Abstract

A submerged anaerobic membrane bioreactor (SAnMBR) was used to treat low-concentration domestic sewage. The effects of hydraulic retention time (HRT) and organic load (OLR) on chemical oxygen demand (COD) removal, methanogenesis, and membrane fouling of the system were investigated. The SAnMBR achieved good COD removal efficiency as well as stable methane production, which were significantly affected by both OLR and HRT. The influent dissolved organic matter (DOM) was decomposed and transformed over time, and DOM concentration was gradually reduced. It can be inferred that the SAnMBR can effectively intercept the production of extracellular polymeric substances and improve effluent quality. The phenomenon of membrane fouling was investigated using various analytical tools. Results demonstrated that the SAnMBR was achieved good transmembrane pressures (TMP) (10–15 kPa), and the hydraulic force generated by the stirring device has a dynamic physical shearing action on the surface of the membrane, which can partly alleviate membrane fouling.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Given China’s population growth and the acceleration of social and economic development and urbanization processes, the amount of urban domestic sewage in China is increasing. Strengthening the efficient treatment and resource utilization of domestic sewage is therefore an important issue that needs to be addressed in China (Gu et al. 2016). Domestic sewage is generally characterized by low concentrations of chemical oxygen demand (COD), nitrogen, and phosphorus. At present, most domestic sewage treatment processes use anaerobic or aerobic biological treatment processes. However, most conventional anaerobic and aerobic biological treatment processes have problems such as poor treatment effects, long hydraulic retention time (HRT), and easy sludge loss. Two of the most pressing problems are high operating costs and the inability to recover energy during sewage treatment (Kassab et al. 2010). Membrane bioreactors (MBR) provide a new high-efficiency wastewater treatment process which combines membrane separation technology with microbiology and biochemistry (Skouteris et al. 2012). This process can effectively avoid low sludge concentrations under the premise of improving the quality of effluent water. This has provided sludge expansion improvements and other benefits to the fields of sewage treatment and sewage resource utilization on a large scale (Domínguez et al. 2012; Liao et al. 2006). However, in-depth research and development of the membrane bioreactor process has found that this process still has several disadvantages: it requires a wide surface area, uses high energy consumption, and is unable to recover energy from the sewage. In order to solve these problems, the emergence of anaerobic membrane biological treatment processes have attracted increased attention from scholars in the field of sewage treatment. The anaerobic membrane bioreactor (AnMBR) has the advantages of extremely high sludge residence time, no loss of biomass in the reactor, good effluent quality, low residual sludge production, small floor space requirements, and the provision of energy recovery from sewage (Lin et al. 2011; Chan et al. 2009). At present, anaerobic membrane biological treatment processes have been applied to the treatment of high-concentration organic wastewater, including starch wastewater, in the food industry, and in slaughter wastewater treatment; they have achieved good pollutant removal and energy recovery efficiencies (Shin and Bae 2018).

According to the structural form of the membrane tank, AnMBR is mainly divided into three types: separated anaerobic membrane bioreactor (SeAnMBR), submerged anaerobic membrane bioreactor (SAnMBR), and tubular anaerobic membrane bioreactor. Among them, SeAnMBR separates the anaerobic tank and the membrane tank and is mainly used to treat high-strength organic wastewater, whereas SAnMBR integrates the anaerobic tank and the membrane tank together, saving floor space and recycling the energy consumed. SAnMBR can provide better pollutant treatment effects and more suitable microbial activity when dealing with low-concentration urban sewage. By coupling the anaerobic biological treatment and membrane treatment processes, SAnMBR can effectively separate HRT and sludge residence time (SRT). It also has the additional advantages of stable operation, strong impact load resistance, and the ability to recover energy gas (Gao et al. 2016; Zhang et al. 2017a, b). Additionally, it has good potential for the treatment of low-concentration domestic sewage (McCarty et al. 2011; Smith et al. 2014). SAnMBR is mainly composed of two units which work in combination to retain and degrade pollutants and thus, remove them from sewage: an anaerobic unit for biodegradation and a membrane unit for physical retention. The anaerobic unit decomposes organic pollutants in sewage into CH4 and CO2 through hydrolysis acidification and biological oxidation stages, whereas the membrane unit physically filters and traps contaminants attached to the surface of the membrane to efficiently remove contaminants (Santos et al. 2017; Liao et al. 2006).

In recent years, the use of SAnMBR to treat low-concentration domestic sewage has become an important area of research in China and globally (Hu et al. 2018; Chen et al. 2017). The results of Smith et al. (2013) show that at 15 °C, SAnMBR can effectively treat domestic sewage and the daily methane production is between 450 and 650 mL/day, of which 50% of the methane remains in the liquid phase (Smith et al. 2013). The results of Giménez et al. (2011) show that the removal efficiency of COD from domestic wastewater was 87% and the methane content in biogas is nearly 55% (Giménez et al. 2011). Martinez-Sosa et al. (2011) also use SAnMBR to treat domestic sewage: here, methane production is 0.2–0.25 LCH4/g of COD removed, and the COD removal efficiency is 90% (Martinez-Sosa et al. 2011). In general, current research on the treatment of low-concentration domestic sewage by SAnMBR is mainly focused on the feasibility of COD removal and methane production. Previous studies have lacked a system able to study methanogenesis characteristics, process parameter influence and optimization, and study membrane fouling during the treatment of low-concentration domestic sewage by SAnMBR.

