Abstract

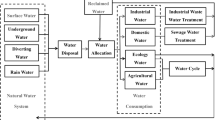

Two major concerns over the chemical industrial park (CIP) operations are high consumption of water resources and large amount of pollutant emissions. This study develops an interval chance-constrained programming model for industrial water resources management (ICCP-IWM) with consideration of multi-uncertainty and multi-environmental constraints. Uncertainties expressed as intervals and probability distributions are merged in the ICCP-IWM framework. The developed model is used to solve a real-world water resource management problem in the Shenyang Chemical Industrial Park to demonstrate its capacity and effectiveness, where the objective is to minimize the system cost of water pathways and pollutant-emission control under a series of constraints. Interval solutions with respect to water resources allocation, wastewater management, and pollutant emissions could be generated. Results indicate that a lower violation risk leads to an increased strictness of the constraints, then to a higher system cost; conversely, a higher violation risk results in a lower system cost, at the expense of an increase in the risk. These findings would be recommended by the decision-makers because of their applicability for practical decision process providing the optimal strategy for sustainable water resource management under multiple uncertainties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Scientific water resource management in the chemical industrial park (CIP) has been increasingly important with intensification of the global water crisis. Over the past decades, the controversial and conflict-riddled issues in water resources, especially in water shortage, mismanagement, and contamination, have become increasingly serious (Davies and Simonovic 2011; Lu et al. 2016; Kanakoudis et al. 2017). Also, these problems have been aggravated by excessive exploitation of resources, inefficient industrial, agricultural and domestic utilization, and negative reactions of nature to human activities (Shi et al. 2014; Ren et al. 2016; Nasiri-Gheidari et al. 2018). The conflict between limited water resources and increased water demands has thus become a serious obstacle to the CIP’s sustainable development. Effective water resource management strategies are thus significant for addressing water crisis and can contribute to the CIP’s sustainable development (He et al. 2017; Geng et al. 2007; Komakech et al. 2011; Al-Ismaili et al. 2017).

Previously, a number of optimization techniques have been developed for expressing uncertainties in the industrial water resource management system. For example, Davijani et al. (2016) focused on the effectiveness of an employment optimization method by managing the allocation of water resources to the agriculture and industry sectors in arid regions. Results revealed that 1096 jobs could be created in the industry and agriculture sectors by optimally allocating water resources in the central desert region of Iran, which constituted an improvement of about 13% relative to the previous situation (non-optimal water utilization). Tiu and Cruz (2016) developed a model for achieving economic and environmental goals of an eco-industrial park, where the economic concern considered piping and operating costs together with freshwater, wastewater, and treatment costs, while the environmental concern mostly focused on the volume and the quality of the water. Results indicated that the considering water volume and quality in minimizing environmental impact could give a better performance than only considering water volume. Liu et al. (2017) proposed a methodology for synthesis of inter-plant heat-integrated water allocation network in the industrial parks, and they introduced inter-plant integration strategies specific to industrial parks. Their solutions showed that simultaneous design surpassed sequential design, while regardless of the design routes, the method could promote symbiotic utilization of resource within the industrial parks and contribute to the sustainable development of process industry.

However, little effort has been devoted to the use of programming models for integrated water resource management in the CIP especially form an environmental perspective (Geng and Yi 2006; Aviso et al. 2010; Liang et al. 2011). With an increase of environmental awareness, the influence of pollutant emissions from the CIP on water quality has become increasingly prominent. Several problems with respect to water consumption and pollutant control have not been substantially addressed (Li et al. 2017; Liu and Zhang 2013; Li and Ma 2015), such as (a) how to cost-effectively allocate available water resources among multiple enterprises and (b) how to simultaneously meet the goals of both economic efficiency and environmental protection. It is thus urgent to develop advanced mathematical programming methods and to seek the optimal water resources management strategies for the CIP’s pollution management (Niu et al. 2016; Cheng et al. 2016). Concurrently, there are multiple uncertainties in the water resource management problems (Chen et al. 2017a; Chen et al. 2017b), resulting in a hardly identifiable system that are associated with natural, social, environmental, technical, and political elements. These factors are plagued with unpredictable natural processes, spatiotemporal heterogeneities, dynamic evolutions, complicated communications, and interactions (Singh 2014). The volatilities of natural conditions, such as climate change, geographic features, and hydrological conditions, and the complications of human activities, complexities of system operations, and risk preference of policymakers as well as their interrelationships are all possible sources of uncertainties (Sousa et al. 2013). Inadequate consideration of such uncertainties probably leads to inefficiencies of water management systems and further disturbs the system balance. A number of studies have been conducted for identifying, assessing, and planning water resource management system with consideration of multiple uncertainties (Lu et al. 2012; Rojas-Torres et al. 2015; Roach et al. 2016; Hu et al. 2016; Jabran et al. 2017). Uncertainties are usually expressed as stochastic parameters and interval values, and they could help seeking participatory and innovative policy and providing management options for water management system. Among the proposed stochastic methods, the chance-constrained programming (CCP) has been proved as an effective approach in tackling uncertainties. There are three main advantages of CCP (Chen et al. 2016): (a) it can notably reduce system complexities through turning a stochastic programming into an equivalent deterministic problem; (b) it can effectively handle uncertainties expressed as probability distribution function at the model’s right-hand-sides; and (c) it can incorporate other uncertain forms within an overall framework, such as discrete intervals with deterministic upper and lower bounds.

