Abstract

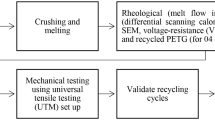

In the present study, the recycled post-consumption polyethylene terephthalate (PET) flakes were investigated as possible raw materials for the production of food packaging. After heating at 220 °C for 1 h, a steaming stage was conducted as a control test to assess the quality of the product. Different samples were characterized by 1H-NMR, FT-IR, DSC/TGA analysis, viscosity index (VI), and trace metals analysis. The results showed that the recycled post-consumed PET flakes’ properties were generally conform to the standard norms of PET except the color of some flakes turned to yellow. Subsequently, a complementary study was undertaken to assess whether the material could be possibly reused for food packaging. For this purpose, rheological, thermal, and mechanical characterizations were performed. The results of the comparative study between the virgin and the recycled PET flakes concluded that the PET recycling affected the rheological properties but did not have any significant effect on their thermal and mechanical characteristics. Hence, it was deduced that the post-consumed PET flakes could be reused as a packaging material except food products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

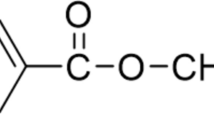

The polyethylene terephthalate (PET) is a commercial food packaging material used also as films and for carbonated soft drinks bottles (Dimitrov et al. 2013). This material is characterized by good thermal and mechanical properties (Awaja and Pavel 2005). During the last decades, PET recycling process has received a considerable attention as an effect of societal pressure to reduce environmental pollution and to develop sustainable waste management (Carta et al. 2003; Fraternali et al. 2014; Nakatani et al. 2017). At natural conditions, PET products have slow decomposition rate. Therefore, recycling processes were considered the best way to economically preserve the PET as a resource and reduce the solid waste pollution generated after its use (Meng et al. 2015). Hence, in order to recycle post-consumer PET, two major processes were applied. These were chemical and mechanical recycling. Generally, the mechanical recycling consisted of contamination removal by sorting, washing, drying, and melting processes (Awaja and Pavel 2005; Nait-Ali et al. 2011). However, during PET melt processing, discoloration was one of the most critical problems that occurred, affecting the properties, and hence the use of the final product. This reduced its suitability as a packaging material for only low-grade products or for those where color was not an issue (Jabbarin 1996). Nevertheless, despite the wealth of research on the topic, the market expansion of recycling by melt processing, and the ever increasing demand on transparent packaging material, the effect of color on the quality of PET as a food packaging material remained under-investigated. Indeed, only few studies treated the discoloration, in particular, during recycling by multiple polymer-processing steps. Most studies (Jabbarin 1996; Dzieciol and Trzeszczynski 1998, 2000; Botelho et al. 2001; Holland and Hay 2002a, b; Coltelli et al. 2007) focused on the mechanisms responsible for the various types of degradation. The initial insights into species leading to yellowing were proposed in studies on thermal and thermal-oxidative degradation (Edge et al. 1994, 1996; Assadi et al. 2004). Jabbarin (1996) attempted to explain that thermo-oxidative degradation was primarily responsible for discoloration of melt processed PET. It was believed to proceed via a radical mechanism. In contrast, Colin and Verdu (2006) argued that discoloration was due to the polyenes formation originated from the vinyl end groups polymerization, taking place during thermal degradation. Chilton et al. (2010) found no evidence of such compounds in the degraded PET. They asserted that this coloration was due to the catalyst addition during the synthesis, or to the storage conditions such as humidity and sun exposure or to the bottles content such as oil and detergents.

More recently, Well (2011) tried to explain the cause of PET yellowing. This scholar argued that it was related to melt processing and reprocessing for recycling operations, especially in the case of bottle to bottle recycling concepts that were introduced into the market all over the world. However, the impact of the post-consumption recycled PET on its quality as a food packaging material was not considered in spite of its importance.

The main objectives of this work were to understand the cause of the recycled PET yellowing phenomenon and to assess its effects on the final product quality. For this purpose, a comparative study between flakes before and after steaming was undertaken based on different characterization techniques. It is expected that this study contributes to a better understanding of recycled PET processing and a higher safety for the consumer’s health.

