Abstract

The commercialization of fruits in markets generates a large amount of waste because they are perishable and have a short shelf life, so, they are discarded. This study aimed to provide a noble end to discarded fruits that have fermentable sugars. Banana, apple, mango and papaya residues were collected from supermarkets and underwent an enzymatic hydrolysis process. The ability of four pectinases, two amylases, one xylanase and one cellulase to release reducing sugars from fruit biomass before fermentation with two yeast strains (S. cerevisiae CAT-1 and S. cerevisiae Angel) for bioethanol production was investigated, obtaining a total of RS (Reducing sugar) of 268.08 mg/mL in banana residues. A fermentation with yeast S. cerevisiae CAT-1 resulted in 98% consumption of RS and the production of a total of 28.02 g/L of ethanol. Furthermore, fermentation with the yeast S. cerevisiae Angel, resulted in 97% RS consumption and 31.87 g/L ethanol production, which was the best result obtained throughout all the tests of hydrolysis, highlighting the banana residue as a promising biomass for the production of bioethanol.

Highlights

-

•We converted of fruit sugars to bioethanol;

-

We use alternative raw material for the production of biofuels;

-

We realized a screening of enzymes to be used in hydrolysis of fruit residues;

-

We studied mix of enzymes in the hydrolysis of fruit residues;

-

Yields of 268.08 mg/mL and 150.22 mg/mL of RS were obtained using the hydrolysis with enzyme Pectinex Ultra SP - L in the fruits Banana and Apple respectively;

-

We realized the fermentations using two different strains of yeast with similar results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of fossil fuels has led to increased greenhouse gas emissions and has all known environmental impacts on the planet. In addition, global geopolitical conflicts have led to price instability of this resource, which is irrenewable and its exploitation is finite. The side effects, along with rapid depletion of fossil fuels, promote the concept of alternative and renewable energy sources, such as biofuels [1, 2]. First-generation biofuels provide a greater balance of sustainability in the energy matrix, but this balance is still deficient. For example, the bioethanol industry still depends on agricultural crops, such as sugarcane and corn, sequestering large fertile lands that would otherwise be used for food production [3]. However, second-generation biofuels can be obtained from different types of waste, which originate a lignocellulosic biomass, such as fruit and vegetable waste. These wastes are plentiful and sustainable and their use can result in low carbon emissions [4].

Consumers tend to reject fruits and vegetables with surface imperfections in supermarkets, and the value of this waste is approximately 34.8 billion dollars annually in the United States alone [5]. In India, 12 million tons of fruit is wasted annually [6]. In Brazil, in 2020 alone, the value of the waste in all the 228 supermarket chains participating in ABRAS (Brazilian Association of Supermarkets) reached 7.6 billion of reals [7]. Fruit and vegetable residues are commonly ignored, and their loss causes nutritional, economic, and environmental problems. Losses and residues originate from unused or unconsumed parts of fruits and vegetables, usually because of flavor requirements and improper handling during operations [8]. For example, waste from mango can constitute 20–50% of the weight of the fruit, and banana can generate 20% waste during handling and processing [9]. Peels and pips, which are the by-products of papaya handling and processing, represent up to 25% of the fruit weight [10, 21]. However, the inedible parts of underused crops can be used in the production of biofuels, thereby reducing the waste generated for a sustainable and greener future [3]. These discarded residues gain a noble purpose when they are used as biomass for the production of biofuels. Depending on the characteristics of underutilized waste, one promising option among emerging recovery technologies is the production of biofuels with a low carbon footprint that does not compete with the food sector [11].

Fruit biomass is composed of cellulose (30–50%), hemicellulose (20–40%), and polymers potentially hydrolyzable into fermentable mono-and disaccharides [12]. Lignin (15–25%) is rich in carbohydrates (glucose, fructose, sucrose, starch) and fiber (pectin), which can be exploited through hydrolysis for conversion into bioethanol [6]. In fact, fruit wastes rich in cellulose and lignine can generate several products to substitute oil base products as methanol, methane, acetic acid [57, 58], furfural [59], food flavours [60]. All these products and biofuel use natural resources searching a sustainable production.

Cellulose is a polysaccharide with a crystalline structure formed by D-glucose molecules that are linearly connected by β− (1,4) glycosidic bonds. Hemicellulose is an amorphous polysaccharide consisting of sugar molecules with five and six carbons, mainly xylose, whereas lignin is a complex polymer composed of aromatic alcohols [13].

However, the pretreatment, hydrolysis, and fermentation of biomass residues have not yet been established on an industrial scale, which can make it difficult to replace the energy matrix in the short term [14]. Therefore, researchers worldwide are searching for alternative raw materials, such as underutilized fruits and vegetables that are usually wasted or discarded and have potential as a source of bioethanol [15]. The obstacle to using these lignocellulosic biomasses is the need for advanced technologies and pretreatments, which makes the final product more expensive than 1G-ethanol [2]. Thus, further studies are needed to investigate the release of sugars from fruit biomass and their subsequent conversion into ethanol.

Pretreatmenteatment of fruits has been studied by physical methods, which disrupt the structure of lignocellulosic biomass [16] including ultrasonic treatment catalyzed by nano-sized particles [17], chemical methods that use acids and bases to change the chemical and physical characteristics of the biomass [18], and enzymatic hydrolysis [19]. Degradation of hemicellulose gives rise to both glucose and other sugars such as xylose, arabinose, mannose, galactose, and rhamnose prior to fermentation, which converts the released sugars into bioethanol and CO2 [6, 20]. Nevertheless, the best treatment of fruit biomass for the industrial production of bioethanol is still not determined, and enzymatic hydrolysis can be a good strategy, as it can break complex molecules such as lignin, pectin, cellulose, and hemicellulose to release sugars. However, the rate of enzymatic hydrolysis is affected by the source of the enzyme, as product inhibition can be influenced by the resistance [3]. Thus, combination of enzymes can help release sugars for further fermentation to produce bioethanol.

The use of residues from the main fruits sold in supermarkets can add to the production of bioethanol, but the fruit biomass is not ready for fermentation. The contents of lignin, cellulose, hemicellulose, and pectin in fruit residues must be subjected to pretreatmenteatment, aiming at the release of reducing sugars that can be fermented [6].

[25] explored the feasibility of pomegranate fruit residue as a possible raw material for the production of second-generation ethanol. However, this work did not include enzymatic pretreatmenteatment for a greater release of sugars. [26] used domestic fruit waste for bacterial fermentation, and reported a yield of 0.30 grams of ethanol per gram of fruit waste used, although the authors did not use pretreatmenteatments for a greater release of sugars.

This research aimed to use fruit residues generated during their commercialization for the production of bioethanol, using enzymes to assist in the process of transforming complex carbohydrates into sugars that can be fermented by microorganisms to bioethanol.

