Abstract

This study investigated the use of a blend of waste vegetable oil and diesel fuel in a diesel tractor engine by comparing the resulting particulate matter (PM) collected on a filter with the PM of diesel fuel. To this purpose, Fourier transform infrared (FTIR) and elemental analyses were carried out and the PM collected on the filters was examined via scanning electron microscopy (SEM). The study also investigated the overall morphology of soot particles from the blend of 75% waste cooking oil (WCO) + 25% diesel (B75) in a diesel engine at three different loads (75%, 50% and 10%) compared with the morphology of the soot particles from diesel fuel (B0). The FTIR spectra of the B75 fuel exhibited the characteristic regions of oxygen bonds. Compared to the B0 fuel, the increased oxidation from the excess oxygen in the B75 fuel reduced the size and number of soot particles. It was also verified that the degree of unsaturation was related to the oxygen content of the B75 fuel. The FTIR spectra of the B75 fuel showed a C = O tensile band methyl ester in 1734 cm−1 and C–O bands at 1214–1362 cm−1. Furthermore, similar FTIR spectra were seen for the diesel fuel (B0) and the B75 fuel. The results showed a significant reduction in soot particle emissions with the WCO-diesel blend. The results of this research have enabled a better evaluation of the effects of different fuel usage on diesel engine combustion performance and emission characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Along with the increased use of fossil fuels throughout the world, the negative effects of this energy have also escalated. Many researchers have shown that the emissions of fossil fuels as an energy source in particular have had negative impacts on the environment and human health (Çanakcı and Özsezen 2005; Kaplan et al. 2006; Ulusoy et al. 2004). Emissions from fossil fuels are a major source of air pollution worldwide (Popovicheva et al. 2017). Elbir et al. (2010) emphasised that in recent years, the number of vehicles and the increased release of emissions into the environment influenced by urban meteorological and topographical conditions have reached dimensions that threaten human health. Predominant among these emissions are pollutants such as CO, CO2, NOx, SO2, HC and CH4 (Arslan 2011; Betha and Balasubramanian 2011; Cherng-Yuan and Lin 2007; Lapuerta et al. 2008a; Jung et al. 2006; Shah et al. 2014). Vehicle-based pollutants are among the most important sources of air pollution and contain heavy metals which can lead to heart disease, cancer, nervous system disorders and liver disease when taken into the human body via respiration (Alkaya and Yıldırım 2000; Taşdemir and Erbaşlar 2007). In Europe, more than 70% of carbon aerosol emissions are vehicle-sourced, although diesel fuel aerosol emissions are envisaged as hazardous pollutants. In Turkey, about 40% of the air pollution experienced in urban centres originates from vehicles (Karabulut and Sayın 2015; Ulusoy 2016). Increasing concerns about environmental impacts in urban areas have led to the development of engine technologies that emit less particulate matter (PM).

The goal of reducing vehicle-sourced pollutants may be achieved by enhancing engine performance, which should improve the emission rate. Biodiesel is the most common among the alternative fuels used in the improvement of emissions. Fatty acid methyl esters (FAMEs) are obtained from vegetable oils via transesterification. Thus, vegetable oils tend to be widely used for biodiesel fuel blends since their soot emission (SE) is less than that of diesel fuel (Agarwal 2007; Giakoumis et al. 2012; Vojtisek-Lom et al. 2012; Tiwari et al. 2018). Moreover, biodiesel is a fuel that can be used without significant modifications to diesel engines (Kumar et al. 2014; Ulusoy et al. 2018).

Compared to diesel, biodiesel contains lower amounts of sulphur and aromatics, which are thought to be critical for nucleation of the polycyclic aromatic hydrocarbons (PAHs) that lead to soot formation (Lapuerta et al. 2008a; Kumar et al. 2014; Song et al. 2006; Vander Wal et al. 2010) . It is thought that not only the chemical composition but also the unsaturation and high oxygen content in biodiesel contribute to the reduction of soot particles (Ulusoy et al. 2004; Kohse-Höinghaus et al. 2010). The degree of unsaturation of biodiesel is an indication of the number of double bonds found in the FAMEs chains. For pure FAMEs, the oxygen content slightly increases the degree of unsaturation due to the saturation and displacement of the double bonds of the two hydrogen atoms (Benjumea et al. 2011).

