Abstract

In the Kingdom of Saudi Arabia (KSA) and Gulf region, a very small amount of municipal solid waste (MSW) is treated for compost production. The produced compost through traditional methods of compost piles and trenches does not coincide with the international standards of compost quality. Therefore, in this study, a continuous thermophilic composting (CTC) method is introduced as a novel and efficient technique for treating food waste into a quality compost in a short period of time. The quality of the compost was examined by degradation rates of organic matter (OM), changes in total carbon (TC), ash contents, pH, dynamics in ammonium nitrogen (NH4-N) and nitrate nitrogen (NO3-N), and nitrification index (NI). The results showed that thermophilic treatment at 60 °C increased the pH of the substrate and promoted degradation and mineralization process. After 30 days of composting, the degree of OM degradation was increased by 43.26 and 19.66%, NH4-N by 65.22 and 25.23%, and NO3-N by 44.76 and 40.05% as compared to runs treated at 25 and 40 °C, respectively. The stability of the compost was attained after 30 to 45 days with quality better than the compost that was stabilized after 60 days of the experiment under mesophilic treatment (25 °C). The final compost also showed stability at room temperature, confirming the rapid degradation and maturation of food waste after thermophilic treatment. Moreover, the quality of produced compost is in line with the compost quality standard of United States (US), California, Germany, and Austria. Hence, CTC can be implemented as a novel method for rapid decomposition of food waste into a stable organic fertilizer in the given hot climatic conditions of KSA and other Gulf countries with a total net saving of around US $70.72 million per year.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In developing countries, the rapid growth in population and urbanization has resulted in a massive generation of municipal solid waste (MSW) that are causing several environmental and economic problems in terms of waste magnitude and potential impacts on water, air, soil, and public health (Cardoen et al. 2015a, b). For instance, in the Kingdom of Saudi Arabia (KSA), the generation rate of MSW reached up to 15 million tons per year with 8 million tons of food waste only (Anjum et al. 2016; Nizami et al. 2017). All the collected MSW are disposed of in the dumpsites or landfills without any material recovery, which results in the soil and groundwater contamination, greenhouse gas (GHG) emissions, waste leachate, and odors along with public health issues (Khan and Kaneesamkandi 2013). In KSA, only the landfills contribute to around 76% of the country’s total methane (CH4) emissions (Wadkar et al. 2013).

Resource recovery of food waste through composting is getting significant attention worldwide as being an eco-friendly and cheap alternative waste management method (Awasthi et al. 2016). The food waste can be diverted from landfills to a beneficial compost for increasing the soil quality and crop growth (Alzaydi et al. 2013; Rahmanian et al. 2015). A limited compost by traditional methods of compost piles and trenches is carried out in KSA and other Gulf countries (Alzaydi et al. 2013). Al-Turki et al. (2013) examined the chemical characteristics of 25 different composts produced in KSA to assess their quality according to local and international standards. Similarly, Alzaydi et al. (2013) conducted a study to determine the physicochemical characteristics of randomly selected samples of compost from selected cities of KSA, including Madinah, Yanbu, Taif, Jeddah, and Makkah. The results of both studies showed that the final compost has high moisture and inorganic contents, unpleasant odors, and low nutritive value along with bad packaging and long process time. Moreover, the levels of toxic metals and micro-nutrient in produced compost were higher in some cases than the limits of European Union (EU) compost standards (Alzaydi et al. 2013; Al-Turki et al. 2013).

The process of composting occurs naturally; however, it can be accelerated through various methods such as introduction of effective microorganisms (Sun et al. 2016), chemical nitrogen activators (Chan et al. 2016), frequent turnings and shredding, and natural additives and minerals (Awasthi et al. 2016). Recently, a new approach of continuous thermophilic composting (CTC) has gained significant attention to enhance the process of organic matter (OM) degradation and produce compost in a short time duration (Xiao et al. 2009; Awasthi et al. 2016). During the CTC, the waste materials are treated at an elevated temperature (40 to 60 °C) for a certain time duration. The temperature is one of the critical parameters for monitoring the rate of biological processes in the composting (Wadkar et al. 2013). High temperature degrades all the complex molecules, reduces the volume by 40–50%, kills pathogens, removes excess moisture, and sanitizes the final product (Awasthi et al. 2016; Xiao et al. 2009; Sun et al. 2016).

In CTC, different systems have been designed such as in-vessel composting system that comprised a closed reactor to avoid heat losses during the process and retain the temperature of the process (Xiao et al. 2009). However, in the scientific literature, there is limited information available on the extrapolation of thermophilic temperature profiles during the composting process (Wadkar et al. 2013), which was the focus of this study. This study aims to develop a continuous thermophilic in-vessel treatment method for efficient food waste composting. The maturity and stability of compost were assessed against the degradation rates of organic matter (OM), changes in total carbon (TC), moisture content (MC), ash contents, pH, and nitrogen derivatives during the active composting stage along with nitrification index (NI). In the context of current knowledge on CTC, the findings of this study using an in-vessel bioreactor could lead to a novel method for treating food waste into a high-quality organic fertilizer in a relatively short period of time.

