Abstract

Soil contamination with benzene, toluene, ethylbenzene and xylene isomers (BTEX) has raised increasing concern because of its high solubility in water and toxicity to biotic communities. This study aims at investigating the process and prospects of deploying bioelectrochemical system (BES) for the removal of BTEX from artificially contaminated soil using Pseudomonas putida YNS1, alongside the reduction of hexavalent chromium (Cr(VI)). The BES was setup with desired operating conditions: initial concentration of BTEX (50–400 mg/L in 100 mL of sterilized water), pH (4–10) and applied potential voltage (0.6–1.2 V) with 10 μL log-phase culture along with the addition of Cr(VI) (10 mg/L). Samples were collected at regular intervals and analysed for BTEX degradation using gas chromatography and Cr(VI) reduction using UV–Vis spectrophotometer. Under optimized conditions (initial BTEX concentration, 200 mg/L; pH 7; and applied voltage 0.8 V with Cr(VI) of 10 mg/L), 92% of BTEX was degraded and 90% Cr(VI) was reduced from the contaminated soil. The intermediates produced during degradation were analysed through gas chromatography-flame ionization detector (GC-FID), and the possible degradation pathway was elucidated. The results indicated that BES could be effective for simultaneous degradation of BTEX along with Cr(VI) reduction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid industrialization has caused several contradictory human–environment interactions, with pollution being the most significant issue. Various types of pollution occur over time causing significant adverse effects on the environment and to human health (Yang 2015). In recent decades, soil pollution has gained greater attention due to oil spills. Accidents during exploration, refining, transport, storage and industrial use represent continuous sources of hydrocarbon contamination in soil and groundwater (Freitas et al. 2011, Khodaei et al. 2017, Zhu et al. 2015). Benzene, toluene, ethylbenzene and xylenes, collectively represented here as BTEX, are the hydrocarbons of utmost concern in contamination events, because of their greater solubility in water and mobility into soils (Watts and Teel 2005). BTEX compounds are enlisted among the top 100 priority pollutants by the US-EPA (United States Environmental Protection Agency) (Dong et al. 2017) and are ranked 78th among the 275 potential threats to human life mentioned in the Comprehensive Environmental Response, Compensation and Liability Act (González et al. 2017). The highly mutagenic and carcinogenic compositions of BTEX make them more toxic and, thus, require effective remediation (Akmirza et al. 2017).

Bioremediation, bioelectrochemical oxidation, advanced oxidation, photo catalysis, sonolysis and radiolysis are some of the prevalent BTEX removal methods. Of these prevalent methods, bioelectrochemical oxidation is relatively inexpensive, durable and energy efficient and mineralizes compounds to a greater extent (Gill et al. 2014). Bioelectrochemical system (BES) uses microorganisms as a catalyst for redox reaction with one or more electrodes usually separated by an ion-conductive matrix on a typical design. Also, BES generates powerful anodic oxidation and cathodic reduction of reduced substrate and a high potential electron acceptor, respectively (Daghio et al. 2017). Li et al. (2019) stated that microbial fuel cells (MFCs) increased the degradation efficiency of petroleum based volatile organic compounds from 38 to 47% (Li et al. 2019). Daghio et al. (2018) deployed BES for BTEX degradation in aqueous solution and stated that the degradation efficiency increased considerably due to the applied electric voltage (Daghio et al. 2018). A similar study was carried out by Chang et al. (2017) to remove benzene from ground water using MFCs with 95% removal efficiency (Chang et al. 2017). However, no attempts have been made to assess the efficiency of BTEX removal from contaminated soil using BES, which highlights the significance of this study.