In various studies, when PMs could not be retained from the exhaust, the PM characterisations of diesel engines were investigated physically and chemically. These studies included steps leading to PM formation such as pyrolysis, surface growth, coagulation, aggregation and oxidation (Neeft et al. 1996; Kalligeros et al. 2003). Surface growth is a process that first develops and then converts nanoparticles into precursor molecules, while coagulation takes place in a single step as a merging process in which small particles collide to form larger spherical particles (Eastwood 2008; Karin et al. 2017).

The particle size distribution of diesel PM emissions has been studied by many researchers. They have reported smaller particles in biodiesel PM emissions than in diesel fuel. Owing to the oxygen in the biodiesel content, better combustion efficiency is achieved, although the fuel has a lower thermal value. For this reason, the released particles are smaller in size (Karin et al. 2013). Particulate matter is very sensitive to sudden changes in engine operating conditions, and the particle size can range from 20 to 200 nm (Kittelson 1998; Soylu 2014).

One product of diesel engine technology that significantly reduces particulate emissions is the diesel particulate filter (DPF). These DPFs play an important role in PM capture and oxidation, processes which involve the most complex behaviour of PM and chemical reaction events. At present, diesel engines do not meet the Euro III Stage B requirements for emissions that are currently in force. Therefore, it is necessary to use DPFs in vehicles operating on biodiesel blends as well as in those operating on diesel fuel in order to meet the current emission limits (Barrios et al. 2014).

This study investigated the use of a biodiesel blend in a diesel engine by comparing the emissions collected on a filter to those of diesel fuel. In the study, a tractor combustion engine was operated at three different loading rates (75%, 50% and 10%) using diesel fuel (B0) and a blend of 75% waste cooking oil (WCO) + 25% diesel (B75). The exhaust emissions were collected on filters during the operation. Fourier transform infrared (FTIR), elemental analyses and scanning electron microscopy (SEM) were used to analyse the characterisation of the SE deposited on the filters, revealing the difference between the two fuels.

Material and methods

The study was carried out using frying vegetable oils originating from domestic, commercial and food industry sources collected from the Marmara region (Turkey) by a waste oil collection organisation. The oils were subjected to methyl ester transesterification at a facility in the region. Testing of the biodiesel was conducted in engine test laboratories where the particles were collected in emission filters. These filters were analysed in a laboratory environment and the results were evaluated. This research was a continuation of that carried out by Ulusoy (2016) in which the performance and emissions of three different fuel mixtures were analysed. In the present study, FTIR, SEM and elemental analysis were used to analyse the unsaturation of the diesel (B0) and biodiesel (B75) fuels and for the characterisation of the SE.

Test engine and measuring system

The biodiesel obtained from WCO (B75) and the diesel fuel (B0) were tested on a 4-cylinder, 4-stroke, 85 HP diesel-powered direct injection, 3908 cm3 engine with a compression ratio of 18/1. For this research, low-sulphur (less than 100 ppm) diesel fuel (B0) sold in Turkey (known as EURO diesel) was used as the reference along with the B75 fuel and the fuel mixtures were prepared by volume. The engine performance tests and exhaust emissions were carried out in accordance with directive 97/68/EC, and the steady state test was conducted at various speed and load simulations in the context of the ISO 8178-C1 8-mode test standard, which includes tractor engines. A schematic layout of the experimental system is given in Fig. 1.

In the study, after testing the engine at a constant engine speed of 2000 min−1 under three different loading conditions (75%, 50% and 10%), the filters obtained were analysed. A HORIBA MDLT-1300 partial-flow mini-dilution tunnel was used for PM removal. Fluorocarbon filters were placed at the connection point on the mini-tunnel system. In order to prevent the filters from burning due to the high temperature of the exhaust gas, a mixture of 30% exhaust gas and 70% ambient air provided by the system was passed along with the exhaust gas for 60 s through the filter placed in the tunnel. At the end of the process, the filter was removed from the tunnel and isolated from the surrounding air in a holding cabinet. The test modes used, test speeds and the weight factors used in the calculations are given in Table 1.

Test fuel

The biodiesel obtained from WCO used in this study had a viscosity of 5.605 mm2/s and a density of 884.8 kg/m3. In addition, the main fatty acid composition of the biodiesel obtained from waste oils according to literature values and mass ratios is given in Table 2.

The types and ratios of FAMEs with C16-C18 carbon atoms are considered to be the most important factors affecting fuel emissions. The number of double bonds (i.e. unsaturation grade) is assumed to play an important role in the formation of SE (Benjumea et al. 2011; Salamanca et al. 2012b). As shown in Table 2, WCO appears to have a monounsaturated oleic acid content (52.9%) that is relatively lower than the unsaturated acid content (67.2%).

