Abstract

The anaerobic co-digestion of the most abundant organic wastes was investigated for enhancing biogas production rate and quality. The used feedstock was composed of fruit and vegetable waste (FVW), waste-activated sludge (WAS), olive mill wastewater (OMW) and cattle manure (CM). A considerable methane yield of 340 L/kg volatile solid (VS) inlet was obtained using single-stage anaerobic sequencing batch reactors (ASBRs). However, VS biodegradation becomes difficult at high organic loading rate (OLR). Therefore, a continuously stirred tank reactor (CSTR) was integrated to the ASBR for waste pre-digestion. The dark fermentation leads to the improvement of organic matter solubilisation and bio-hydrogen productivity, reaching 0.73 L/L/day (H2 content of 49.8%) when pH decreased to 5.8. Therefore, methane productivity increased from 0.6 to 1.86 L/L/day in the methanogenic reactor with a better VS biodegradation (91.1%) at high OLR. Furthermore, the bio-hythane production was performed through a controlled biogas recirculation from the dark fermentation stage into the methaniser to reach 842.4 L/kg VS inlet. The produced biogas was composed of 8% H2, 28.5% CO2 and 63.5% CH4. Therefore, two-stage anaerobic co-digestion with coupled CH4 and H2 recuperation may be an important contribution for pollution control and high-rate bioenergy recovery (21.1 kJ/g VS inlet) from organic wastes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last decade, Tunisia has experienced a sharp increase in the amount of organic wastes that exceeds 8 million tons per year. The major proportions of these wastes are produced from agricultural activity, agro-industry by-products and biological wastewater treatment plants (WWTPs). Large amounts of waste-activated sludge (WAS) are produced in the world, of which about 242,000 m3 per year in Tunisia (Bouallagui et al. 2010), which would readily cause secondary pollution if it is treated and disposed inappropriately (Wang et al., 2018a). Olive oil extraction process generates about 1 million tons per year of olive mill wastewater (OMW) (Dammak et al. 2016), which has a high chemical oxygen demand (COD), ranging from 50 to 150 g/L (McNamara et al. 2008; Justino et al. 2012). Fruit and vegetable waste (FVWs) are produced in large amounts in markets. The whole production of FVW collected from the market of Tunis has been estimated to be around 20–25 tons per day (Bouallagui et al. 2009).

These wastes present an interesting source of potentially biodegradable biomass. Anaerobic digestion is a good solution for organic waste treatment and valorisation, allowing their bioconversion into methane (Gioannis et al. 2017; Moukazis et al. 2018) and hydrogen (Saidi et al. 2018; Wang et al. 2018b), which can be used as renewable energy sources. In addition, the remaining stabilised waste may be used as a soil fertiliser (Toumi et al. 2015). However, the major limit of this technology at large scale is sometimes the lack of waste availability and their complex composition, which causes a disturbance in the fermentation process (Callaghan et al. 2002; Zhang et al. 2014). To remedy this problem, the co-digestion of several wastes with different origins and compositions together in one digester could be a promising alternative to improve the reliability of this process. Several studies have shown that multi-component mixtures of agro-wastes, rural wastes and industrial wastes can be digested successfully, although with some mixtures, a degree of both synergism and antagonism occurred (Misi and Forster 2001; Cavinato et al. 2008; Maranon et al. 2012).

Moreover, the choice of the better reactor configuration is a decisive factor for improving biogas production (Bouallagui et al. 2005; Haider et al. 2015). In recent years, a number of reactor designs have been adapted and developed to reduce the anaerobic digestion limitations of solid wastes, to increase the applied organic loading rate and to decrease the time of fermentation. The application of single-stage system in the digestion of mixed organic wastes at high organic loading becomes difficult (Ganesh et al. 2014; Montanès Alonso et al. 2016). Therefore, two-phase systems appear to be more highly efficient technologies for anaerobic digestion of a mixture of wastes.

This study investigated for the first time the anaerobic co-digestion of the major available organic wastes such as municipal sewage sludge and agro-industrial and agricultural wastes in the two-stage anaerobic system, coupling continuously stirred tank reactor (CSTR) and anaerobic sequencing batch reactor (ASBR). The greatest advantage of the CSTR mode, which was chosen for the dark fermentation performance, is its ability for allowing the buffering of the organic loading and a more constant and homogenised feeding rate for the second methanogenic stage (Parawira et al. 2008; Hidalgo et al. 2014). However, the ASBR mode was used in the second methanogenic stage for decoupling the solid retention time (SRT) from the hydraulic retention time (HRT) in the methanogenic reactor in order to maintain a high concentration of low-growing methanogens.

Authors showed that the energy yield of two-stage systems was lower than that was obtained by a single-stage reactor due to the loss of the hydrogen from the acidogenic phase (Ganesh et al. 2014; Montanès Alonso et al. 2016; Hidalgo et al. 2014). Therefore, the process used in this work was designed with recirculation of biogas (H2 + CO2) from the acidogenic reactor to the methanogenic reactor by a controlled pump to enhance the hydrogenotrophic methanogenic activity in the digester without inhibition by supplementary H2 addition and then to increase the methane productivity (Toumi et al. 2015; Ennouri et al. 2018).

This approach met to produce bio-hydrogen by dark fermentation and methane by anaerobic digestion with the aim to use this gas separately or to constitute the bio-hythane. Therefore, hydrogen and methane are complementary fuels. Cavinato et al. (2012) reported that bio-hythane is a biological gas with an average percentage composition of 10% H2, 30% CO2 and 60% of CH4. Moreover, Porpatham et al. (2007) found that adding 10% of hydrogen in biogas enhanced its combustion rate and improved the thermal efficiency and power output. Benefits of dark fermentation phase without pH regulation on the process efficiency were evaluated. The effects of increasing the organic loading rate (OLR) on the acidification step were examined, and the mass balance and energy recovery assessments were also performed to set the basis for a process extrapolation to a real scale.

Materials and methods

Origin and characteristics of used wastes and inocula

The choice of used wastes was based on their availability in terms of quantity (tons/year) and their nutrient balance complementarity for biological degradation (Bouallagui et al. 2009; Lahdheb et al. 2009; Farhat et al. 2018). In fact, the choice was directed towards cattle manure (CM), FVW, WAS and OMW, which have both vegetable and animal processing origins. The four groups of wastes represent 85% of all organic wastes produced in Tunisia. The WAS was collected from sludge thickeners of the WWTP of Chotrana I (Tunis) treating 50,000 m3 of urban wastewater a day (Bouallagui et al. 2010). They were concentrated by decantation to increase their total solid (TS) content in the feedstock. The OMW was collected from a local (Tunis) three-phase olive oil extraction company (Asses et al. 2009). They were used in their fresh state without modification. FVW (tomato, carrot, potato, apple, orange, lemon, etc.) was collected from the municipal market of Tunis. The mixture of FVW was ground into very fine particles to facilitate the process of digestion by reducing the size of waste and improving their homogenisation. The CM was collected from a cattle farm in Sidi Thabet, Tunis (Toumi et al. 2015).

