Abstract

With the reduction in oil reserves and steady increases in the price of oil, alternative carbon sources like methanol are promising, but an efficient conversion process to fuels and other chemicals is still desired. In this study, we demonstrated for the first time the production of lactic acid from methanol using a lactate dehydrogenase copy number amplifying strategy in Pichia pastoris. We engineered methylotrophic yeast (Pichia pastoris) producing d-lactic acid by d-lactate dehydrogenase gene (d-LDH) integration into the non-transcribed spacer of the ribosomal DNA (rDNA) locus and post-transformational amplification. The resultant engineered strains GS115/S8/Z3 and GS115/S16/Z3 produced 3.48 and 3.26 g/L of d-lactic acid from methanol, respectively, in a 96-h test tube fermentation. To our knowledge, this is the first report about d-lactic acid production from methanol by an engineered P. pastoris strain. The technique of gene integration into the rDNA locus and post-transformational gene amplification could be useful for metabolic engineering in P. pastoris, and the chemical production from methanol by engineered P. pastoris represents a promising industrial technology.

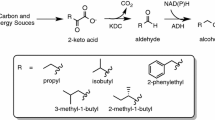

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the exhaustion of oil and steadily rising its prices, securing an alternative carbon feedstocks for fuel and chemicals production becomes an important and urgent issue (Wendisch et al. 2016). Although, renewable and edible sugar or starch crops are promising alternative carbon feedstock for fuel and chemicals production, their prices are also rising steadily owing to a growing world population (Kawaguchi et al. 2016). Renewable and non-edible lignocellulosic biomass also has promise as an alternative carbon feedstock, and efficient utilization technology is under development (De Bhowmick et al. 2018; Kawaguchi et al. 2016; Yamada et al. 2013). Methanol is an already important carbon source in the chemical industry. Recently, methanol production facilities are being set up due to abundance of resources for its production such as natural gas, and the price of methanol has been estimated to decline (Pfeifenschneider et al. 2017). Thus, although methanol toxicity may pose a challenge at large production scales, methods of chemical production from methanol through both chemical processes as well as environmentally friendly biochemical process are highly desired.

There are a limited number of reports that address chemical production from methanol as a sole carbon source through biochemical fermentation by microorganisms. Methylotrophic bacteria such as Methylobacterium extorquens, Methylobacterium organophilum, Methylobacillus glycogenes, and Methylophilus methylotrophus have been most frequently studied for the production of chemicals such as polyhydroxyalkanoate (PHA) (Kim et al. 1996), l-serine (Sirirote et al. 1988), l-threonine (Motoyama et al. 1993), and l-lysine (Gunji and Yasueda 2006). However, genetic and biotechnological knowledge and tools for methylotrophic bacteria are limited (Schrader et al. 2009); therefore, production of chemicals other than PHA and amino acids that can be intrinsically produced is difficult. A limited number of yeast species belonging to the genera Candida, Ogataea, Kuraishia, and Komagataella can grow on methanol as the sole carbon source; therefore, they are classified as methylotrophic yeasts (Fig. 1) (Gellissen 2000; Yurimoto et al. 2011). Although molecular engineering methods for some methylotrophic yeasts are established, these have been largely utilized for recombinant protein production (Gellissen 2000). Thus, novel methods for the production of various chemicals from methanol by metabolically engineered methylotrophic yeasts represent promising technological breakthroughs.

Among the methylotrophic yeast species, Pichia pastoris (Komagataella phaffii) has been most frequently studied, and its genetic engineering tools are well established. Thus far, various types of plasmids, including episomal plasmids (Cregg et al. 1985) as well as low- (Cregg et al. 1985) and multi-copy (Steinborn et al. 2006) integrative plasmids, have been developed for gene recombination in P. pastoris. Among these, multi-copy integrative plasmids for the non-transcribed spacer (NTS) of the ribosomal DNA (rDNA) locus are notable for their high mitotic stability and expression efficiency (Lopes et al. 1989; Steinborn et al. 2006). Marx et al. (2009) reported a novel method based on vector integration into the rDNA locus and post-transformational vector amplification by repeated selection on media with increasing antibiotic concentrations. They reported that intracellular protein production is highly correlated with the gene copy number. This technique would be useful for metabolic engineering in P. pastoris, as metabolic engineering often involves modification of the expression of intracellular proteins.

