Abstract

Disintegration of municipal waste-activated sludge (WAS) is regarded as a prerequisite of the anaerobic digestion process to reduce sludge volume and improve biogas yield. Pretreatment of WAS using thermo-alkaline (TA), H2O2 oxidation, electrolysis and electro-oxidation (EO) processes were investigated and compared in term of COD solubilization and biogas production. For each pretreatment, the influences of different operational variables were studied in detail. At optimum conditions, EO gave the maximum COD solubilization (28 %). The effects of pretreatments under the optimum conditions on anaerobic digestion were experienced with biochemical methane potential assay. Significant increases in biogas yield up to 78 and 40 % were observed respectively in the EO and TA pretreated samples compared to raw sludge. Results clearly revealed that the application of EO is a significant alternative method for the improvement of WAS anaerobic digestion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The biological treatment of municipal wastewater produces a large amount of waste-activated sludge (WAS). The increase of WAS production is attracting more and more attentions to reduce its negative effects on environment and disposal cost. For the treatment of this kind of waste, anaerobic digestion (AD) is widely used as the most cost-effective way for stabilization and energy recovery. WAS is composed of diverse microorganisms, organic and inorganic compounds agglomerated together in a polymeric network formed by extracellular polymeric substances (EPS), including proteins, carbohydrates, lipids and volatile fatty acids (Eskicioglu et al. 2006; Pavlostathis and Gosset 1986). These EPS strongly influence the hydrolysis step of WAS. In order to overcome this rate restricting step and to enhance the digesting capability, various pretreatment techniques such as chemical, mechanical, thermal and biological methods are portrayed in the literature (Kim et al. 2013). These processes disrupt the sludge flocs, disintegrate the bacteria cells and transfer the EPS, intracellular organic matters and divalent cations into the liquid phase of the WAS, and thus, sludge biodegradability in the digester is enhanced (Kavitha et al. 2014). Among these pretreatment methods it can be mentioned ultrasonication (Khanal et al. 2007), microwave irradiation (Dogan and Sanin 2009), thermalization (Valo et al. 2004; Gianico et al. 2013), alkalization (Sahinkaya and Sevimli 2013c) and advanced oxidation methods (Erden and Filibeli 2010; Pham et al. 2010; Tokumura et al. 2007, 2009).

According to previous studies, thermal, chemical and mechanical methods are considered to be very effective due to high solubilization and their effects were evaluated independently so far (Valo et al. 2004). Amalgamations of these methods were also explored and a substantial improvement in sludge degradability was estimated. These include combinations of alkaline and ultrasonic (Kim et al. 2010), ozone oxidation and ultrasonic (Erden and Filibeli 2010), mechanical and thermal (Wett et al. 2010), cation binding agents and biological (Gopi Kumar et al. 2012) and many more combinations.

Within these various WAS disintegration technologies aiming to accelerate the hydrolysis of WAS, advanced oxidation process (AOP) are quite effective and economical (Ana et al. 2015). AOPs are considered clean technologies for the treatment of polluted waters that apply the concept of producing hydroxyl radicals (HO•) (Tunay et al. 2010). The efficiency of AOPs is based on the generation of these highly reactive radicals that are unselective and powerful oxidizing species (E0 = 2.80 V). AOPs can be applied as post-treatment or pre-treatment of biological processes. The integration of different AOPs in a sequence of complementary processes is also a common approach to achieve a biodegradable effluent that can be further treated by a cheaper and conventional biological process, reducing the residence time and reagent consumption in comparison with AOPs alone. AOPs include a series of powerful technologies to treat the WAS. They can implement ozone (O3), hydrogen peroxide (H2O2) and oxygen (O2), among others. Some of the most typical AOPs are the Fenton process, ozonation and catalytic wet peroxide oxidation. Regarding the methodology to generate hydroxyl radicals, AOPs can be divided into chemical, electro-chemical (electro-Fenton), sono-chemical and photochemical processes (photo-Fenton) (Babuponnusami and Muthukumar 2014). Liu et al. (2001) consider AOPs as valuable sludge pretreatment. In fact, Weemaes et al. (2000) and Liu et al. (2001) studied the effect of ozonation on characteristics of waste-activated sludge. Ozone pretreatment removes or solubilizes two thirds of the organic matter in sludge, enhances the subsequent anaerobic digestion but has a negative effect on sludge dewaterability.

Electro-oxidation process is one of the commonly used AOP, is applied for the removal of biorefractory contaminants in the wastewaters (Gogate and Pandit 2004). This method represents a combination of the electrochemical process and the Fenton oxidation. Its oxidation mechanism will generate strong oxidant hydroxyl radicals (OH.) in the acidic condition by the catalytic decomposition of hydrogen peroxide (H2O2). It is based on the fact that hydrogen peroxide (H2O2) can be used as an oxidant in advanced oxidation. The Fe2+/H2O2 system, often referred to as Fenton’s reagent, has dual functions of OH radical peroxidation as well as ferrous/ferric coagulation.