The mixture of feedstock was composed (v/v) of 40% of FVW, 40% of WAS, 10% of OMW and 10% of CM. The proportion of FVW was fixed to 40% because vegetable wastes are present in large quantities in all municipal and wholesale markets. They are also quickly and easily biodegradable, and previous works have shown their important methanogenic potentials (Bouallagui et al. 2009). The proportion of WAS was 40% because it is produced in enormous quantity in WWTPs and its management becomes an obligation to decrease its polluting load. OMW was used in a low percentage of 10% because of its high COD and phenol contents, which could inhibit anaerobic microflora activity (Tsioulpas et al. 2002; Farhat et al. 2018). CM was used with a proportion of 10%. It contains high concentrations of lignin-cellulosic material and ammonia, which offer a buffer effect for the mixture balancing the pH with neutrality. Furthermore, it was used as an inoculum (20% of total seeding sludge) in the start-up of digesters. The higher fraction (50%) of the seed sludge was taken from within these industrial anaerobic digesters located in the WWTP of Chotrana, Tunis. This plant includes four independent semi-continuously digesters. Another fraction of the anaerobic sludge (30%) was taken from a functional laboratory digester treating agro-industrial by-products (Handous et al. 2017). In fact, using different sources of inocula could increase the diversity of anaerobic bacteria and methanogens within the reactors at the start-up phase. Moreover, fresh CM is a potential source of methanogens (Toumi et al. 2015) and the sludge coming from functional digesters contains good-balanced anaerobic bacteria and methanogens (Bouallagui et al. 2010; Ennouri et al. 2016; Handous et al. 2017). This approach could be respected at the industrial scale of this project to a better start-up of the process.

The physical-chemical characteristics of wastes, the mixture of feedstock and the mixture of inocula (anaerobic seed sludge) are shown in Table 1. The used substrates are rich in organic solids with volatile solid (VS)/TS contents between 68.5 and 88% for WAS and FVW, respectively. The WAS and CM are rich in suspended solids (89.6 and 70% of TS, respectively) in the form of microorganism aggregates and fibres, respectively. However, 96% of the dry matter of OMW is represented by the soluble matter, which is more easily accessible to the anaerobic bacteria. The fresh OMW was also characterised by a high total phenol content of 3.92 g/L. The mixture of wastes contains a significant organic matter proportion, which is about of 82.8% relative to the dry matter. This mixture constitutes a good source of nutrients for the growth of the anaerobic microflora with a carbon-to-nitrogen (C/N) ratio of 28.2, which is considered favourable for the anaerobic digestion. Several authors reported that the C/N ratio is an important parameter affecting the bio-methane yield of anaerobic digestion, and the optimal C/N ratio for anaerobic microorganisms was in the range of 20:1–30:1 (Rao and Singh 2004; Zhao et al. 2017). Indeed, Yasin and Wasim (2011) and Al-Juhaimi et al. (2014) showed that a C/N ratio equal to 30 was better for anaerobic digestion of organic wastes.

Single-stage reactor design and operational conditions

In a first trial of experiments, the anaerobic digestion of the mixture of the four organic wastes was carried out in two separated single-stage mesophilic (37 °C) reactors: ASBR1 and ASBR2, which have working capacities of 0.8 and 1.2 L, respectively, and equipped with a magnetic stirring system. The headspace volumes were 0.4 and 0.6 L, respectively. The reactors are free cells with a working cycle of 24 h including 2 h of settling. Initially, the ASBR1 and ASBR2 were seeded with 0.8 and 1.2 L, respectively, with a mixture of anaerobic sludge (inocula) at the same initial concentration of 10.5 g VS/L. In the start-up, the headspace of each reactor was flushed with nitrogen for 10 min and conducted for 10 days without feeding. After that, reactors were fed during 10 days with a mixture of wastes at a low OLR of 1.5 g VS/L/day, corresponding to 25 days of HRT, followed by operations at 1.9 and 2.5 g VS/L/day between days 10 and 30, corresponding to the HRT of 20 and 15 days, respectively. At a steady-state phase, the OLR was decreased to 1.91 g VS/L/day and reactors were kept active during two HRTs of 20 days.

Two-stage reactor design and operational conditions

The anaerobic co-digestion of the mixture of four organic wastes was also investigated in a two-stage process (Fig. 1). The first phase of dark fermentation was done in a CSTR mode while the second phase of methanisation took place in an ASBR. Therefore, in a second time, the inoculum contained in the single-stage ASBR1 (0.8 L) was used for starting the acidification step in the two-stage system. The working mode of this reactor was changed from ASBR1 to CSTR and was coupled to the ASBR2 (1.2 L), which was used as the methanogenic stage. The pre-digested effluent in the hydrolysis-acidification stage was used for feeding the acetogenic and methanogenic populations contained in the second stage. The operation of the two-stage system was based on working at high OLR.

The effect of the gradual increase of the OLR from 4.59 g/L/day up to 8.61 g/L/day and the decrease of the HRT from 10 to 5.3 days on the acidification efficiency, hydrolysis yield and H2 production were particularly studied in the first CSTR stage (Table 3). Therefore, the HRT and the OLR of the methanogenic ASBR depended on the flow rate and the acidified VS concentration in the effluent of the acidogenic reactor. In these operating conditions, the maximum OLR of the methanogenic reactor was 4.2 g/L/day corresponding to the HRT of 8 days. The system was designed with recirculation of biogas (H2 + CO2) from the acidogenic reactor to the methanogenic reactor by a controlled peristaltic pump to enhance mixing within the digester and to increase bio-hythane productivity. Biogas production efficiency, biogas composition and sludge quality were monitored during 94 days to confirm the feasibility of the process.

Physical and chemical analysis

The physical-chemical analyses were performed on samples taken from the inlet and outlet of different digesters (Toumi et al. 2015; Ennouri et al. 2016). TSs, VSs, total suspended solids (TSSs), volatile suspended solids (VSSs),COD, pH, alkalinity and total volatile fatty acids (VFAs) were determined according to the APHA (1998) standard methods. The content of VFAs was determined by the potentiometric titration with 0.1 N NaOH solution and expressed as an acetic acid content. Total nitrogen was determined by the Kjeldahl method. Total carbon (TC) was measured by catalytic oxidation on a TC 1200 Euro glace analyser. Total polyphenol content was determined using the Folin-Ciocalteu method. The total polyphenol concentration was calculated from a calibration curve, using gallic acid as standard (Tabart et al. 2007).