Analysis results for the B75 fuel and B100 (Pure WCO) fuel used in the experiments revealed that the monounsaturated fatty acid content was 24.9% and 24.5% and polyunsaturated fatty acids were 53% and 55.4%, respectively. The total unsaturated fat ratios in Table 2 are higher than those (WCO) values found in the literature due to the fact that the soybean or sunflower frying oil content of the fuel used in the experiments was higher. The high polyunsaturated fat content of the test fuel also affected the amount of PM.

FTIR analyses of filters (soot particles)

The FTIR (JASCO Model FT/IR 6800-ATR) analyses were performed on the samples with a maximum scan rate in the range of 500 cm−1–4000 cm−1. For the FTIR spectroscopy of the SE from the combustion chamber collected on the filter (Fig. 2), the samples were placed on the KBR disc on the ATR module at 500–4000 cm−1 and the spectra were recorded.

Scanning electron microscopy of SE filters

Data on the size and morphology of the SE were obtained using the Quanta 650 FEG HV/LV/ESEM-STEM detector. The soot (about 0.1 mg) was transferred to a separate Eppendorf tube and thoroughly mixed with about 5 mL of dichloromethane. One drop of distilled water was applied to the PELCO® TEM grids (300 mesh) and the filter paper was dried. Then the sample mixture was gently dripped onto the grid and the filter paper was again lightly dried and placed on the Quanta 650 FEG HV/LV/ESEM-STEM detector operated at 20–30 kV voltage. Cross-sectional views of the filters used in the study are shown in Fig. 2. When the images of the particles on the filters are examined, it can be seen that the clearest image was obtained from the B75% 10–2000 sample, whereas the darkest sample, and therefore the one with the largest amount of soot, was B0% 75–2000.

Results and discussion

FTIR spectra of B75 and B0

In order to investigate the unsaturation of the B75 and B0 fuels, the FTIR spectra of the filters obtained from the test results at a constant engine speed of 2000 min−1 were analysed. The FTIR spectra of the B75 and B0 fuel samples are shown in Fig. 3a, b and c. In general, when FTIR spectral analyses are examined, permeability rates vary depending on engine load and fuels.

It appeared that the chemical composition of the PM was compatible with the fuel evaporation resulting from the engine oil combustion, and consisted mostly of alkanes, PAHs and carboxylic acids (Kumar et al. 2014; Agarwal et al. 2011; Omidvarborna et al. 2015a). Similar main peaks can be observed for both fuels at the wave lengths of 1214 cm−1, 1362 cm−1 and 1734 cm−1, as shown in Fig. 3. Depending on the loading rates, the peak points of the B75 fuel permeability rate were high, while the permeability of the B0 fuel was lower.

The spectra of C–O bonds (e.g. esters) normally appear between 1000 and 1300 cm−1 and represent the difference between biodiesel and diesel fuels. There was no significant peak for sulphur bonds in the range of single bonds in the diesel fuel. The difficulty in determining the sulphur concentration in the B0 fuel with the spectrometer used in this study was anticipated. It is also important to note that there was no sulphur in the biodiesel fuel.

At the 1200 cm−1 peaks, the ester has the antisymmetric axial stretching vibrations of the CC(= O)–O bonds, while peaks at about 1214 cm−1 can be assigned to the asymmetric axial stretching vibrations of the OCC bonds. However, these models are insufficient to identify the presence of crude oil in a deteriorated blend resulting from the esterification reaction process or from incomplete conversion due to engine oil leaks (Silverstein et al. 2014; Soares et al. 2008).

The double bond region is seen at 1700–1800 cm−1 at the methyl ester C=O stretching bond, which is essentially a monoalkyl ester. The biodiesel samples showed more unsaturated bonds than diesel fuel at 1700–1800 cm−1 (Fig. 3). These molecules in the double bond region are generally considered to be oleic (C18:1), linoleic (C18:2) and linolenic (C18:3) fatty acids (Salamanca et al. 12). A methyl ester with a strong carbonyl (C–O) signal is observed at 1734 cm−1 in the FTIR spectrum (Bouilly et al. 2012). This unsaturated carbonyl signal appeared in the WCO spectra. It can also be associated with the carboxylic C(O)O and carbonyl C=O groups in carboxylic acids and ketones/aldehydes, respectively (Popovicheva et al. 2015).