In this study, a small-scale SAnMBR system was constructed to study the COD removal and methane production characteristics of a SAnMBR system. The effects of HRT and organic load (OLR) on COD removal and methanogenesis of the system were investigated. Based on this research, dissolved organic matter (DOM) and its relationship to membrane properties (transmembrane pressure difference (TMP) and total resistance) were mainly studied. The research results can provide a technical basis for the application of the new anaerobic membrane biological treatment processes to the treatment of low-concentration domestic sewage.

Materials and methods

Experimental equipment

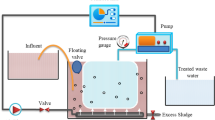

This study used a small-scale SAnMBR system in the laboratory. The schematic of the system is shown in Fig. 1.

The SAnMBR system was composed of the main unit, a monitoring unit, and a gas-collecting unit, wherein the main unit is composed of a hollow fiber membrane, influent pump, mixer, and bioreactor main body. The monitoring unit was mainly used to monitor TMP inside the membrane and was composed of a pressure gage, level controller, temperature sensor, and programmable logic controller (PLC) control device. The gas collection unit was mainly used for collecting and measuring methane gas and was composed of a gas bottle and gas meter.

The reactor was a cylindrical container with an effective volume of 12 L, aspect ratio of 2.25, and internal height of 8 cm in the reactor. PVDF hollow fiber MF membranes with molecular weight cut-off (MWCO) of 0.03 μm used in our study were purchased from MOTIMO Inc. (Tianjin, China). The effective area of the MF membrane was 0.26 m2 and the inner and outer diameters of the hollow fiber are 0.6 and 1.1 mm, respectively. A mixer is situated below the membrane unit. The temperature sensor system was set to operate at 35 °C. The biogas produced in the reactor was absorbed by an acid gas absorption bottle containing 0.1 mol/L NaOH.

Wastewater and inoculum

This experiment uses the domestic sewage of Beijing University of Civil Engineering and Architecture as the target sewage for treatment. The composition of wastewater is shown in Table 1. The sludge inoculated during the start-up period of the system was obtained from the anaerobic digestion tank of a municipal sewage treatment plant in Beijing. The mixed liquor-suspended solids (MLSS) of the inoculated sludge were 2.84 g/L, the mixed liquor volatile-suspended solids (MLVSS) were 2.56 g/L, and the pH was 7.34.

Experimental operating conditions

The level controller was used to control the inlet water of the reactor. The operation mode was constant flux and intermittent water discharge. The opening and stopping times of the effluent pump were 3 min and 1 min, respectively, and the average speed of the mixer was 150 rpm.

The operation of the SAnMBR system includes four periods: start-up period, steady-state period I, steady-state period II, and steady-state period III, as well as post-film cleaning stages, for a total of 145 days. The operating parameters of each period are shown in Table 2.

Analysis method

MLSS, MLVSS, and COD were determined according to Standard Methods (APHA 2005). pH was measured using a pH-meter (WTW, pH 1970; pH-Electrode Sentix41, Xylem Analytics GmbH). Volatile fatty acid (VFA) concentrations were determined via five-point titrations (WRC.1992). DOM and extracellular polymeric substances (EPS) were measured using three-dimensional fluorescence spectroscopy (EEM, Hitachi F-7000) (Martinez-Sosa et al. 2012). The peristaltic pump (BT00-100M, Longer Pump) and the pressure gauge (YB-150A, China) were consecutively connected to the outlet pipe of the membrane, such that the effluent was pumped by the peristaltic pump and the TMP was monitored by the pressure gauge.

Biogas was collected in an aluminum foil air bag and the volume of this biogas was measured by a wet gas flow meter. The methane fraction of the biogas was measured using a gas chromatograph (GC-FID, Thermo Scientific) equipped with a flame ionization detector in accordance with Giménez et al. (2011). The methane determination conditions were as follows: the column was stainless steel (3 mm internal diameter; 3 m height), filled with 80/100 mesh Porapark-Q, column temperature was 50 °C, inlet temperature was 100 °C, detector temperature was 175 °C, and the carrier gases were N2 (50 mL/min), H2 (60 kPa, 50 mL/min), and air (50 kPa, 500 mL/min).

The determination of the concentration of dissolved methane in the effluent was as follows, according to the method described by Souza et al. (2011). First, 25 mL of the effluent sample was collected in a vial of volume 60 mL and immediately sealed with a rubber stopper and a foil paper. These vials were placed at room temperature for 4 h and shaken with a shaker for 30 min to obtain a gas-liquid balance. Next, 0.5 mL of the gas in the headspace of the vial was removed with a sealed syringe and injected into the gas chromatograph to determine the percentage of methane. Subsequently, the bottles were weighed to obtain the liquid weight and gas volume of each bottle. Finally, the dissolved methane concentration in the water was calculated.