Biogas productions were measured daily via a displacement method or by a gas meter of make Ritter (Langendreer, Bochum). The biogas composition was determined using UniChrom gas chromatography (GC). The volume of biogas in normal condition was converted to standard temperature pressure (STP) conditions using combine gas law.

Hydrolysis yield (HY) and acidification yield (AY) were calculated as follows:

where VSSinlet (g/L) and VSSoutlet (g/L) are the concentrations of volatile suspended solids before and after first-stage dark fermentation treatment, respectively.

where VFA production is production volatile fatty acids (g/L) during dark fermentation and VSinlet (g/L) is the volatile solid introduced (g/L) in the CSTR.

All experimental analyses were performed in triplicate. One-way analysis of variance (ANOVA) was performed to compare the performance of reactors between runs at different conditions. To assess the significance of results, p < 0.05 was considered to be statistically significant.

Results and discussion

Performance of single-stage ASBRs

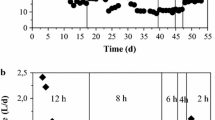

The objective of these experiments is to evaluate the methane potential of mixed wastes in a single-phase ASBR digesters with two working volumes of 0.8 L (ASBR1) and 1.2 L (ASBR2) under different OLRs. Figure 2a, b shows the evolution of biogas production (L/day) and its methane content (%), respectively. The reactors started at a low OLR of 1.53 g/L/day corresponding to an HRT of 25 days (Fig. 2c). An increased daily biogas production in two digesters has been shown during the start-up period. Therefore, methanogenesis requires a latency phase between 5 and 10 days to produce methane especially from complex organic wastes (Erugder et al. 2000; Bolzonella et al. 2005). After that, OLR was increased gradually to 2.55 g/L/day with a reducing HRT from 25 to 20 days and to 15 days. The reactor responded with an increase in VFA concentration (Fig. 3a) and biogas production (Fig. 2a). However, statistical analysis showed a significant increase in the VS concentration in the treated effluent, showing that the decrease of HRT to 15 days affected significantly (p < 0.05) organic matter degradation, which accumulated in digesters (Fig. 2c).

At high OLR, the increase of the VS concentration in the treated effluents was accompanied by the increase of TSS concentration in the supernatant, which could be due to the increase of non-degraded total VS within the reactor and then the bad settling efficiency of the anaerobic sludge. In fact, when biomass settling was incomplete, there was a gradient in the concentration of solids along the reactor height and the average TSS concentration in the effluents increased significantly, showing poor sludge settling (Shao et al. 2008; Lahdheb et al. 2009). These results took into account that high OLR (2–3 g/L/day) and low HRTs could be considered as limit factors for single-phase operation of anaerobic digestion of multiple organic wastes as already mentioned in the literature (Parawira et al. 2008; Ganesh et al. 2014; Stoyanova et al. 2016). Therefore, the OLR was fixed to 1.91 g/L/day by maintaining the HRT to 20 days and it did not increase further until a steady state. The average yield of organic matter removal achieved 74 and 73.6% for ASBR1 and ASBR2, respectively (Table 2).

Analyses showed high levels of total VFAs, around the limits of anaerobic digestion of 2000–2200 mg/L (Bouallagui et al. 2009), in digesters during the first 30 days, which proved that the equilibrium between VFA production and consumption was still not reached (Fig. 3a). In fact, adaptation of hydrolytic and fermentative bacteria was faster than that of acetogenic bacteria and methanogens during the start-up period (Zuo et al. 2014). Therefore, this phase was characterised by a high production of CO2 in the biogas. From the 30th to 70th day, the VFA concentration decreased and stabilised at 520 and 560 mg/L in ASBR1 and ASBR2, respectively. This decrease of VFA was favourable for the correct activity of methanogens to produce methane in a well-balanced anaerobic digestion process. Therefore, values of pH within reactors were around 7–7.5 (Fig. 3b), showing good process stability (Chen et al. 2007; Menardo and Balsari 2012; Montanès Alonso et al. 2016).

Under these conditions, the methane content (%) increased progressively until reaching values of 60.6 and 60.2% for ASBR1 and ASBR2, respectively, after 1 month of digester operation. Indeed, the specific methane production reached 0.336 L CH4/g VS inlet and 0.34 L CH4/g VS inlet for ASBR1 and ASBR2, respectively. These values are close or higher than those mentioned in the literature for anaerobic digestion of each of these organic wastes alone. In fact, methane productions were 0.25, 0.33 and 0.2 L CH4/g VS inlet for FVW (Lin et al. 2011), manure and lignin-rich organic wastes (Azeem et al. 2011), respectively. According to Bolzonella et al. (2005), the specific methane production from anaerobic digestion of WAS alone is generally very low (0.12 L CH4/g MVS degraded). Furthermore, mesophilic anaerobic digestion of sludge is both slow and incomplete due to low cell membrane hydrolysis yield, which are non-biodegradable (Borowski and Szopa 2007). However, other studies have shown that anaerobic co-digestion of several types of organic waste improves the production and the quality of biogas.

Heo et al. (2003) suggested that optimal biodegradation is achieved during co-digestion of sludge and food waste at 10 days of HRT and with 50/50% mixture of co-substrates. The maximum specific production of methane was 0.37 L CH4/g VS inlet. Indeed, Gomez et al. (2006) showed that the methane production obtained during the co-digestion of primary sludge with FVW was significantly greater than that obtained during the anaerobic digestion of primary sludge alone. In addition, Budych-Gorzna et al. (2016) obtained a specific methane yield of 0.39 L CH4/g VS inlet during anaerobic co-digestion of WAS and slaughterhouse wastes.

Performance of two-phase system

Dark fermentation monitoring

The pre-digestion of the mixture of wastes was operated at three HRTs (10, 7 and 5.3 days, respectively) to increase the OLR gradually in order to improve the production of bio-hydrogen and VFA concentration in the fermented effluent, which will feed the second methanogenic reactor. Evolutions of pH value and VFA concentration within the acidogenic digester are shown in Fig. 4a. At the first time (Run1), the OLR was about 4.59 g VS/L/day corresponding to 10 days of HRT. During this phase, a gradual increase in the VFA concentration up to 2.4 g/L was observed and pH value remains close to neutrality, showing that methanogens are again active and are producing methane. During Run2 and Run3, the OLR was increased to 6.95 and 8.61 g VS/L/day, corresponding to HRTs of 6.6 and 5.3 days, respectively. A significant improvement in the hydrolysis of the complex organic material (p < 0.05) and a gradual decrease in pH were observed.