The major components of the biodiesel samples were aliphatic long chain HCs. The presence of a chain is shown as C–H in a shaded field in Fig. 3. The aliphatic −CH2 and −CH3 group vibrations are seen at 3000–2800 cm−1, while the weak absorptions at 3100–3080 are indicative for the presence of unsaturated molecular fragments as C=C in alkenes and aromatic compounds. The peak at 1362 cm−1 was assumed to arise from the CH3 deformations (Chien et al. 2009).

This band was higher for the B75 fuel, but lower for the B0 fuel. The consequence of the oxygen content in the B75 fuel can be observed. Thus, it is logical that diesel fuel and mineral lubricating oil produce compounds containing very little oxygen. The B0 fuel permeability peaks can be produced by the oxidation process that occurs during the combustion of the engine and, although lower, peaks like those of the B75 fuel can be produced. This variability in the B75 fuel produced higher peak values at 50% loading compared to 10% and 75% loading.

Particulate matter and morphology

Figure 4 shows SEM images of the particles of B0 and B75 fuels trapped in the filter at a constant engine speed of 2000 min−1 at loads of 75%, 50% and 10%. Although the B0 and B75 fuel particles are similar in diameter, different distributions can be seen. Both fuel particles appear to be concentrated in a range of about 25–75 nm.

When the nanostructures of the SE of the B0 and B75 fuels are compared (Fig. 4), more amorphous and irregular graphene particles are observed in the B75 samples. In the primary structure of the particles coming from the B75 fuel PM, a great number of misaligned wrinkles or inclined crystals and structural imperfections are quite apparent. In contrast, the B0 fuel soot particles have a more pronounced structure on the outer surfaces of the graphene layers. It is known that due to the oxygen content and aromatic structure of the B75 fuel, the resulting SE is more vulnerable to oxidative attack (Boehman et al. 2005). Consistent with the understanding of the relationship between structure and oxidative activity, the B75 SE led to higher reactivity compared to the B0 fuel soot, partly due to differences in the soot nanostructure. Because the percentage of WCO in the B75 fuel is high, it was seen that the number of particles decreased due to the increase of the oxygen ratio in the fuel blend (Barrios et al. 2014). The reason for this behaviour can be explained by the chemical structure of the fuels. The high levels of the oxygen-containing component and the absence of aromatic molecules in the composition reduced the particle nucleation and increased the oxidation rate (Salamanca et al. 2012a).

When biodiesel fuel is used, extra oxygen molecules are involved in various side reactions that can remove the softeners and affect the growth types of the soot (Omidvarborna et al. 2015a). Generally, after formation, soot particles initially have a typical crust-core structure (Hurt et al. 2000). The soot particles formed by the combustion of the B75 fuel blend with a high WCO ratio became hollow as a result of rapid and capsule-type oxidation (Song et al. 2006). As described by Song et al. (2006), a uniformly structured soot particle becomes an uneven structure during oxidation through internal deformation. Depletion of the internal material results in a more irregular arrangement of the outer shell structure. Thus, biodiesel soot particles are subjected to structural changes as shown in Fig. 4. At all three loading rates, the combustion of the B75 fuel showed that there had probably been oxidation deformation in the structure of the SE.

The results showed the importance of the SEM analyses of the B75 fuel SE for internal structural changes during the oxidation process. The change in diameter in the oxidised SE particles was observed experimentally. The internal oxidation rate was thought to be greater than the surface oxidation rate (Hurt et al. 1993). The results confirmed that the particle size of the SE was reduced during the oxidation process.

Figures 5 and 6 show the particulate size distribution obtained via electron microscopy at different loads (75%, 50% and 10%) for the B0 and the B75 fuels, respectively. The primary nanoparticle size distribution of the B0 and B75 fuels was in the range of 15 ~ 80 nm, which is compatible with the literature. This was observed to vary for both fuels depending on the loading rate.

Elemental carbon analysis

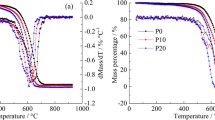

Figure 7 shows the carbon elemental analyses results. According to these findings, the greatest % values were obtained at the 10% load for the B75 fuel and at the 75% load for the B0 fuel. The lowest value was obtained at the 50% load for both fuels. The engine operating conditions and performance were the best at this speed.

Considering the loading state of the engine and the fuel taken into the cylinder, the carbon content of the B75 fuel was found to be high at idle and the 50% loading rate. The combustion chamber was designed for diesel fuel and the physical and chemical properties of the fuel burned in the injector affected the combustion characteristics. In particular, depending on the viscosity, the fuel injection pressure affects the atomized particle size of the fuel.

