol yield was 49 g/kg OMS and was obtained by pretreatment with sulphuric acid and separate fermentation of hydrolysates and solids.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocellulosic biomass has drawn worldwide attention in the past decades, as a promising and sustainable 2nd-generation alternative feedstock for the production of biofuels and other high added-value products. Lignocellulosic biomass is abundant throughout the world and depending on its moisture level and composition it may be stored for a long period of time without deterioration, contributing to the financial sustainability of lignocellulosic biorefineries (Athmanathan and Mosier 2011; Towey et al. 2019). Lignocellulosic materials include different types of wastes and residues of plant origin, such as softwood, hardwood, yard trimmings, food and paper industry wastes and agro-industrial residues, and consist mainly of cellulose, hemicellulose and lignin in different ratios (Stamatelatou et al. 2012). Cellulose contained in the lignocellulosic biomass has a high crystalline structure and is embedded in an amorphous matrix of hemicellulose and lignin, with the latter exhibiting a remarkable resistance against chemical and microbial attack. Due to their recalcitrant nature, lignocellulosic carbohydrates, i.e. cellulose and hemicellulose, can hardly be directly fermented; specific enzymes are required for their further valorisation and hydrolysis towards their monomers (Hutnan et al. 2000), whereas a pretreatment process is also required in order to facilitate enzyme accessibility (Stamatelatou et al. 2012).

Pretreatment of the lignocellulosic biomass can result to its partial dissolving, resulting to the generation of a liquid fraction, the hydrolysate, and a solid fraction that is more vulnerable to enzymatic hydrolysis. As such, pretreatment is considered a crucial step for the facilitation of saccharification. However, in case of further exploitation of hydrolysates via fermentation, an inhibition can be noted due to the formation of inhibitory substances. Thus, the pretreatment methodology selected has to be optimised against several criteria. Different pretreatment methods have been developed for the removal of both structural and compositional barriers, thus improving the yield of the enzymatic hydrolysis of lignocelluloses (Monlau et al. 2013; Siddhu et al. 2019; Tsolcha et al. 2018; Hermosilla et al. 2020). Among them, dilute acid pretreatment has been widely applied for the efficient hydrolysis of hemicellulose into monomeric sugars and the structural transformation of other biomass components, improving thus cellulose conversion (Lima et al. 2013; Antonopoulou et al. 2015; Demiray et al. 2019). However, under severe conditions, compounds such as furaldehydes (furfural and 5-hydroxymethylfurfural (5-HMF)) and acids (i.e. formic and acetic acid) are formed (Cao et al. 2012; Antonopoulou et al. 2016). Alkaline methods, mainly based on NaOH addition, have also been widely proposed, since they cause a partial lignin removal and lignocellulosic biomass swelling, facilitating further enzymatic hydrolysis (Alexandropoulou et al. 2017; Kontogianni et al. 2019; Novakovic et al. 2020). Alkali pretreatment can lead though to the generation of phenolic compounds in the hydrolysates, which could have an inhibitory effect during subsequent fermentations (Antonopoulou et al. 2016). It can therefore be deduced that the selection of the most efficient pretreatment methodology has to be made based on various criteria such as the composition of biomass, the type of bioprocess, the selectivity and tolerance of the microorganisms used etc. In this context, in the present study different pretreatment methodologies and fermentation schemes were assessed for the valorisation of olive mill stones (OMS).

Bioethanol production from second-generation biomass has been extensively investigated in the previous decades (Toor et al. 2020). In this context a lot of research has focused on the sustainable exploitation not only of the cellulosic fraction but also of the hemicellulosic fraction of the biomass, not always leading though to efficient yields. An alternative approach could be the simultaneous production of ethanol and xylitol by microorganisms that can convert C6 and C5 sugars to ethanol and xylitol (Beutler 1988), respectively. Indeed, xylitol is included in the top 12 high added-value intermediate chemicals that can be produced from biomass (Li et al. 2013). It is mostly used in the food industry as a sweetener of low calorific value, substituting sugar but it is also a platform chemical with many other applications (Vallejos and Area 2017).

