Abstract

Aiming to minimize the damage caused by river chemical spills, efficient emergency material allocation is critical for an actual emergency rescue decision-making in a quick response. In this study, an emergency material allocation framework based on time-varying supply-demand constraint is developed to allocate emergency material, minimize the emergency response time, and satisfy the dynamic emergency material requirements in post-accident phases dealing with river chemical spills. In this study, the theoretically critical emergency response time is firstly obtained for the emergency material allocation system to select a series of appropriate emergency material warehouses as potential supportive centers. Then, an enumeration method is applied to identify the practically critical emergency response time, the optimum emergency material allocation and replenishment scheme. Finally, the developed framework is applied to a computational experiment based on south-to-north water transfer project in China. The results illustrate that the proposed methodology is a simple and flexible tool for appropriately allocating emergency material to satisfy time-dynamic demands during emergency decision-making. Therefore, the decision-makers can identify an appropriate emergency material allocation scheme in a balance between time-effective and cost-effective objectives under the different emergency pollution conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, with the rapid economic development and the accelerated urbanization, China is facing an increasing pressure on resource, environment, and ecology caused by a rapid industrial development and revolution (Su et al. 2016). The rise of the frequency and intensity of river chemical spills caused by potential industrial pollution risks requires a strong emphasis on improving our capabilities to make a quick response and alleviate the negative impacts on the environment (Jiang et al. 2012; Liu et al. 2016b; Shi et al. 2014). Emergency material allocation (EMA), which mainly deals with how to efficiently allocate emergency materials to pollution accident sites and satisfy the requirements of emergency rescues before the pollutants disperse in large-scale, plays a fundamental and essential role in decision-making process dealing with river chemical spills in environmental emergency management (Liu et al. 2016a). Therefore, a scientific and reasonable EMA scheme becomes critical for an effective actual emergency decision-making process.

Research on EMA has gained much attention recently in order to obtain optimizing emergency response schemes for emergency rescue to minimize the emergency response time or system cost (Huang and Fan 2010; Liu et al. 2016c). Barbarosoğlu and Arda (2004) developed a two-stage stochastic programming model to plan the first-aid commodity allocation and transportation scheme for disaster-affected areas; Chang et al. (2007) developed two stochastic programming models to allocate rescue resource for flood emergency logistics under scenario planning; Tzeng et al. (2007) constructed a multi-objective relief-distribution model to allocate relief material effectively; Zhang et al. (2012) presented a heuristic algorithm to efficiently solve emergency resource allocation problem dealing with possible secondary disasters; Abounacer et al. (2014) proposed an epsilon-constraint method to deal with the allocation of aid from aid distribution centers to demand points for disaster response; Wex et al. (2014) developed a corresponding decision support model to allocate rescue units and identify routing scheme based on different incident severities in disaster management; Su et al. (2016) proposed an emergency resource allocation model for multiple concurrent incidents caused by natural disaster; Fontem et al. (2016) developed a decomposition-based heuristic method to allocate emergency supplies and identify routing scheme according to the increased threat of natural disasters.

In general, EMA for natural disasters, such as earthquakes and floods, mainly deals with how to efficiently and quickly allocate emergency resources and equipment from supportive centers to disaster incident sites in order to reduce casualties, protect economic property, and maintain social stability (Khayal et al. 2015; Zhang et al. 2016). Therefore, most of the studies on EMA for natural disasters focus on routing selection and vehicle deployment considering various incident risk/severity scenarios to find a shortest path and available vehicle according to road situations from supportive centers to an incident site. However, EMA for river chemical spills primarily aims at identifying optimizing emergency material allocation schemes to minimize the response time and providing differentiated emergency materials to satisfy the requirements of emergency rescues before the pollutants disperse in large-scale. In general, it is not influenced by road situations and vehicle constraint. Moreover, with the unpredictability of river chemical spills, decision-making process for EMA is generally characterized by inherent uncertainty and complexity, which poses further challenge as emergency material demand and supply may vary over time in terms of material type and quantity (Zhou and Reniers 2016). Therefore, a reasonably dynamic EMA is an indispensable decision-making process to improve emergency rescue capability and satisfy the material requirements, especially under the time-varying features of the environmental conditions, in order to reduce environmental negative impacts and economic losses caused by river chemical spills.

