Abstract

Hydrogen generation from food waste anaerobic dark fermentation is identified as a promising strategy for resource recovery. In this work, an innovative strategy of using potassium ferrate (PF), a strong oxidant, to promote anaerobic dark fermentation of food waste to produce hydrogen has been reported. The experimental results revealed that PF enhanced the hydrogen production from food waste, the maximal hydrogen yield was 173.5 mL/g, and the optimal PF dosage was 0.4 g/g total suspended solids. PF shortened the lag phase for hydrogen generation from 120 to 96 h. Mechanisms investigation revealed that PF accelerated the disintegration of organic compounds and increased the soluble organic matter in the liquid phase. The strong oxidation of PF inhibited the processes of hydrolysis, acidification, acetogenesis, homoacetogenesis, and methanogenesis by using synthetic wastewater in the fermentation process. The inhibition of PF on these processes was further verified by the enzyme activity analysis. Economic analysis indicated that 0.1 g/g PF was the optimal dosage. PF treatment is a promising strategy to enhance the production of hydrogen from food waste dark fermentation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food waste, inevitably discharged from kitchens, cafeterias, and restaurants, was produced with large amounts. In China, the annual output of food waste can be up to 82.80 million tons (Kiran et al. 2014). The typical characteristics of food waste are high fat content, high moisture content, and easy to be spoilage, and if the food waste is treated improperly, it will cause the environmental pollution and even threaten ecological health (Dinesh et al. 2018; Jarunglumlert et al. 2018; Zhao et al. 2019). Besides, food waste contains high levels of organic matter, for instance protein, polysaccharide, and grease, which make it as attractive renewable resource (Yin et al. 2016a). With the increase of population, the demand for energy is also on the rise. The global energy crisis drives scientists to recover energy and resources from food waste as much as possible (Li et al. 2014; Zhao et al. 2020). Anaerobic fermentation of food waste to generate energy material such as volatile fatty acids, hydrogen, and/or methane has been regarded as a feasible strategy for food waste treatment because the material resources can be utilized and the food waste is sterilized; in addition, the reduction of food waste has also been achieved (Zhao et al. 2018).

Hydrogen is widely regarded as a promising alternative to fossil fuels because hydrogen has high-energy yield (142.35 kJ/g), which is more than two times higher than hydrocarbon fuels methane (Karadag et al. 2014). In addition, the product after combustion is water rather than greenhouse gas (Wang et al. 2019). Generally, the hydrogen yield from food waste anaerobic fermentation was at a low level (such as 42 mL/g VSS) due to the slow hydrolysis rate and the rapid consumption by methanogenic archaea (Elbeshbishy et al. 2011; Bundhoo et al. 2015). The main components of food waste are carbohydrates (35.5~69.0%), proteins (3.90~21.9%), and lipids (Kiran et al. 2014). Carbohydrates (except lignin, cellulose, and hemicellulose) are readily utilized by fermenting microorganisms and converted to short-chain fatty acids (SCFA) and hydrogen via glycolysis (Wang and Wan 2009; Ni et al. 2006; Tao et al. 2019; Tao et al. 2020). However, proteins are not easy to be attached and hydrolyzed by hydrolase. Compared with the utilization rate of total carbohydrates as high as 85.8%, the protein utilization efficiency was only 40~70% (Yin et al. 2016b). In addition, the disintegration/hydrolysis rate of protein is significantly lower than that of carbohydrates or lipids (Vidal et al. 2000; Qiao et al. 2018). Therefore, the hydrolysis rate of organic matter in food waste has a great influence on the target energy product hydrogen. In order to increase the hydrogen production from food waste dark fermentation, on one hand, the hydrolysis rate of organic should be improved, and on the other hand, the activity of hydrogen consumption bacteria (homoacetogenic bacteria and methanogen) should be suppressed or inhibited. Therefore, many studies have applied pretreatment including physical, biological, and chemical methods to enhance the hydrolysis process of anaerobic fermentation/digestion (Ding et al. 2017; Wang and Wan 2009; Li et al. 2019a, b; Tamilarasan et al. 2018; Chiu and Lo 2016; Yazdanpanah et al. 2018; Zhang et al. 2018). However, high-energy input is a major factor limiting the application of the pretreatment methods abovementioned in practical engineering (Yasin et al. 2013; Zhu et al. 2018; Ariunbaatar et al. 2014). For instance, Kim et al. (2011) investigated the effect of initial pH on hydrogen production by batch anaerobic dark fermentation of food waste, and at initial pH 6.0–9.0, successful hydrogen yield of 1.3~1.9 mol H2/mol hexose added was achieved with a peak value at pH 8.0. Thus, an efficient and economical pretreatment strategy to strengthen the food waste dark fermentation for hydrogen production was urgently needed.

Potassium ferrate (PF) is a new type of water treatment agent. It has many characteristics, such as good oxidation and decontamination effect, excellent coagulation and coagulation aid, excellent sterilization and disinfection effect, and efficient deodorization and deodorization function (Ma and Liu 2002; Fan et al. 2018; Li et al. 2019a, b; Zhu et al. 2019a, b, c, d). PF is recognized as an environmentally friendly water treatment reagent, and the oxidation product is iron hydroxide, which can be removed from wastewater in the form of sludge after flocculation and sedimentation (An et al. 2017; Wang et al. 2015). The strong oxidation of PF can destroy the cell structure of bacteria, inhibit the synthesis of protein and nucleic acid, and hinder the growth and reproduction of bacteria. Considering the above excellent characteristics of PF, it is widely used in drinking water, sewage, and waste-activated sludge treatment. PF oxidation can inactivate Microcystis algae in the drinking water source, destroy cell structural integrity, increase intracellular organic matter in water, and promote the formation of trihalomethane and haloacetic acid (Zhou et al. 2014). The strong oxidation of PF can destroy the sludge flocs and improve the mechanical dewatering ability of sludge. PF can oxidize extracellular polymer of sludge to dissolve and release organic matter, thus providing sufficient substance for the acidogenic microorganisms and methanogens (Li et al. 2018a; He et al. 2018; Li et al. 2018b). In addition, Fe(VI) in PF can be converted to Fe(III) in the process of oxidizing organic matter, which can then be further converted to ferric hydroxide precipitation by hydroxyl radical, a harmless environmental protection material (Feng et al. 2017). Considering the above advantages of PF, PF can be assumed to be applied to food waste dark fermentation to produce hydrogen. Although PF had been proven to be used to enhance sludge disintegration (He et al. 2018; Li et al. 2019a, b), there are some differences in the composition of sludge and food waste, that is, there is no extracellular polymer in food waste, and the content of moisture content in food waste is significantly higher than that in sludge, and the protein content, especially plant proteins of food waste, was high. However, the feasibility of using PF to enhance food waste dark fermentation to produce hydrogen is still unclear.