The maximum hydrolysis yield of 46% was obtained at high OLR. This leads to an increase in the production of VFAs (up to 11.8 g/L) in the culture medium and a decrease of pH value to 5.9 and 5.2, respectively. Indeed, this pH level was favourable to maintain the correct activity of acidogenic bacteria for producing simple monomers, which represent available precursors for methane production in the second reactor. Zuo et al. (2014) as well as Ganesh et al. (2014) suggested that the acidification of organic waste can be inhibited by lowering the pH below to 5, especially in the case of FVW. They performed pH regulation by recirculating the methanisation effluent to the acidification reactor. In this work, the problem of pH does not arise because of the complementarity in the used mixed waste composition and the buffer effect of CM and the WAS (Wang et al. 2003).

Table 3 summarises the operating conditions and the performance of the dark fermentation. Results show that the acidification yield increased significantly (p < 0.05) according to the increase of the OLR and the reduction of the HRT to reach its maximum level of 23.8% at high OLR. In fact, the increase of OLR promotes acidogenesis efficiency. Under these conditions, the rate of VFA production was greater than that of their assimilation by methanogens. As a result, the pH value decreased to stabilise at 5.2. Several authors reported that high OLR application resulted in an accumulation of VFAs during the process of anaerobic digestion (Parawira et al. 2008).

The comparison between the results of this work and other studies shows that the production of VFAs, ranging from 2.4 to 11.8 g/L, was important. According to Zuo et al. (2014), the VFA concentration and the VFA/alkalinity ratio ranged from 4.7 to 5.7 g/L and from 11.5 to 2.9, respectively, in the acidogenic stage during the anaerobic digestion of vegetable waste in the two-stage system with a recirculation of the effluent from the methanogenic reactor to the acidogenic reactor. However, in this work, the buffering effect of WAS and CM addition in the feedstock allowed to maintain the pH value between 5 and 6 without regulation. The alkalinity was 5 g/L at the end of the anaerobic process, showing that even by increasing the OLR up to 8.61 g/L/day, the VFA/alkalinity ratio did not exceed the recommended value of 2.3 corresponding to good acidification efficiency (Zuo et al. 2014).

The evolution of daily biogas production and its content of CH4 and H2 are shown in Fig. 4b. The variation of the OLR has an effect on the daily biogas production, which gradually increased at low OLR with a composition rich in methane and poor in H2. However, increasing the OLR affects the biogas production, which decreased and stabilised at around 1.2 L/day at the end of the experiment. Results show a progressive decrease in the percentage of methane up to a value of 2.7% and a proportional increase in the percentage of bio-hydrogen (H2) up to 49.6%. Therefore, the increase in the OLR during the dark fermentation process favoured the production of bio-hydrogen (Zhang et al. 2007) due the high rate hydrolysis of organic matter. Furthermore, Wang et al. (2018a) showed that the presence of ammonium (NH4+-N) largely enhanced dark fermentation hydrogen production.

The highest H2 productivity of 0.73 L/L/day was obtained with 5.3 days of HRT in the presence of VFA concentration of 11.8 g/L. It is higher than that was obtained by Hidalgo et al. (2014). They demonstrated that the best daily production of biogas was 0.83 L/L/day with a non-quantified bio-hydrogen (H2) production during the anaerobic co-digestion of vegetable oil wastewater mixed with pig manure at an HRT of 2–3 days, while Dareioti et al. (2010) reported higher hydrogen production of 1.72 L/L/day by co-digestion of vegetable wastewater, whey and slurry with proportions of 55:40:5, respectively, in a two-stage mesophilic CSTR digester. Daily biogas and methane production of 0.27 and 0.04 L/L/day, obtained by Zuo et al. (2014) during the anaerobic digestion of plant wastes in the acidogenic reactor with an OLR of 1.7 g/L/day, is also lower than that obtained in this work. According to Ganesh et al. (2014), the daily production of biogas obtained by anaerobic digestion at the level of the acid-generating reactor is equal to 2.6 L/L/day of which only 6% CH4 and 8% H2 were obtained.

Performance of the second methanogenic ASBR

The methanogenic reactor (ASBR) represents the second stage where anaerobic digestion was completed. The effluent obtained from the dark fermentation was used to feed the acetogenic and methanogenic populations. In fact, the OLR of the methanogenic step depends on the quality of pre-digested wastes and the applied HRT, which was decreased from 15 to 8 days corresponding to OLRs of 1.5 and 4.2 g/L/day, respectively. Figure 5a shows that biogas production shifts were proportional to the OLR variation. The best daily biogas production of 5.8 L/day was obtained with the highest OLR of 4.2 g/L/day corresponding to 8 days of HRT. The quality of the biogas (% CH4) was improved as the experiment progressed. A gradual increase in the percentage of methane was also observed. It achieved a maximum value of 63.5%, showing the importance of the pre-digestion stage, which provides the methaniser with easily degradable substances that can be assimilated by methanogenic bacteria. It contains an acetate concentration in the order of 3.25 g/L. In fact, the fermented wastes obtained from the first stage were characterised with high energy potential (0.73 L/g VS inlet) and can be converted quickly to methane.

Change in a biogas rate (empty square), methane content (empty triangle), CO2 (filled circle) and H2 (empty circle) and b pH (empty triangle), alkalinity (empty circle) and VFA concentrations (filled diamond) during the methanogenesis (second stage) of the fermented mixed organic wastes at different OLRs

The good stability of the methanogenic activity was evaluated by measuring the pH and the VFA concentration within the methanogenic reactor, which are represented in Fig. 5b. The pH values varied between 7.1 and 7.23. They were kept close to neutrality throughout the experimental period without any regulation, which confirms the good progress of the anaerobic digestion process. In fact, the good buffering capacity of the digester indicates the stability of the anaerobic bacteria and the appropriate activity of methanogens (Björnsson et al. 2000; Fernández et al. 2015). The VFA concentration gradually decreased during this experimental phase until reaching low values in the order of 260 mg/L, while the alkalinity gradually increased until reaching 1870 mg/L. Therefore, the VFA/alkalinity ratio was around 0.14 at the end of the experiment, indicating good stability of the methanogenic process (Hartmann and Ahring 2005; Wan et al. 2013; Zuo et al. 2014).

Table 4 summarises the performances of the methaniser with different OLRs during the whole experimental phase. The VS removal yield increased to rich a maximum of 87.9% at high OLR. Furthermore, the maximum daily production of biogas (5.8 L/day) and the maximum specific methane yield (0.73 L/g VS inlet) were also obtained at high OLR and particularly during the application of H2/CO2 recirculation from the acidification reactor to the methaniser. In fact, this contribution showed that CO2 and H2 addition at a controlled rate should not inhibit the methanogenic activity. In contrast, it improved the hydrogenotrophic methanogens using CO2 reduction pathways to produce methane (Toumi et al. 2015; Ennouri et al. 2018).