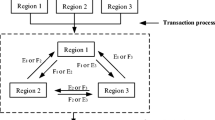

This study aims to develop an interval chance-constrained programing (ICCP) model for industrial water resources management (ICCP-IWM) to address the complexities and uncertainties in the CIP. Through incorporating interval parameter programming (IPP) and CCP within the decision-making framework, the developed ICCP-IWM can effectively reflect multi-uncertainty and multi-environmental constraints in the CIP, such as uncertainties expressed as discrete intervals or stochastic parameters and pollution loads involving chemical oxygen demand and ammonia nitrogen (COD and NH3▬N). Then, the developed ICCP-IWM model will be applied to a real-world case study in the Shenyang Chemical Industrial Park to demonstrate its potential capacities and effectiveness, where multiple strategies in association with water resources allocation, wastewater management, and pollutant emissions under different probability levels will be generated to help the decision-makers guarantee regional water quality and quantity.

Overview of the study region

The Shenyang Chemical Industrial Park is located in the northeast of the industry corridor in the west region of Shenyang (Fig. 1), which is the strategic focus of the Bohai Economic Circle. The Shenyang CIP has achieved a completion of industry agglomeration in a short period due to its rapid economic development. It has created a regional development mode with petrochemical industry (PI), fine chemical industry (FCI), medicinal chemical industry (MCI), and rubber machining industry (RMI) as the cores. Specifically, there are five enterprises categorized into the PI, including Huachen (HC, p = 1), Lahua (LH, p = 2), Gongyebeng (GYB, p = 3), Xinrong (XR, p = 4), and Shihua (SH, p = 5); another five into the FCI, namely, Dongxin (DX, f = 1), Zhongji (ZJ, f = 2), Shenpan (SP, f = 3), Ziquang (ZQ, f = 4), and Dongrui (DR, f = 5) companies; and still another five major companies into the MCI, involving Tianfeng (TF, c = 1), Yirenbao (YRB, c = 2), Dongbei (DB, c = 3), Dongbei_2 (DB2, c = 4), and Yanjiuyuan (YJY, c = 5), and the RMI mainly includes the following companies, Shenyang (SY, r = 1), Shanfeng (SF, r = 2), Shantai (ST, r = 3), Pulisitong (PLST, r = 4), as well as Miqilin (MQL, r = 5). There are two major rivers (Hun River and Xi River) across the Shenyang CIP with a full length of 415 and 78 km, respectively. According to a field investigation, the main pollutants in this CIP are biological oxygen demand, chemical oxygen demand, petroleum, total phosphorus, and ammonia nitrogen, which have significantly exceeded the water quality standard of GB3838-2002 grade V. Among them, the concentrations of ammonia nitrogen, chemical oxygen demand, total phosphorus, and petroleum are at the maximum about 15.5, 6.8, 5.1, and 0.4 times higher than the standards. Currently, the water allocation problems arising from irrational water resource management have been highlighted around the CIP. Irrational utilization of water resources and unreasonable excessive exploitation of underground wells have led to deterioration of local water quality. Additionally, there is an intensifying conflict between economic development and environmental conservation. With respect to the above problems, decision-makers have made a detailed adjustment to the industrial layout and established a unified sewage treatment plant. Moreover, in order to save water resources, additional wastewater reuse facilities have been set up to improve the utilization efficiency of water resources.

Development of the ICCP-IWM model

Key assumptions

Some assumptions should be given before modeling formulation, as follows:

-

The physics of water resource management, such as surface water, groundwater, and water quality pollutant discharge, are normally expressed as non-linear characteristics, which are all mutually interacting. However, this study reasonably simplifies the objective functions and constraints to a linear decision model due to its easy formulation and arithmetic.

-

According to the thematic mandate “Mater Plan of Environment Development in Shenyang Environment and Technological Development Zone” launched by the China’s environment ministry, the year of 2020 is considered as the planning target year, and the final outlook extends to 2030. Thus, a 10-year planning horizon is used for better identifying the variations in water resource management strategies from a long-term perspective. Additionally, the operational design of water resources management system should explicitly consider the supply-demand response, pollutant emissions, and economic performance within the multi-periods under uncertainties, rather than aggregating the planning horizon in a single period. Accordingly, the planning horizon is further divided into two planning periods (i.e., the first period from 2020 to 2025 and the second period from 2026 to 2030).

