Abstract

A novel combined bioreactor integrating anaerobic baffling and anaerobic filtration process was developed and operated for 210 days to treat low-strength rural wastewater. The effects of hydraulic residence time (HRT) and organic loading rate (OLR) on chemical oxygen demand (COD) removal and methane (CH4) production of the combined bioreactor were investigated. The combined bioreactor can start up successfully in 25 days and achieve enhanced performance. The COD removal rate and CH4 yield were influenced significantly by HRT and OLR. The influent COD was removed effectively through the synergistic effects of the anaerobic baffling and anaerobic filtration. The baffle zone played the main role in the degradation of the pollutants, and the filter zone mainly contributed to improve the resistance to shock loading. High-throughput sequencing technology was used to analyze the bacterial and archaeal community structure and diversity. Clostridium_sensu_stricto, Longilinea, Acetoanaerobium, Arcobacter, and Acinetobacter were found to be the dominant bacteria. While Methanothrix and Methanoregula were the dominant archaea, which were responsible for methane generation. This study not only highlights the good energy recovery and resource utilization potential of the combined bioreactor but also presents significant guidance for the application of the combined anaerobic process for low-strength rural wastewater treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, with the rapid growth of China’s rural economy, the discharge of rural wastewater has gradually increased and the quality of the rural water environment is continually affected (Han et al. 2019). Polluted rivers by rural wastewater are common in many rural areas of China. Some indicators (such as COD and ammonia nitrogen) of water supply sources in many rural areas exceed the prescribed limit in varying degrees by the standards for drinking water quality in China (GB5749-2006). The indiscriminate discharge of rural wastewater not only pollutes the water environment but also causes the waste of water resources (Guest et al. 2009; Fouché et al. 2018). Meanwhile, most of the rural wastewater in China is discharged directly without effective treatment because of the scattered distribution of rural areas, insufficient long-term attention, lack of funds for construction and operation, and weak awareness of water environmental protection (Chen et al. 2006; Ma et al. 2019a; Song et al. 2019). Therefore, inadequate treatment of rural wastewater not only results in the waste of most of the potential resources but also leads to the pollution of the surrounding surface water and groundwater, which brings health risks to residents (Gu et al. 2016; Han et al. 2019; Hu et al. 2015). As one of the important sources of water pollution, rural wastewater has become one of the focus issues of the Chinese government and the public.

Rural wastewater is usually characterized by low COD concentration and high nutrient content such as nitrogen (N) and phosphorus (P), few toxic substances, and good biochemical properties (Chen et al. 2019; Ham et al. 2007). At present, aerobic biological or ecological treatment process is generally used for low-strength rural wastewater treatment. Although high treatment efficiency can be achieved, aerobic biological treatment technology still faces some inevitable shortcomings such as high construction and operation costs, high sludge treatment or disposal costs, and inability to recover the potential energy resources in wastewater. It is reported that the main component of the operational costs in rural wastewater treatment is electricity consumption, which is mainly used for aeration in the aerobic biological treatment process (Mizuta and Shimada 2010). In rural areas of China, the high operational costs of aerobic treatment are often unacceptable. The ecological treatment processes such as constructed wetlands, stabilization ponds, and land infiltration have high treatment efficiency, low investment and operational cost, and simple operation; however, large occupation area and vulnerable treatment efficiency limited its wide-range application (Song et al. 2018; Stefanakis and Tsihrintzis 2012). In contrast, anaerobic biological treatment technology can be applied to rural areas with poor economic conditions and decentralized wastewater production because of its low operating costs, less sludge production, better methane potential, and more convenient management (Hahn and Figueroa 2015; Shoener et al. 2014). Although the conventional single anaerobic process is difficult to reach the discharge standard when it is used as the main process, it can be used as an effective pretreatment process for aerobic or ecological treatment. Simultaneously, after anaerobic biological treatment, carbonaceous organic wastes are greatly reduced, while the concentration of nitrogen and phosphorus is basically unchanged. In this way, the effective separation of organic matter from nutrients like nitrogen and phosphorus can be realized (Chen et al. 2017). The treated effluent can be used as nutrient water for agricultural irrigation or garden utilization. In recent years, with the increasing shortage of resources, energy, and water, the application of anaerobic treatment technology has acquired more and more broad application prospects for low-strength rural wastewater treatment.

The widely used anaerobic biological treatment technologies for rural wastewater mainly include upflow anaerobic sludge blanket reactor (UASB), anaerobic biological filter (AF), and anaerobic baffled reactor (ABR) (Amani et al. 2015; Bodkhe 2008; Mortezaei et al. 2018). For the treatment of low-strength rural wastewater, the above monomeric anaerobic processes have their own advantages, disadvantages, and application range. Due to the low influent organic matter content, the difficulty of cultivating granular sludge, the poor internal mixing effect, and the easy loss of sludge, UASB is usually difficult to achieve better treatment effect (Mortezaei et al. 2018). ABR is an improvement of UASB, which consists of a series of UASB by series connection (Li et al. 2016). ABR has a special compartmentalized structure, which can realize the separation of acidogenesis and methanogenesis of the microbial community along different compartments, and improves the operation stability and methane production of the reactor (Stazi and Tomei 2018). However, to a certain extent, the long start-up time and accumulation of volatile fatty acids limit the application of ABR (Feng et al. 2015; Sayedin et al. 2019; Zhu et al. 2014). The AF process consists of one or more vertical filter beds containing inert media, which is used to intercept and adsorb pollutants and functional microorganisms. For the treatment of low-strength rural wastewater, AF has strong shock load resistance and little sludge production (Stazi and Tomei 2018). As AF is filled with fillers, the accumulation of substrates delays biodegradation over a long period of time, and the treatment performance is usually limited when AF is used alone. Moreover, filler blockage can easily cause short flow and reduce treatment efficiency (Bodkhe 2008). ABR, AF and their modified processes have been extensively applied to treat low-strength wastewater (Stazi and Tomei 2018; Reynaud and Buckley 2015). There have been some studies on the combined process of ABR and AF in low concentration wastewater treatment (Bodík et al. 2002; Renuka et al. 2016). However, the performance and mechanism of the combined bioreactor have yet to be explored systematically. To improve the performance of the combined bioreactor, a detailed understanding and knowledge of microbial community structure is required. However, up to now, the available data of microbial community for combined bioreactor treating low concentration wastewater is limited.