In this study, we engineered a P. pastoris construct producing d-lactic acid, which is a value-added monomer for the biodegradable polymer with higher mechanical properties, thermal resistance, and hydrolysis resistance (Tsuji 2005), to enable the chemical production using methanol through an environmentally friendly biochemical fermentation process (Fig. 1). First, we constructed and introduced a multi-copy integrative plasmid for the expression of d-lactate dehydrogenase (d-LDH) from Leuconostoc mesenteroides, which is frequently and effectively used in yeast (Baek et al. 2016; Ishida et al. 2006), into P. pastoris. The copy number of the integrated d-LDH was amplified by post-transformational vector amplification, and the copy number was investigated. Finally, a time course of cell growth and d-lactic acid production from methanol by the engineered P. pastoris strains was obtained.

Materials and methods

Strains and media

Escherichia coli strain HST08 (TaKaRa Bio, Kusatsu, Japan) was used as a host for recombinant DNA manipulation. Recombinant E. coli cells were cultivated on Luria–Bertani (LB) medium (10 g/L tryptone [Nacalai Tesque, Kyoto, Japan], 5 g/L yeast extract [Formedium, Norfolk, UK], and 5 g/L NaCl), supplemented with 100 µg/mL ampicillin sodium salt.

The yeast P. pastoris strain GS115 (Thermo Fisher Scientific, Yokohama, Japan) was used as a host for d-lactic acid production. P. pastoris cells were cultivated on yeast/peptone/dextrose (YPD) medium (10 g/L yeast extract, 20 g/L peptone [Formedium], and 20 g/L glucose), yeast/peptone/methanol (YPM) medium (10 g/L yeast extract, 20 g/L peptone, and 30 g/L methanol), or yeast/peptone/dextrose/sorbitol (YPDS) medium (10 g/L yeast extract, 20 g/L peptone, 20 g/L glucose, and 1 mol/L sorbitol). If necessary, 20 g/L of agar and/or a predetermined amount of Zeocin antibiotic (InvivoGen, CA, USA) was added.

Yeast fermentation

Microplate fermentation was performed in 1 mL of YPM medium, using a 2-mL 96-well deep well plate equipped with a gas permeable seal placed on a rotary plate shaker (Mix-EVR; Taitec, Koshigaya, Japan) set to 30 °C and 1500 rpm. Before microplate fermentation, yeast cells were precultured in a microplate containing 1 mL of YPD medium for 24 h at 30 °C and 1500 rpm. Cells were then collected by centrifugation, washed 2 times with autoclaved water, and used for microplate fermentation.

Test tube fermentation was performed in 5 mL of YPM medium, using a test tube (165 mm in height and 16 mm in diameter) and a reciprocal shaker set to 30 °C and 150 rpm. The fermentation was started by inoculation (initial OD600: 5.0) with a preculture grown in a test tube containing YPD medium for 24 h at 30 °C and 150 rpm.

Plasmid construction and yeast transformation

Primers used for plasmid construction are summarized in Supplementary Table 1. The multicopy integrative vacant plasmid pRDZ was constructed as follows. The DNA fragments encoding the 5′ and 3′ halves of the NTS of rDNA from P. pastoris were PCR amplified using the genomic DNA of P. pastoris GS115 as the template, as well as 5NTSF and 5NTSR or 3NTSF and 3NTSR as the primers, respectively. In addition, the DNA fragment encoding the Zeocin resistance gene was PCR amplified using the plasmid pTEF1/Zeo (Thermo Fisher Scientific) as the template, as well as ZeoF and ZeoR as the primers. The resultant PCR-amplified DNA fragments were inserted into the HindIII/AatII site of the plasmid PUC19 (Thermo Fisher Scientific) using the NEBuilder HiFi DNA Assembly master mix (New England BioLabs, MA, USA).

The multicopy integrative plasmid pRDZ-AO-DLDH (Fig. 2a) for d-LDH expression was constructed as follows. The DNA fragments encoding the AOX1 promoter (pAOX1) and AOX1 terminator (tAOX1) from P. pastoris were PCR amplified using the pPIC9K (Thermo Fisher Scientific) and pPPE (Yamada et al. 2016) plasmids, respectively, as the template, as well as pAOX1F and pAOX1R or tAOX1F and tAOX1R as the primers, respectively. In addition, the DNA fragment encoding d-LDH from L. mesenteroides was PCR amplified using the plasmid pδU_LibDLDH (Yamada et al. 2017a) as the template, as well as DLDHF and DLDHR as the primers. The resultant PCR-amplified DNA fragments were inserted into the EcoRI site of the plasmid pRDZ using the NEBuilder HiFi DNA Assembly master mix. The resultant d-LDH expression plasmid pRDZ-AO-DLDH was linearized with the restriction enzyme AscI and transformed into P. pastoris following a previously described electroporation method (Wu and Letchworth 2004). Transformants were selected on YPDS medium containing 20 g/L agar and 0.1 g/L of Zeocin.