Metals are naturally occurring throughout the Earth’s crust, but several metals, such as cadmium (Cd), chromium (Cr), copper (Cu), mercury (Hg), lead (Pb), nickel (Ni) and zinc (Zn), and the metalloid arsenic (As) are widely used in industries and agriculture and are released into the environment (Tchounwou et al. 2012). Traffic appears to be responsible for the high levels of Cu, Mo, Pb, Sb and Zn and petrochemical plants for the high concentrations of Ni, V, Ba and Cr (Cristaldi et al. 2017, Duruibe et al. 2007). Cr(III) and Cr(VI) get released into the environment alongside BTEX and other VOCs. The ability of Cr(VI) to penetrate biological cells make them very hazardous to human health and necessitate Cr(VI) removal from contaminated soil (Kurniawan et al. 2006). Numerous chemical and biological methods exist for the removal and/or reduction of Cr(VI) from contaminated soil. However, all the existing methods of Cr(VI) removal and/or reduction are either expensive or inefficient for the removal of low concentrations of Cr(VI). Hybrid biological methods such as BES serve as the best solution to this setback (Kurniawan et al. 2006). Thus, the objectives of this study were (i) to study and investigate the progress and enhancement of biodegradability of BTEX mixture (procured from artificially contaminated soil) using an isolated Pseudomonas putida YNS1; (ii) to assess the impact of varying the potential applied across the dimensionally stable electrodes alongside variations in experimental parameters like BTEX initial concentration, dosage of bacterial inoculums and pH; and (iii) simultaneous reduction of Cr(VI) in the contaminated soil.

Materials and methods

Chemicals and bacterial strain

Reagent grade benzene, toluene, ethylbenzene, ortho-xylene, Cr(VI) standard solution (1000 mg/L) and all other chemicals were procured from Sigma-Aldrich (St. Louis, MO, USA) and were used without any further purification. BTEX mixture was prepared by mixing equal volumes of benzene, toluene, ethylbenzene and o-xylene in the ratio of 1:1:1:1; the sum of all the concentrations of equal volume gives the overall concentration of BTEX mixture.

Soil sample

Garden soil samples (below 5 cm) were collected from Chonbuk National University, Iksan, South Korea. The samples were air dried, passed through 2.00-mm sieve (ASTM No. 10) and homogenized. Physiochemical characteristics of the soil sample (Table 1) were determined according to AWWA (1998).

Bacterial inoculum preparation

The bacterial strain (P. putida YNS1) was isolated from oil contaminated sites in South Korea as reported previously (You et al. 2013). The isolate, YNS1, was retrieved using mineral salts medium (KH2PO4 1.0 g/L, K2HPO4 1.0 g/L, NH4NO3 1.0 g/L, MgSO4·7H2O 0.2 g/L, Fe2(SO4)3 0.05 g/L and CaCO3 0.02 g/L) supplemented with BTEX (each 5 mg/L) in the ratio of 1:3 and was used for bioelectrodegradation studies.

BES

Bioelectrodegradation experiments were initially performed in three different conditions (a) biodegradation, in the absence of applied potential; (b) electrodegradation, in the absence of bacterial inoculum; and (c) bioelectrodegradation, in the presence of both bacterial inoculum and applied potential across the electrodes. The soil sample (50 g) was added to the serum bottles (160 mL) with stoppers (90% Teflon and 10% silicone) to avoid the volatilization of VOCs. Graphite plates (10 cm2 area) were used both as anode and cathode and were connected to external power supply using stainless steel wire (Fig. 1). The experimental conditions were as follows: initial concentration of BTEX mixture (50–400 mg/L of 100 mL in sterilized water), pH (4–10), applied potential voltage (0.6–1.2 V) with 10 μL log phase (1 × 107 cells/mL) and P. putida YNS1. Also, Cr(VI) (10 mg/L) was added to the optimized condition for the evaluation of simultaneous reduction during degradation of BTEX compounds. Samples were collected periodically during the incubation time (5 days) and processed immediately. Triplicates were performed for the minimization of error. The overall BTEX degradation percentage was calculated by the following formula,

BTEX degradation (%) = (Degradation of B + Degradation of T + Degradation of E + Degradation of X) / 4

where B: benzene; T: toluene; E: ethylbenzene; and X: O-xylene.