This work, therefore, investigated the feasibility of applying PF to improve the hydrogen production from food waste dark fermentation, and the relevant mechanisms were also revealed. Firstly, the PF dosage of enhanced food waste anaerobic fermentation for hydrogen production was optimized. Secondly, how PF affected the anaerobic fermentation hydrolysis and acidification process of food waste was described in detail. Thirdly, the mechanisms of PF improved the hydrogen production were revealed by analyzing the degradation of organic matter in synthetic wastewater and the activities of related key enzymes in the long-term semi-continuous operation. Finally, the economy of PF enhanced dark fermentation of food waste was evaluated.

Materials and methods

Characteristics of food waste and inoculum

The fermentation substrate used in this work was taken from discarded food waste from school canteens on weekdays. The food waste was mainly contained rice, tofu, vegetables, meat, and steamed buns. After removing the undigested substances such as chopsticks, plastic bags, and bones, the fermentation substrate was crushed into 1~3 mm by a shredder. Afterwards, a certain amount of tap water was added to the food waste (10/1, in terms of volume) to improve its fluidity. NaOH or HCl (2.0 M) was added manually to control the pH value. Finally, the fermentation substrate was transferred to a refrigerator (4 °C) for further use. The main characteristics of fermentation substrate were described as follows: pH 6.8 ± 0.1, total suspended solids (TSS) 17.4 ± 0.3%, volatile suspension solid (VSS) 15.5 ± 0.2% (in terms of wet basis), total COD 232 ± 12.3 g/L soluble COD 2.3 ± 0.2 g/L, and carbohydrates 112.3 ± 10.6 g/L.

The inoculum was taken from the secondary sedimentation tank of a municipal wastewater treatment plant in Qingdao, China. The process adopted by the municipal wastewater treatment plant was modified sequential batch reaction with a capacity of 160,000 m3 per day. First, the inoculum was screened to remove the large particulate insoluble matter and then placed in the refrigerator at 4 °C after 24 h gravity settlement. The main properties of the inoculum are as follows: pH 7.1 ± 0.1, TSS 13260 ± 450 mg/L, VSS 6850 ± 320 mg/L, and SCFA 263 ± 20 mg/L.

Enhancement of hydrogen accumulation from dark fermentation with PF

Batch tests were carried out using identical anaerobic fermentation reactors with a working volume of 1.0 L. The reactor is equipped with a stainless steel mechanical stirrer, and the rotational speed was controlled at 120 rpm. The reactor was controlled by a water bath heating device which was prepared from the outside to control the reaction temperature at 35 °C. In order to prevent hydrogen consumption, the inoculated sludge in this study was heat at 102 °C for 30 min before inoculation modified from the literature (Feng et al. 2014). First, 5.4 L fermentation substrate and 0.6 L inoculum were distributed equally to six identical reactors. The volume ratio of the fermentation substrate to the inoculum was 9/1, and this ratio benefited the consumption of fermentation substrates (Zhao et al. 2017a). Then, a calculated amount of PF was added to each reactor and the content was controlled to 0, 0.1, 0.2, 0.4, 0.6, and 0.8 g/g, respectively. Besides, another replicable reactor was fed with 100 mL of inoculum, and then 0.9 L of deionized water and 6.0 g PF were added to investigate the influence of PF on the inoculated sludge for hydrogen production. Finally, all the reactors were flushed with high purity nitrogen for 60 s to remove oxygen and then sealed with rubber plug for anaerobic dark fermentation. Hydrogen was collected through the gas collecting bag installed above the reactors. The whole fermentation period of hydrogen production lasted 6 days, and the hydrogen content was measured daily from the gas collecting bag.

Effect of PF addition on each step of dark fermentation

Except for the disintegration process of food waste, dark fermentation of organic matter includes hydrolysis, acidification, acetogenesis, homoacetogenesis, and methanogenesis (Saeed et al. 2018; Zhao et al. 2019). Therefore, it is important to investigate the potential impact of PF on those above bioprocesses, and this batch test was divided into five groups (groups I-V) with synthetic wastewater/gas (Table 1). In addition, adding 5.0 mL trace element stock solution to the synthetic wastewater to enhance microbial metabolism, the main compositions of trace element stock solution were presented in the Supporting Information. Finally, nitrogen was injected into all reactors for 60 s to ensure the strict anaerobic condition, and the abovementioned serum bottles were sealed and placed in a water bath air oscillator at a constant temperature of 35 °C. It should be noted that since the inoculum had been heat treated (102 °C for 30 min), the hydrogen consumption can be considered as consumed by the homoacetogenesis process. The effect of PF on the homoacetogenesis process can be assessed by measuring the consumption of hydrogen in the synthesis gas.

