Abstract

A sensitive and selective method was developed and validated for the determination of pyrethrin residues in turnips (turnip leaves, turnip tubers, and the whole of plant) and cultivated soil using gas chromatography coupled with mass spectrometry (GC-MS). Six major components of pyrethrins (pyrethrin I and II, cinerin I and II, and jasmolin I and II) were separated and identified. The method involving solid-phase extraction (SPE) cleanup led to satisfactory average recoveries (88.1–104%) with limits of quantification (LOQs) of 0.05 mg/kg. The dissipation and final residue of pyrethrins in six provinces (among these places, two experiments were conducted in greenhouse and other four experiments in open filed) in China were studied. The trial results suggested that the half-lives of pyrethrins in the whole of turnips and soil were 0.5–1.6 and 1.0–1.3 days, respectively, and the degradation of pyrethrins in the greenhouse was quicker than that in open fields. The final residues of pyrethrins in turnip leaves and tubers were all below the maximum residue limit (MRL) established by the EU (1.0 mg/kg). A pre-harvest interval of 2 days and MRL of 1.0 mg/kg are recommended to ensure food safety standards for pyrethrins in turnips. Long-term risk assessment and short-term risk assessment of turnip tubers were evaluated. Hazard quotient (HQ) and acute hazard index (aHI) were significantly less than 100%, indicating negligible risk for consumption of turnip tubers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

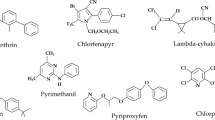

Pyrethrum is extracted from dried and powdered flowers of Tanacetum cinerariifolium, a type of Chrysanthemum. Pyrethrum has been safely applied as an insecticide since a long time ago (Meurer-Grimes 1996; Copping 1998). Its active ingredients are called pyrethrins, which consist of six esters named pyrethrin I and II, cinerin I and II, and jasmolin I and II (Fig. 1) (Lu et al. 2010). Pyrethrin I and II are the major constituents. The relative level of these six compounds and the ratio between pyrethrin I and II are affected by the plant type, the stage of harvest, and the region where the plants grow. Pyrethrin I has a lethal effect, whereas pyrethrin II has a knockdown effect against insects. This difference of action against insects makes their ratio important (Angioni et al. 2005). At present, pyrethrins have been widely used as household insecticides, post-harvest pesticides for crops, and for pest prevention in fruits and vegetables before harvest (Cheng et al. 2005).

Turnips, herbaceous plants of Cruciferae, are cultivated in Europe, Asia, and America. Their roots are edible and rich in sugars, crude protein, and fiber, and they are typically consumed after being fried, boiled, or pickled. Turnips are increasingly becoming popular especially in China. However, turnip cultivation involves high pesticide application to prevent and control viral diseases, mainly those spread by aphids, cabbage webworm, and flea beetle. Among the pesticides used, pyrethrins have been widely used in turnip production because of their high efficiency to control insects at low doses.

Recently, there have been increasing awareness and concern about pyrethrin residues in turnips. The residue definition for compliance with maximum residue limit (MRL) and estimation of dietary intake was total pyrethrins, calculated as the sum of pyrethrin I and II, cinerin I and II, and jasmolin I and II, which was reported by Joint Meeting on Pesticide Residues (JMPR) (Food and Agriculture Organization of the United Nations 2005).The MRL of pyrethrins in turnips is legislated at 1.0 mg/kg by Regulation (EU) No. 396/2005 (The Commission of the European Communities 2008), Japan (The Japan Food Chemical Research Foundation 2006), Australia (Australian Pesticides and Veterinary Medicines Authority 2017), and Korea (Korea Food and Drug Administration 2012). In China, the MRL is not yet established.

Several methods have been developed for the analysis of pyrethrin residues with different matrices using high-performance liquid chromatography (HPLC) (Feo et al. 2010; Leng and Gries 2005), HPLC-MS (Ruiz et al. 2011), liquid chromatography-mass spectrometry (HPLC-MS/MS) (Lu et al. 2010; Peruga et al. 2013), gas chromatography (GC) (Campillo et al. 2006; Chen et al. 2009; Ding et al. 2006; Ding et al. 2007; Wang 2013), and gas chromatography-mass spectrometry (GC-MS) (Feo et al. 2010; Huang 2004; Rawn et al. 2010; Song et al. 2007; Woudneh and Oros 2006) with solid-phase extraction (SPE), dispersive solid phase extraction (d-SPE), or no cleanup. However, the analytical procedures for pyrethrin residues in turnips have not been investigated. In addition, because pyrethrins are applied onto the leaves of turnip plants and can rapidly degrade upon exposure to sunlight, it is difficult to analyze trace amounts of pyrethrin residues in turnips, especially in tubers.