-

The required data for model solution are highly uncertain because of the complexities in reality during the multi-periods, although most of them are relatively accurate. For example, the availability in treatment capacity of the plant is assumed as normal distribution, which can help the decision-maker identify the trade-offs between economic efficiency and constraint violation risk.

Modeling formulation

The CCP is a critical method for dealing with uncertainties in water resource management system based on Monte Carlo simulation. In a practical water resource management system, the trade-offs normally exist between the desire to manage system cost and reduce the level of probability violating the plant’s treatment capacity. A higher probability of satisfying the facility-capacity level usually needs reduction of industry production scale and adoption of more restrictive conservation strategies, resulting in a higher system cost. Consequently, identification of the differences in strategies with a special violation level could provide an effective manner for better understanding the risk-based economic and environmental performances of water resources management system. The CCP could offer useful analyses for balancing the trade-offs among objective function value, violation levels of constraints, and the preset probability. However, it can hardly address independent uncertainties in parameters (e.g., A, B, and C in Appendix A) of objective function and constraints. One potential approach for better accounting for uncertainties is to integrate the IPP method into the CCP modeling framework (Chen et al. 2016). A general mathematical expression of ICCP is shown in Appendix A.

The ICCP-IWM model focuses on conducting optimal water allocation strategies with a minimum system cost as its objective function, which involves costs for water supply (Water), recycling water (Recycle), and wastewater treatment (Treatment), given by:

In this ICCP-IWM model, some modeling constraints should be taken into account, such as constraints of water supply, wastewater treatment, water recycling, and environmental concerns.

-

(1)

Constraint of water supply: it requires that the total amount of water supply should not exceed the maximum water availability.

-

(2)

Constraint of wastewater treatment capacity: it indicates that the amount of wastewater should not exceed the plant’s capacity. However, uncertainties expressed as stochastic characteristics widely exist in the range of treatment capacity due to its great dependence on frequency of external water, equipment maintenance, and reformation. Thus, it is expressed as stochastic inputs into this model based on the CCP approach, where pi is a level of probability violating the plant’s treatment capacity, implying a condition that the constraint is satisfied with at least a probability of 1 − pi. For example, pi = 0.05 represents the probability at which the constraint (1c) is allocated to fail.

-

(3)

Constraint of water recycling: the processed water that is to be reused will be stored in a pool in the wastewater treatment plant, and its amount should not exceed the capacity of the total reservoir.

-

(4)

Constraints of pollutant loads: the amount of discharged pollutants (including COD, SS, and NH3▬N) should be contained at a certain level.

-

(5)

Constraints of water supply: the requirements of water supply should be between the maximum and the minimum demands.

Detailed nomenclatures for variables and parameters are listed in Appendix B.

Data collection

In this study, the economic, environmental, and technological parameters with known their lower and upper bounds were mostly acquired from the government documents, research reports by relevant institutes, or derived from the published papers survey questionnaire and expert consultations. For example, according to the Integrated Wastewater Discharge Standard (GB8978-1996), the secondary effluent standards of COD, SS, and NH3▬N are determined as 300, 30, and 50 mg/L, respectively. Additionally, with the updating and improvement of treatment technology in the Shenyang CIP during the planning horizon, an increase in removal rate of pollutants should be considered in the optimization process. For example, the removal rates of COD were considered as 0.68 and 0.75 in the periods 1 and 2, that of SS were 0.88 and 0.95, and that of NH3-N were 0.72 and 0.78, respectively. Moreover, Tables 1, 2, and 3 list the economic and environmental modeling inputs obtained from Refs. Chen et al. (2017b), Li et al. (2015), and Lu et al. (2016). These imprecise parameters could effectively describe modeling uncertainties and present the real water system with a more efficient manner. Uncertainties associated with wastewater treatment capacity can be projected into a matrix and vectors based on Monte Carlo simulation process, where each execution produces a sample output and the output samples can then be examined stochastically to determine the related cumulative probability distributions, and its procedures can be summarized as follows: (a) generating some random numbers for the treatment capacity; (b) using a special statistical distribution model for transforming there random numbers to random variables, and then for each Monte Carlo run; (c) storing up these obtained variables in an array; (d) generating a value from the array for each parameter and using it as a deterministic input for determining the treatment capacity; (e) obtaining the allowable treatment capacity based on the numerical model and Monte Carlo run; and (f) analyzing the calculation results and generating a cumulative probability distribution (Chen et al. 2017c). Figure 2 shows the probability distribution of treatment capacity. The fitting simulated treatment capacity could be used as important modeling inputs of the ICCP-IWM model to achieve desired operation strategies.

