Abstract

N-Acetyl-d-glucosamine (GlcNAc) is a monosaccharide with great application potential in the food, cosmetic, pharmaceutical, and biomaterial areas. GlcNAc is currently produced by chemical hydrolysis of chitin, but the current processes are environmentally unfriendly, have low yield and high cost. This study demonstrates the potential to produce GlcNAc from α-chitin using chitinases of ten marine-derived Aeromonas isolates as a sustainable alternative to the current chemical process. The isolates were characterized as Aeromonas caviae by multilocus sequence analysis (MLSA) using six housekeeping genes (gltA, groL, gyrB, metG, ppsA, and recA), not presented the virulence genes verified (alt, act, ast, ahh1, aer, aerA, hlyA, ascV and ascFG), but showed hemolytic activity on blood agar. GlcNAc was produced at 37 °C, pH 5.0, 2% (w/v) colloidal chitin and crude chitinase extracts (0.5 U mL−1) by all the isolates with yields from 14 to 85% at 6 h, 17–89% at 12 h and 19–93% after 24 h. The highest yield of GlcNAc was observed by A. caviae CH129 (93%). This study demonstrates one of the most efficient chitin enzymatic hydrolysis procedures and A. caviae isolates with great potential for chitinases expression and GlcNAc production.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chitin is one of the most abundant organic compounds found in nature and the main component of the exoskeleton of arthropods, cell walls of fungi and algae (Zobell and Rittenberg 1938). It is insoluble in water, has acrystalline structure and consists of unbranched chains of N-acetyl-d-glucosamine (GlcNAc), a monosaccharide with great application potential in the food, cosmetic, pharmaceutical and biomaterial areas (Chen et al. 2010; Liu et al. 2013; Jung and Park 2014).

GlcNAc is biocompatible, biodegradable and is also present in the human body. It is a component of hyaluronic acid, glycoproteins, proteoglycans, glycosaminoglycans and other connective tissue structures (Levin et al. 1961) and can even be found in human breast milk (Kobata and Ginsburg 1969; Miller et al. 1994). Studies indicate that GlcNAc is an important component of biomacromolecular synthesis in the human body (Heim et al. 1989; Shoji et al. 1999), is nontoxic and does not alter blood glucose levels (Levin et al. 1961; Liu et al. 2008). GlcNAc is a valuable pharmacological agent in the treatment of a wide variety of diseases, joint injuries, and inflammatory bowel disease and can be used as a substrate for sialic acid production (Chen et al. 2010). Due to the versatile functions of GlcNAc, this compound is considered an essential ingredient in the formulation of cosmetics for the treatment of wrinkles and reduction of skin hyperpigmentation (Sayo et al. 2004; Bissett et al. 2007; Chen et al. 2008). Studies also have described GlcNAc as a potential pathway for bioethanol production as an alternative to the use of glucose as carbon sources by Saccharomyces cerevisiae mutant (Roseman et al. 2010).

GlcNAc has been historically prepared by chemical hydrolysis of chitin, using a strong acid, such as chloric acid (HCl), and carefully selected temperatures (Aam et al. 2010). However, the current processes are environmentally unfriendly, have low yield and high cost. The enzymatic hydrolysis of chitin is an alternative to the chemical process and would not require the use of toxic compounds or generate excessive amounts of wastewater(Chen et al. 2010; Liu et al. 2013; Jung and Park 2014).

Microbial production of GlcNAc has attracted increasing attention due to its advantage as a sustainable alternative to the chemical process (Liu et al. 2013; Jung and Park 2014). Among the microorganisms, marine chitinolytic bacteria show great potential for the production of GlcNAc because of the suggestion that they play a significant role in chitin degradation in the oceans (Zobell and Rittenberg 1938). These bacteria are autochthonous in marine ecosystems, produce chitinases that hydrolyze chitin to biologically useful carbon and nitrogen forms, and consequently, make possible the recycling of chitin in nature (Zobell and Rittenberg 1938; Keyhani and Roseman 1999). The efficiency of these bacteria can be observed in marine sediment because, despite continuous production of chitin in the water column, only traces of this highly insoluble polymer accumulate in marine sediment (Johnstone 1908; Poulicek and Jeauniaux 1989; Alldredge and Gotschalk 1990; Keyhani and Roseman 1999).

Aeromonas is a representative genus of marine chitinolytic bacteria. However, some Aeromonas strains have been reported to induce pathogenicity in fish and humans (Janda and Abbott 2010). Three species of Aeromonas (A. hydrophila, A. caviae, and A. veronii) have been reported to produce systemic infections in humans (Janda et al. 1994; Janda and Abbott 1998). Thus, the potential industrial use of strains belonging to this genus requires an evaluation of their pathogenicity. The most common procedure to examine the potential pathogenicity of Aeromonas strains is the identification of the virulence-associated factors. These factors include the genes involved in the production of the major enterotoxins, hemolysins and secretion systems previously described to be involved in strain pathogenicity (Chacón et al. 2003; Sen and Rodgers 2004; Aguilera-Arreola et al. 2005). In addition, the capability of strains to produce hemolytic activity on blood agar is also considered a direct demonstration of the potential pathogenicity of Aeromonas strains (Aguilera-Arreola et al. 2007).