Materials and methods

Preparation of compost materials

Food waste was collected from the central canteen of King Abdulaziz University (KAU), Jeddah, KSA. The collection of food waste was carried out regularly for 1 week. The collected food waste from the KAU canteen was considered a representative sample, as the waste produced at canteen was composed of all types of food waste. The total number of individuals that enter into canteen every day for breakfast is more than 1000, whereas the total number of individuals exceeds 3000 at lunch time. The collected food waste was segregated into various materials, including vegetables, fruit and bread, meat and grain, rice, and bakery products to estimate the percentage composition of each material. Chemical characterization of collected food waste was carried out according to the standard procedures (FCQAO 1994), and their results are shown in Table 1. The resource materials were shredded and ground into a particle size of up to 2 in, in order to accelerate the biodegradation of OM during the composting process. The MC of feedstock was adjusted below 70% after sun drying for 24 h in order to initiate the composting process (Sun et al. 2016).

Experimental setup

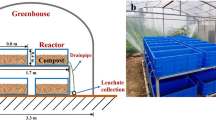

A laboratory scale in-vessel composting bioreactor made of plastic with 10 kg capacity was commissioned to perform the experiments. Dimensions of the unit were as follows: height 0.63 m, diameter 0.51 m, and thickness 10 mm (Fig. 1). About 70% of the vessel was filled with feedstock, while 30% of the area was kept as a head space. The type and capacity of the bioreactor commissioned in this study were according to the previously published works on compost experiments (Table 2). Each 7-kg shredded resource materials of food waste were loaded to the bioreactor and treated under three different temperatures for 60 days. In run A, the incubator temperature was maintained at 25 °C during the entire experimental duration. In run B, the temperature was kept at 40 °C, while in run C, it was maintained at 60 °C for the first 50 days and then was kept at room temperature for the last 10 days. The reason for this was to examine the stability of compost through changes in various physiochemical parameters (Xiao et al. 2009). Chopped dried waste leaves were added as a source of bulking agent (1:0.2) to each bioreactor, on a wet weight basis of the feedstock (An et al. 2012). The addition of bulking agent was to provide aerobic conditions to the microbes as during the initial stage, the mixture was rich in moisture (≥70%) that may lead to poor composting process due to anaerobic conditions (An et al. 2012).

The temperature was recorded from the core of the composting matrix that reached up to 40 °C due to self-heating during the initial days of the experiment. For run A, the incubator temperature was lowered down and maintained at 25 °C, while for run B, it was maintained at 40 °C. Likewise, the incubator temperature for run C was increased to 60 °C and maintained for the desired period of time. The compost mixture was turned/stirred mechanically through an agitator 2 times per day to achieve a uniform mixing and oxygen (O2) supply throughout the experiment (Shi et al. 2016). The aeration method of the composting materials through turning and mixing was followed by the procedures reported by Jindo et al. (2016), Sanchez-Garcia et al. (2015), Latifah et al. (2015), and An et al. (2012). Each experimental run was replicated three times to ensure the impact of experimental runs and to present the mean data with standard deviations.

Analytical and statistical analysis

A compost sample of 20 g was randomly taken from each bioreactor after regular interval of every 5 days throughout the experiment for assessing the compost maturity. MC (%) was determined by drying the sample in an oven at 105 °C for 24 h (Chan et al. 2016). The standard procedures of Hoogsteen et al. (2015), Robertson (2011), and FCQAO (1994)) were followed for measuring the OM, TC, and ash contents. Accordingly, the dried samples were burned at 550 °C in a muffle furnace for 3 h. The remaining mass after burning at 550 °C was measured for percent ash content according to the formula provided by McClements (2005). For analyzing pH, a 1:10 aqueous extract (w/v, wet basis) of fresh compost sample was taken with deionized water after shaking for 2 h in an oscillating shaker (EAWAG 1970). The pH was then measured through Hanna multi-parameter (HI 9828) pH probe. To avoid instrument errors, the meter was first calibrated through standard buffers, including acidic (pH 4), neutral (pH 7–7.5), and basic (pH 10) buffers. Inorganic nitrogen (NH+ 4 and NO− 3) was determined by following the test methods for the compost examination (Thompson et al. 2002). There are various indicators of compost maturity such as NI, germination index (GI), carbon dioxide (CO2) evolution, OM degradation, and microbial biomass. Among these, the most important are NI that is the ratio between NH+ 4 and NO− 3 and OM degradation (Das et al. 2011). These indicators were determined for each experimental run. NI value below 0.5 suggests a fully mature compost, while values up to 3 indicate just a mature compost and value above 3 represent an immature compost (California Compost Quality Council 2001). All of the collected data were subjected to analysis of variance test using SPSS, package 16, statistical software (SPSS Inc., Chicago, IL, USA) at the 5% probability level. Mean data are presented with a standard deviation of three replications.