The oxygen content in the biodiesel positively affected the combustion characteristics. However, this effect could not be realized at the expected level due to the high viscosity at low speeds. However, at high speed, the high injection pressure of the pump ensures better atomization of the fuel. This would result in less carbon emission in full combustion zones.

Conclusions

In this study, during the combustion of the B75 and B0 fuels, the SE particles were collected on a filter and analysed using different techniques. The results of the study data showed that with the biodiesel fuel loading, the amount of SE was significantly lower than with diesel fuel. This reduction was more pronounced at engine loads of 50% and 75%. It is believed that the reduced SE of the biodiesel fuel was mainly due to the oxygen content and the degree of unsaturation resulting from the 75% WCO content. It may also have been due to the lack of aromatic and sulphur compounds in the biodiesel fuel (Omidvarborna et al. 2015a; Silverstein et al. 2014; Soares et al. 2008; Chien et al. 2009; Boehman et al. 2005; Salamanca et al. 2012a; Hurt et al. 2000; Hurt et al. 1993; Xue et al. 2011). Although biodiesel obtained from WCO is of a lower quality than that of various vegetable oil methyl esters, findings of this study show that it produced less PM than diesel fuel according to the loading rates (Ulusoy et al. 2004).

It was observed that the PM produced by the B75 fuel used in the study was less concentrated than in the B0 fuel. As a result, this is supported by an increase in the degree of unsaturation of the methyl esters present in the biodiesel. The B75 PM emissions, a significant reduction in HC, the high oxygen content and low sulphur content and the absence of aromatic species make it a cleaner fuel than B0. However, the chemical composition of the methyl ester present also affects the B75 PM emissions.

The study results are summarised as follows:

It was concluded that smoke opacity, which is a feature related to PM emission, differed between biodiesel tests according to the degree of unsaturation, and this affected the amount of particulate matter collected in the filters. In addition, properties such as density, in-cylinder temperature and cetane number affected the degree of unsaturation of the biodiesel. The high content of linoleic acid and linolenic acid in the fuel had a positive effect on the PM content.

The FTIR spectra of the B75 fuel blend biodiesel obtained from WCO and diesel fuel showed characteristic regions of carbon oxygen double and single bonds. No significant peak of permeability was observed for the B0 fuel due to low sulphur concentration, while the B75 fuel showed no sulphur peak points in the spectrum. The presence of long carbon chains was confirmed by the vibration of the C–H bonds.

The B75 fuel was shown to produce less SE compared to the B0. It was observed that SE particles decreased at 50% and 75% loading rates under ideal operating conditions of the engine.

The size distribution of the B0 fuel SE particles did not follow the same trend as the B75 fuel SE. The SEM analyses of SE particles from the B75 fuel showed structural changes in the emissions caused during the oxidation process. It was observed that these structural changes reduced the size and number of SE particles (Lapuerta et al. 2012, Omidvarborna et al. 2015b).

Laboratory results confirmed that the degree of unsaturation was related to the oxygen content of the biodiesel fuel. The B75 unsaturated biodiesel fuel obtained from WCO formed smaller soot particles, as shown in the SEM images.

As a result of the tests, the FTIR spectra of the B75 fuel showed a C=O stretching band for methyl ester in 1734 cm−1 and C–O bands at 1214 cm−1 and 1362 cm−1. Furthermore, the diesel fuel FTIR spectra were found to be similar to those of the B75 fuel.

This research made it possible to better evaluate how biodiesel fuel usage in diesel engines is effective on combustion performance and emission characteristics. The similarities in the known chemical properties of both B75 and B0 fuels demonstrate that this biodiesel is a good alternative fuel in terms of combustion chemistry.

References

Agarwal AK (2007) Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust Sci. 33(3):233–271. https://doi.org/10.1016/j.pecs.2006.08.003

Agarwal AK, Gupta T, Kothari A (2011) Particulate emissions from biodiesel vs diesel fuelled compression ignition engine. Renew Sust Energy Rev. 15:3278–3300. https://doi.org/10.1016/j.rser.2011.04.002

Alkaya B, Yıldırım M (2000) Reduction methods of vehicle based pollutants. ÇEV-KOR Ekoloji Çevre Dergisi. 34(9):15–20

Arslan R (2011) Emission characteristics of a diesel engine using waste cooking oil as biodiesel fuel. Afr J Biotechnol 10(19):3790–3794. https://doi.org/10.5897/AJB10.2202 ISSN 1684–5315