Material and methods

Collection of fruit residues and sample preparation

Fruit residues were collected from supermarkets in Passo Fundo/RS, Brazil. The most commonly discarded fruits were those rejected by consumers for marks, stains, or overmaturing. We collected bananas, apples, mangoes and papayas.

Each sample containing 50 g of whole fruit (peel, seed, and pulp) plus 50 mL of water, were added in an industrial blender for crushing (Skymsen, Model LI-1,5-N, Brazil). This preparation was carried out for each fruit individually and added in 125 mL Erlenmeyer flasks, and the pH was adjusted to 4.5 using1 M citric acid.

Starch gelatinization

After sample preparation, starch gelatinization was performed. The samples were immersed in a thermostated bath (Tecnal, TE-2005, Piracicaba, Brazil) with agitation until reaching 90°C, maintained for 5 min, and cooled to 52°C (Rempel et al., 2019).

Characteristics of the enzymes

The enzymes used for biomass hydrolysis were donated by Novozymes® and had specific characteristics.

Pectinex® Ultra SP-L is a Polygalacturonase, which hydrolyzes (1,4)-alfa-D-galactosiduronic ligaments in pectate and other galacturonans, with a declared activity of 3300 PGNU/g. A volume of 150 mL/m3 was used for each sample.

Pectinex® Ultra Tropical is a Pectin lyase catalyzes the eliminative cleavage of (1,4)-alpha-D-galacturonan methyl ester, forming oligosaccharides with 4-deoxy-6-O-methyl-alpha-D-galacto- 4-enurosonil at the non-reducing ends, with a declared activity of 5000 PECTU/g. A volume of 150 mL/m3 was used for each sample.

Pectinex® Ultra Pulp is a Pectin lyase, which catalyzes the eliminative cleavage of (1,4)-alpha-D-galacturonan methyl ester, forming oligosaccharides with 4-deoxy-6-O-methyl-alpha-D-galacto-4-enurosonyl groups at non-reducers, with a declared activity of 8600 PECTU/g. A volume of 150 mL/m3 was used for each sample.

Pectinex® Ultra Clear is a Polygalacturonase, which hydrolyzes (1,4)-alpha-D-galactosiduronic bonds in pectate and other galacturonans, with a reported activity of 8600 PGNU/g. A volume of 150 mL/m3 was used for each sample.

Amylase™ AGXXL is a Glycoamylase, which hydrolyzes (1,4)- and (1,6)-alpha-D-glucose bonds at the non-reducing ends of polysaccharides with a declared activity of 400 AGU/g. A volume of 150 mL/m3 was used for each sample. Saczyme® Go 2X is a Glycoamylase, which hydrolyzes (1,4)- and (1,6)-alpha-D-glucose bonds at the non-reducing ends of polysaccharides with a declared activity of 1725 AGU/g. A volume of 100 mL/m3 was used for each sample.

A Ultraflo® Max is a Endo-beta-glucanase, which hydrolyzes (1,3)- or (1,4)- bonds in beta-D-glucan xylanase, which hydrolyzes (1,4)-beta-D-xylosidic bonds to form xylans, with stated activity 250 FXU-S/g and 700 EGU/g. A volume of 100 mL/m3 was used for each sample.

A Celluclast® 1.5 L is a Cellulase, which hydrolyzes (1,4)-beta-D-glycosidic bonds in cellulose and other beta-D-glucans with a reported activity of 700 EGU/g. A volume of 100 mL/m3 was used for each sample.

The enzymes were tested separately and in combinations, assuming that the matrix is complex and that several groups could be hydrolyzed by the parallel and/or synergistic action of the enzymes.

Enzymatic hydrolysis

For the hydrolysis process, enzymes were added to the samples containing fruits after starch gelatinization. Eight samples were prepared for each of the four fruits (32 assays, with replicates), and one enzyme was added to each sample to verify which enzyme would perform best for each tested fruit biomass.

After the first tests using only one enzyme, the combination of all enzymes in each fruit biomass was tested to verify the joint performance. For the fermentation experiments, only the enzymes that showed better activity regarding the release of reducing sugars during the hydrolysis of biomass and fruits were used.

Hydrolysis was carried out in 125 mL- Erlenmeyers (working volume of 50 mL) in a incubator with agitation (Tecnal, model TE-421, Piracicaba, Brazil) at a temperature of 50°C for 180 min. Samples were collected at times zero, 30, 60, 90, 120, 150, and 180 min to determine the concentration of released reducing sugars

Alcohol fermentation

For alcoholic fermentation, the fruit residues were hydrolyzed only by the enzymes that presented the best results in the enzymatic tests. Fermentation took place using two yeasts, S. cerevisiae CAT-1, belonging to the Laboratory of Biochemistry and Bioprocesses of the Uninersidade de Passo Fundo, and S. cerevisiae Angel Thermal Resistance Alcohol Yeast, kindly donated by Novozymes®.

S. cerevisiae CAT-1 was maintained in test tubes at 4°C in slanted solid media (1% yeast extract, 2% peptone, 2% glucose, and 2% agar). Yeast cells were activated using a pre-inoculum prepared in a 250 mL Erlenmeyer flask containing 100 mL of sterile culture medium (1% yeast extract, 2% peptone and 2% glucose). Afterwards, the S. cerevisiae CAT-1 yeast cells from the tube with inclined medium were added to the culture medium and kept in a refrigerated incubator with shaking (Tecnal, model TE-421, Piracicaba, Brazil) for 48 h at 30 ºC. After yeast activation, 10% (v/v) of the pre-inoculum was used to inoculate 100 mL of the same culture medium in a 250 mL Erlenmeyer flask, kept in a refrigerated incubator with agitation (Tecnal, model TE- 421, Piracicaba, Brazil) for 10 h (time required for the yeast to be in an exponential growth phase).

S. cerevisiae Angel Thermal Resistance Alcohol Yeast was activated by adding 0.1 g of dry, stable and concentrated form of the yeast in 100 mL of water, at a concentration of 100 g/L in a thermostated bath (Tecnal, TE- 2005, Brazil) at 35 ºC, for 30 minutes. The hydrolyzed fruit biomass had sterilized in an autoclave at 121°C for 20 min, cooled and subjected to fermentation with the two yeasts separately. Inoculation was performed using 10% (v/v) yeast inoculum. Fermentation was carried out in a 500 mL Erlenmeyer flask with a useful volume of 250 mL at 30°C in an incubator without agitation (P.H.D, model IAOH125, Piracicaba, Brazil). This process was performed under anaerobic conditions. Samples were collected at time zero and every 12 h to determine the concentrations of reducing sugars (RS) and ethanol. The duration of the process was 72 h. Fermentation was conducted according to [27] in an oven at a temperature of 30°C and without stirring.