Results

Water supply

Before modeling solution, the corresponding maximum and minimum targets of water demand in terms of different companies have been predetermined according to their historical demand levels. Four probability levels (pi = 0.01, 0.05, 0.10, and 0.15) are considered for identifying the variations in decisions under multiple uncertainties. As shown in Table 4 where only the solutions under pi = 0.01 and 0.05 are presented, the optimal water allocation strategies fall into the intervals. Results indicate that the amount of allocated water generally decreases with an increased probability level. For example, in the first planning period, the water supply of HC company in the PI is [5.32, 6.36] × 103 m3 (pi = 0.01), and [5.00, 6.12] × 103 m3 (pi = 0.05), respectively. Actually, an increase in violation level normally represents a gradual relaxation of the constraint and a gradual increase in the acceptable risk of its violation. Conversely, a reduction in the violation level represents a more restrictive constraint and a decrease in the acceptable risk of its violation. Additionally, Fig. 3 summarizes the total water flows of industries under different violation risks. Results reveal that the amount of water consumption in the MCI is the largest, which is significantly greater than those of other industries. Apart from the freshwater supply, there are approximately [287.80, 303.25] × 103, [216.57, 273.05] × 103, [196.75, 207.48] × 103, and [173.50, 196.56] × 103 m3 of recycled water from wastewater treatment plants for supporting industrial production under pi = 0.01, 0.05, 0.10, and 0.15, respectively.

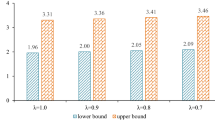

Trade-off between economic and environmental performances

Figure 4 shows the system costs under different pi levels, where the relationship between violation risk and economic performance can be clearly presented. An increase in pi level indicates a higher level of probability violating the plant’s treatment capacity. Consequently, the right-hand treatment capacity (i.e., constraint 1c) is relaxed and the system cost drops, reaching [18.95, 27.42] × 106, [14.69, 24.92] × 106, [12.18, 19.02] × 106, and [11.42, 16.93] × 106 RMB¥ under pi = 0.01, 0.05, 0.10 and 0.15, respectively. Results indicate that the changes in violation risks can result in different optimally economic performances. A lower violation risk corresponds first to an increased strictness of the constraints, then to a higher system cost; conversely, a higher violation risk leads to a lower system cost, which in turn increases the violation risk. Therefore, there is a trade-off between system-constraint violation and economic efficiency.

Figure 5 presents the detailed system costs generated from different industries. Obviously, the highest cost is in the MCI (e.g., under pi = 0.01, the total system cost of [10.59, 16.40] × 106 RMB¥), and the lowest is in the PI (e.g., under pi = 0.01, the total system cost of [1.88, 2.08] × 106 RMB¥). Three major reasons accounting for such variations are summarized as follows: firstly, there are a small number of PI enterprises entering into the CIP at present. Secondly, the MCI has the maximum production scale among four industries. For example, the production efficiencies of companies like DB and YRB in the MCI are significantly higher than those of others. Thirdly, the water demand of companies in the MCI is greater than that in other industries (Table 4). In addition, with consideration of the characteristic of IPP approach, the values of decision variables and objective function can vary from the lower to upper bounds; multiple alternatives can thus be obtained (Table 5). Taking the violation level of 0.05 as an example, alternatives 1, 5, and 9 with lower-bound parameters input may lead to relatively lower amounts of wastewater emission, water supply, and pollution load. Their resulting system costs also become lower due to their lower demands. On the contrary, when the majority of parameters reach their upper bounds in alternatives 8, 12, and 16, they consequently achieve higher system costs with an increase of system demand. Such variations can be also observed under other violation levels, which support the in-depth analysis on the interrelationships among system cost, wastewater emission, and system risk. Generally, a lower violation risk results in a lower probability of system-constraint violation and a higher system cost; conversely, a higher violation risk corresponds to a decreased strictness of the constraints, then to a lower system cost. However, decision-makers are willing to take a neutral attitude towards the trade-off between system cost and violation risk. Therefore, alternatives 7 and 10 would be more comprehensive for them.

Moreover, Fig. 6 presents the relationship among the costs of water supply, water recycling, and wastewater treatment during the two planning periods. Results indicate that the cost of water supply for the MCI is the highest in both periods. The MCI also accounts for the largest proportion of the cost for wastewater treatment. However, there is a slight variation in the cost for wastewater treatment. For example, the treatment cost in the RMI is more than that in the MCI, which suggests that the RMI produces a relatively larger amount of wastewater at a lower treatment efficiency. Thus, the RMI needs to strengthen management to improve water use efficiency and wastewater treatment efficiency. Furthermore, the production scale of the MCI needs to be reduced appropriately, and the corresponding recycling facilities should be strengthened to enhance reuse efficiency.

