Abstract

Pyrolysis of waste materials to produce biochar is an excellent and suitable alternative supporting a circular bio-based economy. One of the properties attributed to biochar is the capacity for sorbing organic contaminants, which is determined by its composition and physicochemical characteristics. In this study, the capacity of waste-derived biochar to retain volatile fuel organic compounds (benzene, toluene, ethylbenzene and xylene (BTEX) and fuel oxygenates (FO)) from artificially contaminated water was assessed using batch-based sorption experiments. Additionally, the sorption isotherms were established. The results showed significant differences between BTEX and FO sorption on biochar, being the most hydrophobic and non-polar contaminants those showing the highest retention. Furthermore, the sorption process reflected a multilayer behaviour and a relatively high sorption capacity of the biochar materials. Langmuir and Freundlich models were adequate to describe the experimental results and to detect general differences in the sorption behaviour of volatile fuel organic compounds. It was also observed that the feedstock material and biochar pyrolysis conditions had a significant influence in the sorption process. The highest sorption capacity was found in biochars produced at high temperature (> 400 °C) and thus rich in aromatic C, such as eucalyptus and corn cob biochars. Overall, waste-derived biochar offers a viable alternative to be used in the remediation of volatile fuel organic compounds from water due to its high sorption capacity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Approximately 20 million tonnes of oil and petroleum products are used worldwide every day (Fingas 2012). The transformation process of petroleum and its transport are sources of soil and water contamination due to accidental spills, poor management of the waste products or leakage in underground storage tanks and transportation pipes (Kim et al. 2011). Since 1970, near 10,000 oil spill incidents from tankers have been recorded, most of them (81%) categorised as small spills (< 7 tonnes) (Paulauskiene et al. 2014; ITOF 2017). The environmental and economic damage caused by a spill is related to the amount of fuel released but, in some cases, a small spillage can affect large areas due to the spread by wind, groundwater and surface water flows (Cech et al. 2017). Diesel, gasoline and other fossil fuels are complex mixtures of organic compounds, most of them toxic and included in the United States Environmental Protection Agency (USEPA) priority pollutant list. BTEX (benzene, toluene, ethylbenzene and m-, p- and o-xylene isomers) is a group of organic aromatic compounds commonly present in petroleum products, mainly in gasoline (USEPA 2010). Gasoline formulations also include fuel oxygenates (FO) as additives to enhance the octane number and to reduce emissions. Among FO, methyl tert-butyl ether (MTBE) and ethyl tert-butyl ether (ETBE) are the most commonly used (Kanai et al. 1994). These compounds are the most volatile and water-soluble components of fuel and can migrate from the contamination source causing important environmental problems (Fries et al. 1994). Additionally, they pose a threat to human health since they cause skin and sensory irritation, affect the nervous system and may be considered hematotoxic and carcinogenic (Wilbur and Bosch 2004).

The development of fast and easy handling remediation strategies with effective tools or materials is required in order to minimise the negative consequences of petroleum spills in surface and ground waters (Silvani et al. 2017). This can be done by physical, chemical or biological processes (Fakhru'l-Razi et al. 2009). The techniques conventionally used to remove BTEX compounds from water can include natural attenuation, chemical oxidation, ozonation, photocatalysis, electrodialysis, membrane-based separation and adsorption (Fakhru'l-Razi et al. 2009; Zaib et al. 2014; Fayemiwo et al. 2017). Other technologies are based on bioremediation which uses microorganisms to degrade the contaminants or phytoremediation (Compton et al. 2003; Moore et al. 2006; Jecu et al. 2008; Weishaar et al. 2009). More specifically, among the physical methods developed, it has been described the effectiveness of air/steam stripping combined with organic vapour membrane to enhance the recovery of the pollutants from water (Wijmans et al. 2006). Particularly, the use of sorbents such as activated carbon, diatomite or zeolite to remove organic contaminants from water has been widely studied (Cornelissen et al. 2005; Aivalioti et al. 2010; Zadaka-Amir et al. 2012). Recently developed sorbents, such as carbon nanotubes or polydimethylsiloxane nanoparticles, have been applied to retain BTEX present in water (Gupta and Kulkarni 2011; Zaib et al. 2014). The sorption potential of other alternative materials such as sewage sludge, wood chips or waste scrap tyres has been also tested for the removal of BTEX from artificially contaminated water with satisfactory results (de Toledo et al. 2018). Activated carbon has also been widely applied in wastewater treatment due to its high adsorption capacity; however, it is difficult to regenerate/reactivate and its application on a large-scale area is expensive (Ali and Gupta 2007). Therefore, research must be focused on finding novel and efficient sorbents, being biochar a low-cost and suitable alternative that will also contribute to a more efficient waste management and to circular economy. Moreover, biochar offers the advantage that it can be produced with wastes or local materials (produced close to a recovering area), avoiding long distance transportation and making the system even more efficient, economically viable and closing cycles.

Biochar is a stable C product obtained from the thermal conversion of biomass in the absence of oxygen at relatively low temperatures (< 700 °C) by the process of pyrolysis (Lehmann and Joseph 2009). Biochar materials are enriched in recalcitrant aromatic carbon and show high resistance to microbial decomposition in soils (Lehmann and Joseph 2009). The potential use of biochar as a soil amendment and in C sequestration has been investigated extensively (Lehmann et al. 2015; Kuppusamy et al. 2016; Chen et al. 2018); but, another important property attributed to biochar is its high sorption capacity, especially of organic compounds (Smernik 2009). The physicochemical properties of biochars, i.e. elemental composition, aromaticity, specific surface area and microporosity, are relevant properties that determine the sorption capacity of biochar (Ahmad et al. 2014; Kupryianchyk et al. 2016; Xiao et al. 2016; Kookan et al. 2017). Additionally, the nature of the contaminant will also affect the removal efficiency, already observed by many authors (Sander and Pignatello 2005; Chen et al. 2008). The main difference between biochar and other organic low cost adsorbents tested by other authors (wood, bagasse, sludge, etc.) lies in the high stability and recalcitrance of biochar, which allows it to remain stable much longer than the original feedstock and to produce long-term benefits (Lehmann et al. 2015).

Within this context, the objective of the present study was to evaluate the potential of biochars to remove volatile fuel organic compounds (VFOC), including BTEX and FO from aqueous solutions. The effect that feedstock material and pyrolysis conditions have on biochar sorption capacity was also assessed. For this purpose, batch-based sorption experiments were designed to characterize the sorption of VFOC.

