Abstract

The availability of natural energy resources and the environmental issues are the most significant issues that are often highlighted by the world communities. With regard to these problems, isobutanol is a higher chain alcohol with four carbons which can be derived from biomass resources and it is potential to become an alternative fuel source besides the biodiesel for a diesel engine. The aim of this study is to evaluate the effect of isobutanol with Calophyllum inophyllum methyl ester and diesel as the ternary blend on physicochemical properties, engine performance, and emission characteristics. Five different fuel blends containing Calophyllum inophyllum biodiesel and isobutanol were tested on a single-cylinder direct injection diesel engine at different engine load of brake mean effective pressure. The physicochemical properties of the fuel blends were measured and then compared with neat diesel. The results indicate that the blend containing isobutanol and CIME gives a slight increase in BSEC and EGT and a minimal drop in BTE as compared to that of neat diesel. Besides that, the tested blends show a reduction of carbon monoxide and unburned hydrocarbon emissions. Meanwhile, all the fuel blends show a minimal increase in carbon dioxide and nitrogen oxides emissions, compared to that of neat diesel. Isobutanol can be proved as a preferred substitute for biodiesel and diesel fuels to achieve desired engine performance and emissions level.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fossil fuels are the main source of energy, and they are dominantly used in various sectors, for instance, transportation, industries, and electricity generation sector as well as for domestic use. However, these fossil fuel sources are limited, and they are continuously decreasing due to superior in energy demand and consumption. The deep concerned about these fossil fuels is its hazardous pollutants generation that associated with the climate change, global warming, and human health (Syahir et al. 2017). Therefore, to cater to this critical scenario, researchers are now focusing on developing renewable fuels which are cost-effective, reliable, safest, and environmentally friendly, hence able to meet the world energy demand. According to the U.S. Energy Information Administration (EIA), renewable energy consumption will gain traction in the world’s total energy consumption projection up to 2050 (EIA 2018). Biofuel is one of the so-called renewable energy. Biofuel can be derived from various biomass resources and it can be categorized into three groups, i.e., (i) solid fuel (e.g., bio-char), (ii) liquid fuel (e.g., biodiesel and bio-alcohol), and (iii) gaseous fuel (e.g., hydrogen and methane). The two most common biofuels are biodiesel and bio-alcohol, which are widely used as replacements to hydrocarbon transportation fuels as well as power generation.

Biodiesel is found to be a notable alternative to conventional diesel fuel. It can be derived from vegetable oil- or animal fat-based fuel that consists of long-chain alkyl esters. Biodiesel offers many advantages over petroleum-based fuel, which is renewable, biodegradable, sustainable, carbon neutral, non-toxic, and eco-friendly (Sajjad et al. 2014). It is gaining popularity and becoming popular because it can reduce pollutant emissions (Devarajan et al. 2017). In fact, biodiesel and its blends emit a lower amount of unburnt hydrocarbon (HC), carbon monoxide (CO), carbon dioxide (CO), and particulate matter (PM) compared to that of diesel fuel. Substantial researchers also highlighted that the biodiesel could increase engine performance and decreases exhaust emissions. Furthermore, the physical and chemical properties of biodiesel are analogous to those for diesel, which make this fuel appealing alternatives for diesel to run in compression ignition engine with little or no modification (Agarwal 2007). However, the major problem of the biodiesel is its lower volatility and cold flow property as compared to that of diesel. Deposit formation and poor atomization are occurred in the combustion area due to the higher viscosity of biodiesel fuel (Dwivedi and Sharma 2014). Therefore, biodiesel cannot be fueled purely in unmodified diesel engines, but it is used as a blend with diesel fuel at a low percentage. Prior to that, the presence of a solvent additive such as alcohol is necessary to be blended with a higher percentage of biodiesel blend in existing diesel engines without any modifications.