Analysis of key enzyme activities

Five semi-continuous anaerobic reactors were implemented to further investigate the effects of PF dosage on food waste dark fermentation from the perspective of microbial metabolism. First, five identical reactors (working volume 1.0 L) were set up, and then 0.5 L of food waste and 0.2 L inoculum were added to each reactor; the detailed information of the inoculum is shown in the Supporting Information. At each feeding time, the calculated PF amount was added to control its concentration of 0.1, 0.2, 0.4, 0.6, and 0.8 g/g, respectively. The temperature of food waste dark fermentation was controlled at 35 °C. The retention time of the semi-continuous reactor was controlled at 96 h by discharging 0.175 L of food waste and supplementing the same volume of fresh food waste every day.

Analytical methods

The determinations of routine analysis indicators including soluble COD, COD, TSS, VSS, pH, and ammonia nitrogen were carried out in accordance with international methods (APHA 1998). Protein was analyzed by Folin-phenol method, bovine serum protein was used as reference material, polysaccharide was determined by phenol-sulfuric acid method, and glucose was used as reference material (Zhao et al. 2017b; Wu et al. 2020). SCFAs, including acetate, propionate, butyrate, and valerate were determined by Agilent 6890 gas chromatography with flame ionization detector. The main detection procedures for SCFA and biogas are detailed in the Supporting Information. The content and composition of biogas (mainly hydrogen and methane) were determined by gas chromatography (Agilent Technologies 7890A, USA) with a TCD detector. The analytical column was 4 mm × 2 m GDX-102 stainless steel column with nitrogen as carrier gas, and the flow rate was 30 mL/min. The temperature of the inlet, the analytical column, and the detector were 40 °C, 40 °C, and 80 °C, respectively, and the gas injection volume was 0.2 mL. The gas volume is calculated by Eq. 1 (Chen et al. 2012).

VH,i and VHi-1 represent the cumulative volume in this and last reactor, and VGi and VGi-1 represent the total volume of the gas in this and last reactor, respectively. CHi and CHi-1 represent the content of hydrogen in this and last reactor, respectively.

For the analysis of key enzyme activities related to hydrogen generation, 25 mL slurry fermentation mixture was centrifuged at 4500 rpm for 10 min before the supernatant was discarded. The supernatant was rinsed twice with 10 mL 100 mM pH 7.4 sodium phosphate buffer solution and suspended in sodium phosphate buffer solution. The suspension mixture was used to break the cell wall by ultrasound for 30 min at 20 kHz, 100 W, 5 s. The ice-water bath mixture was used when the cell wall was broken. The wall-breaking mixtures were 1400 rpm and 4 °C. The supernatant of cell extract was preserved at 4 °C for the determination of enzyme activities. Protease and α-glucosidase are related to hydrogen production were determined and analyzed in this study. The activities of acetate kinase (AK) and butyrate kinase (BK) are related to the synthesis of SCFA. The activity of coenzyme F420 is related to the activity of archaea methanogens. The detailed procedures for the determination of these key enzymes are described in the Supporting Information.

Results and discussion

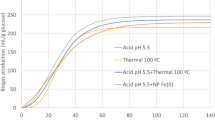

PF dosage optimization for enhanced hydrogen generation

Figure 1 shows the effect of PF addition on the cumulative hydrogen yield from food waste dark fermentation. Hydrogen in each reactor increased sharply and then stabilized with fermentation time. The rapid increase of hydrogen in the early stage was mainly due to the abundant organic matter available in food waste. In the blank, the maximal hydrogen production appeared at 108 h, and the corresponding production was about 57.5 mL/g (0.6 mol-H2/mol-hexose). However, when PF was present, the cumulative amount of hydrogen changed significantly. When PF content was 0.1 g/g, the maximum cumulative amount of hydrogen production from anaerobic fermentation of food waste was 126.8 mL/g, which was about 2.2-fold of that in blank. It indicated that PF can increase hydrogen production from food waste. When the amount of PF further increased to 0.4 g/g, the maximum cumulative hydrogen production also increased to 173.5 mL/g (2.1 mol-H2/mol-hexose), about 3.0 times of that in blank. However, when PF further increased to 0.6 and 0.8 g/g, the maximal hydrogen production showed a downward trend, but the maximum cumulative yield was still higher than that in the blank. The effect of PF on the hydrogen production from inoculated sludge is shown in Fig. S1. The maximal hydrogen production of inoculated sludge was only 10.2 mL/g (0.1 mol-H2/mol-hexose), which was significantly lower than that from food waste dark fermentation (p < 0.05), thus further clarifying that PF promoted the accumulation of hydrogen from food waste. The lag phase is also an important parameter affecting the hydrogen production from food waste dark fermentation. When PF was present, the lag phase for hydrogen production from food waste anaerobic fermentation was 96 h, which was significantly lower than that of the blank (120 h), indicating that PF accelerated the production rate of hydrogen from food waste dark fermentation. Shortening the lag phase has significant advantages in practical engineering, such as reducing the working volume of the fermentation equipment, thereby reducing the capital cost. Therefore, PF not only increased the cumulative hydrogen production of food waste but also shortened the lag phase. Table 2 further displays the comparison of different pretreatment strategies for enhanced anaerobic dark fermentation hydrogen production from food waste. The highest hydrogen production was 219.61 mL/g, which was higher than the result of this work. However, the cost of enzyme pretreatment was high and the process was complex. The price of PF is acceptable and the hydrogen production in this study is satisfactory. Therefore, PF enhanced dark fermentation of food waste to produce hydrogen is a promising and efficient strategy. PF, as a water treatment agent with strong oxidation ability, was often used to treat refractory substances (An et al. 2017; Wang et al. 2015). PF can not only oxidize and degrade inorganic and organic pollutants, remove suspended particulate matter, but also flocculate and stimulate the growth of microorganisms (Ma and Liu 2012). Lan et al. (2011) explored the impact of PF on microbial growth and sludge physicochemical properties, and the results indicated that low concentration of PF promoted microbial growth, and PF decomposed completely at the early stage of microbial stagnation. However, high concentration of PF had adverse effects on microbial growth (Liu et al. 2011), and this explained that high PF concentration reduced hydrogen production in this work.