Materials and methods

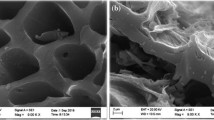

Biochar production and characterization

A wide variety of biochars were selected for this study. These biochars were obtained from a variety of feedstocks: acacia bark (BAcB) and acacia trunk divided in sapwood (BAcSw-1, BAcSw-2, BAcSw-3) and heartwood (BAcHw-1 and BAcHw-2), eucalyptus branches (BEu-1 and BEu-2), pine sawdust (BSd), pine bark (BPb), chicken manure (BCm), olive pomace compost (BOpc), rice husk (BRh), corncob (BCc-1 and BCc-2) and tyre (BTy). Biochars were produced in an experimental unit of biomass pyrolysis under oxygen-limited conditions. The operation conditions varied between 300 and 600 °C and the residence time between 1.5 and 6 h.

The main physicochemical properties of the biochars are shown in Table S1 (Supporting Information). The methodologies used to characterize the biochar samples are briefly described: CHNS elemental analysis was performed using an elemental analyser (TruSpec CHNS LECO); ash content was determined by combustion at 1000 °C during 4 h; oxygen content was estimated as O = 100 – C + N + H + S + ash; pH was measured in a suspension of biochar in deionized water (1:5, w/v); nutrient content (Ca, Mg, K and Na) was determined by atomic absorption spectroscopy using an atomic absorption spectrometer (1100B Perkin Elmer) after wet acid digestion (3 mL HNO3 + 9 mL HCl) in a microwave (Milestone Ethos Plus with HPR-100/10s); thermogravimetric and differential scanning calorimetry analysis (TGA-DSC) scanning of samples was conducted by triplicate using a simultaneous thermal analyser (STA6000 PerkinElmer) in either (i) air atmosphere according to Harvey et al. (2012) procedure to calculate recalcitrance index (R50), or (ii) N2 atmosphere (plus air atmosphere once temperature reached 900 °C), following UNE 32-019-84 standard method for determination of volatile matter (VM) and fixed C (FixC); the C oxidability of biochar was determined by wet oxidation with potassium dichromate (Walkley and Black 1934) and potassium permanganate (Tirol-Padre and Ladha 2004), determining the hardly oxidisable C (ChardlyOx) and easily oxidisable C (CeasyOx), respectively; non oxidisable C (Cnox) was determined by difference between the total C and ChardlyOx.; the most labile C (Cp) was obtained by an extraction with sodium pyrophosphate (Bascom 1986). Additionally, the specific surface area (SSA) was determined applying Brunauer-Emmett-Teller (BET) method to N2 adsorption (Gemini 2360 V2.01 Micromeritics).

Reagents

The following reagents were used: benzene (purity, 99.8%; grade, PAI-ACS (UV-IR-94 HPLC-GPC)), toluene (purity, 99.8%; grade, PAI-ACS (UV-IR-HPLCGPC)), ethylbenzene (purity, 99%; grade, PS), o-xylene (purity, 99%; grade, PA (Reag.USP. Ph. Eur)), m-xylene (purity, 99%; grade, PA (Reag. Ph. Eur)), p-xylene (purity, 99%; grade, PA (Reag.USP)), MTBE (purity, 99.7%; grade, PAI (PAR)) and ETBE (purity, 99%; grade, PA (Reag.USP)). Fluorobenzene (purity, 99%) was used as internal standard for calibration. All reagents were purchased from Panreac Química, S.L.U. (Barcelona, Spain) except fluorobenzene, purchased from Sigma-Aldrich Co, LLC (China). The spiking solutions were prepared in methanol (purity, 99.9%; grade, PAI (PAR)) with each of the reagents (BTEX and FO) at a concentration of 100 and 10,000 mg L−1 for experiments 1 and 2, respectively. Another standard solution was prepared with fluorobenzene (FB) at the concentration of 100 mg L−1. All other chemicals needed in the experiments were of Merck p.a. quality.

Sorption experiments

Experiment 1: headspace analysis approach to assess the sorption of VFOC on biochars

Headspace gas chromatography–mass spectrometry analysis (HS-GC-MS) without matrix effect correction was used to evaluate biochar behaviour in the adsorption of BTEX and FO following the optimised method from Balseiro-Romero and Monterroso (2013). This technique is simple, fast and needs low sample handling, which makes it adequate as a first approach to determine biochar sorption capacity.

A slurry was prepared with 0.5 g of biochar mixed with 2 mL of distilled water in 10 mL-HS analytical vials and 100 μL of spiking solution was added. The total spiking concentration in the experiment was 40 mg kg−1 for ∑FO (the sum of ETBE and MTBE) and 120 mg kg−1 for ∑BTEX (the sum of benzene, toluene, ethylbenzene and xylene isomers). The slurry facilitated a homogeneous distribution of the organic contaminants in the biochar and reduced losses by evaporation (Serrano and Gallego 2006). Once the biochar slurry was spiked with the contaminants, the headspace (HS) vials were hermetically sealed and statically incubated at 4 °C for 7 days. Experiments were carried out in triplicates and the concentration of VFOC was analysed by HS-GC-MS (see section “Instrumental and analytical procedure: HS-GC-MS”).

Experiment 2: sorption isotherms of BTEX and FO for selected biochars

Four biochars produced from different feedstock materials were selected to construct the sorption isotherms of BTEX and FO using batch sorption experiments. Particularly, the samples were obtained from acacia bark (BAcB), chicken manure (BCm), corncob (BCc-2) and eucalyptus (BEu-2). BAcB and BCm were obtained at low temperature, and BCc-2 and BEu-2 were obtained at high-temperature pyrolysis (> 400 °C). Batch experiments were conducted using deionized water containing 5 mM CaCl2 to simulate natural water ionic strength and 5 mM NaN3 to inhibit bacteria degradation (Chen and Yuan 2011; Xiao et al. 2014). The contaminant stock solution (10,000 mg L−1) was diluted in that aqueous solution to obtain an initial concentration ranging from 2 to 600 mg L−1 for each individual compound, specifically 2, 15, 30, 60, 90, 120, 200, 300, 400 and 600 mg L−1. Aliquots of 10 mL of those solutions were added to glass vials containing 0.1 g of biochar and shaken for 36 h (Chen and Yuan 2011, Xiao et al. 2014). The headspace in the tubes was minimised to reduce any contaminant volatilisation during shaking. After equilibrium was reached, solid and aqueous phases were separated by centrifugation at 2100 rpm for 15 min and a 2 mL aliquot of the supernatant was transferred to HS analysis vials. Finally, 50 μL of FB stock solution were added, and the vials were quickly sealed to avoid evaporation.

Experiments were conducted in triplicates and the concentrations of BTEX and FO were analysed by HS-GC-MS. The amount of contaminant sorbed was calculated by difference between the total amount spiked and the amount remaining in the solution at equilibrium.

