Abstract

Industrial and technological growth, sponsored by the new organizational systems generated by the fourth industrial revolution, require adapt new business management ways in the companies. Within the organizational and business area we can conceive all activities as an operations set that are linked to computer systems and information management in the network, achieving more efficiency in the flow, in addition, this new industry perception and businesses includes different analytical tools which are useful to support the customer service efficiency improvement. The research objective is to propose and validate a methodological tool, for evaluating the technological and operational criteria within companies and place them in the right level for a transfer to the new industrial revolution, considering as well the vertical and horizontal systems in Industry 4.0.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Industry 4.0 has been increasing with high expectations, as the current IT infrastructure enables the industry to adopt it quickly and efficiently. The challenge will be to find human talent with the capacity to develop analytical algorithms to develop self-learning intelligence, taking advantage the current infrastructure. In addition, the technology future is conditioned to the scientific areas creation, being an obstacle to the emerging technology adoption without them.

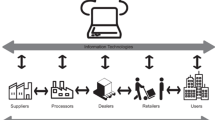

The technological advances are currently used in manufacturing has Industry 4.0. However, the entire present production process will be transformed in this new technological model. For instance, independent manufacturing cells will be unified as a fully integrated production flow; “Intelligent” machines and products will have the possibility to communicate with each other and some decisions will be made autonomously. A new man-machine relationship will replace the classic relationships among suppliers, companies, and customers.

In a market where economic opening is a decisive guideline that causes higher demands, causing all companies to work in continuous improvement scheme and high productivity in processes and management, it is necessary to apply new techniques that allow the value generation and gives market stability.

Technological advance in production systems requires corporations with agile operational processes and efficient information management, to create an organizational synergy and provides competitive advantages within production system and value chain.

Divergences in the management have been issued, impacting essentially the operation of enterprises working on an Industry 4.0 mindset; generating a gap for those which are not under this criteria, showing the fast transformation and achievements obtained from the companies which adopted their processes to the new system.

Systems integration is the first step towards an Industry 4.0 vision and achieving its goals [1]. The systems are analyzed as a whole, considering the productive flow. Structural changes are proposed in the organization and management of physical objects, and connections establishment with information systems [2, 3]; vertical flow refers to company activities development and execution, including basic elements such as: the organizational structure, human factor, departments relationships, technological and management level. In a complementary way, the horizontal flow includes external relations, establishes supplier and customer networks integration, information and management systems and others [4,5,6].

This study consists in evaluation tool creation and structure, with the criteria obtained in the first phase and are completed with reliability and validity studies. The evaluation tool will result in current vertical and horizontal level company integration. This will allow identifying gaps and opportunities to develop other blocks considered in Industry 4.0 [7].

2 Background

The research was carried out through the qualitative content analysis, in which scientific articles, theses, and conference reports were collected and analyzed. Several specialized journals related to the technological advances of I 4.0 and the business management were also considered. The systematic evaluation methodology to propose was based on decisive criteria obtained from the first phase, decisive criteria were obtained to propose a systematic evaluation methodology. In addition, knowledge and technological gaps were obtained, as well as areas of opportunity. The complete study can be consulted in a publication dedicated exclusively to this review [8] the most important results are presented:

Nine blocks were identified that as the backbone of Industry 4.0 [9, 10], including industrial organization and information management and production processes. These blocks were the research focus to obtain panoramic vision of application in the industrial sector, as well as its importance.

The articles were classified into the categories. However, the articles revealed interconnections with the other blocks,The systematic review employed with the category identification considering the highest score, revealed the requirements for the successful application of the categories in the industrial sector and its interdependence with the other blocks.

Finally, the analysis show that the category with the highest growth has been the horizontal and vertical integration of systems, This is because it represents the industrial base in management terms and establishment of relations with other companies. This review not only revealed the nine categories and their applications but also show criteria for the value chain management in terms of planning. Besides, the essential characteristics that a company must have to be able to perform in the Industry 4.0 environment, include socio-technical environments as well as physical objects virtualization through intelligent systems.