Based on the characteristics of low COD concentration, high nitrogen and phosphorus content, and large fluctuation of water quality and quantity in rural wastewater, single conventional anaerobic technology often fails to achieve the desired results. Moreover, they also commonly confronted with the limitations of long start-up time and low treatment efficiency. That is to say, they cannot effectively achieve the goal of reutilization for rural wastewater. To address the problem, a combined reactor was designed to be divided into anaerobic baffle zone and filter zone. The baffle zone was reasonably partitioned to make different types of anaerobic microorganisms grow and metabolize in different regions. The suspended filler was used to effectively expand the attached biofilm reaction zone and strengthen the mass transfer and microbial reaction. Through the interception, adsorption, and biodegradation of the filter material, the filter zone can improve the removal effect of organic matter, maintain the effluent quality of the reactor, and enhance the ability to anti-shock load. The baffle zone was used as the pre-treatment to remove most SS and dissolved organic matter in the influent, so as to avoid blocking the packing of the filter zone. Therefore, the combined reactor can provide a new strategy to solve the problems of long hydraulic retention time, long start-up time, low COD removal rate, and instability for rural wastewater treatment.

In this study, the performance of the combined reactor integrating anaerobic baffling and anaerobic filtration process to treat low-strength rural wastewater was objectively studied. The removal of COD, N, and P as well as the CH4 production under different HRT and OLR were investigated during the start-up and stable operation period of the combined reactor. Based on the 16S rDNA metagenomic high-throughput sequencing technology, the removal mechanisms of pollutants in the combined reactor were investigated by comprehensively characterizing the dominant population and abundance of bacteria and archaea. The main purpose of this work was to provide a practical reference for the application of a combined anaerobic reactor in low-strength rural wastewater treatment.

Materials and methods

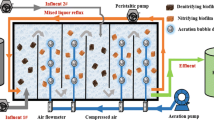

Construction of combined reactor

The combined reactor was made of plexiglass (Fig. 1). The dimensions of the reactor was 80 × 20 × 103 cm3, and the effective volume was 120 L. The reactor consists of an upper baffle zone and a lower filter zone. There were four compartments in the anaerobic baffle zone, each of which was again divided into the upstream chamber and downstream chamber. The upstream chamber was filled with elastic solid filler. The width ratio of the upstream chamber and the downstream chamber was 3:1. At the upper part of the filter zone, a 3-mm aperture plexiglass plate was used as the support plate for the filter material, on which it was filled with the lightweight filter material made of gravel and ceramsite. The particle size of gravel and ceramsite was 5~8 mm and 4~6 mm, respectively, and the filling ratio was 40~50%. Inclined water distribution plate and conical groove were respectively placed in the middle and bottom of the filter zone. The sludge from the anaerobic baffle zone was effectively deposited in the conical groove, which can be refluxed to the baffle zone or discharged, and the blockage of the filter zone can be avoided. The wastewater first entered the baffle zone, and the pollutants that failed to degrade in the baffle zone were further degraded in the filter zone.

Start-up and operation of reactor

The sludge after anaerobic domestication and cultivation was uniformly inoculated into each chamber with a peristaltic pump while stirring, followed by discharge into wastewater. The mixture was allowed to stand for 2 days before the continuous operation. The whole operation period includes the start-up stage (days 0–25) and stable operation stage (days 26–210). The start-up of the reactor adopted the method of keeping the influent concentration unchanged while reducing HRT step by step, and HRT was adjusted from 48 to 33 h and 24 h in sequence. The stable operation period was divided into five stages: A, B, C, D, and E; the corresponding HRT was maintained at 24 h, 18 h, 12 h, 8 h, and 5 h. During the whole operation of the combined reactor, the reaction temperature was maintained at 35 ± 1 °C, and no sludge was discharged. The operating conditions of the combined reactor in each period were shown in Table 1.

Feed wastewater and seed sludge

Actual rural domestic wastewater was used as influent in the combined reactor. During the experiment, the COD concentration in the influent was 187~380 mg/L. The concentration of TP and NH4+-N in the influent were 3.0~7.0 mg/L and 30~60 mg/L, respectively. The value of pH was approximately 6.5~8.5.

The anaerobic sludge used as inoculums was taken from an anaerobic digestion tank of a municipal wastewater treatment plant in Beijing. During the incubation period, some nutrient solution was added, and the supernatant was discharged. In addition, the sludge was stirred occasionally. The characteristics of actual inoculated sludge were shown in Table 2. The inoculation amount of the sludge was approximately 35% of the reactor’s effective volume.

Analytical methods

Chemical oxygen demand (COD), total phosphorus (TP), mixed liquor suspended solids (MLSS), and mixed liquor volatile suspended solids (MLVSS) were measured using standard methods (APHA 2012). The NH4+-N concentration was analyzed by the Nesslerization method at an absorbance of 420 nm using an ultraviolet spectrophotometer (Hach Co., Ltd., DR6000, USA). The total nitrogen (TN) concentration was determined by ultraviolet spectrophotometry with the digestion of basic potassium persulfate at 120~140 °C. The volume of methane gas was measured by a gas chromatograph (Shimadzu, GC2010 Plus, Japan) equipped with a thermal conductivity detector (Chen et al. 2017).

High-throughput 16S rRNA sequencing was used to analyze the bacterial and archaeal community in the reactor. The sludge samples were collected from each compartment of the anaerobic baffle zone during the operation of the combined bioreactor at the HRT of 12 h (on the 106th day). These individual samples were mixed together and used as an analysis sample. Genomic DNA was extracted using the E.Z.N.A. Mag-Bind Soil DNA Kit (Omega, USA)(Xu et al. 2018). The integrity and concentration of extracted DNA were examined by 1% agarose gel electrophoresis. The 16S rRNA gene was amplified in the V3–V4 region with bacterial primers 341F and 805R (5′-CCTACGGGNGGCWGCAG-3′ and 5′-GACTACHVGGGTATCTAATCC-3′), and with archaeal primer 340F and 1000R (5′-CCCTAYGGGGYGCASCAG-3′ and 5′-GGCCATGCACYWCYTCTC-3′). The following PCR was performed: 94 °C reaction for 3 min, then 20 cycles of 20 s at 94 °C, 55 °C for 20 s, 72 °C for 30 s, and final elongation with 5 min at 72 °C. The purified and quantified PCR products were sequenced by Sangon Biotech (Sangon Biotech (Shanghai) Co., Ltd., China) using the Miseq sequencing platform (Illumina, USA). The effective sequences were clustered into OTUs at a similarity threshold of 97% (Su et al. 2019).