Barrios CC, Domínguez-Sáez A, Martín C, Álvarez P (2014) Effects of animal fat based biodiesel on a TDI diesel engine performance, combustion characteristics and particle number and size distribution emissions. Fuel. 117:618–623. https://doi.org/10.1016/j.fuel.2013.09.037

Benjumea P, Agudelo JR, Agudelo AF (2011) Effect of the degree of unsaturation of biodiesel fuels on engine performance, combustion characteristics, and emissions. Energy & Fuel. 25:77–85. https://doi.org/10.1021/ef101096x

Betha R, Balasubramanian R (2011) Emissions of particulate-bound elements from stationary diesel engine: Characterization and risk assessment. Atmos Environ. 45(30):5273–5281. https://doi.org/10.1016/j.atmosenv.2011.06.060

Boehman AL, Song J, Alam M (2005) Impact of biodiesel blending on diesel soot and the regeneration of particulate filters. Energy & Fuel. 19: 1857–64. https://doi.org/10.1021/ef0500585

Bouilly J, Mohammadi A, Iida Y, Hashimoto H, Geivanidis S, Samaras Z (2012) Biodiesel stability and its effects on diesel fuel injection equipment (No. 2012-01-0860). SAE Technical Paper

Çanakcı M, Özsezen AN (2005) Evaluating waste cooking oils as alternative diesel fuel. Gazi University Journal of Science 18(1):81–91

Cherng-Yuan L, Lin HA (2007) Engine performance and emission characteristics of a three-phase emulsion of biodiesel produced by peroxidation. Fuel Process Technol 88(1):35–41. https://doi.org/10.1016/j.fuproc.2006.07.008

Chien YC, Lu M, Chai M, Boreo FJ (2009) Characterization of biodiesel and biodiesel particulate matter by TG, TG–MS, and FTIR. Energy & Fuel. 2009; 23: 202–6. https://doi.org/10.1021/ef800388m

Eastwood P (2008) Particulate Emissions from Vehicles. Vol. 20. John Wiley & Sons Ltd., UK

Elbir T, Bayram A, Kara M, Altıok H, Seyfioğlu R, Erün P, Şimşir S (2010) Examination of air pollution caused by road traffic in İzmir city center. DEU Mühendislik Fak. Fen Mühendislik Dergisi. 12(1):1–17

Giakoumis EG, Rakopoulos CD, Dimaratos AM, Rakopoulos DC (2012) Exhaust emissions of diesel engines operating under transient conditions with biodiesel fuel blends. Prog Energy Combust Sci. 38(5):691–715. https://doi.org/10.1016/j.pecs.2012.05.002

Hurt RH, Sarofim AF, Longwell JP (1993) Gasification-induced densification of carbons: from soot to form coke. Combust Flame 95:430–432. https://doi.org/10.1016/0010-2180(93)90009-R

Hurt RH, Crawford GP, Shim HS (2000) Equilibrium nanostructure of primary soot particles. Proc Combust Inst 28(2):2539–2546. https://doi.org/10.1016/S0082-0784(00)80670-0

Jung H, Kittelson DB, Zachariah MR (2006) Characteristics of SME biodiesel-fueled diesel particle emissions and the kinetics of oxidation. Environ Sci Technol. 40(16):4949–4955. https://doi.org/10.1021/es0515452

Kalligeros S, Zannikos F, Stournas S, Lois E, Anastopoulos G, Teas C, Sakellaropoulos F (2003) An investigation of using biodiesel/marine diesel blends on the performance of a stationary diesel engine. Biomass Bioenergy. 24(2):141–149. https://doi.org/10.1016/S0961-9534(02)00092-2

Kaplan C, Arslan R, Sürmen A (2006) Performance characteristics of sunflower methyl esters as biodiesel. Energy Sources. 28(8):751–755. https://doi.org/10.1080/009083190523415

Karabulut M, Sayın C (2015) Investigation of the effects of biodiesel usage on performance and emissions in an agricultural tractor with three cylinder engine. XIII. Otomotiv ve Yan Sanayi Sempozyumu ve Sergisi. 13-14 Kasım: Maltepe / İstanbul

Karin P, Songsaengchan Y, Laosuwan S, Charoenphonphanich C, Chollacoop N, Katsunori H (2013) Nanostructure investigation of particle emission by using TEM image processing method. Energy Procedia. 34:757–766. https://doi.org/10.1016/j.egypro.2013.06.811