2.1 Vertical integration

The company performance lies in synergy level it possesses, therefore must be considered the crucial elements involved in the creation, development and manufacture of the product as well as its administration [11]; the vertical integration or internal integration mapping is to evaluates the system to identify crucial areas for their assistance in a different manner. Regarding to the vertical integration study, two components have been considered and shown separately for revision purposes. However, in the analysis these components will be merged as they contain similar elements.

Sociotechnical system: This is a key system for the organizations. Considering it depends on the operational success of them, the analysis of the vertical structure is crucial; having as purpose to provide support to the company and achieving the execution of the activities part of the schedule. The socio-technical system must contain three main elements: technological system, organizational system and human operating system [2, 12, 13].

Value creation modules: These are similar to the Socio-technical system,. However they differ in that the value creation modules adds two more elements to complete the activities, causing this module to be analyzed thoroughly and in particular way in each area of value creation modules objective is similar to the one of the socio-technical system. Therefore, it offers support to the operation to be executed correctly. Nevertheless, requires more than the three elements included in the system previosuly described, by the addition of the product and process involved. In that way, the socio-technical system is executed with high synchronization levels. [12].

-

Human operating system provides importance to the human capital as a critical element of change and is directly involved in the progress of the company [14,15,16,17,18,19,20,21].

-

Organizational system in essence, the sequence of operations between the hierarchical levels of the company, a responsibilities delegation, etc [16, 20, 22,23,24,25,26,27,28].

-

Technological system includes all the elements available in technology to carry out the activities of the production process [29,30,31,32,33,34,35].

-

Product Either a product or a service, is included as the result of the three previous systems, without neglecting the particular specifications for each detail and activity within the processes [25, 36,37,38,39,40,41,42, 73].

-

Processes these are the activities that give life to the product, so they are considered in the modules of value creation as the means to achieve the objective.In this case, being a product or a service, it is a systematic analysis that evaluates the process functionally, to discard activities without value [36, 37, 44,45,46,47,48,49,50,51,52,53,54, 73].

2.2 Horizontal integration

There is a complex relationship between the strategic and operational goals from the different levels of the manufacturing systems which inhibit the realization of an intelligent manufacturing system. Therefore, the Stevens model is used to identify aspects of a manufacturing system to be targeted for strategic planning; using standarized techniques and an agile scenario as an operational goal [11, 35, 36, 44, 54,55,56,57,58,59,60,61,62,63,64].

Any improvement in the industry is based on the current situation analysis and the environment study, where they are aimed and which strategies should be considered. Hence, it is essential to develop a conceptual model of integration, that describes the control activities in the manufacturing operations management and the level of the company, with a representation of the physical system and an explicit interface for the analysis of the optimal control [12, 65].

Stevens Model: With this model, it is intended to visualize the performance of the company in overall scheme supply chain operations. This approach defines the integration level from the organizations, as well as the technological absorption level. This point is essential for identify opportunities within the company to be proposed as change elements.

These change elements will be studied both in the internal organization and throughout the company’s supply chain, to be placed in one of the four integration levels proposed by Stevens [66]. To visualize schematically the integration possessed, according to the departments that handle to link the operations synergy.

A business model describes the logic of an organization’s value chain in terms of how the customer value is created and captured; being concisely represented through an interrelated set of elements: the customer, the value proposition, the organizational architecture and economic dimensions [3]. The main purpose is that every organization posseses a business model; being or not explicity articulated, these are required for the companies’ growth.

3 Methodology

The methodology has been divided into two phases for instrument design.The first one is the instrument building and the second refers to the validity and reliability tests regarding to the instrument, according to Hernández-Sampieri [67].

3.1 Instrument design

For the measurement instrument creation, twelve phases were followed. Figure 1 shows the considered stages.

Phases of instrument construction process [67]

3.2 Measurement instrument requirements

Validity, reliability, and objectivity are elements that should not be treated separately. If any of the three are not met or not analyzed, the instrument is not used for conducting a study.

Table 1 shows the measurement instrument requirements, the objectives, and techniques.

4 Information discussion and analysis

The information analysis obtained consists in the instrument development, design phases and measurement instrument requirements, as explained below.

4.1 Instrument design

Was performed exclusively with the monitoring of the phases considered.

Phase 1 Fundamental Redefinition: The research variables were defined, having as purpose to be applied in Mexico on a website with a scale value. The scale reflects the perception of the organization, operations and company clients regarding to the case study.