Analysis of COD mass balance promoted by PF

Food waste dark fermentation is a biocatalytic process, which involves the production and biotransformation of a variety of organic substances (including carbohydrates, proteins, SCFA, ethanol, lactic acid, methane). A COD mass balance is often used to assess the organic compounds transformation (Xiao et al. 2018; Liu et al. 2019). As shown in Fig. 2, at the beginning of food waste fermentation, VSS, carbohydrates, and proteins accounted for 89.6% of the total COD percentage, indicating that there were plenty of organic substances in food waste. With the fermentation time, the COD percentage of VSS, carbohydrate, and protein in food waste showed a downward trend. However, the COD percentage of the intermediate products such as SCFA, lactate, and hydrogen increased significantly, and the increase was related to the PF dosage. In the blank, the COD percentages of VSS, carbohydrates and proteins decreased to 85.4%. When the dosage of PF increased from 0.1 to 0.4 g/g, these COD percentage decreased from 82.6 to 68%, and further increase of PF dosage resulted in insignificant decrease in the COD percentage of VSS, carbohydrate, and protein. As for the COD percentage of hydrogen, when the dosage of PF increased from 0 to 0.4 g/g, the COD percentage of hydrogen increased from 0.13 to 0.49%, indicating that the existence of PF improved the hydrogen production. It is clear that the intermediates content of food waste dark fermentation is closely related to biochemical processes such as hydrolysis, acidification, and acidogenesis. Therefore, it is necessary to investigate the effects of PF addition on each of the above steps in a deep and comprehensive way.

Analysis of COD mass balance in PF enhanced fermentation of food waste. The COD conversion coefficients are 1.42 g COD/g VSS, 8 g COD/g hydrogen, 4 g COD/g methane, 1.5 g COD/g protein, 1.06 g COD/g carbohydrate, 0.875 g COD/g lactate, 1.07 g COD/g acetic, 1.51 g COD/g propionic, 1.82 g COD/g butyric, and 2.04 g COD/g valeric. The error bar represents the standard deviation of triplicate determination

How does PF affect the disintegration of food waste?

Generally, the organic substances (mainly polysaccharides and proteins) in food waste exist in solid or semi-solid forms, which are difficult to be disintegrated and utilized by microorganisms (Zhao et al. 2019). Anaerobic disintegration/hydrolysis of food waste is the process of transforming macromolecular organic matter into small organic substances which can be used by microorganisms, and this process is also considered as a speed-limiting step (Kong et al. 2016). Soluble COD, protein, and carbohydrate content can indicate the hydrolysis efficiency of food waste. As shown in Fig. 3a, the addition of PF promoted the increase of soluble COD content. The dosage of PF increased from 0 to 0.4 g/g, and the content of soluble COD also increased from 16.5 to 21.3 g/L, indicating that PF promoted the disintegration of granular substances in food waste. When the concentration of PF further increased to 0.6 g/g and 0.8 g/g, the concentration of soluble COD decreased to 18.6 g/L and 17.9 g/L, respectively, but they were still higher than those in the blank. In addition, the soluble COD concentration in the inoculum was only 0.35 g/L, which was significantly lower than that in other groups (p < 0.05), indicating that the increase of soluble COD mainly came from food waste rather than from the disintegration of inoculum. Figure 3 b further shows the variation of soluble carbohydrate and protein in the presence of PF. Similarly, increasing the dosage of PF properly promoted the concentrations of soluble carbohydrate and protein. For example, when the dosage of PF was 0.4 g/g, the concentrations of soluble carbohydrate and protein were 8.9 g/L and 2.5 g/L, respectively, and it was about 1.2 and 2.2 times higher than that of the blank, indicating that the presence of PF improved the release of soluble organic matter. The increase of soluble organic matter in food waste was due to the strong oxidation of PF. PF can break some special chains in organic matter, thus increasing the content of small molecular organic matter. High dosages of PF, e.g., 0.6 and 0.8 g/g, however, caused the decrease of soluble carbohydrates and proteins. As shown in the Eq. 2, PF can produce ferric hydroxide colloid when added to fermentation liquid, and ferric hydroxide colloid has good flocculation and precipitation. The addition of excessive PF would lead to flocculation replacing oxidation gradually and becoming the dominant function (Lan et al., 2011). The presence of excessive PF caused flocculation in food waste, which reduced the release of soluble organic matter.

Effect of PF on the production of SCFA from food waste dark fermentation

The liquid-phase end-fermentation products can reflect the metabolic characteristics and microbial community structure changes in the anaerobic fermentation process (Zhao et al. 2019). Different liquid-phase end-fermentation products also represent different fermentation types in the system. The variations of SCFA content and its components in each reactor are shown in Fig. 4. The content of SCFA in each reactor increased first and then stabilized over time. The increase in SCFA concentration was due to the fact that acidogenic microorganisms used the fermentation substrates to synthesize the fermentation intermediate SCFA, while the SCFA content remained unchanged due to the low consumption of SCFA by methanogenic archaea. The maximal concentration of SCFA in the blank was about 10.2 g/L, while the concentration of SCFA in the presence of PF was significantly increased, and the content of SCFA was positively correlated with the dosage of PF. When the dosage of PF increased from 0.1 to 0.8 g/g, the maximal content of SCFA also increased from 11.6 to 14.9 g/L. The maximal yield of SCFA in the inoculum was only 0.8 g/L, which was significantly lower than that in the food waste dark fermentation (p < 0.05). Those results clearly implied that PF promoted the accumulation of SCFA from food waste dark fermentation. It should be noted that high dosage of PF such as 0.6 and 0.8 g/g did not cause the decrease of SCFA content, which may be attributed to the high tolerance of acidogenic bacteria to PF oxidation.