Performance comparison between single-stage and two-stage systems

Experimental results such as VS removal efficiencies (71–71.8%) and specific methane productions (0.336–0.34 L/g VS inlet and 0.42–0.45 L/g VS removed) obtained by using the single-stage ASBR system showed a good performance of this process for the treatment of organic waste. However, this conventional configuration does not support high OLR. Indeed, beyond 1.9 g/L/day with 15 days of HRT, there was an accumulation of non-degraded organic matter at the outlet of the digester. Several authors have suggested the failure of the single-stage digester performance by applying an OLR of 2–3 g/L/day (Verrier et al. 1987; Mata-Alvarez et al. 1992; Ganesh et al. 2014). They showed that anaerobic microorganisms are not well suited to the degradation of high substrate concentration under these conditions.

With the same OLR of 1.9 g VS/L/day, the specific methane yield (0.34 L/g VS inlet) obtained with the single-stage reactor was higher than that obtained by the two-stage process (0.13 L/g VS inlet). However, both the specific methane yield (0.13, 0.26 and 0.32 L/g VS inlet) and the VS removal yield (86, 90.5 and 91.15%) for the two-stage system have increased significantly (p < 0.05) by increasing the OLR (1.5, 2.98 and 4.05 g VS/L/day, respectively). Authors mentioned also that VS removal yields (88–97.5%) obtained with two-stage reactors are higher than those obtained with the single-stage system at an OLR from 4 to 7.67 g VS/L/day (Rajeshwari et al. 2001; Verrier et al. 1987; Raynal et al. 1998; Ganesh et al. 2014). Results of this work confirmed that the integration of the dark fermentation has minimised the inhibitory effect of the high OLR on the methanogenic activity (Hidalgo et al. 2014) and to prevent the slowdown of these microorganisms through the accumulation of VFAs produced by acidogenic bacteria (Lissens et al. 2001). In particular, the two-stage system maintains the stability of the process by controlling the acidification phase to prevent overloading and accumulation of toxic materials (Solera et al. 2002).

The energy yields obtained in this work were considered high compared to those mentioned in the literature. According to Li et al. (2018), the anaerobic co-digestion of food and horticultural wastes in a two-stage reactor has shown an average methane yield of 0.113 L CH4/g VS with an OLR of 4 g VS/L/day. However, Bouallagui et al. (2004) reported a specific biogas production of 0.22 L/g VS inlet and a COD removal yield of 95% during the anaerobic digestion of FVW in a two-stage reactor. Moreover, Dareioti et al. (2010) showed that the VS removal yield and the specific methane production during the anaerobic co-digestion of vegetable water and livestock manure (80/20%, v/v) in a two-stage CSTR reactors at an OLR of 3.63 g COD/L/day were equal to 34.2% and 0.25 L CH4/g COD, respectively. Hidalgo et al. (2014) reported also that specific methane production reached 0.27–0.3 L CH4/g VS removed during the anaerobic co-digestion of used vegetable oils and pig manure at an OLR of 1.5–2.5 g/L/day.

The two-stage system showed better organic matter biodegradation and digester stability even with a high OLR, but their energy yield was still 33% lower than that was obtained by a single-stage reactor (Ganesh et al. 2014) due to the loss of the hydrogen from the acidogenic phase. In fact, the main difference between these two types of processes is the co-production of H2 and CH4 in the two-stage reactor while, at the conventional single-stage reactor, only the production of methane has occurred (Zhu et al. 2008). According to Hidalgo et al. (2014) and Nasr et al. (2012), the two-stage process produces more energy of about 1.7–19.8% compared to the single stage when taking into account the amount of bio-hydrogen produced in the acidogenic reactor. Therefore, the H2 and CH4 co-production with recirculation of biogas (H2 and CO2) from the acidogenic reactor to the methanogenic reactor improved the specific methane production (0.44 L/g VS inlet) by almost 40% compared to that obtained by the single-stage reactor (0.34 L/g VS inlet). This work confirms the feasibility of the anaerobic co-digestion of organic waste at high OLR by using the two-stage process. Aslanzadeh et al. (2014) showed also that anaerobic digestion of industrial food waste and household waste was more stable in two-stage digesters than in single-stage conventional reactors. Therefore, the two-stage anaerobic process is considered as a reliable way to produce bio-hythane (hydrogen and methane) by coupled dark fermentation and anaerobic treatment of a wide range of organic substrates (Schievano et al. 2014).

Mass balance, energy recovery and economic assessments

The mass balance for the one-stage and two-stage systems was calculated. Results are shown in Table 5. Substrate (VS inlet) was converted into methane, carbon dioxide and hydrogen in the biogas, biomass, VFAs and ammonia. The residual matter and the washout biomass were present in the outlet VS of the effluent daily. Results showed that mass recovery from substrates (VS) ranged between 88.5 and 96%. The better mass balance (96%) was obtained with the two-stage process with biogas (CO2 and H2) recirculation from the first stage of dark fermentation to the methaniser (Fig. 6b). It is very likely that the high conversion efficiency of the organic matter into biogas under these conditions was due to improved energy recovery and substance availability after their pre-digestion, which facilitates their assimilation by methanogens. Therefore, the two-stage anaerobic digestion of organic wastes with CH4, CO2 and H2 recuperation may be considered as an efficient technology for organic load reduction and bio-hythane production. This approach could be an important contribution for a global and integrated schema of pollution control and environmental protection.

In order to study the ability of the industrial scale-up of two-stage anaerobic co-digestion of organic wastes, the energy recoveries and economic benefits of processes were also calculated. It was considered that CH4 produced through single-stage or two-stage anaerobic digestion of organic wastes could be transformed into combined electric power and heat (CPH). Calorific value of biogas depends on its CH4 content, and it is assumed that 1 m3 CH4 is equal to 10 kWh (Gebrezgabher et al. 2010) while electrical efficiency is assumed to be 33% and thermal efficiency to be 55% (Cano et al. 2014). Thermal energy could be used within the plant for heating digester and could be utilised for drying digestate, which could be used as a soil amendment in agriculture.

Results showed that when considering the energy recovery only from the CH4, the single-stage digester was characterised by higher electric and thermic energy productions due to the loss of the hydrogen from the acidogenic phase of the two-stage system. However, the gain of energy production associated to the two-stage technology increased gradually by increasing the OLR and the application of biogas recirculation. Therefore, the better electrical and thermal energy productions of 1765.2 and 2942.1 kWh/ton VS, respectively, were obtained at the OLR of 3.44 kg VS/m3/day when the two-stage system was stable after four HRTs of working period.