Phase 2 Focused literature review: Was performed by reviewing the detailed literature, the findings of this review can be found in Saucedo-Martínez [8].

Phase 3 Domain’s identification of the variables to be measured:It was precisely identified the components, dimensions, and factors that integrate the variable, based on horizontal and vertical integration systems.

Phase 4 Key decision-making: It was decided to design a new instrument, to be applied in Mexico, applied by a web page, based on a scales questionnaire.

Phase 5 Instrument construction: In this phase, the categories and the items were designed.

Phase 6 Pilot test: This test was done with group experts in the academic and research area, such that deficiencies must detect in the instrument.

Phase 7 Last version’s preparation of the instrument: Feedback was obtained from the items developed for the instrument until reaching the final version, Fig. 2 shows the survey questionnaire elements.

Phase 8 Personnel training who will administer the instrument: This was done by means of a spreadsheet, to manage the data and to organize them, as well as the codification.

Phase 9 Authorizations to apply the instrument: The authorization for application was made under confidentiality criteria, and not as a case study, if not to evaluate the requirements of the instrument, this is developed in the second section of the methodology.

Phase 10 Instrument application: For evaluating the instrument, experts participated with managerial positions from important companies in the northern region of Mexico in the industrial and service sectors, as well as technology.

Phase 11 Data readiness: The data coding was performed to carry out the analysis of the same.

Phase 12 Analysis: The analysis of the information gave rise to the study of the instrument, in which objectivity and reliability can be determined.

5 Measurement instrument requirements

5.1 Objectivity

Standardization: Objectivity was obtained through standardization in the application of the instrument (same instructions and conditions for all participants) and in the evaluation of the results; as well as employing trained and experienced personnel in the instrument.

5.2 Validity

The validity of a measuring instrument is evaluated based on all types of evidence. The more evidence of content validity, criterion validity and construct validity have a measuring instrument, the latter will come closer to representing the variables it intends to measure.

Total validity = content validity + criterion validity + construct validity

Content validity: This validation was carried out in a systematic way according to the literature review, in which concepts were investigated, until the terms with the highest level of comprehension were defined.

Criterion validity: To perform the criterion validation, tests and comparisons were made with different tools (Table 2).

Construct validity: This validation can represent the most important, is based on a theoretical basis of correlation of concepts, so that it is expressed as links of the items developed with the rest of the methodology.

Expert validity: This validation was done with experts in the field who reinforced the tool with their points of view, to improve the instrument.

5.3 Reliability

The reliability of the instrument was determined by means of the Cronbach alpha variable. For this purpose, the answers obtained in the application to experts were used, analyzing the data in a spreadsheet with a value of 99.2%

Cronbach’s alpha using the equation:

6 Conclusions and future work

This revolution is considered holistic from the point of view that includes all the technologies, tools, skills and knowledge available, to provide systems autonomy, increase levels efficiency, customer service and sustainability.

The inclusion of companies in the new way of operating requires the dissemination of information that allows the understanding and practice of the new modality of carrying out productive activities.

Technologies and the internet play a preponderant role in the new era, being imperative their adoption in companies. Companies must have a previous preparation to their application to operate in Industry 4.0 schemes, to ensure their development in the new system.

The development of an instrument for evaluating the current system, with validation, reliability and objectivity tests, contributes to the detection of business gaps and opportunities to improve the industrial environment.

In the future, it is intended to apply to the productive sector, case studies to generate global reports and analysis that allow investment and growth in technology and process improvement.

References

Schlechtendahl, J., Keinert, M., Kretschmer, F., Lechler, A., & Verl, A. (2014). Making existing production systems Industry 4.0-ready: Holistic approach to the integration of existing production systems in Industry 4.0 environments. Production Engineering, 91(1), 143. https://doi.org/10.1007/s11740-014-0586-3.

Dombrowski, U., & Wagner, T. (2014). Mental strain as field of action in the 4th industrial revolution. Procedia CIRP, 17, 100. https://doi.org/10.1016/j.procir.2014.01.077.

Fielt, E. (2013). Conceptualising business models: Definitions, frameworks and classifications. Journal of Business Models, 1(1), 85. https://doi.org/10.1177/0149206311406265.