Although, the EO process is known to be effective in the oxidation of pollutants and is widely utilized for the treatment of hazardous wastewaters, no studies have been done to confirm that it may disrupt sludge floc structure and contribute to the enhancement of WAS anaerobic treatment. Therefore, the main objective of this study was to investigate the effect of H2O2 oxidation, electrolysis, thermo-alkaline and electro-oxidation on COD solubilization and to explore biochemical methane potential assays for raw WAS and pretreated WAS with the suggested methods at optimized conditions. The effectiveness of these methods on the AD will be compared with respect to biogas yield.

Material and methods

WAS sampling and inocula

The WAS used during this work are thickened secondary sludge obtained from a municipal wastewater treatment plant (WWTP) located in Sidi mansour region (north of Sfax, Tunisia). They are collected in cans and are stored in a cold room (4 °C) so that samples keep their initial biological and physico-chemical characteristics. The mean physico-chemical characteristics of raw WAS are shown in Table 1. For batch anaerobic digestion experiments, the seed sludge was taken from an anaerobic digester installed in a WWTP located in CHARGUIA, Tunisia.

Pretreatment experiments

Thermo-alkaline hydrolysis

In this study, thermo-alkaline pretreatment of sludge was carried out in glass reactors and by using NaOH as an alkaline agent with high disintegration efficiency (Kim et al. 2003). The effect of thermo-alkaline treatment depends on pH. As a first step of experiments, the effect of pH on COD solubilization was studied. pH of WAS samples were firstly adjusted at different values (7.0, 8.0, 10.0, 12.0 and 14.0) by adding 5 N NaOH, and the desired pH values were kept with ± 0.1 unit fluctuations. Then, samples were agitated with a magnetic stirrer for different times (2, 4, 6, 8, 24, 48 and 72 h) at ambient temperature (28 °C). The effect of temperature was carried out in glass reactors containing 300 mL of sludge samples adjusted at pH 10. Reactors were incubated in a stove at various temperatures (50, 105 and 120 °C) during 0, 30, 60, 120, 180 and 240 min. For each temperature, a control test containing raw sludge was operated without adjustment of pH.

H2O2 oxidation

Batch experiments were carried out in 500-mL beakers with 300-mL working volume. Firstly, pH of sludge was adjusted using 1 mol/L H2SO4 or NaOH in order to maintain the desired value. Different amounts of H2O2 (30 % v/v) were added to WAS samples. Samples were maintained in agitation and at room temperature about 2 h.

Electrolysis

Electrolysis pretreatment was carried out in a 500-mL glass reactor using an electric generator ASF type 400/40.10. It was formed by one pair of anodic and cathodic electrodes (cast iron plates) which were positioned approximately 2 cm apart from each other and were dipped in the effluent (Fig. 1). The total effective surface area of electrodes was 0.16 dm2. During this treatment, the main electrochemical reactions are carried out at the anode by oxidation of iron and the cathode by the reduction of water. It is based on the principle of soluble iron anodes.

In each run, 300 mL of raw WAS were treated and operated in batch mode. The aqueous solution of reactants was homogenized by magnetic agitation to avoid sedimentation of WAS particle. In order to evaluate the performance of the electrolysis method, different operational conditions by varying current density, initial pH and reaction time were conducted.

Electro-oxidation

For the EO pretreatment, experiments were carried out in the same electrolytic cell as for electrolysis tests. The H2O2 solution was added after the adjustment of pH to the desired value and the pH of the solution was not controlled during the reaction. Then, the power supply was turned on to initiate the reaction. The contents were continuously stirred using magnetic stirrer. Batch experiments were conducted to optimize parameters governing the EO process like H2O2 concentration, current density and treatment time. All experiments were performed at room temperature.

Batch anaerobic digestion

According to the procedure defined by Eskicioglu et al. (2007), batch anaerobic digestion were conducted to further examine the effect of each studied pretreatment on biogas production. These experiments were carried out under mesophilic conditions (37 ± 1 °C) for 35 days, using 120-mL glass bottles as reactors. Each bottle was fed with an appropriate amount of a substrate and inocula, keeping a VS ratio (VS substrate to VS inocula) at 1:1 in all setups (Khoufi et al. 2015). Before mixing with inocula, all treated sludge samples were adjusted to pH 7.0. A batch control was conducted only with inocula, to estimate the volume of biogas resulting from the auto-fermentation of the inocula biomass. Based on the initial VS contents of WAS sample and inocula, a sufficient amount of deionized water was added in each condition to adjust the working volume inside the batch system to 60 mL and no micro and macronutrients were added.