Material and methods

Materials

The virgin and the recycled PET were kindly supplied by two Tunisian companies: respectively SIPA (a food plastic injection company) and VALORFLAKES (part of the Crystal Industries Group, specialized in the production and development of PET preforms and caps for the bottle industry), located in Zaghouan city. The virgin PET in pellet form, of a food contact grade, was obtained by a chemical synthesis, according to the PET polymer formulation. After this initial processing, it was ready to be transformed by the implementation machines into a final product with a Melt flow index (MFI) of 14 g/10 min. The recovered flakes have undergone only one thermo mechanical recycling after being subjected to post-use environmental factors; they are characterized by an MFI of 54 g/10 min, and will be finally exported to European countries for food contact uses. Since the treated used-bottles were of different colors, three types of flakes were obtained, i.e., white, blue, and dark blue, and experimented.

Sample preparation

The flakes were thermally treated at 220 °C for 1 h, simulating operatory conditions during the quality control test. During this thermal process, some flakes turned to yellow affecting negatively the material color.

To compare the initial flakes before heat treatment and those which turned to yellow after the heat effect, a set made up of around fifty flakes was sampled. Then, each specimen flakes was divided into two reinforced parts. One part was kept as a control at room temperature and the second one was heated in an oven at 220 °C. The yellowed flakes were characterized and compared to the initially unheated part.

Characterization

Structural characterization

Proton nuclear magnetic resonance spectroscopy

The analysis by proton nuclear magnetic resonance spectroscopy (1H NMR) was performed in a mixture of deuterated chloroform (CDCl3) and trifluoroacetic acid (TFA) CDCl3/TFA (3/1 by volume) at 30 °C (Kenwright et al. 1999). The 1H NMR spectra were recorded on a Bruker DRX 400 operating at 400.1 MHz.

Fourier transform infrared spectroscopy (PA/FT-IR) analysis

The infrared spectrum was obtained in a Nicolet Nexux FT-IR in attenuated total reflectance (ATR) mode within the range of 4000–400 cm−1, with a resolution of 4 cm−1 and 32 scans.

Thermal characterization

Thermogravimetric analysis

The thermogravimetric analysis (TGA) was performed on a TA Instrument Q500 thermobalance. The samples were heated from the ambient temperature to 500 °C at a heating rate of 10 °C/min under a nitrogen atmosphere.

Differential scanning calorimetry

The characteristic temperatures and the crystallinity degree for all the studied samples were determined by thermal measurements made on a Perkin-Elmer DSC7 calorimeter, under nitrogen atmosphere. The crystallization and melting temperatures were recorded at the maximum peak, the enthalpies were determined by integrating the peaks, and the glass transition temperature was determined at the midpoint. The samples of 7–10 mg were heated from 35 to 290 °C at a heating rate of 10 °C/min and held in the molten state at 290 °C for 2 min to erase their thermal history. After being cooled to 35 °C at 2 °C/min, they were reheated to 290 °C at 10 °C/min.

The glass transition temperature (Tg), the crystallization temperature (Tc), the crystallization enthalpy (ΔHc), the melting temperature (Tm), and the melting enthalpy (ΔHm) were obtained from the cooling scan and the second heating scan. Furthermore, the crystallinity degree (χc) was calculated according to eq. (1), with ΔH0 = 140 J g−1 (Wunderlich 1973), corresponding to the melting enthalpy of 100% crystalline PET. For the initial PET state evaluation, the (χc) value was calculated by subtracting the cold crystallization enthalpy (ΔHcc) measured in the heating scan.

Viscosity index

The viscosity index (VI) was determined by the direct measurement of PET solution of flow time using an Ubbelohde viscometer. The PET average molar weight in number and weight was determined indirectly from the viscosity index at 25 °C according to eq. (2). The PET was previously dissolved in solvents mixture of phenol/ortho-dichlorobenzene prepared in equal weight (50/50).

where ts, t0, and C referred to the solution flow time, the solvent flow time, and the concentration expressed by weight grams per milliliter of the polymer in the solvent, respectively.

The three PET flakes color types were considered: the white, the blue, and the dark blue. For each flakes color, the viscosity index of four samples was investigated at different flow times (0, 30, 60, 90, 120, 150, and 180 min).

Trace metals’ migration

The conditions for food analyses of specific migration (trace metals migration) were determined according to the European Regulation N°10/2011. The experimented PET flakes (white, blue, and yellow) were exposed to the stimulant (ethanol 20 and 3% aqueous acetic acid) at 60 °C for 10 days. After the contact duration, each stimulant solution including one specific color-type PET (white, blue, and yellow) was analyzed using iCAP 6000 Series inductively coupled optical design (ICP-OES) (Thermo, Germany), according to the ISO 17294-2 method (ISO 2003) modified for the determination of heavy metals in PET. The operating conditions were as follows: RF power was 1318 W; the carrier, the auxiliary, and the nebulizer argon gas flow were 13.0, 0.88, and 0.69 dm3/min, respectively. The limit of quantification (LOQ) for trace metals was Ba (1 mg L−1), Co (0.05 mg L−1), Cu (5 mg L−1), Fe (48 mg L−1), Li (0.6 mg L−1), Mn (0.6 mg L−1), and Zn (25 mg L−1).