Karin P, Boonsakda J, Siricholathum K, Saenkhumvong E, Charoenphonphanich C, Hanamura K (2017) Morphology and oxidation kinetics of CI engine’s biodiesel particulate matters on cordierite diesel particulate filters using TGA. Int J Auto Tech. 18(1):31–40. https://doi.org/10.1007/s12239-017-0003-y

Kittelson DB (1998) Engines and nanoparticles: a review. J Aerosol Sci. 29(5-6):575–588. https://doi.org/10.1016/S0021-8502(97)10037-4

Knothe G, Dunn RO, Bagby MO (1997) Biodiesel: The use of vegetable oils and their derivatives as alternative diesel fuels. ACS Symposium Series 666:172–208

Kohse-Höinghaus K, Oßwald P, Cool TA, Kasper T, Hansen N, Qi F, Westbrook CK, Westmoreland PR (2010) Biofuel combustion chemistry: from ethanol to biodiesel. Angew Chem Int Ed. 49:3572–3597. https://doi.org/10.1002/anie.201001648

Kumar A, Kim DS, Omidvarborna H, Kuppili SK (2014) Combustion chemistry of biodiesel for use in urban transport buses: experiment and modeling.(No. CA-MNTRC-14-1146),.Mineta National Transit Research Consortium, (URL: http://transweb.sjsu.edu/PDFs/research/1146-biodiesel-busfuel-combustion-chemistry.pdf). Accessed 10 Jan 2019

Lai JY, Lin KC, Violi A (2011) Biodiesel combustion: advances in chemical kinetic modeling. Prog Energy Combust Sci. 37(1):1–14. https://doi.org/10.1016/j.pecs.2010.03.001

Lapuerta M, Agudelo JR, Rodríguez-Fernández J (2008a) Diesel particulate emissions from used cooking oil biodiesel. Bioresour Technol. 99:731–740. https://doi.org/10.1016/j.biortech.2007.01.033

Lapuerta M, Armas O, Rodriguez-Fernandez J (2008b) Effect of biodiesel fuels on diesel engine emissions. Prog Energy Combust Sci. 34(2):198–223. https://doi.org/10.1016/j.pecs.2007.07.001

Lapuerta M, Oliva F, Agudelo JR, Boehman AL (2012) Effect of fuel on the soot nanostructure and consequences on loading and regeneration of diesel particulate filters. Combust Flame. 159:844–853. https://doi.org/10.1016/j.combustflame.2011.09.003

Leung DYC, Guo Y (2006) Transesterification of neat and used frying oil: optimization for biodiesel production. Fuel Process Technol. 87(10):883–890. https://doi.org/10.1016/j.fuproc.2006.06.003

Liang F, Lu M, Keener TC, Liu Z, Khang SJ (2005) The organic composition of diesel particulate matter, diesel fuel and engine oil of a non-road diesel generator. J Environ Monitor. 7(10):983–988. https://doi.org/10.1039/b504728e

Neeft J, Makkeem P, Moulijn J (1996) Diesel particulate emission control, review article. Fuel Process Technol 47(1):1–69. https://doi.org/10.1016/0378-3820(96)01002-8

Öğüt H, Oğuz H, Bacak S, Mengeş HO, Köse A, Eryılmaz T (2012) Investigation of the characteristics of biodiesel from Balcı species of safflower. Journal of Agricultural Machinery Science. 8(3):297–300

Omidvarborna H, Kumar A, Kim D (2015a) S. (2015a) Variation of diesel soot characteristics by different types and blends of biodiesel in a laboratory combustion chamber. Sci Total Environ. 544:450–459. https://doi.org/10.1016/j.scitotenv.2015.11.076

Omidvarborna H, Kumar A, Kim DS, Venkata PKP, Bollineni VSP (2015b) Characterization and exhaust emission analyses of biodiesel in different temperature and pressure: laboratory study. J Hazard Tox RadWaste 19:04014030. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000237

Popovicheva OB, Kireeva ED, Shonija NK, Vojtisek-Lom M, Schwarz J (2015) FTIR analysis of surface functionalities on particulate matter produced by off-road diesel engines operating on diesel and biofuel. Environmental Science and Pollution Research 22(6):4534–4544. https://doi.org/10.1007/s11356-014-3688-8