Chemical analysis

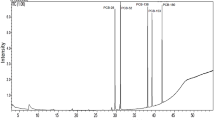

Soil slurry (2 g, wet weight) was mixed with methanol (5 mL) and was mechanically agitated for 15 min. After centrifugation, the supernatant solution (2 mL) was collected, filtered, (0.22 μm to eliminate soil and microbial inoculums) and stored in sealed vials. Degradation of BTEX and intermediate product in the samples were analysed through gas chromatography (Agilent 6890 N, Agilent Technologies Co. Ltd) with DB-5MS column (30 m × 0.25 mm × 0.25 μm) fitted with FID detector. Helium gas was used as a carrier gas and the injector, column and detector temperatures were maintained at 180, 150 and 250 °C, respectively. The concentrations of Cr(VI) in the samples were determined using spectrophotometer (UV–Vis absorption spectrometer, Agilent 8453, USA) employing diphenyl carbazide method (Kulkarni et al. 2017).

Results and discussion

Preliminary studies

Figure 2 a and b show the growth of P. putida YNS1 in the presence of various concentrations of BTEX mixture. From the results, it is evident that the growth rate of the strain decreased with an increase in BTEX concentration. No significant growth was seen in the strain beyond a concentration of 700 mg/L (Figure SF1). BTEX compounds on reaching a certain concentration, severely affect microbial growth and activity because of micro- and macro-level interactions owing to competitive inhibition, toxicity (Haigler et al. 1992) and the formation of toxic intermediaries (Jo et al. 2008). It is well reported that BTEX concentration above 500 mg/L results in substrate inhibition due to bacterial toxicity (Shim et al. 2002). Table 2 and Table ST1 inferred the biodegradation (55%), electrodegradation (10%) and bioelectrodegradation (92%) of BTEX compounds. The effectiveness of the BES may be attributed to the ability of electrochemical systems to create reactive zones (Daghio et al. 2018), where contaminants undergo several redox reactions even at the final stage of the process. The isolate YNS1 may directly react with the electrode or the metabolites of YNS1 may act as an electron shuttle for the disintegration of BTEX compounds (Rabaey et al. 2005). El-Nass et al. (2014) reported that bioelectrochemical system effectively degrade the BTEX compounds compared with conventional methods. Also, the enhanced BTEX degradation in BES could be due to high bacterial population and this was supported by the results from colony foming units (CFU) assay, where a significant difference in the CFU were observed between BES and conventional biodegradation experiments (Figure SF2).

Influence of BTEX concentration

The influence of initial concentration on BTEX degradation was studied at an applied voltage of 0.8 V with an inoculum dose of 0.1 mL. From the results (Fig. 3), it can be inferred that the degradation rate was maximum at lower initial BTEX concentration and decreased gradually with an increase in initial BTEX concentrations. Nearly 92% overall degradation was observed at an initial concentration of 200 mg/L (BTEX each of 50 mg/L), whereas the overall degradation dropped to less than 90% at higher concentrations. Hence, an initial concentration of BTEX (each 50 mg/L) was taken as an ideal concentration for further studies. Change in degradation efficiency can be attributed to the substrate interactions in the reactor that can affect the process either antagonistically or synergistically (Dou et al. 2008). Synergistic reactions enhance degradation by inducing the required catabolic enzymes while antagonistic reactions inhibit degradation by exerting toxicity and competitive inhibition of enzymes (El-Naas et al. 2014). It is evident from previous studies that increase in xylene has a synergistic effect on degradation, while benzene showed an opposite response. Toluene and ethyl benzene have mixed response towards degradation (Jo et al. 2008). Each of the BTEX compounds differ in their rates of degradation. Benzene and xylene had least degradation rates in comparison with the other compounds (Junfeng et al. 2008). Hamed et al. (2003) stated that specific growth rate of P. putida is a decreasing function of concentration, which was found to be in coherence with the study by Li et al. (2006). BTEX compounds on reaching certain concentrations can inhibit microbial activity due to complex micro- and macro-level interactions, which in turn will have a significant impact on the degradation rate of BTEX (Babaarslan et al. 2003).