After adjusting pH to 7.2, all bottles were purged with a gas mixture of 75 % N2 and 25 % CO2 for 3–4 min to supply anaerobic conditions. The serum bottles were then incubated in a temperature-controlled room. The bottles were shaken once a day during the incubation period. Biogas produced in each serum bottle was measured daily using a gas displacement device. The biogas yields at the end of each test were calculated by dividing the cumulative biogas volume by the mass of VS in the feedstock loaded into the bottle at start-up. The cumulative biogas yields in terms of mL Biogas per gram of VS introduced for the different pretreatment conditions were followed in triplicate tests. The biogas production from the experiment without the WAS addition was subtracted.

Analytical methods

The characterization of treated and untreated WAS included determination of the following parameters: pH, soluble chemical oxygen demand (soluble COD), total chemical oxygen demand (total COD), Biological oxygen demand (BOD5), total (TS) and volatile (VS) solids, total (TSS) and volatile (VSS) suspended solids, total kjeldahl nitrogen (TKN), ammonium nitrogen and total phosphorus.

The pH was measured using a pH meter (Metrohm). Total and soluble COD was determined by titration method after a total digestion with H2SO4 and potassium dichromate at 150 °C for 2 h (Knechtel 1978). BOD5 was determined by the manometric method with a respirometer [BSB-ControllerModel 620 T (WTW)]. TS and TSS were determined by weighing samples before and after drying overnight at 105 °C. VS and VSS were analysed, by loss on ignition at 600 °C for 2 h. The total Kjeldahl nitrogen content (TKN) and the ammoniacal nitrogen (N–NH4 +) were analysed as Kjeldahl-N method. Total phosphorus was analysed by means of phosphorus vanadomolybdate yellow colorimetric method. Digestion was performed by heating sample with peroxodisulfate and sulfuric acid. In acids, ortho-phosphate ions react with ammonium vanadate (Scharlau chemie, EU) to form yellow ammonium phosphoric vanadomolybdate. This was photometrically analysed at 430 nm.

The COD solubilization (SCOD) represented the transfer of organic matter from the particulate fraction of the sludge to the soluble fraction. SCOD was calculated according to this formula:

Where SCODafter is the soluble COD after pretreatment, SCOD0 is the soluble COD before pretreatment, and TCOD is the total COD before pretreatment of sludge. This value represented the disintegration degree of WAS that could directly tell the portion of particle substances solubilized by pretreatment (Li et al. 2012).

Results and discussion

Effect on WAS solubilization using different pretreatment processes

The sludge hydrolysis/disintegration is the basic factor for the anaerobic digestion. This step can be realized by the integration of a pretreatment. The principal objective of the first part of this work is to optimize the electro-oxidation (EO) process for maximum disintegration degree in comparison with thermo-alkaline, H2O2 oxidation and electrolysis pretreatments.

Thermo-alkaline pretreatment

Figure 2 shows the effect of pH, agitation time and temperature on sludge solubilization. The first series of hydrolysis experiments were conducted for the optimization of pH reaction at room temperature and during 2 h (Fig. 2a). The COD solubilization of raw sludge (pH 7) was 10.5 %. However, an enhancement of COD solubilization was noted by adjusting pH to 8.0, 10.0, 12.0 and 14.0 and it was found to be 10.7, 13, 13.2 and 13.5 %, respectively. This can be explained that at extremely high pH values, the cell loses its viability; it cannot maintain an appropriate turgor pressure and disrupts (Neyens and Baeyens 2003). Also, it is indicated from experiments that increasing the pH beyond 10.0 is not significant in terms of COD solubilization. A pH 10 for alkaline hydrolysis of WAS seems to be too sufficient for an effective COD solubilization. However, Rani et al. (2012) suggested that the pH 12 was considered to be an optimum condition. On the other hand, 0.5–0.6 g NaOH/g VSS was suggested by Tanaka et al. (1997) because with higher alkali doses VSS solubilization stays constant around 15 %. Banu et al. (2012) showed another effect of Na+ addition, marked deterioration in floc strength and consequently to disintegration of sludge. It is evident that in basic condition chemical bonds in cell walls and membranes were disrupted. Therefore, intracellular organic material is released to the liquid phase and increases the soluble COD (Appels et al. 2010; Banu et al. 2009).

By making WAS sample adjusted at pH 10 under magnetic agitation, it has been noted an increase of soluble COD with the increase of time reaction (Fig. 2b). COD solubilization increased from 11.5 to 19.4 % after 24 h of agitation time and was found to be stable until treatment time of 72 h. Also, it was demonstrated by Rani et al. (2012) that as reaction time increases from 24 to 48 h soluble COD was found to be decreased. The fall in soluble COD after 24 h might be due to the formation of refractory substances. Thus, for the waste-activated sludge sample, a treatment time of 24 h was found to be the optimum.