Analytical methods

Determination of Reducing Sugars

Before de determinations of RS in each sample, proteins were removed using the methodology described by [28], where 0.4 mL of Carrez solutions I and II (15% potassium ferrocyanide solution and 30% zinc sulfate solution, respectively) were added to each sample of hydrolyzed fruits containing 1 mL, in order to precipitate them. Distilled water was then added to the sample to a total volume of 25 mL, followed by centrifugation at 1320g for 5 min (Eppendorf Centrifuge 5810). Filtration was then performed, and 1 ml of the filtrate was used to determine the concentration of the reducing sugars

Reducing sugars (RS) were measured by the colorimetric method with 3,5 dinitrosalicylic acid (DNS), as described by [29], using a standard curve obtained from an anhydrous glucose stock solution. All measurements were performed in triplicate.

Ethanol

The fermented samples were distilled in a benchtop microstill (Tecnal, model TE-012), and the recovered ethanol was analyzed using the acid potassium dichromate method at 600 nm [30].

Reducing Sugars to Etanol conversion

The results convertion of RS to Etanol was obtein in each fermentation test, by the conversion factor from RS to P (YP/RS in g/g) and the volumetric productivity in P (QP in g/L.h) were calculated using Equations (1) and (2), respectively [50].

Date treatments

All experiments were performed in duplicate, and the results are presented as the mean ± standard deviation. Data were treated and evaluated by analysis of variance with a confidence level of 95%, with further analysis using the Tukey test using the Statsoft software (Statistica 7.0, StateSoft Academic Solution, São Paulo, SP, Brazil).

Results and discussion

Enzymatic hydrolysis of fruit biomass

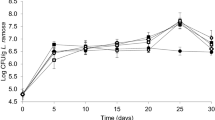

Fig. 1 shows the concentration of reducing sugars over time for each enzymatic treatment applied to biomass from fruit waste.

A higher concentration of reducing sugars was obtained with banana biomass using the enzyme Pectinex Ultra SP-L. The banana biomass had an initial concentration of RS of 109.39 mg/mL and after the hydrolysis the concentration of RS reached 268.08 mg/mL. Pectin is the second most important structural component of bananas that affects their mechanical, structural, and functional properties causing firmness. It is a complex carbohydrate with homogalacturonon chains (smooth regions) and rhamnogalacturonan regions (hairy regions) [31]. The insoluble dietary fiber components present in 100 g of bark of banana are cellulose (18.7 g), hemicellulose (20.3 g) and lignin (16.8 g) [55], while pectin (15.9 g / 100 g) is a component of dietary fiber soluble [56]. As banana ripening advances, more soluble pectin is generated [32]. We added whole banana (peel and pulp) in the advanced stage of ripening to the hydrolysate. In the high stage of ripening, the pectin content in the peel is lower and pectin is more soluble, making facilitating enzymatic hydrolysis. In addition, pectin is soluble in water and acid media [31] and the pH was adjusted to 4.5 to facilitate hydrolysis. Furthermore, we also tested others pectinases (Pectinex tropical, Pectinex Pulp, and Pectinex Clear) and these enzymes did not produce higher concentration of reducing sugars compared to Pectinex Ultra SP-L. However, the other pectinases act on 4-deoxi-6-O-metil-alfa-D-galacto-4-enurosonil (Pectinex Ultra Tropical) and (1,4)-alfa-Dgalacturonana methil ether (Pectinex Ultra Pulp), and is expected that pectin is approximately 65% in the form of homogalacturonan and only 20–35% in other forms. Thus, the Pectinex Ultra SP-L enzyme is more specific for the hydrolysis of banana biomass, whic has pectin as the major carbohydrate in the homogalacturonan form.

Árias et al. [33] reported that pectin in banana peels can be extracted by approximately 54% in dry mass (or 10% in wet basins). Thus, pectin in banana biomass is a potential substrate for generating sugars for further fermentation, and our hydrolysis results show that pectin esterase can generate high concentrations of RS.

Another highlighted result was the hydrolysis of banana biomass by amylase. After hydrolysis, the biomass had an RS concentration of 181 mg/ml. However, the substrate of the amylase (starch) is higher in unripe bananas - approximately 70–80% [19] and is reduced to less than 1% in overripe bananas [34]. However, the starch content of the banana biomass was sufficient to achieve a high concentration of reducing sugars after hydrolysis.

The pretreatmenteatment of apple biomass with Pectinex Ultra SP-L produced the higher concentration of RS (150.22 mg/mL) after 180 min of hydrolysis when compared to the other enzymes utilized. However, the initial concentration of RS in apple biomass was lower than that for banana biomass, and thus, the final concentration of RS in apple was lower than that in banana biomass. Pectin is a major multifunctional component usually found in association with other structural constituents such as cellulose and lignin present in the cell walls of plants [35], including apples. The cellulose concentration in apple is 20.4% (glucan content), hemicelluloses 30.8% (xylan, araban, rhamnosan and polygalacturonan), lignin is 13.2% and ash content 0.9%, being the pectin in the range of 0.5%to 1.6% [36], [61] and the current technology to produce apple juice already includes an enzymatic treatment of the cell walls to increase the extraction yield, reducing sugars, soluble dry matter content, and galacturonic acid [37]. In addition, the initial presence of free sugars makes apple waste a potential biomass for the production of bioproducts [24], including bioethanol. [38] applied a pretreatmenteatment of apple biomass to release sugars for the production of bioethanol. The pretreatmenteatment included heating followed by acidification with citric acid and further enzymatic treatment using CellicCTec®2 (a mixture of cellulase, β-glucosidases, and hemicellulases) and Viscozyme® L (a mixture of beta-glucanases, pectinases, hemicellulases, and xylanases). The apple hydrolysate contained 153 g/L of RS. In contrast, we used only one enzyme, and obtained a similar concentration of of 150.22 mg/L RS. This yield indicates that apple biomass can be used to produce bioethanol. Apple waste is a good source of biomass. Several studies have apple pomace to produce bioethanol. Different strategies have been proposed to improve ethanol production, such as the combination of heating and enzymatic hydrolysis of lignocellulose material [38], removal of lignin using organosolv [23] or direct fermentation of cocultures [24]. However, all strategies to release sugars and further fermentation are still conducted at the laboratory scale, as the final concentration of ethanol is not enough to compete with first generation ethanol production. Therefore, further studies are necessary to improve the production steps.