Appropriate regular resource allocation is a dynamic optimization decision-making process considering the balance between resource demand and supply relationship. In recent years, various dynamic optimization methods have been successfully applied in many applications. Sheu (2007) proposed a logistics distribution method for the urgent requirements for disaster-affected areas considering time-varying relief demand and supply; Wang et al. (2011) developed a genetic algorithm to address task allocation problem of a two-echelon supply chain against stochastic demand; Omar et al. (2013) proposed a just-in-time (JIT) manufacturing system to obtain the supply and the delivery scheme of raw materials considering customer demand rate is linearly decreasing and time-varying; Govindan (2015) developed a mathematical model to schedule purchase orders for inventory replenishment with a time-varying stochastic demand in a two-echelon supply chain system for a minimum system cost objective; Krishna Priya and Bandyopadhyay (2015) identified an optimum mix of various supply equipment for meeting the time-varying demand to reduce the overall cost of the system; Amini Salehi et al. (2016) defined a stochastic robustness method to facilitate resource allocation in a dynamic environment, maximizing the number of tasks to meet their individual deadlines; Luscombe and Kozan (2016) proposed a dynamic scheduling framework to provide real-time support in order to manage and allocate the scarce resources for health care service.

However, most present studies on dynamic optimization decision-making models concentrate more on resource allocation for regular management than emergency material allocation for environmental emergency management. Generally, it is more sensible for EMA with an objective of minimizing emergency response time, rather than minimizing total system cost for river chemical spills (Liu et al. 2017; Mohamadi and Yaghoubi 2017; Quinn and Jacobs 2007; Zhao and Chen 2015). Meanwhile, the emergency material allocation scheme for emergency decision-making should be characterized by flexibility and diversity in order to deal with different pollution conditions. Therefore, developing a dynamic optimization EMA model to accommodate the special characteristic of river chemical spills has more practical significance.

Therefore, the objective of this study is to develop an emergency material allocation framework based on time-varying supply-demand constraint to appropriately allocate emergency material and effectively minimize the emergency response time. The proposed emergency material allocation algorithm (EMAA) can help decision-makers identify optimizing emergency material allocation scheme under time-varying and scarce emergency material supply-demand conditions for the actual emergency rescue decision-making. The paper is organized as follows: the Methodology section presents the development of emergency material allocation system and the corresponding algorithm. The Application of emergency material allocation framework section describes a computational experiment and illustrates results and discussions, where emergency material allocation schemes based on a time-varying allocation process are analyzed. The Conclusions section gives some conclusions.

Methodology

The emergency rescue for emergency pollution accidents should spare no effort to coordinate emergency material allocation in a time-effective manner rather than in an economical effective manner (Fontem et al. 2016; Govindan 2015; Wang et al. 2011). Meanwhile, emergency material allocation for emergency pollution accidents is also a complicated task due to the diversity of pollution conditions and time-varying material supply and demand constraints. Therefore, the developed model can have a certain dynamic characteristic, that is, the supply amount of emergency material in the supportive center and the demand amount of emergency material in the demand point increase with the pollution condition changes. This dynamic structure can easily analyze the impacts of the different conditions on emergency pollution accidents.

Emergency material allocation framework under time-varying supply-demand constraint

In this study, an extremely harsh pollution condition is considered that the pollution source of a river chemical spill is not intercepted timely. The demand amount of emergency material in a pollution-affected site is characterized by a time-varying linear increase based on the chemical spill rate. Hence, emergency material, reserved in the pre-planned warehouses for emergency incident, is inevitably in such a scarce supply state. And the supply amount of emergency material requires a dynamic additional supplement. The replenishment policy for emergency material in the pre-planned warehouses with time-varying supply also approximately fits a linear characteristic based on the chemical spill rate. In this study, the system objective for emergency material allocation is minimizing the emergency response time to make sure that the whole emergency rescue system can support demand point B enough emergency material with a dynamic material replenishment process. The emergency material allocation pattern with single demand point and multi-supportive center is appropriate for only when a single spill incident occurs in water systems, such as slow-flowing rivers, lakes, and reservoirs.