The aim of the present study was to investigate the effect of mild thermo-chemical pretreatment on the enzymatic digestibility of OMS, which is the solid residue remaining after olive oil production in three-phase olive mills. OMS is an agroindustrial lignocellulosic waste, quite abundant in the Mediterranean area, where olive oil production via three-phase olive mills is still in use. It is mainly valorised in rural areas as alternative fuel of high energetic value via its direct combustion, after having extracted the residual oil by secondary extraction using organic solvents (Ruiz et al. 2017). However, there is a legal barrier to the use of OMS as a fuel in Greece; its use for direct energy recovery via combustion is prohibited, unless it has been properly authorised by the authorities (Government Gazettes Β 1388/13.07.09; Β 2654/09.11.11; Β 2499/4.10.2013). As an alternative way of management and valorisation of OMS, its saccharification and further bioconversion via microbial processes have been proposed (Senkevich et al. 2012; Saleh et al. 2014; Ruiz et al. 2017; Antonopoulou et al. 2019). In this context, in the frame of the present study, acidic and alkaline pretreatment methods of the whole OMS biomass, without removing residual oil, were investigated under various conditions, and the pretreated biomass was subsequently subjected to enzymatic hydrolysis aiming to maximise the release of free sugars from the complex lignocellulosic matrix. The possible further valorisation of OMS via fermentation was evaluated for the simultaneous production of ethanol and xylose via the yeast Pachysolen tannophilus either after separation of the hydrolysates from the remaining solids and fermentation of the individual fractions separately or by direct fermentation of the whole slurry resulting from pretreatment. As biocatalyst, the yeast P. tannophilus was selected, based on the following: the reported tolerance of P. tannophilus to phenolic compounds, which are already contained in OMS (~ 0.65 g/L of fermentation media for solids loading 5%) and which also may be released during degradation of lignin (Saleh et al. 2014); the ability of P. tannophilus to consume C5 sugars, i.e. xylose and arabinose (Sathesh-Prabu and Murugesan 2011; Senkevich et al. 2012), which are the hydrolysis products of hemicellulose and correspond to ~ 45% of the holocellulosic content of OMS; and the ability of P. tannophilus to ferment xylose to xylitol, adding thus extra value in the procedure of valorising OMS.

To our knowledge, it is the first time that the effect of pretreatment on the enzymatic digestibility of OMS and the comparison of ethanol and xylitol yields after separate fermentation of hydrolysates and remaining solids and direct fermentation of the whole pretreated slurry, were studied.

Materials and methods

Olive mill stones

OMS were obtained from a three-phase olive mill in Patras, Greece. They were collected in plastic tanks, immediately after the olive extraction process, and were stored at − 21 °C until further processing. Prior to pretreatment or fermentation, the OMS biomass was dried at 70 °C. In order to reduce the particle size and to homogenise the dried biomass, it was then milled using a stainless steel grinder and sieved so as to collect particles of < 1 mm diameter. The final OMS product was characterised and stored at ambient temperature. The compositional characteristics of the final OMS dry product are summarised in Table 1.

Thermal and thermo-chemical pretreatment

Thermal and thermo-chemical treatment experiments were conducted in triplicate in serum vials of 160 ml total volume. In them 50 ml of water or H2SO4, H3PO4 or NaOH solutions, as well as 2.5 g of milled OMS were placed, corresponding to 5% solids loading (5 g/100 ml of added liquid). The vials were sealed with rubber septa, crimped with aluminium seals and thermally treated at various temperatures. After cooling down, the mixture was filtered under vacuum using glass fibre filters (Whatman GF/F 0.7 μm). The pretreated remaining solids (PRS) were washed with distilled water until neutralisation of the pH and were subsequently air dried.

The severity of each pretreatment method applied was calculated by Eq. (1) (Larsson et al. 1999) for thermal and Eq. (2) (Pedersen and Meyer 2010) for acid and alkali pretreatment.

where R0 and R′0 are the dimensionless severity factors; t is the reaction time (min); T is the pretreatment temperature (°C); 100 °C is the temperature of reference; 14.75 is an empirical parameter related to the activation energy, assuming pseudo-first-order kinetics; and pH the resulting pH of the different acidic and alkali suspensions of OMS.

The different conditions tested are summarised in Table 2. The values of R0 for the thermal pretreatment of OMS ranged from 0.79 to 2.9 (Fig. 1a). The values of R′0 of for the thermo-chemical pretreatment of OMS ranged from 7.09 to 8.96 and 6.59 to 8.09, in the case of acid and alkali pretreatment, respectively.

Enzymatic hydrolysis

All enzymatic digestibility experiments were conducted in duplicate in vials of 30-ml total volume. In each, 0.5 g of dried PRS was placed with 7 ml of distilled water. The pH of the mixture was adjusted to 4.8 and was supplemented with 30 FPU Celluclast 1.5L/g TS and 40FPU Novozyme 188/g TS and water, so as to reach a total liquid volume of 10 ml, corresponding to 5% solids loading. The suspensions were incubated at 40 °C, under constant agitation at 150 rpm. Aliquots were removed from the suspension at 3 h, 24 h, and 48 h and the concentration of dissolved sugars was determined. The saccharification yield was determined at 48 h of incubation.