In this study, we demonstrate the ability to produce GlcNAc from α-chitin using chitinases of marine-derived A. caviae isolates. Multilocus sequence analysis (MLSA) was used for differentiation and characterization of the isolates, and their potential pathogenicity was examined by polymerase chain reaction (PCR) using specific virulence-related genes and by hemolytic activity on blood agar.

Materials and methods

Isolates

Sampling and screening

Marine-derived bacteria were isolated from seawater and zooplankton samples from the coast of São Paulo state, Brazil (Souza et al. 2009). Chitinolytic activity was quantified based on size of clear zones around the colonies on chitin agar plates at 28 °C for 96 h (Fig. 1). Culture medium was prepared with the following composition (per liter): (NH4)2SO4, 1.0 g; KH2PO4, 0.2 g; K2HPO4, 1.6 g; MgSO4·7H2O, 0.2 g; NaCl, 0.1 g; FeSO4·7H2O, 0.01 g; CaCl2·2H2O, 0.02 g; colloidal chitin, 10 g; Agar, 15 g (pH 7.0). Colloidal chitin was prepared using α-chitin powder from crab shells (C7170-Sigma-Aldrich Co., St. Louis, MO, USA), according to the method described by Souza et al. (2009). Ten isolates (CH125, CH129, CH147, CH149, CH150, CH151, CH286, CHZ52, CHZ113, and CHZ306) with largest chitin hydrolysis halos were selected for this study.

16S rRNA gene sequencing

Isolates were characterized at the genus level as Aeromonas sp. by complete 16S rRNA gene sequencing. PCR reactions were carried out in a final volume of 50 μL using the following components: 1× PCR Buffer (Invitrogen, Carlsbad, USA), 50 mM MgCl2 (Invitrogen), 0.25 mM DNTP (Invitrogen), 0.3 μM 27F and 1525R primers (Lane 1991), 1 U Taq DNA polymerase (Invitrogen) and template DNA (50 ng). Reactions were performed in Mastercycler ep Gradient S Eppendorf thermocycler (Eppendorf, New York, USA) using the following thermal conditions: initial step at 94 °C for 2 min, followed by 30 cycles (denaturation at 94 °C for 30 s, 62.5 for 30 s and extension at 72 °C for 45 s) with a final extension at 72 °C for 3 min. PCR products were sequenced with the BigDye® Terminator v3.1 Cycle sequencing kit (ThermoFisher Scientific, Waltham, USA) using the ABI 3730 DNA Analyzer (Life Technologies, Carlsbad, USA) and compared with sequences available in GenBank at NCBI (National Center for Biotechnology Information) using BLAST (Basic Local Alignment Search Tool).

Multilocus sequence analysis (MLSA) and verification of virulence-associated factors

Isolates were characterized at species level by MLSA using six housekeeping genes (gltA, groL, gyrB, metG, ppsA, and recA) and verifying the presence of virulence genes using nine potential markers (alt, act, ast, ahh1, aer, aerA, hlyA, ascV and ascFG). Additionally, the hemolytic activity of all strains was verified on blood agar.

For MLSA and virulence genes verification, cells were grown overnight in Luria–Bertani (LB) broth at 28 °C and harvested by centrifugation at 3000×g for 5 min at 4 °C. DNA extraction was done using a Wizard Genomic DNA Purification Kit (Promega Co., Madison, WI, USA), according to the manufacturer’s instructions.

PCR reactions were carried out in a final volume of 50 μL using the following components: 1× PCR Buffer (Invitrogen), 50 mM MgCl2 (Invitrogen), 0.25 mM DNTP (Invitrogen), 0.3 μM each primers (Invitrogen) (Table 1), 1 U Taq DNA polymerase (Invitrogen) and template DNA (50 ng). Reactions were performed in Mastercycler ep Gradient S Eppendorf thermocycler (Eppendorf) using the following thermal conditions: initial step at 94 °C for 2 min, followed by 35 cycles (denaturation at 94 °C for 30 s, annealing (Table 1) for 30 s and extension at 72 °C for 2 min) with a final extension at 72 °C for 3 min.

PCR products were purified with the Wizard® SV Gel and PCR Clean-Up System kit (Promega)according to the manufacturer’s instructions and sequenced with the BigDye® Terminator v3.1 Cycle sequencing kit (ThermoFisher Scientific) using the ABI 3730 DNA Analyzer (Life Technologies).

Amplicons were compared with nucleotide sequences of Aeromonas spp. available in the Aeromonas MLST Database (http://pubmlst.org/aeromonas/). For phylogenetic analysis, chromatograms of sequences were analyzed and edited using the Bioedit 7.0.9.0 program (Ibis Biosciences, Carlsbad, USA). After concatenated and aligned, the sequences were analyzed using the MEGA 7.0 program. Phylogenetic trees were constructed using the neighbor-joining statistical method and the Jukes-Cantor model. The Bootstrap method with 1000 replications was used as the test of phylogeny.

For hemolytic activity verification, strains were grown overnight in LB broth at 28 °C, and three aliquots (5 μL) were inoculated in blood agar plates. The medium was prepared using tryptic soy agar (TSA) with 5% (v/v) defibrinated sheep blood. Plates were incubated at 28 and 37 °C up to 48 h.