The hydrolysis of mango biomass produced three times the initial concentration of RS using Pectinex Clear and Saczyme enzymes. The initial RS concentration was approximately 20 mg/mL, and after 180 min of hydrolysis, the value was 59 mg/mL. The sugar released was only 10.7% of the initial mass of mango biomass. These enzymes use different substrates to produce free sugar, Pectinex Clear acts on the (1,4)-alfa-D-galacturonic acid chain, and Saczyme is a glucoamylase acting on (1,4)- e (1,6)-alfa-D-glucose at the non-reducing ends of polysaccharides. We used both peel and pulp of mango, and the peel comprised 46% cellulose, 25% lignin, 32% de pectin and 28% hemicellulose [22], [62], [63]. However, the enzyme Cellulacast released only 14 mg/mL of RS after 180 min of hydrolysis. [22] performed an alkaline pretreatmenteatment to remove lignin before the enzymatic reaction with cellulase to release 58 mg/mL of glucose from mango peel, but 24 h were necessary to achieve this concentration. Thus, the use of pulp and peel wastes from mangoes can be a good source to obtain sugars for fermentation, as only 180 min was sufficient to generate a similar concentration.

Two pectin esterases (Pectinex Ultra SP-L and Pectinex Clear) and glucoamylase (Saczyme) increased the initial concentration of sugars from ~ 50 to ~ 90 g/L in papaya biomass. Papaya peel is rich in pectin, consists of low methyl-esterified, linear Ca2+-cross-linked homogalacturonan with high molar mass pectin, and can be a potential source of this polysaccharide [10]. In addition, the cell-wall of papaya is a good source of pectin, as it constitutes of 35% pectin, 30% cellulose, 30% hemicellulose, and 5% protein [39]. Thus, this polysaccharide could be a source of sugar after the action enzymatic hydrolysis using esterases of pectin. However, we did not observe the release of sugars following hydrolysis with a cellulase (Cellulaclast). Comparing the three enzymes, Pectinex Ultra SP-L required only 60 min to hydrolyze and to reach the maximum concentration of RS, and both Saczyme and Pectinex Clear required 120 min and 180 min, respectively, to reach the same concentration of RS. [40] crushed papaya waste to produce bioethanol without any pretreatment in a waste:water ratio of 3:1, and the concentration of soluble solids was 4.02%. On the other hand, our enzymatic treatment produced twice this value, as the concentration of RS was approximately 90 mg/mL. Thus, enzymatic treatment can be an alternative to increase the yield of bioethanol production from papaya wastes, as the enzymes Pectinex Ultra SP-L, Pectinex Clear, and Celluclast produced high concentrations of RS. Fig 2 shows the rate of hydrolysis over time for each fruit using the different enzymes.

The Pectinex Ultra SP-L enzyme showed high conversion rates in fruit biomass, except for mango. The conversion rate was higher than 5 mg/mL.min in the banana biomass at the beginning of hydrolysis. The concentration of reducing sugars increased from 109 mg/mL to 268 mg/mL in 30 min (Fig. 1). Subsequently, the concentration of RS was stable, and thus, the rate of hydrolysis decreased with time. Pectinex Ultra SP-L is a polygalacturonase, and the simplified mechanism of pectin hydrolysis is shown in Fig. 3. Banana peel is a good source of pectin [41] and its hydrolysis generates sugars for fermentation. In addition, homogalacturonan is the major pectin form in the cell walls of plants [31]. Thus, it is expected that Pectinex Ultra SP-L produces more sugars than other pectin esterases that hydrolyze pectin by the de-esterification of methoxylated galacturonic acid (Pectinex Ultra Pulp and Pectinex Ultra Tropical).

Different types of pectinases and their action mechanisms on pectin substrates

Source: [54]

Pectin is usually found in association with other compounds, such as cellulose, lignin, or polyphenols, present in the cell walls of plants [31]. The association with other cell wall compounds can impair the access of the enzyme to its substrate, and reduce the production of sugars. Some studies [42, 43] have applied an alkaline pretreatmenteatment in mango fruit to decrease the degree of polymerization and crystallinity of the biomass, swell fibers, and disrupt the lignin structure. We preferred the direct application of enzymes as sustainability points to a lower application of chemical treatment in the biomass, but the release of sugars was not high. Mango stem bark is a source of lignocellulosic material as it comprises 46.8% cellulose (estimated as glucan), 28.1% hemicellulose, and 23.2% lignin [43]. However, the Celluclast enzyme (a cellulase) did not release enough sugars for further fermentation, as we used both pulp and peel from mango and did not perform alkaline pretreatmenteatment.

The rate of hydrolysis using apple biomass was the second-best for generating RS. The best productivities were achieved by two pectin esterases (Pectinex Ultra SP-L and Pectinex Ultra Clear). In fact, pectin esterases are well known enzymes to hydrolyze pectin in the apple matrix as the clarification of apple juice involves the treatment with a mixture of polygalacturonases, pectinase and glucoamylase for 100 min at 55°C followed by ultrafiltration (UF) using tubular membranes of molecular weight cut-off (MWCO) of 100 kDa [44]. Our enzymatic treatment confirmed the efficiency of pectinases to release reducing sugars from apple biomass.

The Ultraflo Max enzyme (an endo-beta-glucanase) also produced reducing sugars, but the hydrolysis rate was lower than that of pectin esterases, as the concentration of homogalacturonan is higher in the fruits than beta-glucans.

Although fruit residues are characterized as biomass composed of cellulose, hemicellulose, and lignin, which can be used for the production of second-generation biofuels, they present some particularities in their chemical composition, which is important for the enzymatic hydrolysis process. Bananas, apples, mangoes and papayas are composed of pectin, fiber, starch, protein and total reducing sugars, such as fructose, sucrose and glucose [45, 23, 46, 47] and each enzyme acts on different substrates.

The hydrolysis of bananas using the enzyme Pectinex Ultra SP-L was the best condition for obtaining RS. Furthermore, the enzyme Pectinex Ultra SP-L was also the best enzyme to hydrolyze apple and papaya biomass. Thus, we performed fermentation with biomass from all fruits. Figure 4 shows the initial, final, and released RS by enzymatic hydrolysis.

Simultaneous hydrolysis with the eight enzymes for each fruit biomass did not show better results in relation to the tests carried out with individual enzymes. Fig 5 shows the results of the enzymatic hydrolysis performed with the mixture of eight enzymes, tested for the hydrolysis of each fruit biomass.

The maximum results occurred with the banana biomass, producing 0.62 mg/mL.min in 30 min, which is statistically equal to that obtained in 60 min (0.52 mg/mL.min) and the amount of available RS went from 108.84 mg/mL to 127.48 mg/mL. This result was lower than that obtained in banana biomass exclusively by the enzyme Pectinex Ultra SP-L, which increased from 109.39 mg/mL to 268.08 mg/mL, that is, 5.29 mg/mL.min, this case may have occurred due to the competition for the substrate that one enzyme can cause the other, which could have been solved by supplementation or increased biomass concentration [66].

Another alternative would be the use of pretreatment techniques to soften the crystalline structure of the biomass before enzymatic hydrolysis. Enzymatic systems containing cocktails of several hydrolytic enzymes are efficient for the complete and simultaneous hydrolysis of all carbohydrates in several raw materials for the production of second generation bioethanol, but before that the biomass must pass through the pretreatment stage, making it more accessible for enzymatic hydrolysis [67].