Results and discussion

Moisture content

The variation in moisture content (MC) values versus the number of days for each experimental run is shown in Fig. 2. Table 3 shows MC in the final compost, whereas a comparison of this study results with other published studies is grouped in Table 4. During the initial stage, the level of MC was high (>60%) that showed the poor physical structure of the compost mixture. There was a significant variation in MC level in each experimental run with time procession. The results showed that in run C, MC was drastically reduced through time. The lowest MC (26.3%) was recorded after 20 days of the experiment, and additional water was required for adequate microbial activities (Fig. 2). The water was added because if MC drops below 30%, microbial activities virtually stop (California Compost Quality Council 2001). According to Ermolaev et al. (2015), this reduction can be attributed to higher activities of thermophilic microbes that decompose the substrate with the release of water vapors along with different gasses. Similarly, run B also showed substantial variation in MC, and it was observed that after 20 days, the MC was 51.4% that was linearly reduced throughout the experimental duration. The final MC level was observed at 33.2% (Table 3). During the active stage, the rapid decomposition produced heat that converted water into vapors. Therefore, a decline in water content happened in the compost matrix (Mohee and Mudhoo 2005; Wadkar et al. 2013).

The least variation in MC level was observed in run A, where the low compost temperature resulted in small changes in MC with the time. Data showed that in comparison to runs C and B in which a notable reduction was observed after 20 days, the required MC of <50% in run A was achieved after 50 days of the experiment (Fig. 2). Furthermore, a slow reduction of MC in run A revealed poor compost process. Statistical analysis also illustrated significant variation among different temperature protocols and time duration, whereas a significant interaction of temperature with time was also reported for food waste composting by Mohee and Mudhoo (2005) and Viel et al. (1987). The results clearly demonstrated that temperature had a vital role in the stabilization of compost (Fig. 2). These results are in line with studies in which the same trend for MC was obtained when the compost units were incubated at higher temperatures (Table 4). Furthermore, Mohee and Mudhoo (2005) and Viel et al. (1987) also stated that the active (thermophilic) phase of composting is characterized by the release of a larger volume of water from compost in the form of leachate and vapors. These observations are in line with the results of this study (Table 3).

pH

The standard deviation error bars showed that after 30 days of the experiment, no significant difference was observed in runs B and C (Fig. 2). The reason for declining pH values after achieving peak values was the release of large quantities of CO2 during decomposition of OM (An et al. 2012). These observations are in line with the work of Sun et al. (2016) and An et al. (2012), who reported that during thermophilic stage, the degradation and mineralization of complex substrate to simpler compounds occur due to the formation of free ammonia (NH3) that increases the pH. In run A, no higher values for pH were observed during the experiment. It was noticed that pH was continually declined and reached to 5.4, whereas the pH value for the final compost after 60 days was observed at 6.13 (Table 3). It shows that during mesophilic stage (temperature below 40 °C), the mesophilic microbes were not able to fully mineralize the OM into stable products. This observation is in line with the work of Liu et al. (2011), who reported that the mesophilic microbes partially degrade OM and result in the formation of different organic acids that cause lowering of compost pH. This partially decomposed OM is required to degrade further by thermophilic microbes to form a stable compost.

During the initial phase of conventional composting, a decline in pH value is observed due to the formation of organic acids by mesophilic microbes during the incomplete oxidation of OM (Wadkar et al. 2013; Liu et al. 2011). A similar phenomenon was observed in this experimental study (Fig. 2). The pH value was dropped from 6.4 to 5.9 in run B and 5.63 in run C within first 5 days, whereas in run A, the decline in pH was observed after 10 days (Fig. 3). Afterward, much higher pH value (10.1) was observed in run C after 20 days, while in run B, peak pH value of 10.1 was noticed within 30 days of the experiment. The rise in pH of the compost is due to the conversion of organic acids to CO2 and formation of ammonium nitrogen (NH4-N) by microbial action (Elango et al. 2009). After 30 days of the experiment, the pH values for runs B and C were steadily reduced with time and reached to 7.5 after 45 days with no significant change up to the end of the experiment (Fig. 2). The pH values for the final compost were within the satisfactory range (7.0–8.0), as recommended by Xiao et al. (2009) and Maso and Blasi (2008).