Calophyllum inophyllum, also known as Penaga Laut in Malaysia, was chosen as biodiesel feedstocks because of its availability in numerous countries in the world and offers remarkable physicochemical properties as compared to other types of biodiesel as mentioned by several researchers (Atabani and Cesar 2014). Ong et al. (2014) conducted experiment using Calophyllum inophyllum methyl ester (CIME) in single-cylinder diesel engine. They found increase in BTE and lower BSFC when 10% of CI biodiesel was blended. Other notable changes are the decrease in CO and smoke emission compared to pure diesel. Another similar study was conducted by How et al. (2018). They investigated engine performance and exhaust emission by using CIME blends of 10%, 20%, 30%, and 50% and neat diesel on four-cylinder common-rail turbocharged diesel engine at different speed and torque conditions. They observed drawbacks in engine performance and emission such as decreased BP, increased BSFC and NOx. They also noticed the reduction of CO and smoke emissions. Similar results had been observed by Ashok et al. (2018) using 30% and 60% of CIME and compared to neat diesel. The engine testing results showed decreased of BTE, CO, and HC, and also increased of NOx emissions.

Alcohols such as methanol and ethanol are often used as alternative hydrocarbon fuel to improve the performance of vehicle engines especially gasoline engine. In addition, various techniques have been introduced to acknowledge the effect of ethanol as a supplementary fuel in a compression ignition engine (Aydin and Ilkılıc 2010). The use of ethanol in biodiesel blend, also known as e-diesel which contains higher oxygen, may improve both diffusive and premixed burning stages. However, the addition of ethanol in biodiesel blend give some limitation due to lower in cetane numbers (CNs), calorific value (CV) and miscibility, higher volatility and reduced ignitability, lower viscosity, and also improper lubricating behavior (Campos-Fernandez et al. 2013). Compared to ethanol, butanol also remarked as more modest and reasonable options due to its significant properties as fuel for use in engines, better performance, and environmental characteristics (Yusoff et al. 2017). Butanol or butyl alcohol can be categorized in two carbon chains structures either straight or branched and it exists in four different isomers, namely, normal butanol (n-butanol), secondary butanol (sec-butanol), isobutanol, and tertiary butanol (tert-butanol). All butanol isomers can reduce the level of exhaust emission due to their high oxygenated contents and low hydrocarbon mole fractions.

There is substantial research that has been conducted to examine the effect of butanol addition as the diesel fuel extender in various biodiesel blends at different volume rate concentration in diesel engines. Altun et al. (2011) studied the effect of n-butanol blending in 20 vol% of cottonseed oil biodiesel-diesel blends (B20) which contain 10 vol% and 20 vol% of n-butanol in biodiesel-diesel blends, denoted as B20Bu10 and B20Bu20, respectively, on the engine performance and exhaust emissions of a single-cylinder direct injection diesel engine. It was noted that the brake thermal efficiency (BTE) and brake specific fuel consumption (BSFC) were slightly increased due to the addition of n-butanol to the blend in comparison to the B20 fuel blend. In addition, significant reductions of HC and CO emission and smoke opacity have been observed except for NOx emission. Yoshimoto et al. (2013) have investigated the effect of alcohol addition containing 0, 20, 40, and 50 mass% of n-butanol in palm oil biodiesel-gas oil blend on the engine performance and emission characteristics of a single-cylinder direct injection diesel engine. It was found that the addition of n-butanol had improved low-temperature fluidity property of palm oil biodiesel blends, enhance the thermal efficiency, and reduce smoke density. However, the HC and CO emissions are higher at lower engine load condition. Besides that, Yilmaz et al. (2014) evaluated the effect of butanol-biodiesel blends in a four-stroke indirect injection diesel engine with butanol concentrations of 5, 10, and 20 vol%. It was reported that the addition of butanol with biodiesel resulted in higher BSFC and CO emissions as compared to neat biodiesel and diesel. The blends showed lower NOx emissions and exhaust gas temperature with the addition of butanol in a biodiesel blend. Moreover, Tüccar et al. (2014) examined the addition of butanol with microalgae biodiesel-diesel blends in a four-cylinder diesel engine. The volume fraction of the butanol was varied at 10 and 20 vol% (denoted as D70B20Bu10 and D60B20Bu20) and the results were then compared with 20 vol% microalgae-diesel blend (D80B20) and neat diesel. The results showed that the power and torque output of the engine was decreasing when the butanol was added to the blends. Still, CO, NOx, and smoke opacity results were reduced due to adding of butanol. Furthermore, Nabi et al. (2017) reported that the emissions such as HC, PM, and particulate number (PN) were significantly reduced, except for NOx emissions with the butanol-diesel blends compared to those of diesel fuel. Damodharan et al. (2017) studied on engine performance and exhaust emission of waste plastic oil (WPO) gained from pyrolysis process and blend it with n-butanol. All three blends, D50-WPO40-B10, D50-WPO30-B20, and D50-WPO20-B30, were compared to neat WPO and diesel. It was found that fuel consumption of all ternary blends shown remarkable result in reducing fuel consumption compared to WPO. BTE and NOx emission were increased due to increasing of n-butanol portion in the blends fuel.