Production of bioethanol from hydrolized fruit biomass

Afterwards, banana, apple, mango, and papaya biomass was hydrolyzed by the enzyme Pectinex Ultra SP-L and subjected to fermentation with two yeast strains to evaluate the production of bioethanol: S. cerevisiae CAT-1 and S. cerevisiae Angel. Figure 6 shows the concentrations of RS and ethanol over the course of the fermentation, and Table 1 shows the ethanol yields and ethanol productivity. In general, banana waste produced higher ethanol concentrations (28–31 g/L) and higher productivity (0.442 g/L.h), and papaya produced low ethanol concentrations (9–12 g/L). However, mango waste showed a higher ethanol yield with regard to sugar consumption.

Lignocellulosic fruit biomass can generate non-fermentable sugars in the hydrolysis process, such as pentoses, in addition to hexoses. Pentoses are also reducing sugars but not always possible to be fermented by common yeasts like S. cerevisiae. Also being a side effect of the pre-treatment applied to these biomasses, the formation of inhibitory by-products, such as furfural. Cofermentation of pentose and hexose is considered the first and most important prerequisite for economically viable conversion of ligno-cellulosic biomass to ethanol. However, lack of robust organisms or fermentation process to convert both hexose and pentose efficiently compromises the overall fermentation performance [64, 65, 66, 67].

Both yeasts (S. cerevisae Angel and S. cerevisae CAT-1) used to the fermentation of the hydrolyzed biomass produced ethanol. However, there was no optimal strain for all fruit biomasses. Similar concentrations of ethanol were produced by both strains using banana and mango biomass (Figs. 6-a and 6-c). The CAT-1 strain produced more ethanol from apple biomass, and the Angel strain produced more ethanol from papaya biomass. Thus, there was no standard behavior regarding ethanol yield.

The banana biomass produced higher concentrations of ethanol. The initial RS concentration of 151.9 mg/L increased after hydrolysis to 359.08 mg/L. The strain Angel used 97% of RS and produced 31.87 g/L of ethanol whereas the CAT-1 produced 28.02 g/L. The yeast CAT-1 consumed 98% of RS, and most of sugars were used in the first 12 h of fermentation. If the global production of banana is approximately 114 million tons [48, 49] it is estimated that 460 kg of banana per ton is rejected. Therefore, banana waste has the potential to produce 3.3 billion liters of ethanol. A total of 7.1 million tons of bananas were produced in Brazil in 2020 [50], and there is potential to produce 200 million liters of ethanol per year.

[50] used banana waste composed of a mixture of pulp, peel, and pseudostem in a proportion of 1:2:10 to produce ethanol. They used acid and enzymatic processes with the application of cellulose and hemicellulose, and the biomass contained 150 g/L of RS. After the fermentation, similar to our results, the broth contained37.8 g/L of ethanol, but the higher concentration of ethanol was reached after 48 h of fermentation. [48] suggested that the minimum concentration of ethanol should be 40 g/L to reduce the cost of the distillation step. As we used a ratio of 1 g/g (biomass to water) for hydrolysis, we believe that a slight adjustment in the ratio of biomass to water can be done to reach a concentration of 40 g/L, and, thus, reduce de cost.

The hydrolyzed apple biomass produced 20.11 g/L of ethanol using S. cervisae Angel and the consumption of sugars was 96%. On the other hand, the CAT-1 strain produced 15.80 g/L of ethanol, and the consumption of RS was only 76%. Thus, the performance of different strains of S. cerevisae can vary for the same substrate, and different ethanol yields can be obtained. [38] studied apple pomace as a biomass to produce bioethanol. After pretreatmenteatment by heating and enzymatic hydrolysis of lignocellulose material, the consumption of RS was 84% and the ethanol concentration was 51 g/L after 72 h of fermentation by S. cerevisae Ethanol Red® with a yield of 0.398 g of ethanol for each gram of sugar consumed. However, the xylose released during the hydrolysis of lignocellulosic biomass cannot be used by S. cerevisae; therefore, some studies have focused on the application of cocultures using S. cerevisiae and filamentous fungi such as Trichoderma and Aspergillus species to produce bioethanol [24]. In addition, approximately 10% of the fermented sugars are consumed by the microorganisms for cell mass synthesis, yeast maintenance, and side reactions that produce lactic acid, acetic acid, and glycerol [51]. Thus, the search for high productivity and high ethanol concentration must continue, as different fruit wastes can be used as substrates, and different microorganisms can be used for fermentation.

The fermentation of hydrolisated mango fruit by both strains of S. cerevisiae produced approximately 15 and 16 g/L of ethanol, and the RS consumption was 91–92%. Several studies have been conducted to produce bioethanol from mango waste. [52] produced a fermented broth by S. cerevisae with 15% (v/v) of ethanol using mango waste. [43] dried mango stem bark residues and applied alkaline pretreatment to the waste. After fermentation with S. cerevisiae using simultaneous saccharification and fermentation, the authors reported an ethanol concentration of 43 g/L and a productivity of 0.914 g/L/h. [53] supplemented mango waste with leachate from vermicomposting to add nutrients to the broth and produced 44 g/L of ethanol after fermentation. We did not add any nutrient supplements as we focused on the application of fruit waste without the addition of chemicals, but the enzyme treatment.

Hydrolyzed papaya waste produced the lowest concentration of ethanol. S. cerevisiae CAT-1 consumed 95% of RS, but the concentration of ethanol in the fermented broth was only 9.32 g/L. S cerevisiae Angel consumed 95% of RS and produced 12.40 g/L of ethanol. [40] tested the direct fermentation of several fruit wastes, such as banana, apple, papaya, and orange, to produce bioethanol. The authors identified that banana has a higher concentration of soluble solids (10.32 Brix) and produced the highest concentration of ethanol (12% v/v). However, using chromatography, the authors identified several co-generated products, including acetaldehyde, acetone, methanol, ethyl acetate, propanol, isobutanol, isoamyl acetate, and isoamyl alcohol. Acetaldehyde is a byproduct of fermentation and can be used to generate high alcohols, such as propanol, isobutanol, and isoamyl alcohol.

Conclusions

Banana, apple, mango, and papaya residues, which are unsuitable for human consumption, were subjected to enzymatic hydrolysis and fermentation to produce bioethanol. Several commercial enzymes were tested for the hydrolysis of fruit waste, but pectin esterase was the best enzyme to release reducing sugars from biomass. The enzyme Pectinex Ultra SP-L doubled the initial concentration of reducing sugars from all fruit biomass, achieving 257 mg of reducing sugar per gram of banana.

Both yeast strains of S. cerevisiae (CAT-1 and Angel) produced ethanol by fermentation of reducing sugars from fruit biomass. Fermented hydrolyzed banana waste generated 30 g/L ethanol.