Capillary rheology

Capillary rheometry was performed using a Rosand Advanced Rheometer System, with twin-bore capability (Malvern Instruments, Malvern, Worcestershire, UK). Each barrel was of 15 mm in diameter. Experiments were run using 1 mm flat entry dies in both barrels. One die was 16 mm length and the second 0.25 mm, allowing the Bagley correction application to the data. The PET apparent melt viscosities were measured at 280 °C, and the entrance pressure (ΔP) was measured directly above the die entrance by a pressure transducer. The material was extruded through the die at controlled linear piston velocity (V), ranging from 5 to 100 mm/min.

Mechanical properties

Tensile testing was carried out using universal testing equipment (MTS Criterion) at ambient temperature at a crosshead speed of 20 mm/min, using a load cell of 10 kN. The tensile mechanical tests were carried out on specimens cut by an injection machine. The specimens tested were in accordance with the kind of dumbbells standards specifications (test “ISO ½”) according to French standard NF T 51-034 and were subject to deformation at constant speed until break. The Young modulus (E), the stress (σy), and strain (εy) at the yield point, and the stress (σB) and the strain (εB) at the break point were measured from stress-strain curves. For each experimental material, ten specimens were tested. The mechanical parameters presented were the average measures of heir corresponding standard deviations.

Results and discussion

Yellowing phenomenon

Structural analysis

NMR analysis

From the first ascertainment, the NMR spectra of two reused PET were superposable and no new peak was evidenced after the heat treatment. Figure 1 shows the NMR spectra of the studied PETs. In line with Geol (2006), this observation may serve to confirm the fact that the yellowed polymer was a PET. Furthermore, it could be noticed that there was no new chemical bond established in the yellowed PET. The calculation of Iso % showed no significant differences between the recycled PET and the yellowed one considering the structural characteristic.

However, after 48 h of heat treatment at 220 °C, the same performed analysis exhibited a PET cross-link occurrence, which prevented its NMR analysis. As was explained by Awaja and Pavel (2005), the cross-linking reaction was initiated by the peroxy radicals formation. These unstable hydroperoxides, as well as the free radicals, were produced by the abstraction of hydrogen from the polymer chain.

According to the NMR analysis, it could be concluded that only the color development was highlighted without any significant chemical modification effect on the flakes quality. Consequently, the NMR would confirm the limited reaction supported by the hydroxyl group occurring during the investigated discoloration.

FTIR spectra

As can be clearly seen in Fig. 2, before and after heating, the PET FTIR spectra did not exhibit any new absorption peak or the removal of an already existing peak. Consequently, the generated thermal oxidation products were characterized by the same structural functions that were in the initial PET material. However, at 1707 cm−1, the absorbance band specific to carbonyl groups (C=O) in the ester linkage, a wider peak was noted for the yellowed PET compared to the nonyellowed one. This would reflect a concentration variation or eventually a new ester formation resulting from the polymer degradation.

The same phenomenon was mentioned by Caruso et al. (2009). These authors reported the slight displacement of the absorption line associated to the carbonyl group (C=O) of the ester function. They rightly deduced that there was a chemical modification inside the material during the heat treatment. They explained this finding by the effect of the PET chains degradation mechanism. In similar studies, Fechine et al. (2004) and Fashandi et al. (2008) reported that during the PET recycling, the chain scission often generated polymer radicals with hydroxyl and carboxyl end groups. These groups acted as catalyst to promote further degradation. The carboxyl end-groups index was determined as the peak areas ratio at 3430 and 1410 cm−1.

Thermal analysis

TGA characterization

Figure 3 shows the thermogravimetric analysis of recycled PET flakes before heat treatment (A1, B1) and after heat treatment (A2, B2). The thermal curves of the 4 experimented PET samples were identical. Indeed, the four samples showed a glass transition temperature of 425 °C, as well as a degradation temperature of 590 °C. This would imply that the polymer presented a thermal stability.

Differential scanning calorimetric

Table 1 summarizes the thermal properties while comparing the recycled material and the recovered yellowed one. It may be noted that the thermal parameters did not present any significant differences between the treated PET flakes.