Influence of applied potential voltage

The influence of applied potential voltage on BTEX degradation was studied under the desired concentration of 200 mg/L (benzene, toluene, ethylbenzene and o-xylene each of 50 mg/L), with an inoculum dosage of 0.1 mL for 5 days of treatment. From the results (Fig. 4) obtained, it can be inferred that, at an applied potential voltage of 0.6 V, the sample showed 60% degradation, which gradually rose up to 92% for 0.8 V, beyond which degradation did not vary much. The removal efficiency of toluene and ethyl benzene was maximum (96% and 95% respectively) when a potential of 0.8 V was applied. Benzene and xylene also showed better removal efficiencies at this potential in comparison with other ranges, thus indicating 0.8 V to be the ideal applied voltage (Daghio et al. 2018). Therefore, 0.8 V was considered for the experimental purpose. Several experimental evidences show that BTEX is more susceptible to electric potential, making oxidation of BTEX effective in the presence of electrochemical systems (Deeb et al. 2001). Experimental evidences show that upon application of electric potential and chemical compounds, electron shuttle is generated by the bacteria which highly facilitates degradation of BTEX compounds. Numerous studies reported that strong linear correlation exists between electric potential and BTEX removal (Deeb et al. 2001, Morlett-Chávez et al. 2010).

Influence of pH

The influence of initial pH on BTEX degradation was studied applying the ideal conditions derived from the previous experimental results following 5 days of treatment. Results (Fig. 5) indicate that the degradation percentage was minimum at acidic pH (4 to 6), while it reached the overall maximum (92%) at pH 7. Beyond pH 7, the degradation slowed down. Hence, neutral pH range was considered as ideal for the purpose of this study. CO2 evolved through metabolic reactions of microorganisms has been found to enhance the neutralization of pH, thus improving the efficiency of the strain (Khodaei et al. 2017). Leson and Winer (1991) have also reported maximum biodegradation of VOCs at pH 7 and 8. Since the isolate, YNS1, is a neutrophilic bacterial strain, the maximum degradation was achieved at pH 7 (Słomińska et al. 2013).

In addition to the aforesaid parameters, several other factors such as soil texture, humidity, temperature, activity of existing microbiota, organic matter, nutrients, salts and other pollutants present in soil have significant synergistic/antagonistic impact over bioavlability of BTEX to the bacterial system and which directly influence the remediation rate of the contaminated soil. Kamala-Kannan and Krishnamoorthy (2006) reported that several abiotic variables such as phosphate, nitrite, nitrate, silicate, organic matter and organic carbon decrease the bioavilability of mercury to the bacteria. Yanto and Tachibana (2014) reported that the synergistic effects of existing soil microbiome to accelerate the biodegradation of petroleum hydrocarbons. Similar identifying attempts are needed to include the impact of the aforesaid external parameters in future researches that greatly facilitate the bioavilability of the pollutant to the bacterial system and degradation efficiency.

Pathway of degradation mechanism

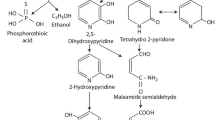

Supplementation of each BTEX component individually revealed the metabolites produced through bioelectrochemical degradation. Based on the intermediaries detected, the possible BTEX degradation pathways are summarized in Fig. 6. Benzene following the intermediaries, phenol, pyrocatechol, 2-hydroxy-2,4-pentadienoic acid, 2-hydroxy-4-oxovalerate and acetaldehyde were disintegrated into carbon-di-oxide and water, and the enzymes monooxygenase, dioxygenase, naphthalene 1,2-dioxygenase (NDO), 2-hydroxymuconate semialdehyde hydrolase, 2-oxopenta-4-enoate hydratase and 4-hydroxy-2-oxovalerate aldolase were involved in the benzene degradation. Ethylbenzene was converted into acetophenone and 2-hydroxyacetophenone in the presence of naphthalene 1,2-dioxygenase, which in the presence of 2-hydroxymuconate semialdehyde hydrolase yielded 3-ethylcatechol and 2-hydroxy-2,4-pentadienoic acid, which then followed the degradation sequence of benzene. Toluene in the presence of aryl-alcohol dehydrogenase yielded benzyl alcohol, which got converted into benzoic acid in the presence of NDO and pyrocatechol in the presence of 1,6-dihydroxycyclohexa-2,4-diene-1-carboxylate dehydrogenase then following benzene pathway. Similarly, o-xylene had the following intermediaries in the presence of the corresponding enzymes: 2-methylbenzyl alcohol in the presence of aryl-alcohol dehydrogenase, 2-methyl benzaldehyde under the activity of NDO, 3-methylcatechol under the activity of 1,6-dihydroxycyclohexa-2,4-diene-1-carboxylate dehydrogenase, 2-hydroxy-2,4-pentadienoic acid in the presence of 2-hydroxymuconate semialdehyde hydrolase and then corresponded to benzene degradation pathway. The aforesaid degradation pathway was in coherence with literature (Wongbunmak et al. 2017).