Fermentation experiments

Fermentations were performed using the yeast P. tannophilus CECT 1426, supplied by the Spanish Type Culture Collection in freeze-dried form. The yeast was revived and stored at 4 °C in slant solid cultures in a medium with the following composition (in g/L): malt extract 20; myco-peptone 1; d-glucose 20; agar 15. Inoculation was performed under sterile conditions with overnight pre-cultures with medium of the above composition, using the microbial pellet that was obtained via centrifugation of a pre-culture aliquot of volume corresponding to 10% of the final culture volume. The pretreated OMS-based substrates that were used in the fermentation tests were of three types, i.e. whole pretreated slurries, OMS hydrolysates and PRS. The above resulted after thermal pretreatment of OMS at 121 °C for 45 min and thermo-chemical pretreatment of OMS at 121 °C for 45 min in different solutions of either H2SO4, H3PO4 or NaOH. In all cases, the pH was adjusted to 4.8 with 4 N NaOH or 4 N HCl prior to fermentation, whereas in the case of slurries and PRS the fermentation media were also supplemented with 30 FPU Celluclast 1.5L/g TS and 40FPU Novozyme 188/g TS as in the hydrolysis experiments and were incubated at 40 °C for 3 h prior to inoculation. Upon inoculation, cultures were incubated at 27 °C, in order to carry out simultaneous saccharification and fermentation (SSF). All fermentation tests were carried out in duplicate, in 50-ml vials and 20-ml working volume in batch mode, under sterile, micro-aerophilic conditions, at 27 °C and constant agitation of 100 rpm. Fermentation media were supplemented with KH2PO4, MgSO4, (NH4)2SO4 1 g/L.

The yields of ethanol (YEtOH) and xylitol (YXylOH) from the consumed carbohydrates during fermentation of the various substrates tested were estimated according to Eqs. (3) and (4), respectively.

The fermentation efficiencies of ethanol (FEEtOH) and xylitol (FEEtOH) in terms of OMS valorisation were estimated according to Eqs. (5) and (6), respectively.

Analytical methods

Total solids (TS), ash content, and Τotal Kjeldahl Νitrogen (TKN) were quantified according to standard methods (APHA, AWWA, WPCF 1995). Crude protein content was determined by multiplying TKN by a factor of 6.25 (Monlau et al. 2012). Total and soluble carbohydrates were quantified according to DuBois et al. (1956). Cellulose, hemicellulose and lignin were determined according to the National Renewable Energy Laboratory (NREL)’s standard laboratory analytical procedure (LAP) for the determination of structural carbohydrates in biomass (Sluiter et al. 2008). Phenolic compounds were determined spectrophotometrically according to the Folin–Ciocalteau method (Waterman and Mole 1994). Ethanol and xylitol were quantified via HPLC-RI (Shodex) with an Aminex HPΧ–87H column (Biorad) according to Ntaikou et al. (2018), and an Aminex HPΧ–87C column (Biorad) at 70 °C with 30% acetonitrile/H20 mobile phase and flow rate of 0.3 mL min−1, respectively.

Results and discussion

Enhancement of saccharification of OMS

The present study aimed to identify methodologies for the exploitation of OMS that would have low requirements in terms of added chemicals, equipment used and energy inputs, thus methods that would be as mild as possible and cost efficient. As such, low temperatures were selected for the pretreatment of OMS, as shown in Table 2. Subsequently, the hydrolysate was separated from the solids via filtration, and the following evaluations were carried out: (a) the efficiency of each method applied against the direct saccharification yield due to pretreatment, estimated as % directly released sugars on the basis of the sugar content in the initial total carbohydrates of OMS (w/w); (b) the effect of each pretreatment method on the enzymatic digestibility of the PRS, estimated as % saccharification of the initial complex carbohydrates content of PRS; and (c) the overall saccharification yields, expressed as g free sugars released from both pretreatment and hydrolysis steps per kg of OMS.

Effect of thermal pretreatment

The saccharification yields of OMS subjected to temperatures from 70 to 130 °C for 45 min and 120 min are illustrated in Fig. 1. It is apparent that the direct release of free sugars is negligible for temperatures below 121 °C, whereas, even at the highest temperature applied, less than 10% of the carbohydrate content of the OMS is solubilised. This observation is in agreement with previous studies on other types of lignocellulosic biomass, according to which, for the efficient fractionation of the lignocellulose during thermal pretreatment, temperatures above 160 °C are required (Rajput and Zeshan 2018). This can be attributed to the decrease of the pH that is observed during the treatment at higher temperatures, due to the release of organic acids from the lignocellulosic biomass (Rajput and Zeshan 2018). Indeed, thermal pretreatment at high temperatures is reported to cause partial solubilisation of hemicellulose and its subsequent degradation towards acids, which further enhances the chemical hydrolysis of hemicellulose (Ferreira et al. 2018). As also shown in Fig. 1b, the enzymatic digestibility of the OMS is hardly affected by the thermal pretreatment in the range of the temperatures tested, regardless of the time of treatment. Indeed even for treatment at 130 °C for 2 h, the complex structure of lignocellulose is only slightly influenced, with the saccharification yields hardly reaching 9%. Consequently, the enzymatic attack was not facilitated appreciably.