Chitin hydrolysis evaluation

Crude enzyme extracts preparation

Isolates were grown in tubes of 50 mL containing 20 mL mineral broth with colloidal chitin at 28 °C under shaking (180 rpm) for 96 h. The medium for inoculum preparation contained the following composition (per L): (NH4)2SO4, 1.0 g; KH2PO4, 0.2 g; K2HPO4, 1.6 g; MgSO4·7H2O, 0.2 g; NaCl, 0.1 g; FeSO4·7H2O, 0.01 g; CaCl2·2H2O, 0.02 g; colloidal chitin, 10 g (pH 7.0).

The crude enzyme extracts were obtained inoculating 2 mL of inoculum in 200 mL of mineral broth (pH 7.0) with 2% (w/v) colloidal chitin and incubated at 28 °C under shaking (180 rpm) for 72 h. The culture supernatant was obtained after centrifugation at 3000×g for 5 min at 4 °C, precipitated with 80% ammonium sulfate at 4 °C for 30 min under shaking and centrifuged at 10,000×g for 20 min at 4 °C. The precipitates were eluted with 2 mL of 50 mM KH2PO4 buffer (pH 5.0) and dialyzed overnight in a regenerated cellulose membrane (MWCO: 6–8 kDa) (Spectrum Labs, Rancho Dominguez, USA) against 50 mM KH2PO4 buffer (pH 5.0) at 4 °C. The buffer used for overnight dialysis was removed and changed three times every 2 h for the complete removal of salts.

Total chitinase activities on crude enzyme extracts were determined by measuring the amount of reducing sugar released after chitin enzymatic hydrolysis. The reducing sugars were measured by the dinitrosalicylic acid method (Miller 1959) and one unit of chitinase activity was defined as the amount of enzyme producing 1 µmol of reducing sugars per minute. A standard curve was obtained with commercial GlcNAc (Sigma-Aldrich).

N-Acetyl-glucosamine production and quantification

GlcNAc production reactions were carried out in a final volume of 1 mL containing 2% (w/v) colloidal chitin in 50 mM KH2PO4 buffer (pH 5.0) and crude enzyme extract (0.5 U mL−1 of total chitinase). Reactions were incubated at 37 °C for 96 h under shaking and stopped at 0, 6, 12, 24, 48, 72 and 96 h after heated at 100 °C for 5 min.

GlcNAc was quantified by high-performance liquid chromatography (HPLC), according to Bassleret al. (1991), using the HPLC Ultimate 3000 System (Dionex, Sunnyvale, CA, USA) with UV Ultimate 3000 diode array detector (Dionex) at 190 nm, Aminex HPX-87H 30 cm × 7.8 mm column (Bio-Rad, Hercules, CA, USA) and 5 mM H2SO4 mobile phase with flow rate of 0.8 mL min−1. GlcNAc concentrations were calculated by comparison of peak areas to standard solutions. The dry weight of colloidal chitin was verified and used for conversion calculations of chitin to GlcNAc, according to Nguyen-Thi and Doucet (2016). Calculations considered that 1 mg of chitin could produce a maximal theoretical yield of 1.08 mg of GlcNAc (Eq. 1).

Results obtained were subjected to one-way analysis of variance (ANOVA) followed by Tukey post-test to determine the significant differences among the yields and productivities. Significant differences were defined as p < 0.05.

Results

Multilocus sequence analysis (MLSA) and verification of virulence-associated factors

MLSA was used for Aeromonas isolates differentiation and characterization. Fragments of the six selected housekeeping genes (gltA, groL, gyrB, metG, ppsA, and recA) were PCR amplified and sequenced by using the primers listed in Table 1.

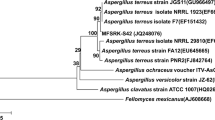

The phylogeny of Aeromonas isolates was analyzed by constructing a neighbor-joining tree from the 2600-bp concatenated sequences of the six housekeeping genes (Fig. 2). Results revealed that all isolates are closely related to A. caviae species (> 98.5% of similarity). Concatenated phylogenetic tree was compared with the trees of each housekeeping gene constructed independently showing no significant differences among them. Basically, none of the six genes influenced in the topology of concatenated tree and the main cluster divisions were maintained. Intraspecies nucleotide substitution rates (different strains within the same species) of the housekeeping gene fragments were < 2% while interspecies nucleotide substitution rates (strains belonging to different species) were > 3%. The mean G + C contents of these gene fragments were 61% (gltA), 61% (groL), 63% (gyrB), 59% (metG), 64% (ppsA) and 59% (recA).

Concatenated neighbor-joining phylogenetic tree based on gltA, groEL, gyrB, metG, ppsA and recA gene sequences of marine-derived Aeromonas caviae isolates. Numbers at nodes indicate bootstrap values (percentages of 1000 replicates). Phylogeny was performed using nucleotide sequences of type strains from three culture collections: Deutsche Sammlung von Mikroorganismen und Zellkulturen (DSM), Colección Española de Cultivos Tipo (CECT) and National Collections of Industrial Food and Marine Bacteria (NCIMB). ID numbers correspond to accession numbers in Aeromonas MLST Database

Nine virulence genes (alt, act, ast, ahh1, aer, aerA, hlyA, ascV and ascFG) were evaluated to examine the potential pathogenicity of A.caviae isolates. All isolates were negative for the potential markers selected.