Reduction of Cr(VI)

The Cr(VI) reduction rate was studied under optimized conditions of 200 mg/L initial BTEX concentration (benzene, toluene, ethylbenzene and o-xylene each at 50 mg/L), pH 7 and an applied potential of 0.8 V (Fig. 7). The aforesaid conditions resulted in 90% Cr(VI) reduction alongside BTEX degradation. It can be inferred from Fig. 7 that the rate of removal showed a steep rise for the initial 3 days after which it gradually decreased and saturated on the 5th day. The Cr(VI) reduction could be due to isolate YNS1 activity. It is reported that Pseudomonas sp. has the potential to synthesize several soluble reductase enzymes, such as chromate reductase, NAD(P)H-dependent extracellular soluble reductases and membrane associated reductases, that may involve in the reduction of chromium. Alternatively, current density has a significant role to play in the reduction of Cr(VI) to Cr(III) (Hu et al. 2017). The efficient reduction at pH 7 was due to the neutrophilic nature of the isolate YNS1 and it is in agreement with the previous study reporting the maximum Cr(VI) reduction at neutral pH (Hu et al. 2017). The efficient reduction of chromium alongside the simultaneous degradation of BTEX proves the effectiveness of the constructed bioelectrochemical system.

Conclusion

This research intends to study the impact of bioelectrodegradation on the removal of BTEX along with the reduction of Cr(VI), a common co-contaminant in many industrial wastes. From the current study, it can be inferred that bacterial growth retards with increase in BTEX concentration and, in our study, the growth was completely inhibited at 700 mg/L. Bioelectrodegradation (92%) was found to be more efficient than other methods at 200 mg/L initial concentration and 0.8 V applied voltage. Under the aforesaid conditions, 90% Cr(VI) reduction was achieved indicating the efficiency of this method. Thus, the findings of the study can be extrapolated to formulate an effective and eco-friendly remediation of BTEX and Cr(VI) contaminated soils.

References

Akmirza I, Pascual C, Carvajal A, Pérez R, Muñoz R, Lebrero R (2017) Anoxic biodegradation of BTEX in a biotrickling filter. Sci Total Environ 587:457–465

AWWA, 1998. Stand. Methods Exam. Water Wastewater, 20th ed. Am. Public Heal. Assoc. Washington, DC

Babaarslan C, Tekeli A, Mehmetoğlu T (2003) Biodegradation of BTEX compounds by a mixed culture obtained from petroleum formation water. Energy Sources 25:733–742

Chang S-H, Wu C-H, Wang R-C, Lin C-W (2017) Electricity production and benzene removal from groundwater using low-cost mini tubular microbial fuel cells in a monitoring well. J Environ Manag 193:551–557

Cristaldi A, Conti GO, Jho EH, Zuccarello P, Grasso A, Copat C, Ferrante M (2017) Phytoremediation of contaminated soils by heavy metals and PAHs. A brief review. Environ Technol Innov 8:309–326

Daghio M, Aulenta F, Vaiopoulou E, Franzetti A, Arends JB, Sherry A, Suárez-Suárez A, Head IM, Bestetti G, Rabaey K (2017) Electrobioremediation of oil spills. Water Res 114:351–370