The compositions of SCFA were closely related to the type of fermentation. Figure 5 further displays the percentage distribution of the individual SCFA component in each group. Acetate and butyrate accounted for the largest proportion in each group, accounting for 73.7–85.9%. The percentage of valerate in each reactor was the lowest, accounting for about 4.8–11.6%. However, the proportions of acetate and propionate were the largest in the inoculum fermentation reactor (Fig. S2), which was similar to previous literature (Zhao et al. 2018). The results showed that the dark fermentation of food waste in the presence of PF belonged to butyric acid fermentation, which was conducive to the production of hydrogen (Song et al. 2006).

Effect of PF on each step of food waste dark fermentation

The PF might have potential impacts on anaerobic dark fermentation microorganisms in biochemical metabolic processes such as hydrolysis, acidogenesis, acetogenesis, and methanogenesis. To clarify those impacts, several batch tests using synthetic wastewater contained model compounds were performed. As shown in Table 3, the presence of PF inhibited the hydrolysis process, and the higher the content of PF, the lower the degradation efficiencies of the model compounds. For instance, in the blank, the degradation efficiencies of BSA and dextran were 21.6% and 42.3%, respectively. When the dosage of PF was 0.4 g/g, the degradation efficiencies of BSA and dextran decreased to 16.5% and 34.5%, respectively. When the dosage of PF further increased to 0.8 g/g, the degradation efficiencies of BSA and dextran also decreased to 15.9% and 31.2%, indicating that the presence of PF inhibited the hydrolysis process. PF has a certain oxidation property, which can inhibit the activity of enzyme to a certain extent, thus reducing the hydrolysis efficiency.

As for acidification, the presence of PF also reduced the degradation of l-alanine and glucose. As shown in Table 3, when the dosage of PF was 0.4 g/g, the degradation rates of l-alanine and dextran were 27.8% and 30.3%, respectively, which were 75.3% and 73.1% of those in the blank. In addition, the higher the dosage of PF, the lower the degradation rate of the model compounds. The strong oxidation of PF also inhibited acidogenic microorganisms. Previous studies have shown that the strong oxidation of PF can destroy the cell integrity of anaerobic microorganisms, thereby affecting metabolism (Lan et al. 2011). The results further implied that PF inhibited the acidification process. Similar experimental results were also found in the acetogenesis and homoacetogenesis processes.

Consumption of acetate to produce methane is the main way of methanogenesis process. This study also investigated the influence of PF on methanogenesis process. As shown in Table 3, the consumption rate of NaAC in the blank group was 65.8% on 2d, while the degradation rate of NaAC decreased rapidly to 61.5% when PF was 0.1 g/g, and the degradation efficiency of NaAC decreased from 51.6 to 30.2% when PF was further increased from 0.2 to 0.8 g/g, indicating that the presence of PF significantly reduced the activity of methanogenous archaea. PF can oxidize bacteria when added to fermentation system. In addition, PF also releases oxygen in the reaction process (Eq. 2). Methanogenic archaea are strictly anaerobic bacteria, and the presence of oxygen can reduce the activity of methanogenic archaea. Figure 6 shows the influence of PF on each step of food waste dark fermentation. Through the above batch tests, it is clear that PF could inhibit hydrolysis, acidification, acetogenesis, homoacetogenesis, and methanogenesis processes to a certain extent, and the inhibition is closely related to the dosage of PF. The generation of hydrogen is the comprehensive result of these bioprocesses. Although hydrolysis and acidification are inhibited by PF, the disintegration process of food waste is significantly accelerated, resulting in a large amount of soluble organic matter in the liquid phase. Therefore, the hydrogen-producing microorganisms utilize the available organic substances to carry out their own metabolism to enhance hydrogen production. He et al. (2018) also reported that the presence of PF can promote the accumulation of SCFA.

Analysis of key enzyme activities

As shown in Fig. 7, the presence of PF inhibited the key enzymes (protein and α-glucosidase) in the hydrolysis process, and the higher the content of PF, the more obvious the inhibition of the relative activity of key enzymes. When the dosage of PF was 0.4 g/g, the relative activities of protease and α-glucosidase decreased to 94.5% and 95.1%, respectively. When the dosage of PF further increased to 0.8 g/g, the relative activities of protein and α-glucosidase further decreased to 86.5% and 81.5%, which were consistent with the results in Table 3. The activities of AK and BK are related to the accumulation of SCFA, and the presence of PF also inhibited AK and BK. F420 is a peculiar coenzyme of Archaea methanogens. The presence of PF significantly suppressed the activity of F420. In Fig. 4, the higher the dosage of PF, the greater the accumulation of SCFA, which can be attributed to the higher inhibition of PF on methanogenic archaea than on the acidification enzymes. PF has been widely used in sludge anaerobic treatment (Li et al. 2018; Li et al. 2019a, b; He et al. 2018). The results showed that PF enhanced the SCFA and methane accumulation in the sludge fermentation process and can also promote sludge dewatering when PF and ultrasound were combined. Therefore, PF was a promising additive for enhancing organic matter anaerobic fermentation for energy recovery. In addition, the strong oxidizing property of PF has a killing effect on pathogens during anaerobic fermentation of organic matter. Therefore, it can be concluded that the presence of PF has a greater benefit for subsequent anaerobic processes.

Economic analysis

Economy is often considered in the operation of anaerobic fermentation of food waste, so it is very important to analyze the economy of dark fermentation of food waste. Compared with the conventional dark fermentation of food waste, increasing PF pretreatment will increase the economic load. However, the valuable product hydrogen, SCFA, will be significantly increased, which makes up for the energy input in the early stage. According to the results of this experiment, the scale-up of the reactor is calculated and its economic feasibility is analyzed. As shown in Table S1, in the blank, an economic benefit of 6553 yuan can be obtained by treating 1 ton of food waste under ideal condition. When the dosage of PF exceeded 0.4 g/g, the economy was poor due to the high pretreatment cost. Compared with the blank, when the dosage of PF was 0.1 g/g, the application of PF pretreatment improved the economics of hydrogen production from anaerobic dark fermentation of food waste, and the saving costs can be up to 2456 yuan. Therefore, from an economic point of view, the optimal dosage of PF was 0.1 g/g.