Though a large number of researches have been thru to evaluate the effect of adding alcohol in biodiesel blend to engine performance and emission characteristics, but still, there were inadequate data and information to acknowledge the effect of branched-chain higher alcohol together with Calophyllum inophyllum methyl ester blend at different engine loads of single-cylinder diesel engine. Hence, this study purposes to examine the effect of isobutanol as a tertiary blend to utilize a pure CIME blend in a diesel engine in relations of physicochemical properties, engine performance, and emission characteristics.

Materials and methods

Sample preparation

Calophyllum inophyllum methyl ester was obtained locally. The petroleum diesel fuel was procured from the local market. Meanwhile, isobutanol was purchased from Merck Sdn. Bhd, Malaysia. Five different fuel blends were prepared, namely, (a) blend containing 10 vol% CIME in diesel (CIB10), (b) blend containing 20 vol% CIME in diesel (CIB20), (c) blend containing 5 vol% of isobutanol + 5 vol% of CIME in diesel (iBu5CIB5), (d) blend containing 10 vol% of isobutanol + 10 vol% of CIME in diesel (iBu10CIB10), and (e) blend containing 15 vol% of isobutanol + 15 vol% of CIME in diesel (iBu15CIB15).

Measurement of physicochemical properties

The physicochemical properties of Calophyllum inophyllum methyl ester and their blends were examined according to the ASTM 6751 and EN 14214 standards. Table 1 shows the list of the equipment used to measure the physicochemical properties of the fuel blends. The CN number and iodine value (IV) were calculated using the following equations. The results of physicochemical properties, i.e., density, viscosity, cloud point, pour point, flash point, acid value, calorific value, and cetane index of neat diesel, Calophyllum Inophyllum methyl ester, and blended fuels are listed in Table 2.

where

AiRepresents the proportion of each component

DRepresents the number of double bonds

MwiRepresents the mass of each element

Evaluation fatty acid methyl esters

The Fatty Acid Composition (FAC) of Calophyllum inophyllum biodiesel has been examined by using Gas Chromatography (GC). Table 3 shows the specifications and operating modes of GC for the test. The FAC content of the Calophyllum inophyllum biodiesel is shown in Table 4. The total ester, methyl linolenate, mono-glyceride, di-glyceride, triglyceride, and free and total glycerin were measured using the following EN14103 standard.

Engine testing

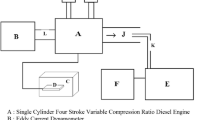

The experiment was carried out at Heat Engine Laboratory, Department of Mechanical Engineering in Faculty of Engineering, University of Malaya. Figure 1 shows the schematic diagram of the engine test setup. The test was performed using a single-cylinder, water-cooled, and naturally aspirates direct injection diesel engine. The tested engine was directly coupled to an eddy current dynamometer. The specifications of the engine and dynamometer are listed in Table 5. The fuel line system was set up by using two separate fuel tanks with two-way valves: one for neat diesel fuel and another one for modified blended fuels. The exhaust emission parameters such as CO, CO2, HC, and NOx emissions were measured using BOSCH BEA-350 exhaust emission analyzer.