Hemolytic activity isolateswere verified by their ability to form halos of hemolysis on blood agar. This ability is also considered a direct demonstration of potential pathogenicity of strains and was evaluated at 28 and 37 °C, environmental and clinical temperatures, respectively.

All isolates showed hemolytic activity at 37 °C after 48 h incubation and eight isolates at 28 °C (Table 2). No strain showed hemolytic activity at 28 or 37 °C with 24 h incubation.

Chitin enzymatic hydrolysis evaluation

To evaluate the GlcNAc production, an enzymatic hydrolysis procedure of colloidal α-chitin was standardized in this study. The HPLC method used was effective and detected GlcNAc with 9.03 min of retention. The dry weight of colloidal chitin (0.74 g L−1) was obtained and used for conversion calculations of chitin to GlcNAc.

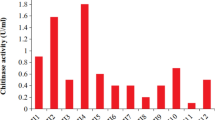

Selective production of GlcNAc from colloidal α-chitin was achieved using of all the A. caviae isolates. According to Fig. 3, minimum and maximum yields were from 10 to 93% during 96 h of enzymatic reaction, and different isolates had already shown high yields in the first 24 h. At 6 h of hydrolysis, for example, the yields were from 14 to 85%, and six isolates (CH125, CH129, CH149, CH151, CHZ113 and CHZ306) showed 60–85% yields of GlcNAc. After 12 h, the yields were from 17 to 89%, and seven isolates (CH125, CH129, CH149, CH151, CHZ113, CHZ306 and CHZ52) showed 81–89% yields. Except for A. caviae CH147 (19% yield), all isolates showed 84–93% yields of GlcNAc after 24 h of hydrolysis. The highest yields of GlcNAc were observed by A. caviae CH129 (93% at 24 h) and A. caviae CHZ306 (92% at 48 h). A. caviae CH147 showed the lowest yields (< 20%) at all times verified.

N-Acetyl-glucosamine production from colloidal α-chitin using crude enzyme extracts of ten marine-derived Aeromonas caviae isolates. Production up to 96 h of enzymatic reaction (a) and analysis of production at 6 h (b), 12 h (c) and 24 h (d). Each data point represents the mean value ± standard deviations of three independent experiments. Different letters mean statistically significant differences according to the Tukey post-test (p < 0.05). Legend: [filled circle] CH125, [filled square] CH129, [filled triangle] CH147, [times symbol] CH149, [open triangle] CH150, [open diamond] CH151, [filled square] CH286, [filled diamond] CHZ52, [minus symbol] CHZ113, [open circle] CHZ306

As shown in Fig. 3, two different behaviors were observed during 96 h of GlcNAc production: (1) progressive increase of GlcNAc concentration in the first 24 h, stabilizing until 96 h (CH147, CH150, CH286, CHZ306, and CHZ52); (2) progressive increase of GlcNAc concentration in the first 24 h with a decline after 24, 48 or 72 h (CH151, CH125, CH129, CH149, and CHZ113). All isolates showed higher productivity at 6 h of reaction, with progressive decreasing over 96 h (Fig. 4). The isolated CH151 reached maximum productivity of 112.5 mg L−1 h−1.

Productivity of N-acetyl-glucosamine production from colloidal α-chitin using crude enzyme extracts of ten marine-derived Aeromonas caviae isolates. Productivity up to 96 h of enzymatic reaction (a) and analysis of productivity at 6 h (b). Each data point represents the mean value ± standard deviations of three independent experiments. Different letters mean statistically significant differences according to the Tukey post-test (p < 0.05)

Discussion

The interest on GlcNAc production has increased thanks to its functional properties and economic interest. However, as chemical processing methods currently face important drawbacks, including low yield, high cost, and environmental pollution, enzymatic processing has shown to be a sustainable alternative to the current chemical process.

Aeromonas demonstrates great potential for application in the enzymatic production of GlcNAc. However, this genus represents a public health concern because some strains have been reported to produce systemic infections in humans and animals (Janda et al. 1994; Janda and Abbott 1998). Thus, MLSA was used to determine phylogenetic relationships among Aeromonas isolates in this study. The chosen genes have proven to be excellent molecular markers, characterizing all isolates as A. caviae species and showing that the discriminatory power of using these housekeeping genes is relatively higher compared to the 16S rRNA gene. The intra and interspecies nucleotide substitutions observed in this study (< 2 and > 3%, respectively) were in accordance with the observations reported by Janda and Abbott (2010). These authors evaluated results from several phylogenetic investigations (Yáñez et al. 2003; Soler et al. 2004; Küpfer et al. 2006; Nhung et al. 2007) and observed that for most housekeeping genes studied, intraspecies nucleotide substitution rates are < 2%, while interspecies values are typical > 3%.

Although A. caviae has been considered one of three Aeromonas species (A. hydrophila, A. caviae and A. veronii) most related to infections in humans (Janda et al. 1994; Janda and Abbott 1998), the strains of this study were negative for the virulence genes checked. As A. caviae is a highly diverse species (Aguilera-Arreola et al. 2007), the strains were subjected to additional tests to verify the ability to form halos of hemolysis on blood agar. Our results showed that all the strains have the ability to express hemolysin, contrary to the results obtained by PCR targeting specific virulence-related genes.