Lee, J., Kao, H. A., & Yang, S. (2014). Service innovation and smart analytics for Industry 4. 0 and big data environment. Procedia CIRP, 16, 3. https://doi.org/10.1016/j.procir.2014.02.001.

Schuh, G., Potente, T., Wesch-potente, C., Weber, A. R., & Prote, Jp. (2014). Collaboration mechanisms to increase productivity in the context of Industrie 4.0. Procedia CIRP, 19(RoMaC), 51. https://doi.org/10.1016/j.procir.2014.05.016.

Vyas, D., & Nijholt, A. (2016). From Mundane to smart: Exploring interactions with ‘smart’ design objects. International Journal of Mobile Human Computer Interaction, 8(1), 59. https://doi.org/10.4018/IJMHCI.2016010103.

Schumacher, A., Erol, S., & Sihn, W. (2016). A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP, 52, 161. https://doi.org/10.1016/j.procir.2016.07.040.

Saucedo-Martínez, J. A., Pérez-Lara, M., Marmolejo-Saucedo, J. A., Salais-Fierro, T. E., & Vasant, P. (2017). Industry 4.0 framework for management and operations: A review. Journal of Ambient Intelligence and Humanized Computing. https://doi.org/10.1007/s12652-017-0533-1.

Gilchrist, A. (2016). Industry 4.0: The industrial internet of things. Bangken, Nonthaburi, Thailand: Apress.

Toro, C., Barandiaran, I., & Posada, J. (2015). A perspective on knowledge based and intelligent systems implementation in Industrie 4. 0. Procedia—Procedia Computer Science, 60, 362. https://doi.org/10.1016/j.procs.2015.08.143.

Joyce, A., & Paquin, R. L. (2016). The triple layered business model canvas: A tool to design more sustainable business models. Journal of Cleaner Production, 135, 1474. https://doi.org/10.1016/j.jclepro.2016.06.067.

Stock, T., & Seliger, G. (2016). Opportunities of sustainable manufacturing in Industry 4. 0. Procedia CIRP, 40(Icc), 536. https://doi.org/10.1016/j.procir.2016.01.129.

Wainstein, M. E., & Bumpus, A. G. (2015). Business models as drivers of the low carbon power system transition: A multi-level perspective. Journal of Cleaner Production, 126, 572. https://doi.org/10.1016/j.jclepro.2016.02.095.

Bauer, W., Hämmerle, M., Schlund, S., & Vocke, C. (2015). Transforming to a hyper-connected society and economy—Towards an “Industry 4. 0”. Procedia Manufacturing, 3(Ahfe), 417. https://doi.org/10.1016/j.promfg.2015.07.200.

Felicio, J. A., Couto, E., & Caiado, J. (2014). Human capital, social capital and organizational performance. Management Decision, 52(2), 350. https://doi.org/10.1108/MD-04-2013-0260.

Hashemy, S. H., Yousefi, M., Soodi, S., & Omidi, B. (2016). Explaining human resource empowerment pattern and organizational excellence among employees of emergency of Guilan’s University Hospitals. Procedia—Social and Behavioral Sciences, 230, 6. https://doi.org/10.1016/j.sbspro.2016.09.002.

Longo, F., Nicoletti, E., & Padovano, A. (2017). Smart operators in industry 4.0: A human-centered approach to enhance operators ’ capabilities and competencies within. Computers and Industrial Engineering. https://doi.org/10.1016/j.cie.2017.09.016.

Pelinescu, E. (2015). The impact of human capital on economic growth. Procedia Economics and Finance, 22, 184. https://doi.org/10.1016/S2212-5671(15)00258-0.

Smits, C. C. A., Justinussen, J. C. S., & Bertelsen, R. G. (2016). Human capital development and a Social License to Operate: Examples from Arctic energy development in the Faroe Islands, Iceland and Greenland. Energy Research and Social Science, 16, 122. https://doi.org/10.1016/j.erss.2016.03.016.

Hecklau, F., Galeitzke, M., Flachs, S., & Kohl, H. (2016). Holistic approach for human resource management in Industry 4.0. Procedia CIRP, 54, 1. https://doi.org/10.1016/j.procir.2016.05.102.