Results and discussions

Performance of the combined reactor

The performance of the combined reactor for low-strength rural wastewater treatment was studied under different operation conditions. Figure 2 shows the variations of the concentration of influent and effluent COD and removal efficiency at different HRTs in the start-up and stable operation periods.

During the start-up period of the combined reactor, the influent COD concentration ranged from 187 to 382 mg/L. In the initial stage (days 1–10) of the start-up phase, the reactor performance was poor and unstable, with the effluent COD concentration of 113~190 mg/L. In the middle and late stages (11–25 days) of the start-up phase, the effluent COD concentration of the reactor gradually decreased to a steady value. After day 18, the removal efficiency of COD increased to more than 66.67%. On day 25, the effluent COD concentration of the reactor was reduced to 65 mg/L, and the removal efficiency of COD reached 70.7%. Meanwhile, the effluent pH value and alkalinity were relatively stable. The sludge activity and settling performance in the baffle zone were both favorable, while the filler in anaerobic baffle zone was dense and the biofilm was brown-yellow. The results showed that the combined reactor has been successfully started on day 25. Compared with other anaerobic reaction technologies for treating low-strength rural wastewater, the combined reactor in this study has a shorter start-up time. Renuka et al. (2016) treated municipal wastewater by a PABFR which took 61 days to start up, while Bodkhe (2009) achieved the start-up operation for an ABR by self-inoculation during 90 days. The special structure and the optimized process conditions of anaerobic baffle zone and filter zone in combined reactor can provide suitable adhesion and growth conditions for the dominant microorganisms such as acid-producing bacteria, hydrogen-producing acetogens, and methanogens, where different types of anaerobic microorganisms can grow rapidly in the shortest time and adapt to the anaerobic environment and functions.

During the stable operation period, the average COD removal efficiencies of the combined reactor under different HRTs of 24 h, 18 h, 12 h, 8 h, and 5 h were 77.0%, 81.9%, 82.2%, 81.4%, and 74.3%, respectively. The removal efficiencies of COD was better when HRT were 8–12 h. The maximum COD removal efficiency was observed when HRT was 12 h. Higher HRT results in lower corresponding influent COD volumetric load, and therefore leads to lower CH4 production and yield. With the further shortening of HRT, the CH4 yield increased to a certain extent. The hydraulic turbulence enhanced and increased the mass transfer power, which was conducive to the reduction of apparent Ks value and the improvement of the COD removal rate (Kato et al. 1997). In the study of domestic sewage treatment by an ABR with bamboo fiber filler, Feng et al. (2008) found that the removal efficiency of COD decreased significantly when the HRT was too short. Therefore, the optimal HRT of the combined reactor was 12 h, and among which, the baffle zone plays an important role in the COD removal (the average removal efficiency of COD was 76.7%). Although the anaerobic filter showed a minor effect on enhancing COD removal, it still played an important role in the whole combined process system. The filter zone can remove pollutants which were not removed in the baffle zone by interception, adsorption, and biodegradation. Meanwhile, the filter zone was also important for improving the resistance to the shock load of the influent, which can ensure high stability and security for the subsequent treatment unit. Therefore, the filter zone was an indispensable part of the whole system. Table 3 lists the performance of various conventional anaerobic reactors for rural or domestic wastewater treatment. Obviously, compared with other anaerobic treatment processes, the combined process exhibited a better COD removal effect for low concentration wastewater treatment.

The removal efficiencies of NH4+-N, TN, and TP by combined reactor during the stable period were studied, and the results were shown in Fig. 3.

During the stable operation period, no obvious removal of TN or TP was observed. In the operation stages A, B, C, D, and E, the average influent TN and TP concentration were 48.72 ± 4.77 mg/L and 4.84 ± 0.43 mg/L, and the average effluent concentration were 45.97 ± 4.52 mg/L and 4.66 ± 0.46 mg/L, with removal efficiencies of 5.57% and 3.85%, respectively. After treatment by a combined reactor, the NH4+-N concentration in effluent increased slightly, with an average increase of 6.63% during the stable operation period. This phenomenon was attributed to the role of ammonification, and kjeldahl nitrogen in the influent was converted to NH4+-N. In addition, in the absence of O2 and other electron acceptors, it was quite difficult for nitrification to occur. So, almost no NH4+-N was converted to other forms of nitrogen except that needed for microorganism growth in the combined bioreactor.

According to observations in Figs. 2 and 3, in stable operation period, the COD removal efficiency of the combined reactor was higher than 74.3%, and the average removal efficiency of TN and TP was above 5.57% and 3.85%, respectively. With a high COD removal capability, the combined reactor, as a follow-up aerobic biological treatment or ecological (constructed wetland, ecological filter bed) pretreatment process, can enormously reduce the removal load of the follow-up process and reduce the investment and engineering area of the aerobic process and ecological process. At the same time, the high COD removal efficiency and the low elimination of N and P of the combined reactor suggested that the combined reactor can effectively separate the organic pollutants from nutrients in the rural wastewater and better retain the nitrogen and phosphorus nutrients in the wastewater (Chen et al. 2017), which will be beneficial for N and P recovery, and the subsequent utilized for crop (Almuktar et al. 2018). Therefore, the combined process has advantages in treating rural wastewater, mainly for better energy recovery and resource utilization potential.

Production of CH4

The CH4 production and CH4 yield are important indicators to measure the operating conditions and characteristics of anaerobic reactors. The variations of CH4 daily production and CH4 yield in the combined reactor during start-up and stable operation period were monitored, as shown in Fig. 4.