Similar results have been observed in studies of virulence in Aeromonas. Wolf (2012), for example, observed low frequency of hemolytic genes (10%) in A. caviae, but hemolytic activity was detected in approximately 80% of them in blood agar plates. In another study (Castilho et al. 2009), the gene responsible for cytolytic enterotoxin (aer), found in 38% of Aeromonas verified, was present only in one strain of A. caviae. However, an unexpected fragment of 400 bp was observed in 78% of A. caviae during the PCR amplifications. This fragment was sequenced and showed homology with several hemolysin genes in Aeromonas. These results demonstrate the genetic and phenotypic variability in Aeromonas and that the gene identification and hemolysin expression on blood agar should be combined to interpret the potential virulence of Aeromonas strains.

Aeromonas is one of the most efficient bacterial groups on chitin hydrolysis. Nevertheless, there are only a few reports on the production of GlcNAc by chitinases from Aeromonas sp (Table 3). For example, Sashiwa et al. (2002) produced GlcNAc from different α-chitins (flakes and powder) with 64–77% yields up to 10 days using A. hydrophila H-2330 crude enzyme extracts. Kuk et al. (2005) produced GlcNAc from colloidal α-chitin using Aeromonas sp. GJ-18 crude enzyme preparations with 83 and 95% yield within 5 and 9 days, respectively. Jamialahmadi et al. (2011) produced GlcNAc from colloidal α-chitin with 79% yield using Aeromonas sp. PTCC 1691 crude enzyme extracts after 24 h. In the current study, GlcNAc was produced from colloidal α-chitin using the crude enzyme extracts of marine-derived Aeromonas isolates. The several kinds of chitinases on crude enzyme extracts, such as endochitinases, chitobiosidases, and N-acetyl-glucosaminidases (data not showed), resulted in efficient production of GlcNAc, with 85% yield and productivity of 112.5 mg L−1 h−1 within 6 h. The highest GlcNAc yield was obtained after 24 h (93%) and the production ranged from 10 to 93% yield during 96 h of reaction.

The results presented here show that is possible to produce GlcNAc from colloidal α-chitin using the crude enzyme extracts of marine-derived Aeromonas isolates. Moreover, the ability to hydrolyze α-chitin is a particularly noteworthy feature for the future development of biocatalytic processes for chitinases production and chitin derivatives, since this form of chitin is highly resistant to degradation due to its crystalline structure and insolubility in water (Mehmood et al. 2010). It is important to mention that the use of colloidal chitin (partially crystallized chitin) as well as the types of chitinases present in the enzymatic extract also has significant influence in GlcNAc production. A colloidal chitin preparation procedure which allows obtaining increasingly decrystallized particles and the use of an enzyme extract with the appropriate amount of endo and exochitinases facilitates enzymatic hydrolysis and GlcNAc production (Hirano and Nagao 1988; Chen et al. 2010).

The decline of GlcNAc concentrations in some tests (CH151, CH125, CH129, CH149, and CHZ113) was a disadvantage of crude enzyme extracts and an important point in the control of GlcNAc production. Data showed that different chitinases of those better characterized on chitin hydrolysis (endochitinases, chitobiosidases, and N-acetyl-glucosaminidases) (Sahai and Manocha 1993; Dahiya et al. 2006) may be present in a relatively high proportion in crude enzyme extracts from chitinolytic bacteria and contribute to a reduction of the final concentration of GlcNAc during long incubation. Chitin deacetylase (Zhao et al. 2010), for example, hydrolyzes the acetyl group of GlcNAc units in glucosamine and acetic acid and could decrease the efficiency of GlcNAc production. Thus, the reaction time is a parameter that requires optimization to maximize GlcNAc yields.

The fact that A. caviae isolates have pathogenic potential is not an obstacle for application their crude enzyme extracts on GlcNAc production, since such extracts are intermediates of the process. Moreover, the crude enzyme extracts used in this study were recovered by centrifugation and pre-purified by salt-precipitation and dialysis. These steps can eliminate many remaining contaminants, such as whole bacteria, cell debris, possible toxins, peptides, DNA, pigments and others small molecular compounds. In a study reported by Louise et al. (1999), for example, the authors describe the enzymatic production of GlcNAc from chitin by Serratia marcescens QM B1466, a human pathogen often involved in hospital-acquired infections. The system based on five steps (chitinolytic enzymes production, enzyme recovery, pretreatment of chitin, chitin hydrolysis and GlcNAc purification) produced GlcNAc with a purity greater than 98%, and no protein contaminants were detectable. Additionally, a wide variety of methodologies can be applied to use chitinolytic enzymes on GlcNAc production. Potential chitinase-coding genes from these isolates, for example, can be selected, cloned and heterologously expressed in organisms recognized as safe, including Escherichia coli K12, Saccharomyces cerevisiae and Pichia pastoris. Thus, this study represents an initial examination of the chitinolytic potential of marine-derived A. caviae strains which is essential for the subsequent application them.

Conclusion

This study demonstrates the potential of GlcNAc production from colloidal α-chitin, using crude enzyme extracts of marine-derived A. caviae isolates. This ability is particularly important because this form of chitin is highly resistant to degradation and the production of these extracts is a relatively inexpensive procedure. The genetic and phenotypic diversity, as well as the capacity to express multiple chitinases are characteristics to be considered in studies with Aeromonas strains. Thus, it is essential to characterize specific strains and optimize the parameters of chitin derivatives production, such as the type of chitin, chitinases and time of hydrolysis.