Daghio M, Tofalos AE, Leoni B, Cristiani P, Papacchini M, Jalilnejad E, Bestetti G, Franzetti A (2018) Bioelectrochemical BTEX removal at different voltages: assessment of the degradation and characterization of the microbial communities. J Hazard Mater 341:120–127

Deeb RA, Hu H-Y, Hanson JR, Scow KM, Alvarez-Cohen L (2001) Substrate interactions in BTEX and MTBE mixtures by an MTBE-degrading isolate. Environ Sci Technol 35:312–317

Dong C-D, Tsai M-L, Chen C-W, Hung C-M (2017) Heterogeneous persulfate oxidation of BTEX and MTBE using Fe3O4−CB magnetite composites and the cytotoxicity of degradation products. Int Biodeterior Biodegradation 124:109–118

Dou J, Liu X, Hu Z (2008) Substrate interactions during anaerobic biodegradation of BTEX by the mixed cultures under nitrate reducing conditions. J Hazard Mater 158:264–272

Duruibe JO, Ogwuegbu M, Egwurugwu J (2007) Heavy metal pollution and human biotoxic effects. Int J Phys Sci 2:112–118

El-Naas MH, Acio JA, El Telib AE (2014) Aerobic biodegradation of BTEX: progresses and prospects. J Environ Chem Eng 2:1104–1122

Freitas JG, Mocanu MT, Zoby JLG, Molson JW, Barker JF (2011) Migration and fate of ethanol-enhanced gasoline in groundwater: a modelling analysis of a field experiment. J Contam Hydrol 119:25–43

Gill R, Harbottle MJ, Smith J, Thornton S (2014) Electrokinetic-enhanced bioremediation of organic contaminants: a review of processes and environmental applications. Chemosphere 107:31–42

González JL, Pell A, López-Mesas M, Valiente M (2017) Simultaneous determination of BTEX and their metabolites using solid-phase microextraction followed by HPLC or GC/MS: an application in teeth as environmental biomarkers. Sci Total Environ 603:109–117

Haigler B, Pettigrew CA, Spain J (1992) Biodegradation of mixtures of substituted benzenes by Pseudomonas sp. strain JS150. Appl Environ Microbiol 58:2237–2244

Hamed TA, Bayraktar E, Mehmetoğlu T, Mehmetoğlu Ü (2003): Substrate interactions during the biodegradation of benzene, toluene and phenol mixtures. Process Biochem 39:27–35

Hu Y, Zhu J, Liu Y (2017) Removal of chromium (VI) from aqueous solutions by electrochemical reduction–precipitation. Int J Electrochem Sci 12:11387–11396

Jo M-S, Rene ER, Kim S-H, Park H-S (2008) An analysis of synergistic and antagonistic behavior during BTEX removal in batch system using response surface methodology. J Hazard Mater 152:1276–1284

Junfeng D, Xiang L, Zhifeng H (2008) Anaerobic BTEX degradation in soil bioaugmented with mixed consortia under nitrate reducing conditions. J Environ Sci 20:585–592

Kamala-Kannan S, Krishnamoorthy R (2006) Isolation of mercury resistant bacteria and influence of abiotic factors on bioavilability of mercury - a case study in Pulicat lake North of Chennai, South East India. Sci Total Environ 367:341–353

Khodaei K, Nassery HR, Asadi MM, Mohammadzadeh H, Mahmoodlu MG (2017) BTEX biodegradation in contaminated groundwater using a novel strain (Pseudomonas sp. BTEX-30). Int Biodeterior Biodegradation 116:234–242

Kulkarni PS, Deshmukh PG, Jakhade AP, Kulkarni SD, Chikate RC (2017) 1, 5 diphenyl carbazide immobilized cross-linked chitosan films: an integrated approach towards enhanced removal of Cr (VI). J Mol Liq 247:254–261

Kurniawan TA, Chan GY, Lo W-H, Babel S (2006) Physico–chemical treatment techniques for wastewater laden with heavy metals. Chem Eng J 118:83–98