Figure 7 shows the COD emissions from various industries when pi = 0.05. The amount of COD emissions depends on many factors, such as the product type and quantity, as well as pros and cons of the water treatment facility. Results indicate that the CMI has higher COD emissions, which is [21.52, 24.82] tonnes in the first period, and the emission of the RMI is [21.11, 25.23] tonnes, with [19.14, 23.00] tonnes and [20.56, 24.86] tonnes in the second period, respectively. In comparison, the COD emissions of the PI and the FCI are relatively lower. Generally, the COD emissions of the CMI and RMI are six or seven times higher than those of the PI and FCI. There are two reasons for these changes: the large-scale production of the CMI itself and the higher COD emissions in the RMI due to chemical reactions. Results show that NH3-N emissions (Fig. 8) of the MCI are more sensitive to the changes in pi values than those of other industries. However, the NH3▬N emissions of all industries basically increase with the rise in pi values. Among them, the MCI has the most obvious change (e.g., under t = 1, the emissions correspond to [2169.02, 2769.89] kg when pi = 0.01; [2543.54, 3914.85] kg when pi = 0.05; [2783.52, 3932.12] kg when pi = 0.10; and [4977.83, 5600.69] kg when pi = 0.15). It indicates that the increase in pi leads to relaxation of constraints and a higher violation risk. The NH3▬N emissions are directly affected by the change of water discharge. In addition, the NH3▬N emissions of the MCI and RMI are generally larger than those of the PI and FCI, mainly due to their larger production scale. According to the solutions of COD emissions, it can be concluded that the RMI has a large production scale, strong capability of producing wastes but relatively lower capacity of pollution treatment, which may lead to excessive pollution. It is necessary to strengthen the control over the RMI, as well as admission and emission standards. Moreover, Fig. 9 shows the total SS emissions under different planning periods. Results indicate that the SS emissions in the first period are generally higher than those in the second period, while a small portion of enterprises also emits higher amounts of SS in the second period. This is because most enterprises tend to update their processing technologies, while there are a few companies (such as GYB) that have a lower processing efficiency. Another reason may be that the second period requires more water supplies and thus leads to more wastewater emissions. Compared with other industries, the MCI and RMI generate more SS emissions, which arise from the relatively larger production scale and water demand in these two industries. Therefore, it is critical to tighten the SS-emission standards of the MCI and RMI and to improve pollution treatment efficiency.

Summarily, since pi levels are used for reflecting the probability violating the treatment capacity, different pi levels bring about varied environmental and economic performances. A higher probability level of treatment capacity (i.e., pi = 0.15) results in a decreased reliability in fulfilling the system demand requirement, leading to lower amounts of wastewater emission and pollutant emissions with a decreased system cost; conversely, decisions at a lower probability level of treatment capacity (i.e., pi = 0.01) correspond to large amounts of wastewater emission and pollutant emissions with an increased system cost, but the risk of violating the treatment capacity abates. Additionally, modeling inputs, especially the economic data, presented as intervals are used for reflecting the volatility of interest rates and inflation rates because of the effects from several factors, such as socio-economic and political aspects. When the decision-makers have a neutral attitude towards the water system, both the lower- and upper-bound modeling inputs should be equally considered. Alternatives 7 and 10 in Table 5 thus would be more comprehensive strategies.

Discussion and conclusions

The reasons for driving this study are twofold. Firstly, a general water resource management frequently focuses on a macro-scale system (e.g., municipal and provincial) or a micro-scale problem (e.g., small reservoir). This study puts more emphasis on a medium-scale system for a CIP, which is responsible for sustainable development of economy and control of pollutant discharge. Secondly, the uncertainties in water resources management system are comprehensively considered for enhancing the robust of modeling solutions. Indeed, there are multiple uncertainties during the optimization process due to spatial and temporal variations in economic/environmental parameters, which not only place them beyond the traditional deterministic optimization methods but also strengthen the conflict-laden water resource allocation among various enterprises. For addressing such issues, it is significantly desired to allocate water resources under multiple uncertainties based on this modeling approach.

In this study, an interval chance-constrained programming model for industrial water resources management (ICCP-IWM) has been formulated for addressing multi-uncertainty regarded as interval, probability distributions, and their combinations. The ICCP-IWM has been applied for planning water resources in the Shenyang CIP, where Monte Carlo technique was used for simulating the treatment capacity, and the probability levels symbolized the reliability in fulfilling the water system requirement (i.e., a higher probability level corresponding to a decreased treatment capacity and leading to a high risk of the water-supply security). Generally, the ICCP-IWM has the following advantages. Firstly, it could effectively deal with the uncertainties in the water resource system, which are characterized by interval and probability distribution. Secondly, it could effectively obtain the optimal water resources management strategy through balancing the trade-off between system cost and violation risk. Thirdly, uncertainty analysis is used to examine robustness of the model solutions. Interval analysis based on ILP approach is applied for reflecting inexact modeling inputs with known the upper- and lower-bounds. Stochastic analysis in used for addressing parameters expressed as stochastic characteristics. Such uncertainty analysis can mathematically deal with inexact and uncertain information within the water resource management system and avoid the drift of the model solutions off the real ones subject to inexactness. Moreover, the decision-making is not kept static but improved by repeatedly communicating with different alternatives. Through such a communication, the robustness of the model solutions can further be enhanced. The model solutions can thus be regarded as mature and used to support final decision-making.