Instrumental and analytical procedure: HS-GC-MS

The analytical system consisted of an autosampler (Agilent-Varian Combi PAL) with HS injection, an oven for heating and agitating the sample vials, a gas chromatograph (Agilent-Varian 450-GC) and a mass spectrometer with ion trap (Agilent-Varian 220-MS). Cycle Composer software (Version 1.5.4; CTC Analytics AG) was used to control the Combi PAL autosampler and MS Workstation software (Version 6.9.3; Varian, Inc.) was used to control the GC-MS system and to process the data.

The operating conditions were established according to Balseiro-Romero and Monterroso (2013). Vials were heated in the oven at 80 °C during 15 min in constant stirring (500 rpm) to achieve equilibrium between phases. When the equilibrium was achieved, 1 mL of HS gas was injected in the chromatograph for analysis. Note that for experiment 1, three phases were present in the tubes (biochar, water and air), and the sorption of the analytes on biochar reduced their migration towards the HS. Therefore, the results from the HS-GC-MS analysis of samples corresponded to the amount of contaminant recovered which is free of sorption and participates in the slurry-HS equilibrium (Balseiro-Romero and Monterroso 2013).

The chromatographic column used was a FactorFour VF-5ms EZ-Guard (supplied by Agilent Technologies) of 30 m × 0.25 mm × 0.25 μm. The column oven temperature varied as follows: 35 °C (held for 5 min), 10 °C min−1 up to 80 °C and 25 °C min−1 up to 200 °C (held for 0.7 min). The carrier gas was helium with a constant flow of 1 mL min−1. The injector was operated at 250 °C and in split 1/10 mode. The mass spectrometer operated in full scan mode. Ionization of the molecules was performed by electron impact, and the ion trap temperature was fixed at 220 °C (Balseiro-Romero et al. 2016a). m- and p-xylene were jointly quantified (hereafter so-called mp-xylene) as they appeared as a combined peak in the chromatograms.

Calibration standards were prepared in 2 mL of distilled water containing 100–10,000 μg L−1 of each individual contaminant and constant concentration of FB (2.5 mg L−1) as internal standard.

Empirical adsorption models

Data from BTEX sorption assays (experiment 2) were described by the two empirical models most commonly used in descriptive analysis on adsorption processes:

where qe is the concentration of each contaminant adsorbed per unit of mass of biochar (g kg−1); Ce is the concentration of each organic compound in the solution (mg L−1); Qmax is the maximum adsorption capacity of each biochar (g kg−1); KL is Langmuir equilibrium constant which is related to the binding strength (L mg−1); KF is a constant related to the adsorption capacity (g L1/n mg−1/n kg−1); n is a constant related to the intensity of adsorption and the heterogeneity of the binding sites.

The fitting of the sorption models was conducted using OriginPro 8 SR0 software. Minimisation of the residual sum of squares (RSS) was used as fitting criteria. Several statistics (R2, χ2) were used to assess the model results.

Statistical analysis

Software IBM SPSS Statistics 24.0 was used to analyse the data. Normality of the data from experiment 1 was tested with a Kolmogorov-Smirnov test. When the data did not follow a normal distribution, they were analysed by a non-parametric test (Kruskal-Wallis test) to characterize the differences in the VFOC recovery between the samples and contaminants behaviour. One-way ANOVA was conducted to assess whether the nature of biochar significantly affects the recovery of the contaminants when it was confirmed that the data followed a normal distribution. A Bonferroni post hoc test was used to analyse differences among the sorption behaviour of biochar samples when normal distribution of the data was confirmed. Pearson correlations were carried out between ΣFO and ΣBTEX recovery and biochar properties in all the samples. Principal component analysis (PCA) was performed using CANOCO 4.5 (ter Braak and Šmilauer 2002) to correlate the sorption capacity determined in experiment 2 with the physicochemical characteristics of the biochar samples. A significance level of 0.05 was considered for all statistical analyses.

Results

BTEX and FO recovery from biochar (experiment 1)

HS-GC-MS analytic data were used to comparatively characterize the recovery of the pollutants that were not sorbed by each biochar sample. The HS-GC-MS results from experiment 1 are shown in Fig. 1, expressed as the percentage of ∑BTEX and ∑FO recovered in solution from the total initially spiked to the system. FO recovery for all the samples was significantly higher than BTEX recovery (p < 0.05). ∑FO recovery varied from 4 to 39 mg kg−1, while ∑BTEX ranged between 0.14 and 54 mg kg−1 (the initial spiking concentration was 40 mg kg−1 for ∑FO and 120 mg kg−1 for ∑BTEX). The maximum ∑FO recovery was found in the presence of biochars produced at low temperatures (HHT ≤ 400 °C) and H/Corg > 0.7, i.e. BSd (97% from the total spiked), followed by BAcHw-2 and BCm (~ 73%). By contrast, the lowest recovery values, associated with higher sorption capacities, were found in the presence of BEu-2 and BCc-1, presenting respectively 10 and 13% recovery of the total FO spiked. Concerning ∑BTEX, the lowest sorption potential was found for BCm (45% recovery of the total BTEX spiked), whereas BEu-2 and BCc-2 showed the highest sorption capacity (0.1 and 0.9% recovery, respectively). The recovery of all contaminants from BEu-2 was significantly lower (p < 0.05) than in all the samples produced at a low temperature (≤ 400 °C), such as all acacia-derived samples, BEu-1, BOpc and BCm.

MTBE showed the highest recovery when comparing the contaminants individually. The highest recovery was found in systems containing BAcHw-2 and BCm (Fig. 2a) (~ 77.5%), and the lowest value was found in BEu-2 (~ 12.3%). The recovery of MTBE and ETBE was not significantly different (p > 0.05). However, the difference between the recoveries of each FO and each BTEX was statistically significant (p < 0.05). Nevertheless, differences among recoveries of the BTEX compounds were not significant (p > 0.05) (Fig. 2b).

The Pearson correlation test was conducted to determine the relationship among VFOC recovery (ΣBTEX and ΣFO) and biochar properties (Table 1). An inverse correlation was found between BTEX and FO recovery and the highest heating temperature (HHT) (p < 0.01), indicating that sorption capacity improved remarkably with increasing HHT. In addition, highly significant positive correlations (p < 0.01) were found between the recovery degree (for both BTEX and FO) and H/Corg ratio and volatile matter (VM). In this case, sorption decreased with increasing values of H/Corg and VM. In general, BTEX sorption was more significantly affected by biochar properties than FO. The pH of biochar was correlated with the FO sorption (p < 0.01), whereas it did not affect significantly the BTEX sorption. There was a positive correlation (p < 0.01) between BTEX sorption and stable carbon forms (Cnox and FixC), which in turn are good indicators of the aromaticity of biochar samples. On the other hand, the BTEX recovery increased significantly with higher content of easily oxidisable C forms (p < 0.05).