It is important to calculate the rate of pesticide digestion to assess the performance of pesticide residues after application (Omirou et al. 2009). To ensure that pesticide residues are less than the stated MRL at harvest, a pre-harvest interval (PHI) is also proposed in MRL regulations (Karmakar and Kulshrestha 2009). With the increasing use of pyrethrins in turnips, there is now considerable attention for determining and monitoring pyrethrin residues in turnip plants. However, there are no residue and dissipation reports of pyrethrins in turnips thus far.

The objective of this study was to develop and validate an effective and sensitive method for the analysis of trace levels of pyrethrins in turnips (leaves, tubers, and the whole plants) and soil. This study was also designed to investigate dissipation dynamics and terminal residues of pyrethrins in open fields and greenhouse. Besides, human exposure to pyrethrin residues via turnips intake was estimated, and the long-term risk and short-term risk were evaluated. The results provide directions on the proper and safe application of pyrethrins.

Materials and methods

Materials and reagents

Pyrethrins (technical grade 30%) were obtained from Toronto Research Chemicals Inc. (Canada). The standard stock solution (1000 mg/L) of pyrethrins was dissolved with acetone and stored at −20 °C. The working solution (100 mg/L) was also ready and stored at −20 °C. Acetone and n-hexane were both supplied by Mreda Technology Inc. (Beijing, China) while acetonitrile was supplied by Fisher (Shanghai, China), and they were all HPLC grade. Anhydrous sodium sulfate (Na2SO4) and sodium chloride (NaCl) were supplied by Beijing Chemical Reagents Company (Beijing, China). CNWBOND Florisil SPE Cartridge (500 mg, 3 mL), CNWBOND HC-C18 SPE Cartridge (500 mg, 3 mL), and CNWBOND NH2 SPE Cartridge (500 mg, 3 mL) were all obtained from ANPEL Laboratory Technologies Inc. (Shanghai, China). The formulation, an emulsion in water (EW) containing 1.5% pyrethrins, was kindly provided by Inner Mongolia Qingyuan Paul Biotechnology Co. Ltd. (Inner Mongolia, China).

Field experiments

The study including a dissipation dynamic experiment and a final residue experiment was conducted at six different places, Beijing City, Jiangsu Province, Hunan Province, Zhejiang Province, Heilongjiang Province, and Shandong Province in the year 2016. Among these provinces, in Heilongjiang and Shandong Provinces, the field experiments were conducted in greenhouses. The dissipation and final residue experiments were performed simultaneously only in two places (Beijing and Shandong), while in other four places, only the final residue experiment were conducted.

The design of the field experiment for dissipation and residue is shown in Table 1. There were seven treatments including six pyrethrin treatments and one control treatment. Each treatment consisted of three replicate plots (except for soil dissipation) and each plot was 30 m2. In the control treatment, no pesticide was used but the same amount of water was sprayed throughout the period. The plots of different treatments were separated by a buffer area of 30 m2.

For the purpose of evaluating the dissipation of pyrethrins in whole plants and soil, 1.5% pyrethrin EW was dissolved in water and applied at active constituent 60.75 g a.i./ha (gram of active gradient per hectare, 1.5 times the recommended high dosage) on the surface of plants and soil. Whole plant turnips (about 1 kg) and the soil (0–10-cm depth, 1–2 kg) were randomly collected at 2 h, 1, 2, 3, 5, 7, 10, 14, 21, and 30 days (only soil) after application.

The dosage levels for the terminal residue experiments were set at 40.5 g a.i./ha (recommended high dosage) and 60.75 g a.i./ha. Each treatment was sprayed three and four times, respectively. All the experiments were set at three intervals of 2, 5, and 7 days between the last pesticide application and turnip harvest time. Turnip plants (leaves and tubers) and soil samples were collected at random from each plot, ensuring the sample representative.