Results and discussion

Operating characteristics of the SAnMBR system

Based on two indicators—influent COD removal efficiency and the daily methane production—the operation and characteristics of the SAnMBR system in the start-up period and the steady-state period were studied. The results are shown in Fig. 2.

The results in Fig. 2 show that during the 30-day start-up period, the influent COD removal efficiency and the daily methane production by the SAnMBR system first increased and then stabilized. In the first 13 days, the influent COD removal efficiency was < 60%, and the daily methane production was only 152.8 mL/day. By the end of the start-up period, the COD removal efficiency was 72%, while the daily methane production was 360.31 mL/day. In general, during the start-up period, the COD removal efficiency and the daily methane production were relatively low in the SAnMBR system. This was mainly because during the start-up period, the newly inoculated anaerobic sludge in the system was still in an adaptive state, and the anaerobic microorganisms were slow to grow, resulting in lower activity, thus limiting the degradation of influent COD and methane production (Demirel and Scherer 2008; Moletta et al. 2005; Basset et al. 2014).

During the steady-state period, COD removal efficiency and the daily methane production of the SAnMBR system were both relatively high and relatively stable. During the steady-state period, the corresponding HRTs were controlled at 15 h, 10 h, and 6 h, respectively, and the average COD removal efficiencies were 80.23%, 82.69%, and 78.19%, respectively. Correspondingly, the average daily methane production values were 408 mL/day, 755 mL/day, and 1026 mL/day, respectively. This indicated that during the steady-state period, the dominant microbial population in the system had adapted to the environmental changes, and the microbial activity was gradually enhanced and in a relatively increased state, so that the COD removal efficiency and daily methane production were both high.

Effect of HRT on COD removal and methanogenesis in the SAnMBR system

HRT is one of the important parameters affecting COD degradation and methanogenesis in the SAnMBR system (Yue et al. 2015; Huang et al. 2011). The characteristics of COD removal and methanogenesis in the SAnMBR system were investigated during the steady-state period, when HRT was 15 h, 10 h, and 6 h, respectively. The results are shown in Figs. 2 and 3.

Figure 2 shows that in the steady-state periods I, II, and III of the SAnMBR system, when HRT was 15 h, the OLR of the SAnMBR system was lower, the COD concentration of the effluent was lower, and the stability was approximately 100 mg/L. When the HRT was 10 h, the effluent COD concentration was 94–119 mg/L, and the COD removal efficiency was approximately 82.69%. When the HRT was 6 h, the COD removal efficiency of the system was reduced to approximately 78.19%. It can be seen that the reduction of HRT had a certain impact on the COD removal efficiency of the SAnMBR system. As the HRT was varied, the anaerobic microorganisms in the system need to undergo an adaptation process to cope with the HRT changes (Watanabe et al. 2016).

In summary, HRT had a measurable effect on COD removal within the SAnMBR system, but the SAnMBR system had a certain impact on load resistance. It can operate stably when the HRT was 6–15 h, and the COD removal efficiency was > 70%. The effluent COD was below 110 mg/L.

Figure 3 shows that as HRT decreased, the amount of methane produced per unit of COD gradually decreased. For example, when HRT was 15 h, the amount of methane produced per unit of COD was 80.43 mL/g COD (methane yield was 0.28 mL CH4/g COD removed), and when the HRT was lowered to 6 h, the amount of methane produced per unit of COD was reduced to 58.70 mL/g COD (methane yield was 0.20 mL CH4/g COD removed). Many researchers have reported similar observations, for example Sutton et al. (2011) and Hu and Stuckey (2006). However, with the decrease in HRT, the amount of methane produced per unit of volume and the amount of methane produced per unit of MLVSS increased gradually. When HRT was 15 h, the amount of methane produced per unit of volume and the amount of methane produced per unit of MLVSS were 34.66 L/m3/day and 6.45 mL/g MLVSS/day, respectively. When HRT was reduced to 8 h, the amount of methane produced per unit of volume and the amount of methane produced per unit of MLVSS increased to 66.49 L/m3/day and 11.18 mL/g MLVSS/day, respectively. This indicated that even if the system HRT was lowered and the organic load was increased, the methanogens can maintain high activity and function well.

The methane gas generated during the treatment of sewage by SAnMBR will partly escape in gaseous form, while the other part will dissolve in the liquid phase (Martinez-Sosa et al. 2011). The results in Fig. 3 show that the amount of gaseous methane and dissolved methane produced by the SAnMBR system increased with the decrease in HRT; however, the ratio of dissolved methane production to total methane production was relatively stable. The average was approximately 36.72% (Yeo and Lee 2013; De Graaff et al. 2010). This was in agreement with the findings of scholars such as Smith et al. (2013), who found that the dissolved methane production of the SAnMBR system accounted for 30–60% of total methane production (Smith et al. 2013).