BTEX sorption isotherms (experiment 2)

Once the general sorption behaviour of a wide variety of biochar was assessed (experiment 1), four of those biochar samples (i.e. BEu-2, BCc-2, BAcB and BCm) were selected to study their sorption capacity in detail. Firstly, this experiment confirmed the low capacity of biochar to retain MTBE, ETBE or benzene. The four biochars tested only sorbed these pollutants at the three or four first spiking concentrations (2, 15, 30, 60 mg L−1) (Fig. S1 in the Supporting Information), making impossible the adjustment to any empirical model. MTBE was the least sorbed: between 1 and 60% was sorbed at low concentrations (≤ 30 mg L−1), being BCm the biochar which showed the highest sorption capacity (0.386 g kg−1 at an initial spiking concentration of 30 mg L−1). In the case of ETBE, BEu-2 was able to retain 90% at the lowest spiking concentration (2 mg L−1), but the highest sorption capacity was found in BAcB (0.837 g kg−1 were retained at an initial spiking concentration of 30 mg L−1). At relatively low benzene concentration (≤ 60 mg L−1), ~ 80% of the amount spiked was sorbed on BEu-2, whereas ~ 50% was immobilised by BCm.

Hence, the fitting of the sorption models was evaluated for toluene, ethylbenzene and xylene isomers. Experimental data reflected a multilayer sorption behaviour; an example can be seen at Fig. 3, where the sorbed concentration of toluene, qe (g kg−1), was plotted against the equilibrium concentration in aqueous solution, Ce (mg L−1), for the four biochars studied. Initially, at low concentration in solution, < 100 mg L−1, BTEX were sorbed on the surface of biochars creating a monolayer, until saturation was achieved. Then, when the concentration of BTEX is relatively high, an inflexion point is observed and the isotherm showed an s-shaped behaviour, which indicates a change in the sorption mechanism. This second step may be attributed to the interaction among layers of organic compounds following surface saturation, due to their hydrophobic nature (Breus and Mishchenko 2006; Limousin et al. 2007). Although sorption differences between materials were observed at the first layer, these differences were minimised at the second layer. Other authors have also reported this multilayer behaviour in the sorption of organic pollutants. This is the case of Fiorentin et al. (2010) and Scheufele et al. (2016), who studied the retention of blue 5G dye onto dry orange bagasse and sugarcane bagasse surface, respectively. These authors found that Langmuir and Freundlich models where adequate to reproduce the adsorption data at low dye concentrations, whereas after the saturation point, a second sorption layer appeared at high concentrations, which produced an increase in the sorption capacity of the materials.

Accordingly, the fitting of the empirical sorption models was conducted considering only the first layer, where the biochar surface was involved. Langmuir and Freundlich isotherms were fitted to experimental data for each sorbent, and the fitting model parameters and their corresponding errors are shown in Table 2. For the fitting, we have considered all the experimental data points, including replicates. As shown in Fig. 4 and Fig. 5, the experimental data are better described by the Langmuir model. This is supported by the highest correlation coefficients (R2) and the lowest reduced chi-square values (χ2) obtained for the Langmuir model, which ranged from 0.72 to 0.98 and from 0.05 to 1.47, respectively. R2 values obtained with the Freundlich model ranged between 0.46 and 0.95, while χ2 did so between 0.09 and 3.46. For the five contaminants studied (toluene, ethylbenzene and xylene isomers), the best fitting of the Langmuir model was found for eucalyptus biochar (BEu-2), and the worst for acacia bark biochar (BAcB), especially for o-xylene (R2 = 0.72). An exception was found for toluene, ethylbenzene and xylenes sorption on corncob biochar (BCc-2), which exhibited a Freundlich behaviour.

Sorption isotherms of a toluene and b ethylbenzene for the four biochars (BEu-2, BCc-2, BCm and BAcB). Results are expressed as the average concentration (points) ± the standard deviation (whiskers) (n = 3), solid lines to the fitting of the Langmuir model and dashed lines to the fitting of the Freundlich model

Sorption isotherms of a o-xylene and b mp-xylene for the four biochars (BEu-2, BCc-2, BCm and BAcB). Results are expressed as the average concentration (points) ± the standard deviation (whiskers) (n = 3), solid lines to the fitting of the Langmuir model and dashed lines to the fitting of the Freundlich model

Comparing the different adsorbent materials, BEu-2 presented the highest Qmax value for all the organic compounds studied, followed by BCc-2, BCm and BAcB (Table 2). The Langmuir constant, KL, varied from 0.02–0.05 for all the organic pollutants in BCm to ~ 6 for o-xylene sorption in BEu-2. This constant is related to the binding strength, indicating that the affinity of the organics for the BCm was smaller. KL varied depending on the physicochemical properties of the contaminant (Table S2 in Supporting Information), following the general trend ethylbenzene > o-xylene > toluene > mp-xylene.

For the Freundlich model, the constant 1/n was lower than the unit for all the cases studied (Table 2), which means a downward curved isotherm (L-type isotherm), indicating less competition for sorption sites and a sorption energy decrease with increasing surface concentration (Site 2001). The 1/n values declined from BCm to BEu-2, with highest and lowest values of 0.71 and 0.17, respectively, indicating a reduction of linearity to strong non-linearity. Regarding the Freundlich constant, KF, the highest values were found in BEu-2 and BCc-2, which is in agreement with the results obtained for the Langmuir constant and reflects the higher sorption capacity of these samples. KF values followed a trend depending on the organic pollutants and biochar type, which was ethylbenzene > toluene > mp-xylene > o-xylene in BCc-2 and BEu-2 biochars; however KF for o-xylene was higher than that for mp-xylene in BCm and BAcB biochars.

Principal components analysis (PCA) was performed with Langmuir and Freundlich parameters obtained for toluene and the physicochemical properties of the biochars used as sorbent material. The first three principal components (PC) accounted for 100% of total variability of the physicochemical properties, with PC1 and PC2 accounting for 70.9% and 25.0%, respectively (Fig. 6). As expected, the samples were spread through the plot, since they were produced from different feedstock material and had different physicochemical properties. However, biochar samples can be separated into biochars obtained at low highest heating temperature (HHT ≤ 400 °C) plotted in the negative area of PC1, and biochars produced over 400 °C, on the positive area. Biochars were plotted from the negative to the positive PC1 axis according to its sorption capacity and aromaticity following this order: BCm < BAcB < BCc-2 < BEu-2. Properties related to biochar aromaticity, such as H/Corg, total C, Cnox, as well as the Freundlich parameters scored mainly in component 1. The presence of a narrow angle between SSA, Langmuir parameters (KL and Qmax) and Freundlich constant (KF) denoted a high correlation between these factors, while n was better correlated with biochar aromaticity and hydrophobicity, showing a narrow angle with Cnox and an inverse correlation with H/Corg, O/Corg and (O+N)/C ratios (located in the opposite quadrant). The best correlation between KF and H/Corg was found for toluene (R2 = 0.87) and the worst was found for o-xylene (R2 = 0.76), which is the less VFOC (boiling point 144.5 °C). PCA was also conducted for the other contaminants obtaining similar results and correlations as for toluene (data not shown).