Implications

In this work, the feasibility of using PF to enhance anaerobic dark fermentation of food waste to produce hydrogen was verified, and the underlying mechanism had been revealed for the first time. When the dosage of PF was 0.4 g/g, the maximum hydrogen production was 173.5 mL/g (2.1 mol-H2/mol-hexose), which was about 1.2 times that of the blank group. In addition, PF shortened the lag phase of dark fermentation. Mechanisms revealed that PF could promote the disintegration of food waste. To the best of our knowledge, this is the first time that PF was applied to enhance anaerobic dark fermentation of food waste to produce hydrogen. The experimental results obtained in this study not only help to use the anaerobic dark fermentation of food waste to produce hydrogen but also explain the application of PF in food waste. Although the amount of PF added in this work was a bit large, when PF is coupled with other process conditions (such as pH, temperature), it may reduce the amount of PF added and produce a synergistic effect on the production of hydrogen, which is also one of the research directions in the future.

Applying appropriate strategies to improve food waste dark fermentation to produce energy substances hydrogen has been widely aroused the interest of the scholars. Anaerobic fermentation can effectively utilize the organic substances such as proteins and polysaccharides available in food waste. Pathogens and refractory pollutants in food waste can affect the performance of dark fermentation. PF is highly oxidative and has been proved to promote the decomposition of refractory organic compounds such as diclofenac and trichloromethane (Wang et al. 2015; Li et al. 2016). Therefore, it can be inferred that the application of PF can inactivate pathogens to a certain extent or promote the decomposition of refractory organic matter, which needs further experimental exploration.

Conclusion

In this work, a new strategy, namely the application of PF, a strong oxidant, to improve the production of hydrogen from dark fermentation of food waste has been reported for the first time. The results showed that PF significantly promoted the production of hydrogen from food waste, and the hydrogen yield was 173.5 mL/g when the dosage of PF was 0.4 g/g. In addition, PF shortened the lag phase for dark fermentation of food waste. The mechanism investigation showed that PF promoted the content of soluble organic matter in food waste. When PF was 0.4 g/g, the concentration of soluble COD was 21.3 g/L; the concentrations of soluble protein and soluble polysaccharide were 8.9 and 2.5 g/L, respectively, which were significantly higher than those of the blank. However, the presence of PF caused different degrees of inhibition on the hydrolysis, acidification, acetogenesis, homoacetogenesis, and methanogenesis processes. Economic analysis indicated that 0.1 g/g PF was the optimal dosage.

References

APHA (American Public Health Association), 1998. Standard methods for the examination of water and wastewater, twentieth ed. (Washington)

An Y, Zhou Z, Yao J, Niu T, Qiu Z, Ruan D, Wei H (2017) Sludge reduction and microbial community structure in an anaerobic/anoxic/oxic process coupled with potassium ferrate disintegration. Bioresour Technol 245:954–961

Ariunbaatar J, Panico A, Esposito G, Pirozzi F, Lens PN (2014) Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl Energy 123:143–156

Bundhoo MZ, Mohee R, Hassan MA (2015) Effects of pre-treatment technologies on dark fermentative biohydrogen production: a review. J Environ Manag 157:20–48

Chen Y, Xiao N, Zhao Y, Mu H (2012) Enhancement of hydrogen production during waste activated sludge anaerobic fermentation by carbohydrate substrate addition and pH control. Bioresour Technol 114:349–356

Chiu SLH, Lo IMC (2016) Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environ Sci Pollut Res 23(24):24435–24450

Chu CF, Li YY, Xu KQ, Ebie Y, Inamori Y, Kong HN (2008) A pH-and temperature-phased two-stage process for hydrogen and methane production from food waste. Int J Hydrog Energy 33(18):4739–4746

Dinesh GK, Chauhan R, Chakma S (2018) Influence and strategies for enhanced biohydrogen production from food waste. Renew Sust Energ Rev 92:807–822

Ding L, Cheng J, Qiao D, Yue L, Li YY, Zhou J, Cen K (2017) Investigating hydrothermal pretreatment of food waste for two-stage fermentative hydrogen and methane co-production. Bioresour Technol 241:491–499

Elbeshbishy E, Hafez H, Dhar BR, Nakhla G (2011) Single and combined effect of various pretreatment methods for biohydrogen production from food waste. Int J Hydrog Energy 36(17):11379–11387

Fan J, Lin BH, Chang CW, Zhang Y, Lin TF (2018) Evaluation of potassium ferrate as an alternative disinfectant on cyanobacteria inactivation and associated toxin fate in various waters. Water Res 129:199–207

Feng M, Cizmas L, Wang Z, Sharma VK (2017) Activation of ferrate (VI) by ammonia in oxidation of flumequine: kinetics, transformation products, and antibacterial activity assessment. Chem Eng J 323:584–591

Feng Y, Zhang Y, Quan X, Chen S (2014) Enhanced anaerobic digestion of waste activated sludge digestion by the addition of zero valent iron. Water Res 52:242–250

Han W, Ye M, Zhu AJ, Zhao HT, Li YF (2015) Batch dark fermentation from enzymatic hydrolyzed food waste for hydrogen production. Bioresour Technol 191:24–29

He ZW, Liu WZ, Gao Q, Tang CC, Wang L, Guo ZC, Zhou A, Wang AJ (2018) Potassium ferrate addition as an alternative pre-treatment to enhance short-chain fatty acids production from waste activated sludge. Bioresour Technol 247:174–181