Effect of combined thermal and chemical pretreatment

In order to investigate the combined effect of thermal and chemical treatment, OMS was further exposed to two different acids, i.e. sulphuric (SA) and phosphoric acid (PA), and an alkali, i.e. sodium hydroxide (SH), during heating at the same range of temperatures that were previously tested. Since the time of thermal treatment did not seem to have any effect on the saccharification of OMS, pretreatment for 45 min was selected, as less energy demanding. The results concerning direct saccharification and hydrolysis are shown in Fig. 2 a and b, respectively. It is of great interest that in the presence of either SA or PA almost 40% of the complex carbohydrates of the OMS are actually hydrolysed at the higher temperatures (an ~ 8-fold increase), whereas at the lower temperatures tested, i.e. 70 °C and 100 °C, the saccharification yield was below 5%. According to the literature, the main reaction that occurs during acid pretreatment is the hydrolysis of hemicellulose, especially xylan, since glucomannan is more stable. Under acidic conditions furfural and hydroxymethylfurfural (HMF) generation can also form as a result of xylose and galactose, mannose and glucose dehydration, respectively (Carrere et al. 2016). This, however, can be avoided if mild conditions are selected (Xavier et al. 2018). On the other hand, SH seems to have almost the same effect on the direct saccharification of carbohydrates for all temperatures tested, which is considerably lower than the saccharification yields achieved from acid pretreatment.

Saccharification yields a after thermo-chemical pretreatment of OMS for 45 min at different temperatures using different chemical agents, and b after enzymatic hydrolysis of the pretreated remaining solids (PRS), measured as % released sugars per initial complex carbohydrate content in each case. CRL, control (no pretreatment); THM, thermal pretreatment; SA, sulphuric acid 15‰ (v/v); PA, phosphoric acid 15% (v/v); SH, sodium hydroxide 15‰ (w/v)

Regarding the effect of thermo-chemical pretreatment on the enzymatic digestibility of PRS, it can be noted that its effectiveness depends on the chemical agent used, with SH leading to the highest saccharification (Fig. 2b). The digestibility seems also to be enhanced by higher temperatures. Indeed, the saccharification yield increased from 48 to 90% during hydrolysis of SH when pretreated OMS at 70 °C and 130 °C, respectively. This can be attributed to the lignin breakdown that is imposed by alkali pretreatment, and also to the decrease of polymerisation degree and crystallinity of the cellulose (Mosier et al. 2005). As such, SH did not lead to direct release of sugars but enhanced greatly the enzymatic digestibility of the OMS.

The enzymatic digestibility of acid-pretreated OMS seems to be less affected, reaching 62% (SA, 130 °C). It should be noted, however, that an increasing tendency is noted on the enzymatic digestibility of PRS for both acids in the range of temperatures tested. The lower saccharification degree when using acids compared with alkali is in agreement with the literature, according to which, the remaining cellulose in the pretreated biomass is less vulnerable to hydrolysis, since it is protected from the lignin seal. Indeed, lignin is reported to be hardly dissolved in most cases of acidic pretreatment, but it can be disrupted to a high degree, leading thus to increased cellulose susceptibility to enzymes (Yang and Wyman 2004). The final saccharification yields after the different pretreatments are summarised in Table 3. As shown, the highest yield was 445 g free sugars/kg OMS corresponding to hydrolysis of 89% of the complex carbohydrates of OMS that was noted for 1.5% SH at 130 °C. The second highest yield was 422 g free sugars/kg OMS, noted for 1.5% SH at 121 °C, corresponding to 85% hydrolysis of the complex carbohydrates of OMS.

Effect of concentration of acids and alkali during thermo-chemical pretreatment

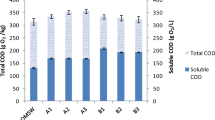

The effect of saccharification of OMS after thermo-chemical pretreatment was further investigated in terms of the concentration of chemical agents. For that reason, pretreatment for 45 min at 121 °C was applied using 5, 10 and 15‰ (v/v) of SA; 5, 10 and 15%, (v/v) PA; and 5, 10 and 15‰ (w/v) SH. The results of direct sugar release and enzymatic saccharification are illustrated in Fig. 3a and b, respectively. It can be noted that the increasing concentrations of both SA and PA lead to higher saccharification, whereas the increasing tendency of direct saccharification by SH is not statistically significant. Enzymatic saccharification also seems to be affected by the concentration of the chemical agent for both acids. It is of great interest though that in the case of alkali treatment, the saccharification yields also increase for increasing concentration of the chemical agent. The on-going study of the structural changes of OMS due to pre-treatment is expected to provide important information towards the explanation of these findings.