In summary, within a certain range, reducing HRT was beneficial to the generation of methane gas in the SAnMBR system. At the same time, the reduction of HRT was beneficial to the reduction of the reactor volume and thus reduces the system infrastructure cost (An et al. 2009). However, reducing HRT by too much may reduce the COD removal efficiency of the SAnMBR system. Therefore, in practical applications, system COD removal efficiency, methane production, and engineering construction investment should be considered comprehensively, and reasonable system HRT parameters should be selected (Jeong et al. 2010).

Effect of OLR on COD removal and methanogenesis in the SAnMBR system

The effects of OLR on the characteristics of COD removal and methanogenesis in the SAnMBR system were investigated. The results are shown in Figs. 2 and 4.

It can be concluded from Fig. 2 that in the steady-state periods I, II, and III of the SAnMBR system, the corresponding average OLRs were 0.72 kg COD/m3/day, 1.18 kg COD/m3/day, and 1.42 kg COD/m3/day, respectively. The OLR appropriately increased within a certain range and improved the COD removal efficiency to some extent (Nie et al. 2017). Overall, the COD removal efficiency in the steady-state period of the SAnMBR system remains relatively stable, which reflects the good impact load resistance of the SAnMBR. In spite of that, there was an increase in the load, but it still remained at very low values. This is because when microbial and substrate contact time and contact space were reduced, mass transfer was not sufficient, and EPS on the surface of microbial cells can protect the reactor and mitigate shock by reducing the mass transfer rate between substrate and sludge (Feng et al. 2008). It was worth noting that in the early stage of stable operation of the SAnMBR system, as the OLR suddenly increased from 1.40 kg COD/m3/day to 1.74 kg COD/m3/day, the COD removal efficiency decreased from 82.90 to 77.05%, and then stabilized at 80.08%. When the OLR was further increased, the excessive VFAs produced by hydrolysis inhibit the methanogen activity, resulting in a significant influence on the COD removal efficiency.

Figure 4 shows that as the OLR increases, the daily production of methane shows a positive trend. When the OLR was 0.72 kg COD/m3/day, 1.18 kg COD/m3/day, and 1.42 kg COD/m3/day, the average daily methane production of the system was 408 mL/day, 755 mL/day, and 1027 mL/day, respectively. In particular, the OLR increased from 1.18 to 1.42 kg COD/m3/day, and the daily production of methane increased significantly. This is similar to the results of Michaud et al. (2002): in the anaerobic fixed-film reactor, the daily gas production of methane also increased significantly with the increase of OLR (Michaud et al. 2002). This is because with the increase of OLR, the system produced more VFAs, which increased the amount of substrate available for methanogens, thereby increasing the daily production of methane to a certain extent. However, when the OLR exceeded a certain limit, VFAs accumulate in excess of the methanogens’ ability to utilize them and in fact begin to impede methanogen activity, and thus, the amount of methane produced decreases. Abdullah et al. (2015) have shown that with the increase of OLR to 2 kg COD/m3/day, the methane production increased gradually, but when the OLR was further increased, the methane production showed a downward trend (Abdullah et al. 2015). This is because when the concentration of VFAs was above a certain limit, the activity of methanogens will be inhibited, so that the daily increase in methane production was slow or even decreased. OLR therefore had a large effect on the daily methane production of the SAnMBR system. This finding was consistent with the results of Yeo et al. (2015) and other scholars (Yeo et al. 2015; Lin et al. 2011). The daily production of methane was directly proportional to the OLR. As the OLR increases, the amount of methane production increased linearly. However, OLR was not the only factor affecting the daily production of methane. In practical applications, comprehensive factors such as influent COD concentration, HRT, and SRT should be considered.

The generation of VFAs during the steady-state periods of the SAnMBR

The characteristics of VFA generation during the steady-state periods of the SAnMBR system were studied. The results are shown in Fig. 5.

It can be concluded from Fig. 5 that VFA concentration in the SAnMBR system was 65.6–170.78 mg/L, with an average of 119.1 mg/L during the steady-state periods of the entire SAnMBR system. The overall growth was stable in the early stage, the mid-term fluctuations were rising, and the later stage was gradually stable. The VFA concentration was greatly affected by the OLR. In steady-state period I, the HRT of the SAnMBR system was 15 h, and the VFA concentration gradually decreased from 83.56 to 65.58 mg/L (average 75.24 mg/L), which was related to the low and stable OLR at this stage. In steady-state period II, the system HRT was 10 h, and the VFA concentration was 98.87–153.35 mg/L (average 132.17 mg/L). At this stage, the VFA concentration increased due to the rapid increase of OLR. In steady-state period III, the system HRT decreased to 6 h, and the VFA concentration was 134.65–170.78 mg/L (average 149.87 mg/L). As a result of the increase in OLR, the VFAs produced by acid-producing bacteria metabolism can exceed the range that methanogens can use, and the effectiveness of methanogens was clearly inhibited. But as the microorganisms in the system have gradually adapted to higher OLR, the number and activity of methanogens have increased, which can then stably degrade VFAs produced during the hydrolysis fermentation stage (Xiao et al. 2016; Shi et al. 2017). In summary, the SAnMBR system maintained a stable and good operating condition with a HRT of 6 h.