Figure 2c gives the results of COD solubilization of WAS hydrolysed at pH 10.0 and incubated at different temperature: 50, 105 and 120 °C. The results noted that temperature has a synergistic effect on alkaline hydrolysis of WAS. However, under the study conditions increasing the temperature to 120 °C did not give a significant effect on the COD solubilization. A maximum value of COD solubilization about 26 % was obtained by incubation of sample at 105 °C during 2 h. This percentage of solubilization is still close compared to that found by Rani et al. (2012), which is around 23 %. But, this result was obtained by adjusting the pH of WAS at 12.0 and then treating the sample in the thermostatic bath at 60 °C.

Smith and Goransson (1992) studied the thermochemical pretreatment using Ca(OH)2 and NaOH at temperature of 120–160 °C. The addition of NaOH gave a higher solubilization up to 40–60 %. Even though, sodium decreases the dewaterability of the sludge. The choice of this alkaline agent was made from different studies indicated that, for anaerobic digestion, pretreatment with NaOH was more efficient than using other alkaline agents (Kim et al. 2003; Lin et al. 2007).

H2O2 oxidation

H2O2 is one of the most powerful oxidant used in the treatment of some specific pollutant such as cyanides and organic compounds. It decomposes exothermically into water and oxygen gas depending on temperature, solution pH and presence of impurities and stabilizers (Tunay et al. 2010).

The suitability of this chemical oxidation was tested in this work for sludge disintegration. Batch experiments were carried out to enumerate the influence of different operational parameters such as H2O2 concentration, reaction time and solution pH. Figure 3 gives the main results of this part of work. The first observation that can be noted is the instantaneous solubilization of organic matter just after H2O2 addition to raw WAS. COD solubilization was increased with the increase of H2O2 amount and time reaction. Maximum solubilization of 16 % was observed at the end of the experience containing 1.8 g/L of H2O2 (Fig. 3a). It is noted that the increase of H2O2 amount to a value greater than 1.8 g/L does not improve organic matter solubilization. In fact, according to Gogate and Pandit (2004), the use of excessive amounts of H2O2 may deteriorate the efficiency of the overall degradation process. Furthermore, rates of solubilization were found to decrease by increasing hydrogen peroxide dose.

In a second step of experiments, different pH of medium were tested in the presence of 1.8 g H2O2/L, as the optimum dose for the disintegration of WAS according to previous experiments. Results plotted in Fig. 3b demonstrate that COD solubilization was improved in acidic condition. The best percentage of solubilization about 19.2 % was obtained at pH 3.0 in comparison to raw sludge 10.7 %. This result showed that hydrogen peroxide alone had an effect on sludge disintegration. During this reaction, active forms of oxidant are generally the hydroxyl radicals (OH.) and hydroperoxyl radicals (HO2 .) generated from the decomposition of hydrogen peroxide. These radicals attack on sludge particles leads to the destruction of cell wall of microorganism, resulting in not only generation of soluble COD but also the sludge particle reduction (Kim et al. 2009). Furthermore, the use of this kind of oxidation had shown to be an effective way to reduce odors and destroy pathogenic organisms in WAS (Kim et al. 2009). According to these results, organic matter may be released and solubilized during the disruption of the sludge flocs and cells by using hydrogen peroxide alone (Kim et al. 2009). To improve the disintegration yield, many researches have focused on the use of hydrogen peroxide by combination with UV light (Ana et al. 2015), ozone (Mika et al. 2011), microwave (Wang et al. 2009) and catalyst such as Fe2+ (Neyens and Baeyens 2003; Kim et al. 2009). Once in solution, H2O2 can react with the Fe2+ ions thus initiating the so called Fenton’s radical reaction chain which leads to the production of the reactive oxygen species OH. (Yu et al. 2010). The latter one, given its high reactivity, is capable to attack and effectively degrade the organic compounds constituting the cell wall, thus leading to its rupture and the subsequent release of intracellular content in solution.

Electrolysis

The electrolytic treatment used in this study is based on the principle of soluble iron anodes. The main electrochemical reactions are effected at the anode by iron oxidation and at the cathode by water reduction. The effect of current density, reaction time and pH of reaction medium on the disintegration of sludge will be discussed in this section. Figure 4 presents the main results of this part of study. WAS samples were treated for 4 h by electrolysis at pH medium adjusted to 3 and 7. The current density maintained for these experiments was 0.63 A/dm2. As expected, a slight increase in COD solubilization was observed in comparison to raw sludge (Fig. 4a). Adding to this, treating at pH 3 was observed to be more effective on COD solubilization than pH 7. In fact, the disintegration degree increases to 13.5 and 12 % at pH 3.0 and 7.0, respectively. The resulting particle disintegration and microbial cell lysis during electrolysis pretreatment can be explained by the effect of the ohmic heating, electrophoresis and electro-osmosis (Yuan et al. 2011; Ibeid et al. 2013).