References

Aam BB, Heggset EB, Norberg AL, Sorlie M, Vårum KM, Eijsink VG (2010) Production of chitooligosaccharides and their potential applications in medicine. Mar Drugs 5:1482–1517. doi:10.3390/md8051482

Aguilera-Arreola MG, Hernández-Rodríguez C, Zúñiga G, Figueras MJ, Castro-Escarpulli G (2005) Aeromonas hydrophila clinical and environmental ecotypes as revealed by genetic diversity and virulence genes. FEMS Microbiol Lett 242:231–240. doi:10.1016/j.femsle.2004.11.011

Aguilera-Arreola MG, Hernández-Rodríguez C, Zúñiga G, Figueras MJ, Garduño RA, Castro-Escarpulli G (2007) Virulence potential and genetic diversity of Aeromonas caviae, A. veronii and A. hydrophila clinical isolates from Mexico and Spain: a comparative study. Can J Microbiol 53:877–887. doi:10.1139/W07-051

Alldredge AL, Gotschalk CC (1990) The relative contribution of marine snow of different origins to biological processes in coastal waters. Cont Shelf Res 10:41–58. doi:10.1016/0278-4343(90)90034-J

Bassler BL, Yu C. Lee YC, Roseman S (1991) Chitin utilization by marine bacteria. Degradation and catabolism of chitin oligosaccharides by Vibrio furnissii. J Biol Chem 266:24276–24286

Bissett DL, Farmer T, McPhail S, Reichling T, Tiesman JP, Juhlin KD, Hurley GJ, Robinson MK (2007) Genomic expression changes induced by topical N-acetylglucosamine in skin equivalent cultures in vitro. J Cosmet Dermatol 6:232–238. doi: 10.1111/j.1473-2165.2007.00339.x

Castilho MC, Castro TL, Araújo VS, Trajano RS, Santos PA, Pimenta PM, Lucheze K, Melo JT, Gonçalves AM, Nogueira RT, de Luna MG, Freitas-Almeida AC (2009) High frequency of hemolytic and cytotoxic activity in Aeromonas spp. Isolated from clinical, food and environmental in Rio de Janeiro, Brazil. Antonie Van Leeuwenhoek 96:53–61. doi:10.1007/s10482-009-9335-6

Chacón MR, Figueras MJ, Castro-Escarpulli G, Soler I, Guarro J (2003) Distribution of virulence genes in clinical and environmental isolates of Aeromonasspp. Antonie Van Leeuwenhoek 84:269–278. doi:10.1023/A:1026042125243

Chacón MR, Soler L, Groisman EA, Guarro J, Figueiras JM (2004) Type III secretion system genes in clinical Aeromonas isolates. J Clin Microbiol 42:1285–1287. doi:10.1128/JCM.42.3.1285-1287.2004

Chen RH, Hsu CN, Chung MY, Tsa WL, Liu CH (2008) Effect of different concentrations of collagen, ceramides, N-acetyl glucosamine, or their mixture on enhancing the proliferation of keratinocytes, fibroblasts and the secretion of collagen and/or the expression of mRNA of type I collagen. J Food Drug Anal 16:66–74

Chen JK, Shen CR, Liu CL (2010) N-Acetylglucosamine: production and applications. Mar Drugs 8:2493–2516. doi:10.3390/md8092493

Chopra AK, Houston CW, Peterson JW, Jin GF (1993) Cloning, expression, and sequence analysis of a cytolytic enterotoxin gene from Aeromonas hydrophila. Can J Microbiol 39:513–523. doi:10.1139/m93-073

Dahiya N, Tewari R, Hoondal GS (2006) Biotechnological aspects of chitinolytic enzymes: a review. Appl Microbiol Biotechnol 71:773–782. doi:10.1007/s00253-005-0183-7

Granum PE, O’Sullivan K, Tomás JM, Ormen O (1998) Possible virulence factors of Aeromonas spp. from food and water. FEMS Immunol Med Microbiol 21:131–137. doi:10.1016/S0928-8244(98)00041-8

Heim HK, Oestmann A, Thiele H, Sewing KH (1989) Incorporation of N-acetyl-[14C]d-glucosamine and [3H]l-leucine by isolated pig gastric mucosal cells. Digestion 44:26–35. doi:10.1159/000199889

Heuzenroeder MW, Wong CYF, Flower RLP (1999) Distribution of two hemolytic toxin genes in clinical and environmental isolates of Aeromonas spp.: correlation with virulence in a suckling mouse model. FEMS Microbiol Lett 174:131–136. doi:10.1016/S0378-1097(99)00130-5

Hirano S, Nagao N (1988) An improved method for the preparation of colloidal chitin by using methanesulfonic acid. Agr Biol Chem 52:2111–2112. doi:10.1271/bbb1961.52.2111

Il’ina AV, Zueva OY, Lopatin SA, Varlamov VP (2004) Enzymatic hydrolysis of α-chitin. Appl Biochem Microbiol 40:35–38. doi:10.1023/B:ABIM.0000010348.46961.e2