The ICCP-IWM model optimizes system costs with respect to water supply, water recycling, and wastewater treatment with consideration of the impact of uncertainty in treatment capacity on the final decisions. Results disclosed that the allocation of water resources in the four industries has a significant impact on their economic performance. Among them, the MCI and RMI had a relatively larger amount of water demand, which were identified as the major contributors to COD, SS, and NH3▬N emissions. Therefore, it was necessary to strengthen the adjustment to its industrial structure, improve the efficiency of wastewater treatment, and develop more stringent emission standards for pollutants. Additionally, results demonstrated that the changes in violation risks could lead to varied economic performances. A higher violation risk led to a lower system cost but a higher violation risk. Conversely, a lower violation risk resulted first in higher strictness of the constraints, then in a higher system cost. Moreover, the optimal objective and decision variables were obtained by analyzing the relationship between system cost and violation risk. Alternative 7 with system cost of [15.46, 19.43] × 106 RMB¥ and alternative 10 with system cost of [13.05, 16.41] × 106 RMB¥ might be the optimal choices, because their system risk levels were at the medium level, which might correspond to higher stability and reliability as compared to another alternatives. The feasible ranges for decision variables under different pi levels were useful for decision-makers to justify the obtained alternatives directly.

This study is the first attempt to apply the ICCP-IWM model for supporting water sustainable development in the Shenyang CIP under multiple uncertainties. This study suggests that the ICCP can be considered as an effective tool in addressing other regional environmental management problems, such as air emissions reduction and energy resource management. For instance, the advanced ICCP method could be applied for reflecting the performance risk of pollutant-mitigation strategies in compliance with the environmental targets and assisting the decision-makers in conducting desired management policies under uncertainties. However, two concerns should be considered for the improvement of the current ICCP-IWM model. Firstly, the ICCP approach has a powerful capacity in dealing with the violation risk of a special constraint with a single-objective modeling framework, but it hardly addresses the trade-offs, especially when multiple objectives have been merged into the decision-making process (Chen et al. 2018a, b). Thus, further studies should be focused on reducing such limitations. Secondly, future efforts should be concentrated on developing a novel multi-level water-resource management model through establishing the input-output relationships among the higher, medium, and lower levels (Chen et al. 2017a).

References

Al-Ismaili AM, Ahmed M, Al-Busaidi A, Al-Adawi S, Tandlich R, Al-Amri M (2017) Extended use of grey water for irrigating home gardens in an arid environment. Environ Sci Pollut Res Int 24(15):13650–13658

Aviso KB, Tan RR, Culaba AB, Cruz JB (2010) Bi-level fuzzy optimization approach for water exchange in eco-industrial parks. Process Saf Environ Prot 88(1):31–40

Chen Y, Lu H, Li J, Huang G, He L (2016) Regional planning of new-energy systems within multi-period and multi-option contexts: a case study of Fengtai, Beijing, China. Renew Sust Energ Rev 65:356–372

Chen Y, He L, Guan Y, Lu H, Li J (2017a) Life cycle assessment of greenhouse gas emissions and water-energy optimization for shale gas supply chain planning based on multi-level approach: case study in Barnett, Marcellus, Fayetteville, and Haynesville shales. Energy Convers Manag 134:382–398

Chen Y, He L, Lu H, Ren L, He L (2017b) A leader-follower-interactive method for regional water resources management with considering multiple water demands and eco-environmental constraints. J Hydrol 548:121–134

Chen YZ, He L, Li J (2017c) Stochastic dominant-subordinate-interactive scheduling optimization for interconnected microgrids with considering wind-photovoltaic-based distributed generations under uncertainty. Energy 130:581–598

Chen YZ, He L, Li J, Zhang SY (2018a) Multi-criteria design of shale-gas-water supply chains and production systems towards optimal life cycle economics and greenhouse gas emissions under uncertainty. Comput Chem Eng 109:216–235

Chen Y, He L, Zhao H, Li J (2018b) Energy-environmental implications of shale gas extraction with considering a stochastic decentralized structure. Fuel 230:226–243

Cheng X, He L, Lu H, Cheng Y, Ren L (2016) Optimal water resources management and system benefit for the Marcellus shale-gas reservoir in Pennsylvania and West Virginia. J Hydrol 540:412–422

Davies EGR, Simonovic SP (2011) Global water resources modeling with an integrated model of the social–economic–environmental system. Adv Water Resour 34(6):684–700