Current density is the most important parameter, which influences the reaction rate of electrochemical processes. The influence of applied current density on the COD solubilization was examined by electrolyzing WAS samples at pH 3 under different current densities and the results obtained are shown in Fig. 4b. The results showed an effective effect of current density on COD solubilization. The electrolysis at current density of 2.5 and 3.75 A/dm2 offered faster COD solubilization than at current density of 0.63 and 1.25 A/dm2. This may be due to the fact that an increase in current density increased the amount of oxidized iron generated from the electrode. The observed result is similar to that of results reported in the literature (Chiang et al. 1995). Consequently, the increase in current density increases the applied potential proportionately. However, the electrolysis at current density of 3.75 A/dm2 had shown a decrease of soluble COD of supernatants in comparison to other currents densities. This can be explained by the acceleration of organic matter mineralization than the solubilization reaction. Thus, it is advisable to limit the current density to avoid adverse effects such as heat generation and higher power consumption (Xu et al. 2014). As result of this part of study, the electrolysis treatment at current density of 2.5 A/dm2 gave the best degree of WAS disintegration after 2 h of reaction. The findings of this study were in well line with those of Zhen et al. (2013). However, low-soluble COD observed in the current and previous studies together demonstrated the limited enhancement of electrolysis on sludge disruption.

Electro-oxidation

Based on results of H2O2 oxidation and electrolysis treatment, disintegration of WAS is possible by using these methods but the yields of COD solubilization were not significantly important. However, the electrolysis pretreatment, especially if assisted by chemical methods (Zhen et al. 2014), will become more energy efficient for sludge treatment as they solubilize sludge and obviate the need for high voltages. Furthermore, the combined treatment can not only reduce the required quantity of chemicals and energy, but also greatly enhance the efficiency of WAS anaerobic digestion by the synergistic functions, and thus is more economically attractive. Yet, to the best of our knowledge, no studies have been carried out in the literature to evaluate the effectiveness of combined electrical and H2O2 oxidation pretreatment on sludge disintegration/solubilization and subsequent anaerobic digestion. This reaction is among the most eco-friendly electrochemical AOPs and basically consists of an electrically assisted Fenton process. The Fenton reagents can be added to the reactor and the anode material is an inert electrode or, alternatively, only H2O2 is added and Fe2+ is provided from sacrificial cast iron anodes (Nidheesh and Gandhimathi 2012). A combination of electrochemical and Fenton process, namely electro-Fenton method was developed for the improved oxidation of organic compounds (Babuponnusamia and Muthukumar 2012). In the present study, this method is suggested to improve the solubilization of WAS. Therefore, various parameters involved in EO reaction, especially the pH, current density, the concentration of H2O2 and the processing time were studied. Data of EO optimization are presented in Fig. 5.

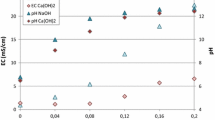

At a first step of experiments, the effect of pH was studied. The initial pH of raw WAS is in the range of neutrality and it is known that Fenton reaction is optimal at pH 3. Thus, experiments of EO were conducted at pH 7 and pH 3 under a current density of 2.5 A/dm2 and in the presence of 1.8 g/L H2O2. By applying the EO process, the percentage of COD solubilization was increased to 23.2 and 17.9 % after 2 h of reaction at pH 3.0 and pH 7.0, respectively (Fig. 5a). That was expected as pH 3 is the best condition to allow the Fenton’s peroxidation (Khoufi et al. 2006).

Figure 5b gives the results of the effect of current density during EO experiments. These experiments were conducted with WAS samples adjusted at pH 3 and in the presence of a H202 concentration about 1.8 g/L. Data show that the best degree of solubilization was obtained at the end of experiments and this for all current densities tested. Maximum COD solubilization was obtained at current density of 2.5 A/dm2 after 2 h of treatment. In this case, COD solubilization reached 28 % against 10.5 % in the raw sludge. Besides, H2O2 concentration effect on the COD solubilization during EO treatment was studied (Fig. 5c). Results had shown that the experience with 1.8 g/L H2O2 gave the best result of sludge solubilization (28 %) in comparison with other tests. Adding to this, it was noted that pH had increased to value in the range of neutrality which is favorable for anaerobic post-treatment. Therefore, based on all of these results, a current density of 2.5 A/dm2, a dose of 1.8 g/L H2O2, an initial pH of 3.0 and a treatment time of 2 h are the best conditions for maximum solubilization of sludge by EO. It can be noted that the optimum current density and H2O2 concentration for EO are the same as for electrolysis and H2O2 oxidation pretreatment previously studied. Results have proven that the combination of these operational parameters in the same pretreatment experiment has improved the COD solubilization as was expected before. A significant increase about 18 % compared to raw WAS was registered. This result is in the same range as about thermo-alkaline pretreatment. Very recently, combination between electrolysis and alkali pretreatment has shown to be an efficient alternative for sludge modification prior to anaerobic digestion (Zhen et al. 2014). The effect of the studied pretreatments on biogas production will be discussed in the subsequent section.