There was almost no CH4 produced until day 4. By day 10, the daily production of CH4 could reach above 100 mL/day, and the CH4 yield was about 10 mL CH4/g COD. After day 19, the CH4 daily production and CH4 yield were stable above 300 mL/day and 14.8 mL CH4/g COD, respectively. During the start-up period, anaerobic microorganisms proliferated slowly and had low activity, especially methanogens, which were mainly responsible for the speed-limiting step in the process of anaerobic biogas production. With the increased of start-up operation time, especially at the end of the start-up period, the quantity and activity of anaerobic microorganisms such as methanogens increased steadily in the reactor, and the daily production of CH4 gradually stabilized to a higher value.

During the stable operation period, the corresponding CH4 yield at a reactor HRT of 24 h, 18 h, 12 h, 8 h, and 5 h were 41 mL CH4/g COD, 54 mL CH4/g COD, 56 mL CH4/g COD, 48 mL CH4/g COD, and 42 mL CH4/g COD, respectively. With the shortening of HRT, the yield of CH4 showed a trend of first increasing and then decreasing. This phenomenon was due to the activity and abundance of various microorganisms on the anaerobic biofilm which were continuously enhanced after the combination reactor entered the stable stage, so that the COD removal efficiency and CH4 yield were significantly improved. However, when HRT were decreased to 8 h and 5 h, a large amount of COD was accumulated on the surface of the biofilm, which hindered the prompt degradation of some substrates. Meanwhile, partial produced CH4 dissolved and outflowed out with effluent, resulting in a slight decrease in CH4 yield. In this study, the actual yield of CH4 (30–70 mL CH4/g COD) was much lower than theoretical methane yield at standard conditions (350 mL CH4/g COD). From the viewpoint of COD mass balance, dissolved methane or organic substances converted into biomass and other substances might be responsible for the low methane recovery observed. The dissolution of CH4 produced by anaerobic bioreactions in water is a common phenomenon (Crone et al. 2016; Souza et al. 2011). Liu et al. (2013) found that dissolved CH4 accounted for about 45% of the total CH4 production when AnMBR was used to treat municipal wastewater with a COD concentration of 200 mg/L at 30 °C. Besides, the growth of anaerobic microorganisms and anaerobic reduction of sulfates of the influent also consume part of the influent COD.

The effect of OLR on CH4 daily production in the combined reactor during the stable operation was shown in Fig. 5.

During the stable operation period, the corresponding average daily CH4 production at average OLR of 0.2 kg COD/(m3 day), 0.29 kg COD/(m3 day), 0.46 kg COD/(m3 day), 0.76 kg COD/(m3 day), and 0.98 kg COD/(m3 day) was 998 mL/day, 1724 mL/day, 3439 mL/day, 5231 mL/day, and 5405 mL/day, respectively.

Apparently, along with increasing OLR, the daily production of CH4 gradually increased. This can be attributed to the increase of the matrix diffusion gradient and improve the effect of gas-liquid-microbial mass transfer caused by the increase of OLR (Song et al. 2018). As a result, the production of CH4 increased accordingly. Lei et al. (2018) pointed out that OLR was the most important limiting parameter for CH4 production among the factors of anaerobic reactor structure, influent water quality, environmental temperature, sludge concentration, OLR, etc.

The fitting of the CH4 daily production and OLR in the combined reactor showed a good correlation. The formula was CH4 (g) = 6026.83 OLR0.8 (R2 = 0.80), when the OLR was in the range of 0.2~0.98 kg COD/(m3 day). Within this OLR range, CH4 production was higher and CH4 production increased with the increase of OLR, and the system can achieve better performance (Fig. 5). Similar research results in the anaerobic treatment of rural wastewater were pointed out by Yeo et al. (2015). In their study, the daily production of CH4 also increased significantly with the increase of OLR. However, when OLR increased to a certain extent, it may also have a negative effect on the CH4 production and CH4 yield. Krishna et al. (2008) found that when OLR increased from 0.61 kg COD/(m3 day) to 1.51 kg COD/(m3 day), the CH4 yield also increased from 0.18 to 0.23 m3/kg COD. However, with a further increase of OLR to 2 kg COD/(m3 day), the yield of CH4 decreased to 0.19 m3/kg COD. This probably due to the sludge loading (F/M) of the anaerobic system was more suitable for the growth and reproduction of methanogens at low OLR level. Nevertheless, excessive OLR would lead to the accumulation of VFA in the system, thus inhibiting the activity of anaerobic microorganisms, especially methanogens, and reducing the production of methane in the system (Dereli et al. 2012).

Overall, the actual yield of CH4 in the combined anaerobic treatment system was mainly affected by HRT and OLR, as well as the solubility of CH4. In the practical application of combined process to treat rural wastewater, appropriate HRT and OLR parameters should be selected according to the influent characteristics and effluent requirements, so as to improve CH4 yield to a certain extent. Therefore, many factors should be considered comprehensively in the design and operation of the combined reactor. At the same time, the water quality parameters like temperature, pH, and hydraulic parameters such as viscosity should be properly adjusted to reduce the proportion of soluble methane, so as to maximize the actual yield of CH4 without affecting the wastewater treatment effect.

Anti-shock load

The anti-shock load capacity of the reactor to the fluctuation of water quality and quantity was one of the important design indexes for rural wastewater treatment facilities, especially for the small-scale or scattered wastewater treatment facilities with lacking wastewater regulation and storage facilities (Feng et al. 2009; Renuka et al. 2016). Generally, shock load includes hydraulic shock load caused by changing HRT and water quality shock load caused by the fluctuation of influent concentration. In this study, the combined reactor obtained a water quality shock by increasing influent COD concentration to 3 times of the original state and maintaining for 5 h at HRT of 12 h. The reactor effluent was sampled and monitored every 1 h after increasing the influent COD concentration. The operation of the reactor during the shock load period and the recovery period were shown in Fig. 6a. The influent COD concentration of the reactor was 948–1025 mg/L during the shock load period and then reverted to 253–379 mg/L. The effluent concentration of COD first increased and then decreased under the influence of water quality shock. When the reactor ran to the 16th hour (11 h after the end of shock load), the COD removal efficiency reached 74.2% with the original microorganism gradually adapting to the influent matrix concentration, indicating that the reactor has returned to the stable operation state.