At first, there is a need to warm up the engine till reaching steady-state condition by using normal diesel fuel. Then, switch from the normal diesel fuel to blended fuels by using the two-way valve to allow the test on the engine. The engine was run for 15 to 20 min for each specific fuel blend before the test began. It was to make sure the balance of normal diesel fuel will be removed from the fuel lines. In this research, the engine was tested at different engine load with brake mean effective pressure (BMEP) ranging from 1.97 to 7.88 bar with an increment of 0.985 bar. The experiment was repeated for three times and the average values were collected for graphical use. After finishing the test of each blend fuels, switch the two-way valve from blended fuels to normal diesel fuel to allow it to enter the engine so that the blended fuels can drain completely from the fuel lines.

Result and discussion

Engine performance analysis

Brake specific energy consumption (BSEC)

Brake specific energy consumption (BSEC) is the efficient of energy obtained from given fuel. BSEC also defined as product of BSFC times to calorific value of fuel and compared those fuel with different calorific values. BSEC is more precise measure for comparing fuels with different calorific values. It is understood that the lower amount of BSEC is notably desirable and proving that more operative the utilization of fuel energy to produce effective work. Figure 2 shows the variation of the BSEC as a function of engine load (BMEP). The BSEC of all the tested blends decreases with an increase in engine load. It can also be observed that the BSEC for CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend is higher compared to neat diesel, with an average increase of 7.7, 6.4, 9.3, 14.2, and 17.5%, respectively. The slight increase of BSEC for all the fuel blends was caused by the lower energy content of the biodiesel and its modified blends. The heating value of CIME and isobutanol is lower than neat diesel with 11% and 26%, respectively, resulting in lower per unit mass of heating values of the modified blends. Therefore, a higher amount of fuel blend is needed to produce the same engine power output of a diesel engine in comparison to the neat diesel. Similar findings were observed by Ashok et al. (2018) who determines the conceivable reason of BSEC to increased was because of low calorific value, high boiling point, and viscosity value of the fuel. By increasing percentage of biodiesel in the blended fuels, BSEC will increase due to decrease of calorific value in the blended fuels.

Brake thermal efficiency (BTE)

Brake thermal efficiency (BTE) is a measure of the efficiency of an engine to produce brake power from thermal input over the fuel amount supplied. BTE can be expressed as the ratio of brake power (the amount of power available at the crankshaft with frictional losses) and fuel power (the product of the calorific value of fuel and mass flow rate). Figure 3 represents the variation of brake thermal efficiency of the tested fuel at different engine loads (BMEP). It can be observed that the results of the BTE are a stark contrast with a variation of BSFC of the tested fuel blends in Fig. 3. The BTE was low at lower engine load and subsequently increase with higher engine load. Besides that, the maximum BTE of the tested fuel blends was observed at the highest engine load (BMEP) of 7.88 bar, whereby the CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend produced the maximum BTE of 22.14, 21.29, 22.99, 22.57, and 17.84%, respectively. It can be seen that the CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend shows an average reduction of 6.3, 5.1, 8.7, 12.3, and 19.3%, respectively, relative to neat diesel. The increasing isobutanol content in the blend causes a slight drop in BTE. This is due to the lower energy content of isobutanol than diesel and biodiesel. Similar findings were observed by (Sanli et al. 2015), whereby the BTE of the biodiesel and alcohol blend was lower than diesel.