Effect of the different pretreatment on the biogas production

Batch anaerobic digestion assays were carried out to reveal the feasibility of using combined EO pretreatment to improve the anaerobic biodegradability of the WAS in comparison to thermo-alkaline, electrolysis and H2O2 oxidation pretreatments. The biogas production processes ran for about 35 days until no more biogas production was observed. A batch named control was also monitored as a serum containing only the inocula (without addition of substrate: raw sludge or pretreated sludge).

Figure 6 gives the cumulative daily biogas production during batch anaerobic fermentation of raw and pretreated WAS. From these results, it is noted that the cumulative biogas production of pretreated samples were improved compared to the raw sludge. Also, it is clear that the EO pretreatment consistently increased the biogas production rate of sludge in comparison to all other pretreatments. This can be explained by the increase of sample biodegradability. Thus, soluble COD released during EO is more accessible by anaerobic consortium that can be rapidly converted to biogas. High biogas yield was achieved with EO pretreatment with up to 78 % improvement over the non-pretreated sludge after 35 days of mesophilic operation. Indeed, the yield increased from 41.2 to 146.8 mL of biogas/g VS introduced respectively for raw and EO pretreated WAS. H2O2 oxidation also achieved higher biogas production relative to raw but it was not as effective as EO pretreatment. An enhancement of biogas production about 30.2 % was registered by digesting WAS treated by H2O2. By comparing the evolution of biogas production, EO pretreatment accelerated the digestion process and 83.5 % of biogas volume was produced after 12 days against 73 % in the case of raw sludge and in the same time of digestion. It is clear that the EO pretreatment consistently increased anaerobic hydrolysis rate of sludge. This was also observed for the other studied pretreatment. So, it can be concluded that EO is the effective method for improving anaerobic biodegradability and biogas yield. After 35 days of digestion period, the biogas production ceased indicating that the digestate did not undergo any further degradation.

Table 2 shows the variation of COD and VS removal after anaerobic digestion of raw and pretreated sludge. In batch containing raw WAS, COD removal was in the range of 17.3 %. At the same anaerobic condition, COD removal increased to 17.9, 21.5, 21.6, 30.2 % after H2O2 oxidation, electrolysis, thermo-alkaline and EO pretreatment, respectively. Thus, each pretreatment gave an advantage in COD removal improvement compared to non-pretreatment. The highest COD removal was achieved in batch digesting EO-pretreated sludge which explains the maximum biogas production during this fermentation. The same conclusion was noted by comparing the VS removal. The improvement of VS removal was almost due to the effects of pretreatments, which help to break down the microbial cells for faster subsequent degradation. It eventually facilitates the decomposition reaction which leads to biodegrade more compounds during anaerobic digestion.

Conclusion

The study represented the first scientific attempt on the application of electrolysis in combination with H2O2 oxidation pretreatment, electro-oxidation, for improving WAS anaerobic digestion. The effectiveness of this method was compared to a conventional pretreatment, thermo-alkaline hydrolysis. For each pretreatment, operational conditions were optimized in batch condition. Based on the experimental data and analysis the following conclusions are drawn:

-

In the case of thermo-alkaline hydrolysis, a maximum solubilization about 26 % was obtained by adjusting the pH to 10 and incubation at 105 °C for 2 h.

-

H2O2 oxidation under optimum conditions (pH 3.0, 1.8 g/L H2O2 and 2 h) increased the degree of solubilization to a value of 19.2 %.

-

In case of electrolysis, the maximum solubilization (17.5 %) was found by treating the sludge at pH 3.0 and applying a current density of 2.5 A/dm2.

-

In the presence of 1.8 g/L of H2O2 and applying the same operational conditions as electrolysis, EO improved the solubilization of COD to 28 %.

-

Highest biogas yield was achieved with EO pretreatment with up to 78 and 40.5 % improvements over the non-pretreated sludge and pretreated by thermo-alkaline, respectively.

-

Therefore, for an ideal comparison of pretreatment effectiveness in anaerobic digestion of the WAS, besides disintegration degrees other key factors, such as the compositions of soluble organics released after pretreatment, should also be taken account of.