Jarunglumlert T, Prommuak C, Putmai N, Pavasant P (2018) Scaling-up bio-hydrogen production from food waste: feasibilities and challenges. Int J Hydrog Energy 43(2):634–648

Karadag D, Köroğlu OE, Ozkaya B, Cakmakci M, Heaven S, Banks C (2014) A review on fermentative hydrogen production from dairy industry wastewater. J Chem Technol Biotechnol 89(11):1627–1636

Kim DH, Kim SH, Jung KW, Kim MS, Shin HS (2011) Effect of initial pH independent of operational pH on hydrogen fermentation of food waste. Bioresour Technol 102(18):8646–8652

Kiran EU, Trzcinski AP, Ng WJ, Liu Y (2014) Bioconversion of food waste to energy: a review. Fuel 134:389–399

Kong X, Wei Y, Xu S, Liu J, Li H, Liu Y, Yu S (2016) Inhibiting excessive acidification using zero-valent iron in anaerobic digestion of food waste at high organic load rates. Bioresour Technol 211:65–71

Lan H, Liu X, Wang L, Chen Y (2011) Effect of potassium ferrate on growth of microorganisms and physicochemical characters of sludge. China Environ Sci 31(8):1285–1288 (In Chinese)

Lee C, Lee S, Han SK, Hwang S (2014) Effect of operational pH on biohydrogen production from food waste using anaerobic batch reactors. Water Sci Technol 69(9):1886–1893

Li M, Zhao Y, Guo Q, Qian X, Niu D (2008) Bio-hydrogen production from food waste and sewage sludge in the presence of aged refuse excavated from refuse landfill. Renew Energy 33(12):2573–2579

Li WW, Yu HQ, He Z (2014) Towards sustainable wastewater treatment by using microbial fuel cells-centered technologies. Energy Environ Sci 7(3):911–924

Li Q, Jin W, Ma X, Li G, Chen G, Gao N, Liao W (2016) Study on the degradation of triclosan in aqueous by potassium ferrate. China Environ Sci 36(9):2665–2671 (In Chinese)

Li W, Yu N, Fang A, Liu B, Ren N, Xing D (2019a) Co-treatment of potassium ferrate and ultrasonication enhances degradability and dewaterability of waste activated sludge. Chem Eng J 361:148–155

Li W, Yu N, Liu Q, Li Y, Ren N, Xing D (2018a) Enhancement of the sludge disintegration and nutrients release by a treatment with potassium ferrate combined with an ultrasonic process. Sci Total Environ 635:699–704

Li L, He J, Xin X, Wang M, Xu J, Zhang J (2018b) Enhanced bioproduction of short-chain fatty acids from waste activated sludge by potassium ferrate pretreatment. Chem Eng J 332:456–463

Liu X, Xu Q, Wang D, Wu Y, Yang Q, Liu Y, Wang Q, Li X, Li H, Zeng G, Yang G (2019) Unveiling the mechanisms of how cationic polyacrylamide affects short-chain fatty acids accumulation during long-term anaerobic fermentation of waste activated sludge. Water Res 155:142–151

Li Y, Jin Y, Borrion A, Li H (2019b) Current status of food waste generation and management in China. Bioresour Technol 273:654–665

Ma J, Liu W (2002) Effectiveness and mechanism of potassium ferrate (VI) preoxidation for algae removal by coagulation. Water Res 36(4):871–878

Ni M, Leung DY, Leung MK, Sumathy K (2006) An overview of hydrogen production from biomass. Fuel Process Technol 87(5):461–472

Qiao X, Zhao C, Shao Q, Hassan M (2018) Structural characterization of corn stover lignin after hydrogen peroxide presoaking prior to ammonia fiber expansion pretreatment. Energy Fuels 32 32(5):6022–6030

Silva FM, Mahler CF, Oliveira LB, Bassin JP (2018) Hydrogen and methane production in a two-stage anaerobic digestion system by co-digestion of food waste, sewage sludge and glycerol. Waste Manag 76:339–349

Saeed MA, Ma H, Yue S, Wang Q, Tu M (2018) Concise review on ethanol production from food waste: development and sustainability. Environ Sci Pollut Res 25(29):28851–28863

Song J, Ren N, An D, Duan Z (2006) Conversion and comparation for biological hydrogen production fermentative types. Water Purification Technol 25(6):55–59 (In Chinese)

Tamilarasan K, Arulazhagan P, Rani RU, Kaliappan S, Banu JR (2018) Synergistic impact of sonic-tenside on biomass disintegration potential: acidogenic and methane potential studies, kinetics and cost analytics. Bioresour Technol 253:256–261

Tao Z, Yang Q, Yao F, Huang X, Wu Y, Du M, Chen S, Liu X, Li X, Wang D (2019) The inhibitory effect of thiosulfinate on volatile fatty acid and hydrogen production from anaerobic co-fermentation of food waste and waste activated sludge. Bioresour Technol:122428. https://doi.org/10.1016/j.biortech.2019.122428

Tao Z, Wang D, Yao F, Huang X, Wu Y, Du M, Chen Z, An H, Li X, Yang Q (2020) The effects of thiosulfinates on methane production from anaerobic co-digestion of waste activated sludge and food waste and mitigate method. J Hazard Mater 384:121363. https://doi.org/10.1016/j.jhazmat.2019.121363

Vidal G, Carvalho A, Mendez R, Lema J M (2000) Influence of the content in fats and proteins on the anaerobic biodegradability of dairy wastewaters. Bioresour Technol 74: 231-239.