Banana biomass was highlighted both for the yield of reducing sugars and for the generation of bioethanol, showing tthe potential of this residue for this purpose, considering the availability in which it is found.

Availability of data and materials

Raw data is not available to download

References

Saravanan A, Kumar PS, Jeevananthamd S, Karishma S, V DVN (2022) Recent advances and sustainable development of biofuel production from lignocellulosic biomass. Bioresour Technol 344:126203. https://doi.org/10.1016/j.biortech.2021.126203

Kumar M, Sun Y, Rathour R, Pandey A, Thakur IS, Tsang DCW (2020) Algae are potential feedstocks for the production of biofuels and value-added products: opportunities and challenges. Sci Total Environ 716:137116. https://doi.org/10.1016/j.scitotenv.2020.137116

Pocha CKR, Chia SR, Chia WY, Koyande AK, Nomanbhay S, Chew KW (2022) Utilization of agricultural lignocellulosic wastes for biofuels and green diesel production. Chemosphere 290:133246. https://doi.org/10.1016/j.chemosphere.2021.133246

Lin CY, Lu C (2021) Development perspectives of promising lignocellulose feedstocks for the production of advanced generation biofuels: a review. Rev Renew sustainable energy 136:110445. https://doi.org/10.1016/j.rser.2020.110445

Hingston ST, Noseworthy TJ (2020) On the epidemic of food waste: Idealized prototypes and aversion to misshaping fruits and vegetables. Food Qual preferences 86:103999. https://doi.org/10.1016/j.foodqual.2020.103999

Panahi HKS, Dehhaghi M, Guillemin GJ, Gupta VK, Lam SS, Aghbashlo M, Tabatabaei M (2022) Bioethanol production from carbohydrate-rich food waste. Curr Opinions Food Sci 43:71–81. https://doi.org/10.1016/j.cofs.2021.11.001

ABRAS - Associação Brasileira de Supermercados (2021) https://www.abras.com.br/. Accessed 01 October 2022

Sagar NA, Pareek S, Sharma S, Yahia EM, Lobo MG (2018) Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr Rev Food Sci Food Saf 17:512–531. https://doi.org/10.1111/1541-4337.12330

Banerjee J, Singh R, Vijayaraghavan R, MacFarlane D, Patti AF, Arora A (2017) Bioactives from fruit processing waste: green approaches to valuable chemicals. Food Chem 225:10–22. https://doi.org/10.1016/j.foodchem.2016.12.093

Koubala BB, Christiaens S, Kansci G, Loey AMV, Hendrickx ME (2014) Isolation and structural characterization of papaya peel pectin. Food Res Int 55:215–221. https://doi.org/10.1016/j.foodres.2013.11.009

Esparza I, Jiménez-Moreno N, Bimbela F, Ancín-Azpilicueta C, Gandía LM (2020) Fruit and vegetable waste management: Conventional and emerging approaches. J Environ Manage 265:110510. https://doi.org/10.1016/j.jenvman.2020.110510

Conesa C, Seguí L, Laguarda-Miró N, Fito P (2016) Microwaves are a pretreatment method for enhancing the enzymatic hydrolysis of pineapple industrial waste for bioethanol production. Food and bioproduct processing 100:203–213. https://doi.org/10.1016/j.fbp.2016.07.001

Musci JJ, Montaña M, Rodríguez-Castellón E, Lick ID, Casella ML (2020) Selective aqueous-phase hydrogenation of glucose and xylose over ruthenium-based catalysts: Influence of the support. Mol Catal 495:111150. https://doi.org/10.1016/j.mcat.2020.111150

Rempel A, Biolchi GN, Antunes ACF, Gutkoski JP, Treichel H, Colla LM (2021) Cultivation of microalgae in media containing emergent pollutants and effects on growth, chemical composition, and use of biomass for enzymatic hydrolysis. Bioenergy Res 14:265–277. https://doi.org/10.1007/s12155-020-10177-w

Chitranshi R, Kapoor R (2021) Utilization of over-ripened fruit (waste fruit) for the eco-friendly production of ethanol. Int J Plant Res 33:270–276. https://doi.org/10.1007/s42535-020-00185-8

Bayar N, Bouallegue T, Achour M, Kriaa M, Bougatef A, Kammoun R (2017) Ultrasonic extraction of pectin from Opuntia ficus indica cladodes after mucilage removal: optimization of experimental conditions and evaluation of chemical and functional properties. Food Chem 235:275–282. https://doi.org/10.1016/j.foodchem.2017.05.029

Rekha B, Saravanathamizhan R (2021) Preparation and characterization of biomass-based nanocatalysts for hydrolysis and fermentation of catalytic hydrolysates to bioethanol. Biomass Convers biorefineries 20:01207. https://doi.org/10.1007/s13399-020-01207-w

Koupaie EH, Dahadha S, Lakeh AB, Azizi A, Elbeshbishy E (2019) Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production: a review. J Environ Manage 233:774–784. https://doi.org/10.1016/j.jenvman.2018.09.106

Zabed HM, Akter S, Yun J, Zhang G, Awad FN, Qi X, Sahu JN (2019) Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew Sustain Energy Rev 105:105–128. https://doi.org/10.1016/j.rser.2019.01.048

Fakayode OA, Akpabli-Tsigbe NDK, Wahia H, Tu S, Ren M, Zhou C, Ma H (2021) Integrated bioprocess for bioethanol production from watermelon rind biomass: Ultrasound-assisted deep eutectic solvent pretreatment, enzymatic hydrolysis, and fermentation. Renewable Energy 180:258–270. https://doi.org/10.1016/j.renene.2021.08.057

Abdulla R, Derman E, Ravintaran PT, Jambo SA (2018) Fuel ethanol production from papaya waste using immobilized Saccharomyces cerevisiae. Sanrem 11:112–123. http://drs.nio.org/drs/handle/2264/5162

Nieves DC, Ruiz HA, Cárdenas LZ, Alvarez GM, Aguilar CN, Ilyina A, Hernández JLM (2016) Enzymatic hydrolysis of chemically pretreated mango stem bark residues at high solid loading. Ind Crops Prod 83:500–508. https://doi.org/10.1016/j.indcrop.2015.12.079

Borujeni NE, Karimi K, Denayer JFM, Kumar R (2022) Apple pomace biorefinery for ethanol, mycoprotein, and value-added biochemicals production by. Mucor indicus Energy 240:122–469. https://doi.org/10.1016/j.energy.2021.122469

Evcan E, Tari C (2015) Production of bioethanol from apple pomace using cocultures: conversion of agro-industrial waste to value-added products. Energy 88:775–782. https://doi.org/10.1016/j.energy.2015.05.090