Saccharification yields (a), after thermo-chemical pretreatment of OMS at 121 °C, for 45 min with different concentrations on chemical agents and (b) after enzymatic hydrolysis of the pretreated remaining solids (PRS), measured as % released sugars per initial complex carbohydrate content in each case. CRL, control (no pretreatment); THM, thermal pretreatment; SA, sulphuric acid; PA, phosphoric acid; SH, sodium hydroxide. 5 and 15 after each abbreviation refer to the concentration of the aquatic solution of SA (‰ v/v), PA (% v/v) and HS (‰ w/v) during pretreatment

Alcoholic fermentation of pretreated OMS

The enhancement of the digestibility of OMS by to pretreatment was further assessed via its fermentation to ethanol and xylitol. Alcoholic production from the hydrolysates, the PRS and the whole pretreated slurry was assessed, and yields were compared in order to investigate the possible inhibitory effect of sugar degradation products on the fermentation process. Consequently, as fermentation substrates, thermally (121 °C for 45 min) and thermo-chemically (by addition of either H2SO4, H3PO4 or NaOH at 121 °C for 45 min) pretreated OMS were used. In the case of PRS and slurry fermentation, the media were supplemented with 30 FPU Celluclast 1.5L/g TS and 40FPU Novozyme 188/g TS as in the hydrolysis experiments and were incubated at 40 °C for 3 h prior to inoculation.

The maximum theoretical yields of ethanol (YEtOH_max) and xylitol (YXylOH-max) production during fermentation were assumed to be 0.51 g EtOH/g consumed hexose, 0.51 g EtOH/g consumed pentose and 0.91 g XylOH/g consumed xylose, based on Eqs. (7), (8) and (9) respectively, according to which, 2 mol of ethanol per mol of hexose, 1.67 mol of ethanol per mol of pentose and 0.9 mol of xylitol per mol of xylose are generated, respectively.

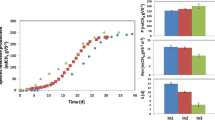

The YEtOH from the fermented hydrolysates, PRS and slurries that were generated from different pretreatment types are illustrated in Fig. 4. It is apparent that the acidic hydrolysates, either via SA or PA, exhibited the lowest yields, which ranged from 0.13 g EtOH/g carb. to 0.16 EtOH/g carb. corresponding to 25% and 31% of the YEtOH_max. The YEtOH from alkali-pretreated hydrolysates were considerably higher, i.e. 0.21 g EtOH/g carb. and 0.19 g EtOH/g carb., corresponding to 42% and 37% of the YEtOH_max. The lowest yields of acidic hydrolysates compared with the alkali ones can be attributed to the type of sugars that are contained in each type. As such, acidic hydrolysates consist of C5 sugars, i.e. xylose and arabinose that are generated upon disruption of the hemicellulose. As previously reported (Sathesh-Prabu and Murugesan 2011; Senkevich et al. 2012; Saleh et al. 2014), the fermentation of such substrates by P. tannophilus strains leads in general to lower ethanol yields than those obtained from C6 sugars. Moreover, xylose fermentation by P. tannophilus is mainly forwarded to xylitol production (Carvalho et al. 2004; Romero et al. 2007; Saleh et al. 2014; Xavier et al. 2018) and as such, lower ethanol yields should be expected. On the contrary, ethanol yields from the acid-pretreated residues are comparatively higher than those of the alkali-pretreated ones. This could be due to the fact that the acid PRS are almost free of xylose, which is released in the hydrolysates (Saleh et al. 2014) and as such fermentation towards ethanol is favoured.

Ethanol yields from hydrolysates (a), pretreated remaining solids (PRS) (b) and whole OMS slurries (c) derived from thermo-chemical pretreatment of OMS at 121 °C, for 45 min with different concentrations of chemical agents. THM, thermally pretreated OMS; SA, sulphuric acid; PA, phosphoric acid; SH, sodium hydroxide; SA.H, sulphuric acid hydrolysate of OMS; PA.H, phosphoric acid hydrolysate of OMS; SH.H, sodium hydroxide hydrolysate of OMS; SA.S, sulphuric acid–pretreated solids; PA.S, phosphoric acid pretreated solids; SH.S, sodium hydroxide–pretreated solids. 5 and 15 after each abbreviation refer to the concentration of the aquatic solution of SA (‰ v/v), PA (% v/v) and HS (‰ w/v) during pretreatment