Viscosity index

The VI was performed on flakes heat-treated for different periods of time. After a 48-h treatment in the oven at 220 °C, the yellowed PET presented a crosslinking phenomenon. Hence, the flakes were dissolved in the solvent and the VI analysis became impossible.

Therefore, it was imperative to proceed by sorting the PET flakes by color (white, blue, and dark blue). In addition, the steaming was conducted for 30, 60, 90,120, and 180 min at 220 °C. Table 2 shows the obtained results from this procedure. As can be seen in Fig. 4, the variation of the white PET flakes was more significant than that for the blue PET flakes. In fact, after 90 min, their VI decreased by 38% (Gantillon et al. 2009), implying the modification of the PET average molecular weight. For the blue PET flakes and for the dark blue PET flakes, the VI decrease was of 23 and 15%, respectively. This difference may be explained by the fact that white PET flakes were more readily affected by the heat while the dark blue flakes were the most resistant to heat. This would be probably due to the presence of antioxidant in the dark blue polymer.

After 120, 150, and 180 min steaming, there was a crosslinking phenomenon. It seems that beyond a 90-min exposure to heat, the polymers became insoluble. As was explained by Awaja et al. (2004), the formation of crosslinking bridges is catalyzed by the temperature and chemical functions resulting from the thermo-oxidative degradation such as chains cleavage and free radicals establishment.

Trace metals migration

The results of the trace metals for the three types of the experimented PET—the white, the blue, and the yellow—are presented in Table 3. It should be mentioned that the Sb, Ba, Co, Cu, and Zn were below the equipment detection concentrations. Furthermore, low concentrations were recorded for iron, lithium, and magnesium for the different types of PET while compared to the limits set by the European Regulation No. 10/2011. These results confirmed that the entire colored PET conformed to the European Regulation including the yellowed one for the investigated metals.

As these plastic materials are destined to European countries where the quality control is performed upon the receipt of the goods, it could be deduced that the yellowing phenomenon would not be generated by a trace metal migration, since PET flakes were conformed for the 8 most important metals investigated. Hence, it does not represent a threat to the health of the consumer when the recycled PET flakes are used for food packaging. This study confirms and adopts previous researchers’ (Ciolacu et al. 2006 and Chilton et al. 2010) explanations of this phenomenon; namely the yellowing of the polymer was caused by the possible oxidation/degradation reactions occurring during the mechanical recycling in presence of water and O2, and because of the drying conditions.

Virgin and recycled PET comparison

Capillary rheology

The flow curves (Fig. 5) representing the viscosity variation in function of the shear showed a pseudoplastic behavior manifest in the decrease of viscosity at the increase of shear.

Pseudoplasticity of virgin PET was slightly more pronounced compared to that of the recycled one. As a result, the virgin PET would be slightly more polydisperse than the recycled material. At the same shear value, the ɳ of virgin PET was more important than that of the recycled one. It is probable that the virgin polymer chain lengths are longer than those of the recycled PET. During the use and regeneration process, PET undergoes partial degradation through hydrolysis, oxidation, and transesterification reactions which lead to the splitting of the polymer chain, thus reducing the molar masses of the recycled PET. Moreover, in total agreement with Kong and Hay (2003), this study confirmed the idea that the presence of water and PVC in the flakes promoted PET chain scission during normal extrusion.

Similarly, Karayannidis and Psalida (2000) found that at a processing temperature of 280 °C, hydrolysis reactions occurred between water and PET originating short chains with acid and hydroxyl-ester end groups. Moreover, the thermal cleavage of the PET ester bond shortened PET chains with acid and vinyl ester end-groups. Also, Awaja and Pavel (2005) observed that post consumer PET (POSTC-PET) underwent a decrease in molecular weight when it was recycled in a normal extrusion system. Finally, Nait-Ali et al. (2011) confirmed that during POSTC-PET melt processing, thermal and hydrolytic degradation reactions were responsible for the PET molecular weight reduction or [η].

These findings support Awaja and Pavel’s (2005) call for further physico-chemical investigations to preserve molecular weight and viscosity parameters that would meet the requirements of packaging intended for the conservation and transport of foodstuffs.

Differential scanning calorimetric

The differential scanning calorimetric (DSC) tests were performed in order to identify the effects of reprocessing steps on crystallization and melting behavior of virgin and recycled PET flakes.

The DSC samples were taken from the tensile specimen.