DOM variation characteristics of the SAnMBR system

EM quantifies DOM in water and quickly reveals the classification and content of organic pollutants. The DOM contents of the SAnMBR influent, mixed liquid, and effluent were analyzed to obtain a three-dimensional spectrum of each sample. The results are shown in Fig. 6.

Combined with the fluorescence recognition spectrum of common organic matter (Che et al. 2003), the DOM contents of the SAnMBR influent, system mixture, and effluent were identified, and it can be concluded that zone I was aromatic protein 1, zone II was aromatic protein 2, zone III was fulvic acid, zone IV was soluble microbial byproducts (SMP), and zone V was humic acid. The organic matter in effluent (EfOM) was reported as a major foulant. The EfOM was more similar to that of mixed liquid than influent, especially in zones II, III, and V. The results indicated that the EfOM foulant was sourced from anaerobic digestion, rather than natural organic matter (NOM) as in influent (Sun et al. 2016; Zhang et al. 2017a, b).

Fluorescence intensity can be used to characterize the degree of organic contamination in wastewater. The DOM fluorescence intensity gradually weakens, and COD removal had a certain correlation with this (Hudson et al. 2007). It can be seen from the results in Fig. 6 that the center position of the characteristic fluorescence peak slightly shifted with the operation of the reactor, indicating that the DOM types of the reactor water, mixture, and effluent are similar, in which aromatic protein was the main component, followed by SMP. The two were still difficult to completely remove under biodegradation and membrane retention, in agreement with Martin-Garcia et al. (2011) who obtained similar results (Martin-Garcia et al. 2011). The fluorescence peaks of the influent, mixed liquid, and effluent were weakened in turn, and the main peak area gradually decreased, indicating that the influent DOM concentration gradually decreased as the decomposition and transformation continued. The DOM concentration in the mixed liquid decreased more obviously. This is consistent with the removal effect and characteristics of the influent COD by the SAnMBR as described in the above section: operating characteristics of the SAnMBR system. In addition, there is almost no offset in the center of the position of the three unit peaks of the SAnMBR, but the spectral intensity of the EEM has changed. In other words, the structure of the sewage through the anaerobic unit biological treatment, and then through the membrane unit to filter the retained protein, did not change significantly, but the substance concentration decreased, indicating that the SAnMBR can effectively intercept the treatment of EPS and improve effluent quality.

Membrane pollution characteristics of the SAnMBR system

The main factors affecting pollution removal by the SAnMBR membrane were the physical and chemical properties of membrane modules, the properties of microorganisms and sludge (EPS, MLSS, sludge viscosity, etc.), and system operating conditions. Among these, EPS is an important source of membrane pollution.

The EPS layer of the mud cake layer on the surface of the membrane was analyzed by EEM, and the EPS three-dimensional spectrum of each sample in different operation periods (45 day, 90 day, and 127 day) was obtained. The results are shown in Fig. 7.

It can be seen from Fig. 7 that with the operation of the SAnMBR, the EPS content of the mud cake layer on the surface of the membrane gradually increased, and the main components were SMP (the peak Ex/Em is located at 275/330–360 nm, which is a tryptophan protein) and aromatic protein. HU et al. (2018) pointed out that EPS affected the evolution of the structure and properties of the mud cake layer. The protein is hydrophobic and more likely to adhere to the surface of the membrane. It was considered to be the main pollution factor leading to rapid increase of TMP and total membrane resistance. Especially in the case of higher volume loads, as there are greater EPS concentrations, fine particles and colloids accumulate in the mud cake layer as the volumetric load increased (Hu et al. 2018).

Figure 8 shows no change in the concentration of polysaccharide during the stable operation stage of the SAnMBR. The concentration ranged from 52.32 to 92.64 mg/L, while the protein concentration and EPS concentration increased with the number of days of SAnMBR operation, from 83.49 to 298.64 mg/L and 142.02 to 387.02 mg/L. It can be seen that the trend and rhythm of the two are almost identical: generally speaking, at first, they gradually increased, then shown a slow decline in the middle, and finally they gradually increased, indicating that protein is the decisive factor affecting EPS. C/P, the ratio of protein to polysaccharide, changes in line with the EPS trend. When the SAnMBR was operated for about 60 days, the trend in EPS tends to be stable, and C/P is generally maintained between 0.3 and 0.4, indicating that microbial growth metabolism in the anaerobic unit and influent nutrients reach a dynamic equilibrium relationship. During the course of the experiment, it was found that by changing the rotation speed of the stirring device, it was possible to have a certain influence on the total film resistance. When the stirring speed was too fast, the growth of the anaerobic unit sludge flocs will be affected; when the stirring speed was too slow, the sludge will be precipitated, and the material basis of the anaerobic unit microorganisms was not uniform enough. Therefore, the operation of the stirring device not only mixed the anaerobic unit sludge and sewage, but also formed a good anaerobic biological reaction environment, and the hydraulic force formed by the stirring also has a dynamic physical shearing action on the surface of the membrane wire, to a certain extent relieving membrane fouling in the SAnMBR (Burman and Sinha 2017; Chang et al. 2002). The SAnMBR has higher membrane resistance, and lower fouling rates compared with MBR. The low fouling rate may be attributed to the hydrodynamic shear-force induced by the mechanical agitator.