As an emergency material scheduling problem with single demand point and multi-supportive center based on time-varying supply and demand constraint, let A = {A1, A2, …, An} be a finite set of potential supportive centers. And both the supply amount xi of emergency material in the supportive center i (i = 1, 2, …, n) and the demand amount y of emergency material in the demand point B increase over time. Hence, emergency rescue capability of the supportive center i can be expressed as xi = ai + biti, where ai is the initial storage amount of emergency material in the supportive center i and bi is the change rate of emergency material. Meanwhile, pollution condition of the demand point B can be expressed as y = c + et, where c is the initial demand amount of emergency material in the demand point B and e is the change rate of emergency material. In fact, the initial storage amount of emergency material for all the supportive centers can be expressed as \( \sum \limits_{i=1}^n{a}_i \), if \( \sum \limits_{i=1}^n{a}_i<c \); all the supportive centers cannot guarantee the requirement of emergency material for the demand point B and need some time to replenish the related emergency material.

Emergency material allocation algorithm

In the emergency rescue system, it is supposed that the requirements of the demand point B can be satisfied at time t = T, which is the theoretically critical emergency response time. Hence, supportive center i has (T − di) hour as the replenishment time to prepare additional emergency materials. Hence, the storage amount of emergency material xi in the supportive center i can be expressed as

where ai is the initial storage amount of emergency material in the supportive center i, bi is the change rate of emergency material, di is the transportation time from supportive center i to the demand point B, and T is the emergency response time for whole emergency rescue system. For the demand point B, multiple supportive centers are supposed to allocate emergency material for demand point B. Hence, the time when the last supportive center arrives at demand point B and the requirement of emergency material for the demand point B can be guaranteed is the emergency response time for whole emergency rescue system.

The demand amount of emergency material y of the demand point B can be expressed as

where c is the initial demand amount of emergency material in the demand point B and e is the change rate of emergency material.

It is assumed that all the potential supportive centers are supposed to allocate emergency materials to the demand point B. In order to satisfy the requirements of the demand point, \( \sum \limits_{i=1}^n{x}_i=y \). Hence,

Thus, the theoretically critical emergency response time T can be obtained and expressed as follows:

However, some potential supportive centers are distributed too far away from the pollution-affected site (demand point B) and yield to guaranteeing an effective emergency rescue for the demand point B in time T (di > T). Hence, the theoretically critical emergency response time T is not the practically critical emergency response time in the whole rescue system.

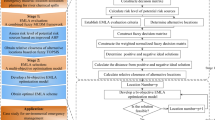

Then, an enumeration method is applied to obtain the emergency material allocation scheme. Let T′ represent the practically critical emergency response time (T′ < T). Step 1, sort the potential supportive centers i in ascending order according to their di values. And select a series of supportive centers which meet the relationship (di < T). Step 2, let \( {d}_i^{\prime } \) be the transportation time of the ith supportive center after the sort. In the new set of supportive centers, it is assumed that T′ and \( {d}_i^{\prime } \) meet the relationship (\( {d}_i^{\prime }<{T}^{\prime }<{d}_{i+1}^{\prime } \)). Hence, the number of supportive centers (j) which is qualified to support the emergency materials to the demand point can be obtained. Step 3, put the number of supportive centers (j) into Eq. (5) and calculate the practically critical emergency response time T′ according to Eq. (5).

If T′ does not satisfy the constraints (\( {d}_i^{\prime }<{T}^{\prime }<{d}_{i+1}^{\prime } \)), a new relationship (\( {d}_{i\hbox{-} 1}^{\prime }<{T}^{\prime }<{d}_i^{\prime } \)) would be built. And the iteration of Step 2 and Step 3 would be continued until the calculated T′ meets Eq. (5). And, if T′ satisfies the constraints (\( {d}_i^{\prime }<T<{d}_{i+1}^{\prime } \)), the assumption is valid. Then, according to Eq. (2), the practical supply amount of emergency material \( {x}_i^{\prime } \) in the supportive center i can be expressed as

Hence, the practical demand amount of emergency material in the demand point B can be expressed as

The algorithm is presented in Fig. 1 and explained as follows:

The pseudo-code for EMAA can be shown in Algorithm 1.

Application of emergency material allocation framework

Overview of the study region

The south-to-north water transfer is a large-scale national project to optimize regional water resource utilization and allocate water resource from Jiangsu province to Beijing due to the shortage and uneven distribution of water resources in China. However, various hazardous chemical industries are located in Jiangsu province and have threatened to the project channel and related rivers. Therefore, water supply security in Jiangsu province is critical to guarantee the effective implementation of the project. Meanwhile, appropriate EMA decision-making for Jiangsu province in order to carry out emergency rescue in a quick response dealing with river chemical spills can play an important role in ensuring water quality protection and supply security, reducing economic damage and maintaining social stability for the implementation of the project. In this study, the distribution of representative hazardous chemical industries (risk sources) and feasible emergency material warehouses in Jiangsu province is shown in Fig. 2.