The effect of hydraulic shock load caused by the reduction of HRT in the reactor was studied. The HRT was shortened from 12 to 1 h and maintained for 5 h. After that, the reactor had recovered to the original HRT of 12 h. Figure 6b shows the operation of the reactor during the hydraulic shock load period and recovery period. The removal efficiency of COD was decreased from 74.0 to 41.2% in the process of HRT shortening. At 9 h (4 h after the shock load), the COD removal efficiency gradually increased to 63.6%. When the operation was continued until the 11th hour (6 h after the end of the impact load), the COD removal efficiency reached 70.4%, which was restored to the original hydraulic shock load state. The hydraulic shock increased the dead volume of the reactor and formed a channel flow, which reduced the contact time and space between the microorganisms and the substrate, and weakened the mass transfer effect. Moreover, the transient hydraulic shock caused activated sludge to be washed away, but there was still more biomass in the reactor because of the interception of the filter materials. The EPS on the surface of microorganism can stabilize the floc structure of sludge, so that the reactor can avoid or mitigate the shock (Shi et al. 2017). Grobicki and Stuckey (1991) reported that ABR could restore to its original state after hydraulic shock for 24 h. Renuka et al. (2016) studied the effect of a transient hydraulic shock to the anaerobic baffle filter reactor, which was twice better than that of the recovery of the conventional ABR due to the addition of filter material to the reactor.

Thus, after hydraulic shocks, the combined anaerobic reactor still contains high biomass concentration and strong stability because of the existence of elastic solid filler and filter material, as well as the special compartmentalized structure of the reactor. Compared with other anaerobic reactors, the recovery time of the combined reactor was shorter, which reduced the adverse effects of sudden changes in water quality and quantity of rural wastewater.

Microbial community analysis of combined reactor

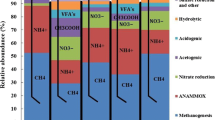

Microbiological characteristics of bacteria

Based on the 16S rDNA metagenomic high-throughput sequencing, the bacterial community in the baffle zone of the combined reactor was further identified at the phylum and genus level (Fig. 7). At the phylum level, 30 bacterial phyla were detected. Firmicutes (29.80%), Chloroflexi (21.10%), Proteobacteria (20.18%), and Bacteroidetes (8.71%) were the predominant phyla in all bacterial communities. Previous researchers have proved that these bacterial phyla were the dominant phyla in the anaerobic treatment of rural wastewater, urban wastewater, pharmaceutical, food, and paper, as well as other wastewater(Beale et al. 2016; Fykse et al. 2016; Guo et al. 2015; Sundberg et al. 2013). Planctomycetes (2.77%), Euryarchaeota (2.08%), Acidobacteria (1.91%), Synergistetes (1.47%), Actinobacteria (0.88%), Ignavibacteriae (0.79%), Spirochaetes (0.69%), and Candidatus_Saccharibacteria (0.67%) were the subdominant phyla in the baffle zone. These dominated phyla accounted for 91.05% of the total bacterial gene sequences. The remaining of the phyla was designated as “others.”

At the genus level, 244 bacterial genera were detected. The 30 most abundant of them were selected for Fig. 7b. Clostridium_sensu_stricto, Longilinea, Acetoanaerobium, and Arcobacter were the most dominant genera in the systems, which showed the relative abundance > 5%. Eleven bacterial genera (e.g., Acinetobacter, Acidaminobacter, Proteocatella, Ornatilinea) with a relatively low abundance of < 5% and > 0.8. Bacteria of the genus Clostridium_sensu_stricto had a relatively high abundance of 8.41% in the combined bioreactor, which was well known to be functional bacteria for hydrolysis and acidification (Ma et al. 2019b). Longilinea (accounting for 5.89% in total valid sequence) from the phylum of Chloroflexi was an obligately anaerobic syntrophic bacteria that played an important role in converting carbohydrates and amino acid to acetate and H2 (Song et al. 2017; Yamada et al. 2006). Genus Acinetobacter (accounting for 3.68%) have been found to possess efficient lipase secretion capability (Ma et al. 2015). The relative abundance of genus Levilinea was 1.26%, which was the major acidogenic/acetogenic bacteria (Gui et al. 2019). Thermogutta (accounting for 1.49%) was considered to be the source of esterase, which can degrade a variety of polymers and aromatic compounds. These prominent genera ensured the degradation ability of organics matter in the reactor. Needs to pay attention were, the functions of the remaining 15 bacterial genera (e.g., Anaerovorax, Paracoccus, Ignavibacterium, and Thauera) were also found in previous studies. Thauera (accounting for 0.72%) was a Gram-negative bacterium of β-Proteobacteria which can degrade aromatic compounds as an electron donor for denitrification and absorb a certain amount of phosphorus under hypoxia conditions (Xu et al. 2018). The system also contained some other functions of bacteria with a lower relative abundance. Syntrophorhabdus was a common hydrogen-producing acetic acid bacterium capable of decomposing fatty acids and alcohols to acetic acid and H2 (Ban et al. 2013). Paludibacter had been reported to utilize glycogen and soluble starch as growth substrates (Shu et al. 2015). The genera of Pseudomonas was found to be capable to degrade refractory compounds (Adebusoye et al. 2007). Comamonas has the ability to remove phenols and PAHs (Ma et al. 2015).

Taken together, the anaerobic reactor contained a number of organic hydrolysis acidizing bacteria which promoted the removal of organic matter. On the other hand, the microbial population was poorly correlated with nitrogen and phosphorus removal, which ensured that nitrogen and phosphorus nutrients were retained in the water as much as possible.

Microbiological characteristics of archaea

Generally, the composition of archaea was closely related to methane production in the wastewater treatment system. To further evaluate the function of the archaeal community, the archaeal community structure at the genus level was investigated (Fig. 8).