Exhaust gas temperature

Exhaust gas temperature (EGT) is a measure of the gas temperature at the exhaust manifold. The EGT can be used for optimizing fuel economy, diagnosis, and prognosis of an engine (Von Moll et al. 2014). Figure 4 shows the variation of exhaust gas temperature (EGT) of the tested blend at different engine load (BMEP). It can be seen that the EGT of all the tested fuels was increased with the increase of engine load. The EGT reaches maxima at engine load (BMEP) of 7.88 bar. The EGT for all the fuel blends that increases with the increase of engine load is due to higher fuel consumption of the fuel inside the engine to meet load requirements. Besides that, it can be observed that the EGT of the CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend shows an average increment of 24.5, 27.2, 21.8, 17.6, and 22.2%, respectively, relative to neat diesel. The presence of isobutanol as the ternary blend would result in a reduction of EGT in comparison with the binary blend of CIME in diesel. In fact, the CIB5iBu5 and CIB10iBu10 blends give a lower increment of EGT than CIB10 and CIB20, respectively. This may be due to the higher heat of vaporization and lower cetane number of isobutanol than the CIME, which is reflected by a drop in EGT (Yusoff et al. 2018). Nevertheless, the increasing amount of the CIME in the blends would result in lower vapor pressure, which results in the delayed ignition, poor atomization, and problematic combustion, and eventually causes a more distinct rise of EGT.

Emission analysis

Unburned hydrocarbons (HC)

Unburned HC is the hydrocarbon emitted by the burning of heterogeneous air/fuel mixture in an engine. Figure 5 shows the result of HC emissions for all tested fuel at different engine load (BMEP). It can be seen that the HC emission concentration of all the tested fuel were higher at lower load condition, while decreases with increasing engine load. The lower formation of HC emissions can be caused by the higher in-cylinder temperature at higher engine load. Besides that, it can be observed that CIB10 blend produced the lowest concentration of HC emissions among the tested fuel blends with an average reduction of 26.85% relative to that of neat diesel. The CIB20 and CIB5iBU5 blends produced a lower concentration of HC emissions by an average reduction of 20.06 and 12.04%, respectively, with respect to neat diesel. However, the additional of isobutanol in the blends increases the concentration of HC emissions. In fact, the CIB10iBu10 and CIB15iBu15 blends show a higher concentration of HC emissions, with an average increment of 15.12 and 20.68%, respectively, with respect to neat diesel. The higher form of the HC emissions from these blends is due to the incomplete combustion in the cylinder engine, whereby the inhomogeneous charge of fuel mixing and air which cause an increase of HC emissions. It also can be found that the presence of isobutanol in the fuel blends increases the formation of HC emissions. This is due to the higher heat of vaporization of isobutanol than the diesel fuel, which then results in higher HC formation (Rakopoulos et al. 2010). Besides that, isobutanol has a lower cetane number than diesel fuel, thus it reduces the cetane number of the ternary blends of CIB10iBu10 and CIB15iBu15, which marks in a longer ignition delay for the blended fuel. Therefore, it requires additional time for the fuel blend to evaporate, lead to increasing lean outer flame zone, and eventually increase in HC emission formation (Wei et al. 2014).

Carbon monoxide (CO)

Carbon monoxide (CO) is produced in the incomplete combustion of carbon-containing fuel in an internal combustion engine. Figure 6 shows the result of CO emission with varying engine load (BMEP). The trend of CO emissions is similar to HC emissions, where the concentration of CO emissions is higher at lower engine load and vice versa. The formation of CO emission is lower at higher engine load due to higher in-cylinder temperature (Wei et al. 2014). It is apparent that the CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend produces a lower concentration of CO emissions relative to that of neat diesel, with an average reduction of 6.6, 10.2, 16.7, 25.8, and 33.9%, respectively. The significant reduction of abnormal CO emissions is due to the presence of oxygen in isobutanol and CIME, which then improves combustion of fuel, and consequently results in lower incomplete combustion product of CO emissions. A similar result was observed by (Kumar et al. 2016).