Wang Y, Liu H, Liu G, Xie Y, Gao S (2015) Oxidation of diclofenac by potassium ferrate (VI): reaction kinetics and toxicity evaluation. Sci Total Environ 506:252–258

Wang D, Zhang D, Xu Q, Liu Y, Wang Q, Ni BJ, Yang Q, Li X, Yang F (2019) Calcium peroxide promotes hydrogen production from dark fermentation of waste activated sludge. Chem Eng J 355:22–32

Wu P, Huo P, Wang Y, Dong Y, Cui Y, Chen Z, Zhang Y, Wu X (2020) Practicality of effluent containing Rubrivivax gelatinosus culturing the crucian carp. Aquaculture 514:734418. https://doi.org/10.1016/j.aquaculture.2019.734418

Wang J, Wan W (2009) Factors influencing fermentative hydrogen production: a review. Int J Hydrog Energy 34(2):799–811

Xiao B, Qin Y, Zhang W, Wu J, Qiang H, Liu J, Li YY (2018) Temperature-phased anaerobic digestion of food waste: a comparison with single-stage digestions based on performance and energy balance. Bioresour Technol 249:826–834

Yasin NHM, Mumtaz T, Hassan MA (2013) Food waste and food processing waste for biohydrogen production: a review. J Environ Manag 130:375–385

Yazdanpanah A, Ghasimi DSM, Kim MG, Nakhla G, Hafez H, Keleman M (2018) Impact of trace element supplementation on mesophilic anaerobic digestion of food waste using Fe-rich inoculum. Environ Sci Pollut Res 25(29):29240–29255

Yin J, Yu X, Zhang Y, Shen D, Wang M, Long Y, Chen T (2016a) Enhancement of acidogenic fermentation for volatile fatty acid production from food waste: effect of redox potential and inoculum. Bioresour Technol 216:996–1003

Yin B, Liu H, Wang Y, Bai J, Liu H, Fu B (2016b) Improving volatile fatty acids production by exploiting the residual substrates in post-fermented sludge: protease catalysis of refractory protein. Bioresour Technol 203:124–131

Yuan T, Bian S, Ko JH, Wu H, Xu Q (2019) Enhancement of hydrogen production using untreated inoculum in two-stage food waste digestion. Bioresour Technol 282:189–196

Zhao J, Liu Y, Wang D, Chen F, Li X, Zeng G, Yang Q (2017a) Potential impact of salinity on methane production from food waste anaerobic digestion. Waste Manag 67:308–314

Zhao C, Qiao X, Cao Y, Shao Q (2017b) Application of hydrogen peroxide presoaking prior to ammonia fiber expansion pretreatment of energy crops. Fuel 205:184–191

Zhao J, Liu Y, Wang Y, Lian Y, Wang Q, Yang Q, Wang D, Xie G, Zeng G, Sun Y, Li X, Ni B (2018) Clarifying the role of free ammonia in the production of short-chain fatty acids from waste activated sludge anaerobic fermentation. ACS Sustain Chem Eng 6(11):14104–14113

Zhao J, Jing Y, Zhang J, Sun Y, Wang Y, Wang H, Bi X (2019) Aged refuse enhances anaerobic fermentation of food waste to produce short-chain fatty acids. Bioresour Technol 121547 https://doi.org/10.1016/j.biortech.2019.121547

Zhao J, Xin M, Zhang J, Sun Y, Luo S, Wang H, Wang Y, Bi X (2020) Diclofenac inhibited the biological phosphorus removal: performance and mechanism. Chemosphere:125380. https://doi.org/10.1016/j.chemosphere.2020.125380

Zhang M, Gao M, Yue S, Zheng T, Gao Z, Ma X, Wang Q (2018) Global trends and future prospects of food waste research: a bibliometric analysis. Environ Sci Pollut Res 25(25):24600–24610

Zhou S, Shao Y, Gao N, Zhu S, Li L, Deng J, Zhu M (2014) Removal of Microcystis aeruginosa by potassium ferrate(VI): impacts on cells integrity, intracellular organic matter release and disinfection by-products formation. Chem Eng J 251:304–309

Zhu J, Zhao Y, Li X, Chen W (2018) Effects of chlorimuron-ethyl on soil microorganisms and enzyme activities under moderate salt stress. Fresenius Environ Bull 27(4):2358–2365

Zhu J, Fug L, Jin C (2019a) Study on the biodegradation characteristics of isofenphos-methyl and isolation of an isofenphos-methyl degrading bacterium, Bacillus atrophaeus IM-5. Fresenius Environ Bull 28(3):1794–1800

Zhu J, Fu L, Jin C, Meng Z, Yang N (2019b) Study on the isolation of two atrazine-degrading bacteria and the development of a microbial agent. Microorganisms 7(3):80. https://doi.org/10.3390/microorganisms7030080

Zhu J, Fu L, Meng Z, Jin C (2019c) Characteristics of an atrazine degrading bacterium and the construction of a microbial agent for effective atrazine degradation. Water Environ J. https://doi.org/10.1111/wej.12491

Zhu J, Zhao Y, Ruan H (2019d) Comparative study on the biodegradation of chlorpyrifos-methyl by Bacillus megaterium CM-Z19 and Pseudomonas syringae CM-Z6. An Acad Bras Cienc, 91(3). 91: e20180694. https://doi.org/10.1590/0001-3765201920180694

Funding

This research was financially supported by the project of National Natural Science Foundation of China (NSFC) (No. 51908305; 51978350), the Project funded by China Postdoctoral Science Foundation (2019M660162), the Open Project Fund of Qingdao University of Technology (QUTSEME201906), Qingdao Science and Technology Program (17-3-3-77-nsh), and the Shandong Province Key Research and Development Program, China (2017GSF217009).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOC 56 kb)

Rights and permissions

About this article

Cite this article

Kuang, Y., Zhao, J., Gao, Y. et al. Enhanced hydrogen production from food waste dark fermentation by potassium ferrate pretreatment. Environ Sci Pollut Res 27, 18145–18156 (2020). https://doi.org/10.1007/s11356-020-08207-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08207-3