Collected samples of turnip plants (leaves, tubers, and whole plants) were homogenized with a blender (Philips, China). All samples were stored at −20 °C for further analysis.

Sample pre-treatment

Turnip leaves, turnip tubers, the whole plants, and soil samples (20 g) were weighed into 50-mL plastic centrifuge tubes. Samples were subsequently mixed and extracted for 2 min with 20 mL acetonitrile and 3 g NaCl by a vortex mixer and then centrifuged for 5 min at 3800 rpm. A volume of 10 mL supernatant acetonitrile was transferred into a 100-mL flask. Then, it was rotary concentrated to an almost-dry state (about one drop of liquid) and blown to dryness with nitrogen. The residue was redissolved with 1 mL acetone + n-hexane (1 + 9; v + v) for SPE cleanup. Anhydrous Na2SO4 (1 g) was added into Florisil SPE cartridge and preconditioned with 10 mL n-hexane, and then, the extract was introduced into the Florisil SPE cartridge. The compounds in the cartridge were eluted with 10 mL acetone + n-hexane (1 + 9; v + v), collected in a flask, and evaporated to dryness. The residue was dissolved with 1 mL acetone and filtered with 0.22-μm filter membrane for GC-MS analysis.

GC-MS conditions

GC-MS analysis was conducted with an Agilent Technologies 6890N GC system equipped with an Agilent 7683 series autosampler, mass selective detector (MSD) model 5975B network, and a 30 m × 0.25-mm (i.d.) DB-5MS fused-silica capillary column (0.25-μm film thickness). An aliquot of 2 μL of sample extract was injected into the gas chromatography. The injector temperature was set at 260 °C and the carrier gas was helium (99.999% purity) at a flow rate of 1.2 mL/min. The oven temperature program was initially kept at 100 °C for 1 min, then ramped up at a rate of 10 °C/min to 270 °C and held for 1 min, then finally ramped at 1 °C/min to 280 °C and held for 1 min.

The mass spectrometer was in the electron ionization mode. Ion source, quadrupole, and transfer line temperatures were 230, 150, and 280 °C, respectively. Solvent delay time of 4.0 min was set. The MS system was set in selective ion monitoring (SIM) mode, and the mass spectra were obtained at the electron energy of 70 eV. GC-MS conditions of pyrethrins are shown in Table 2.

Statistical analysis

The levels of pyrethrin residues (the sum of pyrethrin I and II, cinerin I and II, and jasmolin I and II) in samples were calculated according to Eq. (1):

where X is the concentration (mg/kg) of pyrethrin residues in the test samples, ∑A i represents the total peak area of pesticide residues in the sample extraction solution, c is the concentration (mg/L) of pesticide residues in the standard working solution, V represents the final volume (mL) of the sample extraction solution, ∑A si is the total peak area of pesticide residues in the standard working solution, and m is the corresponding mass (g) of the test sample in the final sample solution.

The dissipation patterns of pyrethrins in the whole turnip plants and soil were fitted using the first-order kinetic equation (Eq. (2)), and half-life of residue dissipation was calculated using Eq. (3).

where t represents the time (day) between pesticide application and turnip harvest, C 0 represents the initial concentration (mg/kg), C is the residue concentration (mg/kg) at time t, k is the degradation coefficient (day−1), and t 1/2 is the time required for the pesticide residue level to fall to half of initial residue level after pesticide application. Systat Sigmaplot v12.0 software was used in the statistical process of fitting k.

Dietary exposure and long-term consumer risk assessment of turnip tubers were calculated by using the following equations (Lin et al. 2017):

And the short-term risk assessment were calculated using Eqs. (6) and (7):

where EDI represents the estimated daily intake (mg/kg bw day), STMR is the calculated median residue level (mg/kg), Fi is the daily turnip tuber intake (kg/day), bw is the mean body weight (bw; kg), ADI represents the acceptable daily intake of pyrethrins (mg/kg/day bw), ESTI is the estimated short-term daily intake (mg/kg bw day), HR is the calculated highest residue level (mg/kg), ARfD is the acute reference dose (mg/kg bw), and HQ and aHI are the hazard quotient and acute hazard index, respectively.