The information of representative potential risk sources and pre-planning emergency material warehouses are shown in Tables 1 and 2 (Liu et al. 2016a). WZ12, WZ19, XJ1, XJ2, and XJ3 are emergency material warehouses in level I and would give priority to emergency rescue to risk sources within 2 h, and WZ2, WZ9, WZ15, WZ18, and WZ22 are emergency material warehouses in level II, guaranteeing to allocate emergency materials to risk sources within 3 h. And related emergency materials and equipment, such as activated carbon, activated alumina, ferrous sulfate, sacks, pontoons, oil containment boom, and so on, are pre-stored in these ten emergency material warehouses and kept in a ready-to-be-used state.

Results and discussion

In this study, the proposed emergency material allocation framework is applied to a computational experiment for EMA decision-making in case of river chemical spills in Jiangsu province according to the above information. As a computational experiment in this study, it is supposed that risk source FXY6 occurs river chemical spill and the pollution source of a river chemical spill is not intercepted timely. Hence, effective decision-making for emergency rescue before the pollutants disperse in large-scale is particularly important. The system objective for emergency material allocation is minimizing the emergency response time to make sure that the whole emergency rescue system can allocate risk source FXY6 enough emergency material with a dynamic material replenishment process. The demand amount of emergency material in pollution-affected site is characterized by a time-varying linear increase based on the chemical spill rate, which is expressed as y = 1800 + 3000T. And the supply amount of emergency material requires a dynamic additional replenishment. The supply amount of emergency material in supportive center Ai also approximately fits a linear relationship based on the chemical spill rate, which is expressed as xi = ai + 1500(T − di). For emergency material sacks, as an example, the initial demand (c) in risk source FXY6, the initial storage amount (ai) in emergency material warehouses, and the transportation time (di) from risk source FXY6 to emergency material warehouses are shown in Table 3.

The results of emergency material allocation scheme

In this study, the theoretically critical emergency response time T is obtained for the emergency material allocation system based on Eq. (4) and T = 1.932 h. Some potential supportive centers are eliminated which are distributed too far away from demand point J = 6 and yield to guaranteeing an effective emergency rescue for the demand point J = 6 in time T. The emergency material warehouses which can be selected as supportive centers and allocate emergency materials to the incident should meet the relationship di < T. Then, a new series dnewj is built, sorting the potential supportive centers i in ascending order according to their transportation times di. And the new series \( {d}_i^{\prime } \) contains emergency material warehouses WZ12, WZ18, WZ15, and WZ9. Finally, the practically critical emergency response time T′ is calculated by the enumeration method according to Eq. (5) and T′ = 1.7425 h. Finally, the emergency material warehouses selected as supportive centers and the supply amount of the sacks can be calculated by Eqs. (6) and (7). Hence, emergency material allocation Scheme 1, as the optimizing scheme in the allocation system, is obtained and shown in Table 4, with an emergency response time at 1.7425 h. Due to relatively distant location and low storage of WZ9, WZ9 are supposed to play only a minor role in the whole allocation system. Therefore, emergency material allocation Scheme 2 is calculated by EMAA without the participation of WZ9, obtaining an emergency response time at 2.1 h. Meanwhile, if a river chemical spill is rather serious, the nearest supportive center WZ12 can be selected and allocate emergency materials for an initial system rescue based on its initial storage amount of emergency material without a dynamic material replenishment which results in a relatively high emergency response time at 2.54 h shown in emergency material allocation Scheme 3.