a Plasmid for D-LDH integration into the NTS of the rDNA locus. 5′NTS and 3′NTS, 5′ half and 3′ half of NTS of rDNA; pAOX1 and tAOX1, promoter and terminator of AOX1; D-LDH; d-lactate dehydrogenase gene from L. mesenteroides; Zeor, Zeocin resistance gene. b Schematic illustration of the construction of engineered P. pastoris strains

Analysis of growth and metabolites

The OD600 of each culture broth was measured as described previously (Yamada et al. 2017b). The d-lactic acid concentration was determined using the d-/l-lactic acid assay kit (Megazyme, Wicklow, Ireland) and the Multiskan GO microplate reader (Thermo Fisher Scientific). The detection limit of d- and l-lactic acid was 0.21 mg/L, according to the manufacturer.

The methanol concentration was determined by a colorimetric method using 4-amino-3-hydrazino-5-mercapto-1,2,4-triazole (AHMT) (Avigad 1983). Culture broths were centrifuged at 14,000×g at 4 °C for 10 min, and the resulting culture supernatants were diluted appropriately. Subsequently, 240 µL of diluted culture supernatants were mixed with 10 µL of 250 mM potassium phosphate buffer (pH 7.5) containing 0.25 U of alcohol oxidase (A2404; Sigma-Aldrich Japan, Tokyo, Japan) and incubated for 20 min at 25 °C. After incubation, 250 µL of 5 mol/L potassium hydroxide and 250 µL of AHMT solution (5 g/L AHMT and 20 g/L hydrochloric acid) were added to the reaction solutions, which were subsequently incubated for 20 min at 25 °C. Reaction solutions were vortexed following the addition of 250 µL of potassium periodate solution (7.5 g/L potassium periodate and 0.2 mol/L potassium hydroxide). The absorbance at 550 nm of the solutions was then measured using the Multiskan GO microplate reader. The methanol concentrations were calculated following a standard curve constructed using methanol as the standard.

Real-time PCR analysis

The integrated copy number of each engineered strain was quantified using real-time PCR as described previously (Yamada et al. 2017b). Template genomic DNA was isolated from yeast cells cultivated in YPD medium for 24 h at 30 °C. All primers used for real-time PCR analysis are also summarized in Supplementary Table 1. The normalized gene copy number was calculated using the actin gene (ACT1) (GenBank: AF216956.1) as the house keeping gene.

Analysis of intra-cellular d-LDH activity

Yeast cells were cultivated in test tubes containing 5 mL of YPM medium for 24 h and collected by centrifugation at 10,000×g and 4 °C for 1 min. Collected cells were washed twice and resuspended in 300 µL of 100 mM potassium phosphate buffer (pH 7.0). The cell suspension was mixed with 500 µL of zirconia beads (0.45 mm in particle diameter) and introduced into a bead crusher µT-12 (Taitec) for 900 s. Cell lysates were centrifuged at 10,000×g and 4 °C for 5 min and the supernatants were then collected as cell-free extracts.

The d-LDH activity in the cell-free extracts was determined using d-lactic acid as the substrate, as described previously (Tokuhiro et al. 2009). One unit of d-LDH activity was defined as the amount of enzyme that releases 1 µmol NADH in 1 min at 30 °C. The protein concentration in cell-free extracts was measured by the Bradford method (Bradford 1976) using bovine serum albumin (Sigma-Aldrich Japan) as the standard.