Abbreviations

- AD:

-

Anaerobic digestion

- BMP:

-

Biochemical methane potential

- C/N:

-

Carbon to nitrogen ratio

- COD:

-

Chemical oxygen demand

- CODs:

-

Soluble chemical oxygen demand

- CODt:

-

Total chemical oxygen demand

- EPS:

-

Extracellular polymeric substances

- TKN:

-

Total Kjeldahl Nitrogen

- TS:

-

Total solids

- VS:

-

Volatile solids

- VSS:

-

Volatile suspended solids

References

Ana RR, Olga CN, Manuel FRP, Adrián MTS (2015) An overview on the advanced oxidation processes applied for the treatment of water pollutants defined in the recently launched Directive 2013/39/EU. Environ Int 75:33–51

Appels L, Degrève J, Van der Bruggen B, Van Impe J, Dewil R (2010) Influence of low temperature thermal pre-treatment on sludge solubilization, heavy metal release and anaerobic digestion. Bioresource Technol 101:5743–5748

Babuponnusami A, Muthukumar K (2014) A review on Fenton and improvements to the Fenton process for wastewater treatment. J Environ Chem Eng 2:557–572

Babuponnusamia A, Muthukumar K (2012) Advanced oxidation of phenol: a comparison between Fenton, electro-Fenton, sono-electro-Fenton and photo-electro-Fenton processes. Chem Eng J 183:1–9

Banu JR, Uan DK, Yeom IT (2009) Nutrient removal in an A2O-MBR reactor with sludge reduction. Bioresource Technol 100:3820–3824

Banu JR, Kaliappan S, Adishkumar S, Uan DK, Yeom IT (2012) A novel method of sludge pretreatment using the combination of alkalis. J Environ Biol 33:249–253

Chiang LC, Chang JE, Wen TC (1995) Indirect oxidation effect in electrochemical oxidation treatment of landfill leachate. Water Res 29:671–678

Dogan I, Sanin FD (2009) Alkaline solubilization and microwave irradiation as a combined sludge disintegration and minimization method. Water Res 43:2139–2148

Erden G, Filibeli A (2010) Improving anaerobic biodegradabilityof biological sludges by Fenton pre-treatment: effects onsingle stage and two-stage anaerobic digestion. Desalination 25:58–63

Eskicioglu C, Kennedy KJ, Droste RL (2006) Characterization of soluble organic matter of waste activated sludge before and after thermal pretreatment. Water Res 40:3725–3736

Eskicioglu C, Droste RL, Kennedy KJ (2007) Performance of anaerobic waste activated sludge digesters after microwave pretreatment. Water Environ Res 79:2265–2273

Gianico A, Braguglia CM, Cesarini R, Mininni G (2013) Reduced temperature hydrolysis at 134°C before thermophilic anaerobic digestion of waste activated sludge at increasing organic load. Bioresource Technol 143:96–103

Gogate PR, Pandit AB (2004) A review of imperative technologies for wastewater treatment: oxidation technologies at ambient conditions. Adv Env Res 8:501–551

Gopi Kumar S, Merrylin J, Kaliappan S, Adish Kumar S, Ick TY, Rajesh Banu J (2012) Effect of cation binding agents on sludge solubilization potential of bacteria. Biotechnol Bioprocess Eng 17:346

Ibeid S, Elektorowicz M, Oleszkiewicz JA (2013) Modification of activated sludge properties caused by application of continuous and intermittent current. Water Res 47:903–910

Kavitha S, Adish Kumar S, Kaliappan S, Yeom IT, Rajesh Banu J (2014) Improving the amenability of municipal waste activated sludge for biological pretreatment by phase-separated sludge disintegration method. Bioresource Technol 169:700–706

Khanal SK, Grewell D, Sung S (2007) Ultrasound applications in wastewater sludge pretreatment: a review. Environ Sci Technol 37:277–313

Khoufi S, Aloui F, Sayadi S (2006) Treatment of olive oil mill wastewater by combined process electro-Fenton reaction and anaerobic digestion. Water Res 40:2007–2016

Khoufi S, Louhichi A, Sayadi S (2015) Optimization of anaerobic co-digestion of olive mill wastewater and liquid poultry manure in batch condition and semi-continuous jet-loop reactor. Bioresource Technol 182:67–74

Kim J, Park C, Kim TH, Lee M, Kim S, Kim SW, Leej J (2003) Effects of various pretreatments for enhanced anaerobic digestion with waste activated sludge. J Biosci Bioeng 95:271–275

Kim TH, Lee SR, Nam YK, Yang J, Park C, Lee M (2009) Disintegration of excess activated sludge by hydrogen peroxide oxidation. Desalination 246:275–284

Kim DH, Jeong E, Oh SE, Shin HS (2010) Combined (alkaline + ultrasonic) pretreatment effect on sewage sludge disintegration. Water Res 44:3093–3100

Kim J, Yu Y, Lee C (2013) Thermo-alkaline pretreatment of waste activated sludge at low-temperatures: effects on sludge disintegration, methane production, and methanogen community structure. Bioresource Technol 144:194–201

Knechtel JR (1978) A more economical method for the determination of chemical oxygen demand. Water Pollut Control 116:25–27

Li H, Li C, Liu W, Zou S (2012) Optimized alkaline pretreatment of sludge before anaerobic digestion. Bioresource Technol 123:189–194