The total energy recovery was also calculated based on the energy values of bio-hydrogen and methane at standard temperature and pressure. The energy values of hydrogen and methane were reported to be 12.71 and 37.78 kJ/L, respectively (Fu et al. 2017; Fernandez et al. 2015). Results showed that the cumulative energy recovery of two-stage fermentation (13.44 kJ/g VS inlet) was 5% higher than that of one-stage fermentation (12.7 kJ/g VS inlet). Furthermore, the recirculation of CO2 and H2 from the acidogenic stage to the methaniser increased the energy recovery by 56 and 65% compared to the two-stage system without biogas recirculation and to the one-stage digester, respectively. Higher energy recovery from two-stage fermentation was also reported by other works. According to Fu et al. (2017), the energy recovery from two-stage fermentation of vinasse was 12.9% higher than that of one-stage fermentation. Similarly, Nathao et al. (2013) showed 18% higher energy recovery from two-stage fermentation than that of single-stage fermentation, when they studied anaerobic digestion of food waste.

In the scale-up phase and the economic evaluation of processes, it has been considered a mixture waste flow of 20,000 tons/year based on the case of the municipal landfill of Tunis, Tunisia. The mixture of waste was considered to contain 20% of FVW, 20% of WAS, 10% of CM and 10% of OMW. Therefore, the electrical energy productions were estimated to be equal to 854,200 and 1,352,000 kWh/year for one-stage and two-stage processes, respectively (Table 5). The price of electrical energy is set at 0.09 €/kWh (Farhat et al. 2018), which corresponds to a net benefit at almost 3.84 and 6.08 €/ton or 76,878 and 121,680 € per year for one-stage and two-stage processes, respectively.

The industrial-scale plants were sized on the basis of the quantity of waste available in the Tunis region and on the operating conditions used in the experimental phase. In this case, the industrial digester, with a capacity of about 20,000 m3 of organic waste per year, can be either a single stage with a useful volume of 1096 m3 or two stages with a total useful volume of 730.48 m3 (292.08 m3 for the first stage and 438.4 m3 for the second stage). Therefore, the extrapolation on an industrial scale will be carried out on a two-stage system because the volume of the digester is less important. The cost of an installation is very variable depending on its size and configuration. Indeed, the maximum investment of an installation whose electrical power is 168.5 kW amounts to 842,500 €, knowing that the investment in the general case is between 3000 and 5000 € per installed power kW (Carlini et al. 2017). Moreover, the operating cost, the transportation cost and the maintenance cost represent about 20% of the initial investment and are subjected to an average annual increase of 2% (Gebrezgabher et al. 2010).

Total benefits include electricity cost (121,680 €/year); waste treatment cost (4 € per ton corresponding to a total cost of 80,000 €/year), which should respect the stringent environmental control regulations; and the cost of digestate (50,000 €/year), which would be used in agriculture practice. The total benefits were estimated to be equal to 251,680 € per year, corresponding to a payback time on investment of about 4 years, which is considered interesting (Morin et al. 2010).

Conclusion

Results showed that anaerobic co-digestion of FVW, WAS, OMW and CM in a centralised digester is an interesting option for improving energy recovery from different kinds of organic wastes. It gives the possibility of treating wastes, which cannot be easily treated separately at low cost. However, the high OLR remains the major problem of anaerobic co-digestion of organic waste in a single-phase process. In this study, it was favourable to increase the OLR by the integration of a dark fermentation as a pre-digestion stage for improving the organic matter hydrolysis and VFA production. Therefore, the maximum hydrolysis yield of 46% was obtained at a high OLR of 8.61 g/L/day, corresponding to an HRT of 5.3 days, which leads to the highest H2 productivity of 0.73 L/L/day and an increase in the production of VFAs up to 11.8 g/L. The fermented wastes obtained from the first stage were used to feed the methanogenic digester. They have shown high energy potential of 0.73 L/g VS inlet. Furthermore, the recirculation of CO2 and H2 from the acidogenic stage to the methaniser increased the energy recovery by 56 and 65% compared to the two-stage system without biogas recirculation and to the one-sate digester, respectively.

References

Al-Juhaimi FY, Hamad SH, Al-Ahaideb IS, Al-Otaibi MM, Ghafoor K, Abbasi T, Abbasi SA (2014) Biogas production through the anaerobic digestion of date palm. BioResources 9:3323–3333

APHA (1998) Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association, Washington DC

Aslanzadeh S, Rajendran K, Taherzadeh MJ (2014) A comparative study between single- and two-stage anaerobic digestion processes: effects of organic loading rate and hydraulic retention time. Interna Biodeter Biodeg 95:181–188

Asses N, Ayed L, Bouallagui H, Sayedi S, Hamdi M (2009) Biodegradation of different molecular mass polyphenols derived from olive mill wastewaters by Geotrichum candidum. Inter Biodeter Biodeg 63:407–413

Azeem K, Muhammad A, Muzammil A, Tariq M, Lorna D (2011) The anaerobic digestion of solid organic waste. Wast Manag 31:1737–1744

Björnsson L, Murto M, Mattiasson B (2000) Evaluation of parameters for monitoring an anaerobic co-digestion. Appl Microbiol Biotechnol 54:844–849

Bolzonella D, Pavan P, Battistoni P, Cecchi F (2005) Mesophilic anaerobic digestion of waste activated sludge: influence of the solid retention time in the wastewater treatment process. Process Biochem 40:1453–1460

Borowski S, Szopa J-S (2007) Experiences with the dual digestion of municipal sewage sludge. Bioress Technol 98:1199–1207

Bouallagui H, Haouari O, Touhami Y, Bencheikh R, Marouani L, Hamdi M (2004) Effect of temperature on the energy production from anaerobic digestion of fruitand vegetable waste. Process Biochem 39:2143–2148

Bouallagui H, Touhami Y, Ben Cheikh R, Hamdi M (2005) Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem 40:989–995

Bouallagui H, Lahdheb H, Ben Romdan E, Rachdi B, Hamdi M (2009) Improvement of fruit and vegetable waste anaerobic digestion performance and stability with co-substrates addition. J Environment Manag 90:1844–1849

Bouallagui H, Marouani L, Hamdi M (2010) Performances comparison between laboratory and full-scale anaerobic digesters treating a mixture of primary and waste activated sludge. Resources Conserv Recycl 55:29–33

Budych-Gorzna M, Smoczynski M, Popiel-Oleskowicz P (2016) Enhancement of biogas production at municipal wastewater treatment plant by co-digestion with poultry industry waste. Appl Energy 161:387–394

Callaghan F-J, Wase D-A-J, Thayanithy K-S, Forster CF (2002) Continuous co-digestion of cattle slurry with fruit and vegetable wastes and chicken manure. Biomass Bioenergy 27:71–77

Cano R, Neilfa A, Fdz-Polanco M (2014) Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: energy and economic feasibility study. Bioresour Tchnol 168:14–22

Carlini M, Mosconi EM, Castellucci S, Villarini M, Colantoni A (2017) An economical evaluation of anaerobic digestion plants fed with organic agro-industrial waste. Energies 10:1165. https://doi.org/10.3390/en10081165