Variation in organic matter and ash content

The percent OM and ash content observed during the study are plotted in Fig. 3. Initially, the resource materials were rich in organics (>90%) that were decreased in different experimental runs. The results showed that OM decomposition is directly linked with temperature as it was observed that at low temperature (25 °C), a lower degradation of OM was noticed, whereas the composting bioreactor treated with elevated temperature (60 °C) showed a maximum degree of OM degradation. In response to initial OM content (92.4%), the values after 60 days were 60.18% in run A (Table 3). In run C, a drastic reduction in OM was observed after 25 days (53.5%) with no significant changes up to the end of the experiment (Fig. 3). This shows that the microbes consumed all bio-transformable and available organic components. The high rate of OM degradation in compost bioreactor incubated at high temperature can also be linked with pH, where higher substrate pH neutralizes acidic conditions and facilitates mineralization (An et al. 2012). The work of Xiao et al. (2009) reported that alkaline pH is advantageous for critical enzyme activity like ligninase and cellulose. Hence, CTC can hasten the degradation in very short time than conventional composting. Moreover, biological justification for eminent decomposition is that at high temperature, the dominant thermophilic microbes like Actinomyces sp., Bacillus sp., Clostridium thermocellum, Geobacillus sp., Hydrogenobacter sp., Methanothermobacter, Micromonospora sp., Pseudonocardia sp., Symbiobacterium sp., and Thermus thermophilus (Ryckeboer et al. 2003; Westerman and Bicudo 2005) decompose the complex organic molecules, including fats, proteins, and carbohydrates that result in a linear reduction in OM (Zhang et al. 2016). Similarly, poor organic decomposition in compost reactor incubated at 25 °C was due to low microbial activities and low pH value. These factors according to An et al. (2012) were responsible for inhibiting the composting process.

Ash is the inorganic portion that is mainly composed of cations associated with phosphates, carbonates, sulfates, and nitrates (Venglovsky et al. 2005). Decomposition process consumes O2 and produces CO2, metabolic water, and a net loss in OM that is the accumulation of inorganic components like ammonium, phosphates, and nitrates, thus increase inorganic content of the material (Zhang et al. 2016). The results showed a noticeable difference in ash content accumulation between different temperature ranges (Fig. 3). This showed a positive correlation between ash content and temperature where high ash content was determined in compost bioreactor kept at high temperature (Table 3). The values for OM decomposition and ash content in run B showed that 40 °C is a separation point on which thermophilic stage dominates the mesophilic stage. ANOVA for OM and ash content showed significant variation among experimental duration and temperature regimes, whereas interaction of both factors was also recorded highly significant. Standard deviation error bar revealed that after 30 days, no significant difference had been observed between experimental runs B and C.

Total carbon

The total carbon (TC) value of food waste was 51.34% (Table 1). All experimental runs showed different trends in TC. The NI was decreased quickly to stable values in run C followed by run B, whereas a slow decrease was noticed in run A (Fig. 3). The decline in TC is an indicator of compost maturity (Bernal et al. 2009). In run C, TC descended quickly during the first 25 days and then stabilized to 29.7%, as afterward no significant changes were observed (Fig. 3). For run B, a gradual decrease in TC was observed through time interval, and after 40 days, stability in terms of TC was achieved. The maximum reduction in TC showed a high decomposition rate in both runs B and C, whereas low reduction in TC in run A showed the poor process. Mean values for TC in compost after 60 days were 33.4% in run A, 25.7% for run B, and 27.9% for run C (Table 3).

Microbes decompose the organic materials from which carbon is used as an energy source while nitrogen is utilized for the formation of cell structure (Elango et al. 2009). Tiquia (2005) reported a direct relation of temperature rise with microbial diversity and their activities. At high temperature, specialized microbes metabolize complex compounds like lignin more than 2/3, whereas during mesophilic stage, only readily degradable components are metabolized by the mesophilic microbes (Rashid et al. 2016). Compaction in substrate occurs when carbon compounds collapse and demolish as a result of biodegradation during composting. Therefore, a high bulk density in compost material is observed as compared to the initial waste substrate (Awasthi et al. 2016). The results of TC as shown in Table 3 are in line with the work of Mena et al. (2003) and Bernal et al. (2009), which reported that during the thermophilic stage, a reduction in TC occurs due to the conversion of organic carbon to inorganic compounds along with CO2 production, whereas in later stages, low changes in TC were due to a reduction in readily degradable organic carbon (Turan and Ergun 2007).