Figure 8 shows that genus Methanothrix from phylum of Euryarchaeota was the most widely represented genus in all archaea communities, accounting for 64.34% of the total reads. Methanothrix was an obligate acetic acid nutritious methanogenic archaea, which only utilized acetic acid to produce CH4 and CO2. However, Rotaru et al. (2014) also found that electrons could be used to reduce CO2 to produce methane. The genus Methanoregula (accounting for 16.62%) was the subdominant archaeal genus in the anaerobic reactor. As an acid-resistant hydrotrophic methanogen, Methanoregula was able to use H2 and formate as an electron donor to reduce CO2 to produce CH4. The presence of acid-tolerant hydrotrophic methanogens can effectively improve the stability in anaerobic reactors, and considering that most methanogens were susceptible to the influence of acidity and alkalinity. Methanolinea (accounting for 5.19%) was a hydrogenotrophic methanogen, which mainly produced methane using formic acid and hydrogen as a matrix. Besides, the system also contained some other functions archaea. Methanosphaerula, similar to Methanoregula, was also an acid-resistant hydrogen nutrition methanogen, and with an abundance of 1% in the reactor. Methanobacterium and Methanospirillum were hydrogenotrophic methanogens with abundances of 1.07% and 4.86%, respectively. Methanomassiliicoccus with an abundance of 2.38% was an obligate methylotrophic methanogenic archaeon.

Under the metabolic action of Methanothrix and Methanoregula, the organic acids, H2 and CO2, were converted into methane, which effectively avoided the accumulation of H2 and VFAs. Current results indicated that anaerobic reactor provided a better environment for the growth of different types of anaerobic microorganisms, enabling different types of anaerobic microorganisms to function under the optimal conditions and environment (Ban et al. 2013).

Conclusion

Removal efficiency, methane production, anti-shock performances, and microbial community were investigated for a novel combined bioreactor treating low-strength rural wastewater at 35 ± 1 °C. Enhancement of COD removal and CH4 yield was obtained for the combined reactor. N and P nutrients for plant growth were retained in the effluent, which has better potential for wastewater resource utilization. The daily production of methane was significantly affected by OLR and HRT. With the decreased of HRT and the increased of OLR, the methane production increased. The fitting formula of CH4 daily production and OLR was CH4 (g) = 6026.83 OLR0.8 (R2 = 0.80), when the OLR was in the range of 0.2~0.98 kg COD/(m3 day). However, the magnitude of methane production will decrease when OLR was too high (above 0.98 kg COD/(m3 day)). In response to shock fluctuation of the influent load, the combined anaerobic bioreactor had good operating stability and can recover quickly after the shock load. Therefore, the combined reactor can better reduce the adverse effects caused by sudden fluctuations in the quality and quantity of rural wastewater. At the genus level, the main functions of the most representative bacterial genera of Clostridium_sensu_stricto, Longilinea, Acetoanaerobium, Arcobacter, and Acinetobacter were organic matter hydrolysis acidification, ensuring the COD removal, and the predominant archaeal genera of Methanothrix and Methanoregula had the principal function for producing methane with organic fermentation and hydrolysate as the main substrate, avoiding the accumulation of H2 and VFAs. Compared with the aerobic process, the energy consumption of the combined anaerobic process is mainly in the operation of the pump, heating, or temperature maintenance, which is relatively low.

References

Adebusoye SA, Ilori MO, Picardal FW, Amund OO (2007) Cometabolic degradation of polychlorinated biphenyls (PCBs) by axenic cultures of Ralstonia sp. strain SA-5 and Pseudomonas sp. strain SA-6 obtained from Nigerian contaminated soils. World J Microbiol Biotechnol 24(1):61–68

Almuktar SAAAN, Abed SN, Scholz M (2018) Wetlands for wastewater treatment and subsequent recycling of treated effluent: a review. Environ Sci Pollut Res 25(24):23595–23623

Amani T, Nosrati M, Mousavi SM, Elyasi S (2015) Study of microbiological and operational parameters in thermophilic syntrophic degradation of volatile fatty acids in an upflow anaerobic sludge blanket reactor. J Environ Chem Eng 3(1):507–514

APHA (2012) Standard methods for the examination of water and wastewater, twenty-second ed. American Public Health Association/American Water Works Association/Water Environment Federation, Washington

Ban Q, Li J, Zhang L, Jha AK, Nies L (2013) Linking performance with microbial community characteristics in an anaerobic baffled reactor. Appl Biochem Biotechnol 169(6):1822–1836

Beale DJ, Karpe AV, McLeod JD, Gondalia SV, Muster TH, Othman MZ, Palombo EA, Joshi D (2016) An ‘omics’ approach towards the characterisation of laboratory scale anaerobic digesters treating municipal sewage sludge. Water Res 88:346–357

Bodík I, Kratochvíl K, Herdová B, Tapia G, Gašpariková E (2002) Municipal wastewater treatment in the anaerobic-aerobic baffled filter reactor at ambient temperature. Water Sci Technol 46(8):127–135

Bodkhe S (2008) Development of an improved anaerobic filter for municipal wastewater treatment. Bioresour Technol 99(1):222–226

Bodkhe SY (2009) A modified anaerobic baffled reactor for municipal wastewater treatment. J Environ Manag 90(8):2488–2493

Chen M, Chen J, Du P (2006) An inventory analysis of rural pollution loads in China. Water Sci Technol 54(11–12):65–74

Chen R, Nie YL, Ji JY, Utashiro T, Li Q, Komori D, Li YY (2017) Submerged anaerobic membrane bioreactor (SAnMBR) performance on sewage treatment: removal efficiencies, biogas production and membrane fouling. Water Sci Technol 76(5–6):1308–1317

Chen J, Liu YS, Deng WJ, Ying GG (2019) Removal of steroid hormones and biocides from rural wastewater by an integrated constructed wetland. Sci Total Environ 660:358–365

Crone BC, Garland JL, Sorial GA, Vane LM (2016) Significance of dissolved methane in effluents of anaerobically treated low strength wastewater and potential for recovery as an energy product: a review. Water Res 104:520–531

Dereli RK, Ersahin ME, Ozgun H, Ozturk I, Jeison D, van der Zee F, van Lier JB (2012) Potentials of anaerobic membrane bioreactors to overcome treatment limitations induced by industrial wastewaters. Bioresour Technol 122:160–170