Cavinato C, Pavan P, Bolzonella D, Cecchi F (2008). Single phase extreme thermophilic (70 °C) anaerobic co-digestion of sewage sludge and organic fractionof municipal solid waste. In: proceedings of the fifth ISAD-SW, 24–28 May, Hammamet, Tunisia

Cavinato C, Bolzonella D, Fatone F, Cecchi F, Pavan P (2012) Optimization of two-phase thermophilic anaerobic digestion of biowaste for bio-hythane production through reject water recirculation. Bioresour Technol 102:8605–8611

Chen Y, Jiang S, Yuan H, Zhou Q, Gu G (2007) Hydrolysis and acidification of waste activated sludge at different pH. Water Res 41:683–689

Dammak I, Neves M, Isoda H, Sayadi S, Nakajima M (2016) Recovery of polyphenols from olive mill wastewater using drowning-out crystallization based separation process. Bioressour Technol 34:326–335

Dareioti M-A, Dokianakis S-N, Stamatelatou K, Zafiri C, Kornaros M (2010) Exploitation of olive mill wastewater and liquid cow manure for biogas production. Waste Manag 30:1841–1848

Ennouri H, Miladi B, Zahedi D-S, Fernández Güelfo L-A, Solera R, Hamdi M, Bouallagui H (2016) Effect of thermal pretreatment on the biogas production and microbial communities balance during anaerobic digestion of urban and industrial waste activated sludge. Bioresour Technol 214:184–191

Ennouri et al. 2018 in the text should be changed with Ennouri et al 2016 which wa cited in the list of references as Ennouri H, Miladi B, Zahedi D-S, Fernández Güelfo L-A, Solera R, Hamdi M, Bouallagui H (2016). Effect of thermal pretreatment on the biogas production and microbial communities balance during anaerobic digestion of urban and industrial waste activated sludge. Bioresour Technol 214: 184-191

Farhat A, Manai I, Gtari M, Bouallagui H (2018). Effect of enhancing nutrient balance in anaerobic digester feedstock by co-substrate addition on the microbial diversity and energy production from municipal sewage sludge. J Biosci Bioeng https://doi.org/10.1016/j.jbiosc.2018.04.014

Fernandez C, Cuetos M-J, Martinez E-J, Gomez X (2015) Thermophilic anaerobic digestion of cheese whey: coupling H2 and CH4 production. Biomass Bioenergy 81:55–62

Fu S-F, Xu X-H, Dai M, Yuan X-Z, Guo R-B (2017) Hydrogen and methane production from vinasse using two-stage anaerobic digestion. Proc Safty Environ Prot 107:81–86

Ganesh R, Torrijos M, Sousbie P, Lugardon A, Steyer J-P, Delgenes J-P (2014) Single-phase and two-phase anaerobic digestion of fruit and vegetable waste: comparison of start-up, reactor stability and process performance. Waste Manag 34:875–885

Gebrezgabher S-A, Meuwissen M-P-M, Prins B-A-M, Oude Lansink A-G (2010) Economic analysis of anaerobic digestion—a case of green power biogas plant in the Netherland. NJAS-Wagening J Life Sci 57:109–115

Gioannis G-D, Muntoni A, Polettini PR, Spiga D (2017) Energy recovery from one- and two-stage anaerobic digestion of food waste. Waste Manag 68:595–602

Gómez X, Cuetos M-J, Moran A, Garcia A-I (2006) Anaerobic co-digestion of primary sludge and the fruit and vegetable fraction of the municipal solid wastes conditions for mixing and evaluation of the organic loading rate. Renew Ener 31:2017–2024

Haider M-R, Zeshan Yousaf S, Malik R-N, Visvanathan C (2015) Effect of mixing ratio of food waste and rice husk co-digestion and substrate to inoculum ratio on biogas production. Bioresour Technol 190:451–457

Handous N, Gannoun H, Hamdi M, Bouallagui H (2017). Two-stage anaerobic digestion of meat processing solid wastes: methane potential improvement with wastewater addition and solid substrate fermentation. Waste Biomass Valor DOI https://doi.org/10.1007/s12649-017-0055-2

Hartmann H, Ahring B-K (2005) Anaerobic digestion of the organic fraction of municipal solid waste: influence of co-digestion with manure. Water Res 39:1543–1552

Heo N-H, Park S-C, Lee J-S, Kang H, Park D-H (2003) Single-stage anaerobic codigestion for mixture wastes of simulated Korean food waste and waste activated sludge. Appel Biochem Biotechnol 105–108:567–567

Hidalgo D, Marti-Marroquin J-M, Sastre E (2014) Single-phase and two phase anaerobic co-digestion of residues from the treatment process of waste vegetable oil and pig manure. Bioenergy Res 7:670–680

Justino C-I, Freitas R-P, Rocha-Santos T-A, Panteleitchouk T-S, Duarte A-C (2012) Olive oil mill wastewaters before and after treatment: a critical review from the ecotoxicological point of view. Ecotoxicol 21:615–629

Lahdheb H, Bouallagui H, Hamdi M (2009) Improvement of activated sludge stabilisation and filterability during anaerobic digestion by fruit and vegetable waste addition. Bioresour Technol 100:1555–1560

Li W, Loh K-C, Zhang J, Tong Y-W, Dai Y (2018) Two-stage anaerobic digestion of food waste and horticultural waste in high-solid system. Appl Energy 209:400–408

Lin J, Zuo J, Gan L, Li P, Liu F, Wang K, Chen L, Gan H (2011) Effects of mixture ratio on anaerobic co-digestion with fruit and vegetable waste and food waste of China. J Environ Sci 23:1403–1408

Lissens G, Vandevivere P, De Baere L, Biey E-M, Verstrae W (2001) Solid waste digesters: process performance and practice for municipal solid waste digestion. Water Sci Technol 44:91–102

Maranon E, Castrillón L, Quiroga G, Fernández-Nava Y, Gómez X, García M-M (2012) Co-digestion of cattle manure with food waste and sludge to increase biogas production. Waste Manag 32:1821–1825

Mata-Alvarez J, Cecchi F, Llabrés P, Pavan P (1992) Anaerobic digestion of the Barcelona central food market organic wastes: plant design and feasibility study. Bioresour Technol 42:33–42

McNamara C-J, Anastasiou C-C, O’Flaherty V, Mitchell R (2008) Bioremediation of olive mill wastewater. Int Biodeter Biodeg 61:127–134

Menardo S, Balsari P (2012) An analysis of the energy potential of anaerobic digestion of agricultural by-products and organic waste. Bioenerg Res 5:759–767

Misi S-N, Forster C-F (2001) Batch co-digestion of multi-components agro-wastes. Bioresour Technol 80:19–28