The total resistance of TMP and membrane was directly related to membrane fouling and was an important indicator for evaluating the performance of the SAnMBR system. The change in TMP and total membrane resistance over time in the SAnMBR stabilization phase is shown in Fig. 9.

It can be seen from Fig. 9 that with the stable operation of the SAnMBR system, TMP and total membrane resistance increased over time, similar to the results of Khan et al. (2019). During the stable operation period from 29 to 85 days, the TMP changed slowly, generally maintaining between 10 and 15 kPa. The SAnMBR operated well during this time. During day 1 to day 85, TMP and total membrane resistance increased slowly, because the mud cake layer formed on the membrane surface was thinner, the EPS concentration was lower, and the membrane fouling was lighter. On the 85th to the 127th day, TMP increased almost exponentially, with TMP rising to 30.4 kPa and total membrane resistance rising to 24.7 × 1012 m−1. At this time, the volumetric load rose to 2.69 kg COD/(m3/day). At higher loads, accumulation of metabolites, change in sludge properties (biopolymer production), and biofilm formation will block membrane pores and reduce membrane filtration performance, increasing TMP and membrane total resistance. When the TMP was greater than 30.0 kPa, the membrane module needed to be cleaned (Khan et al. 2019). After the 128th day, the membrane module was hydraulically cleaned and briefly operated for 18 days. The TMP rapidly rose from 14.0 to 18.9 kPa, and the total membrane resistance rose from 5.49 × 1012 to 7.84 × 1012 m−1. It can be seen that although simple physical cleaning can slow down the membrane fouling, the long-running membrane pores have been blocked by small particulate matter, and TMP will rise rapidly after a short time. The results show that the SAnMBR was able to achieve TMP within an acceptable range (10–15 kPa), but that simple physical cleaning cannot eliminate the phenomenon of membrane pore blockage. However, the hydraulic force generated by the stirring device has a dynamic physical shearing action on the surface of the membrane, which can alleviate the membrane fouling of the SAnMBR to some extent.

Conclusion

Removal efficiency, methane production, and membrane fouling performances were investigated for a SAnMBR treating sewage at 35 ± 1 °C. Our main findings are as follows.

- 1.

The SAnMBR achieved a desirable COD removal efficiency (85.75%) and stable methane production (1103 mL/day), which were significantly affected by both OLR and HRT. With the higher OLR and shorter HRT, biomass concentration was higher, which can result in higher amount of methane production.

- 2.

The main component of influent DOM was aromatic protein, followed by soluble microbial by-products. And the influent DOM was decomposed and transformed gradually, reducing the concentration with the operation of the reactor.

- 3.

The polysaccharide concentration did not change significantly, while the protein and EPS concentration increased, from 83.49 to 298.64 mg/L and 142.02 to 387.02 mg/L, respectively, during the stable operation stage of the SAnMBR. It can indicate that protein was the decisive factor affecting the formation of EPS, which was more susceptible to membrane fouling.

- 4.

TMP and total membrane resistance continued to increase (up to 30.4 kPa and 24.7 × 1012 m−1) during the operation of the SAnMBR. The SAnMBR showed the best performance, when TMP was in the range of 10–15 kPa. The hydraulic force generated by the stirring device has a dynamic physical shearing action on the surface of the membrane, which can alleviate the membrane fouling of the SAnMBR to some extent.

References

Abdullah AGL, Idris A, Ahmadun FR, Baharin BS, Emby F, MegatMohd Noor MJ, Nour AH (2015) A kinetic study of a membrane anaerobic reactor (MAR) for treatment of sewage sludge. Desalination 183:439–445

An YY, Yang FL, Bucciali B, Wong F (2009) Municipal wastewater treatment using a UASB coupled with cross-flow membrane filtration. J Environ Eng-ASCE 135:86–91

Basset N, López-Palau S, Dosta J, Mata-Álvarez J (2014) Comparison of aerobic granulation and anaerobic membrane bioreactor technologies for winery wastewater treatment. Water Sci Technol 69:320–327

Burman I, Sinha A (2017) A review on membrane fouling in membrane bioreactors: control and mitigation. Environ Contam:281–315