Davijani MH, Banihabib ME, Anvar AN, Hashemi SR (2016) Optimization model for the allocation of water resources based on the maximization of employment in the agriculture and industry sectors. J Hydrol 533(1):430–438

Geng Y, Yi J (2006) Integrated water resource management at the industrial park level: a case of the Tianjin Economic Development Area. Int J Sust Dev World Ecol 13(1):37–50

Geng Y, Côté R, Tsuyoshi F (2007) A quantitative water resource planning and management model for an industrial park level. Reg Environ Chang 7(3):123–135

He L, Du P, Chen YZ, Lu HW, Cheng X, Chang B, Wang Z (2017) Advances in microbial fuel cells for wastewater treatment. Renew Sust Energ Rev 71:388–403

Hu Z, Chen Y, Yao L, Wei C, Li C (2016) Optimal allocation of regional water resources: from a perspective of equity–efficiency tradeoff. Resour Conserv Recycl 109:102–113

Jabran K, Riaz M, Hussain M, Nasim W, Zaman U, Fahad S, Chauhan BS (2017) Water-saving technologies affect the grain characteristics and recovery of fine-grain rice cultivars in semi-arid environment. Environ Sci Pollut Res Int 24(14):12971–12981

Kanakoudis V, Tsitsifli S, Papadopoulou A, Curk BC, Karleusa B (2017) Water resources vulnerability assessment in the Adriatic Sea region: the case of Corfu Island. Environ Sci Pollut Res Int 24(25):1–14

Komakech HC, Mul ML, Zaag PVD, Rwehumbiza FB (2011) Water allocation and management in an emerging spate irrigation system in Makanya catchment, Tanzania. Agric Water Manag 98(11):1719–1726

Li J, Ma XC (2015) Econometric analysis of industrial water use efficiency in China. Environ Dev Sustain 17(5):1209–1226

Li XM, Lu HW, Li J, Du P, Xu M, He L (2015) A modified fuzzy credibility constrained programming approach for agricultural water resources management—a case study in Urumqi, China. Agric Water Manag 156:79–89

Li J, He L, Fan X, Chen YZ, Lu HW (2017) Optimal control of greenhouse gas emissions and system cost for integrated municipal solid waste management with considering a hierarchical structure. Waste Manag Res 35(8):874–889

Liang S, Lei S, Zhang T (2011) Achieving dewaterization in industrial parks. J Ind Ecol 15(4):597–613

Liu C, Zhang K (2013) Industrial ecology and water utilization of the marine chemical industry: a case study of Hai Hua Group (HHG), China. Resour Conserv Recycl 70:78–85

Liu L, Song H, Zhang L, Du J (2017) Heat-integrated water allocation network synthesis for industrial parks with sequential and simultaneous design. Comput Chem Eng 108:408–424

Lu HW, Huang GH, He L (2012) Simulation-based inexact rough-interval programming for agricultural irrigation management: a case study in the Yongxin County, China. Water Resour Manag 26(14):4163–4182

Lu HW, Du P, Chen YZ, He L (2016) A credibility-based chance-constrained optimization model for integrated agricultural and water resources management: a case study in South Central China. J Hydrol 537:408–418

Nasiri-Gheidari O, Marofi S, Adabi F (2018) A robust multi-objective bargaining methodology for inter-basin water resource allocation: a case study. Environ Sci Pollut Res Int 25(3):2726–2737

Niu K, Wu J, Yu F, Guo J (2016) Construction and operation costs of wastewater treatment and implications for the paper industry in China. Environ Sci Technol 50(22):12339–12347

Ren L, He L, Lu H, Chen Y (2016) Monte Carlo-based interval transformation analysis for multi-criteria decision analysis of groundwater management strategies under uncertain naphthalene concentrations and health risks. J Hydrol 539:468–477

Roach T, Kapelan Z, Ledbetter R, Ledbetter M (2016) Comparison of robust optimization and info-gap methods for water resource management under deep uncertainty. J Water Resour Plan Manag 142(9):04016028

Rojas-Torres MG, Nápoles-Rivera F, Ponce-Ortega JM, Serna-González M, Guillén-Gosálbez G, Jiménez-Esteller L (2015) Multiobjective optimization for designing and operating more sustainable water management systems for a city in Mexico. AIChE J 61(8):2428–2446

Shi B, Lu HW, Ren LX, He L (2014) A fuzzy inexact two-phase programming approach to solving optimal allocation problems in water resources management. Appl Math Model 38(23):5502–5514

Singh A (2014) Simulation–optimization modeling for conjunctive water use management. Agric Water Manag 141(141):23–29

Sousa MR, Frind EO, Rudolph DL (2013) An integrated approach for addressing uncertainty in the delineation of groundwater management areas. J Contam Hydrol 148(3):12–24

Tiu BTC, Cruz DE (2016) An MILP model for optimizing water exchanges in eco-industrial parks considering water quality. Resour Conserv Recycl 119:89–96

Acknowledgements

The authors thank the editor and the anonymous reviewers for their helpful comments and suggestions.