Discussion

The general behaviour of different carbonaceous pyrolysed materials to immobilise volatile fuel organic compounds, BTEX and FO, from contaminated water was assessed. The results varied widely depending on the properties of the organic compounds and the sorbent matrix, which in turn was strongly affected by the feedstock material (Zhang et al. 2015) and the pyrolysis conditions (Bornemann et al. 2007). Overall, a significant difference could be observed between ∑BTEX and ∑FO sorption, being the recovery higher for the FO compounds in all the samples. This may be related to the nature and physicochemical properties of the contaminants (Table S2; Supporting information). FO compounds are the most volatile (the boiling points of MTBE and ETBE are 55 and 69 °C, respectively), water soluble (water solubilities of MTBE and ETBE at 25 °C are 51.6 and 26 g L−1, respectively; while for BTEX it varies between 0.14 and 1.80 g L−1) and hydrophilic compounds (based on their octanol-water coefficient log values of 1.06 and 1.48 for MTBE and ETBE, respectively). The higher solubility and volatility of FO compounds is related to a higher mobility in soils and aqueous systems (Balseiro-Romero and Monterroso 2013; Balseiro-Romero et al. 2016b). Similarly, significant differences were found in the recovery of benzene and xylene isomers, increasing the recovery degree according to the volatility of the compound (BTEX volatility varied in the following order: benzene > toluene > ethylbenzene > mp-xylene > o-xylene (Table S2 in the Supporting Information)). Biochar materials tend to be hydrophobic and non-polar, and BTEX molecules may have a high affinity for these materials: non-polar compounds tend to be attracted by non-polar phases (Goss and Schwarzenbach 2003). In the same way, FO compounds showed a lower affinity for biochar materials and were poorly sorbed by biochar. Aivalioti et al. (2010) obtained the same differences between adsorbates when studying BTEX and MTBE sorption onto thermally modified diatomite, observing a higher sorption for BTEX, especially xylenes, than for MTBE. Xiao et al. (2014) attributed the lower adsorption of MTBE compared to benzene, to the differences in the kinetic diameter. The molecular size of MTBE (0.62 nm) (Sano et al. 1995) is almost twice the size of benzene (0.35 nm) (Xiao et al. 2014). Therefore, with a pore-filling mechanism, benzene may be more strongly sorbed and sequestered in biochar micropores.

A wide variation in the recovery of the contaminants was found depending on the biochar, ranging from 2 to 53%, which reflected the contribution of different sorption mechanisms depending on the physicochemical properties of the sorbents. Several authors stated that two processes mainly govern the sorption of organic compounds by biochar: adsorption on carbonised fractions and partition in non-carbonised fractions (Chen et al. 2008; Zhang and Lu 2016; Zhang et al. 2017). The forces that control the interaction between biochar surfaces and organic pollutants are ionic electrostatic attraction, hydrogen bonding, hydrophobic interaction and π-π electron–donor–acceptor interaction (π-π EDA) (Sander and Pignatello 2005; Zhang and Lu 2016). The latter is related to the observed increase in the aromaticity of the studied biochar with the increase of the pyrolysis temperature, which may favour the formation of a graphene-like surface. As stated by Sun et al. (2012), these graphene-like structures are capable of interacting with both electron donors and electron acceptors. Results obtained in experiment 1 showed a direct correlation between BTEX and FO sorption with pyrolysis temperature (Table 1). A significantly lower recovery was found for high temperature biochars (HHT > 400 °C), such as BEu-2 or BCc. This may be due to the loss of O- and H-containing functional groups with increasing temperatures, which is reflected in a less polar character and higher aromaticity of biochar (Antal and Grønli 2003; Uchimiya et al. 2011; Ahmad et al. 2014). Moreover, BTEX recovery increased in biochar with higher O/C molar ratio, which is an indicative of surface hydrophilicity (Chun et al. 2004). On the other hand, the lowest O/C values found in biochar (O/C < 0.1) are indicative of a similar behaviour to active carbon and surface water repellence, thereby a higher attraction of hydrophobic compounds such as BTEX was observed for these biochars. This is also in agreement with the (O+N)/C ratio, which is an indicator of polarity (Xiao et al. 2014) and decreases with increasing pyrolysis temperatures. The studied biochars showed higher sorption rates with lower (O+N)/C ratios.

Additionally to the pyrolysis conditions and physicochemical characteristics of the contaminant, the sorption process will be affected by the feedstock material used to prepare the biochar samples. The highest recovery of BTEX and FO occurred with materials rich in ash and inorganic compounds, such as BCm, BOpc or BAcB. A high proportion of inorganic compounds increases the hydrophilic character of the samples due to the nature of these particles, thus decreasing the sorption of hydrophobic compounds (Bornemann et al. 2007). Other authors have found an indirect effect of biochar mineral content on the sorption capacity of organic compounds, since the mineral fraction also reduces the formation of aromatic structures during pyrolysis (Smernik 2009). This was also observed by Balseiro-Romero and Monterroso (2013) when studying the sorption of BTEX and FO on different soil samples, with lower sorption levels found in soils with higher inorganic fraction. Differences in the sorption capacity of BEu-2 and BCc-2 biochars pyrolysed at similar temperatures (~ 500 °C), were observed, which may be due to feedstock composition (Zhao et al. 2013) and to the differences in SSA. The content of aromatic carbon is often associated with lignin content. In this case, eucalyptus is richer in lignin since its content in hardwood is about 35% (Anderson and Tillman 1977), while in corncob is ~ 12% (Pointner et al. 2014). Furthermore, eucalyptus biochar exhibited great hydrophobicity when its water holding capacity was determined (data not shown), which also explained the strong interaction with hydrophobic organic compounds.