Results and discussion

Optimization of GC-MS conditions

In order to monitor pesticide residues, GC with flame ionization detector (FID), electron capture detector (ECD), and mass spectrometry (MS) detection have been widely used. It is feasible to develop multi-residue analysis methods for the emergence of MS systems. Moreover, the MS systems increase the specificity of target pesticide identification and achieve high-sensitivity trace-level determination (Picó et al. 2004; Picó et al. 2000).

The temperature-rising procedure is a key parameter influencing retention time, selectivity, and peak shape in GC separation, especially for the analysis of multi-residues. In this work, because of the late retention time of the six compounds, elevated temperature was initially set as 100 °C. Thereafter, the rates of temperature rising of 5, 10, 15, and 20 °C/min were initially tested. Better separation and sharper peaks were obtained at a ramped rate of 10 °C/min. For separation of jasmolin II and pyrethrin II, the heating speed after 270 °C was reduced, and rates of 0.5, 1, and 2 °C/min were tested. Jasmolin II and pyrethrin II could not be separated when the temperature was increased at intervals of 2 °C/min. However, a good separation of these two compounds was obtained when the intervals were changed to 0.5 and 1 °C/min, but sharper peaks were achieved in the latter case. For the purpose of saving time, 280 °C (hold for 1 min) was set as the end of the temperature-rising procedure and all compounds showed satisfactory response during this period (Fig. 2).

Optimization of sample pre-treatment

Three extracting solvents of acetonitrile, −diethyl ether, and acetone were considered in this study. Though there is better solubility of pyrethrins in the latter two solvents, they are harmful to people because of their low boiling point and high volatility, especially for acetone, which induces paralysis effects in the nervous system (Zhu 2013). Therefore, acetonitrile, as a common polar organic solvent, was chosen as the extraction solvent, ensuring satisfactory extraction efficiency for pyrethrins. NaCl was subsequently added, which was helpful for the separation of aqueous and organic phases, improving the extraction efficiencies.

There were three SPE cartridges (C18, Florisil, and NH2) compared with cleanup in subsequent steps. As shown in Fig. 3, poor recoveries were obtained with C18 and NH2 SPE cartridges, which were 62.3, 68.2, 74.6, and 60.8% and 58.3, 70.4, 47.3, and 63.4% for leaves, tubers, the whole plant, and soil, respectively. Even when the amount of eluent was increased, there was no obvious improvement for recoveries. This may be because pyrethrins were adsorbed onto the sorbent. As such, the two SPE cartridges were not suitable for cleaning up pyrethrins. Satisfactory recovery (70–110%) and purification results were obtained when Florisil SPE cartridge was investigated. Thus, Florisil SPE cartridge was employed for cleanup.

Method validation

The use of matrix-matched calibration is a common approach that could avoid the impact of possible matrix enhancement or suppression effects on the quantitative analysis. Because the level of pyrethrin residues in practical samples is the total quantities of six analytes, which was calculated using Eq. (1), we used the total quantities of the six analytes to verify the method. Known pesticide amounts were added to the four representative extracts (turnip leaves, turnip tuber, the whole plant, and soil) from control plots to obtain the matrix-matched calibration solutions. Linearity experiments of pyrethrins were performed in the range of 0.2–10 mg/L for all matrices. Satisfactory linearity was achieved with correlation coefficient (R 2) higher than 0.99. The limit of detection (LOD) was defined as the concentration with a signal-to-noise ratio (S/N)of 3, and the limit of quantification (LOQ) was the lowest spiking level (You et al. 2014). The LODs of the pyrethrins ranged from 0.012 to 0.024 mg/kg and the LOQs were 0.05 mg/kg, which are shown in Table 3.

Recovery studies were estimated by spiking the blank samples at three different concentration levels (0.05, 0.1, and 1.0 mg/kg). Five parallel samples for each spiking level were extracted, purified, and analyzed according to above methods (Ferrer et al. 2011). As shown in Table 4, the average recovery of pyrethrins was in the range of 88.1–104%, with the relative standard deviation (RSD) ranging from 1.1 to 8.3%, which indicated satisfactory accuracy and precision of this method.