Dhande DY, Nighot DV, Sinaga N, Dahe KB (2021) Extraction of bioethanol from waste pomegranate fruits as a potential feedstock and its blending effects on the performance of a single-cylinder SI engine. Renew Sustainable Energy Reviews 149:111–349. https://doi.org/10.1016/j.rser.2021.111349

Sarkar D, Gupta K, Poddar K, Biswas R, Sarkar A (2019) The direct conversion of fruit waste to ethanol using the marine bacterial strain Citrobacter sp. E4. Process Saf Environ Prot 128:203–210. https://doi.org/10.1016/j.psep.2019.05.051

Rempel A, Sossella FS, Margarites AC, Astolfi AL, Steinmetz RLR, Kunzc A, Treichel H, Colla LM (2019) Bioethanol from Spirulina platensis biomass and the use of residuals to produce biomethane: an energy-efficient approach. Bioresour Technol 288:121588. https://doi.org/10.1016/j.biortech.2019.121588

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with Folin-phenol reagent. J Biológical Chem 193:265–275. https://doi.org/10.1016/S0021-9258(19)52451-6

Miller GL (1959) Use of dinitrosalicylic acid reagent for the determination of reducing sugars. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Salik FLM, Povh NP (1993) Electrophotometric method for developing alcohol contents in hydroalcoholic mixtures. In: Annals of the National Congress of the Society of Sugar and Alcohol Technicians of Brazil 262–266

Mellinas C, Ramos M, Jiménez A, Garrigós MC (2020) Recent trends in the use of pectin from agro-waste residues as a natural biopolymer for food packaging applications. Materials 13:673. https://doi.org/10.3390/ma13030673

Mugampoza D, Gafuma S, Kyosaba P, Namakajjo R (2020) Characterization of Pectin from Pulp and Peel of Ugandan Cooking Bananas at Different Stages of Ripening. J Food Res 9:67–77. https://doi.org/10.5539/jfr.v9n5p67

Árias D, Rodríguez J, Loppez B, Mendez P (2021) Evaluation of the physicochemical properties of pectin extracted from Musa paradisiaca banana peel under different pH conditions in the formation of nanoparticles. Heliyon 7:06–059. https://doi.org/10.1016/j.heliyon.2021.e06059

Phillips KM, McGinty RC, Couture G, Pehrsson PR, McKillop K, Fukagawa NK (2021) Dietary fiber, starch, and sugars in bananas at different stages of ripeness in the retail Market. PubMed Central 16: 0253366. https://doi.org/10.1371/journal.pone.0253366

Noreen A, Nazli ZH, Akram J, Rasul I, Mansha A, Yaqoob N, Iqbal R, Tabasum S, Zuber M, Zia KM (2017) Pectin-functionalized biomaterials: A new viable approach for biomedical applications: A review. Int J Biol Macromol 101:254–272. https://doi.org/10.1016/j.ijbiomac.2017.03.029

Canteri MHG, Moreno L, Wosiacki G, Scheer AP (2012) Pectin: from raw material to final product. Polímeros 22:149–157. https://doi.org/10.1590/S0104-14282012005000024

Sharma HP, Sugandha HP (2017) Enzymatic extraction and clarification of fruit juices: a review. Crit Rev Food Sci Nutr 57:1215–1227. https://doi.org/10.1080/10408398.2014.977434

Molinuevo-Salces B, Riaño B, Hijosa-Valsero M, González-García I, Paniagua-García AI, Hernández D, Garita-Cambronero J, Díez-Antolínez R, García-Gonzáleza MC (2020) Valorization of apple pomace for biofuel production: A biorefinery approach. Biomass Bioenergy 142:105785. https://doi.org/10.1016/j.biombioe.2020.105785

Brasil IM, Gomes C, Puerta-Gomez A, Castell-Perez ME, Moreira RG (2012) Polysaccharide-based multilayered antimicrobial edible coating enhances quality of fresh-cut papaya. LWT - Food Science and Technology 47:39–45. https://doi.org/10.1016/j.lwt.2012.01.005

Da Silva JM, Pereira NF, De Campos DVB, Izolani AO, Carraro VM, Cardoso CE, Pereira CSS (2018) Study of the Fermentation Process of Different Fruit Biomasses. Teccen 11:58–64. https://doi.org/10.21727/teccen.v11i2.1331

Maneerat N, Tangsuphoom N, Nitithamyong A (2017) Effect of extraction conditions on the properties of pectin from banana peels and its function as a fat substitute in salad cream. J Food Sci Technol 54:386–397. https://doi.org/10.1007/s13197-016-2475-6

Camesasca L, Ramírez MB, Guigou M, Ferrari MD, Lareo C (2015) Evaluation of dilute acid and alkaline pretreatments, enzymatic hydrolysis, and fermentation of napiergrass for ethanol production. Biomass Bioenergy 74:193–201. https://doi.org/10.1016/j.biombioe.2015.01.017

Carrillo-Nieves D, Ruiz HA, Aguilar CN, Ilyina A, Parra-Saldivar R, Torres JA, Hernández JLM (2017) Process alternatives for bioethanol production from mango stem bark residues. Bioresour Technol 239:430–436. https://doi.org/10.1016/j.biortech.2017.04.131

Ramos-Aguilar AL, Victoria-Campos CI, Ochoa-Reyes E, Ornelas-Paz JJ, Zamudio-Flores PB, Rios-Velasco C, Reyes-Hernandez J, Perez-Martínez JD, Ibarra-Junquera V (2017) Physicochemical properties of apple juice during sequential steps of industrial processing and functional properties of pectin fractions from the generated pomace. LWT Food Sci Technol 86:465–472. https://doi.org/10.1016/j.lwt.2017.08.030

Emaga TH, Andrianaivo RH, Wathelet B, Tchango JT, Paquot M (2007) Effects of maturation stage and variety on the chemical composition of banana and plantain peels. Food Chem 103:590–600. https://doi.org/10.1016/j.foodchem.2006.09.006

Arora A, Banerjee J, Ranganathan V (2018) Process design and techno-economic analysis of an integrated mango-processing waste biorefinery. Ind Crops Prod 116:24–34. https://doi.org/10.1016/j.indcrop.2018.02.061

Cypriano DZ, Silva LL, Tasic L (2018) High-value-added products from orange juice industrial waste. Waste Manag 79:71–78. https://doi.org/10.1016/j.wasman.2018.07.028

Guerrero AB, Ballesteros I, Ballesteros M (2018) The potential of agricultural banana waste for bioethanol production. Fuel 174:114170. https://doi.org/10.1016/j.fuel.2017.10.105

Santos SF, Cardoso RCV, Borges IMP, Almeida AC, Andrade ES, Ferreira IO, Ramos LC (2020) Post-harvest losses of fruits and vegetables in supply centers in Salvador, Brazil: analysis of determinants, volumes, and reduction strategies. Waste Manag 101:161–170. https://doi.org/10.1016/j.wasman.2019.10.007