Results

Construction of engineered P. pastoris strains

A total of 64 engineered P. pastoris strains were constructed by transformation and post-transformational vector amplification by repeated selection on increased Zeocin concentrations as follows (Fig. 2b). The multicopy integrative plasmid pRDZ-AO-DLDH expressing d-LDH was transformed into P. pastoris GS115 and selected on YPDS medium containing 20 g/L agar and 0.1 g/L of Zeocin. Subsequently, 16 engineered strains with good growth on this medium were selected by visual inspection and named GS115/S*/Z1 (*: 1–16). These selected strains were streaked on YPD medium containing 20 g/L agar and 0.5 g/L of Zeocin. Subsequently, 16 engineered strains with good growth on this medium were selected from each engineered strain (GS115/S*/Z1 (*: 1–16)) by visual inspection and named GS115/S*/Z2 (*: 1–16). This streaking and selection procedure was repeated twice more using YPD medium containing 20 g/L agar and 1.0 and then 2.0 g/L of Zeocin, and selected transformants were named GS115/S*/Z3 (*: 1–16) and GS115/S*/Z4 (*: 1–16), respectively.

Evaluation of engineered P. pastoris strains for d-lactic acid production

To evaluate d-lactic acid production by the 64 engineered P. pastoris strains, they were cultivated in YPM medium containing methanol as the sole carbon source using a microplate for 48 h, at which time the d-lactic acid production was determined.

As shown in Fig. 3, some engineered strains successfully produced d-lactic acid from methanol. The strains could be categorized into three groups based on d-lactic acid production and Zeocin tolerance. The first group (S1/Z*, S2/Z*, S7Z*, S11/Z*, S12/Z*, S14/Z*, and S16/Z*) had some correlation between d-lactic acid production and Zeocin tolerance. The second group (S3/Z*, S6/Z*, and S8/Z*) had no correlation between d-lactic acid production and Zeocin tolerance. The third group (S4/Z*, S5/Z*, S9/Z*, S10/Z*, S13/Z*, and S15/Z*) hardly produced d-lactic acid. The best and the second-best d-lactic acid producing strain were GS115/S16/Z3 (5.35 g/L) and GS115/S8/Z3 (5.27 g/L), respectively.

Correlation between d-LDH copy number, activity, and d-lactic acid production in engineered P. pastoris strains

To evaluate the correlation between d-LDH copy number, activity and d-lactic acid production, 10 engineered strains (GS115/S1Z1, GS115/S3Z1, GS115/S6Z3, GS115/S8Z1, GS115/S8Z2, GS115/S8Z3, GS115/S8Z4, GS115/S14Z1, GS115/S15Z1, and GS115/S16Z3) with varying levels of d-lactic acid production were selected and evaluated.

As shown in Fig. 4a, it was confirmed that each strain had different d-LDH copy numbers just after transformation (following exposure to 0.1 g/L of Zeocin). In the case of strains GS115/S8Z* (*: 1–4), the d-LDH copy number increased with a change in Zeocin exposure from 0.1 to 1.0 g/L, whereas it did not increase following a change from 1.0 to 2.0 g/L of Zeocin exposure. As shown in Fig. 4b, the d-LDH copy number and activity were approximately proportional to each other (correlation coefficient = 0.798). We confirmed that d-LDH activity and d-lactic acid production were also nearly proportional to each other (correlation coefficient = 0.725) (Fig. 4c). The d-LDH copy number and activity in the GS115/S8/Z3 and GS115/S16/Z3 strains were 4 and 27.2 U/µg-protein and 9 and 43.5 U/µg-protein, respectively.

Correlation between a Zeocin resistance and d-LDH copy number, b d-LDH copy number and d-LDH activity, and c d-LDH activity and d-lactic acid production in 10 engineered P. pastoris strains. Broken lines represent approximate straight line. Each correlation coefficient is 0.293 (a), 0.798 (b), and 0.725 (c)

Evaluation of cell growth and d-lactic acid production from methanol by engineered P. pastoris strains

To evaluate cell growth and d-lactic acid production from methanol, engineered strains GS115/S8/Z3 and GS115/S16/Z3, as well as their parent strain GS115, were cultivated in YPM medium with methanol as the sole carbon source, and a time course of methanol and d-lactic acid concentrations was obtained.

The time course methanol and d-lactic acid concentrations (based on OD600 measurements) are shown in Fig. 5, and the exact values are presented in Table 1. As shown in Fig. 5a, engineered strains GS115/S8/Z3 and GS115/S16/Z3 and their parent strain GS115 demonstrated very similar methanol consumption rates during the early portion of the time course (0–120 h). During the latter portion of the time course, both engineered strains consumed methanol completely, whereas the parent strain did not. As shown in Fig. 5b, the parent strain did not produce any measurable d-lactic acid. In contrast, although, engineered strains GS115/S8/Z3 and GS115/S16/Z3 showed different d-LDH activity in microplate cultivation (Fig. 4c), they produced d-lactic acid steadily until 96 h of fermentation with almost the same titer, productivity, and yield, before reaching a plateau. After 192 h of fermentation, only GS115/S16/Z3 continued to consume d-lactic acid. As shown in Fig. 5c, engineered strains GS115/S8/Z3 and GS115/S16/Z3 and their parent strain exhibited similar levels of cell growth. However, only GS115/S16/Z3 showed rapid cell growth after 192 h of fermentation.