Chan YJ, Chong MF, Law CL, Hassell DG (2009) A review on anaerobic–aerobic treatment of industrial and municipal wastewater. Chem Eng J 155:1–18

Chang IS, Le Clech P, Jefferson B, Judd S (2002) Membrane fouling in membrane bioreactors for wastewater treatment. J Environ Eng 128:1018–1029

Che W, Westerhoff P, Leenheer JA, Booksh K (2003) Fluorescence excitation-emission matrix regional integration to quantify spectra for dissolved organic matter. Environ Sci Technol 37:5701–5710

Chen C, Guo WS, Ngo HH, Chang SW, Nguyen DD, Nguyen PD, Bui XT, Wu X (2017) Impact of reactor configurations on the performance of a granular anaerobic membrane bioreactor for municipal wastewater treatment. Int Biodeterior Biodegrad 121:131–138

De Graaff MS, Temmink H, Zeeman G, Buisman CJN (2010) Anaerobic treatment of concentrated black water in a UASB reactor at a short HRT. Water 2:101–119

Demirel B, Scherer P (2008) The roles of acetotrophic and hydrogenotrophic methanogens during anaerobic conversion of biomass to methane: a review. Rev Environ Sci Biotechnol 7:173–190

Domínguez L, Cases V, Birek C, Rodríguez M, Prats D (2012) Influence of organic loading rate on the performance of ultrafiltration and microfiltration membrane bioreactors at high sludge retention time. Chem Eng J 181:132–143

Federation WE, APHA (2005) Standard methods for the examination of water and wastewater. Am Public Health Assoc Washington DC

Feng H, Hu L, Mahmood Q, Qiu C, Fang C, Shen D (2008) Anaerobic domestic wastewater treatment with bamboo carrier anaerobic baffled reactor. Int Biodeter Biodegr 62:232–238

Gao WJ, Han MN, Xu CB, Liao BQ, Hong Y, Cumin J (2016) Performance of submerged anaerobic membrane bioreactor for thermomechanical pulping wastewater treatment. J Water Process Eng 13:70–78

Giménez JB, Robles A, Carretero L, Durán F, Ruano MV, Gatti MN, Ribes J, Ferrer J, Seco A (2011) Experimental study of the anaerobic urban wastewater treatment in a submerged hollow-fibre membrane bioreactor at pilot scale. Bioresour Technol 102:8799–8806

Gu BJ, Fan LC, Ying ZC, Xu Q, Luo WD, Ge Y, Scott S, Chang J (2016) Socioeconomic constraints on the technological choices in rural sewage treatment. Environ Sci Pollut Res 23:1–8

Hu AY, Stuckey DC (2006) Treatment of dilute wastewaters using a novel submerged anaerobic membrane bioreactor. J Environ Eng 132:190–198

Hu YS, Yang Y, Yu SC, Wang XC, Tang JL (2018) Psychrophilic anaerobic dynamic membrane bioreactor for domestic wastewater treatment: effects of organic loading and sludge recycling. Bioresour Technol 270:62–69

Huang Z, Ong SL, Ng HY (2011) Submerged anaerobic membrane bioreactor for low-strength wastewater treatment: effect of HRT and SRT on treatment performance and membrane fouling. Water Res 45:705–713

Hudson N, Baker A, Reynolds D (2007) Fluorescence analysis of dissolved organic matter in natural, was te and polluted waters—a review. River Res Appl 23:631–649

Jeong E, Kim HW, Nam JY, Shin HS (2010) Enhancement of bioenergy production and effluent quality by integrating optimized acidification with submerged anaerobic membrane bioreactor. Bioresour Technol 101:S7–S12

Kassab G, Halalsheh M, Klapwijk A, Fayyad M, Van Lier JB (2010) Sequential anaerobic–aerobic treatment for domestic wastewater – a review. Bioresour Technol 101:3299–3310

Khan MA, Ngo HH, Guo W, Liu Y, Nghiem LD, Chang SW, Nguyen DD, Zhang S, Luo G, Jia H (2019) Optimization of hydraulic retention time and organic loading rate for volatile fatty acid production from low strength wastewater in an anaerobic membrane bioreactor. Bioresour Technol 271:100–108

Liao BQ, Kraemer JT, Bagley DM (2006) Anaerobic membrane bioreactors: applications and research directions. Environ Sci Technol 36:489–530

Lin HJ, Chen JR, Wang FY, Ding LX, Hong HC (2011) Feasibility evaluation of submerged anaerobic membrane bioreactor for municipal secondary wastewater treatment. Desalination 280:120–126

Martinez-Sosa D, Helmreich B, Netter T, Paris S, Bischof F, Horn H (2011) Anaerobic submerged membrane bioreactor (AnSMBR) for municipal wastewater treatment under mesophilic and psychrophilic temperature conditions. Bioresour Technol 102:10377–10385

Martinez-Sosa D, Helmreich B, Horn H (2012) Anaerobic submerged membrane bioreactor (AnSMBR) treating low-strength wastewater under psychrophilic temperature conditions. Process Biochem 47:792–798