The overall efficiencies of OMS biotransformation, i.e. the FEEtOH and FEXylOH, were also assessed and are presented in Table 4 and Table 5. In order to evaluate the obtained results, the maximum theoretical estimated fermentation efficiencies for ethanol (FEETOH_max) and xylitol (FEXylOH_max) were also estimated, having the values 253.3 ± 10.8 g EtOH/kg OMS and 185.7 ± 9.4 g XylOH/kg OMS, respectively. Those were estimated based on Eqs. (7), (8) and (9) and the overall carbohydrate content of OMS, which could theoretically be completely converted to ethanol or the xylan content, which could theoretically be completely converted to xylitol. It can be noted that the obtained FEs for both alcohols were considerably lower compared with the theoretical ones. The optimum FEEtOH and FEXylOH were both observed for the separated fermentation of hydrolysates and PRS, after pretreatment with SH0.5 and SA1.5, reaching values of 31% and 26% to the corresponding theoretical values, respectively. It can be observed that all types of pretreatment enhanced the bioconversion of the waste compared with the control. The relative increase of alcohol production compared with the control is more dramatic in the case of ethanol. Indeed the ethanol yield increased by 180% (for separate fermentation SH1.5 fractions), whereas the xylitol yield increased by 90% compared with the control (for separate fermentation SA1.5 fractions). This could be due to the fact that cellulose bioconversion is greatly facilitated after alkali pretreatment due to its optimised hydrolysis. In general the separate fermentation of hydrolysates and solids seemed to favour the production of ethanol after alkali pretreatment of the biomass. This could also be attributed to the elimination of the inhibitory effect of phenolics which remain in the hydrolysate, and as such the fermentation of free of phenolics PRS is optimised.

The recovery of ethanol per kg of OMS obtained from different types of PRS in the present study is comparable with those obtained in the study of Antonopoulou et al. (2019), in which the whole pretreated (at similar conditions) biomass without separation of hydrolysates from the solids was fermented using the P. tannoplilus strain DSMZ 70352. Saleh et al. (2014), using the rich in xylose acid hydrolysates of olive stones as fermentative substrate via P. tannoplilus strain ATCC32691, observed that xylitol formation is considerably favoured over ethanol. This is in agreement with the findings of the present study, since as shown in Table 4 and Table 5, the acid hydrolysates resulted in relatively higher xylitol yields than ethanol yields, in all cases.

Conclusions

The application of thermal pretreatment alone on OMS did not achieve efficient hydrolysis of the lignocellulosic biomass in the range of temperatures tested, i.e. from 70 to 130 °C. However, the biomass that was pretreated at 121 °C and 130 °C was more vulnerable to enzymatic hydrolysis than the non-pretreated control OMS samples. The combined thermal and acid pretreatment on the other hand led to high solubilisation of OMS, reaching 40% saccharification of the OMS carbohydrates for temperatures above 121 °C, whereas it also enhanced the subsequent enzymatic digestibility. The combined thermal and alkali pretreatment, although it does not enhance the direct saccharification of OMS compared with thermo-acid pretreatment, seems to facilitate greatly the subsequent enzymatic digestibility of OMS. A very significant enhancement of the alcohol yields, especially that of ethanol, was achieved by the pretreatment.

References

Alexandropoulou M, Antonopoulou G, Fragkou E, Ntaikou I, Lyberatos G (2017) Fungal pretreatment of willow sawdust and its combination with alkaline treatment for enhancing biogas production. J Environ Manag 203:704–713. https://doi.org/10.1016/j.jenvman.2016.04.006

Antonopoulou G, Dimitrellos G, Beobide AS, Vayenas D, Lyberatos G (2015) Chemical pretreatment of sunflower straw biomass: the effect on chemical composition and structural changes. Waste Biomass Valor 6:733–746. https://doi.org/10.1007/s12649-015-9388-x

Antonopoulou G, Vayenas D, Lyberatos G (2016) Ethanol and hydrogen production from sunflower straw: the effect of pretreatment on the whole slurry fermentation. Biochem Eng J 116:65–74. https://doi.org/10.1016/j.bej.2016.06.014

Antonopoulou G, Kampranis A, Ntaikou I, Lyberatos G (2019) Enhancement of liquid and gaseous biofuels production from agro-industrial residues after thermo-chemical and enzymatic pretreatment. Front Sustain Food Syst 3. https://doi.org/10.3389/fsufs.2019.00092

APHA, AWWA, WPCF (1995) Standard methods for the examination of water and wastewater. MA Franson (Ed.) American Public Health Association, Washington, DC

Athmanathan A, Mosier NS (2011) Effect of storage method and duration on the bioprocessing of lignocellulosic biomass. 11AIChE - 2011 AIChE annual meeting, conference proceedings