Discussion

In the case of strains GS115/S8Z* (*: 1–4), the d-LDH copy number did not increase following a change from 1.0 to 2.0 g/L of Zeocin exposure (Fig. 4a). Although, the reason for the phenomenon is not clear, it may be due to the complicated gene loss and amplification mechanisms in the rDNA locus (Ganley et al. 2009). Similar result in multi-copy integration and protein production in P. pastoris is also reported (Marx et al. 2009). The maximum integrated d-LDH copy number was 9 in GS115/S16/Z3 (Fig. 4a). It was comparable to results from a previous study on multi-copy integration into the rDNA locus and post-transformational vector amplification in P. pastoris. In this prior study, the human serum albumin (HSA) gene and the human superoxide dismutase (HSOD) gene were introduced into the rDNA locus in P. pastoris, and both genes were integrated at a copy number of around 5–10 (Marx et al. 2009). Multi-copy integration into the rDNA locus has also been conducted in yeasts other than P. pastoris. In Hansenula polymorpha, the integration of approximately 30 gene copies into the rDNA locus was achieved (Klabunde et al. 2002), and in Saccharomyces cerevisiae, over 60 copies of a gene were integrated into the rDNA locus (Lopes et al. 1991). Although the integrated gene copy number was found to vary depending on the gene of interest and species of yeast, the technique of multi-copy integration into the rDNA locus is useful for the enhancement of copy numbers of genes of interest in various yeast species.

Although, 6 out of 16 strains showed Zeocin tolerance, they hardly produced d-lactic acid after post transformational gene amplification (Fig. 3). It may be due to the complicated gene loss and amplification mechanisms in the rDNA locus (Ganley et al. 2009). The rDNA locus in eukaryote is consisted by many repeated gene structure and gene loss and amplification are frequently occurred. Those stains may lost d-LDH gene in their first transformation. Besides, although some strains had correlation between d-lactic acid production and Zeocin tolerance, other strains had no correlation (Fig. 3). This phenomenon may due to the excess number of integrated d-LDH. Moon et al. (2016) reported that excess number of integrated tHMG1 by rDNA-based multi-copy integration in S. cerevisiae generates an inhibitory effect on the physiology of host cells and leads to the reduction of target squalene production. Thus, adequate stain screening is important for metabolic engineering using gene integration into the rDNA locus and post-transformational gene amplification in P. pastoris.

d-LDH copy number and activity were nearly proportional to each other (Fig. 4b). This result is in accordance with a prior report showing that intracellular protein production is tightly correlated with the gene copy number (Marx et al. 2009). Clearly, there is a limit to the amplification of the copy number of an integrated gene, and the copy number of such a gene is not necessarily directly proportional to the activity of the desired enzyme (Yamada et al. 2010). However, multi-copy integration into the rDNA locus has useful applications in metabolic engineering, such as for the overexpression of intracellular proteins in the yeast P. pastoris.

Both the engineered strains that produced d-lactic acid (GS115/S8/Z3 and GS115/S16/Z3) consumed methanol completely, whereas the parent strain (GS115) did not, during 192 h of fermentation. Besides, it should be noted although the d-lactic acid production and cell growth of both engineered strains reached plateau, methanol was further consumed steadily after 96 h of fermentation. Although the methanol assimilation pathway is subjected to extensive regulation and still not fully understood (Celik et al. 2010; Yurimoto et al. 2011), the intracellular maintenance of NADH/NAD+ levels is thought to play a crucial role. The intermediate product formaldehyde is highly toxic to cells (Yurimoto et al. 2011), and over 90 mol% of formaldehyde formed from methanol is discarded as carbon dioxide immediately in the presence of an excess amount of methanol, in order to reduce its toxicity (Celik et al. 2010). In the oxidation process of one molecule of formaldehyde to carbon dioxide, two molecules of NADH are produced (Fig. 1), causing intracellular redox imbalance. However, in the formation of d-lactic acid from pyruvate, one molecule of NADH is consumed, which may contribute to more rapid methanol consumption in engineered strains. This high capacity for NADH formation of P. pastoris has been used for the construction of the yeast cells capable of reducing acetoin into 2,3-butanediol efficiently (Schroer et al. 2010). The metabolic engineering strategy taking account for the high capacity of NADH formation of P. pastoris during methanol metabolisation should be important in future research.