Funding

This research was supported by the Strategic Priority Research Program of Chinese Academy of Sciences (XDA20040302) and Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Proposed ICCP method

Proposed ICCP method

A general mathematical expression of CCP can be given by:

subject to

where X denotes a vector of decision variables, and A(t), B(t), and C(t), respectively, denote the sets with random element defined on a probability space T, t ∈ Τ. Based on the solution algorithm of CCP, it presents a certain level of probability pi ∈ [0, 1] for each constraint i and requires that this constraint should be satisfied with at least a probability of 1 − pi, given by:

However, the above inequalities are usually non-linear, and the set of feasible constraints is convex only for some particular distributions and certain levels of pi. Then, the constraint (A4) can be transformed as follows:

where bi(t)(pi) = Fi−1(pi), given the cumulative distribution function of bi and the probability of violating constraint i. Then, the CCP can be transformed into a deterministic model, as follows:

CCP can effectively handle the stochastic uncertainties at the right-hand sides (i.e., Bi) with probability density function available. However, it can hardly address independent uncertainties in cj and communicate them into the constraints. One potential approach for better accounting for uncertainties in A, B, and C is to incorporate the ILP within the CCP framework, where intervals are used for reflecting uncertainties in A and C, as follows:

subject to:

An interactive algorithm can be given to solve the ICCP model. The above model can be divided into the upper- and lower-bound submodels, expressed as:

where xj+ (j = 1, 2, …, k1) represents the upper-bound variables, while xj− (j = k1 + 1, k1 + 2, k1 + 1, …, n) represents the lower-bound variables. According to the above upper-level submodel, the lower-level one can be stated as follows:

Through solving the above two submodels, the optimal solution can be obtained (i.e., [f−opt, f+opt] and [x−opt, x+opt]).

Nomenclatures for parameters and variables

Variables | |

|---|---|

CWft | Water supply for the MCI (m3) |

FWft | Water supply for the FCI (m3) |

PWpt | Water supply for the PI (m3) |

RWft | Water supply for the RMI (m3) |

Parameters | |

APCt | Total SS emissions in planning time t (kg) |

APNt | Total NH3▬N emissions in planning time t (kg) |

AWt | Water availabilities in planning time t (m3) |

CCDct | COD emission rate in the MCI (kg/m3) |

CCNft | NH3-N emission rate in the FCI (kg/m3) |

CCRct | SS emission rate in the MCI (kg/m3) |

CWct,max | The maximum water supply for the MCI companies (m3) |

CWct,min | The minimum water supply for the MCI companies (m3) |

FCDft | COD emission rate in the FCI (kg/m3) |

FCNct | NH3▬N emission rate in the MCI (kg/m3) |

FCRft | SS emission rate in the FCI (kg/m3) |

FWft,max | The maximum water supply for the FCI companies (m3) |

FWft,min | The minimum water supply for the FCI companies (m3) |

PCDpt | COD emission rate in the PI (kg/m3) |

PCNpt | NH3-N emission rate in the PI (kg/m3) |

PCRpt | SS emission rate in the PI (kg/m3) |

PFpt | Water consumption coefficient for the PI (m3/m3) |

PWpt,max | The maximum water supply for the PI companies (m3) |

PWpt,min | The minimum water supply for the PI companies (m3) |

RCDrt | COD emission rate in the RMI (kg/m3) |

RCNrt | NH3▬N emission rate in the RMI (kg/m3) |

RCRrt | SS emission rate in the RMI (kg/m3) |

RCt | Unit cost for recycling water treatment (RMB¥/m3) |

RCWt | Capacity of the impounding reservoir (m3) |

RWrt,max | The maximum water supply for the RMI companies (m3) |

RWrt,min | The minimum water supply for the RMI companies (m3) |

TCDt | Total COD emissions in planning time t (kg) |

TCt | Unit cost for wastewater treatment (RMB¥/m3) |

Tt | Planning time (year) |

TWWt | The minimum treatment capacity for the wastewater treatment plant (m3) |

WCt | Unit cost for water use (RMB¥/m3) |

αt | Treatment efficiency for recycling water (%) |

γt | COD removal rate (%) |

ηt | SS removal rate (%) |

ξt | NH3▬N removal rate (%) |

Rights and permissions

About this article

Cite this article

He, L., Chen, Y., Kang, Y. et al. Optimal water resource management for sustainable development of the chemical industrial park under multi-uncertainty and multi-pollutant control. Environ Sci Pollut Res 25, 27245–27259 (2018). https://doi.org/10.1007/s11356-018-2758-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2758-8