As is shown in Table 4, there was no significant difference between the Tg, Tm, and Tc values for the two types of the experimented PETs. Therefore, the same degree of cristallinity for both PET types would imply that the mechanical recycling process adopted did not affect the thermal characteristic of the plastic. This finding corroborates with Dombre et al.’s (2014) results on thermal characteristics of virgin and recycled PET concluding that virgin and recycled PET exhibited the same crystallinity degree.

In a similar study, Castro Lopez et al. (2014) reveled that for commercial recycled PET supplied by Catalana de Polimers S.A., Grup LaSeda, Barcelona, Spain, Tg values were similar to the corresponding virgin PET value. Furthermore, the melting behavior was like that of the mechanically reprocessed samples after several cycles with two neat peaks at approximately 244.4 and 236.7 °C. In addition, an increase in the crystallization rate and crystallinity was observed in the recycled PET flakes as opposed to the virgin PET flakes. These scholars explained the difference by the use of the mechanical processing.

Traction

The tensile parameters of all the experimented samples are reported in Table 5.

Firstly, we noted a slight loss in term of rigidity of the PET after recycling (Young’s modulus (E) for virgin PET = 767 MPa and 709 MPa for the recycled one. On the other hand, a gain in ductility is registered; after recycling, ΔLr increase 343 to 490%. The recorded differences in mechanical properties between recycled PET flakes and virgin PET flakes were not significant. This finding corroborates with that reported by Castro Lopez et al. (2014).

Awaja and Pavel (2005) explained this observation by the fact that the recycled PETs were able to maintain some of the tensile mechanical properties of virgin PET or even improve the impact strength.

Conclusion

This study attempted to investigate whether recycled PET flakes could be reused for food packaging. Although the yellowing of some recycled PET flakes would have a nontoxic effect mainly because of the absence of 8 toxic trace metals, this study suggested some solutions to reduce its intensity if not totally eradicate it.

It also revealed that apart from a yellowing effect, the recycled PET flakes’ thermal and mechanical properties were not altered significantly.

Nevertheless, further investigations are imperative to find out definite ways of eliminating the yellowing process and creating a totally safe material for food packaging from recycled PET flakes.

References

Assadi R, Colin X, Verdu J (2004) Irreversible structural changes during PET recycling by extrusion. Polym 45:4403–4412

Awaja F, Pavel D (2005) Recycling of PET (Review). Eur Polym J 41:1453–1477

Awaja F, Daver F, Kosior E (2004) Recycled poly(ethylene terephthalate) chain extention by a reactive extrusion process. Polym Eng Sci 44:1579–1587

Botelho G, Queiros A, Liberal S, Gijsman P (2001) Studies on thermal and thermo-oxidative degradation of poly(ethylene terephthalate) and poly(butylene terephthalate). Polym Degrad Stab 74:39–48

Carta D, Cao G, D’Angeli C (2003) Chemical recycling of poly(ethylene terephthalate) (pet) by hydrolysis and glycolysis. Environ Sci Pollut Res 10:390–394

Caruso MM, Davis DA, Shen Q, Odom SA, Sottos NR, White SR, Moore JS (2009) Mechanically-induced chemical changes in polymeric materials. Chem Rev 109:5755–5798

Castro Lopez MM, Ares Pernas AI, Lopez MJA, Latorre AL et al (2014) Assessing changes on poly(ethylene terephthalate) properties after recycling: mechanical recycling in laboratory versus postconsumer recycled material. Mater Chem Phys 147:884–894

Chilton T, Burnley S, Nesaratnam S (2010) A life cycle assessment of the closed-loop recycling and thermal recovery of post-consumer PET. Resour Conserv Recycl 54:1241–1249

Ciolacu CF, Choudhury LNR, Naba K (2006) Colour formation in poly(ethylene terephthalate) during melt processing. Polym Degrad Stab 91:875–885

Colin X, Verdu J (2006) Polymer degradation during processing. Comptes Rendus Chimie Académie des Sciences Chimie 9:1380–1390

Coltelli MB, Bianchi S, Aglietto M (2007) Poly(ethylene terephthalate) (PET) degradation during the Zn catalysed transesterification with dibutyl maleate functionalized polyolefins. Polym 48:1276–1286

Dimitrov N, Krehula LK, Sirocic AP, Hrnjak-Murgic Z (2013) Analysis of recycled PET bottles products by pyrolysis-gas chromatography. Polym Degrad Stab 98:972–979

Dombre C, Marais S, Chappey C, Lixon-Buquet C, Chalier P (2014) The behaviour of wine aroma compounds related to structure and barrier properties of virgin, recycled and active PET membranes. J Membr Sci 463:215–225