Following the depletion of methanol, only GS115/S16/Z3 consumed d-lactic acid (Fig. 5). This phenomenon is frequently observed in lactic acid production by engineered S. cerevisiae strains (Baek et al. 2016; Pacheco et al. 2012). In S. cerevisiae, two monocarboxylate permeases Jen1 (Casal et al. 1999) and Ady2 (Paiva et al. 2004) were identified. Jen1 mediates the transport of lactate, pyruvate, acetate, and propionate, whereas Ady2 mediates the transport of acetate, propionate, and formate. Interestingly, Jen1 and Ady2 are involved in lactic acid uptake when major carbon substrates are depleted, whereas when the acid accumulates within the cell, they can also mediate its efflux (Pacheco et al. 2012). In l-lactic acid production from glycerol in engineered P. pastoris, overexpression of the putative lactate transporter Pas, which has significant similarity to S. cerevisiae, Jen1, led to higher levels of l-lactic acid production (de Lima et al. 2016). After transporting lactic acid into the cell, which could be converted into pyruvate by LDH (Garvie 1980). Although, why the only one engineered strain could consume d-lactic acid is still unknown, it might be come from different intracellular NADH/NAD+ level. The expression of monocarboxylate permeases strongly influences lactic acid production and consumption in yeast including P. pastoris, and thus this should be modified appropriately for efficient production of d-lactic acid from methanol in P. pastoris in future research.

Although we successfully demonstrated the production of chemicals from methanol through a biochemical process using engineered P. pastoris, the titer, productivity, and yield of d-lactic acid achieved in this study (Table 1) should be improved more for its practical application. To date, l- and d-lactic acid production by various microorganisms from various carbon sources other than methanol has been reported (Gao et al. 2011; Hofvendahl and Hahn-Hägerdal 2000; Sauer et al. 2008). In general, the efficiency of lactic acid production from lignocellulosic biomass is reduced compared to that from sugars such as glucose and molasses owing to the low efficiency of lignocellulosic biomass decomposition and the formation of toxic compounds derived from it. However, even from the lignocellulosic biomass sugarcane bagasse, Lactococcus lactis achieved 10.9 g/L, 0.17 g/L/h, and 0.36 g/g for the titer, production, and yield of l-lactic acid, respectively (Laopaiboon et al. 2010). To improve the titer and production of lactic acid by engineered P. pastoris, the tolerance to methanol, formaldehyde, and lactic acid, as well as the methanol consumption rate should be improved. In addition, to improve the yield of lactic acid, the formation of carbon dioxide, which may account for over 90 mol% of carbon distribution (Celik et al. 2010), should be decreased. These improvements represent opportunities for further research.

Conclusion

In this study, we describe a successful proof of concept for chemical production from methanol through an environmentally friendly biochemical fermentation process. To our knowledge, this is the first report about d-lactic acid production from methanol by an engineered P. pastoris strain. The technique of gene integration into the rDNA locus and post-transformational gene amplification is useful for metabolic engineering in P. pastoris. Although the titer, productivity, and yield of d-lactic acid from methanol requires further improvement, P. pastoris can produce various chemicals (Schwarzhans et al. 2017), and thus the production of chemicals from methanol by engineered P. pastoris strains represents a promising industrial technology.

References

Avigad G (1983) A simple spectrophotometric determination of formaldehyde and other aldehydes: application to periodate-oxidized glycol systems. Anal Biochem 134:499–504

Baek SH, Kwon EY, Kim YH, Hahn JS (2016) Metabolic engineering and adaptive evolution for efficient production of D-lactic acid in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 100:2737–2748

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Casal M, Paiva S, Andrade RP, Gancedo C, Leao C (1999) The lactate-proton symport of Saccharomyces cerevisiae is encoded by JEN1. J Bacteriol 181:2620–2623

Celik E, Calik P, Oliver SG (2010) Metabolic flux analysis for recombinant protein production by Pichia pastoris using dual carbon sources: effects of methanol feeding rate. Biotechnol Bioeng 105:317–329