Estrin, S., Mickiewicz, T., & Stephan, U. (2016). Human capital in social and commercial entrepreneurship. Journal of Business Venturing, 31(4), 449. https://doi.org/10.1016/j.jbusvent.2016.05.003.

Vidotto, J. D. F., Ferenhof, H. A., Selig, P. M., & Bastos, R. C. (2017). A human capital measurement scale. Journal of Intellectual Capital, 18(2), 316. https://doi.org/10.1108/MRR-09-2015-0216.

Bücker, I., Hermann, M., Pentek, T., & Otto, B. (2016). Towards a methodology for Industrie 4 . 0 Transformation. Springer International Publishing Switzerland 1, 209. https://doi.org/10.1007/978-3-319-39426-8.

Ferriols, F. J., Mula, J., & Díaz-Madroñero, M. (2013). Supply chain management as the company engine in automotive manufacturing, vol. 46. IFAC. https://doi.org/10.3182/20130619-3-RU-3018.00614.

Syntetos, A. A., Babai, Z., Boylan, J. E., Kolassa, S., & Nikolopoulos, K. (2016). Supply chain forecasting: Theory, practice, their gap and the future. European Journal of Operational Research, 252(1), 1. https://doi.org/10.1016/j.ejor.2015.11.010.

Brandenburg, M. (2016). Supply chain efficiency, value creation and the economic crisis—An empirical assessment of the European automotive industry 2002–2010. International Journal of Production Economics, 171, 321. https://doi.org/10.1016/j.ijpe.2015.07.039.

Ojha, D., Shockley, J., & Acharya, C. (2016). Supply chain organizational infrastructure for promoting entrepreneurial emphasis and innovativeness: The role of trust and learning. International Journal of Production Economics, 179, 212. https://doi.org/10.1016/j.ijpe.2016.06.011.

Golmoradi, R., & Sattari Ardabili, F. (2016). The effects of social capital and leadership styles on organizational learning. Procedia-Social and Behavioral Sciences, 230, 372. https://doi.org/10.1016/j.sbspro.2016.09.047.

Ahuett-Garza, H., & Kurfess, T. (2018). A brief discussion on the trends of habilitating technologies for Industry 4.0 and smart manufacturing. Manufacturing Letters. https://doi.org/10.1016/j.mfglet.2018.02.011.

Davies, R., Coole, T., & Smith, A. (2017). Review of socio-technical considerations to ensure successful implementation of Industry 4.0. Procedia Manufacturing, 11, 1288. https://doi.org/10.1016/j.promfg.2017.07.256.

Lee, K. S., & Chen, W. (2017). A long shadow: Cultural capital, techno-capital and networking skills of college students. Computers in Human Behavior, 70, 67. https://doi.org/10.1016/j.chb.2016.12.030.

Kolberg, D., & Zühlke, D. (2015). Lean automation enabled by Industry 4.0 technologies. IFAC-PapersOnLine, 28(3), 1870. https://doi.org/10.1016/j.ifacol.2015.06.359.

Zhao, S., Technology, S., Cheng, B., Technology, S., Yu, L., Corporation, C., et al. (2016). Internet of things service provisioning platform for cross-application cooperation. International Journal of Web Services Research, 13(1), 1. https://doi.org/10.4018/IJWSR.2016010101.

Müller, J. M., Buliga, O., & Voigt, K. I. (2018). Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0, Technological Forecasting and Social Change (December 2017), 0. https://doi.org/10.1016/j.techfore.2017.12.019.

Barreto, L., Amaral, A., & Pereira, T. (2017). Industry 4.0 implications in logistics: An overview. Procedia Manufacturing, 13, 1245. https://doi.org/10.1016/j.promfg.2017.09.045.

Santos, K., Loures, E., Piechnicki, F., & Canciglieri, O. (2017). Opportunities assessment of product development process in Industry 4.0. Procedia Manufacturing, 11, 1358. https://doi.org/10.1016/j.promfg.2017.07.265.

Schöggl, J. P., Baumgartner, R. J., & Hofer, D. (2017). Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. Journal of Cleaner Production, 140, 1602. https://doi.org/10.1016/j.jclepro.2016.09.195.