Jamialahmadi K, Behravan M, Fathi Najafi M, Tabatabaei Yazdi M, Shahverdi AR, Faramarzi MA (2011) Enzymatic production of N-acetyl-d-glucosamine from chitin using crude enzyme preparation of Aeromonas sp. PTCC1691. Biotechnology 10:292–297. doi:10.3923/biotech.2011.292.297

Janda JM, Abbott AL (1998) Evolving concepts regarding the genus Aeromonas: an expanding panorama of species, disease presentation, and unanswered questions. Clin Infect Dis 27:332–344. doi:10.1086/514652

Janda JM, Abbott SL (2010) The genus Aeromonas: taxonomy, pathogenicity, and infection. Clin Microbiol Rev 23:35–73. doi:10.1128/CMR.00039-09

Janda JM, Guthertz LS, Kokka RP, Shimada T (1994) Aeromonas species in septicemia: laboratory characteristics and clinical observations. Clin Infect Dis 19:77–83. doi:10.1093/clinids/19.1.77

Johnstone J (1908) Conditions of life in the sea. University Press, Cambridge

Jung WJ, Park RD (2014) Bioproduction of chitooligosaccharides: present and perspectives. Mar Drugs 12:5328–5356. doi:10.3390/md12115328

Jung WJ, Souleimanov A, Park RD, Smith DL (2007) Enzymatic production of N-acetyl chitooligosaccharides by crude enzyme derived from Paenibacillus illioisensis KJA-424. Carbohydr Polym 67:256–259. 10.1016/j.carbpol.2006.05.005

Keyhani NO, Roseman S (1999) Physiological aspects of chitin catabolism in marine bacteria. Biochim Biophys Acta 1473:108–122. doi:10.1016/S0304-4165(99)00172-5

Kingombe CI, Huys G, Tonolla M, Albert MJ, Swings J, Peduzzi R, Jemmi T (1999) PCR detection, characterization, and distribution of virulence genes in Aeromonas spp. Appl Environ Microbiol 65:5293–5302

Kobata A, Ginsburg V (1969) Oligosaccharides of human milk: I. Isolation and characterization. Arch Biochem Biophys 130:509–513. doi:10.1016/0003-9861(69)90063-0

Kuk JH, Jung WJ, Jo GH, Kim YC, Kim KY, Park RD (2005) Production of N-acetyl-beta-d-glucosamine from chitin by Aeromonas sp. GJ-18 crude enzyme. Appl Microbiol Biotechnol 68:384–389. doi:10.1007/s00253-004-1877-y

Küpfer M, Kuhnert P, Korczak BM, Peduzzi R, Demarta A (2006) Genetic relationships of Aeromonas strains inferred from 16S rRNA, gyrB and rpoB gene sequences. Int J Syst Evol Microbiol 56:2743–2751. doi:10.1099/ijs.0.63650-0

Lane DJ (1991) 16S/23S rRNA sequencing. In: Stackebrandt E, Oodfellow M (eds) Nucleic acid techniques in bacterial systematics. Wiley, Chichester, pp 115–163

Levin RM, Krieger NN, Winzler RJ (1961) Glucosamine and N-acetyl glucosamine tolerance in man. J Lab Clin Med 58:927–932

Liu Y, Li Z, Liu G, Jia J, Li S, Yu C (2008) Liquid chromatography–tandem mass spectrometry method for determination of N-acetylglucosamine concentration in human plasma. J Chromatogr B 862:150–154. doi:10.1016/j.jchromb.2007.11.043

Liu Y, Shin HD, Chen R, Li J, Du G, Chen J (2013) Microbial production of glucosamine and N-acetylglucosamine: advances and perspectives. Appl Microbiol Biotechnol 97:6149–6158. doi:10.1007/s00253-013-4995-6

Louise CA, Pedro A, Charles AH (1999) Process for producing N-acetyl-d-glucosamine. US Patent no. 5998173

Martino ME, Fasolato L, Montemurro F, Rosteghin M, Manfrin A, Patarnello T, Novelli E, Cardazzo B (2011) Determination of microbial diversity of Aeromonas strains on the basis of multilocus sequence typing, phenotype, and presence of putative virulence genes. Appl Environ Microbiol 77:4986–5000. doi:10.1128/AEM.00708-11

Mehmood MA, Gai Y, Zhuang Q, Wang F, Xiao X, Wang F (2010) Aeromonas caviae CB101 contains four chitinases encoded by a single gene chi1. Mol Biotechnol 44:213–220. doi:10.1007/s12033-009-9227-z

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. doi:10.1021/ac60147a030

Miller JB, Bull S, Miller J, Mcveagh P (1994) The oligosaccharide composition of human milk: temporal and individual variations in monosaccharide components. J Pediatr Gastr Nutr 19:371–376

Nguyen-Thi N, Doucet N (2016) Time-dependent synthesis of N-acetyl-d-glucosamine by N-acetylhexosaminidase and chitinase C from Streptomyces coelicolor A3(2). J Biotechnol 220:25–32

Nhung PH, Hata H, Ohkusu K, Noda M, Shah MM, Goto K, Ezaki T (2007) Use of the novel phylogenetic marker dnaJ and DNA-DNA hybridization to clarify interrelationships within the genus Aeromonas. Int J Syst Evol Microbiol 57:1232–1237. doi:10.1099/ijs.0.64957-0