The sorption isotherms for BTEX and FO confirmed the competence of pollutants for the sorption sites of the pyrolysed materials. The compounds that have a more polar and hydrophilic character, i.e. ETBE, MTBE and benzene, showed a lower retention on biochar. It is noteworthy that despite a significantly higher hydrophobicity of ethylbenzene and xylenes with respect to toluene (KOW = 1412.5 for ethylbenzene, o-xylene and p-xylene; KOW = 1584.9 for m-xylene; KOW = 489.8 for toluene), the calculated Qmax was in the same order of magnitude for all the adsorbates. Similar results were obtained by Bornemann et al. (2007) for toluene and benzene adsorption on different wood-derived biochars. This behaviour was attributed to a pore filling mechanism, indicating that when identical volume of the sorbates is added into the system, the sorption of these compounds on the biochar might be similar (Chiou et al. 2000; Bornemann et al. 2007).

Traditional Langmuir and Freundlich models were adequate to detect general differences in the sorption behaviour of VFOC (BTEX and FO) by different biochars. BTEX sorption on three of the four sorbent materials studied was described by the Langmuir model (BEu-2, BCm and BAcB), although the fitting was less accurate for BCm and BAcB (lower R2 values than for BEu-2). This may be due to the fact that the last biochars were less homogeneous, that is, the feedstock material was a mixture of different compounds, such as feathers, proteins, digested food, bedding material or minerals in the case of BCm. By contrast, BTEX sorption on corncob biochar exhibited a Freundlich sorption behaviour. Bornemann et al. (2007) also obtained different fittings to Langmuir and Freundlich models depending on the characteristics of the biochar used. Nevertheless, each model contributed with relevant information to understand the sorption process, e.g. Langmuir model is useful to determine the maximum sorption capacity (Qmax) allowing the comparison among the biochars studied and helps to choose the best sorbent material. The values of Qmax obtained for the four biochars tested were four orders of magnitude greater than those obtained for the same pollutants using diatomite as adsorbent (Aivalioti et al. 2010). Comparing the results obtained in the present study with the sorption capacity of other organic low cost sorbent such as waste scrap tyres, the Qmax of biochars is higher or in the same order of magnitude than the values obtained by other authors that varied between 0.61 to 3.72 for BTEX (de Toledo et al. 2018). Moreover, Qmax was highly correlated with SSA of each biochar, which in turn is associated with the HHT and the aromatic character of biochar, e.g. larger surface areas were found in BEu-2 and BCc-2, which were pyrolysed over 400 °C. These two samples presented higher aromaticity and lower polarity and hydrophilicity than BCm and BAcB, as reflected by the molar ratios H/C, (O+N)/C and O/C, which resulted in a higher sorption capacity. This is consistent with the results obtained by Xiao et al. (2014).

Finally, information about the linearity of the sorption process was obtained from the fitting to the Freundlich model. The parameter 1/n decreased following the sequence BCm > BCc-2 > BAcB > BEu-2, indicating a higher non-linearity with this decrease and, therefore, a sorption mechanism based on adsorption onto carbonised material porous in the last three biochars (Chen et al. 2008; Lattao et al. 2014). BCm presented 1/n values close to 0.7, pointing out to a more linear behaviour than the other samples and therefore some partitioning into the non-carbonised parts of the sample (Lattao et al. 2014). This was consistent with the HHT which was the lowest of all the biochars studied, indicating that this sample was the richest in non-carbonised organic matter. Both Freundlich and Langmuir parameters were highly correlated with H/Corg ratio, as showed in PCA (Fig. 6). Similarly to the behaviour found for naphthalene by Xiao et al. (2016), log KF was correlated with H/C.

Conclusions

The study reveals that all the biochars tested may be considered as low-cost sorbents for volatile fuel organic contaminants in contaminated water. As expected, not all biochars presented the same sorption capacity, being the characteristics of the contaminant, the pyrolysis conditions (especially HHT) and the nature of the feedstock material the main factors affecting the sorption behaviour and capacity.

The most volatile and hydrophilic compounds, such as MTBE, ETBE and benzene, were poorly retained on biochar, unlike the non-polar and hydrophobic compounds (toluene, ethylbenzene and xylene isomers), which were more strongly sorbed. The results showed that biochar obtained at high pyrolysis temperatures (> 400 °C), i.e. BEu-2, showed a better performance in the removal of organic compounds from water; sorption was favoured with a higher aromatic carbon content and specific surface area. Other physicochemical properties of the biochar related with the feedstock material such as ash and nutrient content negatively affected the sorption behaviour.

The sorption of VFOC on biochar reflected a multilayer behaviour and a relatively high sorption capacity of the biochar produced at high temperature (> 400 °C). Langmuir and Freundlich models were adequate to describe the experimental results and to detect general differences in the sorption behaviour of VFOC by the different biochars. Langmuir model adequately described the non-linear sorption of BTEX on biochar surfaces. Biochars produced at low temperatures (≤ 400 °C) such as BCm showed a more linear sorption behaviour due to the presence of non-carbonised organic matter.

References

Ahmad M, Rajapaksha AU, Lim JE, Zhang M, Bolan N, Mohan D, Vithanage M, Lee SS, Ok YS (2014) Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere 99:19–23

Aivalioti M, Vamvasakis I, Gidarakos E (2010) BTEX and MTBE adsorption onto raw and thermally modified diatomite. J Hazard Mater 178:136–143

Ali I, Gupta VK (2007) Advances in water treatment by adsorption technology. Nat Protoc 1:2661–2667

Anderson LL, Tillman DA (1977) Fuels from waste. Academic Press, New York

Antal MJ, Grønli M (2003) The art, science, and technology of charcoal production. Ind Eng Chem Res 42:1619–1640

Balseiro-Romero M, Monterroso C (2013) A headspace-analysis approach to assess the sorption of fuel volatile compounds by soils. Soil Sci Soc Am J 77:800–808

Balseiro-Romero M, Gkorezis P, Kidd PS, Vangronsveld J, Monterroso C (2016a) Enhanced degradation of diesel in the rhizosphere of after inoculation with diesel-degrading and plant growth-promoting bacterial strains. J Environ Qual 45:924–932

Balseiro-Romero M, Chaves-Padín R, Monterroso C (2016b) Development and optimization of headspace (HS) and headspace-solid phase microextraction (HS-SPME) for the determination of volatile fuel compounds in environmental samples. SJSS 6:230–243

Bascom C (1986) Distribution of pyrophosphate extractable iron and organic carbon in soils of various groups. J Soil Sci 19:251–256

Bornemann LC, Kookana RS, Welp G (2007) Differential sorption behaviour of aromatic hydrocarbons on charcoals prepared at different temperatures from grass and wood. Chemosphere 67:1033–1042

Breus IP, Mishchenko AA (2006) Sorption of volatile organic contaminants by soils (a review). Eurasian Soil Sci 39:1271–1283