The comparison for each supportive center

On the whole, Fig. 3 compares the current condition in the studied area with the solution that the model has proposed, such as the comparison between the initial storage amount (ai) of emergency material and supply amount (xi) of emergency material in different emergency material warehouses and the comparison between the transportation time (di) and the practically critical emergency response time (T′). Meanwhile, the comparison of emergency material allocation for each supportive center among three schemes is also shown in Fig. 3. The emergency material warehouses WZ12 and WZ 15 play an important role in the actual emergency rescue process with relatively supply amount of emergency materials. However, the emergency material warehouses WZ12 and WZ18 have significant advantages in replenishing emergency materials based on their excellent locations. Meanwhile, the comparison of three emergency material allocation schemes is shown in Fig. 4. In terms of emergency response time and total supply amount of emergency materials, emergency material allocation Scheme 1, as the optimizing scheme in the allocation system, minimizes the emergency response time to make sure that the whole emergency rescue system can meet the time-varying requirements of the emergency materials with a dynamic emergency decision-making process. However, although emergency material allocation Scheme 2 requires a higher emergency response time and supply amount of emergency materials for the actual emergency decision-making, it only needs three emergency material warehouses (WZ12, WZ15, and WZ18) as supportive centers to meet the emergency material requirements of demand point J = 6 and can, in some extent, reduce the total rescue system cost and avoid potential uncertain factors in the rescue process. As for emergency material allocation Scheme 3, the emergency response time and supply amount of emergency materials compared to Scheme 1 inevitably are affected. Nonetheless, the emergency materials allocated by WA12 to risk source J = 6 can be supplied at the first time and emergency treatment technology, such as adsorption dam, can be built to prevent the pollutions from dispersing in large-scale, waiting for the follow-up emergency material support from other supportive centers. Therefore, the decision-makers can make a flexible selection among the three emergency material allocation schemes according to the different emergency pollution conditions and external environment influences.

Conclusions

In this study, an emergency material allocation framework is developed for the actual emergency rescue decision-making in response to river chemical spills. The proposed approach considers dynamic features of pollution environments so as to meet the requirements of emergency material allocation in river chemical spills and help the decision-makers to find the most suitable task allocation scheme in a quick response. The proposed framework is then applied to a computational experiment for emergency material allocation decision-making in Jiangsu province. And the results put forward the three optimizing emergency material schemes to assist decision-makers in implementing different optimizing emergency material allocation strategies coping with varying emergency pollution conditions in keeping a balance between the response time and the emergency rescue cost.

The results suggested that the developed framework was effective in reflecting dynamic and uncertainty characteristics in the actual emergency rescue decision-making process and demonstrated that (a) the developed framework can tackle the dynamic emergency material allocation problem and obtain emergency material allocation schemes under a time-varying supply-demand constraint for the actual emergency rescue decision-making; (b) the developed framework minimizes the emergency response time, satisfying time-varying emergency material demand for the whole emergency rescue system in an effective emergency response; and (c) the developed framework can help decision-makers to identify an appropriate emergency material allocation scheme with flexible decision-making according to different emergency pollution conditions with time-effective and cost-effective manners.

However, two following improvements are recommended for future studies. First, the linear characteristic to describe time-varying supply-demand relationship may require future improvements in considering more complexities expressed as fuzzy set, possibilities, and stochastic to support the developed framework for satisfying real-world applications. Thus, it can be used as an efficient tool for describing a nonlinear characteristic dealing with river chemical spill problems. Second, the developed framework has been proposed for a single pollution-affected site. It is also necessary to advance a dynamic optimization method to tackle these emergency material allocation problems for emergency rescue among multiple pollution-affected sites which may be influenced by pollution accidents in the same time.

References

Abounacer R, Rekik M, Renaud J (2014) An exact solution approach for multi-objective location-transportation problem for disaster response. Comput Oper Res 41:83–93

Amini Salehi M, Smith J, Maciejewski AA, Siegel HJ, Chong EKP, Apodaca J, Briceño LD, Renner T, Shestak V, Ladd J, Sutton A, Janovy D, Govindasamy S, Alqudah A, Dewri R, Prakash P (2016) Stochastic-based robust dynamic resource allocation for independent tasks in a heterogeneous computing system. J Parallel Distrib Comput 97:96–111

Barbarosoğlu G, Arda Y (2004) A two-stage stochastic programming framework for transportation planning in disaster response. J Oper Res Soc 55:43–53

Chang M-S, Tseng Y-L, Chen J-W (2007) A scenario planning approach for the flood emergency logistics preparation problem under uncertainty. Transport Res E: Log Transport Rev 43:737–754

Fontem B, Melouk SH, Keskin BB, Bajwa N (2016) A decomposition-based heuristic for stochastic emergency routing problems. Expert Syst Appl 59:47–59

Govindan K (2015) The optimal replenishment policy for time-varying stochastic demand under vendor managed inventory. Eur J Oper Res 242:402–423

Huang Y, Fan Y (2010) Modeling uncertainties in emergency service resource allocation. J Infrastruct Syst 17:35–41

Jiang JP, Wang P, Lung WS, Guo L, Li M (2012) A GIS-based generic real-time risk assessment framework and decision tools for chemical spills in the river basin. J Hazard Mater 227-228:280–291