Martin-Garcia I, Monsalvo V, Pidou M, Le-Clech P, Judd SJ, McAdam EJ, Jefferson B (2011) Impact of membrane configuration on fouling in anaerobic membrane bioreactors. J Membr Sci 382:41–49

McCarty PL, Bea J, Kim J (2011) Domestic wastewater treatment as a net energy producer-can this be achieved? Environ Sci Technol 45:7100–7106

Michaud S, Bernet N, Buffière P, Roustan M, Moletta R (2002) Methane yield as a monitoring parameter for the start-up of anaerobic fixed film reactors. Water Res 36:1385–1391

Moletta R, Mataalvarez J, Moletta R (2005) Winery and distillery wastewater treatment by anaerobic digestion. Water Sci Technol 51:137

Nie Y, Chen R, Tian X, Li YY (2017) Impact of water characteristics on the bioenergy recovery from sewage treatment by anaerobic membrane bioreactor via a comprehensive study on the response of microbial community and methanogenic activity. Energy 139:459–467

Santos FS, Ricci BC, Neta LSF, Amaral MCS (2017) Sugarcane vinasse treatment by two-stage anaerobic membrane bioreactor: effect of hydraulic retention time on changes in efficiency, biogas production and membrane fouling. Bioresour Technol 245:342–350

Shi XC, Lin J, Zuo JE, Li P, Li XX, Guo XL (2017) Effects of free ammonia on volatile fatty acid accumulation and process performance in the anaerobic digestion of two typical bio-wastes. J Environ Sci 55:49–57

Shin C, Bae J (2018) Current status of the pilot-scale anaerobic membrane bioreactor treatments of domestic wastewaters: a critical review. Bioresour Technol 247:1038–1046

Skouteris G, Hermosilla D, López P, Negro C, Blanco Á (2012) Anaerobic membrane bioreactors for wastewater treatment: a review. Chem Eng J 198:138–148

Smith AL, Skerlos SJ, Raskin L (2013) Psychrophilic anaerobic membrane bioreactor treatment of domestic wastewater. Water Res 47:1655–1665

Smith AL, Stadler LB, Cao L, Love NG, Raskin L, Skerlos SJ (2014) Navigating wastewater energy recovery strategies: a life cycle comparison of anaerobic membrane bioreactor and conventional treatment systems with anaerobic digestion. Environ Sci Technol 48:5972–5981

Souza CL, Chernicharo CAL, Aquino SF (2011) Quantification of dissolved methane in UASB reactors treating domestic wastewater under different operating conditions. Water Sci Technol 64:2259–2264

Sun J, Guo L, Li Q, Zhao Y, Gao M, She Z, Wang G (2016) Structural and functional properties of organic matters in extracellular polymeric substances (EPS) and dissolved organic matters (DOM) after heat pretreatment with was te sludge. Bioresour Technol 219:614–623

Sutton PM, Melcer H, Schraa OJ, Togna AP (2011) Treating municipal wastewater with the goal of resource recovery. Water Sci Technol 63:25–31

Watanabe R, Nie Y, Takahashi S, Wakahashi S, Li YY (2016) Efficient performance and the microbial community changes of submerged anaerobic membrane bioreactor in treatment of sewage containing cellulose suspended solid at 25°C. Bioresour Technol 216:128–134

Xiao KK, Zhou Y, Guo CH, Maspolim Y, Ng WJ (2016) Impact of undissociated volatile fatty acids on acidogenesis in a two-period anaerobic system. J Environ Sci 42:196–201

Yeo H, Lee HS (2013) The effect of solids retention time on dissolved methane concentration in anaerobic membrane bioreactors. Environ Technol 34:2105–2112

Yeo H, An J, Reid R, Rittmann BE, Lee HS (2015) Contribution of liquid/gas mass-transfer limitations to dissolved methane oversaturation in an-aerobic treatment of dilute wastewater. Environ Sci Technol 49:10366–10372

Yue XD, Koh YK, Ng HY (2015) Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res 86:96–107

Zhang QY, Tan GH, Stuckey DC (2017a) Optimal biogas sparging strategy, and the correlation between sludge and fouling layer properties in a submerged anaerobic membrane bioreactor (SAnMBR). Chem Eng J 319:248–257

Zhang Z, Guo L, Li Q, Zhao Y, Gao M, She Z (2017b) Study on substrate metabolism process of saline waste sludge and its biological hydrogen production potential. Environ Sci Pollut Res 24:16383–16395

Acknowledgments

The author would like to express my sincere gratitude to the financial support of China’s “13th Five-Year Plan” for Major Science and Technology Program for Water Pollution Control and Treatment (2017ZX07102004-005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Tian, H., Luan, X. et al. Submerged anaerobic membrane bioreactor for low-concentration domestic sewage treatment: performance and membrane fouling. Environ Sci Pollut Res 27, 6785–6795 (2020). https://doi.org/10.1007/s11356-019-07135-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-07135-1