Ammonium nitrogen, nitrate nitrogen, and nitrification index

The initial NH+ 4-N content in the composting materials was 72.5 mg/kg (Table 1). Table 3 shows NH+ 4-N content in final compost, whereas Fig. 4 shows a variation in NH+ 4-N content in all experimental runs. ANOVA results demonstrated that temperature protocols, experiment duration, and their interaction had significant variation in terms of mineral nitrogen contents. During the first 5 days, the only minor difference in NH+ 4-N content was examined, whereas with compost procession, a rapid increase in run C was observed. After 30 days of the experiment, a peak value of 187.2 mg/kg for NH+ 4-N content was observed (Fig. 4). Similarly, in run B, a rapid mineralization resulted in a high accumulation of NH+ 4-N, and after 35 days, the maximum value of 167.8 mg/kg was observed. Run A showed the least rise in NH+ 4-N concentration that showed low compost process. After achieving peak values, a gradual decrease with time was observed that reached up to 149.3 and 163.5 mg/kg in runs B and C, respectively, at the end of the experiment (Table 3). This slight decrease in the concentration was due to nitrification phenomenon along with the formation and emissions of NH3 (Awasthi et al. 2016).

Formation and volatilization of free NH3 can coincide with high pH values. Maximum production of NH3 occurs at high pH. In this study, when pH became neutral, the stabilization in NH+ 4-N content was observed. This stabilization can coincide with inhibition in the conversion of NH+ 4-N to NH3. The process of ammonification results in the production of ammonium during degradation of OM (Sanchez-Monedero et al. 2001). The level of NH+ 4-N observed in each experimental run reflected the rate of nitrogen transformation and degradation process. High-temperature composting bioreactor showed high degradation rates in comparison to the low-temperature bioreactor (Fig. 4). These results are in line with the work of Hu et al. (2009), who reported that when composting reaction reached to thermophilic phase, the active mineralization leads to high NH+ 4-N accumulation. However, low degradation rates during composting hinder nitrogen transformation processes (An et al. 2012).

The changes in NO− 3-N showed that by increasing reactor temperature, an increased nitrification process was observed. A high concentration of NO− 3-N was recorded in run C (Fig. 4). The results showed that with time, a linear increase in run C was observed that reached up to 102.6 mg/kg after 35 days followed by run B with NO− 3-N contents 92.2 mg/kg after 45 days. The utmost value for NO− 3-N in run A was 63.3 mg/kg after 40 days of the experiment (Fig. 4). On the last day of experiment, the NO− 3-N concentration was 47.1 mg/kg in run A, 76.6 mg/kg in run B, and 87.3 mg/kg in run C (Table 3). The results confirmed that high nitrification rate occurred in composting bioreactor incubated at high temperature. A similar trend was also observed by Makaly et al. (2000), who reported that NO− 3-N concentration increased to specific values and after that decreased to certain values.

The possible factors behind this reduction are changes in the concentration of NH3, MC, and pH (Al-Jabi et al. 2008). Similarly, low NO− 3-N content accumulation at low temperature (25 °C) was due to anaerobic conditions that resulted in high MC, which inhibited the conversion of NH3 to nitrates (Turan and Ergun 2007). The results of this study are not in agreement with the findings of Al-Jabi et al. (2008) that reported inhibition of nitrification process when the temperature exceeded to 40 °C due to the activity of nitrobactors, whereas other indicated that the oxidizing activities of nitrosomonas from NH3 to nitrates are not disturbed even at high temperature (above 60 °C) (Xiao et al. 2009; Westerman and Bicudo 2005). Therefore, it proved that at thermophilic temperature, certain microbes are present, which can sustain and degrade complex components into simpler molecules (Turan and Ergun 2007).

The values of NI for all experimental runs are shown in Table 3 and Fig. 5. The stability and maturity in run C were achieved after 25 days, while in run B, it was achieved after 40 days. In run A, a non-linear trend was observed with NI value of 2.6 at the end of the experiment (Table 3). High biological activities in run C resulted in a more stable product in a relatively short period as compared to run A (Fig. 5). Current results are in agreement with the findings of Xiao et al. (2009) who reported that CTC could short the processing time.

A route to successful implementation of thermophilic composting in Gulf regions

Composting is gaining significant attention in comparison to other waste treatment technologies for material recovery due to its easy implementation and affordable economics (Awasthi et al. 2016). From an economic perspective, composting saves waste disposal and landfill cost by diverting the waste from disposal to valuable organic fertilizer. In the case of KSA, the total amount of food waste is around 8 million tons per year. According to Nizami et al. (2017), the disposal of waste to landfill in KSA costs about US $50 to US $100 per ton depending on the area and type of waste. Therefore, the conversion of KSA’s food waste to organic fertilizer will directly save the disposal cost (tipping fees) that amounts up to US $40 million per year considering the waste disposal cost of US $50 as a conservative value (Table 5). In addition, the produced compost can play a major role in revenue generation due to its high market value with price that ranged from US $50 to US $200 per ton. Hence, after compensating the operating cost of around US $220.48 million for food waste compost facility in KSA, a total net saving from the compost facility can be around US $70.72 million per year (Table 5).