Montanès Alonso R, Solera del Rio R, Perez Garcia M (2016) Thermophilic and mesophilic temperature phase anaerobic co-digestion (TPAcD) compared with single-stage co-digestion of sewage sludge and sugar beet pulp lixiviation. Biomass Bioenergy 93:107–115

Morin P, Marcos B, Moresoli C, Laflamme CB (2010) Economic and environmental assessment on the energetic valorization of organic material for a municipality in Quebec, Canada. Appl Energy 87:275–283

Moukazis I, Pellera F-M, Gidarakos E (2018) Slaughterhouse by-products treatment using anaerobic digestión. Waste Manag 71:652–662

Nasr N, Elbeshbishy E, Hafez H, Nakhla G, E-l H, Naggar M (2012) Comparative assessment of single-stage and two-stage anaerobic digestion for the treatment of thin stillage. Bioresour Technol 111:122–126

Nathao C, Sirisukpoka U, Pisutpaisal N (2013) Production of hydrogen and methane by one and two stage fermentation of foodwaste. Int J Hydrogen Energy 38:15764–15769

Parawira W, Read J-S, Mattiasson B, Björnsson L (2008) Energy production from agricultural residues: high methane yields in pilot-scale two-stage anaerobic digestion. Biomass Bioenergy 32:44–50

Porpatham E, Ramesh A, Nagalingam B (2007) Effect of hydrogen addition on the performance of a biogas fuelled spark ignition engine. Int J Hydrog Energy 32:2057–2065

Rajeshwari K-V, Panth D-C, Lata K, Kishore V-V-N (2001) Novel process using enhanced acidification and a UASB reactor for biomethanation of vegetable market waste. Waste Manag Res 1:292–300

Rao MS, Singh SP (2004) Bioenergy conversion studies of organic fraction of MSW: kinetic studies and gas yield–organic loading relationships for process optimisation. Bioresour Technol 95:173–185

Raynal J, Delgenes JP, Moletta R (1998) Two-phase anaerobic digestion of solid waste by a multiple liquefaction reactors process. Bioresour Technol 65:97–103

Saidi R, Liebgott P-P, Gannoun H, Ben Gaida L, Miladi B, Hamdi M, Bouallagui H, Auria R (2018) Biohydrogen production from hyperthermophilic anaerobic digestion of fruit and vegetable wastes in seawater: simplification of the culture medium of Thermotoga maritime. Waste Manag 71:474–484

Schievano A, Tenca A, Lonati S, Manzini E, Adani F (2014) Can two-stage instead of one-stage anaerobic digestion really increase energy recovery from biomass. Appl Energ 124:335–342

Shao X, Peng D, Teng Z, Ju X (2008) Treatment of brewery wastewater using anaerobic sequencing batch reactor (ASBR). Bioresour Technol 8:3182–3186

Solera R, Romero L-I, Sales D (2002) The evolution of biomass in a two-phase anaerobic treatment process during start-up. Chem Biochem Eng 16:25–29

Stoyanova E, Lundaa T, Bochmann G, Fuchs W (2016). Overcoming the bottlenecks of anaerobic digestion of olive mill solid waste by two stage fermentation. Environ. Technol. https://doi.org/10.1080/09593330.2016.1196736

Tabart J, Kevers C, Sipel A, Pincemail J, Defraigne J-O, Dommes J (2007) Optimisation of extraction of phenolics and antioxidants from black currant leaves and buds and of stability during storage. Food Chem 105:1268–1275

Toumi J, Miladi B, Farhat A, Nouira S, Hamdi M, Gtari M, Bouallagui H (2015) Microbial ecology overview during anaerobic codigestion of dairy wastewater and cattle manure and use in agriculture of obtained bio-fertilisers. Bioresour Technol 198:141–149

Tsioulpas A, Dimou D, Iconomou D, Aggelis G (2002) Phenolic removal in olive oil mill wastewater by strains of Pleurotus spp. in respect to their phenol oxidase (laccase) activity. Bioresour Technol 84:251–257

Verrier D, Ray F, Albagnac G (1987) Two-phase methanization of solid vegetable wastes. Biol Wastes 22:163–177

Wan S, Sun L, Douieb Y, Sun J, Luo W (2013) Anaerobic digestion of municipal solid waste composed of food waste, waste paper, and plastic in a single-stage system: performance and microbial community structure characterization. Bioresour Technol 146:619–627

Wang C-C, Chang C-W, Chu C-P, Lee D-J, Chang B-V, Liao C-S (2003) Producing hydrogen from wastewater sludge by Clostridium bifermentans. J Biotechnol 102:83–92

Wang D, Duan YY, Yang Q, Liu Y, Ni BJ, Wang Q, Zeng G, Li X, Yuan Z (2018a) Free Ammonia enhances dark fermentative hydrogen production from waste activated sludge. Water Res 133:272–281

Wang D, Liu X, Zeng G, Zhao J, Liu Y, Wang Q, Chen F, Li X, Yang Q (2018b) Understanding the impact of cationic polyacrylamide on anaerobic digestion of waste activated sludge. Water Res 2018(130):281–290

Yasin M, Wasim M (2011) Anaerobic digestion of buffalo dung, sheep waste and poultry litter for biogas production. J Agric Res 49:73–82

Zhang Z-P, Taya J-H, Showa K-Y, Yan R, Liang D-T, Lee D-J, Jiang WJ (2007) Biohydrogen production in a granular activated carbon anaerobic fluidized bed reactor. Int J Hydrog Energy 32:185–191

Zhang W, Wei Q, Wu S, Qi D, Li W, Zuo Z, Dong R (2014) Batch anaerobic co-digestion of pig manure with dewatered sewage sludge under mesophilic conditions. Appl Energy 128:175–183

Zhao J, Liu Y, Wang D, Chen F, Li X, Zeng G, Yang Q (2017) Potential impact of salinity on methane production from food waste anaerobic digestion. Waste Manag 67:308–314

Zhu H, Stadnyk A, Béland M, Seto P (2008) Co-production of hydrogen and methane from potato waste using a two-stage anaerobic digestion process. Bioresour Technol 99:5078–5084

Zuo Z, Wub S, Zhang W, Dong R (2014) Performance of two-stage vegetable waste anaerobic digestion depending on varying recirculation rates. Bioresour Technol 162:266–272

Acknowledgements

The authors wish to acknowledge the Ministry of Higher Education and Scientific Research in Tunisia, which has facilitated the carried work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Bingcai Pan

Rights and permissions

About this article

Cite this article

Farhat, A., Miladi, B., Hamdi, M. et al. Fermentative hydrogen and methane co-production from anaerobic co-digestion of organic wastes at high loading rate coupling continuously and sequencing batch digesters. Environ Sci Pollut Res 25, 27945–27958 (2018). https://doi.org/10.1007/s11356-018-2796-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2796-2