Dzieciol M, Trzeszczynski J (1998) Studies of temperature influence on volatile thermal degradation products of poly(ethylene terephthalate). J Appl Polym Sci 69:2377–2381

Dzieciol M, Trzeszczynski J (2000) Volatile products of poly(ethylene terephthalate) thermal degradation in nitrogen atmosphere. J Appl Polym Sci 77:1894–1901

Edge M, Allen NS, Wiles R (1994) Polymer paper identification of luminescent species contributing to the yellowing of poly(ethylene terephthalate) on degradation. The Manchester Metropolitan University, and W. McDonald and S. V. Mortlock. ICI Films, Wilton, UK

Edge M, Willes R, Allen NS, McDonald WA et al (1996) Characterisation of the species responsible for yellowing in melt degraded aromatic polyesters I: yellowing of poly(ethylene terephthalate). Polym Degrad Stab 53:141–151

Fashandi H, Zadhoush A, Haghighat M (2008) Effect of orientation and crystallinity on the photodegradation of poly(ethylene terephthalate) fibers. Polym Eng Sci 48:949–956

Fechine GJM, Rabello MS, Souto Maior RM, Catalani LH (2004) Surface characterization of photodegraded poly(ethylene terephthalate). The effect of ultraviolet absorbers. Polym 45:2303–2308

Fraternali F, Spadea S, Berardi VP (2014) Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Constr Build Mater 61:293–302

Gantillon B, Spitz R, McKenna TF (2009) The solid state postcondensation of PET, 2a toward the development of a new dispersed phase solid state process. Macromol Mater Eng 289:106–112

Geol S (2006) Stratégies de modifications physico-chimiques des polyesters semi-cristallins. Application à la fabrication de bouteilles en poly(éthylène téréphtalate)

Holland BJ, Hay JN (2002a) The thermal degradation of PET and analogous polyesters measured by thermal analysis–Fourier transform infrared spectroscopy. Polym 43:1835–1847

Holland BJ, Hay JN (2002b) Analysis of comonomer content and cyclic oligomers of poly(ethylene terephthalate). Polym 43:1797–1804

International Standardization Organization (2003) ISO 17294–2 standard method

Jabbarin SA (1996) Poly(ethylene terephthalate). In: Polymeric materials encyclopaedia.8 New York, CRC press 6114

Karayannidis GP, Psalida EA (2000) Chain extension of recycled poly(ethylene terephthalate) with 2,2-(1,4-phenylene) bis(2-oxazoline). J Appl Polym Sci 77:2206–2211

Kenwright AM, Peace SK, Richerds RW, Bunn A et al (1999) End group modification in poly(ethylene terephthalate). Polym 40:2035–2040

Kong Y, Hay JN (2003) Multiple melting behaviour of poly(ethylene terephthalate). Polym 44:623–633

Meng T, Klepacka AM, Florkowski WJ, Braman K (2015) What drives an environmental horticultural firm to start recycling plastics? Results of a Georgia survey. Resour Conserv Recycl 102:1–8

Nait-Ali LK, Colin X, Bergeret A (2011) Kinetic analysis and modelling of PET macromolecular changes during its mechanical recycling by extrusion. Polym Degrad Stab 96:236–246

Nakatani J, Konno K, Moriguchi Y (2017) Variability-based optimal design for robust plastic recycling systems. Resour Conserv Recycl 116:53–60

Règlement (UE) No 10/2011 de la Commission du 14 janvier 2011 concernant les matériaux et objets en matière plastique destinés à entrer en contact avec des denrées alimentaires (Texte présentant de l’intérêt pour l’EEE)

Well F (2011) An overview: twenty years of PET bottle to bottle recycling. Resour Conserv Recycl 55:856–875

Wunderlich B (1973) Macromolecular physics 1 a. Press New York and London 1:389

Acknowledgments

This research was carried out in the framework of a MOBIDOC thesis funded by the European Union in the frame of PASRI program. This study was supported by IMP@Lyon 1 for the mechanical and thermal studies. The authors would like to thank Dr. Ayadi Hajji for his help with proofreading, correcting the English, and editing this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Masmoudi, F., Fenouillot, F., Mehri, A. et al. Characterization and quality assessment of recycled post-consumption poly(ethylene terephthalate) (PET). Environ Sci Pollut Res 25, 23307–23314 (2018). https://doi.org/10.1007/s11356-018-2390-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2390-7