The findings of this study along with the economic benefits of the compost recommend that future research should be focused on treating the waste containing complex compounds in an economical way. For instance, the CTC of sludge from industrial wastewater treatment comprised antibiotics, dyes, pathogens, and phytotoxic compounds (Khan et al. 2017). These compounds mostly remained unaffected during natural composting due to the short thermophilic stage. Similarly, slaughterhouse waste is also problematic for the Gulf countries due to the presence of complex substances like fats and high organic nitrogen that resist degradation. Therefore, CTC could be a suitable option for reduction and stabilization of these complex wastes into value-added products. Moreover, further research is required on the potential of various resources that can be added to the composting system as amendments, including biochar and natural zeolites to optimize the overall process. Nevertheless, other technologies should also be examined for treating food waste such as microbial fuel cells (MFCs) in which food waste can be used for renewable energy production (Pasupuleti et al. 2015). The energy production of MFCs can be enhanced due to heterogeneous nutrient mixture of food waste that will act as a biocatalyst to meet the electron requirement by the circuit.

Conclusions

The composting of food waste at high temperature can reduce the process time without compromising the compost quality. The compost stability was achieved within 30 to 45 days in run C after high-temperature (60 °C) treatment and even remained unchanged when kept at room temperature. This confirms the rapid degradation and maturation of food waste after thermophilic treatment. Moreover, the quality of produced compost was in line with compost standard of United States (US), California, Germany, and Austria. Therefore, it is concluded that heating the materials to an elevated temperature and maintaining that temperature throughout the composting process along with a suitable supply of air and turning of the pile can complete the compost cycle in 30 to 45 days. This will also assure the appropriate sanitization of final compost according to the international guidelines of compost handling and production. Hence, considering the significant generation of food waste and hot and desert climatic conditions of the Kingdom of Saudi Arabia (KSA) and other Gulf countries, composting either in-vessel or windrow or aerated static pile can be a promising alternative for producing a quality organic fertilizer in relatively short period of time. Composting will not only provide sustainable management to municipal solid waste (MSW) in Gulf countries but will also fulfill compost demand in the region that was estimated to be about 500,000 tons per year in 2015 only in KSA with total net savings of US $70.72 million per year.

References

Al-Jabi LF, Halalsheh MM, Badarneh DM (2008) Conservation of ammonia during food waste composting. Environ Technol 29(10):1067–1073

Al-Turki A, El-Hadidy Y, Al-Romian F (2013) Assessment of chemical properties of locally composts produced in Saudi Arabia composts locally produced. Int J Curr Res 5:3571–3578

Alzaydi A, Alsolaimani S, Ramadan M (2013) Demand, practices and properties of compost in the western region of the Kingdom of Saudi Arabia. Aus J Basic Appl Sci 7(7):768–776

An CJ, Huang GH, Yao Y, Sun W, An K (2012) Performance of in-vessel composting of food waste in the presence of coal ash and uric acid. J Hazard Mater 203:38–45

Anjum M, Miandad R, Waqas M, Tarar IA, Alafif Z, Aburiazaiza AS, Barakat MA, Akhtar T (2016) Solid waste management in Saudi Arabia: a review. J App Agric Biotechnol 1(1):13–26

Awasthi MK, Pandey AK, Bundela PS, Wong JW, Li R, Zhang Z (2016) Co-composting of gelatin industry sludge combined with organic fraction of municipal solid waste and poultry waste employing zeolite mixed with enriched nitrifying bacterial consortium. Bioresour Technol. doi:10.1016/j.biortech.2016.02.026

Ballardo C, Abraham J, Barrena R, Artola A, Gea T, Sánchez A (2016) Valorization of soy waste through SSF for the production of compost enriched with bacillus thuringiensis with biopesticide properties. J Environ Manag 169:126–131

Bernal MP, Alburquerque JA, Moral R (2009) Composting of animal manures and chemical criteria for compost maturity assessment: a review. Bioresour Technol 100:5444–5453

California Compost Quality Council (2001) California Compost Quality Council, 2001. CCQC-Compost Maturity Index

Cardoen D, Joshi P, Diels L, Sarma PM, Pant D (2015a) Agriculture biomass in India: part 2. Post-harvest losses, cost and environmental impacts. Resour Conserv Recycl 101:143–153

Cardoen D, Joshi P, Diels L, Sarma PM, Pant D (2015b) Agriculture biomass in India: part 1. Estimation and characterization. Resour Conserv Recycl 102:39–48

Chan MT, Selvam A, Wong JW (2016) Reducing nitrogen loss and salinity during ‘struvite’ food waste composting by zeolite amendment. Bioresour Technol 200:838–844