Carbon dioxide (CO2)

All fuels, which contain carbon in their molecular structure produce CO2 after combustion. The CO2 emissions from the exhaust of the engine describe the full combustion of the fuel inside the engine. Figure 7 shows the result of CO2 emission with varying engine load (BMEP). From the graph, it can be observed that the concentration of CO2 emissions of blends fuel containing biodiesel and isobutanol are higher than neat diesel at all engine load range, except at the lowest BMEP of 1.97 bar. On average, it is shown that the concentration of CO2 emissions of the CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend increased by 5.7, 10.8, 8.8, 4.6, and 7.7%, respectively, relative to neat diesel. A greater amount of CO2 emissions produced by the engine is due to the presence of more oxygen contents in fuel blends, which then produces more complete combustion, as well as reducing incomplete combustion products such as CO emissions. A similar finding was observed whereby the presence of the oxidizing agent in the biodiesel such as hydroxyl radical OH and oxygen contents enhanced the conversion of CO to CO2 in the emissions (Karabektas and Hosoz 2009). Therefore, this indicates that the fuel combustion could be improved by the addition of biodiesel and isobutanol in the blend.

Nitrogen oxides (NOx)

Nitrogen oxides (NOx) are produced by the endothermic reaction of nitrogen and oxygen takes place inside the engine cylinder during the combustion cycle at high temperature. Figure 8 depicts the result of NOx emission with varying engine load (BMEP). It can be noted that by increasing the engine load, the concentration of NOx emissions of the blends fuel containing biodiesel and isobutanol is significantly higher than the neat diesel (Yang et al. 2016). The NOx emissions increase at higher engine load is due to more injection and combustion of fuel inside the cylinder (Yang et al. 2017). On average, the concentration of the CIB10, CIB20, iBu5CIB5, iBu10CIB10, and iBu15CIB15 blend increased by 10.96, 23.11, 4.56, 16.19, and 6.86%, respectively, relative to neat diesel. The increase of NOx emissions is due to the higher oxygen concentration of the fuel blends containing biodiesel and isobutanol, which leads to a higher temperature of the mixture during combustion of the fuel and EGT, especially at higher engine load. As alcohol fuels contained more oxygen contents as compared to petroleum diesel fuel, this extra oxygen content in the fuel increases the temperature of the combustion mixture. This higher temperature of the combustion process enhanced the formation of NOx emissions (Sayin et al. 2012). Besides that, it can be observed that the presence of isobutanol in the ternary blends could reduce the formation of NOx emissions in comparison with the binary blend of CIME in diesel. In fact, the ternary blend of iBu5CIB5 and iBu10CIB10 produces lower CO emissions in comparison to a binary blend of CIB10 and CIB20 with an average of 5.76 and 5.62%, respectively. Isobutanol which has a higher heat of vaporization and lower cetane number reduces the exhaust gas temperature and consequently releases lower NOx emission concentration.

Conclusion

In this research, the effect on engine performance and exhaust emission characteristics of isobutanol blended with CIME and diesel were examined and compared with neat diesel fuel in a single-cylinder diesel engine at various engine load with BMEP (1.97–7.88 bar). The following conclusions are represented based on the results of this experiment:

-

The ternary fuel blends containing isobutanol in biodiesel-diesel show reduction in density, kinematic viscosity, flash point, and cetane number relative to that of the binary fuel blends. However, both binary and ternary fuel blends have lower calorific value with respect to neat petroleum diesel.

-

The addition of isobutanol and CIME in the fuel blend shows a slight increase in BSFC and EGT and a minimal drop in BTE as compared to that of neat diesel. Besides that, the presence of isobutanol in ternary blend reduces EGT with respect due to lower cetane number and higher heat of vaporization of the alcohol.