Dissipation of pyrethrins in the whole turnip plant and soil

The dynamic degradation trends of pyrethrins in whole plants and the soil at Beijing and Shandong Provinces are shown in Fig. 4. It is worth noting that the experiments of Beijing were performed in open fields, while the Shandong’s were conducted in greenhouse. The initial concentrations of pyrethrins in whole plants were 0.3263 and 0.4811 mg/kg, while in the soil were 0.0130 and 0.1052 mg/kg in Beijing and Shandong Provinces, respectively. The differences in the initial concentrations may be due to different planting densities or uneven spraying at the two sites. The reason for the high residues in whole turnip plants may be that the pesticide was applied directly on leaf surfaces and less on the soil.

Figure 4a shows the dissipation curve of pyrethrins in whole plants in Beijing and Shandong Provinces. The dissipation of pyrethrins could be described by the first-order equations of C = 0.3263e −0.4466 t (Beijing) and C = 0.4811e −1.3227 t (Shandong), with correlation coefficients (R) of 0.7561 and 0.9233 and half-life of 1.6 and 0.5 day, respectively. The half-life of pyrethrins in Beijing was longer than that in Shandong, which demonstrated that the degradation of pyrethrins in the greenhouse is quicker than that in open fields. This phenomenon may be caused by the higher temperatures in greenhouses. At 21 days after application, the residue level of pyrethrins decreased to more than 90% with the concentration <0.05 mg/kg (the lowest spiking level concentration) at the two sites.

The dissipation of pyrethrins in soil is presented in Fig. 4b. The first-order kinetic equations of pyrethrins were C = 0.0130e −0.5430 t (Beijing) and C = 0.1052e −0.6684 t (Shandong), with correlation coefficients (R) of 0.9507and 0.9746, respectively. The t 1/2 of pyrethrins in soil was 1.3 and 1.0 day in Beijing and Shandong, respectively, which also showed that degradation of pyrethrins in greenhouses is relatively quicker than that in open fields.

Terminal residues of pyrethrins in turnip leaves, turnip tubers, and soil

Table 5 shows the final residues of pyrethrins in turnip leaves at the six experimental sites. The residues of pyrethrins were lower than LOQs only in Shandong Province (in greenhouse), which indicates that degradation of pyrethrins in the greenhouse was quicker than in open fields. In Heilongjiang Province (another greenhouse place), the degradation of residues was higher than that of LOQs. However, the terminal residues of pyrethrins at the two dosage levels were all below 1 mg/kg (the MRL established by EU, Japan, etc.). There were no obvious differences at different intervals and dosages.

Final residues of pyrethrins in turnip tubers in the six provinces are presented in Table 6. The residues of pyrethrins were all below LOQs in Beijing, Shandong, and Heilongjiang Provinces. Though it could be detected in other places, the residues in turnip tubers were lower than those in turnip leaves. There was a similar result (Table 7) that no pyrethrins were detected in soil, and the reason might be that the pesticide was applied directly on turnip leaves, and not on the tubers and soil.

Our results showed that, under the tested experimental conditions, the terminal residues of pyrethrins at different intervals of 2, 5, and 7 days were all below the MRL in turnip leaves and tubers. Based on the results of terminal residues and the MRL established by EU and Japan, the dosage of 40.5–60.75 g a.i./ha and a PHI of 2 days could be recommended for pyrethrin EW formulation to be applied on turnips. In addition, we also recommend the MRL of pyrethrins on turnips in China of 1.0 mg/kg, which was derived using the OECD calculator.

Risk assessment of pyrethrins

Though there is rapid degradation and low residue of pyrethrins in turnips, there is no meaning of zero risk for human intake. Intake risks of pyrethrins in turnip tubers were calculated in this paper. The average body for an average adult is 63 kg in China and the daily turnip tubers (light vegetables) intake is 0.1837 kg/day (Xu et al. 2017). The ADI for pyrethrins is 0.04 mg/kg bw (GB 2763-2016: maximum residue limits for pesticide in food) and ARfD is 0.2 mg/kg bw (FAO 1999). The STMR and HR of pyrethrins in turnip tubers are 0.052 and 0.28 mg/kg, respectively. For long-term risk assessment, the calculated HQ value of pyrethrins was 0.37%. For short-term risk assessment, the aHI value was 0.41%. The HQ and aHI were both less than 100%, which indicated that there was hardly any chronic or acute risk for the intake of turnip tubers.