Beutler HO (1988) Xylitol. In: Beutler HU (ed) Methods of enzymatic analysis, vol VI, 3rd edn. VCH Publishers (UK) Ltd., Cambridge, pp 484–490

Cao S, Pu Y, Studer M, Wyman C, Ragauskas AJ (2012) Chemical transformations of Populus trichocarpa during dilute acid pretreatment. RSC Adv 2:10925–10936. https://doi.org/10.1039/C2RA22045H

Carrere H, Antonopoulou G, Affes R, Passos F, Battimelli A, Lyberatos G, Ferrer I (2016) Review of feedstock pretreatment strategies for improved anaerobic digestion: from lab-scale research to full-scale application. Bioresour Technol 199:386–397. https://doi.org/10.1016/j.biortech.2015.09.007

Carvalho W, Batista MA, Canilha L, Santos JC, Converti A, Silva SS (2004) Sugarcane bagasse hydrolysis with phosphoric and sulfuric acids and hydrolysate detoxification for xylitol production. Chem Technol Biotechnol 79:1308–1312. https://doi.org/10.1002/jctb.1131

Demiray E, Karatay SE, Donmez G (2019) Improvement of bioethanol production from pomegranate peels via acidic pretreatment and enzymatic hydrolysis. Environ Sci Pollut Res 26:29366–29378. https://doi.org/10.1007/s11356-019-06020-1

DuBois M, Gilles K, Hamilton J, Rebers P, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Ferreira JA, Brancoli P, Agnihotri S, Bolton K, Taherzadeh MJ (2018) A review of integration strategies of lignocelluloses and other wastes in 1st generation bioethanol processes. Process Biochem 75:173–186. https://doi.org/10.1016/j.procbio.2018.09.006

Hermosilla E, Schalchli H, Diez MC (2020) Biodegradation inducers to enhance wheat straw pretreatment by Gloeophyllum trabeum to second-generation ethanol production. Environ Sci Pollut Res 27:8467–8480. https://doi.org/10.1007/s11356-019-07460-5

Hutnan M, Drtil M, Mrafkova L (2000) Anaerobic biodegradation of sugar beet pulp. Biodegradation 11:203–211. https://doi.org/10.1023/A:1011139621329

Kontogianni N, Barampouti EM, Mai S, Malamis D, Loizidou M (2019) Effect of alkaline pretreatments on the enzymatic hydrolysis of wheat straw. Environ Sci Pollut Res 26:35648–35656. https://doi.org/10.1007/s11356-019-06822-3

Larsson S, Palmqvist E, Hahn-Hagerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant N-O (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzym Microb Technol 24:151–159. https://doi.org/10.1002/btpr.2102

Li Z, Qu H, Li C, Zhou X (2013) Direct and efficient xylitol production from xylan by Saccharomyces cerevisiae through transcriptional level and fermentation processing optimizations. Bioresour Technol, 149: 413–419. https://doi.org/10.1016/j.biortech.2013.09.101

Lima CSS, Conceicao MM, Silva FLH, Lima EE, Conrado LS, Leao DAS (2013) Characterization of acid hydrolysis of sisal. Appl Energy 102:254–259. https://doi.org/10.1016/j.apenergy.2012.09.061

Monlau F, Barakat A, Steyer JP, Carrere H (2012) Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks. Bioresour Technol 120:241–247. https://doi.org/10.1016/j.biortech.2012.06.040

Monlau F, Barakat A, Trably E, Dumas C, Steyer J-P, Carrere H (2013) Lignocellulosic materials into biohydrogen and biomethane: impact of structural features and pretreatment. Crit Rev Environ Sci Technol 43:260–322. https://doi.org/10.1080/10643389.2011.604258

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686. https://doi.org/10.1016/j.biortech.2004.06.025

Novakovic J, Kontogianni N, Barampouti EM, Mai S, Moustakas K, Malamis D, Loizidou M (2020) Towards upscaling the valorization of wheat straw residues: alkaline pretreatment using sodium hydroxide, enzymatic hydrolysis and biogas production. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-08905-y

Ntaikou I, Menis N, Alexandropoulou M, Antonopoulou G, Lyberatos G (2018) Valorization of kitchen biowaste for ethanol production via simultaneous saccharification and fermentation using co-cultures of the yeasts Saccharomyces cerevisiae and Pichia stipitis. Bioresour Technol 263:75–83. https://doi.org/10.1016/j.biortech.2018.04.109

Pedersen M, Meyer AS (2010) Lignocellulose pretreatment severity—relating pH to biomatrix opening. New Biotechnol 27:739–750. https://doi.org/10.1016/j.nbt.2010.05.003