Das M, Uppal HS, Singh R, Beri S, Mohan KS, Gupta VC, Adholeya A (2011) Co-composting of physic nut (Jatropha curcas) deoiled cake with rice straw and different animal dung. Bioresour Technol 102(11):6541–6546

EAWAG (1970) Methods of sampling and analysis of solid wastes. Swiss Federal Institute for Water Supply, Sewage Purification and Water Pollution Control, Dubendorf

Elango D, Thinakaran N, Panneerselvam P, Sivanesan S (2009) Thermophilic composting of municipal solid waste. Appl Energy 86(5):663–668

Ermolaev E, Jarvis A, Sundberg C, Smars S, Pell M, Jönsson H (2015) Nitrous oxide and methane emissions from food waste composting at different temperatures. Waste Manag 46:113–119

FCQAO (1994) Methods book for analysis of compost (125 p. Federal, Stuttgart

Hoogsteen MJJ, Lantinga EA, Bakker EJ, Groot JCJ, Tittonell PA (2015) Estimating soil organic carbon through loss on ignition: effects of ignition conditions and structural water loss. Eur J Soil Sci 66(2):320–328

Hu Z, Lane R, Wen Z (2009) Composting clam processing wastes in a laboratory-and pilot-scale in-vessel system. Waste Manag 29:180–185

Jia X, Wang M, Yuan W, Ju X, Yang B (2016) The influence of biochar addition on chicken manure composting and associated methane and carbon dioxide emissions. BioResourc 11(2):5255–5264

Jindo K, Sonoki T, Matsumoto K, Canellas L, Roig A, Sanchez-Monedero MA (2016) Influence of biochar addition on the humic substances of composting manures. Waste Manag 49:545–552

Khan MSM, Kaneesamkandi Z (2013) Biodegradable waste to biogas: renewable energy option for the Kingdom of Saudi Arabia. Intl J Innovation App Stud 4(1):101–113

Khan MZ, Nizami AS, Rehan M, Ouda OKM, Sultana S, Ismail IMI, Shahzad K (2017) Microbial electrolysis cells for hydrogen production and wastewater treatment: a case study of Saudi Arabia. Appl Energy 185(1):410–420

Latifah O, Ahmed OH, Susilawati K, Majid NM (2015) Compost maturity and nitrogen availability by co-composting of paddy husk and chicken manure amended with clinoptilolite zeolite. Waste Manag Res 33(4):322–331

Liu D, Zhang R, Wu H, Xu D, Tang Z, Yu G, Shen Q (2011) Changes in biochemical and microbiological parameters during the period of rapid composting of dairy manure with rice chaff. Bioresour Technol 102(19):9040–9049

Madrini B, Shibusawa S, Kojima Y, Hosaka S (2016) Effect of natural zeolite (clinoptilolite) on ammonia emissions of leftover food-rice hulls composting at the initial stage of the thermophilic process. J Agric Meteorol 72(1):12–19

Makaly BE, Mortier H, Verstraete W (2000) Nitrogen transfer from grey municipal solid waste to high quality compost. Bioresour Technol 73(1):47–52

Makan A, Assobhei O, Mountadar M (2014) Initial air pressure influence on in-vessel composting for the biodegradable fraction of municipal solid waste in Morocco. Intern J Environ Sci Technol 11(1):53–58

Maso MA, Blasi AB (2008) Evaluation of composting as a strategy for managing organic wastes from a municipal market in Nicaragua. Bioresour Technol 99(11):5120–5124

McClements DJ (2005) Food emulsions: principles, practice and techniques, 2nd edn. CRC Press, Boca Raton

Mena E, Garrido A, Hernandez T, Garcia C (2003) Bioremediation of sewag sludge by composting. Commun Soil Sci Plant Anal 34(7):957–971

Mohee R, Mudhoo A (2005) Analysis of the physical properties of an in-vessel composting matrix. Powder Technol 155(1):92–99

Nakasaki K, Nagasaki K, Ariga O (2004) Degradation of fats during thermophilic composting of organic waste. Waste Manag Res 22(4):276–282

Nizami AS, Shahzad K, Rehan M, Ouda OKM, Khan MZ, Ismail IMI, Almeelbi T, Basahi JM, Demirbas A (2017) Developing waste Biorefinery in Makkah: a way forward to convert urban waste into renewable energy. App Energy 186(2):189–196

Pasupuleti SB, Srikanth S, Mohan SV, Pant D (2015) Continuous mode operation of microbial fuel cell (MFC) stack with dual gas diffusion cathode design for the treatment of dark fermentation effluent. Intern J Hydrogen Energy 40(36):12424–12435