Popovicheva OB, Irimiea C, Carpentier Y, Ortega IK, Kireeva ED, Shonija NK, Focsa C (2017) Chemical composition of diesel/biodiesel particulate exhaust by FTIR spectroscopy and mass spectrometry: Impact of fuel and driving cycle. Aerosol Air Qual Res. 17(7):1717–1734. https://doi.org/10.4209/aaqr.2017.04.0127

Salamanca M, Mondragón F, Agudelo JR, Santamaría A (2012a) Influence of palm oil biodiesel on the chemical and morphological characteristics of particulate matter emitted by a diesel engine. Atmos Environ 62:220–227. https://doi.org/10.1016/j.atmosenv.2012.08.031

Salamanca M, Mondragón F, Agudelo JR, Benjumea P, Santamaría A (2012b) Variations in the chemical composition and morphology of soot induced by the unsaturation degree of biodiesel and a biodiesel blend. Combust Flame. 159:1100–1108. https://doi.org/10.1016/j.combustflame.2011.10.011

Shah AN, Yun-shan G, Shah FH, Mughal HU, Naveed A (2014) Effect of biodiesel on particulate numbers and composition emitted from turbocharged diesel engine. Int J Environ Sci Technol. 11(2):385–394

Silverstein RM, Webster FX, Kiemle DJ, Bryce DL (2014) Spectrometric identification of organic compounds. 531, 7th Edition ,John Wiley & Sons.

Soares IP, Rezende TF, Silva RC, Castro EVR, Fortes IC (2008) Multivariate calibration by variable selection for blends of raw soybean oil/biodiesel from different sources using Fourier transform infrared spectroscopy (FTIR) spectra data. Energy & Fuel. 2008; 22(3): 2079‒83. https://doi.org/10.1021/ef700531n

Song J, Alam M, Boehman AL, Kim U (2006) Examination of the oxidation behavior of biodiesel soot. Combust Flame 146:589–604. https://doi.org/10.1016/j.combustflame.2006.06.010

Soylu S (2014) Examination of PN emissions and size distributions of a hybrid city bus under real world urban driving conditions. Int J Auto Tech 15(3):369-376. https://doi.org/10.1007/s12239-014-0039-1

Taşdemir Y, Erbaşlar T (2007) The association of some air pollutants with the meteorological parameters in an urban atmosphere. Uludağ Univ J Faculty Eng 12(2)

Tiwari A, Rajesh VM, Yadav S (2018) Biodiesel production in micro-reactors: a review. Energy for Sustainable Development 43:143–161. https://doi.org/10.1016/j.esd.2018.01.002

Ulusoy Y (2016) Investigation of performance and emissions effects of waste vegetable oil methyl ester in a diesel engine. Uludağ University Journal of the Faculty of Engineering. 21(2):299–308

Ulusoy Y, Tekin Y, Cetinkaya M, Karaosmanoglu F (2004) The engine tests of biodiesel from used frying oil. Energy Sources. 26(10):927–932. https://doi.org/10.1080/00908310490473219

Ulusoy Y, Arslan R, Tekin Y, Sürmen A, Bolat A, Şahin R (2018) Investigation of performance and emission characteristics of waste cooking oil as biodiesel in a diesel engine. Petroleum Science 15:396–404. https://doi.org/10.1007/s12182-018-0225-2

Vander Wal RL, Bryg VM, Hays MD (2010) Fingerprinting soot (towards source identification): Physical structure and chemical composition. J Aero Sci. 41:108–117. https://doi.org/10.1016/j.jaerosci.2009.08.008

Vojtisek-Lom M, Czerwinski J, Leníček J, Sekyra M, Topinka J (2012) Polycyclic aromatic hydrocarbons (PAHs) in exhaust emissions from diesel engines powered by rapeseed oil methylester and heated non-esterified rapeseed oil. Atmos Environ. 60:253–261. https://doi.org/10.1016/j.atmosenv.2012.06.035

Xue J, Grift TE, Hansen AC (2011) Effect of biodiesel on engine performances and emissions. Renew Sust Energ Rev. 15(2):1098–1116. https://doi.org/10.1016/j.rser.2010.11.016

Yaakob Z, Narayanan BN, Padikkaparambil S (2014) A review on the oxidation stability of biodiesel. Renew Sust Energ Rev. 35:136–153. https://doi.org/10.1016/j.rser.2014.03.055

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ulusoy, Y. Investigation of particulate matter by FTIR, TEM and elemental analyses in a diesel engine operating on diesel and waste cooking oil-biodiesel. Environ Sci Pollut Res 27, 500–509 (2020). https://doi.org/10.1007/s11356-019-06741-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-06741-3