Leson G, Winer AM (1991) Biofiltration: an innovative air pollution control technology for VOC emissions. J Air Waste Manage Assoc 41:1045–1054

Li H, Liu YH, Luo N, Zhang XY, Luan TG, Hu JM, Wang ZY, Wu PC, Chen MJ, Lu JQ (2006) Biodegradation of benzene and its derivatives by a psychrotolerant and moderately haloalkaliphilic Planococcus sp. strain ZD22. Res Microbiol 157:629–636

Li X, Zheng R, Zhang X, Liu Z, Zhu R, Zhang X, Gao D (2019) A novel exoelectrogen from microbial fuel cell: bioremediation of marine petroleum hydrocarbon pollutants. J Environ Manag 235:70–76

Morlett-Chávez JA, Ascacio-Martínez JÁ, Rivas-Estilla AM, Velázquez-Vadillo JF, Haskins WE, Barrera-Saldaña HA, Acuña-Askar K (2010) Kinetics of BTEX biodegradation by a microbial consortium acclimatized to unleaded gasoline and bacterial strains isolated from it. Int Biodeterior Biodegradation 64:581–587

Rabaey K, Boon N, Höfte M, Verstraete W (2005) Microbial phenazine production enhances electron transfer in biofuel cells. Environ Sci Technol 39:3401–3408

Shim H, Shin E, Yang S-T (2002) A continuous fibrous-bed bioreactor for BTEX biodegradation by a co-culture of Pseudomonas putida and Pseudomonas fluorescens. Adv Environ Res 7:203–216

Słomińska M, Król S, Namieśnik J (2013) Removal of BTEX compounds from waste gases; destruction and recovery techniques. Crit Rev Environ Sci Technol 43:1417–1445

Tchounwou PB, Yedjou CG, Patlolla AK, Sutton DJ (2012) Heavy metal toxicity and the environment, molecular, clinical and environmental toxicology. Springer, pp:133–164

Watts RJ, Teel AL (2005) Chemistry of modified Fenton’s reagent (catalyzed H2O2 propagations–CHP) for in situ soil and groundwater remediation. J Environ Eng 131:612–622

Wongbunmak A, Khiawjan S, Suphantharika M, Pongtharangkul T (2017) BTEX-and naphthalene-degrading bacterium Microbacterium esteraromaticum strain SBS1-7 isolated from estuarine sediment. J Hazard Mater 339:82–90

Yang T (2015) Dynamic assessment of environmental damage based on the optimal clustering criterion–taking oil spill damage to marine ecological environment as an example. Ecol Indic 51:53–58

Yanto DHY, Tachibana S (2014) Potential of fungal co-culturing for accelerated biodegradation of petroleum hydrocarbons in soil. J Hazard Mater 278:454–463

You Y, Shim J, Cho CH, Ryu MH, Shea PJ, Kamala-Kannan S, Chae JC, Oh BT (2013) Biodegradation of BTEX mixture by Pseudomonas putida YNS1 isolated from oil-contaminated soil. J Basic Microbiol 53:469–475

Zhu L, Wang Y, Jiang L, Lai L, Ding J, Liu N, Li J, Xiao N, Zheng Y, Rimmington GM (2015) Effects of residual hydrocarbons on the reed community after 10 years of oil extraction and the effectiveness of different biological indicators for the long-term risk assessments. Ecol Indic 48:235–243

Funding

This work was supported by the BK21 plus program through the National Research Foundation (NRF) funded by the Ministry of Education of Korea and supported by the National Research Foundation of Korea (Nano-Material Fundamental Technology Development, 2016M3A7B4909370).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Bingcai Pan

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 1721 kb)

Rights and permissions

About this article

Cite this article

Mohan, H., Lim, JM., Cho, M. et al. Remediation of BTEX and Cr(VI) contamination in soil using bioelectrochemical system—an eco-friendly approach. Environ Sci Pollut Res 27, 837–845 (2020). https://doi.org/10.1007/s11356-019-07029-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-07029-2