Cech M, Davis P, Gambardella F, Haskamp A, Herrero González P, Spence M, Larivé JF (2017) Performance of European cross-country oil pipelines: Statistical summary of reported spillages in 2015 and since 1971. CONCAWE Reports

Chen B, Yuan M (2011) Enhanced sorption of polycyclic aromatic hydrocarbons by soil amended with biochar. J Soils Sediments 11:62–71

Chen B, Zhou D, Zhu L (2008) Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ Sci Technol 42:5137–5143

Chen Y, Camps-Arbestain M, Shen Q, Singh B, Cayuela ML (2018) The long-term role of organic amendments in building soil nutrient fertility: a meta-analysis and review. Nutr Cycl Agroecosyst 111(2–3):103–125

Chiou CT, Kile DE, Rutherford DW, Sheng G, Boyd SA (2000) Sorption of selected organic compounds from water to a peat soil and its humic-acid and humin fractions: potential sources of the sorption nonlinearity. Environ Sci Technol 34:1254–1258

Chun Y, Sheng G, Chiou GT, Xing B (2004) Compositions and sorptive properties of crop residue-derived chars. Environ Sci Technol 38:4649–4655

Compton HR, Prince GR, Fredericks SC, Gussman CD (2003) Phytoremediation of dissolved phase organic compounds: optimal site considerations relative to field case studies. Remediation 13:21–37

Cornelissen G, Gustafsson Ö, Bucheli TD, Jonker MTO, Koelmans AA, Van Noort PCM (2005) Extensive sorption of organic compounds to black carbon, coal, and kerogen in sediments and soils: mechanisms and consequences for distribution, bioaccumulation, and biodegradation. Environ Sci Technol 39:6881–6895

De Toledo RA, Hin Chao U, Shen T, Lu Q, Li X, Shim H (2018) Development of hybrid processes for the removal of volatile organic compounds, plasticizer, and pharmaceutically active compound using sewage sludge, waste scrap tyres, and wood chips as sorbents and microbial immobilisation matrices. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-018-2877-2

Fakhru'l-Razi A, Pendashteh A, Abdullah LC, Biak DR, Madaeni SS, Abidin ZZ (2009) Review of technologies for oil and gas produced water treatment. J Hazard Mater 170:530–551

Fayemiwo OM, Daramola MO, Moothi K (2017) BTEX compounds in water - future trends and directions for water treatment. Water SA 43:602–613

Fingas M (2012) Oil spills in the basic of oil spill cleanup. CRC Press, Boca Raton

Fiorentin LD, Trigueros DEG, Módenes AN, Espinoza-Quiñones FR, Pereira NC, Barros STD, Santos OAA (2010) Biosorption of reactive blue 5G dye onto drying orange bagasse in batch system: kinetic and equilibrium modelling. Chem Eng J 163:68–77

Fries MR, Zhou J, Chee-Sanford J, Tiedje JM (1994) Isolation, characterization, and distribution of denitrifying toluene degraders from a variety of habitats. Appl Environ Microbiol 60:2802–2810

Goss K-U, Schwarzenbach RP (2003) Rules of thumb for assessing equilibrium partitioning of organic compounds: successes and pitfalls. J Chem Educ 80:450–455

Gupta R, Kulkarni GU (2011) Removal of organic compounds from water by using a gold nanoparticle–poly (dimethylsiloxane) nanocomposite foam. ChemSusChem 4:737–743

Harvey O, Kuo L, Zimmerman A, Louchouarn P, Amonette J, Herbert BE (2012) An index-based approach to assessing recalcitrance and soil carbon sequestration potential of engineered black carbons (biochars). Environ Sci Technol 46:1415–1421

ITOF (2017) Oil tanker spill statistics 2016. Impact PR & Design Limited, Canterbury

Jecu L, Gheorghe A, Popea F, Rosu A, Stoica A, Stroescu M (2008) Potential of microbial species in biodegradation of volatile organic compounds from waters. Chem Eng Trans 14:501–507

Kanai H, Inouye V, Goo R, Chow R, Yazawa L, Maka J (1994) GC/MS analysis of MTBE, ETBE, and TAME in gasolines. Anal Chem 66:924–927

Kim D, Song W, Lu JC (2011) Interdisciplinary investigation of contaminants fate and transport at a former UST site (10-year case study). Environ Earth Sci 64:277–291

Kookan R, Graber E, Smernik R (2017) Guiding principles for measuring sorption of organic compounds on biochars. In: Singh B, Camps-Arbestain M, Lehmann J (eds) . Biochar a guide to analytical methods. CSIRO Publishing, Clayton South, pp 141–150

Kuppusamy S, Thavamani P, Megharaj M, Venkateswarly K, Naidu R (2016) Agronomic and remedial benefits and risks of applying biochar to soil: current knowledge and future research directions. Environ Int 87:1–12

Kupryianchyk D, Hale S, Zimmerman AR, Harvey O, Rutherford D, Abiven S, Knicker H, Schmidt HP, Rumpel C, Cornelissen G (2016) Sorption of hydrophobic organic compounds to a diverse suite of carbonaceous materials with emphasis on biochar. Chemosphere 144:879–887

Lattao C, Cao X, Mao J, Schmidt-Rohr K, Pignatello JJ (2014) Influence of molecular structure and adsorbent properties on sorption of organic compounds to a temperature series of wood chars. Environ Sci Technol 48:4790–4798

Lehmann J, Joseph S (2009) Biochar for environmental management: an introduction. In: Lehmann J, Joseph S (eds) Biochar for environmental management: science and technology, 1st edn. Earthscan, London, pp 1–12

Lehmann J, Abiven S, Kleber M, Pan G, Singh BP, Sohi SP, Zimmerman AR (2015) Persistence of biochar in soil. In: Lehmann J, Joseph S (eds) Biochar for environmental management: Science, technology and implementation, 2nd edn. Earthscan, London, pp 289–300

Limousin G, Gaudet JP, Charlet L, Szenknect S, Barthès V, Krimissa M (2007) Sorption isotherms:a review on physical bases, modelling and measurement. Appl Geochem 22:249–275

Moore FP, Barac T, Borremans B, Oeyen L, Vangronsveld J, van der Lelie D, Campbell CD, Moore ERB (2006) Endophytic bacterial diversity in poplar trees growing on a BTEX-contaminated site: the characterisation of isolates with potential to enhance phytoremediation. Syst Appl Microbiol 29:539–556

Paulauskiene T, Jucike I, Juščenko N, Baziuke D (2014) The use of natural sorbents for spilled crude oil and diesel cleanup from the water surface. Water Air Soil Pollut 225:1–12