Cregg JM, Barringer KJ, Hessler AY, Madden KR (1985) Pichia pastoris as a host system for transformations. Mol Cell Biol 5:3376–3385

de Lima PB, Mulder KC, Melo NT, Carvalho LS, Menino GS, Mulinari E, de Castro VH, Dos Reis TF, Goldman GH, Magalhaes BS, Parachin NS (2016) Novel homologous lactate transporter improves l-lactic acid production from glycerol in recombinant strains of Pichia pastoris. Microb Cell Fact 15:158

De Bhowmick G, Sarmah AK, Sen R (2018) Lignocellulosic biorefinery as a model for sustainable development of biofuels and value added products. Bioresour Technol 247:1144–1154

Ganley AR, Ide S, Saka K, Kobayashi T (2009) The effect of replication initiation on gene amplification in the rDNA and its relationship to aging. Mol Cell 35:683–693

Gao C, Ma C, Xu P (2011) Biotechnological routes based on lactic acid production from biomass. Biotechnol Adv 29:930–939

Garvie EI (1980) Bacterial lactate dehydrogenases. Microbiol Rev 44:106–139

Gellissen G (2000) Heterologous protein production in methylotrophic yeasts. Appl Microbiol Biotechnol 54:741–750

Gunji Y, Yasueda H (2006) Enhancement of l-lysine production in methylotroph Methylophilus methylotrophus by introducing a mutant LysE exporter. J Biotechnol 127:1–13

Hofvendahl K, Hahn–Hägerdal B (2000) Factors affecting the fermentative lactic acid production from renewable resources1. Enzyme Microb Technol 26:87–107

Ishida N, Suzuki T, Tokuhiro K, Nagamori E, Onishi T, Saitoh S, Kitamoto K, Takahashi H (2006) d-Lactic acid production by metabolically engineered Saccharomyces cerevisiae. J Biosci Bioeng 101:172–177

Kawaguchi H, Hasunuma T, Ogino C, Kondo A (2016) Bioprocessing of bio-based chemicals produced from lignocellulosic feedstocks. Curr Opin Biotechnol 42:30–39

Kim SW, Kim P, Lee HS, Kim JH (1996) High production of Poly-β-hydroxybutyrate (PHB) from Methylobacterium organophilum under potassium limitation. Biotechnol Lett 18:25–30

Klabunde J, Diesel A, Waschk D, Gellissen G, Hollenberg CP, Suckow M (2002) Single-step co-integration of multiple expressible heterologous genes into the ribosomal DNA of the methylotrophic yeast Hansenula polymorpha. Appl Microbiol Biotechnol 58:797–805

Laopaiboon P, Thani A, Leelavatcharamas V, Laopaiboon L (2010) Acid hydrolysis of sugarcane bagasse for lactic acid production. Bioresour Technol 101:1036–1043

Lopes TS, Klootwijk J, Veenstra AE, van der Aar PC, van Heerikhuizen H, Raué HA, Planta RJ (1989) High-copy-number integration into the ribosomal DNA of Saccharomyces cerevisiae: a new vector for high-level expression. Gene 79:199–206

Lopes TS, Hakkaart GJ, Koerts BL, Raue HA, Planta RJ (1991) Mechanism of high-copy-number integration of pMIRY-type vectors into the ribosomal DNA of Saccharomyces cerevisiae. Gene 105:83–90

Marx H, Mecklenbrauker A, Gasser B, Sauer M, Mattanovich D (2009) Directed gene copy number amplification in Pichia pastoris by vector integration into the ribosomal DNA locus. FEMS Yeast Res 9:1260–1270

Moon HY, Lee DW, Sim GH, Kim HJ, Hwang JY, Kwon MG, Kang BK, Kim JM, Kang HA (2016) A new set of rDNA-NTS-based multiple integrative cassettes for the development of antibiotic-marker-free recombinant yeasts. J Biotechnol 233:190–199

Motoyama H, Anazawa H, Katsumata R, Araki K, Teshiba S (1993) Amino acid production from methanol by Methylobacillus glycogenes mutants: Isolation of l-glutamic acid hyper-producing mutants from M. glycogenes strains, and derivation of l-threonine and l-lysine-producing mutants from them. Biosci Biotechnol Biochem 57:82–87

Pacheco A, Talaia G, Sa-Pessoa J, Bessa D, Goncalves MJ, Moreira R, Paiva S, Casal M, Queiros O (2012) Lactic acid production in Saccharomyces cerevisiae is modulated by expression of the monocarboxylate transporters Jen1 and Ady2. FEMS Yeast Res 12:375–381