Anderl, R. (2014). Advanced engineering of smart products and smart production, technological innovations in the produuct develoment. In 19 th International Seminar on High Tecnology, 1.

Thoben, Kd, Busse, M., Denkena, B., & Gausemeier, J. (2014). Editorial: System-integrated Intelligence—New challenges for product and production engineering in the context of Industry 4. 0. Procedia Technology, 15, 1. https://doi.org/10.1016/j.protcy.2014.09.028.

Nunes, M. L., Pereira, A. C., & Alves, A. C. (2017). Smart products development approaches for Industry 4.0. Procedia Manufacturing, 13, 1215. https://doi.org/10.1016/j.promfg.2017.09.035.

Xing, K., & Ness, D. (2016). Transition to product-service systems: Principles and business model. Procedia CIRP, 47, 525. https://doi.org/10.1016/j.procir.2016.03.236.

Sousa-Zomer, T. T., & Cauchick Miguel, P. A. (2015). Sustainable business models as an innovation strategy in the water sector: An empirical investigation of a sustainable product-service system. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2016.07.063.

Toro-Jarrín, M. A., Ponce-Jaramillo, I. E., & Güemes-Castorena, D. (2016). Methodology for the of building process integration of business model canvas and technological roadmap. Technological Forecasting and Social Change, 110, 213. https://doi.org/10.1016/j.techfore.2016.01.009.

Imran, S., Sanin, C., Szczerbicki, E., & Toro, C. (2015). Virtual engineering object/virtual engineering process: A specialized form of cyber physical system for Industrie 4. 0. Procedia—Procedia Computer Science, 60, 1146. https://doi.org/10.1016/j.procs.2015.08.166.

Geissdoerfer, M., Bocken, N. M. P., & Hultink, E. J. (2016). Desing thinking to enhace the sustainable business modelling process—A workshop based on a value mapping process. Journal of Cleaner Production, 135, 1218.

Tarhan, A., Turetken, O., & Reijers, H. A. (2016). Business process maturity models: A systematic literature review. Information and Software Tecnology: Elsevier, 75, 122.

Küber, C., Westkämper, E., Keller, B., & Jacobi, H. F. (2016). Planning method for the design of flexible as well as economic assembly and logistics processes in the automotive Industry. Procedia CIRP, 41, 556. https://doi.org/10.1016/j.procir.2015.12.038.

Liep, Ž., & Sakalas, A. (2014). Evaluation of human capital role in the value creation process. Procedia—Social and Behavioral Sciences, 156(April), 78. https://doi.org/10.1016/j.sbspro.2014.11.123.

Aledo Ruíz, M. D., Gutiérrez, J. O., Martínez-Caro, E., & Cegarra-Navarro, J. G. (2016). Linking an unlearning context with firm performance through human capital. European Research on Management and Business Economics, 23(1), 1. https://doi.org/10.1016/j.iedeen.2016.07.001.

Metallo, C., Agrifoglio, R., Schiavone, F., & Mueller, J. (2018). Understanding business model in the Internet of Things industry, Technological Forecasting and Social Change (2017). https://doi.org/10.1016/j.techfore.2018.01.020.

Zhong, R. Y., Newman, S. T., Huang, G. Q., & Lan, S. (2016). Big Data for supply chain management in the service and manufacturing sectors: Challenges, opportunities, and future perspectives. Computers and Industrial Engineering, 101, 572. https://doi.org/10.1016/j.cie.2016.07.013.

Volker, S., & Prostean, G. (2016). Research of automotive change management and combined risk-management models. Procedia—Social and Behavioral Sciences, 221, 395. https://doi.org/10.1016/j.sbspro.2016.05.129.

Liukkonen, M., & Tsai, T. N. (2016). Toward decentralized intelligence in manufacturing: Recent trends in automatic identification of things. International Journal of Advanced Manufacturing Technology, 87(9–12), 2509. https://doi.org/10.1007/s00170-016-8628-y.

Tantik, E., & Anderl, R. (2017). Potentials of the asset administration shell of Industrie 4.0 for service-oriented business models. Procedia CIRP, 64, 363. https://doi.org/10.1016/j.procir.2017.03.009.

Möller, D. P. (2016). Guide to computing fundamentals in cyber-physical systems. https://doi.org/10.1007/978-3-319-25178-3.