-

Regarding exhaust emission characteristics, the CIB10 blend shows the largest reduction of HC emissions among all the tested fuel blends. The addition of isobutanol in fuel blends increases the formation of HC emissions relative to neat. Meanwhile, all the tested fuel blends containing isobutanol and CIME show a decreasing trend in CO emissions and minimal increase in CO2 emissions due to improving complete combustion. The fuel blends show a slight increase in NOx emissions. However, the addition of isobutanol in the ternary blend reduces NOx formation in comparison with the binary blend due to a lower higher temperature of the mixture during combustion and EGT.

In general, the addition of isobutanol with Calophyllum inophyllum methyl ester showed the deficient result of the engine performance but improves on exhaust emission characteristics. The remarkable properties of isobutanol and CIME in the fuel blends reduce emissions. Hence, it is concluded that the desired engine performance and compromise emissions level can be achieved by blending the higher alcohol in a lower volume ratio.

References

Agarwal AK (2007) Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energ Combust 33:233–271

Altun S, Oner C, Yasar F, Adin H (2011) Effect of n-butanol blending with a blend of diesel and biodiesel on performance and exhaust emissions of a diesel engine. Ind Eng Chem Res 50:9425–9430

Ashok B, Nanthagopal K, Vignesh DS (2018) Calophyllum inophyllum methyl ester biodiesel blend as an alternate fuel for diesel engine applications. Alex Eng J 57:1239–1247

Atabani AE, Cesar AD (2014) Calophyllum inophyllum L. - a prospective non-edible biodiesel feedstock. Study of biodiesel production, properties, fatty acid composition, blending and engine performance. Renew Sust Energ Rev 37:644–655

Aydin H, Ilkılıc C (2010) Effect of ethanol blending with biodiesel on engine performance and exhaust emissions in a CI engine. Appl Therm Eng 30:1199–1204

Campos-Fernandez J, Arnal JM, Gomez J, Lacalle N, Dorado MP (2013) Performance tests of a diesel engine fueled with pentanol/diesel fuel blends. Fuel 107:866–872

Damodharan D, Sathiyagnanam AP, Rana D, Rajesh Kumar B, Saravanan S (2017) Extraction and characterization of waste plastic oil (WPO) with the effect of n-butanol addition on the performance and emissions of a DI diesel engine fueled with WPO/diesel blends. Energ Convers Manage 131:117–126

Devarajan Y, Munuswamy DB, Nagappan B (2017) Emissions analysis on diesel engine fuelled with cashew nut shell biodiesel and pentanol blends. Environ Sci Pollut R 24:13136–13141

Dwivedi G, Sharma MP (2014) Impact of cold flow properties of biodiesel on engine performance. Renew Sust Energ Rev 31:650–656

EIA (2018) International energy outlook 2018, U.S. Energy Information Administration, Washington, DC (United States)

How HG, Masjuki HH, Kalam MA, Teoh YH, Chuah HG (2018) Effect of Calophyllum Inophyllum biodiesel-diesel blends on combustion, performance, exhaust particulate matter and gaseous emissions in a multi-cylinder diesel engine. Fuel 227:154–164

Karabektas M, Hosoz M (2009) Performance and emission characteristics of a diesel engine using isobutanol-diesel fuel blends. Renew Energy 34:1554–1559

Kumar BR, Saravanan S, Rana D, Nagendran A (2016) A comparative analysis on combustion and emissions of some next generation higher-alcohol/diesel blends in a direct-injection diesel engine. Energ Convers Manage 119:246–256

Von Moll A, Behbahani AR, Fralick GC, Wrbanek JD, Hunter GW (2014): A review of exhaust gas temperature sensing techniques for modern turbine engine controls, 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, pp. 3977

Nabi MN, Zare A, Hossain FM, Bodisco TA, Ristovski ZD, Brown RJ (2017) A parametric study on engine performance and emissions with neat diesel and diesel-butanol blends in the 13-Mode European Stationary Cycle. Energy Convers Manag 148:251–259

Ong HC, Masjuki HH, Mahlia TMI, Silitonga AS, Chong WT, Leong KY (2014) Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energ Convers Manage 81:30–40