Paiva S, Devaux F, Barbosa S, Jacq C, Casal M (2004) Ady2p is essential for the acetate permease activity in the yeast Saccharomyces cerevisiae. Yeast 21:201–210

Pfeifenschneider J, Brautaset T, Wendisch VF (2017) Methanol as carbon substrate in the bio-economy: metabolic engineering of aerobic methylotrophic bacteria for production of value-added chemicals. Biofuel Bioprod Biorefin 11:719–731

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids: expanding the markets. Trends Biotechnol 26:100–108

Schrader J, Schilling M, Holtmann D, Sell D, Filho MV, Marx A, Vorholt JA (2009) Methanol-based industrial biotechnology: current status and future perspectives of methylotrophic bacteria. Trends Biotechnol 27:107–115

Schroer K, Peter Luef K, Stefan Hartner F, Glieder A, Pscheidt B (2010) Engineering the Pichia pastoris methanol oxidation pathway for improved NADH regeneration during whole-cell biotransformation. Metab Eng 12:8–17

Schwarzhans JP, Luttermann T, Geier M, Kalinowski J, Friehs K (2017) Towards systems metabolic engineering in Pichia pastoris. Biotechnol Adv 35:681–710

Sirirote P, Tsuneo Y, Shoichi S (1988) l-Serine production from methanol and glycine with an immobilized methylotroph. J Ferment Technol 66:291–297

Steinborn G, Böer E, Scholz A, Tag K, Kunze G, Gellissen G (2006) Application of a wide-range yeast vector (CoMed™) system to recombinant protein production in dimorphic Arxula adeninivorans, methylotrophic Hansenula polymorpha and other yeasts. Microb Cell Fact 5:33

Tokuhiro K, Ishida N, Nagamori E, Saitoh S, Onishi T, Kondo A, Takahashi H (2009) Double mutation of the PDC1 and ADH1 genes improves lactate production in the yeast Saccharomyces cerevisiae expressing the bovine lactate dehydrogenase gene. Appl Microbiol Biotechnol 82:883–890

Tsuji H (2005) Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci 5:569–597

Wendisch VF, Brito LF, Gil Lopez M, Hennig G, Pfeifenschneider J, Sgobba E, Veldmann KH (2016) The flexible feedstock concept in industrial biotechnology: Metabolic engineering of Escherichia coli, Corynebacterium glutamicum, Pseudomonas, Bacillus and yeast strains for access to alternative carbon sources. J Biotechnol 234:139–157

Wu S, Letchworth GJ (2004) High efficiency transformation by electroporation of Pichia pastoris pretreated with lithium acetate and dithiothreitol. Biotechniques 36:152–154

Yamada R, Tanaka T, Ogino C, Kondo A (2010) Gene copy number and polyploidy on products formation in yeast. Appl Microbiol Biotechnol 88:849–857

Yamada R, Hasunuma T, Kondo A (2013) Endowing non-cellulolytic microorganisms with cellulolytic activity aiming for consolidated bioprocessing. Biotechnol Adv 31:754–763

Yamada R, Kimoto Y, Ogino H (2016) Combinatorial library strategy for strong overexpression of the lipase from Geobacillus thermocatenulatus on the cell surface of yeast Pichia pastoris. Biochem Eng J 113:7–11

Yamada R, Wakita K, Mitsui R, Ogino H (2017a) Enhanced d-lactic acid production by recombinant Saccharomyces cerevisiae following optimization of the global metabolic pathway. Biotechnol Bioeng 114:2075–2084

Yamada R, Wakita K, Ogino H (2017b) Global metabolic engineering of glycolytic pathway via multicopy integration in Saccharomyces cerevisiae. ACS Synth Biol 6:659–666

Yurimoto H, Oku M, Sakai Y (2011) Yeast methylotrophy: metabolism, gene regulation and peroxisome homeostasis. Int J Microbiol 2011:101298

Acknowledgements

This work was partly supported by Japan Society for the Promotion of Science KAKENHI (Grant Number 18K14069) to RY.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yamada, R., Ogura, K., Kimoto, Y. et al. Toward the construction of a technology platform for chemicals production from methanol: d-lactic acid production from methanol by an engineered yeast Pichia pastoris. World J Microbiol Biotechnol 35, 37 (2019). https://doi.org/10.1007/s11274-019-2610-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-019-2610-4