Khayal D, Pradhananga R, Pokharel S, Mutlu F (2015) A model for planning locations of temporary distribution facilities for emergency response. Socio Econ Plan Sci 52:22–30

Krishna Priya GS, Bandyopadhyay S (2015) Optimum sizing of supply equipment for time varying demand. Comput Chem Eng 83:72–78

Liu J, Guo L, Jiang JP, Jiang DX, Liu RT, Wang P (2016a) A two-stage optimization model for emergency material reserve layout planning under uncertainty in response to environmental accidents. J Hazard Mater 310:30–39

Liu RT, Jiang JP, Guo L, Shi B, Liu J, Du ZL, Wang P (2016b) Screening of pollution control and clean-up materials for river chemical spills using the multiple case-based reasoning method with a difference-driven revision strategy. Environ Sci Pollut Res Int 23:11247–11256

Liu Y, Li Z, Liu J, Patel H (2016c) A double standard model for allocating limited emergency medical service vehicle resources ensuring service reliability. Transport Res C: Emerg Technol 69:120–133

Liu J, Guo L, Jiang JP, Jiang DX, Wang P (2017) Emergency material allocation and scheduling for the application to chemical contingency spills under multiple scenarios. Environ Sci Pollut Res Int 24:956–968

Luscombe R, Kozan E (2016) Dynamic resource allocation to improve emergency department efficiency in real time. Eur J Oper Res 255:593–603

Mohamadi A, Yaghoubi S (2017) A bi-objective stochastic model for emergency medical services network design with backup services for disasters under disruptions: an earthquake case study. Int J Disaster Risk Reduct 23:204–217

Omar M, Sarker R, Othman WAM (2013) A just-in-time three-level integrated manufacturing system for linearly time-varying demand process. Appl Math Model 37:1275–1281

Quinn NWT, Jacobs KC (2007) Design and implementation of an emergency environmental response system to protect migrating salmon in the lower San Joaquin River, California. Environ Model Softw 22:416–422

Sheu J-B (2007) An emergency logistics distribution approach for quick response to urgent relief demand in disasters. Transport Res E: Log Transport Rev 43:687–709

Shi SG, Cao J, Feng L, Liang W, Zhang L (2014) Construction of a technique plan repository and evaluation system based on AHP group decision-making for emergency treatment and disposal in chemical pollution accidents. J Hazard Mater 276:200–206

Su Z, Zhang G, Liu Y, Yue F, Jiang J (2016) Multiple emergency resource allocation for concurrent incidents in natural disasters. Int J Disaster Risk Reduct 17:199–212

Tzeng GH, Cheng HJ, Huang TD (2007) Multi-objective optimal planning for designing relief delivery systems. Transport Res E Log Transport Rev 43:673–686

Wang KJ, Makond B, Liu SY (2011) Location and allocation decisions in a two-echelon supply chain with stochastic demand—a genetic-algorithm based solution. Expert Syst Appl 38:6125–6131

Wex F, Schryen G, Feuerriegel S, Neumann D (2014) Emergency response in natural disaster management: allocation and scheduling of rescue units. Eur J Oper Res 235:697–708

Zhang J-H, Li J, Liu Z-P (2012) Multiple-resource and multiple-depot emergency response problem considering secondary disasters. Expert Syst Appl 39:11066–11071

Zhang C, Liu X, Jiang YP, Fan B, Song X (2016) A two-stage resource allocation model for lifeline systems quick response with vulnerability analysis. Eur J Oper Res 250:855–864

Zhao M, Chen Q (2015) Risk-based optimization of emergency rescue facilities locations for large-scale environmental accidents to improve urban public safety. Nat Hazards 75:163–189

Zhou J, Reniers G (2016) Simulation analysis of the use of emergency resources during the emergency response to a major fire. J Loss Prev Process Ind 44:1–11

Acknowledgements

The authors are extremely grateful to the editors and anonymous reviewers for their insightful comments and suggestions.

Funding

This research was supported by the National Natural Science Foundation of China (71471050) and HIT Environment and Ecology Innovation Special Funds (Grant No. HSCJ201607).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Liu, J., Guo, L., Jiang, J. et al. Emergency material allocation with time-varying supply-demand based on dynamic optimization method for river chemical spills. Environ Sci Pollut Res 25, 17343–17353 (2018). https://doi.org/10.1007/s11356-018-1489-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-1489-1