Conclusion

In this study, a GC-MS method was developed and validated to estimate pyrethrin residues in turnips (turnip leaves, turnip tubers, and whole plants) and soil. Considering the linearity, recovery, accuracy, repeatability, and limits of quantification, the method was found to be satisfactory qualitatively and quantitatively. The final residues and dissipation in a turnip-field ecosystem were also investigated with the developed analytical method. The results showed that the dissipation of pyrethrins in the whole of plants and soil was faster, with the half-lives of 0.5–1.6 and 1.0–1.3 days, respectively. Differences in pyrethrin degradation in greenhouse and in open fields were also clarified, and it was demonstrated that the degradation of pyrethrins in the former was quicker than in the latter. Final residues in turnip leaves and tubers were all much below the MRL of pyrethrins established by the EU and Japan (1.0 mg/kg) when the field experiments were conducted at PHI of 2, 5, and 7 days. According the results of final residues, a PHI of 2 days and a MRL of 1.0 mg/kg could be recommended to ensure food safety standards for pyrethrins in turnips. Long-term risk assessment and short-term risk assessment were calculated. The HQ and aHI were 0.37 and 0.41%, respectively, which were both significantly lower than 100% and implied that the risk of pyrethrin use in turnip tubers at the recommended dosage was negligible to humans.

References

Angioni A, Dedola F, Minelli EV, Barra A, Cabras P, Caboni P (2005) Residues and half-life times of pyrethrins on peaches after field treatments. J Agr Food Chem 53:4059–4063

Australian Pesticides and Veterinary Medicines Authority (2017) Agricultural and Veterinary Chemicals Code Instrument No. 4 (MRL Standard) 2012. https://www.legislation.gov.au/Details/F2017C00455

Campillo N, Penalver R, Aguinaga N, Hernandez-Cordoba M (2006) Solid-phase microextraction and gas chromatography with atomic emission detection for multiresidue determination of pesticides in honey. Anal Chim Acta 562:9–15

Chen M, Lu W, Han Y, Huang Q, Sun G (2009) Simultaneous determination of 36 pesticides in river water and sea water using solid phase extraction-gas chromatography. Fenxi Ceshi Xuebao 28:1378–1383

Cheng XS, Zhao P, Yong YU (2005) Natural insecticidal pyrethrum. Pesticides 44:391–394

Copping LG (1998) The biopesticide manual: world compendium. Biopesticide Manual World Compendium. Farnham, pp 32–33

Ding M, Fang X-z, Fei X-q, Gong B-c, Chen Y (2006) Quick determination and degradation of pyrethrins residues in non-environmental pollution persimmon fruit and soil. Jiangxi Nongye Daxue Xuebao 28:512–515

Ding M, Fang X, Fei X (2007) Determination of pyrethrins residues in non-environmental pollution persimmon by gas chromatography. Nongyao 46:178–181

Feo ML, Eljarrat E, Barceló D, Barceló D (2010) Determination of pyrethroid insecticides in environmental samples. Trac-Trend Anal Chem 29:692–705

Ferrer C, Martínez-Bueno MJ, Lozano A, Fernández-Alba AR (2011) Pesticide residue analysis of fruit juices by LC–MS/MS direct injection. One year pilot survey. Talanta 83:1552–1561

Food and Agriculture Organization of the United Nations (1999) List of pesticides evaluated by JMPR and JMPS-P. http://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/JMPR/Reports_1991-2006/REPORT1999.pdf

Food and Agriculture Organization of the United Nations (2005) List of pesticides evaluated by JMPR and JMPS-P http://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/JMPR/JMPR05report.pdf

Huang X (2004) Analytical method for pyrethrins in natural extracts by GC-MS. Nongyao Kexue Yu Guanli 25:6–9

Karmakar R, Kulshrestha G (2009) Persistence, metabolism and safety evaluation of thiamethoxam in tomato crop. Pest Manag Sci 65:931–937

Korea Food & Drug Administration (2012) MRLs for Pesticides in Foods. Korea, pp 89