Lin JG, Chang CN, Chang SC (2007) Enhancement of anaerobic digestion of waste activated sludge by alkaline solubilization. Bioresource Technol 62:85–90

Liu JC, Lee CH, Lai JY, Wang KC, Hsu YC, Chang BV (2001) Extracellular polymers of ozonized waste activated sludge. Water Sci Technol 44:137–142

Mika ETS, Tonni AK, Wai-hung L (2011) Degradation of chelating agents in aqueous solution using advanced oxidation process (AOP). Chemosphere 83:1443–1460

Neyens E, Baeyens J (2003) A review of thermal sludge pre-treatment processes to improve dewaterability. J Hard Mater 98(1–3):51–67

Nidheesh PV, Gandhimathi R (2012) Trends in electro-Fenton process for water and wastewater treatment: an overview. Desalination 299:1–15

Pavlostathis SG, Gosset JM (1986) A kinetic model for anaerobic digestion of biological sludge. Biotechnol Bioeng 27:1519–1530

Pham TTH, Brar SK, Tyagi RD, Surampalli RY (2010) Influence of ultrasonication and Fenton oxidation pre-treatment on rheological characteristics of wastewater sludge. Ultrason Sonochem 17:38–45

Rani U, Kumar A, Yeom IT, Banu RJ (2012) Low temperature thermochemical pretreatment of dairy WAS for anaerobic digestion process. Bioresource Technol 103:415–424

Sahinkaya S, Sevimli MF (2013) Synergistic effects of sono-alkaline pretreatment on anaerobic biodegradability of waste activated sludge. J Ind Eng Chem 19:197–206

Smith G, Göransson J (1992) Generation of an effective carbon source for denitrification through thermal hydrolysis of pre-precipitated sludge. Water Sci Technol 25:211–218

Tanaka S, Kobayazhi T, Kamiyama K, Bildan H (1997) Effects of thermochemical pretreatment on the anaerobic digestion of waste activated sludge. Water Sci Technol 35:209–215

Tokumura M, Sekine M, Yoshinari M, Znad HT, Kawase Y (2007) Photo-Fenton process for excess sludge disintegration. Process Biochem 42:627–633

Tokumura M, Katoh H, Katoh T, Znad HT, Kawase Y (2009) Solubilization of excess sludge in activated sludge process using the solar photo-Fenton reaction. J Hard Mater 162:1390–1396

Tunay O, Kabadasli I, Arslan I, Olmez-Hanci T (2010) Chemical oxidation applications for industrial waste waters. IWA Publishing, New York

Valo A, Carrère H, Delgenès JP (2004) Thermal, chemical and thermo-chemical pre-treatment of waste activated sludge for anaerobic digestion. J Chem Technol Biotechnol 79:1197–1203

Wang Y, Wei Y, Liu J (2009) Effect of H2O2 dosing strategy on sludge pretreatment by microwave-H2O2 advanced oxidation process. J Hard Mater 169:680–684

Weemaes M, Grootaerd H, Simoens F, Verstraete W (2000) Anaerobic digestion of ozonized biosolids. Water Res 34:2330–2336

Xu L, Liu W, Wu Y, Poheng L, Wang A, Li S (2014) Trehalose enhancing microbial electrolysis cell for hydrogen generation in low temperature (0°C). Biores Technol 166:458–463

Yu Q, Lei HY, Li Z, Li HL, Chen K, Zhang XH, Liang RL (2010) Physical and chemical properties of waste-activated sludge after microwave treatment. Water Res 44:2841–2849

Yuan HP, Yan XF, Yang CF, Zhu NW (2011) Enhancement of waste activated sludge dewaterability by electro-chemical pretreatment. J Hard Mater 187:82–88

Zhen GY, Lu XQ, Li YY, Zhao YC (2013) Innovative combination of electrolysis and Fe (II)-activated persulfate oxidation for improving the dewaterability of waste activated sludge. Biores Technol 136:654–663

Zhen GY, Lu XQ, Li YY, Zhao YC (2014) Combined electrical-alkali pretreatment to increase the anaerobic hydrolysis rate of waste activated sludge during anaerobic digestion. Appl Energ 128:93–102

Acknowledgments

This research was supported by “Contrats Programmes de Ministère de l’Enseignement Supérieur et de la Recherche Scientifique”, Tunisie and by the International Foundation for Science, Research Grant Agreement No W/5412-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Rights and permissions

About this article

Cite this article

Feki, E., Khoufi, S., Loukil, S. et al. Improvement of anaerobic digestion of waste-activated sludge by using H2O2 oxidation, electrolysis, electro-oxidation and thermo-alkaline pretreatments. Environ Sci Pollut Res 22, 14717–14726 (2015). https://doi.org/10.1007/s11356-015-4677-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-4677-2