Pointner M, Kuttner P, Obrlik T, Jäger A, Kahr H (2014) Composition of corncobs as a substrate for fermentation of biofuels. Agron Res 12:391–396

Sander M, Pignatello JJ (2005) Characterization of charcoal adsorption sites for aromatic compounds: insights drawn from single-solute and bi-solute competitive experiments. Environ Sci Technol 39:1606–1615

Sano T, Hasegawa M, Kawakami Y, Yanagishita H (1995) Separation of methanol/methyl-tert-butyl ether mixture by pervaporation using silicalite membrane. J Membr Sci 107:193–196

Scheufele FB, Módenes AN, Borba CE, Ribeiro C, Espinoza-Quiñones FR, Bergamasco R, Pereira NC (2016) Monolayer–multilayer adsorption phenomenological model: kinetics, equilibrium and thermodynamics. Chem Eng J 284:1328–1341

Serrano A, Gallego M (2006) Sorption study of 25 volatile organic compounds in several Mediterranean soils using headspace-gas chromatography-mass spectrometry. J Chromatogr A 1118:261–270

Silvani L, Vrchotova B, Kastanek P, Demnerova K, Pettiti I, Papini MP (2017) Characterizing biochar as alternative sorbent for oil spill remediation. Sci Rep 7:1–10

Site AD (2001) Factors affecting sorption of organic compounds in natural sorbent/water systems and sorption coefficients for selected pollutants. a review. J Phys Chem Ref Data 30:187–439

Smernik RJ (2009) Biochar and sorption of organic compounds. In: Lehmann J, Joseph S (eds) Biochar for environmental management: Science and technology, 1st edn. Earthscan, London, pp 289–300

Sun K, Jin J, Keiluweit M, Kleber M, Wang Z, Pan Z, Xing B (2012) Polar and aliphatic domains regulate sorption of phthalic acid esters (PAEs) to biochars. Bioresour Technol 118:120–127

ter Braak CJF, Šmilauer P (2002) CANOCO reference manual and CanoDraw for Windows User's guide: Software for Canonical Community Ordination (version 4.5). Microcomputer Power

Tirol-Padre A, Ladha J (2004) Assessing the reliability of permanganate oxidizable carbon as an index of soil labile carbon. Soil Sci Soc Am J 68:969–978

Uchimiya M, Wartelle LH, Klasson KT, Fortier CA, Lima IM (2011) Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J Agric Food Chem 59:2501–2510

USEPA (2010) Waste and cleanup risk assessment glossary. Available at: http://www.epa.gov/oswer/riskassessment/glossary.htm. Accessed 1 July 2015

Walkley A, Black IA (1934) An examination of Degtjareff method for determining soil organic matter and a proposed modification of the chromic acid titration method. Soil Sci 37:29–38

Weishaar JA, Tsao D, Burken JG (2009) Phytoremediation of BTEX hydrocarbons: potential impacts of diurnal groundwater fluctuation on microbial degradation. Int J Phytoremediation 11:509–523

Wijmans JG, Kamaruddin HD, Segelke SV, Wessling SV, Baker RW (2006) Removal of dissolved VOCs from water with an air stripper/membrane vapor separation system. Sep Sci Technol 32:2267–2287

Wilbur S, Bosch S (2004) Interaction profile for: Benzene, toluene, ethylbenzene and xylenes (BTEX). Agency for Toxic Substances and Disease Registry, U.S. Department of Health and Human Services, Public Health Service, Atlanta

Xiao L, Bi E, Du B, Zhao X, Xing C (2014) Surface characterization of maize-straw-derived biochars and their sorption performance for MTBE and benzene. Environ Earth Sci 71:5195–5205

Xiao X, Chen Z, Chen B (2016) H/C atomic ratio as a smart linkage between pyrolytic temperatures, aromatic clusters and sorption properties of biochars derived from diverse precursory materials. Sci Rep 6:22644

Zadaka-Amir D, Nasser A, Nir S, Mishael YG (2012) Removal of methyl tertiary-butyl ether (MTBE) from water by polymer-zeolite composites. Microporous Mesoporous Mater 151:216–222

Zaib Q, Aina OD, Ahmad F (2014) Using multi-walled carbon nanotubes (MWNTs) for oilfield produced water treatment with environmentally acceptable endpoints. Environ Sci: Processes Impacts 16:2039–2047

Zhang M, Lu L (2016) Biochar for organic contaminant management in water and wastewater. In: Sik Ok Y, Uchimiya SM, Chang SX, Bolan N (eds) Biochar: production, characterization, and applications. CRC Press, Boca Raton, pp 221–244

Zhang X, McGrouther K, He L, Huang H, Lu K, Wang H (2015) Biochar for organic Contaminant Management in Soil. In: Sik Ok Y, Uchimiya SM, Chang SX, Bolan N (eds) Biochar: production, characterization, and applications. CRC Press, Boca Raton, pp 140–165

Zhang X, Gao B, Zheng Y, Hu X, Creamer AE, Annable MD, Li Y (2017) Biochar for volatile organic compound (VOC) removal: sorption performance and governing mechanisms. Bioresour Technol 245:606–614

Zhao L, Cao X, Mašek O, Zimmerman A (2013) Heterogeneity of biochar properties as a function of feedstock sources and production temperatures. J Hazard Mater 256–257:1–9

Acknowledgements

The authors thank the laboratory technicians of the Department of Soil Science and Agricultural Chemistry of the USC for the assistance in biochar characterization and Alvaro Gil from the Ceramic Institute of the USC for the BET measurement. The authors also thank CVAN (Centro de Valorización Ambiental del Norte. Touro, Spain) for the production of the biochar samples.

Funding

This work was supported by the Group of Excellence GI-1245, AMBIOSOL (Instituto de Investigaciones Tecnológicas, Universidade de Santiago de Compostela; GRC2014/003) financed by Xunta de Galicia and co-funded by the European Regional Development Fund (FEDER-Galicia) under research project “Micotecnosol”-Conecta Peme 2014 (2014-CE131). The authors belong to the CRETUS Strategic Partnership (AGRUP2015/02), co-funded by FEDER (UE). Dr. Balseiro-Romero was granted a postdoctoral fellowship (Programa de axudas á etapa posdoutoral; ED481B 2017/073) by the Consellería de Cultura, Educación e Ordenación Universitaria (Xunta de Galicia, Spain).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(DOCX 170 kb)

Rights and permissions

About this article

Cite this article

Saiz-Rubio, R., Balseiro-Romero, M., Antelo, J. et al. Biochar as low-cost sorbent of volatile fuel organic compounds: potential application to water remediation. Environ Sci Pollut Res 26, 11605–11617 (2019). https://doi.org/10.1007/s11356-018-3798-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-3798-9