Leng G, Gries W (2005) Simultaneous determination of pyrethroid and pyrethrin metabolites in human urine by gas chromatography–high resolution mass spectrometry. J Chromatogr B 814:285–294

Lin H, Dong B, Hu J (2017) Residue and intake risk assessment of prothioconazole and its metabolite prothioconazole-desthio in wheat field. Environ Monit Assess 189:236

Lu C, Liu X, Dong F, Xu J, Song W, Zhang C, Li Y, Zheng Y (2010) Simultaneous determination of pyrethrins residues in teas by ultra-performance liquid chromatography/tandem mass spectrometry. Anal Chim Acta 678:56–62

Meurer-Grimes B (1996) Pyrethrum flowers. Production, chemistry, toxicology, and uses. Brittonia 48:613–614

Omirou M, Vryzas Z, Papadopoulou-Mourkidou E, Economou A (2009) Dissipation rates of iprodione and thiacloprid during tomato production in greenhouse. Food Chem 116:499–504

Peruga A, Hidalgo C, Sancho JV, Hernández F (2013) Development of a fast analytical method for the individual determination of pyrethrins residues in fruits and vegetables by liquid chromatography–tandem mass spectrometry. J Chromatogr A 1307:126–134

Picó Y, Font G, Moltó JC, Mañes J (2000) Pesticide residue determination in fruit and vegetables by liquid chromatography–mass spectrometry. J Chromatogr A 882:153–173

Picó Y, Blasco C, Font G (2004) Environmental and food applications of LC–tandem mass spectrometry in pesticide-residue analysis: an overview. Mass Spectrom Rev 23:45–85

Rawn DFK, Judge J, Roscoe V (2010) Application of the QuEChERS method for the analysis of pyrethrins and pyrethroids in fish tissues. Anal Bioanal Chem 397:2525–2531

Ruiz I, Morales A, Oliva J, Barba A (2011) Validation of an analytical method for the quantification of pyrethrins on lemons and apricots using high-performance liquid chromatography/mass spectrometry. J Environ Sci Health, Part B 46:530–534

Song S, Ma X, Li C (2007) Rapid multiresidue determination method for 100 pesticides in vegetables by one injection using gas chromatography/mass spectrometry with selective ion storage technology. Anal Lett 40:183–197

The commission of the European Communities (2008) http://ec.europa.eu/food/plant/pesticides/eu-pesticides-database/public/?event=pesticide.residue.CurrentMRL&language=EN. Accessed 04 July 2016

The Japan Food Chemical Research Foundation (2006). http://www.m5.ws001.squarestart.ne.jp/foundation/agrdtl.php?a_inq=56400. Accessed 06 November 2016

Wang J-f (2013) GC method for analyzing pyrethrins in disc mosquito coil. Zhonghua Weisheng Shachong Yaoxie 19(298–299):304

Woudneh MB, Oros DR (2006) Quantitative determination of pyrethroids, pyrethrins, and piperonyl butoxide in surface water by high-resolution gas chromatography/high-resolution mass spectrometry. J Agric Food Chem 54:6957–6962

Xu Z, Zhang C, Yu J, et al. (2017) Field investigations of dissipations and residues of cyazofamid in soil and tomato: risk assessment of human exposure to cyazofamid via tomato intake. Environ Sci Pollut Res 24:1–10

You X, Lin L, Liu F (2014) Dissipation and residues of clethodim and its oxidation metabolites in a rape-field ecosystem using QuEChERS and liquid chromatography/tandem mass spectrometry. Food Chem 143:170–174

Zhu X (2013) The analysis and detection of harmful gas benzene、toluene、methanol and acetone in laboratory. Chin Med Mod Dist Educ Chin 11:157–160

Funding

This work was supported by the Institute for the Control of Agrochemicals, Ministry of Agriculture of the People’s Republic of China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Zhihong Xu

Rights and permissions

About this article

Cite this article

Feng, X., Pan, L., Wang, C. et al. Residue analysis and risk assessment of pyrethrins in open field and greenhouse turnips. Environ Sci Pollut Res 25, 877–886 (2018). https://doi.org/10.1007/s11356-017-0015-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-0015-1