Uchôa PZ, Porto RCT, Battisti R, Marangoni C, Sellin N, Souza O (2021) Ethanol from residual biomass of banana harvest and commercialization: A three-waste simultaneous fermentation approach and a logistic-economic assessment of the process scaling-up towards a sustainable biorefnery in Brazil. Industrial Crops & Products 174:114170. https://doi.org/10.1016/j.indcrop.2021.114170

Ballesteros M, Oliva JM, Negro MJ, Manzanares P, Ballesteros I (2004) Ethanol from lignocellulosic materials by simultaneous saccharification and fermentation (SFS) with Kluyveromyces marxianus CECT 10875. Process Biochem 39:1843–1848. https://doi.org/10.1016/j.procbio.2003.09.011

Saifuddin M, Khandaker MM, Hossain ABMS, Jahan S, Mat NB, Boyce AN (2014) Bioethanol Production from Mango Waste (Mangifera indica L. cv chokanan): Biomass as Renewable Energy. Aust J Basic Appl Sci 8:229–237. https://doi.org/10.1111/1541-4337.12330

Aleman-Ramirez JL, Pérez-Sariñana BY, Torres-Arellano S, Saldaña-Trinidad S, Longoria A, Sebastian PJ (2020) Bioethanol production from Ataulfo mango supplemented with vermicompost leachate. Catal Today 353:173–179. https://doi.org/10.1016/j.cattod.2019.07.028

Diano N, Grimaldi T, Bianco M, Rossi S, Gabrovska K, Yordanova G, Godjevargova T, Grano V, Nicolucci C, Mita L, Bencivenga U, Canciglia P, Mita DG (2008) Apple juice clarification using immobilized pectolytic enzymes in packed or fluidized bed reactors. J Agric Food Chem 56:11477. https://doi.org/10.1021/jf8019437

Oberoi HS, Sandhu SK, Vadlani PV (2012) Statistical optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod Process 90:257–265. https://doi.org/10.1016/j.fbp.2011.05.002

Oliveira TIS, Morsyleide FR, Cavalcante FL, Pereira PHF, Moates GK, Wellner N, Mazzetto SE, Waldron KW, Azevedo HMC (2016) Optimization of pectin extraction from banana peels with citric acid by using response surface methodology. Food Chem 198:113–118. https://doi.org/10.1016/j.foodchem.2015.08.080

Cheng Y-S, Mutrakulcharoen P, Chuetor S, Cheenkachorn K, Tantayotai P, Panakkal EJ, Sriariyanun M (2020) Recent Situation and Progress in Biorefining Process of Lignocellulosic Biomass: Toward Green Economy. Appl Sci Eng Progress 13:299–311. https://doi.org/10.14416/j.asep.2020.08.002

Sriariyanun M, Heitz JH, Yasurin P, Asavasanti S, Tantayotai P (2019) Itaconic Acid: A Promising and Sustainable Platform Chemical? Appl Sci Eng Progress 12:75–82. https://doi.org/10.14416/j.asep.2019.05.002

Rachamontree P, Douzou T, Cheenkachorn K, Sriariyanun M, Rattanaporn K (2020) Furfural: A Sustainable Platform Chemical and Fuel. Appl Sci Eng Progress 13:3–10. https://doi.org/10.14416/j.asep.2020.01.003

Panakkal EJ, Kitiborwornkul N, Sriariyanun M, Ratanapoompinyo J, Yasurin P, Asavasanti S (2021) Production of Food Flavouring Agents by Enzymatic Reaction and Microbial Fermentation. Appl Sci Eng Progress 14:297–312. https://doi.org/10.14416/j.asep.2021.04.006

Luo J, Ma Y, Xu Y (2020) Valorization of apple pomace using a two-step slightly acidic processing strategy. Renawable Energy 152:793–798. https://doi.org/10.1016/j.renene.2020.01.120

Bello F, Chimphango A (2021) Optimization of lignin extraction from alkaline treated mango seed husk by high shear homogenization-assisted organosolv process using response surface methodology. Int J Biol Macromol 167:1379–1392. https://doi.org/10.1016/j.ijbiomac.2020.11.092

Karim R, Nahar K, Zohora FT, Islam MM, Bhuiyan RH, Jahan MS, Shaikh MM (2022) Pectin from lemon and mango peel: Extraction, characterisation and application in biodegradable film. Carbohydr Polym Technol Appl 4:100258. https://doi.org/10.1016/j.carpta.2022.100258

Pornkamol U, Friedrich S (2010) Continuous production of ethanol from hexoses and pentoses using immobilized mixed cultures of Escherichia coli strains. J Biotechnol 150:215–223. https://doi.org/10.1016/j.jbiotec.2010.08.002

Soares LB, Bonan CIDG, Biazi LE, Dionísio SR, Bonatelli ML, Andrade ALD, Renzano EC, Costa AC, Ienczak JL (2020) Investigation of hemicellulosic hydrolysate inhibitor resistance and fermentation strategies to overcome inhibition in non-saccharomyces species. Biomass Bioenergy 137:105549. https://doi.org/10.1016/j.biombioe.2020.105549

Kai L, Jin-Cheng Q, Chen-Guang L, Feng-Wu B (2016) Optimization of pretreatment, enzymatic hydrolysis and fermentation for more efficient ethanol production by Jerusalem artichoke stalk. Bioresour Technol 221:188–194. https://doi.org/10.1016/j.biortech.2016.09.021

Soni SK, Sharma A, Soni R 2023 Microbial Enzyme Systems in the Production of Second Generation Bioethanol.Sustainability15:3590https://doi.org/10.3390/su15043590

Acknowledgement

The author Danúbia Paula Cadore Favavretto would like to thank the University of Passo Fundo (UPF) for the scholarship.

Funding

This study was financed in part by the University of Passo Fundo.

Author information

Authors and Affiliations

Contributions

Danúbia Paula Cadore Favaretto: Conceptualization, Methodology, Formal analysys and investigation, Writing. Alan Rempel: Methodology, Writing.Julia Roberta Lanzini: Methodology.Ana Carolina Mattana Silva: Methodology.Tauane Lazzari: Methodology.Luiza Desengrini Barbizan: Methodology.Vandré Barbosa Brião: Conceptualization, Writing, Reviewing and Editing, Supervision.Luciane Maria Colla: Conceptualization, Methodology.Helen Treichel: Conceptualization, Methodology.

Corresponding author

Ethics declarations

Ethical approval

This declaration is not applicable.

Competing interests

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Favaretto, D.C., Rempel, A., Lanzini, J.R. et al. Fruit residues as biomass for bioethanol production using enzymatic hydrolysis as pretreatment. World J Microbiol Biotechnol 39, 144 (2023). https://doi.org/10.1007/s11274-023-03588-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-023-03588-2