Pichyangkura R, Kudan S, Kuttiyawang K, Sukwattanasinitt M, Aiba S (2002) Quantitative production of 2-acetoamodo-2-d-glucose from crystalline chitin by bacterial chitinase. Carbohydr Res 337:557–559. doi:10.1016/S0008-6215(02)00007-1

Poulicek M, Jeauniaux C (1989) Chitin biomass in marine sediments. In: Skjak-Braek G, Anthonsen T, Sandford P (eds) Chitin and chitosan. Elsevier Applied Science, London, pp 151–155

Roseman S, Li X, Comb D (2010) Conversion of chitin into N-acetylglucosamine, glucosamine and bioethanol. Patent, no. WO 2010/123784 A2

Sahai AS, Manocha MS (1993) Chitinases of fungi and plants: their involvement in morphogenesis and host-parasite interaction. FEMS Microbiol Rev 11:317–338. doi: 10.1016/0168-6445(93)90004-S

Sashiwa H, Fujishima S, Yamano N, Kawasaki N, Nakayama A, Muraki E, Hiraga K, Oda K, Aiba S (2002) Production of N-acetyl-d-glucosamine from alpha-chitin by crude enzymes from Aeromonas hydrophila H-2330. Carbohydr Res 337:761–763. doi:10.1016/S0008-6215(02)00034-4

Sashiwa H, Fujishima S, Yamano N, Kawasaki N, Nakayama A, Muraki E, Sukwattanasinitt M, Pichyangkura R, Aiba S (2003) Enzymatic production of N-acetyl-d-glucosamine from chitin. Degradation study of N-acetylchitooligosaccharide and the effect of mixing of crude enzymes. Carbohydr Polym 51:391–395. 10.1016/S0144-8617(02)00192-3

Sayo T, Sakai S, Inoue S (2004) Synergestic effect of N-acetylglucosamine and retinoids on hyaluronan production in human keratinocytes. Skin Pharmacol Physiol 17:77–83. doi:10.1159/000076017

Sen K, Rodgers M (2004) Distribution of six virulence factors in Aeromonas species isolated from US drinking water utilities: a PCR identification. J Appl Microbiol 97:1077–1086. doi:10.1111/j.1365-2672.2004.02398.x

Shoji A, Iga T, Inagaki S, Kobayashi K, Matahira Y, Sakai K (1999) Metabolic disposition of [14C] N-acetylglucosamine in rats. Chitin Chitosan Research 5:34–42

Soler L, Yáñez MA, Chacon MR, Aguilera-Arreola MG, Catalán V, Figueras MJ, Matínez-Murcia AJ (2004) Phylogenetic analysis of the genus Aeromonas based on two housekeeping genes. Int J Syst Evol Microbiol 54:1511–1519. doi:10.1099/ijs.0.03048-0

Souza CP, Rosero EMB, Almeida BC, Martins G, Albertini IS, Rivera ING (2009) Culture medium for isolating chitinolytic bacteria from seawater and plankton. World J Microb Biotechnol 25:2079–2082. doi:10.1007/s11274-009-0098-z

Wang G, Clark CG, Liu C, Pucknell C, Munro CK, Kruk TM, Caldeira R, Woodward DL, Rodgers FG (2003) Detection and characterization of the hemolysin genes in Aeromonas hydrophilaand Aeromonas sobria by multiplex PCR. J Clin Microbiol 41:1048–1054. doi:10.1128/JCM.41.3.1048-1054.2003

Wolf S (2012) Características de virulência em estirpes de Aeromonas spp. Dissertation, Universidade Federal do Paraná

Yamamoto S, Kasai H, Arnold DL, Jackson RW, Vivian A, Harayama S (2000) Phylogeny of the genus Pseudomonas: intrageneric structure reconstructed from nucleotide sequences of gyrB and rpoD genes. Microbiology 146:2385–2394. doi:10.1099/00221287-146-10-2385

Yáñez MA, Catalán V, Apráiz D, Figueras MJ, Martínez-Murcia AJ (2003) Phylogenetic analysis of members of the genus Aeromonas based on gyrBgene sequences. Int J Syst Evol Micr 53:875–883. doi:10.1099/ijs.0.02443-0

Zhao Y, Park R, Muzzarelli RAA (2010) Chitin deacetylases: properties and applications. Mar Drugs 8:24–46. doi:10.3390/md8010024

Zobell CE, Rittenberg SC (1938) The occurrence and characteristics of chitinoclastics bacteria in the sea. J Bacteriol 35:75–287

Acknowledgements

The authors would like to thank the efforts of Irma Nelly Gutierrez Rivera (in memoriam), which devoted years of research to environmental microbiology. The authors also thank the financial support provided from Sao Paulo Research Foundation (FAPESP), Grants 2012/16824-0 and 2013/18773-6.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cardozo, F.A., Gonzalez, J.M., Feitosa, V.A. et al. Bioconversion of α-chitin into N-acetyl-glucosamine using chitinases produced by marine-derived Aeromonas caviae isolates. World J Microbiol Biotechnol 33, 201 (2017). https://doi.org/10.1007/s11274-017-2373-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-017-2373-8