Rajput AA, Zeshan VC (2018) Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw. J Environ Manag 221:45–52. https://doi.org/10.1016/j.jenvman.2018.05.011

Romero I, Moya M, Sanchez S, Ruiz E, Castro E, Bravo V (2007) Ethanolic fermentation of phosphoric acid hydrolysates from olive tree pruning. Ind Crop Prod 25:160–168. https://doi.org/10.1016/j.indcrop.2006.08.008

Ruiz E, Romero-Garcia JM, Romero I, Manzanares P, Negro MJ, Castro E (2017) Olive-derived biomass as a source of energy and chemicals. Biofuels Bioprod Biorefin 11:1077–1094. https://doi.org/10.1002/bbb.1812

Saleh M, Cuevas M, Garcia JF, Sanchez S (2014) Valorization of olive stones for xylitol and ethanol production from dilute acid pretreatment via enzymatic hydrolysis and fermentation by Pachysolen tannophilus. Biochem Eng J 90:286–293. https://doi.org/10.1016/j.bej.2014.06.023

Sathesh-Prabu C, Murugesan AG (2011) Potential utilization of sorghum field waste for fuel ethanol production employing Pachysolen tannophilus and Saccharomyces cerevisiae. Bioresour Technol 102:2788–2792. https://doi.org/10.1016/j.biortech.2010.11.097

Senkevich S, Ntaikou I, Lyberatos G (2012) Bioethanol production from thermo-chemically pretreated olive mill solid residues using the yeast Pachysolen tannophilus. Global Nest J 14:118–124. https://doi.org/10.30955/gnj.000861

Siddhu MAH, Li W, He Y, Liu G, Chen C (2019) Steam explosion pretreatment of rice straw to improve structural carbohydrates anaerobic digestibility for biomethanation. Environ Sci Pollut Res 26:22189–22196. https://doi.org/10.1007/s11356-019-05382-w

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure

Stamatelatou K, Antonopoulou G, Ntaikou I, Lyberatos G (2012) The effect of physical, chemical, and biological pretreatments of biomass on its anaerobic digestibilty and biogas production. In: Mudhoo A (ed) Biogas production: pretreatment methods in anaerobic digestion. Scrivener Publishing LLC, pp 55–90. https://doi.org/10.1002/9781118404089.ch3

Toor M, Kumar SS, Malyan SK, Bishnoi NR, Mathimani T, Rajendran K, Pugazhendhi A (2020) An overview on bioethanol production from lignocellulosic feedstocks. Chemosphere 242 art. no. 125080. https://10.1016/j.chemosphere.2019.125080

Towey R, Webster K, Darr M (2019) Influence of storage moisture and temperature on lignocellulosic degradation. AgriEngineering 1:332–342. https://doi.org/10.3390/agriengineering1030025

Tsolcha ON, Tekerlekopoulou AG, Akratos CS, Antonopoulou G, Aggelis G, Genitsaris S, Moustaka-Gouni M, Vayenas DV (2018) A Leptolyngbya-based microbial consortium for agro-industrial wastewaters treatment and biodiesel production. Environ Sci Pollut Res 25:17957–17966. https://doi.org/10.1007/s11356-018-1989-z

Vallejos ME, Area MC (2017) Xylitol as bioproduct from the agro and forest biorefinery. Food Bioconversion 2:411–432. https://doi.org/10.1016/B978-0-12-811413-1.00012-7

Waterman PG, Mole S (1994) Analysis of phenolic plant metabolites. Blackwell Scientific Publications, Oxford

Xavier FD, Bezerra GS, Santos SFM, Oliveira LSC, Silva FLH, Silva AJO, Conceicao MM (2018) Evaluation of the simultaneous production of xylitol and ethanol from sisal fiber. Biomolecules 8: art. no. 2. https://doi.org/10.3390/biom8010002

Yang B, Wyman CE (2004) Effect of xylan and lignin removal by batch and flow through pretreatment on the enzymatic digestibility of corn stover cellulose. Biotechnol Bioeng 86:88–95. https://doi.org/10.1002/bit.20043

Funding

We acknowledge financial support of this work by the project “Research infrastructure for Waste Valorization and Sustainable Management of Resources, INVALOR” (MIS 5002495) which is implemented under the “Action for the Strategic Development on the Research and Technological Sector”, funded by the Operational Programme “Competitiveness, Entrepreneurship and Innovation” (NSRF 2014-2020) and co-financed by Greece and the European Union (European Regional Development Fund).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ntaikou, I., Siankevich, S. & Lyberatos, G. Effect of thermo-chemical pretreatment on the saccharification and enzymatic digestibility of olive mill stones and their bioconversion towards alcohols. Environ Sci Pollut Res 28, 24570–24579 (2021). https://doi.org/10.1007/s11356-020-09625-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09625-z