Feng HJ, Hu LF, Mahmood Q, Qiu CD, Fang CR, Shen DS (2008) Anaerobic domestic wastewater treatment with bamboo carrier anaerobic baffled reactor. Int Biodeterior Biodegrad 62(3):232–238

Feng HJ, Hu LF, Mahmood Q, Fang CR, Qiu CD, Shen DS (2009) Effects of temperature and feed strength on a carrier anaerobic baffled reactor treating dilute wastewater. Desalination 239(1–3):111–121

Feng J, Wang YL, Ji XY, Yuan DQ, Li H (2015) Performance and bioparticle growth of anaerobic baffled reactor (ABR) fed with low-strength domestic sewage. Front Env Sci Eng 9(2):352–364

Florencio L, Kato MT, Cardoso de Morais J (2001) Domestic sewage treatment in full-scale UASBB plant at Mangueira, Recife, Pernambuco. Water Sci Technol 44(4):71–77

Fouché O, Lasagna M, Danert K (2018) Groundwater under threat from diffuse contaminants: improving on-site sanitation, agriculture and water supply practices. Environ Sci Pollut Res 26(3):2023–2025

Fykse EM, Aarskaug T, Madslien EH, Dybwad M (2016) Microbial community structure in a full-scale anaerobic treatment plant during start-up and first year of operation revealed by high-throughput 16S rRNA gene amplicon sequencing. Bioresour Technol 222:380–387

Grobicki A, Stuckey DC (1991) Performance of the anaerobic baffled reactor under steady-state and shock loading conditions. Biotechnol Bioeng 27(4):344–355

Gu BJ, Fan LG, Ying ZC, Xu QS, Luo WD, Ge Y, Scott S, Chang J (2016) Socioeconomic constraints on the technological choices in rural sewage treatment. Environ Sci Pollut Res 23(20):20360–20367

Guest JS, Skerlos SJ, Barnard JL, Beck MB, Daigger GT, Hilger H, Jackson SJ, Karvazy K, Kelly L, Macpherson L, Mihelcic JR, Pramanik A, Raskin L, van Loosdrecht MCM, Yeh D, Love NG (2009) A new planning and design paradigm to achieve sustainable resource recovery from wastewater. Environ Sci Technol 43(16):6126–6130

Gui XF, Xu WC, Cao HB, Ning PG, Zhang YX, Li YP, Sheng YX (2019) A novel phenol and ammonia recovery process for coal gasification wastewater altering the bacterial community and increasing pollutants removal in anaerobic/anoxic/aerobic system. Sci Total Environ 661:203–211

Guo JH, Peng YZ, Ni BJ, Han XY, Fan L, Yuan ZG (2015) Dissecting microbial community structure and methane-producing pathways of a full-scale anaerobic reactor digesting activated sludge from wastewater treatment by metagenomic sequencing. Microb Cell Factories 14:1–11

Hahn MJ, Figueroa LA (2015) Pilot scale application of anaerobic baffled reactor for biologically enhanced primary treatment of raw municipal wastewater. Water Res 87:494–502

Ham JH, Yoon CG, Jeon JH, Kim HC (2007) Feasibility of a constructed wetland and wastewater stabilisation pond system as a sewage reclamation system for agricultural reuse in a decentralised rural area. Water Sci Technol 55(1–2):503–511

Han YP, Ma JW, Xiao BY, Huo XC, Guo XS (2019) New integrated self-refluxing rotating biological contactor for rural sewage treatment. J Clean Prod 217:324–334

Hu Y, Jing ZQ, Sudo Y, Niu QG, Du JR, Wu J, Li YY (2015) Effect of influent COD/SO42− ratios on UASB treatment of a synthetic sulfate-containing wastewater. Chemosphere 130:24–33

Kato MT, Field JA, Lettinga G (1997) The anaerobic treatment of low strength wastewaters in UASB and EGSB reactors. Water Sci Technol 36(6–7):375–382

Kobayashi HA, Stenstrom MK, Mah RA (1983) Treatment of low strength domestic wastewater using the anaerobic filter. Water Res 17:903–909

Krishna GVTG, Kumar P, Kumar P (2008) Treatment of low strength complex wastewater using an anaerobic baffled reactor (ABR). Bioresour Technol 99(17):8193–8200

Lei Z, Yang SM, Li YY, Wen W, Wang XC, Chen R (2018) Application of anaerobic membrane bioreactors to municipal wastewater treatment at ambient temperature: a review of achievements, challenges, and perspectives. Bioresour Technol 267:756–768

Li XM, Guo L, Yang Q, Zeng GM, Liao DX (2007) Removal of carbon and nutrients from low strength domestic wastewater by expanded granular sludge bed-zeolite bed filtration (EGSB-ZBF) integrated treatment concept. Process Biochem 42(8):1173–1179

Li SN, Nan J, Gao F (2016) Hydraulic characteristics and performance modeling of a modified anaerobic baffled reactor (MABR). Chem Eng J 284:85–92

Liu Z, Yin H, Dang Z, Liu Y (2013) Dissolved methane: a hurdle for anaerobic treatment of municipal wastewater. Environ Sci Technol 48(2):889–890

Ma JW, Zhao QB, Laurens LL, Jarvis EE, Nagle NJ, Chen SL, Frear CS (2015) Mechanism, kinetics and microbiology of inhibition caused by long-chain fatty acids in anaerobic digestion of algal biomass. Biotechnol Biofuels 8:141–252

Ma SJ, Ma HJ, Hu HD, Ren HQ (2019a) Effect of mixing intensity on hydrolysis and acidification of sewage sludge in two-stage anaerobic digestion: characteristics of dissolved organic matter and the key microorganisms. Water Res 148:359–367

Ma YH, Zhai YK, Zheng XG, He SB, Zhao M (2019b) Rural domestic wastewater treatment in constructed ditch wetlands: effects of influent flow ratio distribution. J Clean Prod 225:350–358

Mizuta K, Shimada M (2010) Benchmarking energy consumption in municipal wastewater treatment plants in Japan. Water Sci Technol 62(10):2256–2262