Prause, M., & Weigand, J. (2016). Industry 4. 0 and object-oriented development: Incremental and architectural change. Journal of Technology Management and Innovation, 11(2), 104.

Tjahjono, B., Esplugues, C., Ares, E., & Pelaez, G. (2017). What does Industry 4.0 mean to supply chain? Procedia Manufacturing, 13, 1175. https://doi.org/10.1016/j.promfg.2017.09.191.

Li, D. (2016). Perspective for smart factory in petrochemical industry. Computers and Chemical Engineering, 91, 136. https://doi.org/10.1016/j.compchemeng.2016.03.006.

Tupa, J., Simota, J., & Steiner, F. (2017). Aspects of risk management implementation for Industry 4.0. Procedia Manufacturing, 11, 1223. https://doi.org/10.1016/j.promfg.2017.07.248.

Benešová, A., & Tupa, J. (2017). Requirements for education and qualification of people in Industry 4.0. Procedia Manufacturing, 11, 2195. https://doi.org/10.1016/j.promfg.2017.07.366.

Miškuf, M., & Iveta, Z. (2016). Comparison between multi-class classifiers and deep learning with focus on Industry 4.0. In Proceedings of 28th international conference cybernetics & informatics (K&I), pp. 1–5.

Lom, M., Priibyl, O., & Svitek, M. (2016). Industry 4.0 as a Part of Smart Cities (pp. 2–7). Prague: Smart Cities Symposium.

Mosterman, P. J., & Zander, J. (2015). Industry 4.0 as a cyber-physical system study. Software and Systems Modeling. https://doi.org/10.1007/s10270-015-0493-x.

Arnold, C., Kiel, D., & Voigt, K. I. (2017). Innovative business models for the industrial internet of things, (pp. 1–12 ). Springer, Originalarbeit. https://doi.org/10.1007/s00501-017-0667-7.

Reinheimer, S. (2015). Rezension Industrie 4.0 in Produktion, Automatisierung und Logistik (pp. 802–806). Springer IFachmedien: Wiesbad.

Stevens, G. C. (2005). Integrating the supply chain.

Hernández Sampieri, R., Fernández Collado, C., & Baptista Lucio, M. D. P. (2014). Metodología de la investigación (6th ed.). México: McGraw-Hill.

Rockwell-Automation, The Connected Enterprise Maturity Model, Rockwell Automation. (2014). http://literature.rockwellautomation.com. Accessed 24 May 2017.

FH-Obersterreich, Fitness-Check für industrie 4.0 Entwickelt, FH-Obersterreich. (2015). https://www.fh-ooe.at/facebook/fitness-check-fuer-industrie-40-entwickelt/. Accessed 24 May 2017.

Consult, Industry 4.0 Readiness Online Self-Check for Businesses, IMPULS Foundation of the German Engineering Federation (VDMA). (2015). https://www.industrie40-readiness.de/?lang=en. Accessed 10 June 2017.

competitividad, HADA - Herramienta de Autodiagnóstico Digital Avanzada, Gobierno de Espaa. (2016). https://hada.industriaconectada40.gob.es. Accessed 12 June 2017.

Lanza, G., Nyhuis, P., Ansari, S.M., Kuprat, T., & Liebrecht, C. (2016). Empowered and implementation strategy for Industry 4.0, Befhigungs-und Einfhrungsstrategien fr Industrie 4.0.

PWC, The Industry 4.0/Digital Operations Self Assessment, PricewaterhouseCoopers. (2016). https://i40-self-assessment.pwc.de/i40/landing/. Accessed 23 June 2017.

Acknowledgements

The authors thank the Consejo Nacional de Ciencia y Tecnología (CONACYT) for the support provided to the development of this research, as well as the Universidad Autónoma de Nuevo Len for being the study house to knowledge generation and the Facultad de Ingeniería Mecánica y Eléctrica (FIME) by the support granted.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pérez-Lara, M., Saucedo-Martínez, J.A., Marmolejo-Saucedo, J.A. et al. Vertical and horizontal integration systems in Industry 4.0. Wireless Netw 26, 4767–4775 (2020). https://doi.org/10.1007/s11276-018-1873-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11276-018-1873-2