Rakopoulos D, Rakopoulos C, Hountalas D, Kakaras E, Giakoumis E, Papagiannakis R (2010) Investigation of the performance and emissions of bus engine operating on butanol/diesel fuel blends. Fuel 89:2781–2790

Sajjad H, Masjuki H, Varman M, Kalam M, Arbab M, Imtenan S, Rashed M (2014) Comparative study of gas-to-liquid fuel, B5 diesel and their blends with respect to fuel properties, engine performance and exhaust emissions. RSC Adv 4:44529–44536

Sanli H, Canakci M, Alptekin E, Turkcan A, Ozsezen AN (2015) Effects of waste frying oil based methyl and ethyl ester biodiesel fuels on the performance, combustion and emission characteristics of a DI diesel engine. Fuel 159:179–187

Sayin C, Gumus M, Canakci M (2012) Effect of fuel injection pressure on the injection, combustion and performance characteristics of a DI diesel engine fueled with canola oil methyl esters-diesel fuel blends. Biomass Bioenergy 46:435–446

Syahir A, Zulkifli N, Masjuki H, Kalam M, Alabdulkarem A, Gulzar M, Khuong L, Harith M (2017) A review on bio-based lubricants and their applications. J Clean Prod 168:997–1016

Tüccar G, Özgür T, Aydın K (2014) Effect of diesel–microalgae biodiesel–butanol blends on performance and emissions of diesel engine. Fuel 132:47–52

Wei L, Cheung C, Huang Z (2014) Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 70:172–180

Yang PM, Lin KC, Lin YC, Jhang SR, Chen SC (2016) Emission evaluation of a diesel engine generator operating with a proportion of isobutanol as a fuel additive in biodiesel blends. Appl Therm Eng 100:628–635

Yang K, Wei L, Cheung CS, Tang CL, Huang ZH (2017) The effect of pentanol addition on the particulate emission characteristics of a biodiesel operated diesel engine. Fuel 209:132–140

Yilmaz N, Vigil FM, Benalil K, Davis SM, Calva A (2014) Effect of biodiesel–butanol fuel blends on emissions and performance characteristics of a diesel engine. Fuel 135:46–50

Yoshimoto Y, Kinoshita E, Shanbu L, Ohmura T (2013) Influence of 1-butanol addition on diesel combustion with palm oil methyl ester/gas oil blends. Energy 61:44–51

Yusoff M, Zulkifli N, Masjuki H, Harith M, Syahir A, Kalam M, Mansor M, Azham A, Khuong L (2017) Performance and emission characteristics of a spark ignition engine fuelled with butanol isomer-gasoline blends. Transp Res Part D: Transp Environ 57:23–38

Yusoff M, Zulkifli N, Masjuki H, Harith M, Syahir A, Khuong L, Zaharin M, Alabdulkarem A (2018) Comparative assessment of ethanol and isobutanol addition in gasoline on engine performance and exhaust emissions. J Clean Prod 190:483–495

Funding

This work received financial assistance from the University of Malaya through Fundamental Research Grant Scheme (FRGS) grant title: “Improvement of Diesel Engine Key Fuel Properties by Optimizing Alcohol – Biodiesel – Diesel Blend Ratio for Low Greenhouse Gas Emission” with Project no.: FP051-2015A, Project code: FRGS/1/2015/TK07/UM/01/1 and the University of Malaya Research Grant (UMRG Programme) – AET (Innovative Technology, ITRC) grant title: “Development of New Technologies for Electrical Discharge Machine for High Performance and Productivity” with Project no.: RP039C-15AET.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alwi, A., Zulkifli, N.W., Sukiman, N.L. et al. Evaluation of engine performance and exhaust emission characteristics in a diesel engine using isobutanol— Calophyllum inophyllum biodiesel—diesel ternary blends . Environ Sci Pollut Res 26, 11815–11826 (2019). https://doi.org/10.1007/s11356-019-04603-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-04603-6