Mortezaei Y, Amani T, Elyasi S (2018) High-rate anaerobic digestion of yogurt wastewater in a hybrid EGSB and fixed-bed reactor: optimizing through response surface methodology. Process Saf Environ 113:255–263

Nasr FA, Doma HS, Nassar HF (2008) Treatment of domestic wastewater using an anaerobic baffled reactor followed by a duckweed pond for agricultural purposes. Environmentalist 29(3):270–279

Renuka R, Mohan SM, Sowmiya B, Raj SA (2016) Performance evaluation of panelled anaerobic baffle-cum-filter reactor in treating municipal wastewater. Ecol Eng 97:1–12

Reynaud N, Buckley CA (2015) The anaerobic baffled reactor (ABR) treating communal wastewater under mesophilic conditions: a review. Water Sci Technol 73(3):463–478

Rotaru A-E, Shrestha PM, Liu F, Shrestha M, Shrestha D, Embree M, Zengler K, Wardman C, Nevin KP, Lovley DR (2014) A new model for electron flow during anaerobic digestion: direct interspecies electron transfer to Methanosaeta for the reduction of carbon dioxide to methane. Energy Environ Sci 7(1):408–415

Sayedin F, Kermanshahi-pour A, He QS (2019) Evaluating the potential of a novel anaerobic baffled reactor for anaerobic digestion of thin stillage: effect of organic loading rate, hydraulic retention time and recycle ratio. Renew Energy 135:975–983

Shi YH, Huang JH, Zeng GM, Gu YL, Chen YN, Hu Y, Tang B, Zhou JX, Yang Y, Shi LX (2017) Exploiting extracellular polymeric substances (EPS) controlling strategies for performance enhancement of biological wastewater treatments: an overview. Chemosphere 180:396–411

Shoener BD, Bradley IM, Cusick RD, Guest JS (2014) Energy positive domestic wastewater treatment: the roles of anaerobic and phototrophic technologies. Environ Sci Proc Impacts 16(6):1204–1222

Shu DT, He YL, Yue H, Wang QY (2015) Microbial structures and community functions of anaerobic sludge in six full-scale wastewater treatment plants as revealed by 454 high-throughput pyrosequencing. Bioresour Technol 186:163–172

Song GQ, Xi HB, Zhou YX, Fu LY, Xing X, Wu CY (2017) Influence of organic load rate (OLR) on the hydrolytic acidification of 2-butenal manufacture wastewater and analysis of bacterial community structure. Bioresour Technol 243:502–511

Song P, Huang GH, An CJ, Shen J, Zhang P, Chen XJ, Shen J, Yao Y, Zheng RB, Sun CX (2018) Treatment of rural domestic wastewater using multi-soil-layering systems: performance evaluation, factorial analysis and numerical modeling. Sci Total Environ 644:536–546

Song P, Huang GH, An CJ, Zhang P, Chen XJ, Ren S (2019) Performance analysis and life cycle greenhouse gas emission assessment of an integrated gravitational-flow wastewater treatment system for rural areas. Environ Sci Pollut Res 26(25):25883–25897

Souza CL, Chernicharo CA, Aquino SF (2011) Quantification of dissolved methane in UASB reactors treating domestic wastewater under different operating conditions. Water Sci Technol 64(11):2259–2264

Stazi V, Tomei MC (2018) Enhancing anaerobic treatment of domestic wastewater: state of the art, innovative technologies and future perspectives. Sci Total Environ 635:78–91

Stefanakis AI, Tsihrintzis VA (2012) Effects of loading, resting period, temperature, porous media, vegetation and aeration on performance of pilot-scale vertical flow constructed wetlands. Chem Eng J 181-182:416–430

Su CY, Deng QJ, Lu YX, Qin RH, Chen SL, Wei JW, Chen ML, Huang Z (2019) Effects of hydraulic retention time on the performance and microbial community of an anaerobic baffled reactor-bioelectricity Fenton coupling reactor for treatment of traditional Chinese medicine wastewater. Bioresour Technol 288:121508

Sundberg C, Al-Soud WA, Larsson M, Alm E, Yekta SS, Svensson BH, Sorensen SJ, Karlsson A (2013) 454 pyrosequencing analyses of bacterial and archaeal richness in 21 full-scale biogas digesters. FEMS Microbiol Ecol 85(3):612–626

Xu WC, Zhang YX, Cao HB, Sheng YX, Li HB, Li YP, Zhao H, Gui XF (2018) Metagenomic insights into the microbiota profiles and bioaugmentation mechanism of organics removal in coal gasification wastewater in an anaerobic/anoxic/oxic system by methanol. Bioresour Technol 264:106–115

Yamada T, Sekiguchi Y, Hanada S, Imachi H, Ohashi A, Harada H, Kamagata Y (2006) Anaerolinea thermolimosa sp. nov., Levilinea saccharolytica gen. nov., sp. nov. and Leptolinea tardivitalis gen. nov., sp. nov., novel filamentous anaerobes, and description of the new classes Anaerolineae classis nov. and Caldilineae classis nov. in the bacterial phylum Chloroflexi. Int J Syst Evol Microbiol 56(Pt 6):1331–1340

Yeo H, An J, Reid R, Rittmann BE, Lee HS (2015) Contribution of liquid/gas mass-transfer limitations to dissolved methane oversaturation in anaerobic treatment of dilute wastewater. Environ Sci Technol 49(17):10366–10372

Zhu G, Zou R, Jha AK, Huang X, Liu L, Liu C (2014) Recent developments and future perspectives of anaerobic baffled bioreactor for wastewater treatment and energy recovery. Crit Rev Environ Sci Technol 45(12):1243–1276

Acknowledgments

This work was financially supported by the Science and Technology Major Projects of China’s “13th Five-Year Plan” under the Water Pollution Control and Governance (2017ZX07102004-005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Liu, X., Gao, L. et al. Performance and microbial community of a novel combined anaerobic bioreactor integrating anaerobic baffling and anaerobic filtration process for low-strength rural wastewater treatment. Environ Sci Pollut Res 27, 18743–18756 (2020). https://doi.org/10.1007/s11356-020-08263-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08263-9