Rahmanian N, Ali SHB, Homayoonfard M, Ali NJ, Rehan M, Sadef Y, Nizami AS (2015) Analysis of Physiochemical Parameters to Evaluate the Drinking Water Quality in the State of Perak, Malaysia. J Chem 2015:1–10. doi:10.1155/2015/716125

Rashid MI, Mujawar LH, Shahzad T, Almeelbi T, Ismail IMI, Oves M (2016) Bacteria and fungi can contribute to nutrients bioavailability and aggregate formation in degraded soils. Microbiol Res 183:26–41

Robertson S (2011) Direct estimation of organic matter by loss on ignition: methods. SFU Soil Science Lab, Burnaby 11p

Ryckeboer J, Mergaert J, Coosemans J, Deprins K, Swings J (2003) Microbiological aspects of biowaste during composting in a monitored compost bin. J app Microbiol 94(1):127–137

Sadaka S, El-Taweel A (2003) Effects of aeration and C: N ratio on household waste composting in Egypt. Compost Sci Utiliz 11(1):36–40

Sanchez-Garcia M, Alburquerque JA, Sánchez-Monedero MA, Roig A, Cayuela ML (2015) Biochar accelerates organic matter degradation and enhances N mineralisation during composting of poultry manure without a relevant impact on gas emissions. Bioresour Technol 192:272–279

Sanchez-Monedero MA, Roig A, Paredes C, Bernal MP (2001) Nitrogen transformation during organic waste composting by the Rutgers system and its effects on pH, EC and maturity of the composting mixtures. Bioresour Technol 78:301–308

Shi H, Wang XC, Li Q, Jiang S (2016) Degradation of typical antibiotics during human feces aerobic composting under different temperatures. Environ Sci Poll Res 23:1–12

Stamou I, Antizar-Ladislao B (2016) The impact of silver and titanium dioxide nanoparticles on the in-vessel composting of municipal solid waste. Waste Manag 56:71–78

Sun D, Lan Y, Xu EG, Meng J, Chen W (2016) Biochar as a novel niche for culturing microbial communities in composting. Waste Manag 54:93–100

Thompson WH, Leege P, Millner P, Watson M (2002) Test methods for the examination of composting and compost (TMECC) Washington, US Composting Council Research and Education Foundation and the United States Department of Agriculture

Tiquia SM (2005) Microbial community dynamics in manure composts based on 16S and 18S rDNA T-RFLP profiles. Environ Technol 26:1101–1114

Turan NG, Ergun ON (2007) Ammonia uptake by natural zeolite in municipal solid waste compost. Environ Prog 26(2):149–156

Venglovsky J, Sasakova N, Vargova M, Pacajova Z, Placha I, Petrovsky M, Harichova D (2005) Evolution of temperature and chemical parameters during composting of the pig slurry solid fraction amended with natural zeolite. Bioresour Technol 96(2):181–189

Viel M, Sayag D, Andre L (1987) Optimisation of agricultural industrial wastes management through in-vessel composting. Biol Wastes 20(3):167–185

Wadkar DV, Modak PR, Kote AS (2013) Aerobic-thermophilic composting of municipal solid wastes using solar energy. J Environ Res Develop 7(4A):1489–1495

Wang JY, Stabnikova O, Ivanov V, Tay STL, Tay JH (2003) Intensive aerobic bioconversion of sewage sludge and food waste into fertiliser. Waste Manag Res 21(5):405–415

Westerman PW, Bicudo JR (2005) Management considerations for organic waste use in agriculture. Bioresour Technol 96:215–221

Xiao Y, Zeng GM, Yang ZH, Shi WJ, Huang C, Fan CZ, Xu ZY (2009) Continuous thermophilic composting (CTC) for rapid biodegradation and maturation of organic municipal solid waste. Bioresour Technol 100(20):4807–4813

Zhang J, Lü F, Shao L, He P (2014) The use of biochar-amended composting to improve the humification and degradation of sewage sludge. Bioresour Technol 168:252–258

Zhang J, Sui Q, Li K, Chen M, Tong J, Qi L, Wei Y (2016) Influence of natural zeolite and nitrification inhibitor on organics degradation and nitrogen transformation during sludge composting. Environ Sci Poll Res 23(2):1324–1334

Acknowledgments

Authors acknowledge the Deanship of Scientific Research (DSR) at King Abdulaziz University, Jeddah, Saudi Arabia for financial support to complete this work. Authors are also thankful to King Abdulaziz University for their financial and technical assistance to our Center of Excellence in Environmental Studies (CEES).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Waqas, M., Almeelbi, T. & Nizami, AS. Resource recovery of food waste through continuous thermophilic in-vessel composting. Environ Sci Pollut Res 25, 5212–5222 (2018). https://doi.org/10.1007/s11356-017-9358-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9358-x